Global Sliding-Mode Suspension Control of Bearingless Switched Reluctance Motor under Eccentric Faults to Increase Reliability of Motor

Abstract

1. Introduction

- An increase in the output power of the motor. To improve the output power of the motor, the axial and radial lengths of the motor must be increased. Moreover, magnetic bearings occupy a rather long axial length of the magnetic bearing motor. Therefore, the critical speed of the rotor will decrease if the axial size of the motor increases, which will result in an increase in output power, which mainly depends on the increase in the radial size of the motor. However, the radial size of the motor is limited by the material’s mechanical strength; meanwhile, the increase in the radial size of the motor will result in a rise in the volume of the magnetic bearing.

- High cost. Magnetic bearings require high-performance power amplifiers and expensive displacement sensors.

- Limited application. Due to large size and high cost, the magnetic bearing motor has limited application in many areas.

1.1. Bearingless Motor

- ➢

- Easy miniaturization and high speed. Suspended winding is wound on the stator poles; therefore, the axial size is smaller relative to the magnetic bearing motor, which may reduce the size of the motor size and increase the critical speed.

- ➢

- High output power. A bearingless motor can generate more power if the shaft length is the same as the magnetic bearing motor.

- ➢

- Low cost. The number of wires as well as inverters is less in the bearingless drive.

- ➢

- Ultra-clean application. Due to seal-free and no-lubrication characteristics, bearingless motors can be applied to ultra-clean applications.

1.2. Development of BSRM

1.3. A Global Sliding-Mode Control (GSMC) Approch for Eccentric Fault Analysis of BSRM

1.4. Objectives

- ■

- A comparison study was undertaken between robust controllers such as SMC and GSMC to obtain minimized eccentric effect under different parameter varying conditions.

- ■

- BSRM mathematical modeling was done, and the assumption is made that an individual phase is magnetically decoupled.

- ■

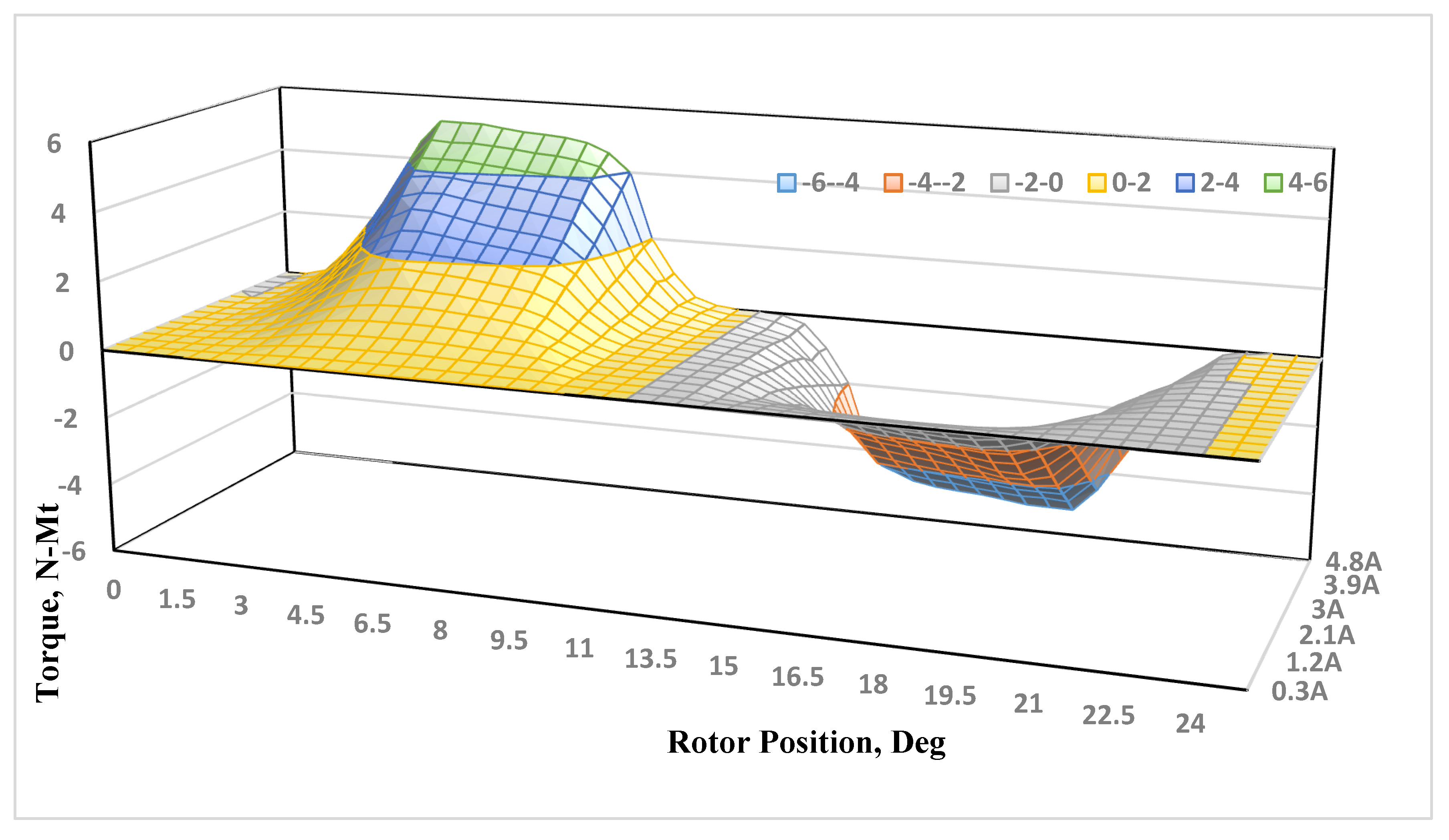

- The finite element method (FEM) is used to analyze the characteristics of the proposed structure, which includes magnetic flux distribution, inductance, torque, and suspended force. In addition to its decoupled nature, the short flux paths in the stator and eccentric effects are also discussed.

