Brittleness Evaluation in Shale Gas Reservoirs and Its Influence on Fracability

Abstract

:1. Introduction

2. Reviewing and Evaluating the Existing Brittleness Indices

2.1. Brittleness Indices Based on Rock Elastic Parameters

2.2. Brittleness Indices Attained from Rock Mineral Compositions

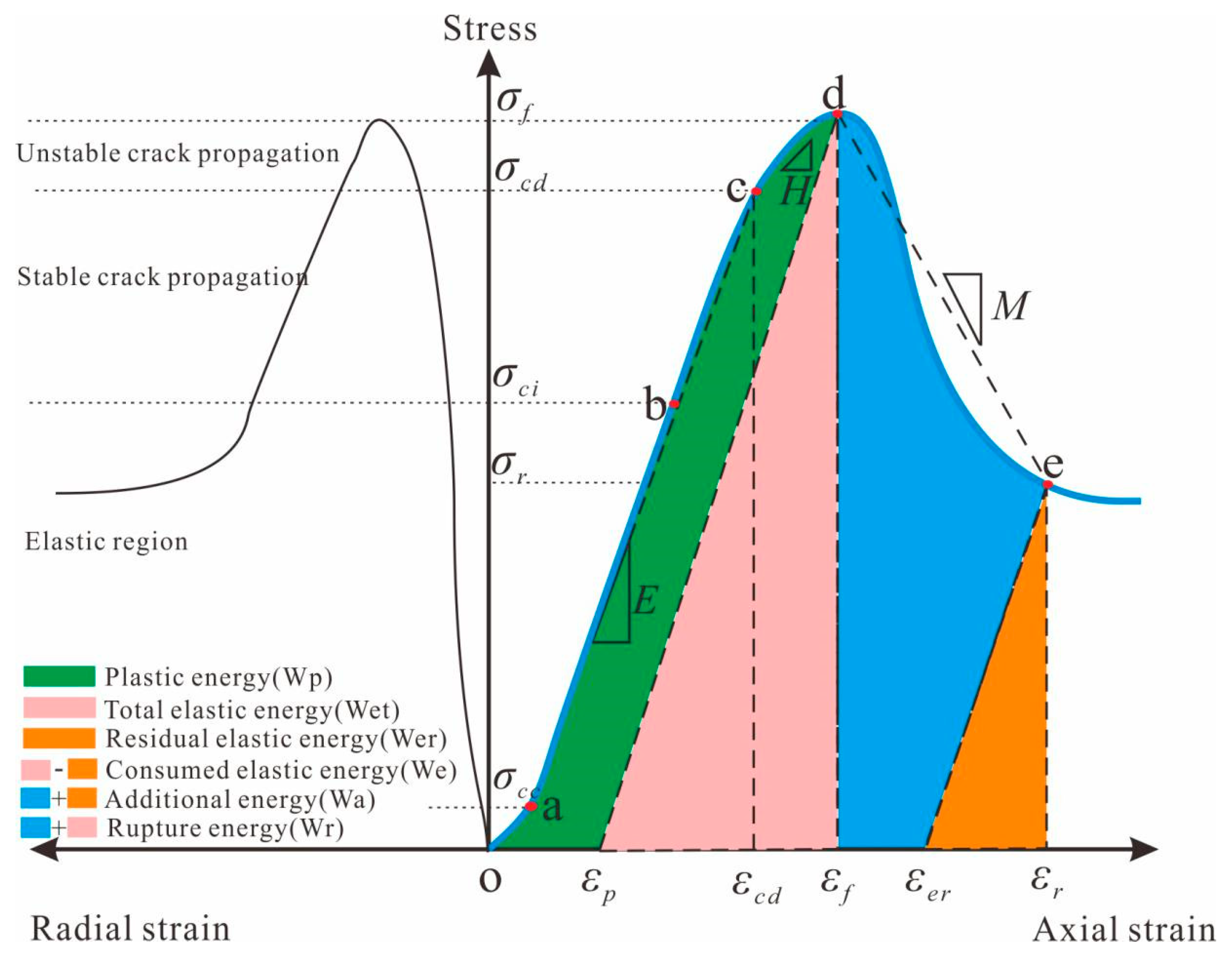

2.3. Energy-Based Brittleness Indices Derived from Rock Stress-Strain Curves

3. Materials and Measurements

3.1. Materials

3.2. Measurements

4. Results

4.1. The Difference of Mechanism between Diverse Brittleness Indices

4.2. The Effect of Confining Pressure on Brittleness

5. Discussion

5.1. Correlations of Brittleness and Elastic Parameters

5.2. Correlations of Brittleness with Mineral Composition

5.3. Correlation of Brittleness and Fracability

5.3.1. In-Situ Earth Stresses

5.3.2. Temperature Effects

5.3.3. Natural Fractures

6. Conclusions

- The brittleness index assessment methods based on rock elastic parameters and mineral compositions lack a scientific theory basis. The brittleness index derived from stress-strain curves according to energy conservation law is reliable because it can comprehensively reflect the deformation and rupture characteristic of rock.

- For rocks with a higher Young’s modulus, the consumed elastic energy (We) is insufficient to generate a complex fracture network, leading to the reduced rock brittleness index. Because the surrounding stress limits the radial dilation of rocks, there are weak correlations between Poisson’s ratio and brittleness.

- When a rock is composed of a variety of brittle minerals of moderate content, many weak structural planes exist between different mineral particles, which contributes to the development of cracks. Therefore, this type of rock is more brittle. By contrast, rocks which mainly consist of excessive amount of quartz or carbonate minerals are characterized by high cohesiveness. There are few weak structural planes in this type of rock, which leads to poor brittleness.

