Deep Learning Image-Based Defect Detection in High Voltage Electrical Equipment

Abstract

:1. Introduction

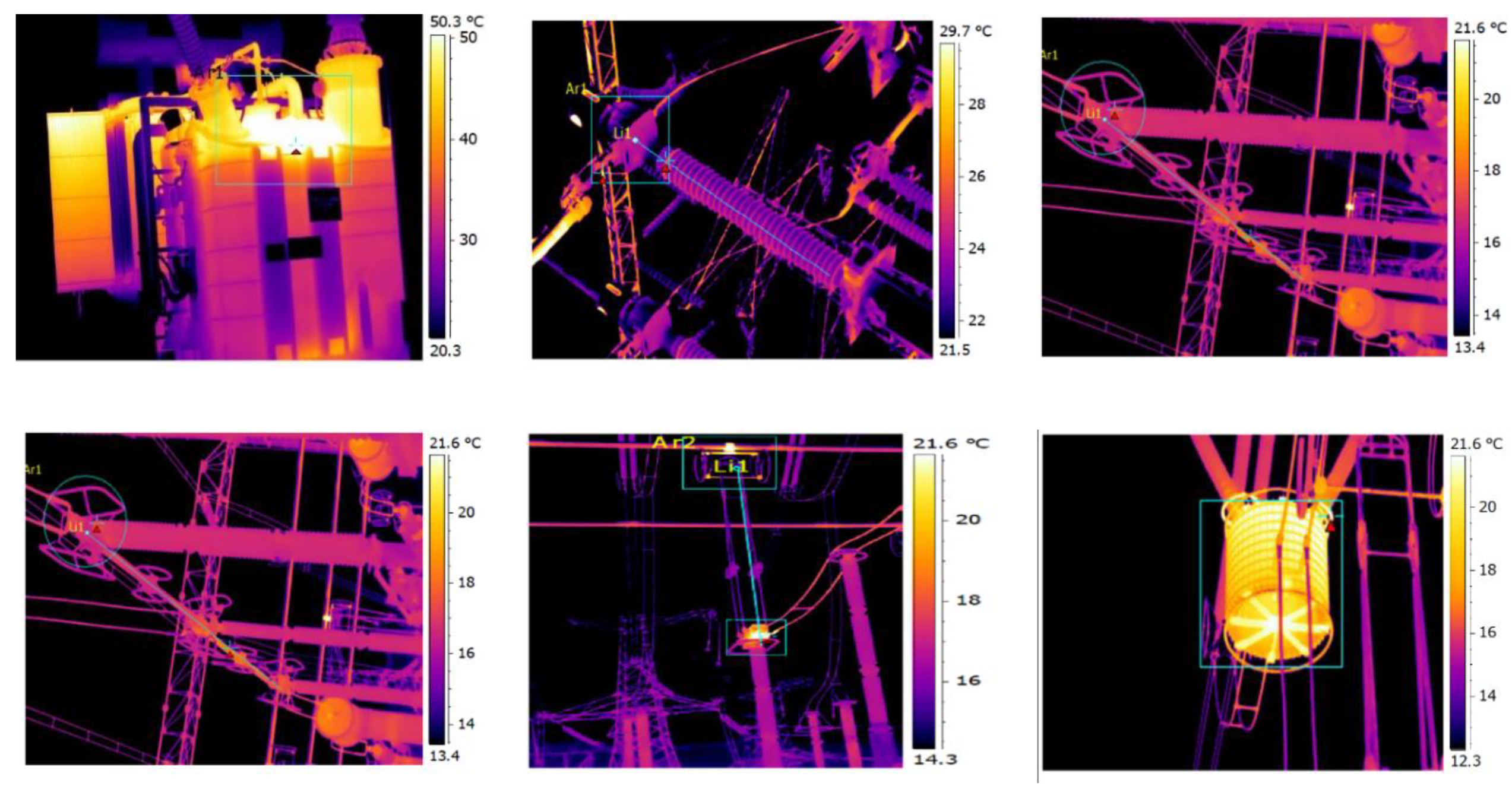

2. Defects in High Voltage Electrical Equipment

2.1. Defects in a High Voltage Power Transformer

2.2. Defects in Circuit Breakers

2.3. Defects in Surge Arresters

2.4. Defect in Cutout Switch Bus Fuse Connections

2.5. Defect of Insulation in Power Substation

3. Proposed Approach for High Voltage Electrical Equipment Using Deep Learning

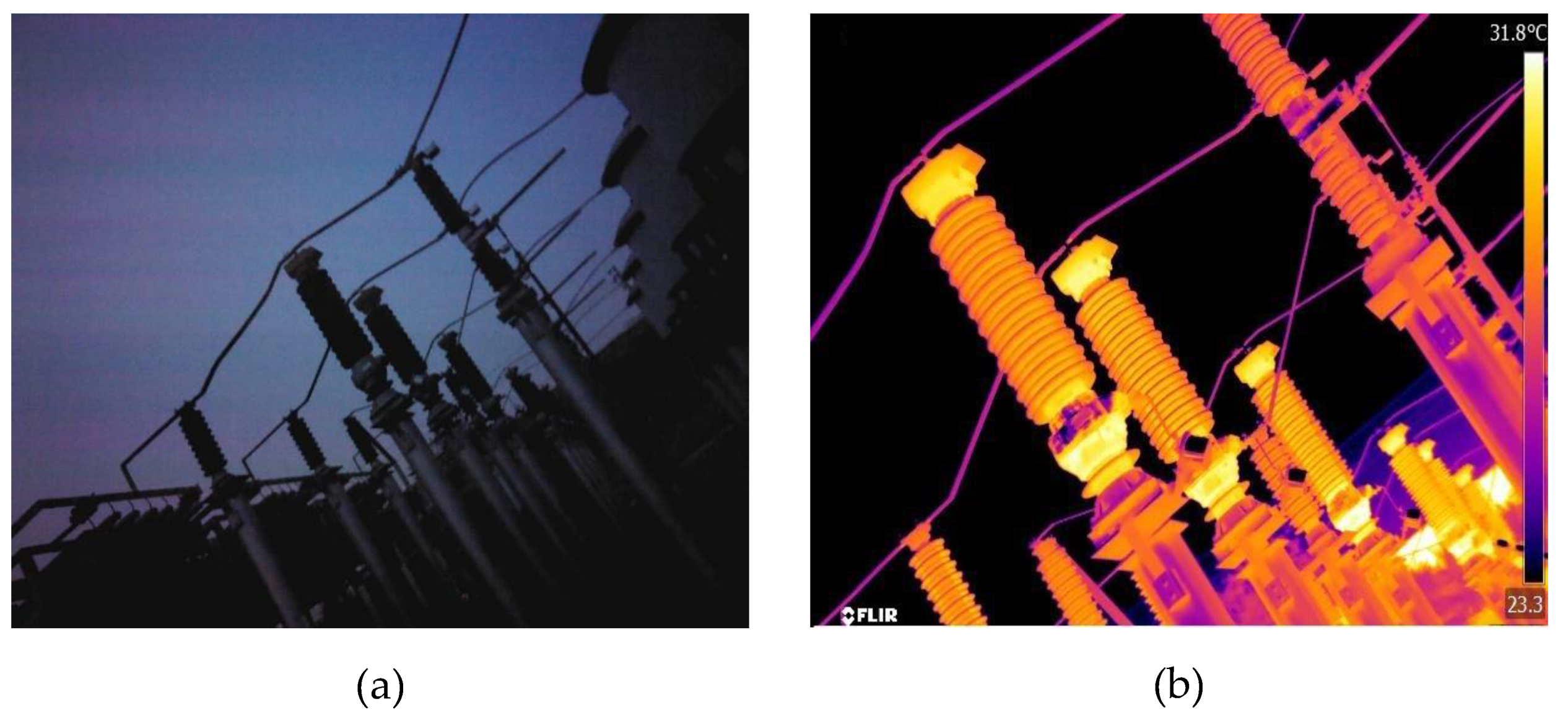

3.1. Infrared Imaging and Temperature Criteria Approach

3.2. Deep Thermal Features

3.3. Random Forest Classification

3.4. Support Vector Machine (SVM)

4. Experimental Evaluation

- Total Non-Defective Equipment correctly classified,

- Total Defective Equipment classified as Non-Defective Equipment, and

- Total Non-Defective Equipment classified as Defective Equipment.

5. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| DL | Deep Learning |

| RF | Random Forest |

| SVM | Support Vector Machine |

| CT | Current Transformer |

| CNN | Convolutional Neural Networks |

| NFPA | National Fire Protection Association |

| ANN | Artificial Neural Network |

| ASTM | American Society for Testing and Materials |

| MLP | Multi-Layer Perceptron |

| R-FCSN | Region-Based Fully Convolutional Siamese Network |

| VLAD | Vector of Locally Aggregated Descriptors |

| NETA | National Electrical Testing Association |

| NB | Naïve Bayes |

| BayesNet | Bayesian Network |

References

- Korendo, Z.; Florkowski, M. Thermography-Based Diagnostics of Power Equipment. Power Eng. J. 2001, 15, 33–42. [Google Scholar] [CrossRef]