- ■

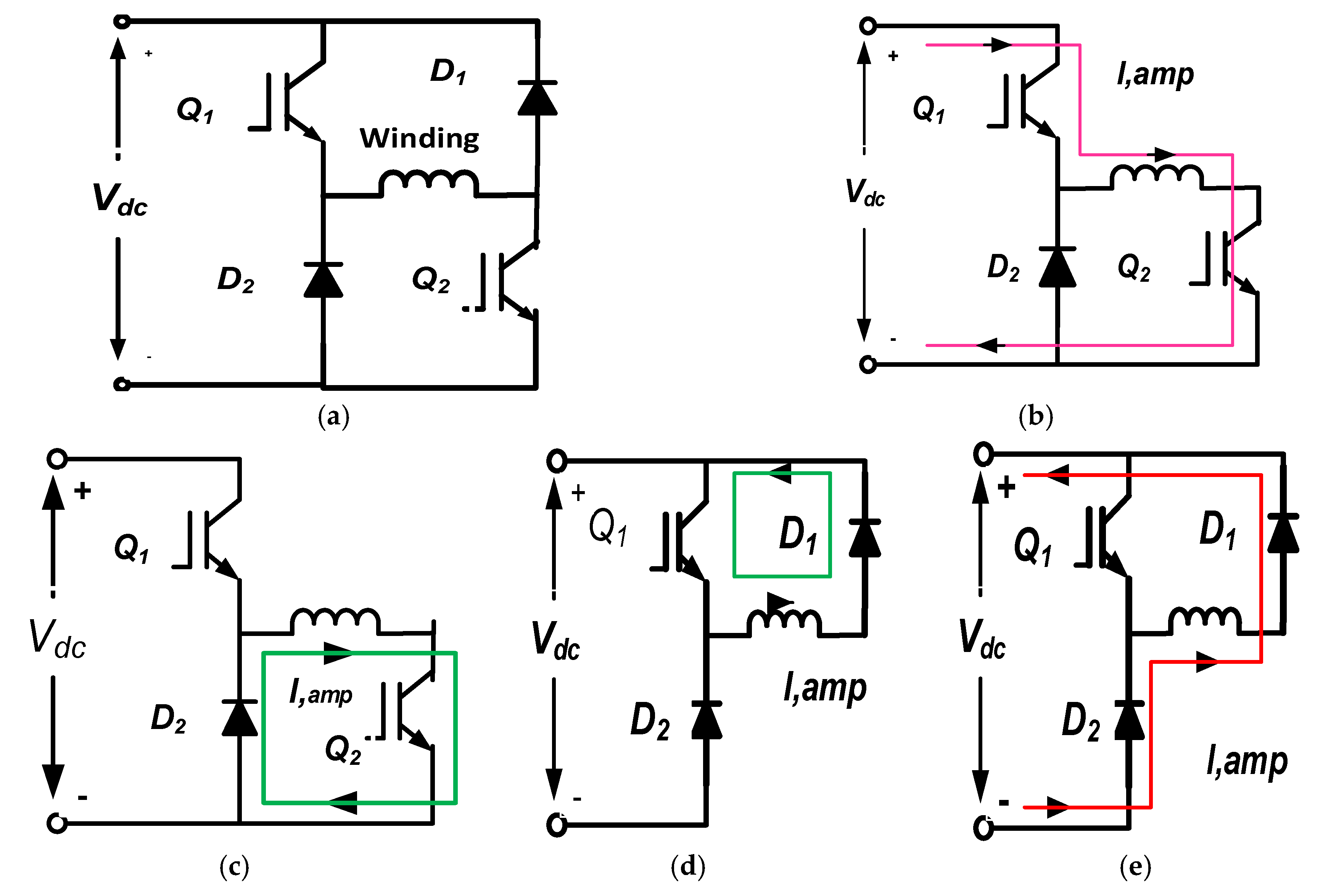

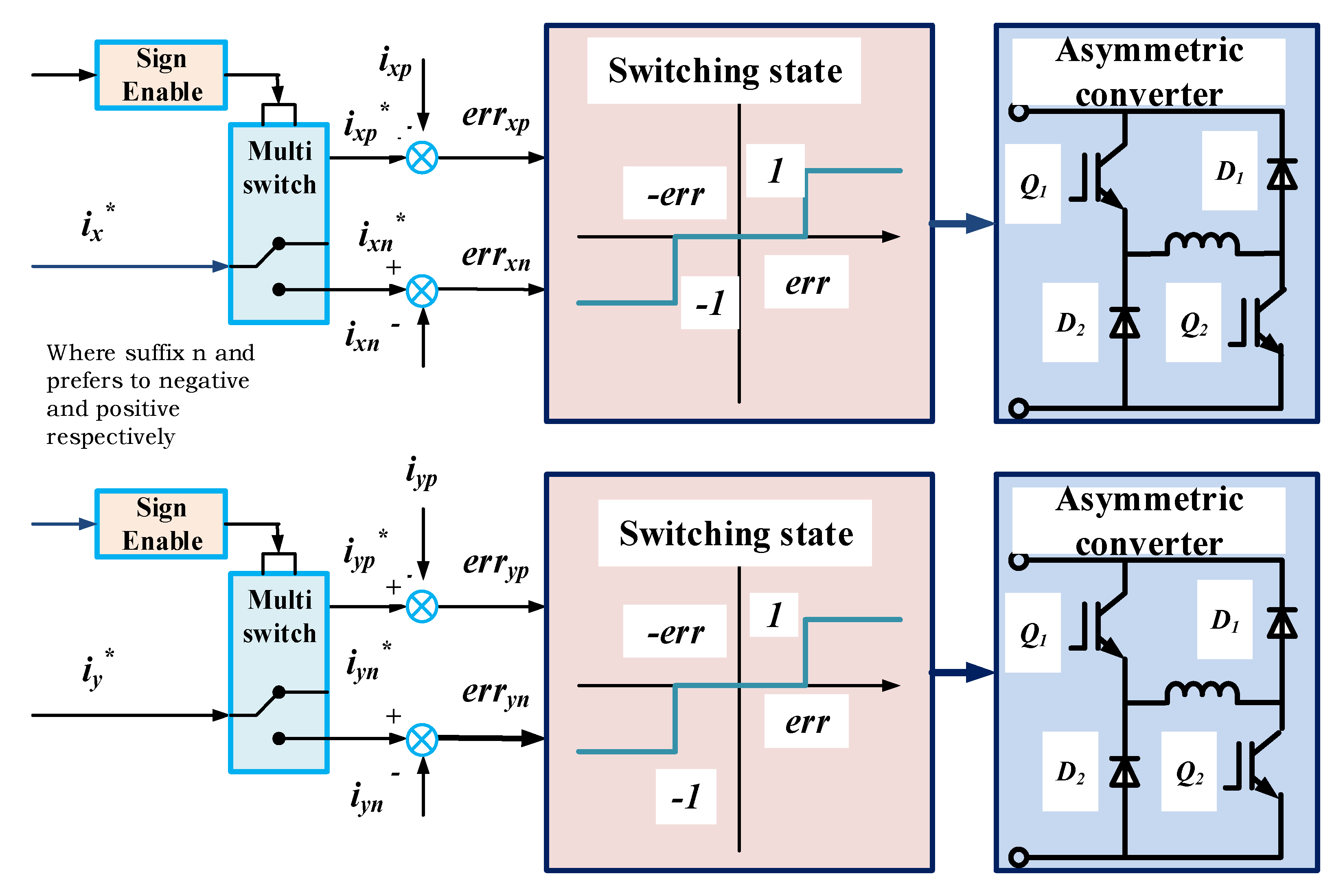

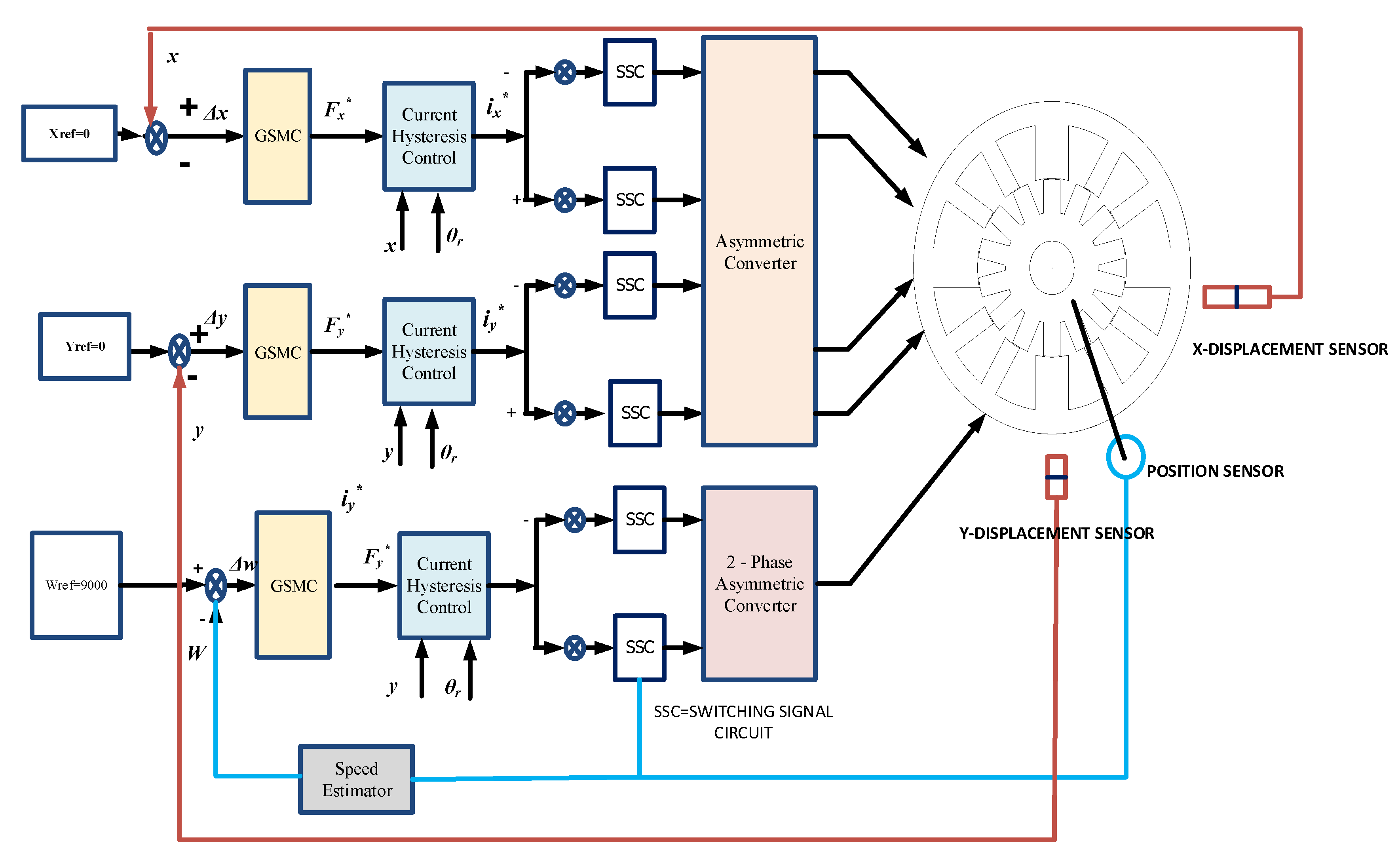

- The converter-based power electronic operation and its modes of operation, switching rules, switching control strategy, and converter topology are also discussed.

- ■

- A simulation model is set up to validate the proposed methodology.

- ■

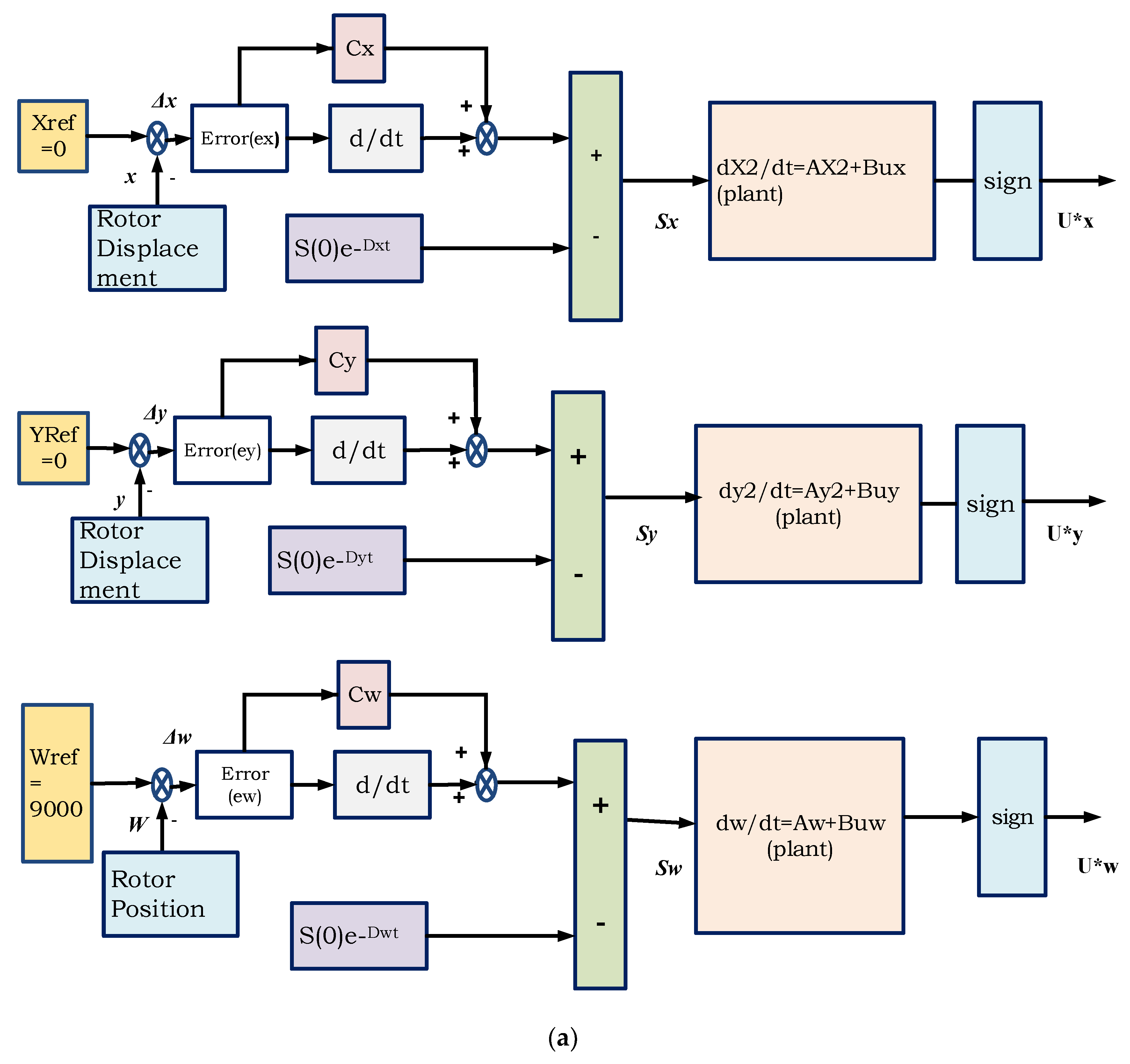

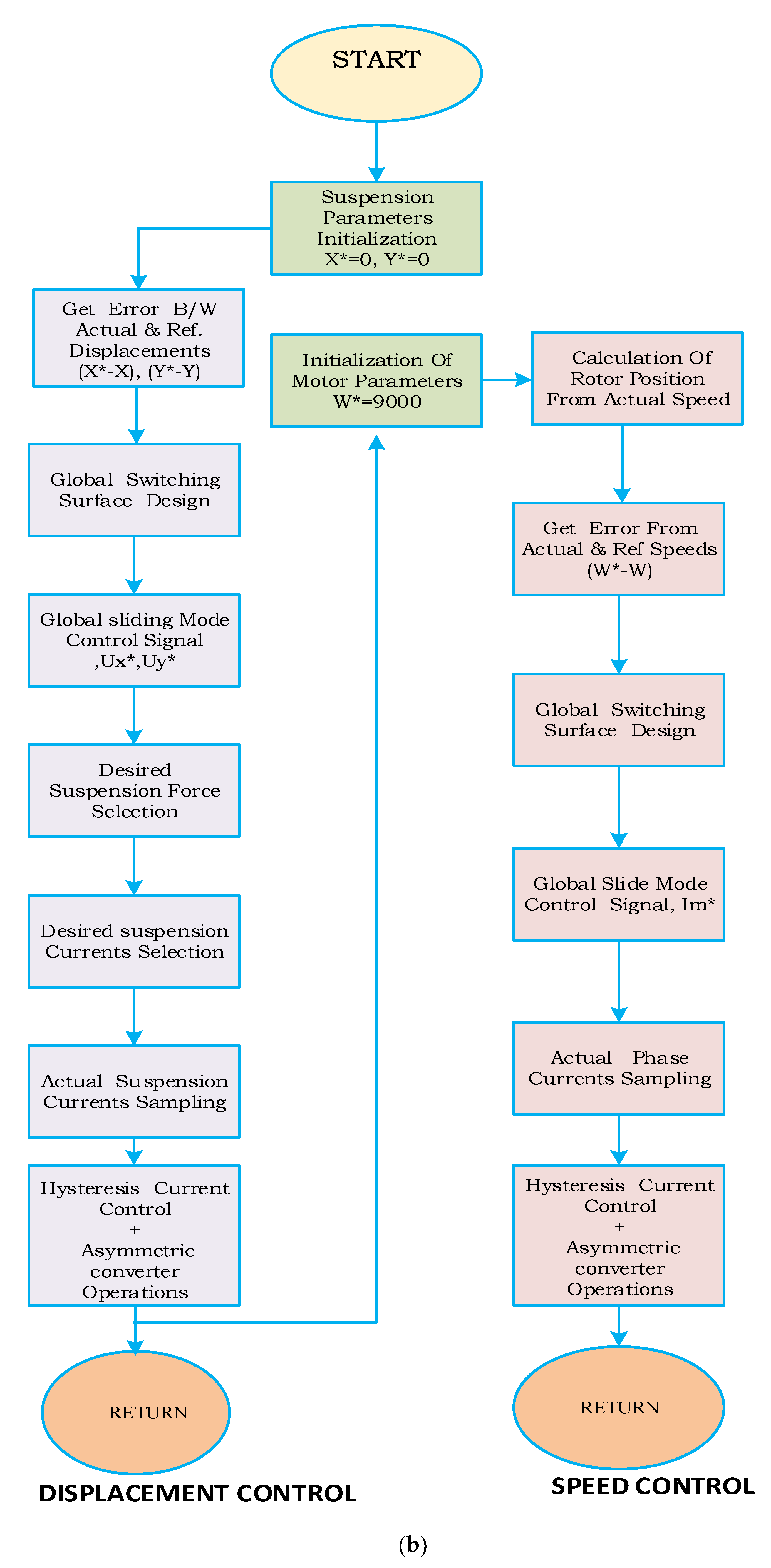

- The simulation of the BSRM is systematically characterized into three steps.

- ➢

- As a primary step, the displaced rotor in any one of the four quadrants in the air gap must be successfully pulled back to the center position with the help of the proposed GSMC suspension controller along with the asymmetric converter, hysteresis controller, and rotor displacement sensors.

- ➢

- The next step is to run the motor at the rated speed by exciting phase currents.

- ➢

- Lastly, to examine the disturbance rejection ability and robustness properties of BSRM, different suspension loads, change of references, and rotor weights are applied separately.

- ■

- With the substantial existence of decoupled behavior between suspension and motor parameters, the suspension and motor loads are applied simultaneously, and the performance properties are shown individually.

