A Converter with Automatic Stage Transition Control for Inductive Power Transfer

Abstract

:1. Introduction

2. Basic Structure and System Modeling

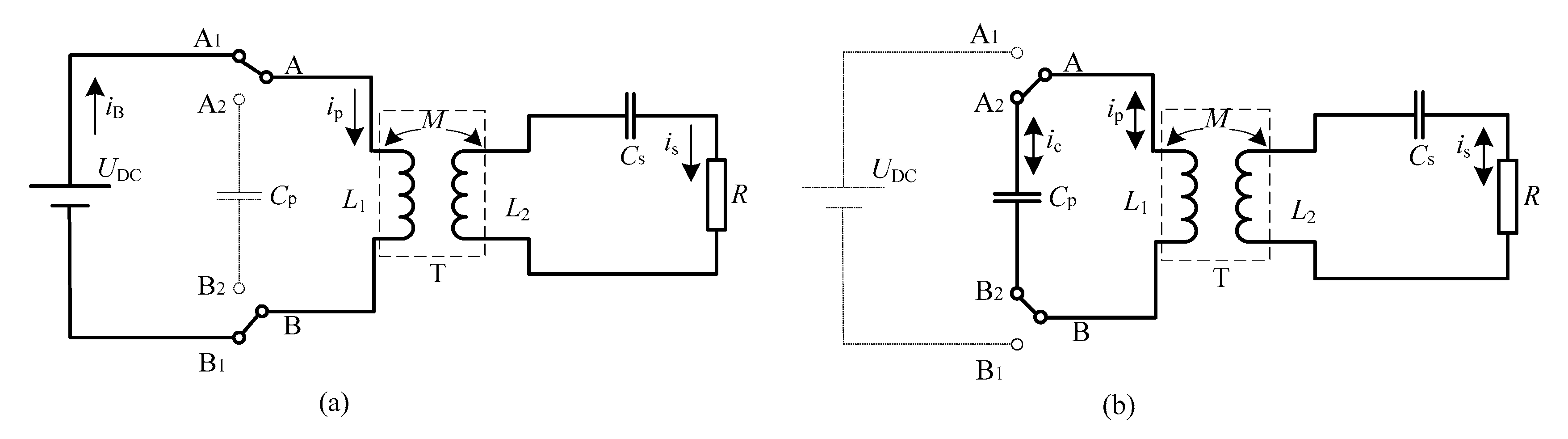

2.1. Basic Structure of the IIEIFR IPT System

2.2. System Modeling

3. The IIEIFR IPT Power Converter

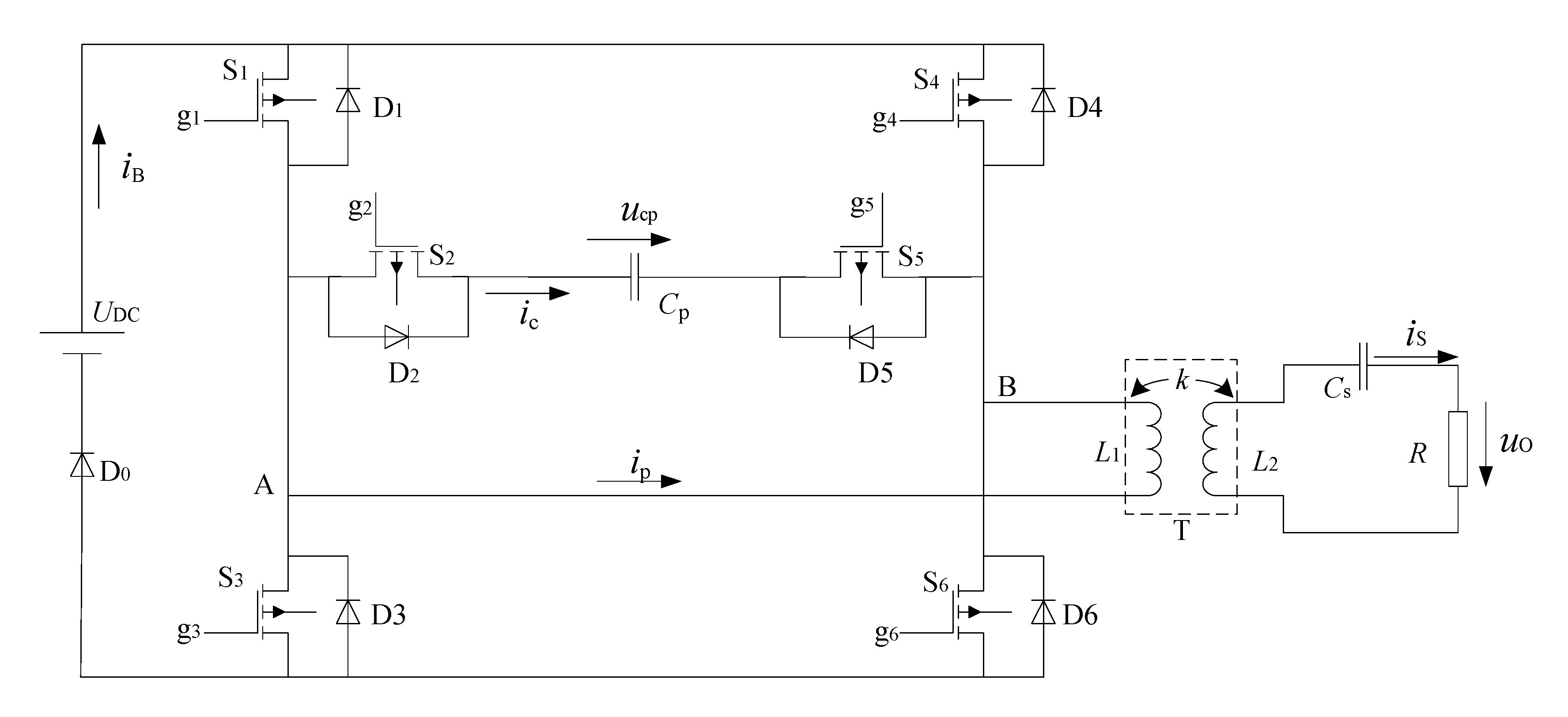

3.1. Topology of the IIEIFR IPT System