- Ge, Z.; Du, X.; Yang, L.; Yang, Y.; Li, Y.; Jin, Y. Performance Monitoring of Direct Air-Cooled Power Generating Unit with Infrared Thermography. Appl. Therm. Eng. 2011, 31, 418–424. [Google Scholar] [CrossRef]

- Lahiri, B.B.; Bagavathiappan, S.; Jayakumar, T.; Philip, J. Medical Applications of Infrared Thermography: A Review. Infrared Phys. Technol. 2012, 55, 221–235. [Google Scholar] [CrossRef]

- Gill, P. Electrical Power Equipment Maintenance and Testing; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Bougriou, C.; Bessaïh, R.; Le Gall, R.; Solecki, J. Measurement of the Temperature Distribution on a Circular Plane Fin by Infrared Thermography Technique. Appl. Therm. Eng. 2004, 24, 813–825. [Google Scholar] [CrossRef]

- Balaras, C.A.; Argiriou, A.A. Infrared Thermography for Building Diagnostics. Energy Build. 2002, 34, 171–183. [Google Scholar] [CrossRef]

- Royo, R.; Albertos-Arranz, M.A.; Cárcel-Cubas, J.A.; Payá, J. Thermographic Study of the Preheating Plugs in Diesel Engines. Appl. Therm. Eng. 2012, 37, 412–419. [Google Scholar] [CrossRef]

- Manana, M.; Arroyo, A.; Ortiz, A.; Renedo, C.J.; Perez, S.; Delgado, F. Field Winding Fault Diagnosis in DC Motors during Manufacturing Using Thermal Monitoring. Appl. Therm. Eng. 2011, 31, 978–983. [Google Scholar] [CrossRef]

- Titman, D.J. Applications of Thermography in Non-Destructive Testing of Structures. NDT E Int. 2001, 34, 149–154. [Google Scholar] [CrossRef]

- Al-Kassir, A.R.; Fernandez, J.; Tinaut, F.V.; Castro, F. Thermographic Study of Energetic Installations. Appl. Therm. Eng. 2005, 25, 183–190. [Google Scholar] [CrossRef]

- Jadin, M.S.; Taib, S. Recent Progress in Diagnosing the Reliability of Electrical Equipment by Using Infrared Thermography. Infrared Phys. Technol. 2012, 55, 236–245. [Google Scholar] [CrossRef] [Green Version]

- Improving Electrical System Reliability with Infrared Thermography Source. Available online: http://www.Infraredelectrical.Com/Index.Html (accessed on 2 October 2019).

- Chou, Y.C.; Yao, L. Automatic Diagnosis System of Electrical Equipment Using Infrared Thermography. In Proceedings of the 2009 International Conference of Soft Computing and Pattern Recognition, Malacca, Malaysia, 4–7 December 2009; pp. 155–160. [Google Scholar]

- Infraspection Institute. Standard for Infrared Inspection of Electrical Systems & Rotating Equipment; Infraspection Institute: Burlington, NJ, USA, 2008; pp. 1–18. [Google Scholar]

- Fire, N.; Association, P.; Park, B.; Box, P.O. NFPA 750 Standard on Water Mist Fire Protection Systems 2000 Edition; National Fire Protection Association: Quincy, MA, USA, 2000. [Google Scholar]

- ASTM International. Standard Guide for Examining Electrical and Mechanical Equipment with Infrared Thermography; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Abbas, A.K.; Heimann, K.; Blazek, V.; Orlikowsky, T.; Leonhardt, S. Neonatal Infrared Thermography Imaging: Analysis of Heat Flux during Different Clinical Scenarios. Infrared Phys. Technol. 2012, 55, 538–548. [Google Scholar] [CrossRef]

- Jadin, M.S.; Taib, S.; Ghazali, K.H. Finding Region of Interest in the Infrared Image of Electrical Installation. Infrared Phys. Technol. 2015, 71, 329–338. [Google Scholar] [CrossRef] [Green Version]

- Jin, L.; Zhang, D. Contamination Grades Recognition of Ceramic Insulators Using Fused Features of Infrared and Ultraviolet Images. Energies 2015, 8, 837–858. [Google Scholar] [CrossRef] [Green Version]

- Almeida, C.A.L.; Braga, A.P.; Nascimento, S.; Paiva, V.; Martins, H.J.A.; Torres, R.; Caminhas, W.M. Intelligent Thermographic Diagnostic Applied to Surge Arresters: A New Approach. IEEE Trans. Power Deliv. 2009, 24, 751–757. [Google Scholar] [CrossRef]