1.5. Paper Organization

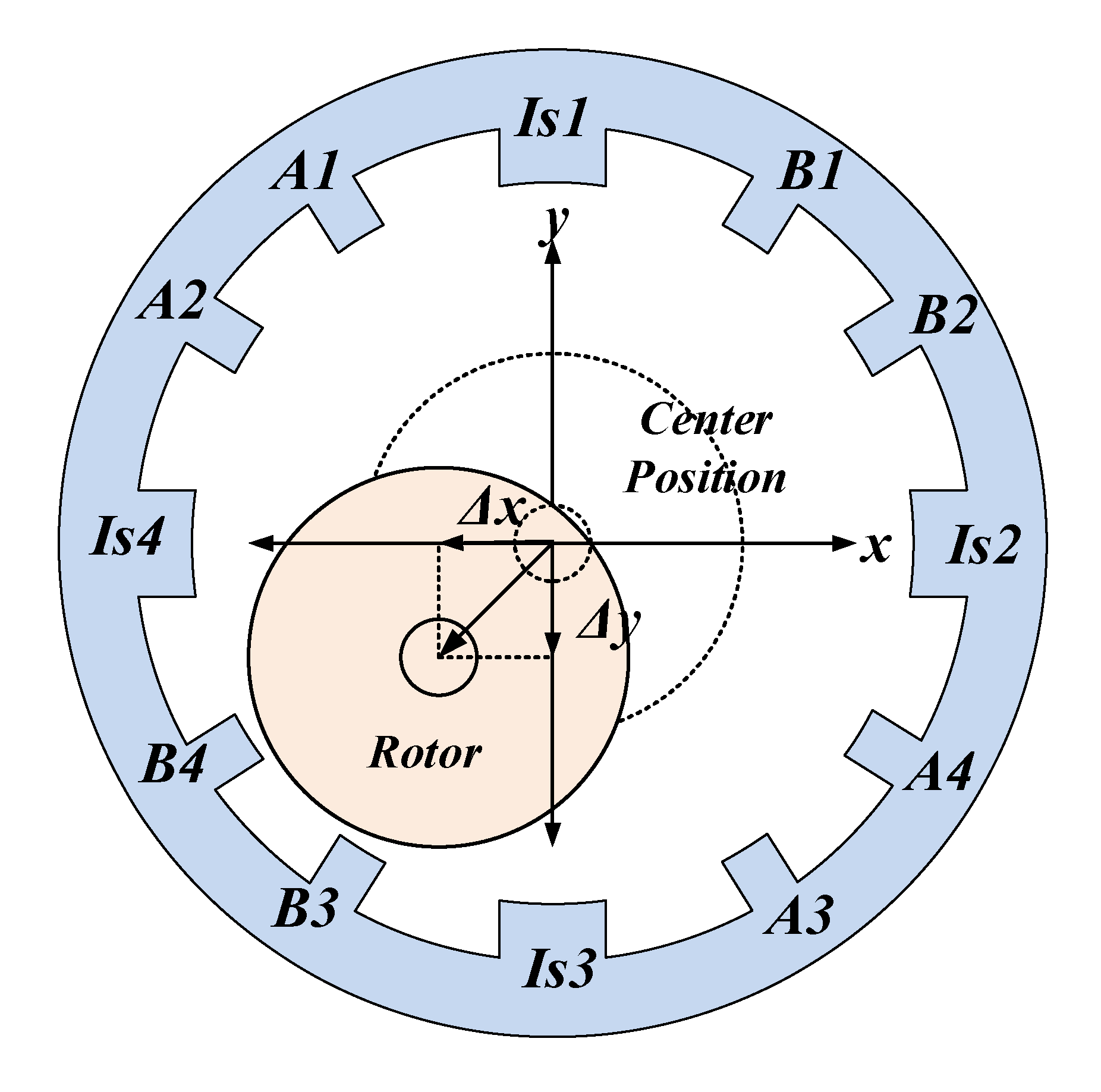

2. Operating Principle and Modeling of BSRM

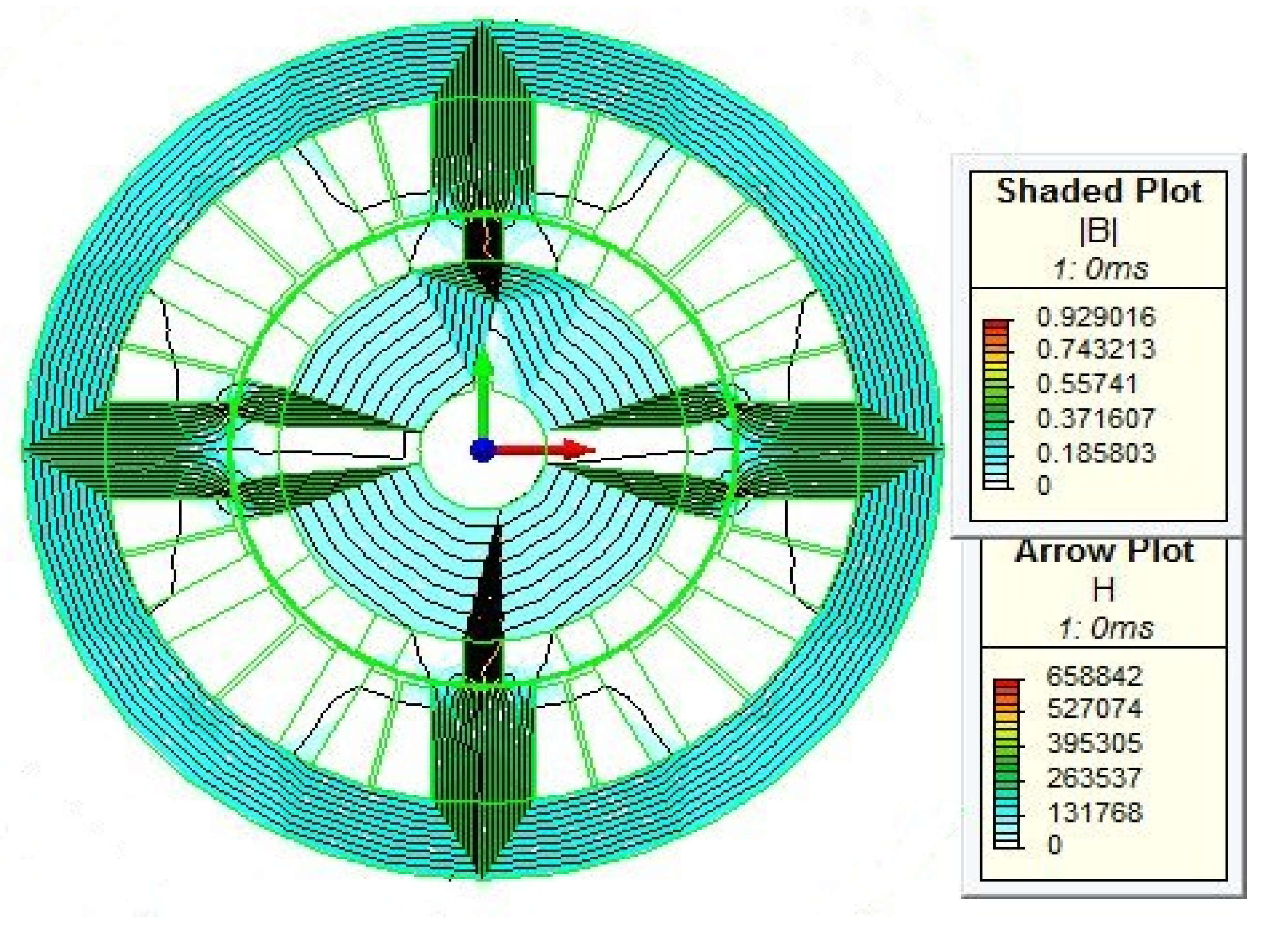

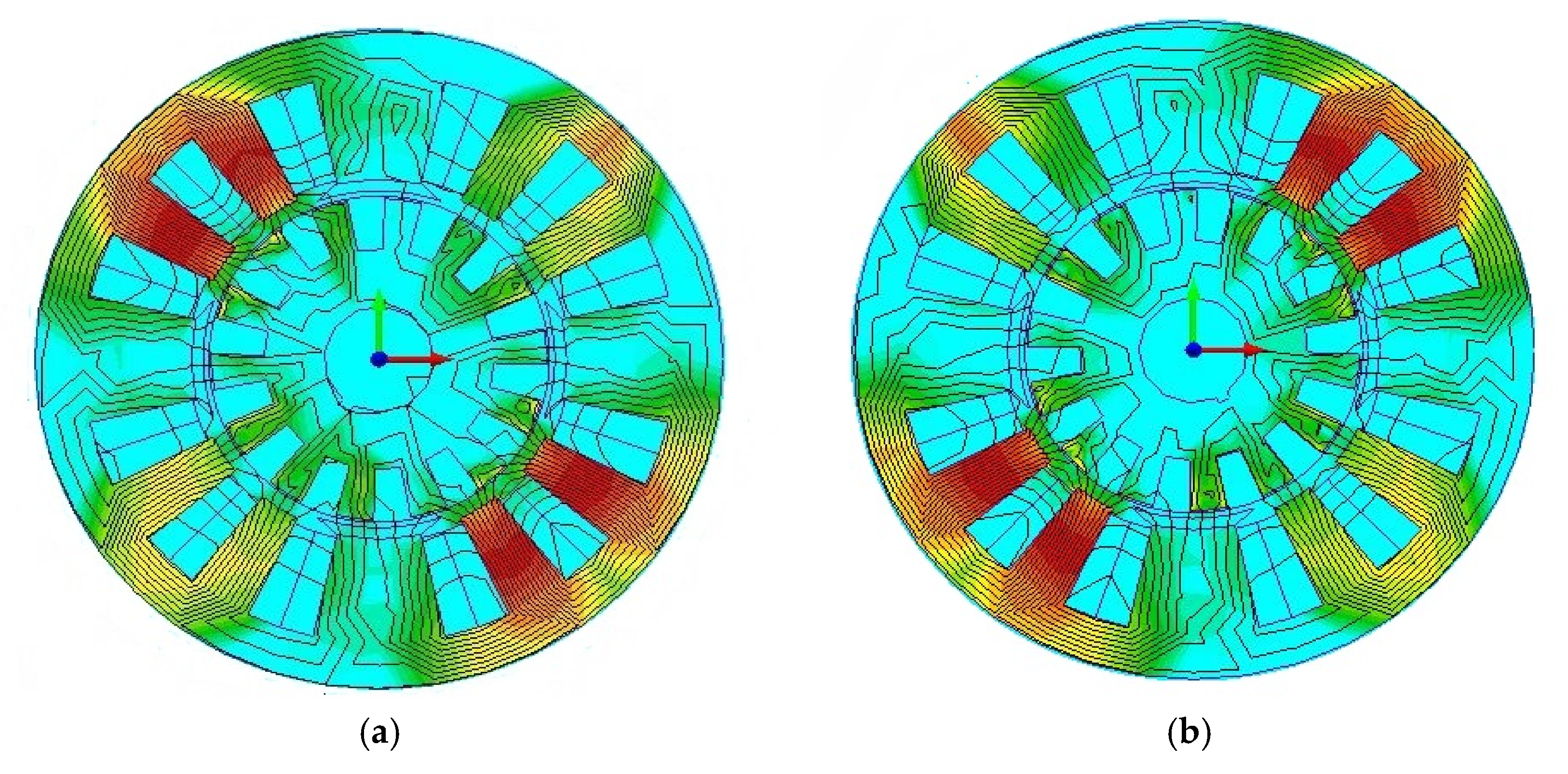

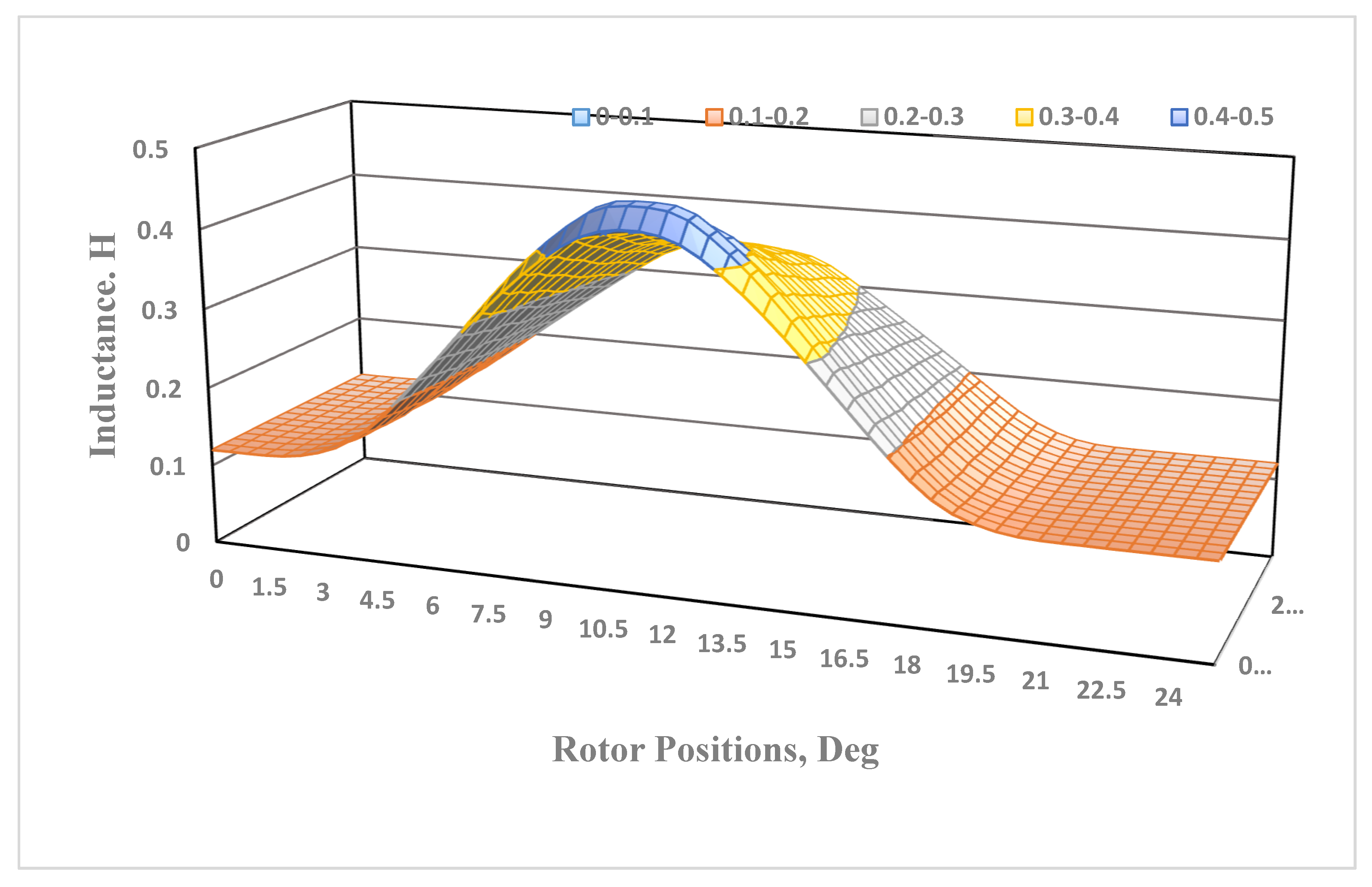