- The premise of fracability evaluation is to accurately assess rock brittleness. Apart from the brittleness index, the minimum horizontal principal stress should also be regarded as an essential parameter in selecting potential fracturing layers. The most suitable fracturing layers possess a high brittleness index and low minimum horizontal stress. Poisson’s ratio positively correlates with the minimum horizontal stress. Therefore, with the increased Poisson’s ratio, the minimum horizontal stress increases, resulting in a reduced fracability index.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- King, G. Thirty years of gas shale fracturing: What have we learned? In Proceedings of the Society of Petroleum Engineers (SPE) Annual Technical Conference and Exhibition, Florence, Italy, 19–22 September 2010. [Google Scholar]

- Zhou, J.; Huang, H.; Milind, D. A new physics-based modeling of multiple non-planar hydraulic fractures propagation. In Proceedings of the Unconventional Resources Technology Conference, San Antonio, TX, USA, 20–22 July 2015. [Google Scholar]

- Rybacki, E.; Meier, T.; Dresen, G. What controls the mechanical properties of shale rocks? Part II: Brittleness. J. Pet. Sci. Eng. 2016, 144, 39–58. [Google Scholar] [CrossRef] [Green Version]

- Hetenyi, M. Handbook of Experimental Stress Analysis; John Wiley & Sons Press: New York, NY, USA, 1950; ISSN 0016-0032. [Google Scholar]

- Ramsay, J.G. Folding and Fracturing of Rocks; McGraw-Hill Press: London, UK, 1967; pp. 44–47. [Google Scholar]

- Andreev, G.E. Brittle Failure of Rock Materials: Test Results and Constitutive Models; Brookfield Press: Rotterdam, The Netherlands, 1995; p. 446. [Google Scholar]

- Jaeger, J.C.; Cook, N.G.W.; Zimmerman, R.W. Fundamentals of Rock Mechanics; Blackwell Press: Oxford, UK, 2007. [Google Scholar]

- Tarasov, B.; Potvin, Y. Universal criteria for rock brittleness estimation under triaxial compression. Int. J. Rock Mech. Min. Sci. 2013, 59, 57–69. [Google Scholar] [CrossRef]

- Jahandideh, A.; Jafarpour, B. Optimization of hydraulic fracturing design under spatially variable shale fracability. J. Pet. Sci. Eng. 2016, 138, 174–188. [Google Scholar] [CrossRef]