- Jaffery, Z.A.; Dubey, A.K. Design of Early Fault Detection Technique for Electrical Assets Using Infrared Thermograms. Int. J. Electr. Power Energy Syst. 2014, 63, 753–759. [Google Scholar] [CrossRef]

- Zou, H.; Huang, F. An Intelligent Fault Diagnosis Method for Electrical Equipment Using Infrared Images. In Proceedings of the Chinese Control Conference (CCC), Hangzhou, China, 28–30 July 2015; pp. 6372–6376. [Google Scholar]

- Zhao, Z.; Fan, X.; Xu, G.; Zhang, L.; Qi, Y.; Zhang, K. Aggregating Deep Convolutional Feature Maps for Insulator Detection in Infrared Images. IEEE Access 2017, 5, 21831–21839. [Google Scholar] [CrossRef]

- Li, H.; Wang, B.; Li, L. Research on the Infrared and Visible Power-Equipment Image Fusion for Inspection Robots. In Proceedings of the 2010 1st International Conference on Applied Robotics for the Power Industry, CARPI 2010, Montreal, QC, Canada, 5–7 October 2010. [Google Scholar]

- Zhou, Q.; Zhao, Z. Substation Equipment Image Recognition Based on SIFT Feature Matching. In Proceedings of the 2012 5th International Congress on Image and Signal Processing, CISP 2012, Chongqing, China, 16–18 October 2012; pp. 1344–1347. [Google Scholar]

- Zhao, Z.; Fan, X.; Qi, Y.; Zhai, Y. Multi-Angle Insulator Recognition Method in Infrared Image Based on Parallel Deep Convolutional Neural Networks. In Communications in Computer and Information Science; Springer: Berlin, Germany, 2017; Volume 773, pp. 303–314. [Google Scholar]

- Ullah, I.; Yang, F.; Khan, R.; Liu, L.; Yang, H.; Gao, B.; Sun, K. Predictive Maintenance of Power Substation Equipment by Infrared Thermography Using a Machine-Learning Approach. Energies 2017, 10, 1987. [Google Scholar] [CrossRef] [Green Version]

- Mopuri, K.R.; Babu, R.V. Object Level Deep Feature Pooling for Compact Image Representation. In Proceedings of the IEEE Computer Society Conference on Computer Vision and Pattern Recognition Workshops, IEEE Computer Society, Boston, MA, USA, 7–12 June 2015; pp. 62–70. [Google Scholar]

- Fei-Fei, L.; Perona, P. A Bayesian Hierarchical Model for Learning Natural Scene Categories. In Proceedings of the 2005 IEEE Computer Society Conference on Computer Vision and Pattern Recognition (CVPR 2005), San Diego, CA, USA, 20–25 June 2005. [Google Scholar]

- Lowe, D.G. Distinctive Image Features from Scale-Invariant Keypoints. Int. J. Comput. Vis. 2004, 60, 91–110. [Google Scholar] [CrossRef]

- Bay, H.; Tuytelaars, T.; Van Gool, L. SURF: Speeded up Robust Features. In Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Berlin, Germany, 2006. [Google Scholar]

- Jégou, H.; Douze, M.; Schmid, C.; Pérez, P. Aggregating Local Descriptors into a Compact Image Representation. In Proceedings of the IEEE Computer Society Conference on Computer Vision and Pattern Recognition, San Francisco, CA, USA, 13–18 June 2010; pp. 3304–3311. [Google Scholar]

- Jégou, H.; Perronnin, F.; Douze, M.; Sánchez, J.; Pérez, P.; Schmid, C. Aggregating Local Image Descriptors into Compact Codes. IEEE Trans. Pattern Anal. Mach. Intell. 2012, 34, 1704–1716. [Google Scholar] [CrossRef] [Green Version]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet Classification with Deep Convolutional Neural Networks. In Advances in Neural Information Processing Systems; MIT Press: Cambridge, MA, USA, 2012; pp. 84–90. [Google Scholar]

- Simonyan, K.; Zisserman, A. Very Deep Convolutional Networks for Large-Scale Image Recognition. arXiv 2014, arXiv:1409.1556. [Google Scholar]

- Oquab, M.; Bottou, L.; Laptev, I.; Sivic, J. Learning and Transferring Mid-Level Image Representations Using Convolutional Neural Networks. In Proceedings of the IEEE Computer Society Conference on Computer Vision and Pattern Recognition, Columbus, OH, USA, 24–27 June 2014; pp. 1717–1724. [Google Scholar]