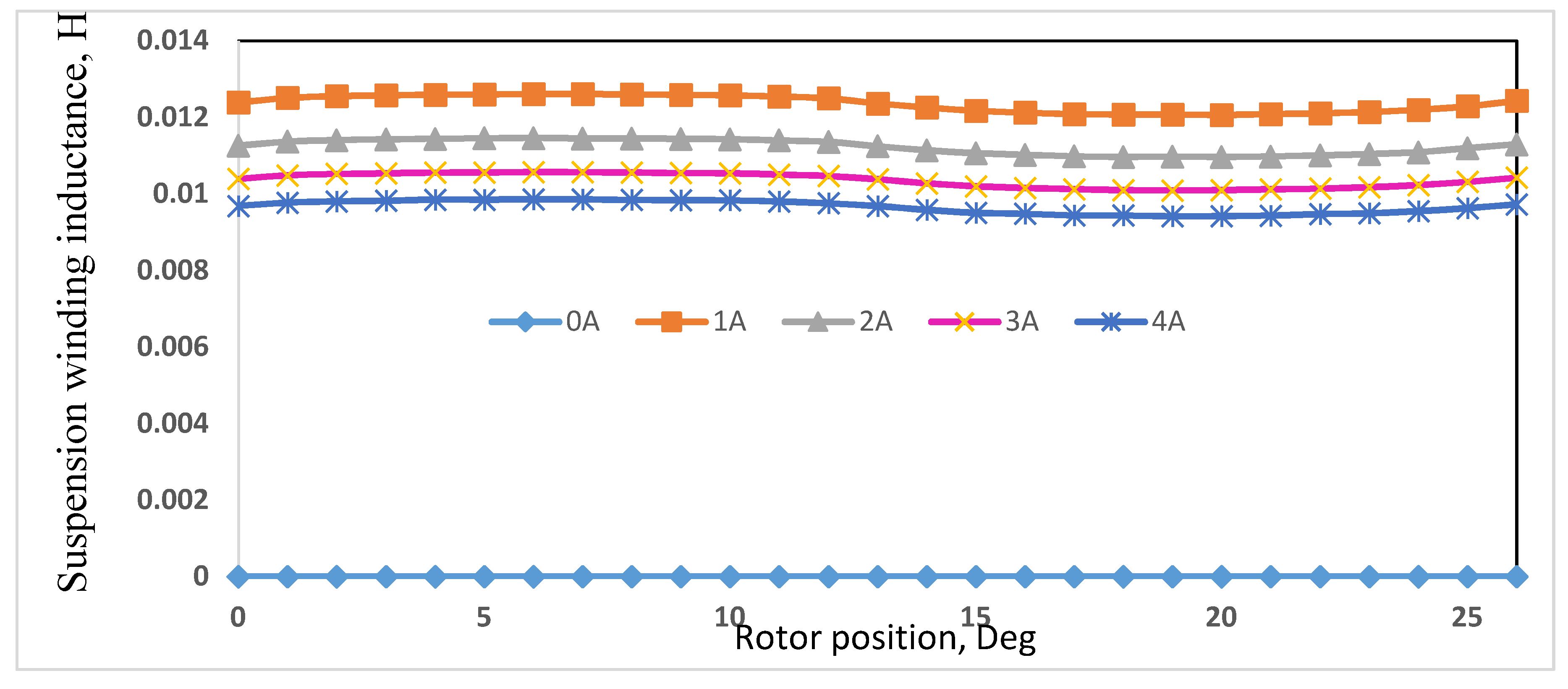

2.1. FEM Analysis

2.2. Rotor Modeling (Suspension Control)

2.3. Modeling of BSRM for Motor Control

2.4. Switching Control Strategy

3. Modeling of Global Sliding-Mode Controller