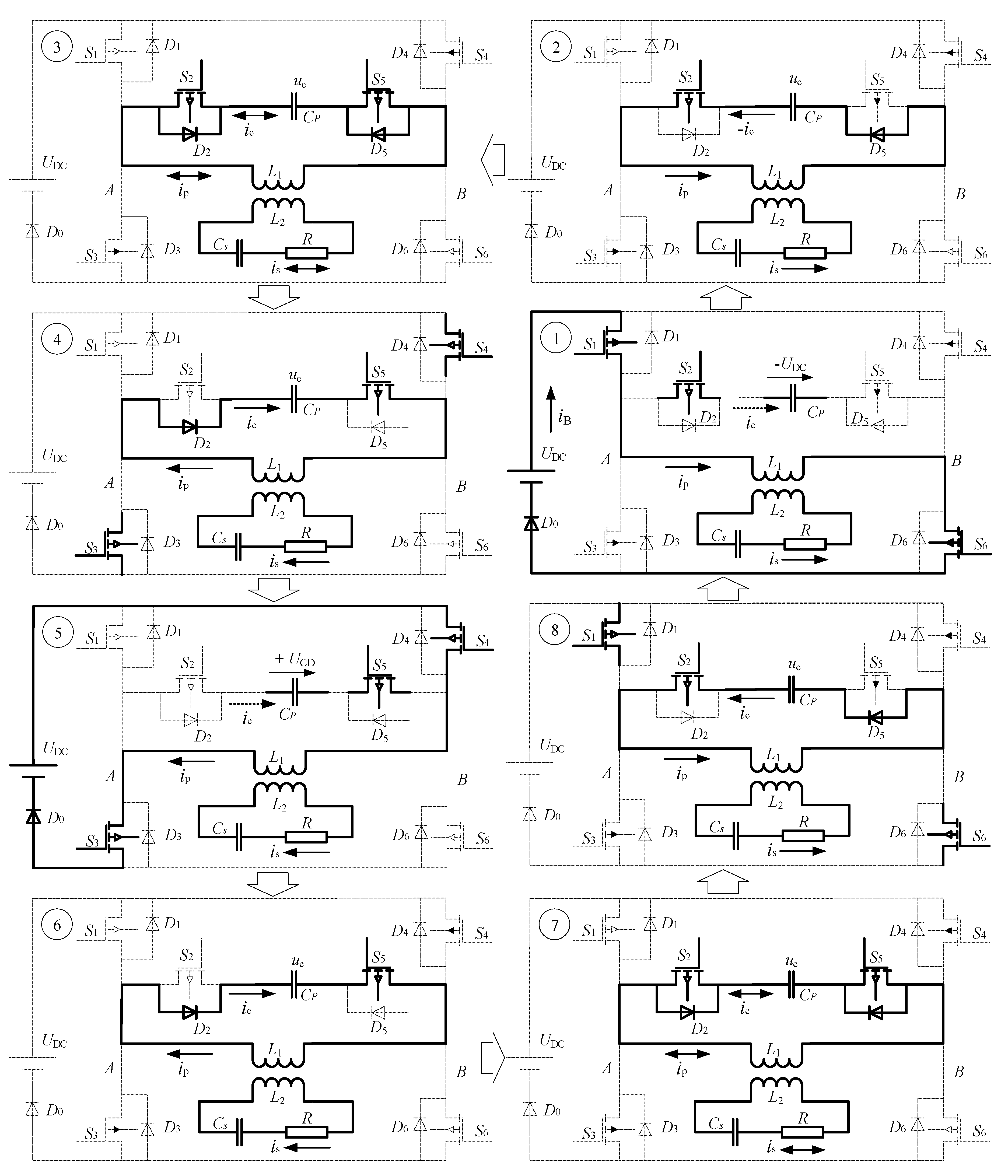

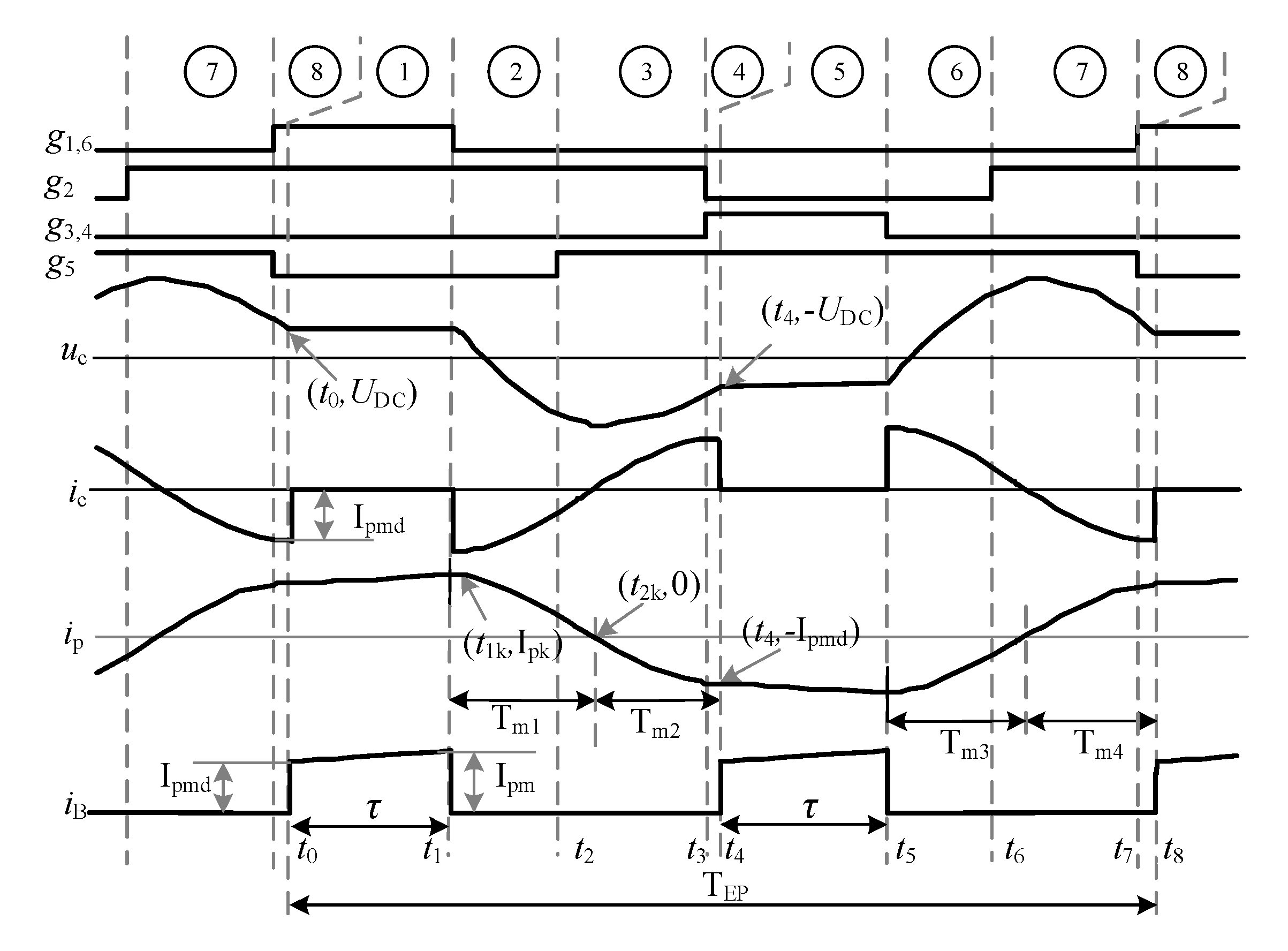

3.2. State Transition Analysis

3.3. The Calculation of Parameters

3.3.1. The Amplitude and Phase Angle of Primary Current

3.3.2. The Energy Injection Time

3.4. Output Power

4. Experimental Verification

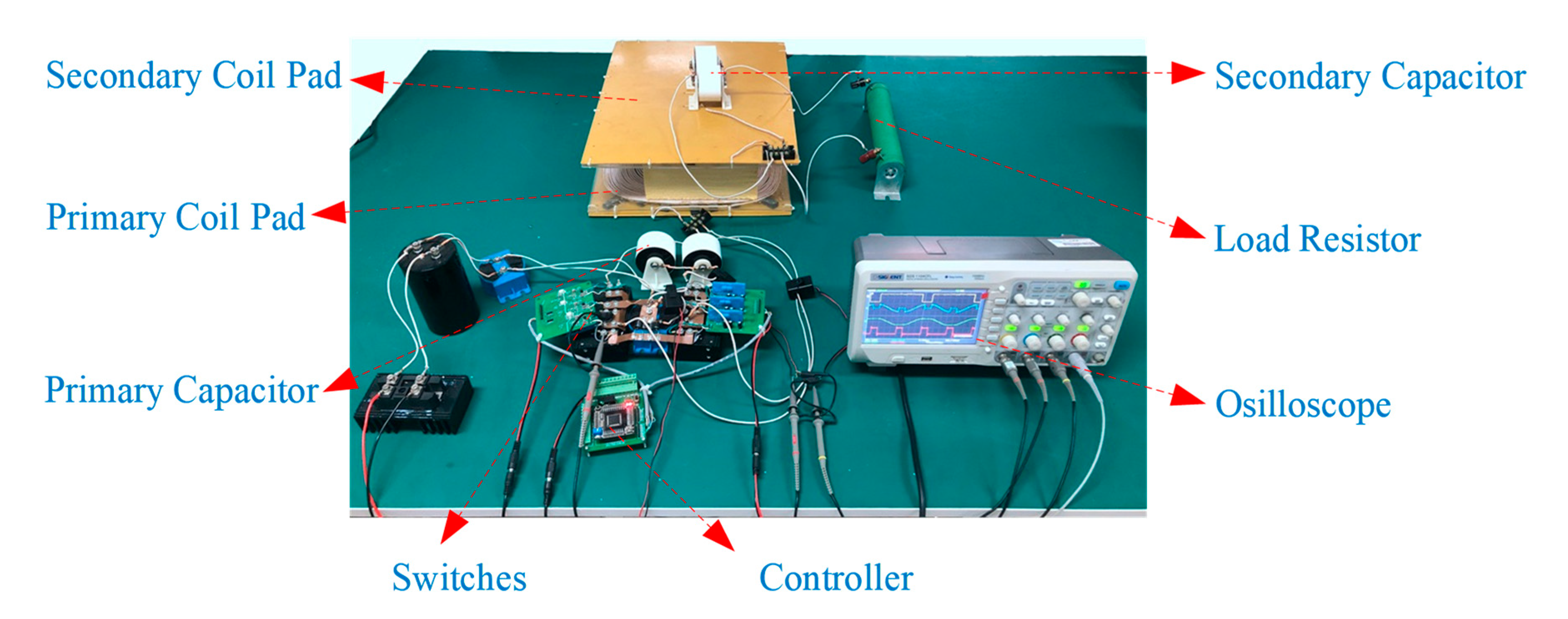

4.1. The Experimental Prototype

4.2. Experimental Results