- Rickman, R.; Mullen, M.J.; Petre, J.E.; Grieser, W.V.; Kundert, D. A practical use of shale petrophysics for stimulation design optimization: All shale plays are not clones of the Barnett Shale. In Proceedings of the Society of Petroleum Engineers (SPE) Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008. [Google Scholar]

- Jarvie, D.M.; Hill, R.J.; Ruble, T.E.; Pollastro, R.M. Unconventional shale-gas systems: The Mississippian Barnett shale of north-central Texas as one model for thermogenic shale-gas assessment. AAPG Bull. 2007, 91, 475–499. [Google Scholar] [CrossRef]

- Wang, F.P.; Gale, J.F. Screening criteria for shale-gas systems. Gulf Coast Assoc. Geol. Soc. 2009, 59, 779–793. [Google Scholar]

- Jin, X.; Shah, S.N.; Roegiers, J.C.; Zhang, B. An integrated petrophysics and geomechanics approach for fracability evaluation in shale reservoirs. Soc. Pet. Eng. J. 2015, 20, 518–526. [Google Scholar] [CrossRef]

- Hajiabdolmajid, V.; Kaiser, P. Brittleness of rock and stability assessment in hard rock tunneling. Tunn. Undergr. Space Technol. 2003, 18, 35–48. [Google Scholar] [CrossRef]

- Holt, R.M.; Fjar, E. Brittleness of shales: Relevance to borehole collapse and hydraulic fracturing. J. Pet. Sci. Eng. 2015, 131, 200–209. [Google Scholar] [CrossRef]

- Bai, M. Why are Brittleness and Fracability not Equivalent in Designing Hydraulic Fracturing in Tight Shale Gas Reservoirs. Petroleum 2016, 2, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Rahimzadeh, K.I.; Ameri, M.; Molladavoodi, H. Shale brittleness evaluation based on energy balance analysis of stress-strain curves. J. Pet. Sci. Eng. 2018, 167, 1–19. [Google Scholar] [CrossRef]

- Jin, X.; Shah, S.N.; Roegiers, J.-C.; Zhang, B. Fracability evaluation in shale reservoirs—An integrated petrophysics and geomechanics approach. In Proceedings of the Society of Petroleum Engineers (SPE) Annual Technical Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2014. [Google Scholar]

- Altamar, R.; Marfurt, K. Mineralogy-based brittleness prediction from surface seismic data: Application to the Barnett Shale. Interpretation 2014, 2, T1–T17. [Google Scholar]

- Rybacki, E.; Reinicke, A.; Meier, T.; Makasi, M.; Dresen, G. What controls the mechanical properties of shale rocks?—Part I: Strength and Young’s modulus. J. Pet. Sci. Eng. 2015, 135, 702–722. [Google Scholar] [CrossRef]

- Fjæret, E.; Holt, R.M.; Horsrud, P.; Raaen, A.M.; Risnes, R. Petroleum Related Rock Mechanics, 2nd ed.; Elsevier Press: Amsterdam, The Netherlands, 2008; p. 491. ISBN 978-0-444-50260-5. [Google Scholar]

- Gholami, R.; Rasouli, V.; Sarmadivaleh, M.; Minaeian, V.; Fakhari, N. Brittleness of gas shale reservoirs: A case study from the north Perth basin, Australia. J. Nat. Gas Sci. Eng. 2016, 33, 1244–1259. [Google Scholar] [CrossRef] [Green Version]

- Heidari, M.; Khanlari, G.R.; Torabi, K. Effect of Porosity on Rock Brittleness. Rock Mech. Rock Eng. 2014, 47, 785–790. [Google Scholar] [CrossRef]

- Zhou, H.X.; Wang, G.M.; Cao, Y.C. Controlling effect of texture on fracability in lacustrine fine-grained sedimentary rocks. Mar. Pet. Geol. 2019, 101, 195–210. [Google Scholar]

- Brace, W.F.; Paulding, B.R.; Scholz, C. Dilatancy in fracture of crystalline rocks. J. Geophys. Res. 1966, 71, 3939–3953. [Google Scholar] [CrossRef]