4. Results and Discussions

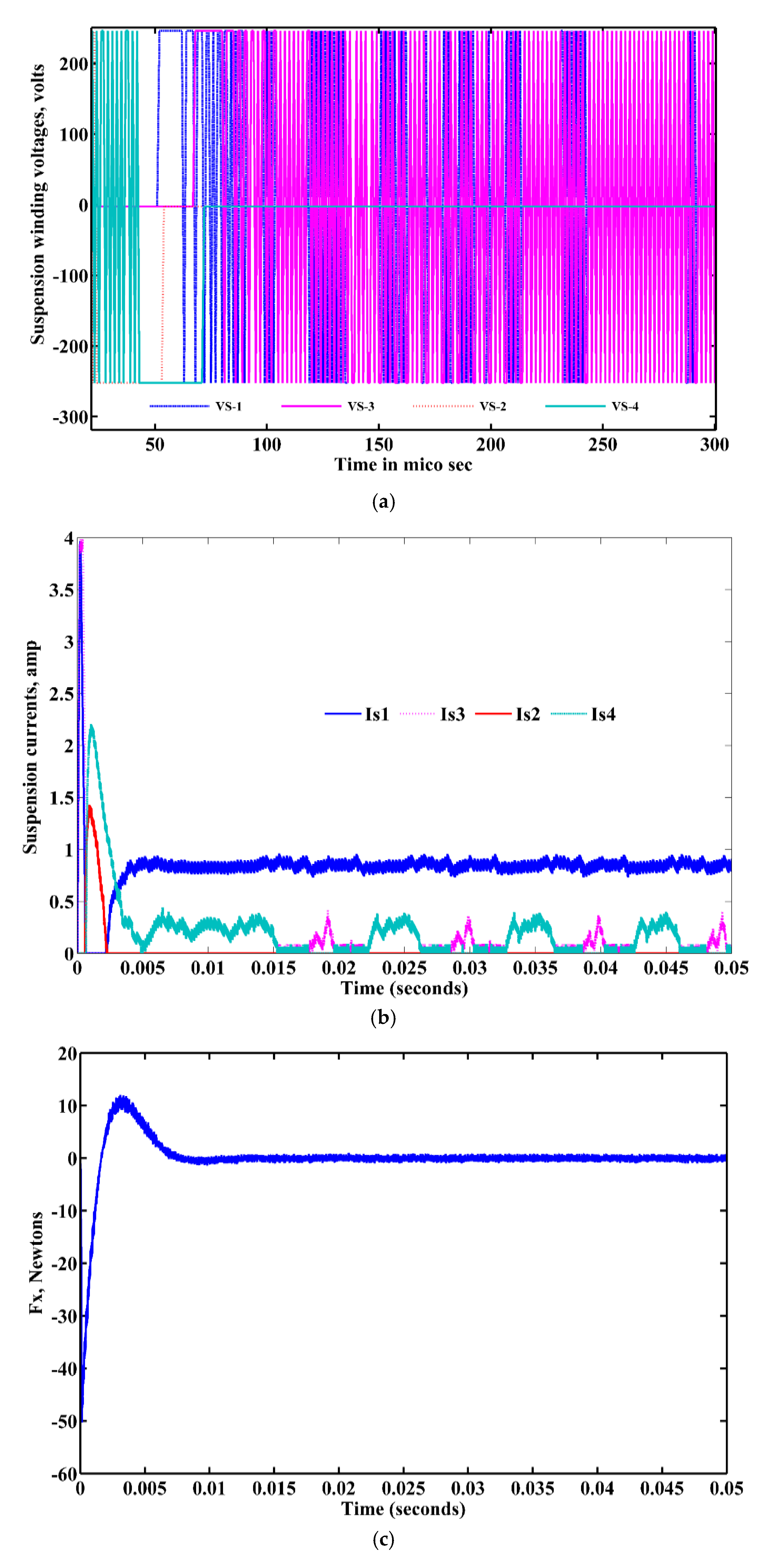

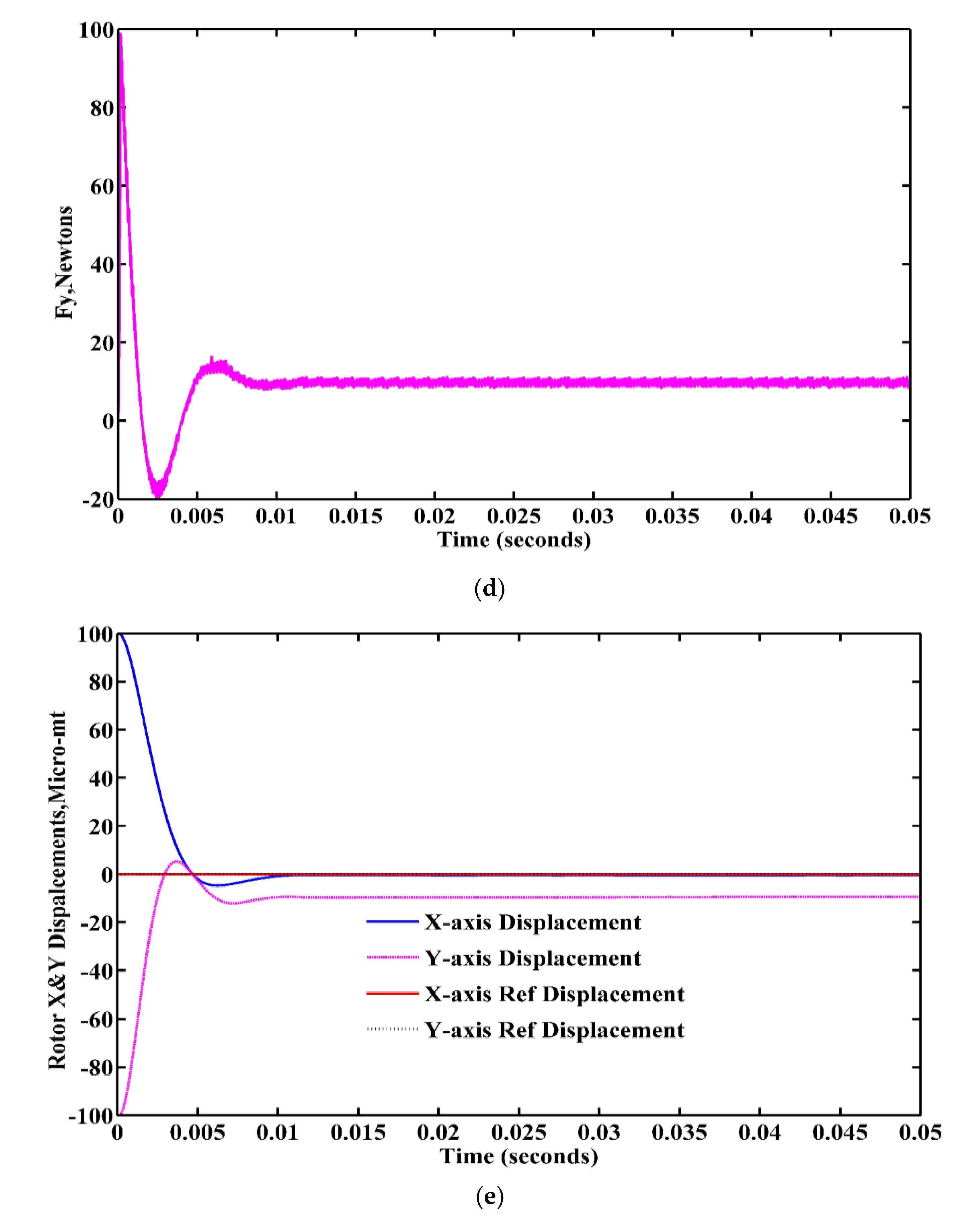

4.1. Levitation Control of BSRM

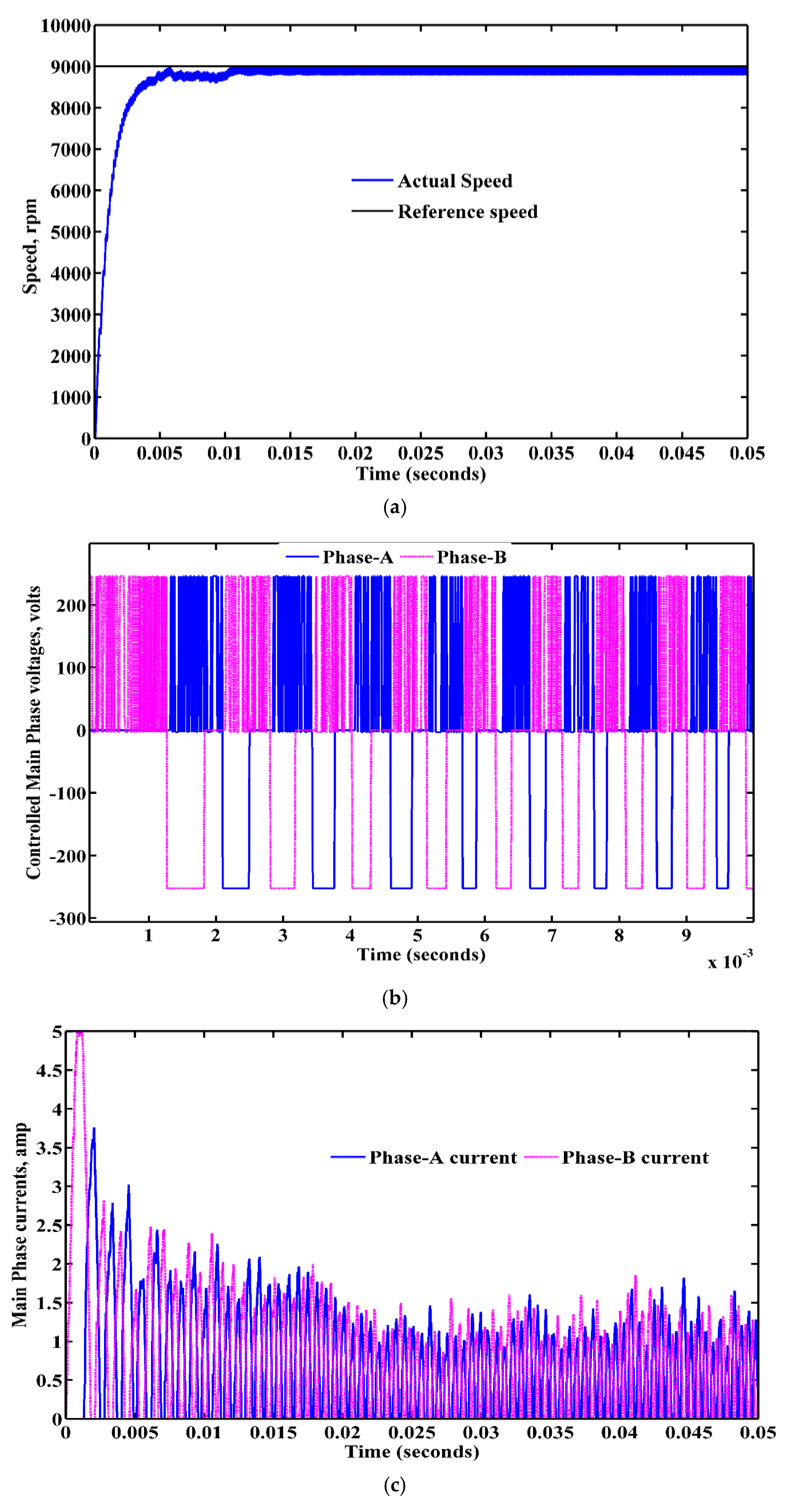

4.2. Accelerating the Rotor to the Desired Speed