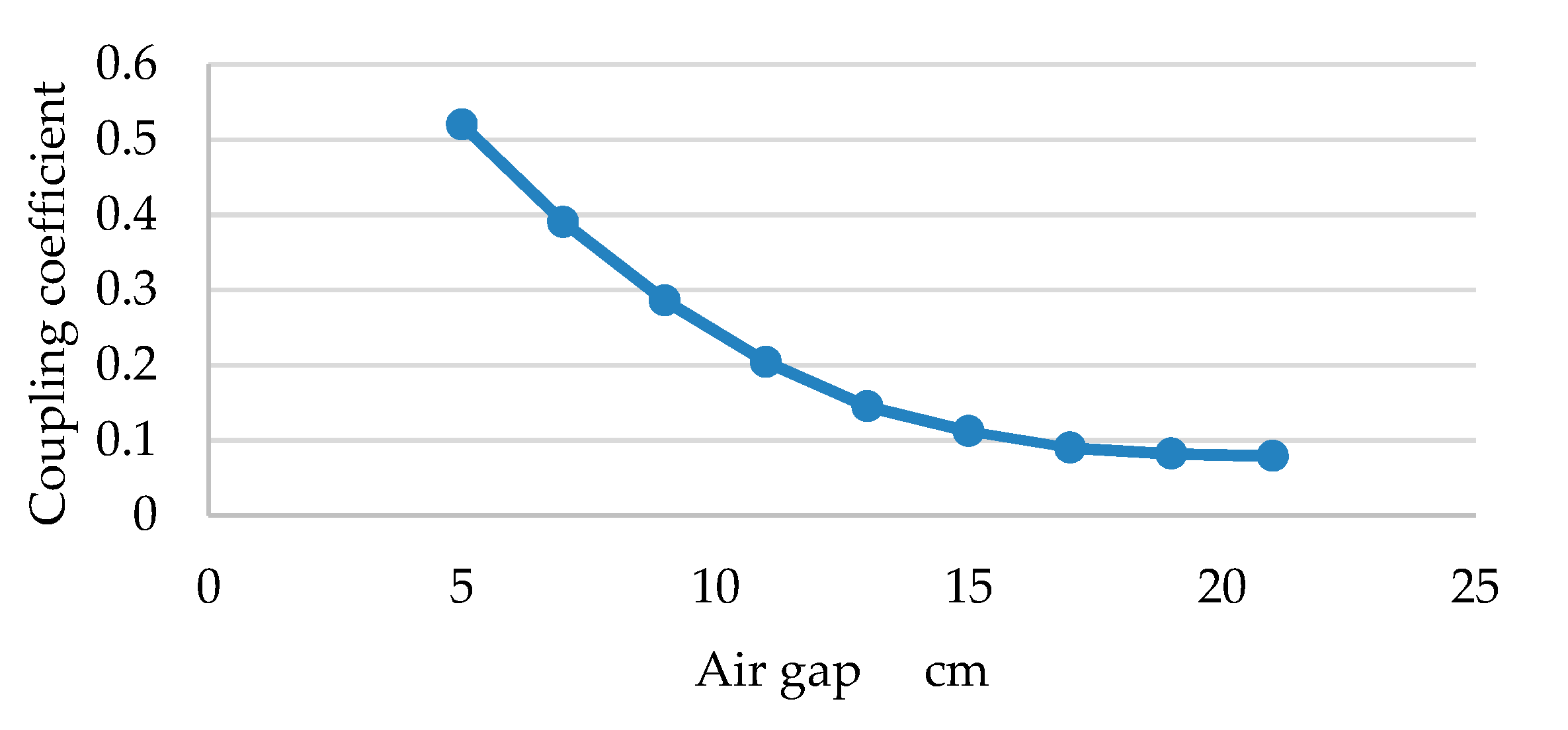

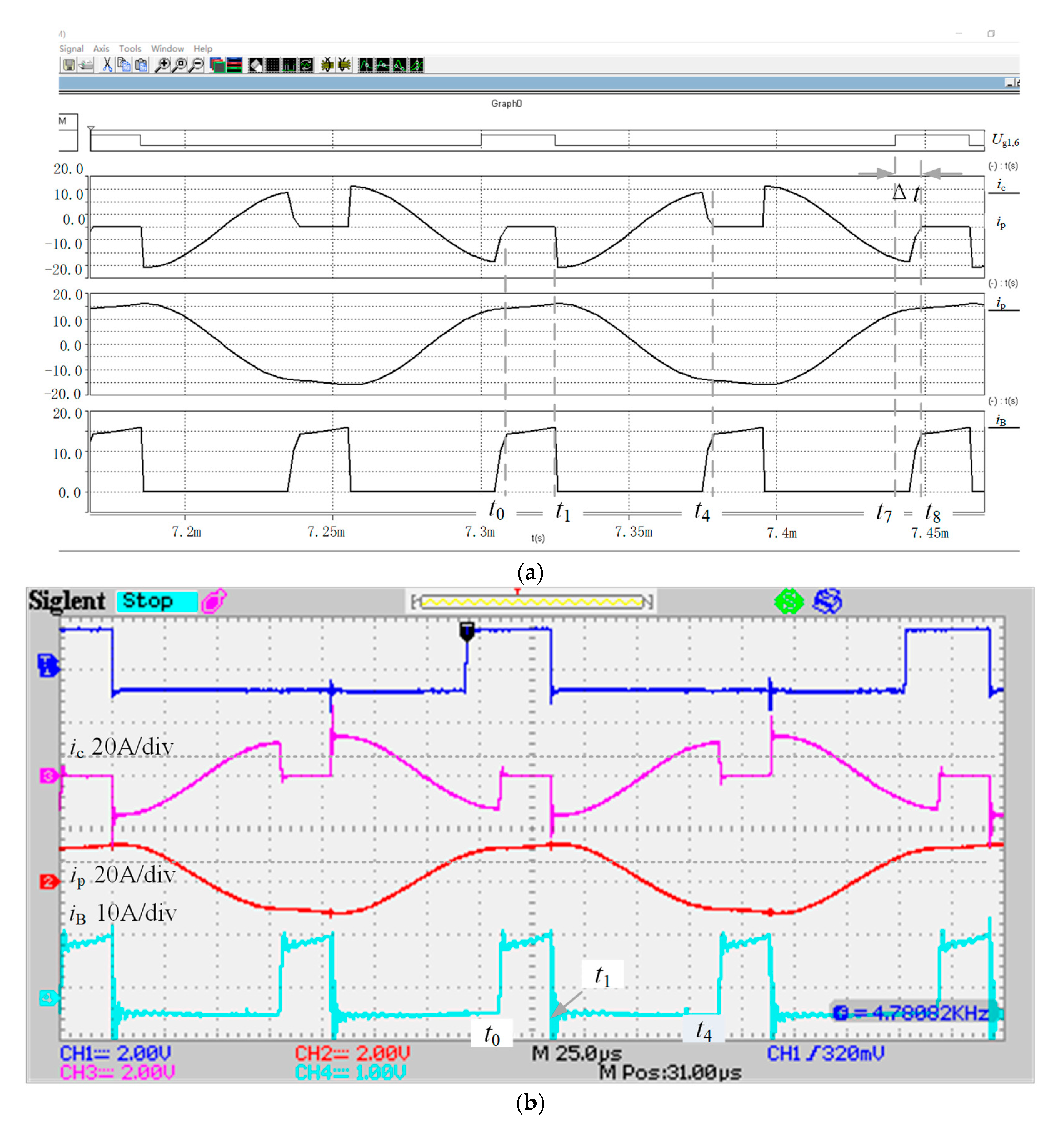

4.2.1. Features of the IIEIFR IPT System

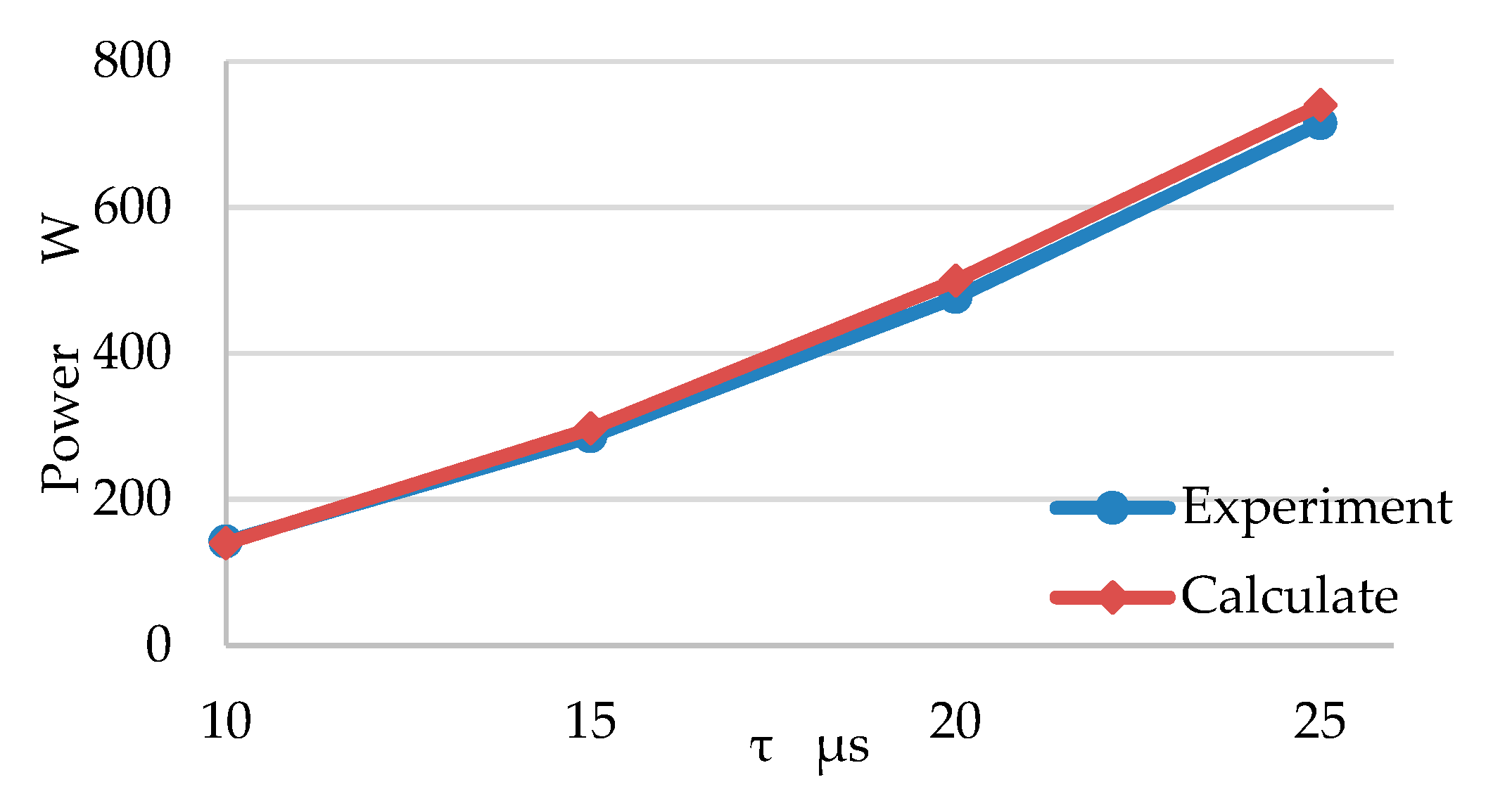

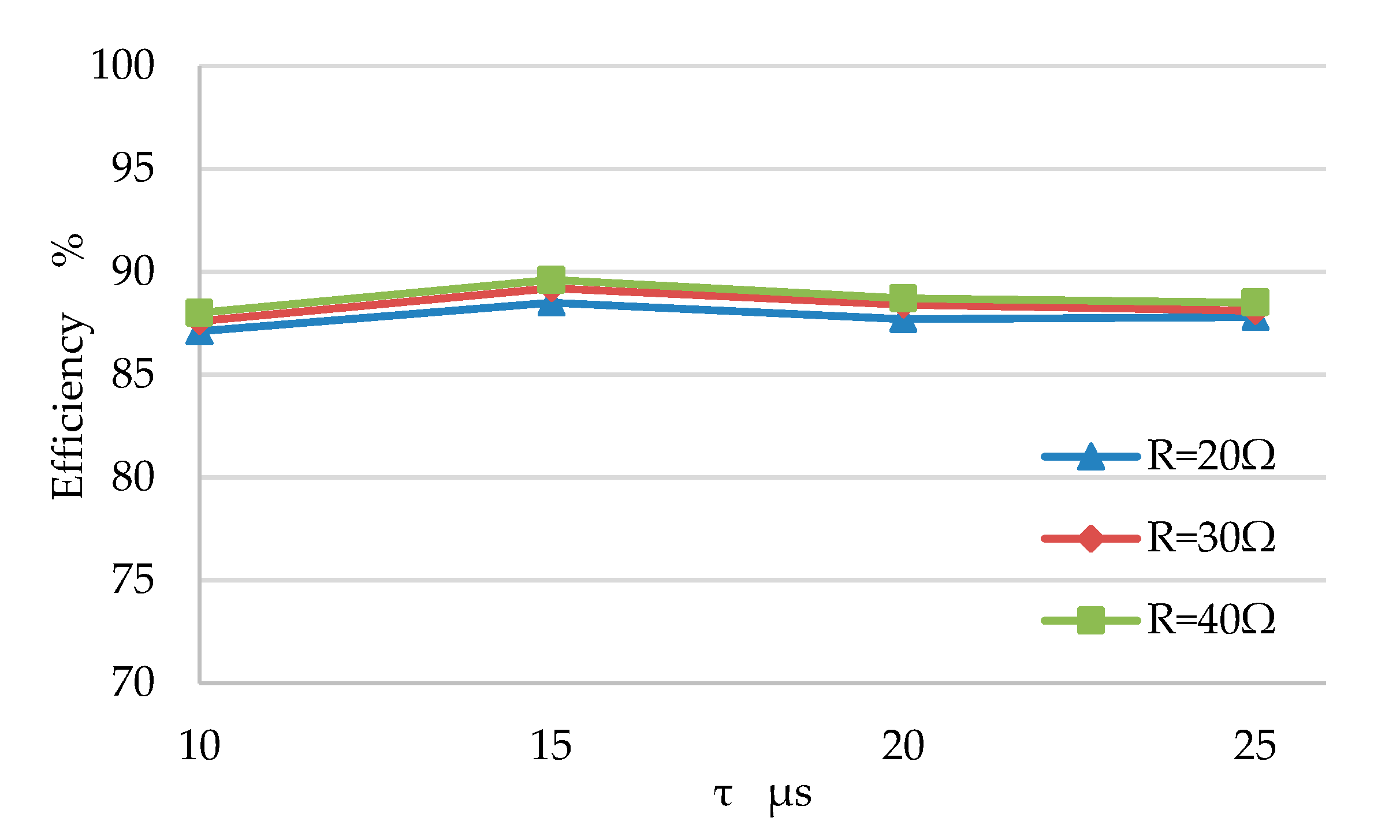

4.2.2. Power Control

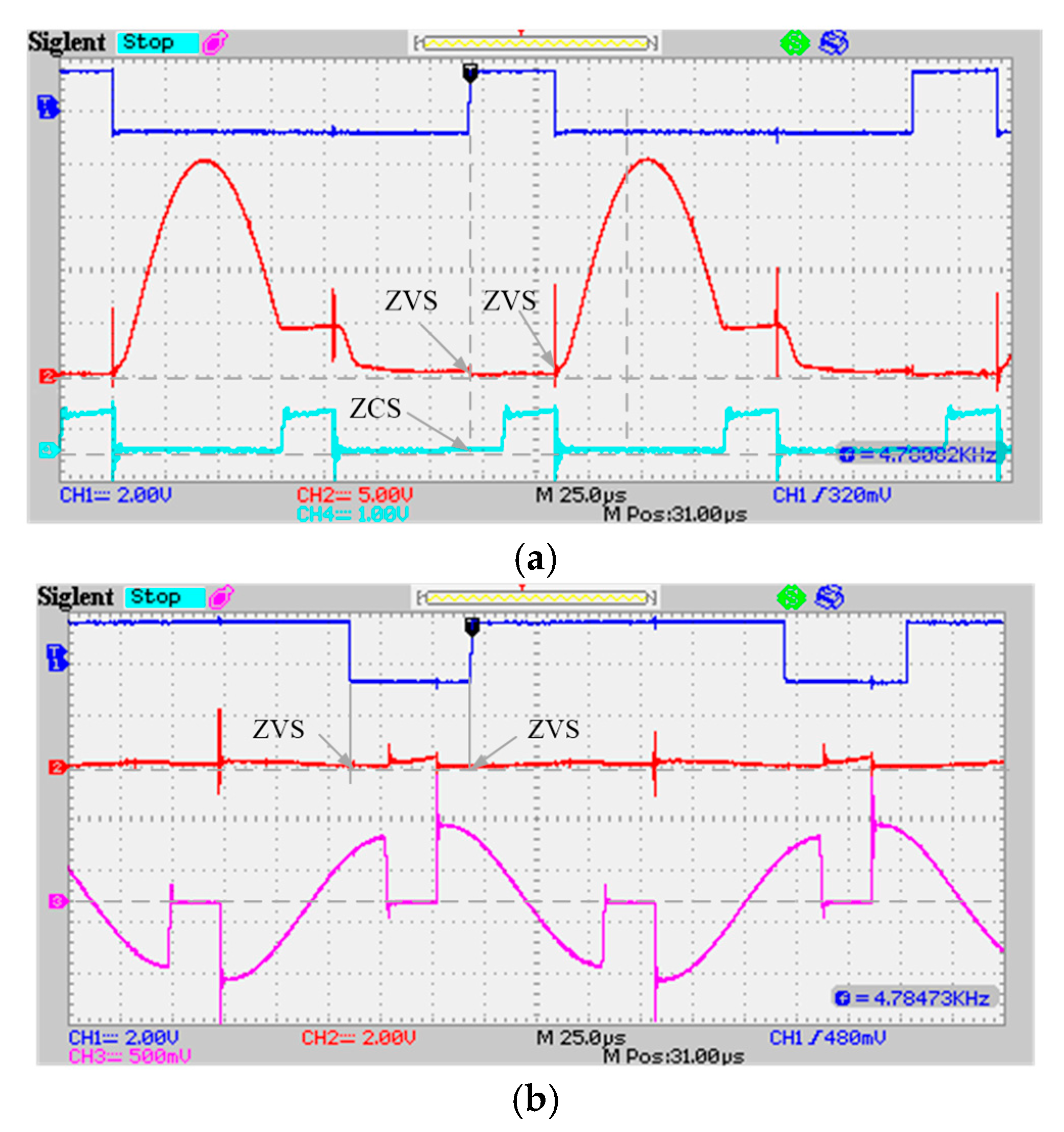

4.2.3. Soft Switching Condition

5. Conclusions and Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Zhong, W.; Lee, C.K.; Hui, S.Y.R. General