- Goodman, R.E. Introduction to Rock Mechanics, 2nd ed.; John Wiley & Sons Press: New York, NY, USA, 1989. [Google Scholar]

- Ranjith, P.G.; Jasinge, D.; Song, J.Y.; Choi, S.K. A study of the effect of displacement rate and moisture content on the mechanical properties of concrete: Use of acoustic emission. Mech. Mater. 2008, 40, 453–469. [Google Scholar] [CrossRef]

- Ai, C.; Zhang, J.; Li, Y.W.; Zeng, J.; Yang, X.L.; Wang, J.G. Estimation criteria for rock brittleness based on energy analysis during the rupture process. Rock Mech. Rock Eng. 2016, 49, 4681–4698. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Shao, S.; Chen, B.K.; Lashin, A.; Rathnaweera, T.D. Mechanical behaviour of Australian Strathbogie granite under in-situ stress and temperature conditions: An application to geothermal energy extraction. Geothermics 2017, 65, 44–59. [Google Scholar] [CrossRef]

- Wawersik, W.R.; Fairhurst, C. A study of brittle rock fracture in laboratory compression experiments. Int. J. Rock. Mech. Min. Sci. 1970, 7, 561–575. [Google Scholar] [CrossRef]

- Yan, D.T.; Chen, D.Z.; Wang, Q.C.; Wang, J.G. Geochemical changes across the ordovician-silurian transition on the yangtze platform, South China. Sci. China Ser. D Earth Sci. 2009, 1, 40–56. [Google Scholar] [CrossRef]

- Huang, L.Q.; Liu, W.; Bo, D.Y. Characteristics, Petrogenesis and Resource Significance of the Limestone with Polygonal Reticulate Structure of Pagoda Formation, in Northwestern Hunan Province. Earth Sci. 2019, 44, 399–414. [Google Scholar]

- Liu, S.; Deng, B.; Zhong, Y.; Ran, B.; Yong, Z.; Sun, W. Unique geological features of burial and superimposition of the Lower Paleozoic shale gas across the Sichuan Basin and its periphery. Earth Sci Front. 2016, 23, 11–28. [Google Scholar]

- Xi, Z.D.; Tang, S.H.; Wang, J. The reservoir characterization and shale gas potential of the Niutitang formation: Case study of the SY well in northwest Hunan Province, South China. J. Pet. Sci. Eng. 2018, 171, 687–703. [Google Scholar] [CrossRef]

- Shimizu, H.; Ito, T. A study of the effect of brittleness on hydraulic fracture complexity using a flow-coupled discrete element method. J. Pet. Sci. Eng. 2018, 160, 372–383. [Google Scholar] [CrossRef]

- Hiyama, M.; Shimizu, H.; Ito, T.; Tamagawa, T.; Tezuka, K. Distinct Element Analysis for hydraulic fracturing in shale-effect of brittleness on the fracture propagation. In Proceedings of the 47th US Rock Mechanics/Geomechanics Symposium, American Rock Mechanics Association, San Francisco, CA, USA, 23–26 June 2013. [Google Scholar]

- Akinbinu, V.A. Relationship of brittleness and fragmentation in brittle compression. Eng. Geol. 2017, 221, 82–90. [Google Scholar] [CrossRef]

- Zhou, X.P.; Lian, Y.J.; Wong, L.N. Understanding the fracture behavior of brittle and ductile multi-flawed rocks by uniaxial loading by digital image correlation. Eng. Fract. Mech. 2018, 199, 438–460. [Google Scholar] [CrossRef]

- Schuyler, J.N.; Mclennan, J.D. Interaction of geology, mechanical properties and in-situ stresses in hydraulic fracturing: Rock Mechanics in Productivity and Protection. Int. J. Rock Mech. Min. Sci. 1985, 22, 145–156. [Google Scholar] [CrossRef]

- Moghadam, A.; Harris, N.B.; Ayranci, K. Brittleness in the Devonian Horn River shale, British Columbia, Canada. J. Nat. Gas Sci. Eng. 2019, 62, 247–258. [Google Scholar] [CrossRef]