4.3. Robust Behavior of Rotor under Different Loads and Changes of Parameters

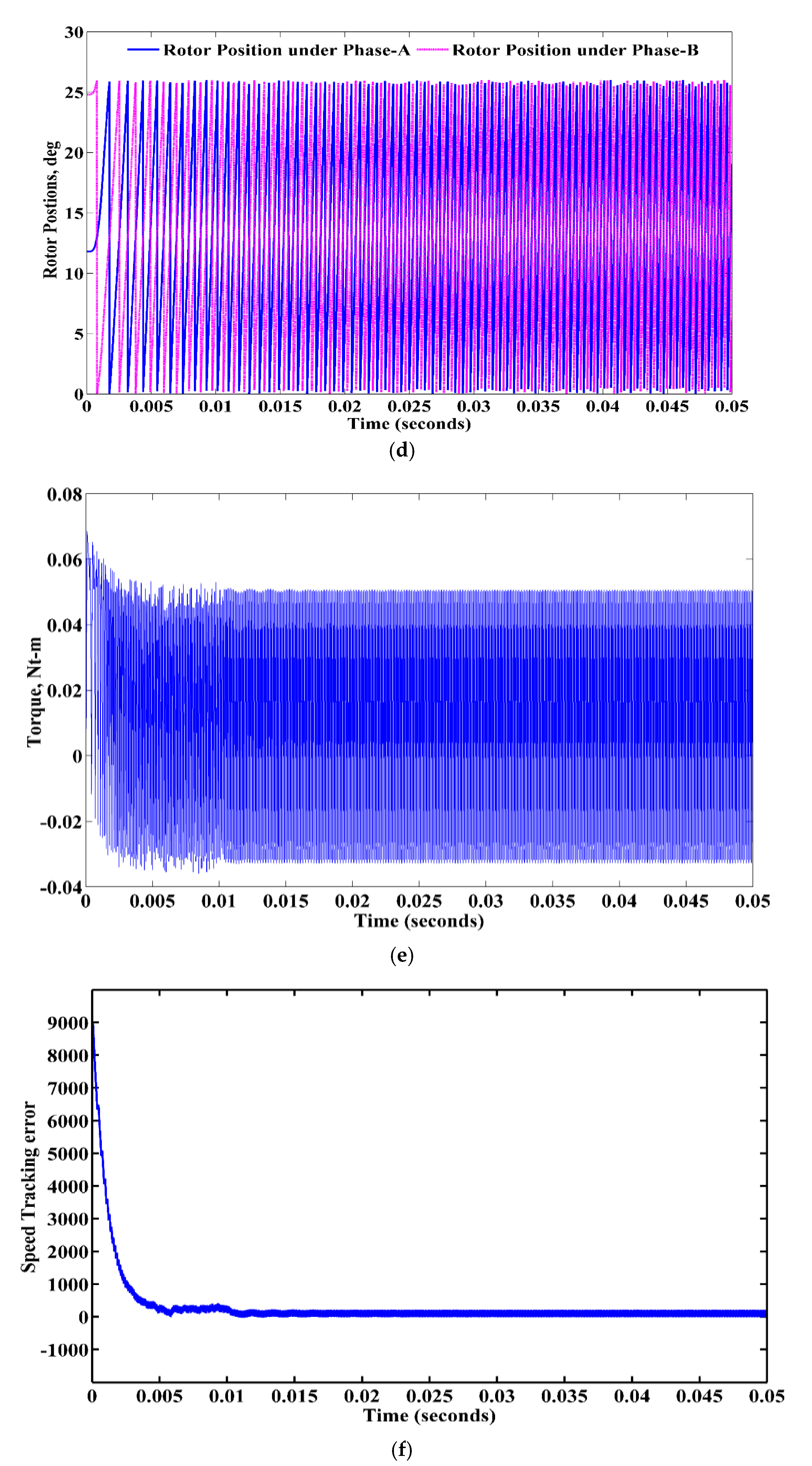

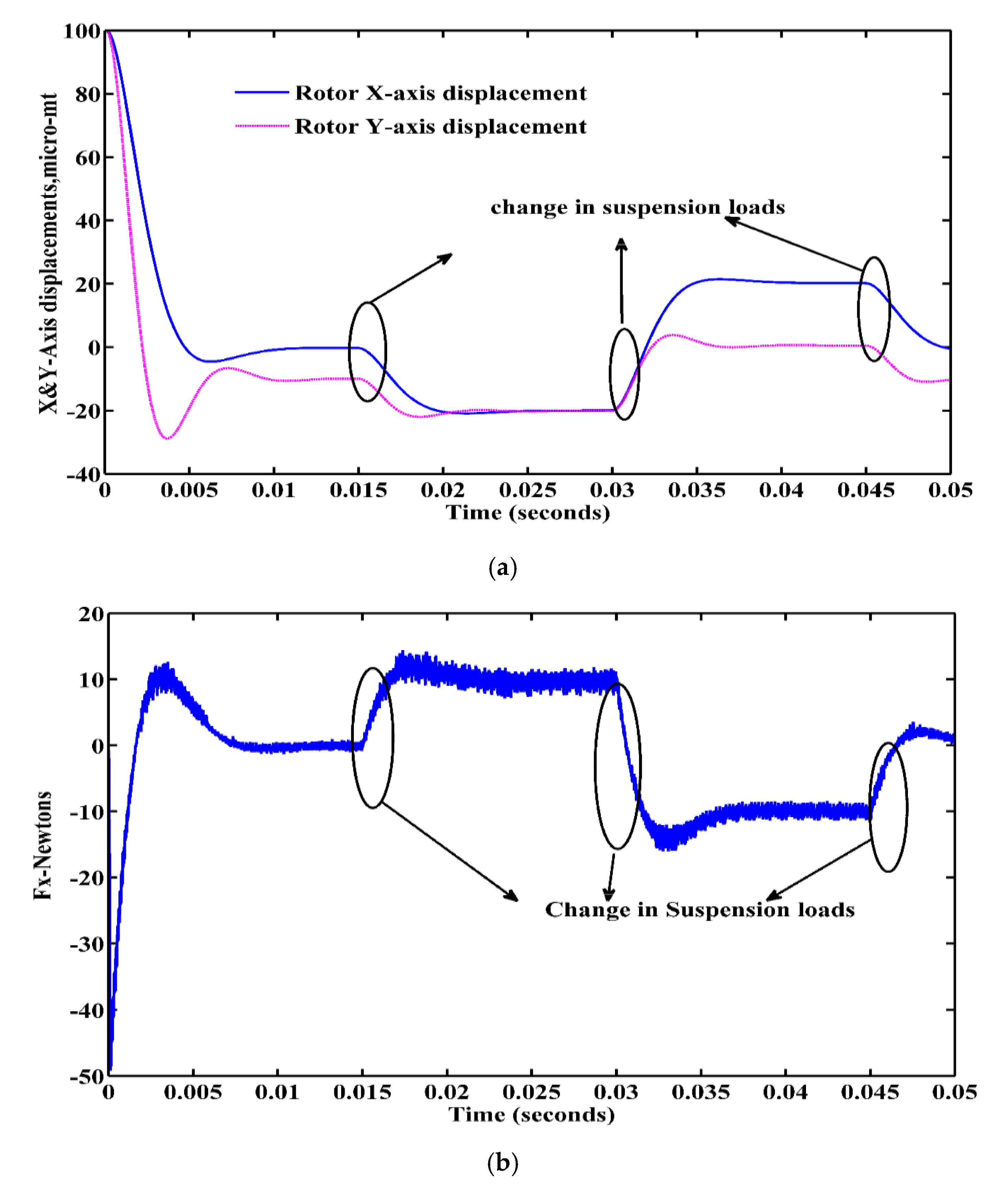

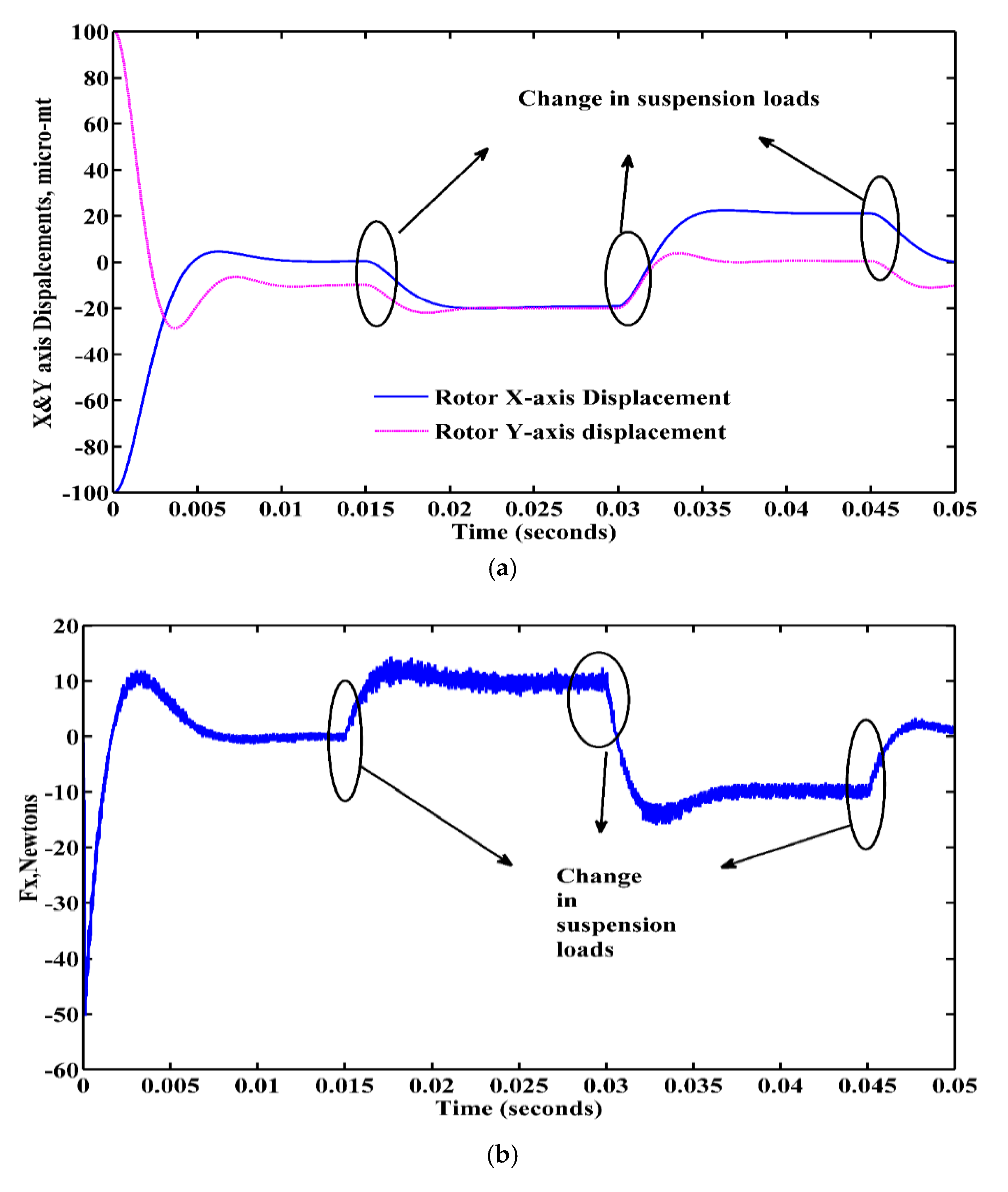