analysis on the use of tesla’s resonators in domino forms for wireless power transfer. IEEE Trans. Ind. Electron. 2013, 60, 261–270. [Google Scholar] [CrossRef]

- Steckiewicz, A.; Stankiewicz, J.M.; Choroszucho, A. Numerical and circuit modeling of the low-power periodic WPT systems. Energies 2020, 13, 2561. [Google Scholar] [CrossRef]

- Barman, S.D.; Reza, A.W.; Kumar, N.; Karim, M.E.; Munir, A.B. Wireless powering by magnetic resonant coupling: Recent trends in wireless power transfer system and its applications. Renew Sustain. Energy Rev. 2015, 51, 1525–1552. [Google Scholar] [CrossRef]

- Lee, S.-H.; Kim, J.-H.; Lee, J.-H. Development of a 60 kHz, 180 kW, Over 85% Efficiency Inductive Power Transfer System for a Tram. Energies 2016, 9, 1075. [Google Scholar] [CrossRef]

- Campi, T.; Cruciani, S.; Feliziani, M. wireless power transfer technology applied to an autonomous electric UAV with a small secondary coil. Energies 2018, 11, 352. [Google Scholar] [CrossRef]

- Lu, Y.; Ma, D.B. Wireless power transfer system architectures for portable or implantable applications. Energies 2016, 9, 1087. [Google Scholar] [CrossRef]

- Kim, C.G.; Seo, D.H.; You, J.S.; Park, J.H.; Cho, B.H. Design of a contactless battery charger for cellular phone. IEEE Trans. Ind. Electron. 2001, 48, 1238–1247. [Google Scholar] [CrossRef]

- Ibrahim, M.; Pichon, L.; Bernard, L.; Razek, A.; Houivet, J.; Cayol, O. Advanced modeling of a 2-kW series–series resonating inductive charger for real electric vehicle. IEEE Trans. Veh. Technol. 2015, 64, 421–430. [Google Scholar] [CrossRef]