- Ren, S.; He, K.; Girshick, R.; Sun, J. Faster R-CNN: Towards Real-Time Object Detection with Region Proposal Networks. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 1137–1149. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, W.; Anguelov, D.; Erhan, D.; Szegedy, C.; Reed, S.; Fu, C.Y.; Berg, A.C. SSD: Single Shot Multibox Detector. In Proceedings of the European Conference on Computer Vision, Amsterdam, The Netherlands, 11–14 October 2016; Volume 9905, pp. 21–37. [Google Scholar]

- Dai, J.; Li, Y.; He, K.; Sun, J. R-FCN: Object Detection via Region-Based Fully Convolutional Networks. arXiv 2016, arXiv:1605.06409v2. [Google Scholar]

- Zeiler, M.D.; Fergus, R. Visualizing and Understanding Convolutional Networks. In Lecture Notes in Computer Science (including subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Cham, Switzerland, 2014; Volume 868, pp. 818–833. [Google Scholar]

- Amit, Y.; Geman, D. Shape Quantization and Recognition with Randomized Trees. Neural Comput. 1997, 9, 1545–1588. [Google Scholar] [CrossRef] [Green Version]

- Ho, T.K. The Random Subspace Method for Constructing Decision Forests. IEEE Trans. Pattern Anal. Mach. Intell. 1998, 20, 832–844. [Google Scholar]

- Dietterich, T.G. Experimental Comparison of Three Methods for Constructing Ensembles of Decision Trees: Bagging, Boosting, and Randomization. Mach. Learn. 2000, 40, 139–157. [Google Scholar] [CrossRef]

- Freund, Y.; Schapire, R.E. Experiments with a New Boosting Algorithm. In Proceedings of the 13th International Conference Machine Learning, Bari, Italy, 3–6 July 1996. [Google Scholar]

- Shawe-Taylor, J.; Cristianini, N. Kernel Methods for Pattern Analysis; Cambridge University Press: New York, NY, USA, 2004. [Google Scholar]

- Breiman, L.; Friedman, J.H.; Olshen, R.A.; Stone, C.J. Classification and Regression Trees; Routledge: Abingdon, UK, 2017. [Google Scholar]

- Breiman, L. Bagging Predictors. Mach. Learn. 1996, 24, 123–140. [Google Scholar] [CrossRef] [Green Version]

- Bühlmann, P.; Yu, B. Analyzing Bagging. Ann. Stat. 2002, 30, 927–961. [Google Scholar] [CrossRef]

- Buja, A.; Stuetzle, W. Observations on Bagging. Stat. Sin. 2006, 16, 323. [Google Scholar]

- Biau, G.; Devroye, L. On the Layered Nearest Neighbour Estimate, the Bagged Nearest Neighbour Estimate and the Random Forest Method in Regression and Classification. J. Multivar. Anal. 2010, 101, 2499–2518. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Kumar, S.R.; Mitra, M.; Zhu, W.J.; Zabih, R. Image indexing using color correlograms. In Proceedings of the IEEE Computer Society Conference on Computer Vision and Pattern Recognition, San Juan, PR, USA, 17–19 June 1997. [Google Scholar]

- LeNet-5—A Classic CNN Architecture—engMRK. Available online: https://engmrk.com/lenet-5-a-classic-cnn-architecture/ (accessed on 15 December 2019).

- Russakovsky, O.; Deng, J.; Su, H. ImageNet Large Scale Visual Recognition Challenge. Int. J. Comput. Vis. 2015, 115, 211–252. [Google Scholar] [CrossRef] [Green Version]

| Class of High Voltage Equipment | ΔT (°C) | Recommended Suggestion |

|---|---|---|

| Non-Defective High Voltage Equipment | <21 | Normal working equipment |

| Defective High Voltage Equipment | ≥21 | Defective equipment, high priority equipment |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ullah, I.; Khan, R.U.; Yang, F.; Wuttisittikulkij, L. Deep Learning Image-Based Defect Detection in High Voltage Electrical Equipment. Energies 2020, 13, 392. https://doi.org/10.3390/en13020392

Ullah I, Khan RU, Yang F, Wuttisittikulkij L. Deep Learning Image-Based Defect Detection in High Voltage Electrical Equipment. Energies. 2020; 13(2):392. https://doi.org/10.3390/en13020392

Chicago/Turabian StyleUllah, Irfan, Rehan Ullah Khan, Fan Yang, and Lunchakorn Wuttisittikulkij. 2020. "Deep Learning Image-Based Defect Detection in High Voltage Electrical Equipment" Energies 13, no. 2: 392. https://doi.org/10.3390/en13020392