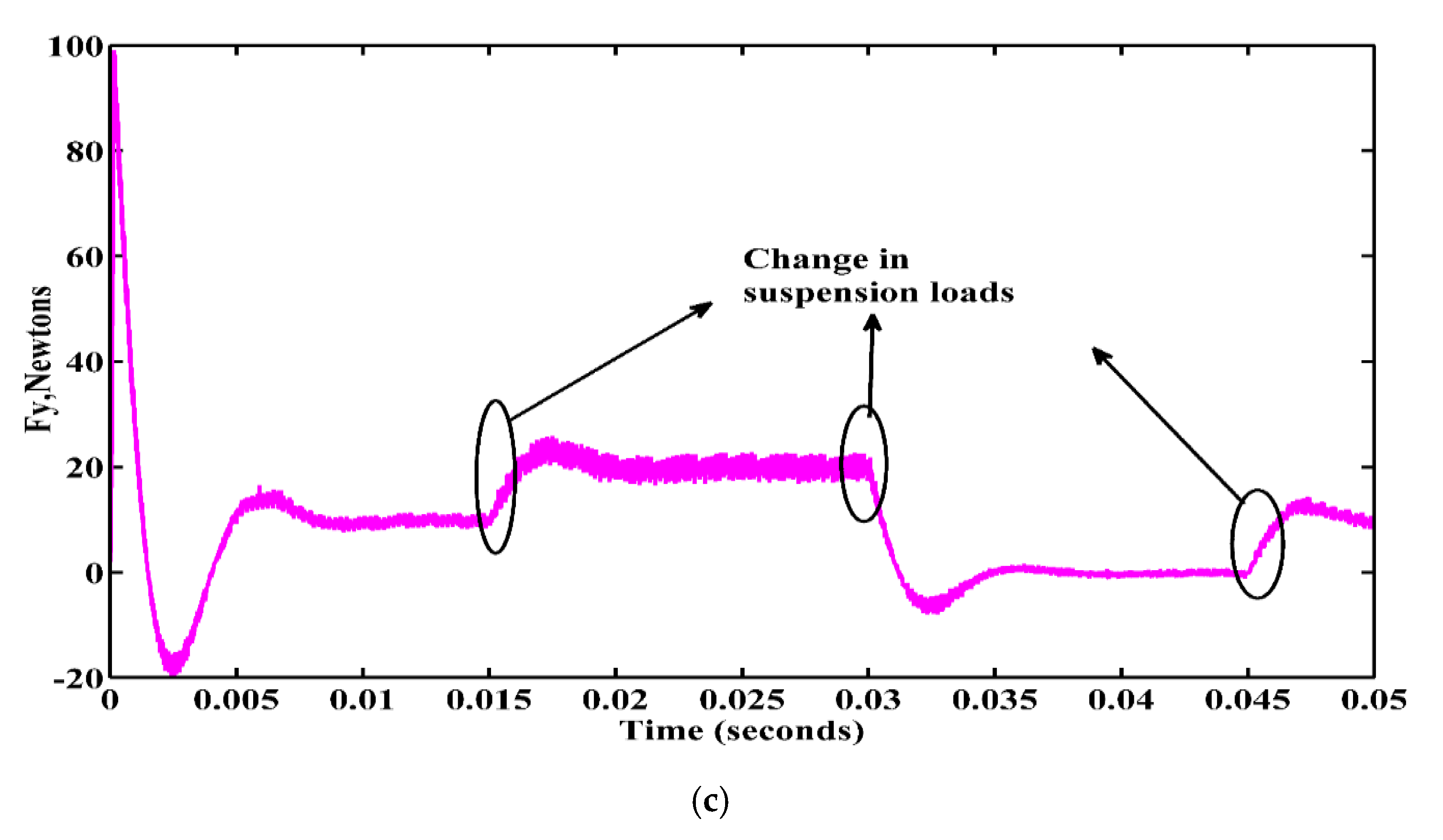

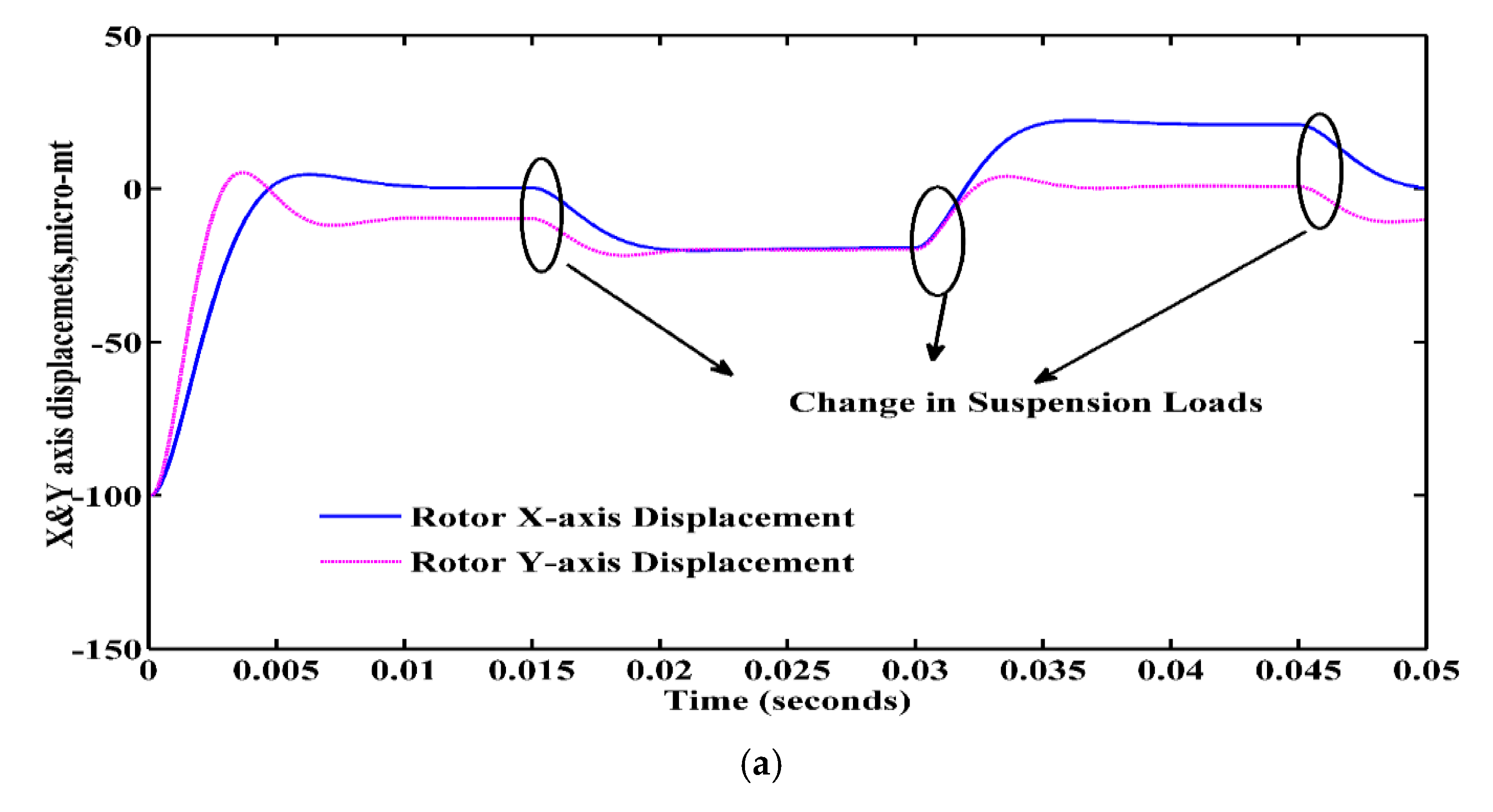

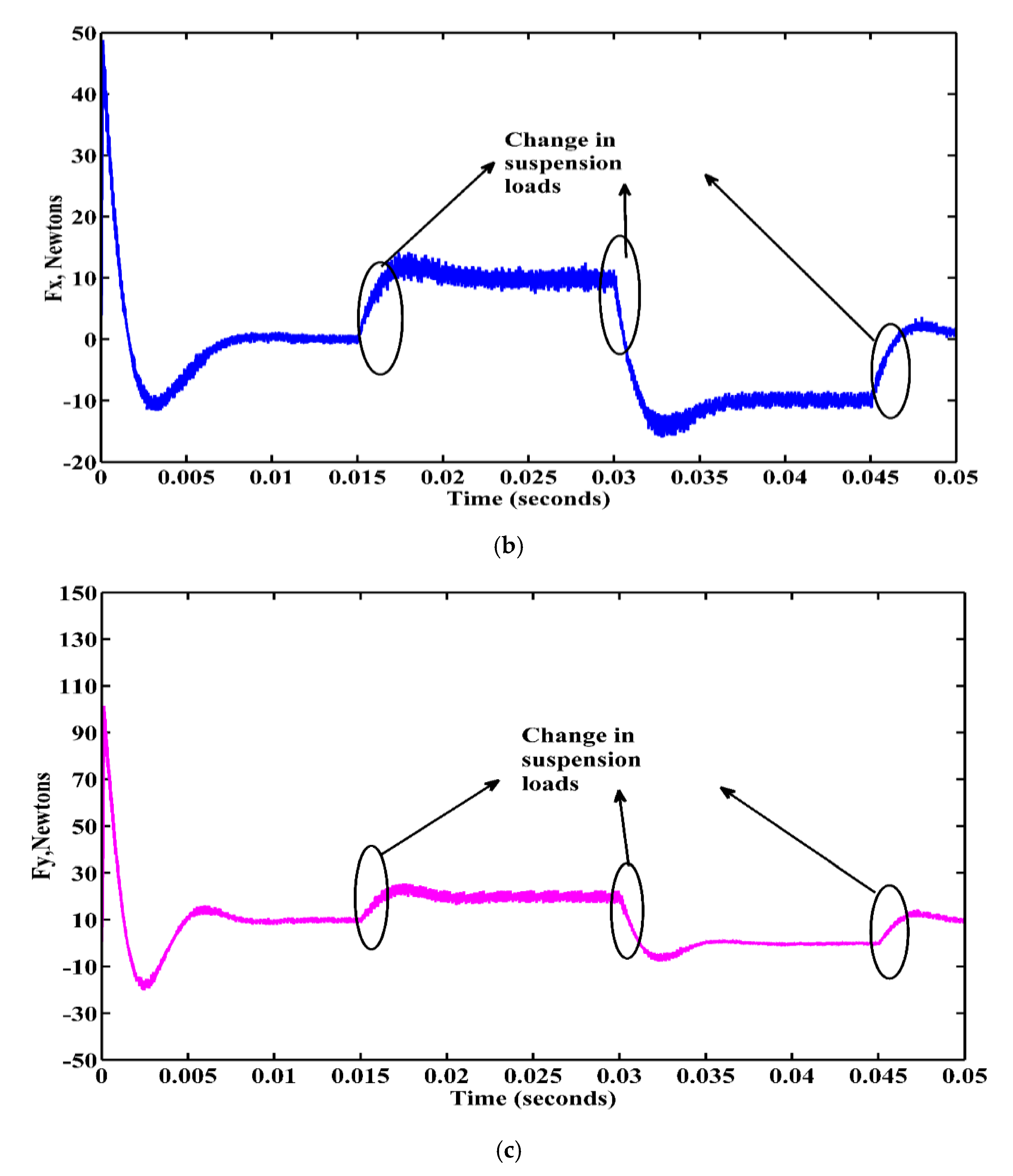

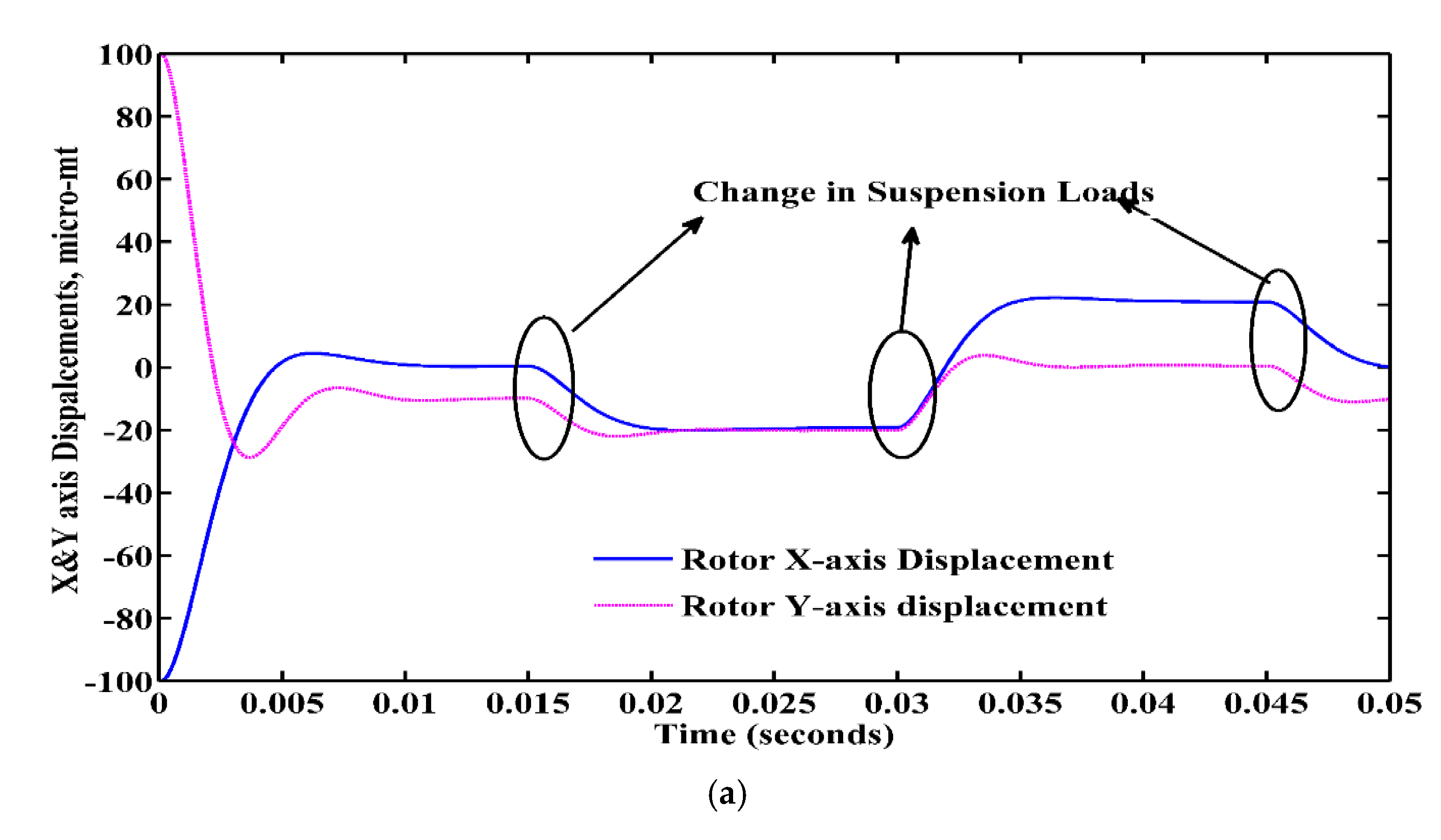

4.3.1. Variation of Suspension Loads

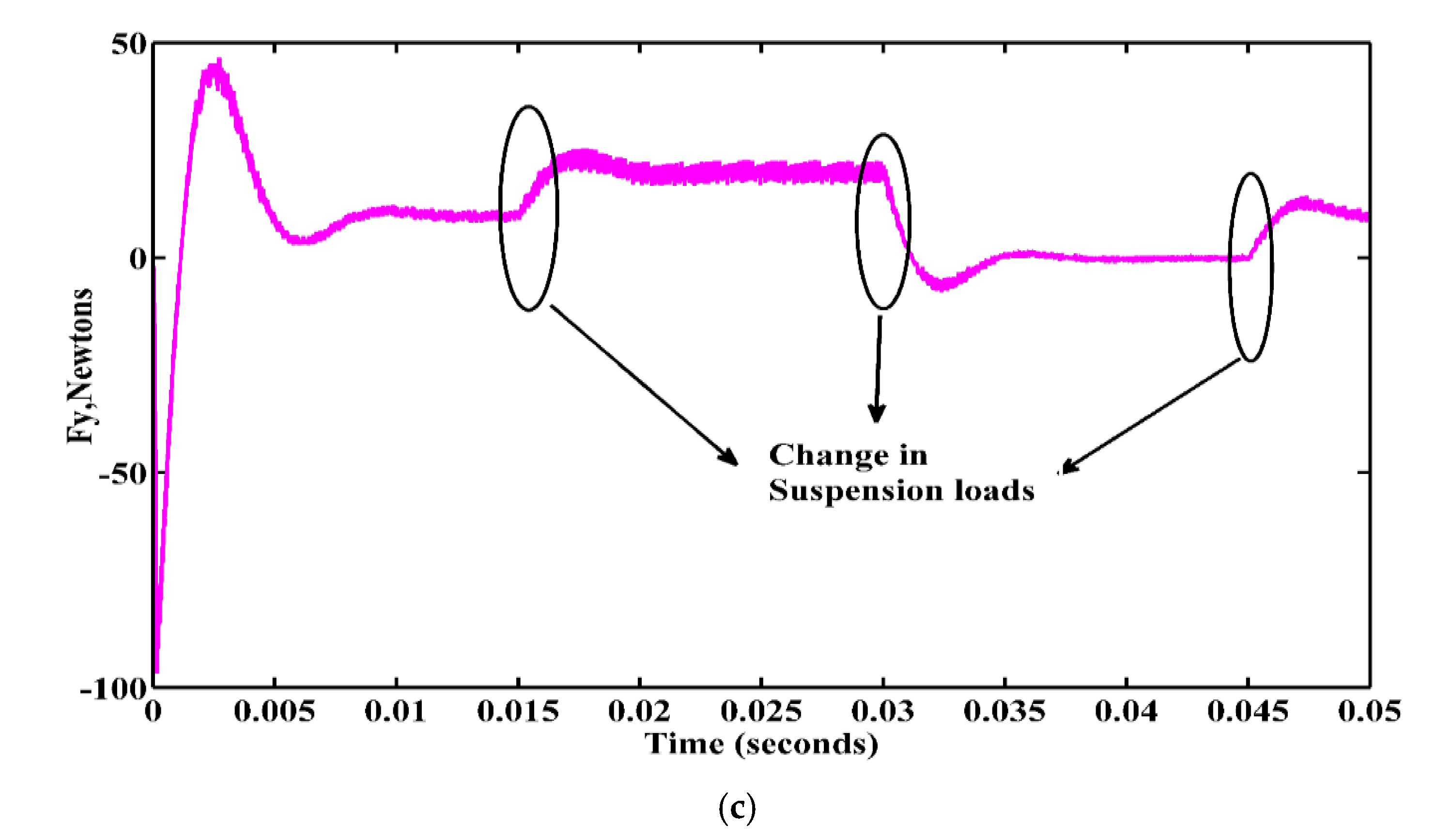