- Villa, J.L.; Sallan, J.; Osorio, S.J.F.; Llombart, A. High-misalignment tolerant compensation topology for icpt systems. IEEE Trans. Ind. Electron. 2012, 59, 945–951. [Google Scholar] [CrossRef]

- Choi, S.Y.; Gu, B.W.; Jeong, S.Y.; Rim, C.T. Advances in wireless power transfer systems for roadway-powered electric vehicles. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 3, 18–36. [Google Scholar] [CrossRef]

- Zheng, C.; Ma, H.; Lai, J.S.; Zhang, L. Design considerations to reduce gap variation and misalignment effects for the inductive power transfer system. IEEE Trans. Power Electron. 2015, 30, 6108–6119. [Google Scholar] [CrossRef]

- Cirimele, V.; Diana, M.; Freschi, F.; Mitolo, M. Inductive power transfer for automotive applications: State-of-the-art and future trends. IEEE Trans. Ind. Appl. 2018, 54, 4069–4079. [Google Scholar] [CrossRef]

- Matysik, J.T. The current and voltage phase shift regulation in resonant converters with integration control. IEEE Trans. Ind. Electron. 2007, 54, 1240–1242. [Google Scholar] [CrossRef]

- Gati, E.; Kampitsis, G.; Manias, S. Variable frequency controller for inductive power transfer in dynamic conditions. IEEE Trans. Power Electron. 2017, 32, 1684–1696. [Google Scholar] [CrossRef]

- Matysik, J.T. A new method of integration control with instantaneous current monitoring for class D series-resonant converter. IEEE Trans. Ind. Electron. 2006, 53, 1564–1576. [Google Scholar] [CrossRef]

- Moghaddami, M.; Sundararajan, A.; Sarwat, A.I. A power-frequency controller with resonance frequency tracking capability for inductive power transfer systems. IEEE Trans. Ind. Appl. 2018, 54, 1773–1783. [Google Scholar] [CrossRef]

- Miller, J.M.; Onar, O.C.; Chinthavali, M. Primary-side power flow control of wireless power transfer for electric vehicle charging. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 147–162. [Google Scholar] [CrossRef]

- Madawala, U.K.; Neath, M.; Thrimawithana, D.J. A power–frequency controller for bidirectional inductive power transfer systems. IEEE Trans. Ind. Electron. 2013, 60, 310–317. [Google Scholar] [CrossRef]

- Berger, A.; Agostinelli, M.; Vesti, S.; Oliver, J.A.; Cobos, J.A.; Huemer, M. A wireless charging system applying phase-shift and amplitude control to maximize efficiency and extractable power. IEEE Trans. Power Electron. 2015, 30, 6338–6348. [Google Scholar] [CrossRef]

- Dede, E.J. Improving the efficiency of IGBT series-resonant inverters using pulse density modulation. IEEE Trans. Ind. Electron. 2011, 58, 979–987. [Google Scholar] [CrossRef]

- Fujita, H.; Akagi, H. Pulse-density-modulated power control of a 4 kw, 450 kHz voltage-source inverter for induction melting applications. IEEE Trans. Ind. Appl. 1996, 32, 279–286. [Google Scholar] [CrossRef]

- Li, H.L.; Hu, A.P.; Covic, G.A. Development of a discrete energy injection inverter for contactless power transfer. In Proceedings of the 2008 3rd IEEE Conference on Industrial Electronics and Applications, Singapore, 3–5 June 2008; pp. 1757–1761. [Google Scholar] [CrossRef]

- Li, H.L.; Hu, A.P.; Covic, G.A. A direct AC–AC converter for inductive power-transfer systems. IEEE Trans. Power Electron. 2012, 27, 661–668. [Google Scholar] [CrossRef]

- Chen, L.; Hong, J.; Guan, M.; Wu, W.; Chen, W. A power converter decoupled from the resonant network for wireless inductive coupling power transfer. Energies 2019, 12, 1192. [Google Scholar] [CrossRef]

- Chen, L.; Hong, J.; Guan, M.; Lin, Z.; Chen, W. A converter based on independently inductive energy injection and free resonance for wireless energy transfer. Energies 2019, 12, 3467. [Google Scholar] [CrossRef]

- Sallán, J.; Villa, J.L.; Llombart, A.; Sanz, J.F. Optimal design of ICPT systems applied to electric vehicle battery charge. IEEE Trans. Ind. Electron. 2009, 56, 2140–2149. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| UDC | 100 V |

| Cp, Cs | 0.88 μF |

| L1, L2 | 640 μH |

| R | 10–40 Ω |

| S1–6 | IXFN56N90 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Hong, J.; Lin, Z.; Luo, D.; Guan, M.; Chen, W. A Converter with Automatic Stage Transition Control for Inductive Power Transfer. Energies 2020, 13, 5268. https://doi.org/10.3390/en13205268

Chen L, Hong J, Lin Z, Luo D, Guan M, Chen W. A Converter with Automatic Stage Transition Control for Inductive Power Transfer. Energies. 2020; 13(20):5268. https://doi.org/10.3390/en13205268

Chicago/Turabian StyleChen, Lin, Jianfeng Hong, Zaifa Lin, Daqing Luo, Mingjie Guan, and Wenxiang Chen. 2020. "A Converter with Automatic Stage Transition Control for Inductive Power Transfer" Energies 13, no. 20: 5268. https://doi.org/10.3390/en13205268