- Xi, Z.D.; Tang, S.H.; Zhang, S.H. Characterization of quartz in the Wufeng Formation in northwest Hunan Province, south China and its implications for reservoir quality. J. Pet. Sci. Eng. 2019, 179, 979–996. [Google Scholar] [CrossRef]

- Xi, Z.D.; Tang, S.H.; Li, J. Pore characterization and the controls of organic matter and quartz on pore structure: Case study of the Niutitang Formation of northern Guizhou Province, South China. J. Nat. Gas Sci. Eng. 2019, 61, 18–31. [Google Scholar] [CrossRef]

- Wu, J.J.; Zhang, S.H.; Cao, H. Fracability evaluation of shale gas reservoir-A case study in the Lower Cambrian Niutitang formation, northwestern Hunan, China. J. Pet. Sci. Eng. 2018, 164, 675–684. [Google Scholar] [CrossRef]

- Wang, D.B. A novel experimental approach for fracability evaluation in tight-gas reservoirs. J. Nat. Gas Sci. Eng. 2015, 23, 239–249. [Google Scholar] [CrossRef]

- Fu, H.J.; Wang, X.Z.; Zhang, L.X. Geological controls on artificial fracture networks in continental shale and its fracability evaluation: A case study in the Yanchang Formation, Ordos Basin, China. J. Nat. Gas Sci. Eng. 2015, 26, 1285–1293. [Google Scholar] [CrossRef]

- Willis, R.B.; Fontaine, J.S.; Owlen, P.L. Geology and geometry: A review of factors affecting the effectiveness of hydraulic fracturing. In Proceedings of the Society of Petroleum Engineers (SPE) Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005; pp. 1–8. [Google Scholar]

- Economides, M.J.; Nolte, K.G. Reservoir Stimulation, 3rd ed.; John Wiley & Sons Press: New York, NY, USA, 2000. [Google Scholar]

- David, J.; Breig, J.; LeCompte, B.; Kopal, M. Effective geochemical and geomechanical characterization of shale gas reservoirs from the wellbore environment: Caney and the woodford shale. In Proceedings of the Society of Petroleum Engineers (SPE) Annual Technical Conference and Exhibition, The Woodlands, TX, USA, 31 March–1 April 2009; pp. 1–20. [Google Scholar]

- Biot, M.A. General theory of three-dimensional consolidation. J. Appl. Phys. 1941, 12, 155–164. [Google Scholar] [CrossRef]

- Engelder, T.; Fischer, M.P. Influence of poroelastic behavior on the magnitude of minimum horizontal stress, Sh in overpressured parts of sedimentary basins. Geology 1994, 22, 949–952. [Google Scholar] [CrossRef]

- Ni, X.M.; Wang, Y.B.; Jie, M.X. Stress influence in different tectonic positions on fracturing interstitial morphology. J. China Coal Soc. 2008, 33, 505–508. [Google Scholar]

- Tang, S.H.; Zhu, B.C.; Yan, Z.F. Effect of crustal stress on hydraulic fracturing in coalbed methane wells. J. China Coal Soc. 2011, 36, 65–69. [Google Scholar]

- Tang, H.; Li, S.; Zhang, D. The effect of heterogeneity on hydraulic fracturing in shale. J. Pet. Sci. Eng. 2017, 162, 292–308. [Google Scholar] [CrossRef]

- Li, Z.; Li, L.; Li, M. A numerical investigation on the effects of rock brittleness on the hydraulic fractures in the shale reservoir. J. Nat. Gas Sci. Eng. 2018, 50, 22–32. [Google Scholar] [CrossRef]

| Samples | Formation | Qz (wt%) | Fsp (wt%) | Cb (wt%) | Clay (wt%) | Py (wt%) | TOC (wt%) |

|---|---|---|---|---|---|---|---|

| 1 | Longmaxi | 48.0 | 20.0 | 11.0 | 19.0 | 2.0 | 0.22 |

| 2 | 30.0 | 10.0 | 40.0 | 16.0 | 4.0 | 1.92 | |

| 3 | 45.0 | 16.0 | 4.0 | 30.0 | 5.0 | 1.65 | |

| 4 | Wufeng | 62.0 | 16.0 | 2.0 | 18.0 | 2.0 | 2.27 |

| 5 | 72.0 | 9.0 | 5.0 | 14.0 | 0 | 1.75 | |

| 6 | 53.0 | 13.0 | 16.0 | 17.0 | 1.0 | 6.48 | |

| 7 | 75.0 | 2.0 | 4.0 | 19.0 | 0 | 2.31 | |

| 8 | Baota | 15.6 | 3.8 | 71.2 | 9.4 | 0 | 0.34 |

| 9 | 17.8 | 4.3 | 75.7 | 2.2 | 0 | 1.02 |

| Samples | Formation | E (Gpa) | ν | Wet | Wer | We | Wr | Wp | Wa | BI1 | BI2 | BI | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Longmaxi | 22.4 | 0.21 | 123 | 60 | 31 | 7 | 23 | 33 | 12 | 9 | 0.72 | 0.55 | 0.63 |

| 2 | 31.7 | 0.30 | 242 | 150 | 102 | 39 | 63 | 114 | 0 | 51 | 0.55 | 0.62 | 0.58 | |

| 3 | 35.3 | 0.28 | 266 | 90 | 140 | 16 | 124 | 266 | 147 | 142 | 0.46 | 0.43 | 0.45 | |

| 4 | Wufeng | 26.9 | 0.19 | 228 | 105 | 91 | 19 | 72 | 72 | 48 | 17 | 1.00 | 0.55 | 0.78 |

| 5 | 42.1 | 0.32 | 262 | 100 | 52 | 21 | 31 | 74 | 0 | 43 | 0.43 | 0.48 | 0.45 | |

| 6 | 35.1 | 0.16 | 264 | 173 | 172 | 74 | 98 | 185 | 0 | 87 | 0.50 | 0.56 | 0.53 | |

| 7 | 56.7 | 0.22 | 275 | 200 | 96 | 51 | 45 | 188 | 39 | 143 | 0.24 | 0.32 | 0.28 | |

| 8 | Baota | 37.8 | 0.23 | 244 | 170 | 61 | 30 | 31 | 73 | 98 | 41 | 0.43 | 0.19 | 0.31 |

| 9 | 55.5 | 0.23 | 269 | 225 | 74 | 54 | 20 | 182 | 0 | 162 | 0.10 | 0.26 | 0.18 |

| Sample | Sh (Mpa) | Sh_n | BI | BIn | FI |

|---|---|---|---|---|---|

| 1 | 23 | 0.72 | 0.63 | 0.76 | 0.74 |

| 2 | 36 | 0.32 | 0.58 | 0.67 | 0.50 |

| 3 | 32 | 0.43 | 0.45 | 0.45 | 0.44 |

| 4 | 21 | 0.79 | 0.78 | 1.00 | 0.89 |

| 5 | 46 | 0.00 | 0.45 | 0.45 | 0.22 |

| 6 | 14 | 0.99 | 0.53 | 0.58 | 0.79 |

| 7 | 24 | 0.68 | 0.28 | 0.17 | 0.42 |

| 8 | 28 | 0.56 | 0.31 | 0.22 | 0.39 |

| 9 | 32 | 0.45 | 0.18 | 0.00 | 0.22 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, Y.; Tang, S.; Xi, Z. Brittleness Evaluation in Shale Gas Reservoirs and Its Influence on Fracability. Energies 2020, 13, 388. https://doi.org/10.3390/en13020388

Ye Y, Tang S, Xi Z. Brittleness Evaluation in Shale Gas Reservoirs and Its Influence on Fracability. Energies. 2020; 13(2):388. https://doi.org/10.3390/en13020388

Chicago/Turabian StyleYe, Yapei, Shuheng Tang, and Zhaodong Xi. 2020. "Brittleness Evaluation in Shale Gas Reservoirs and Its Influence on Fracability" Energies 13, no. 2: 388. https://doi.org/10.3390/en13020388