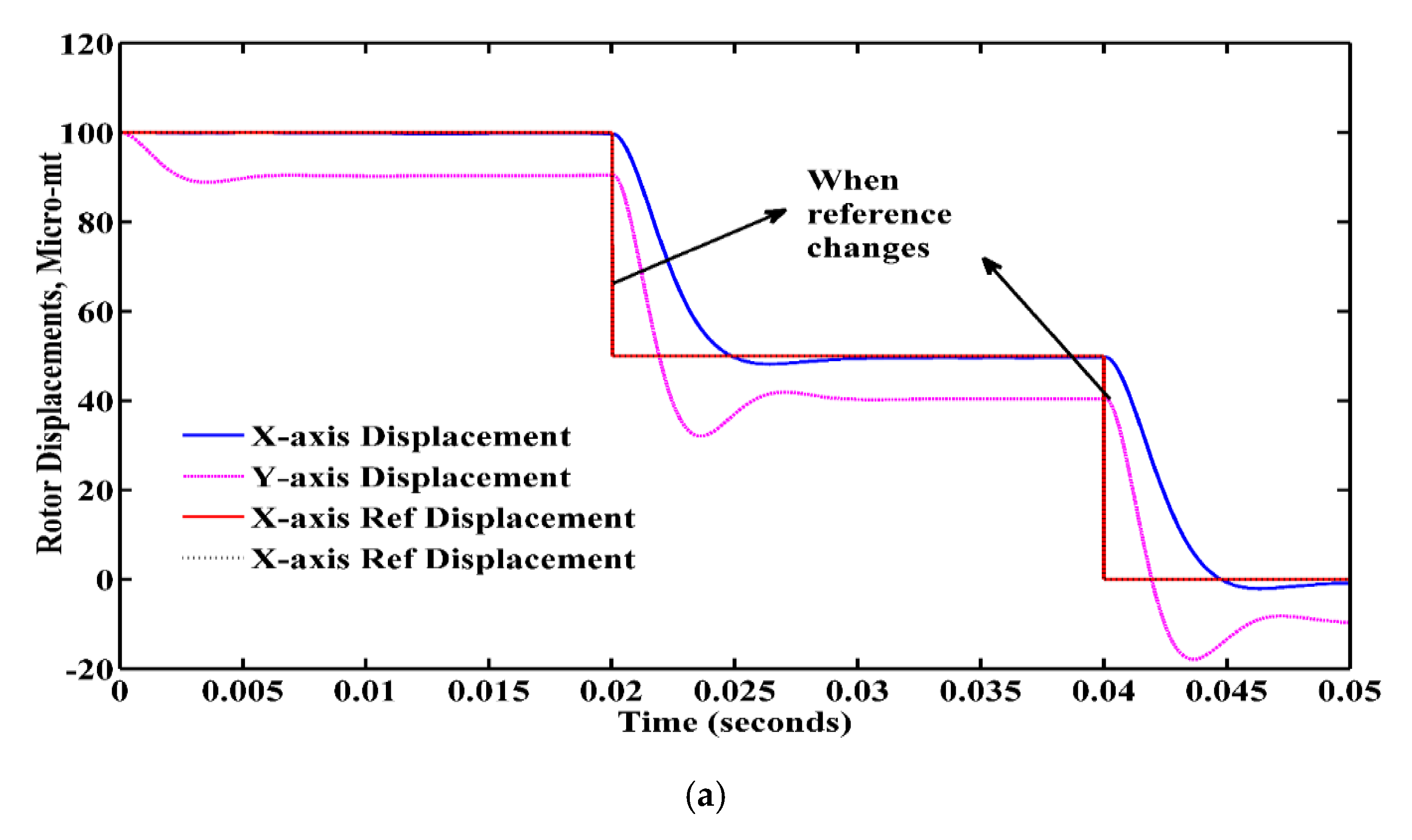

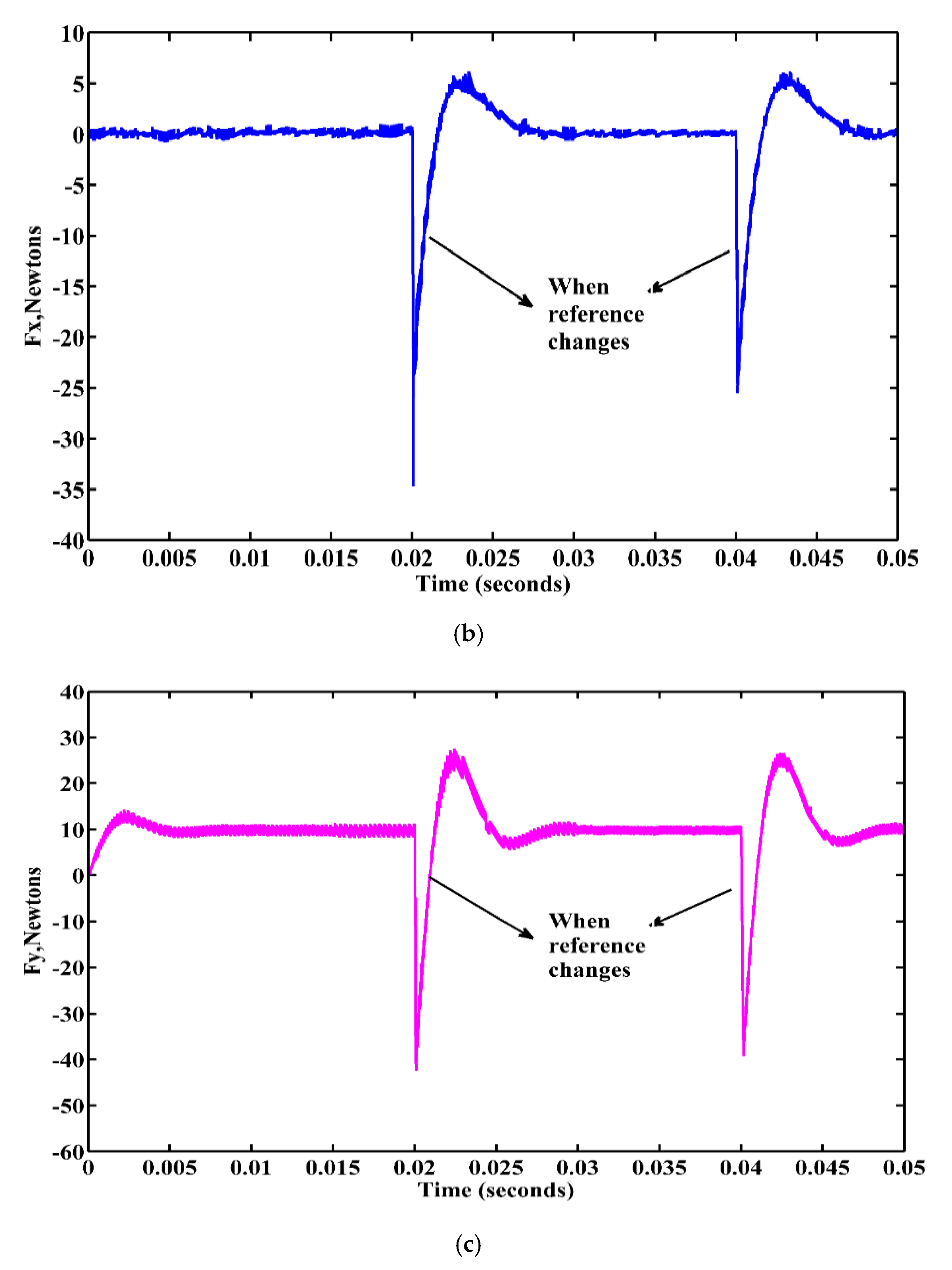

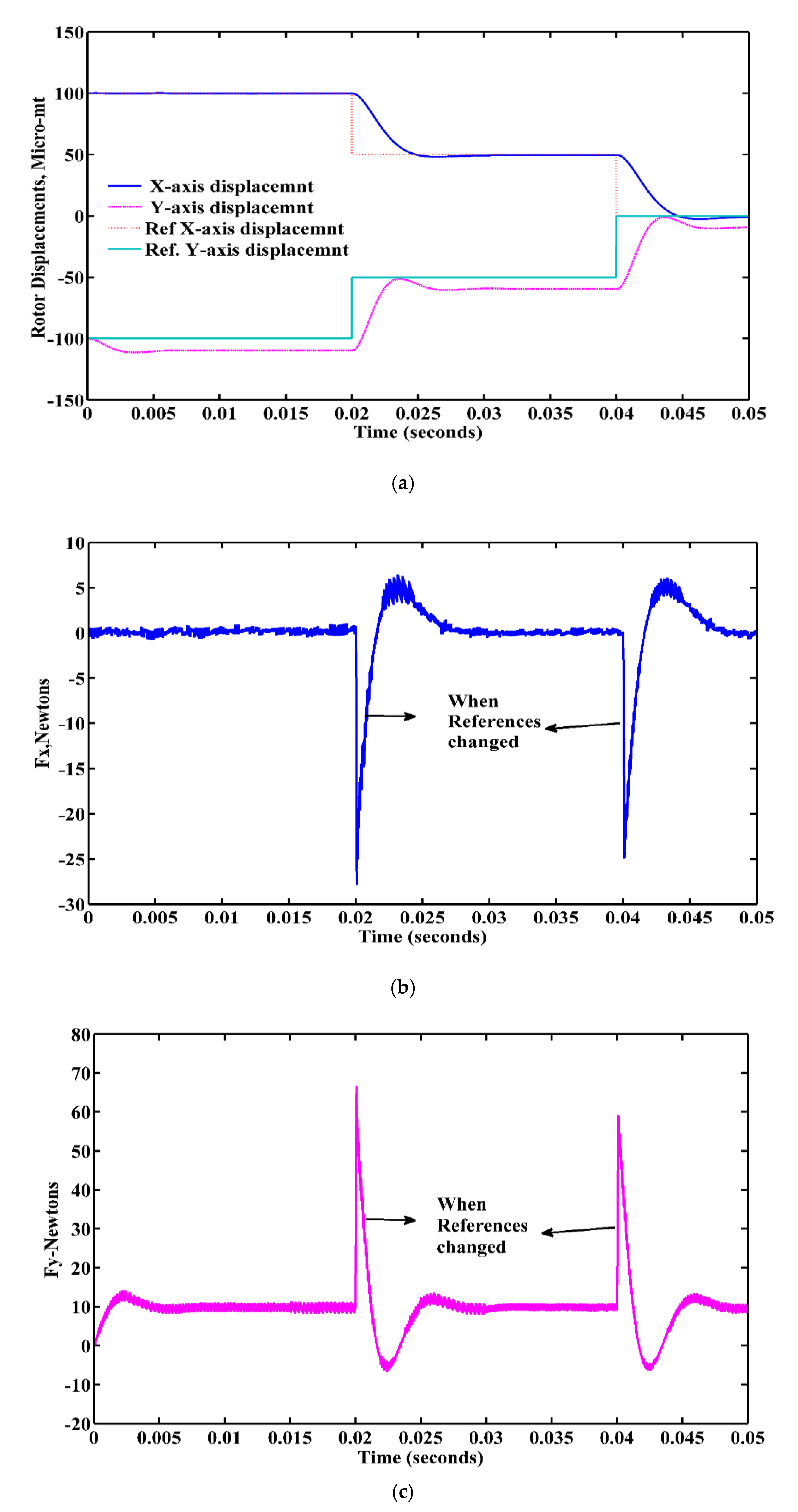

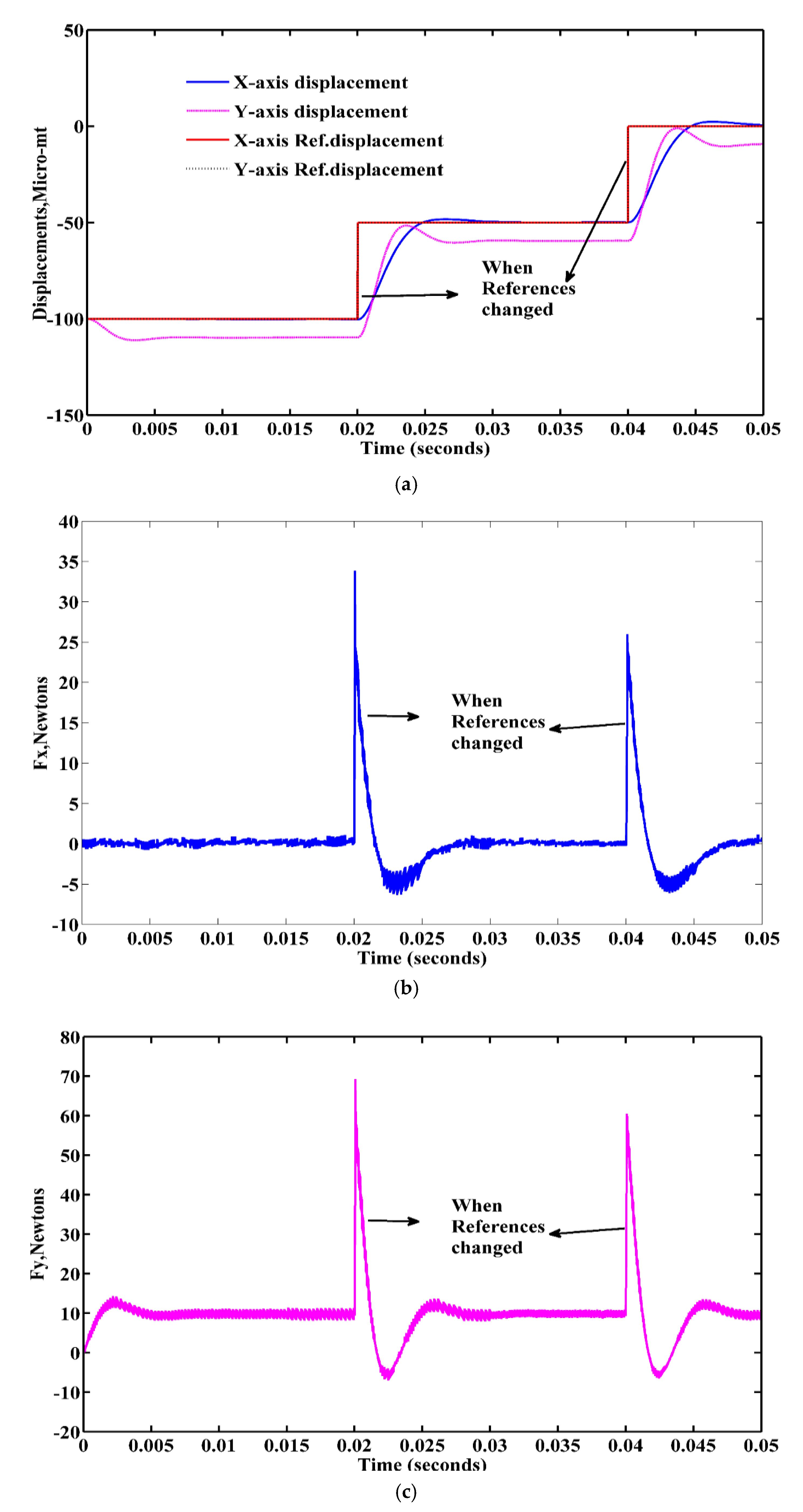

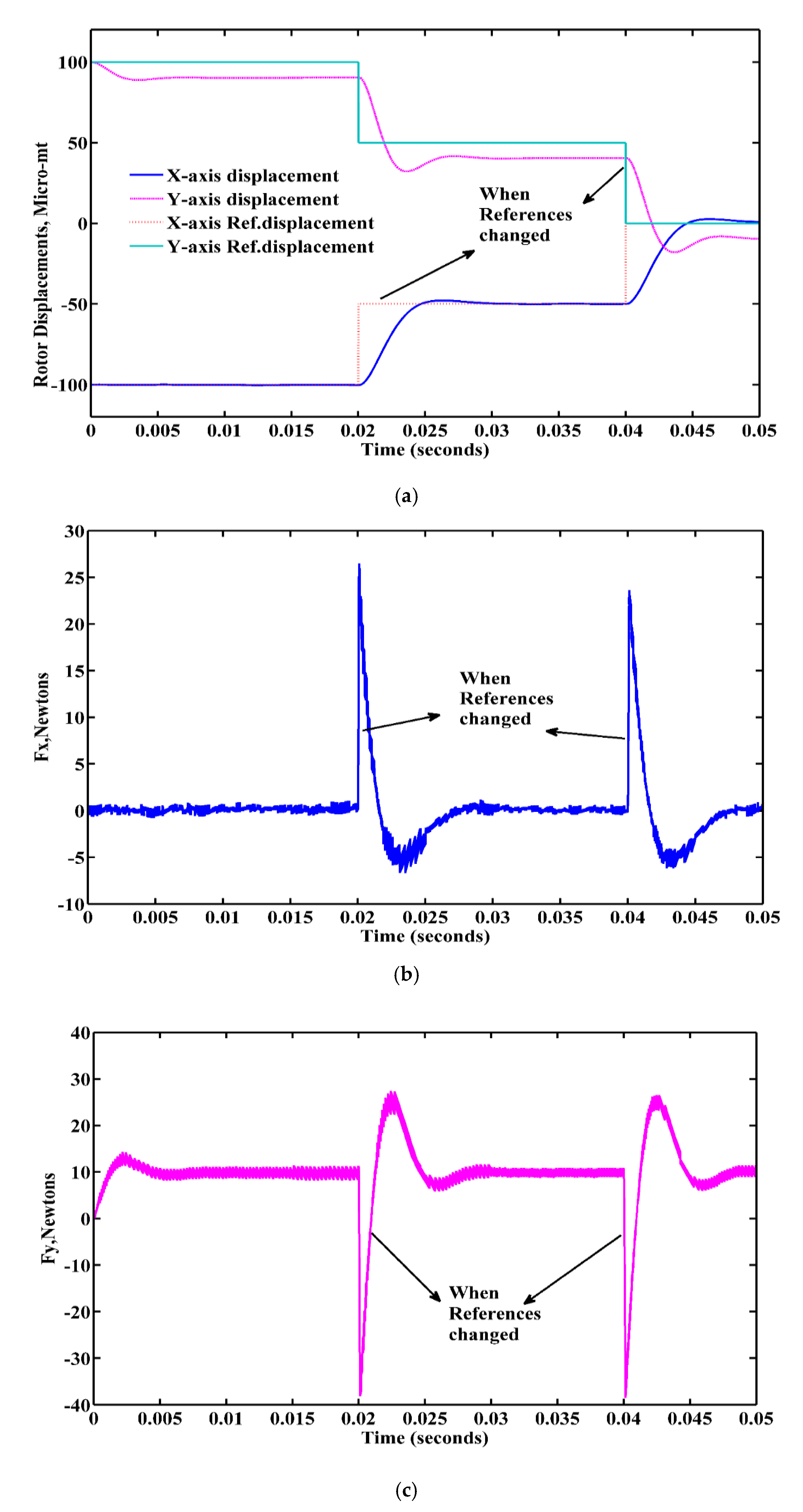

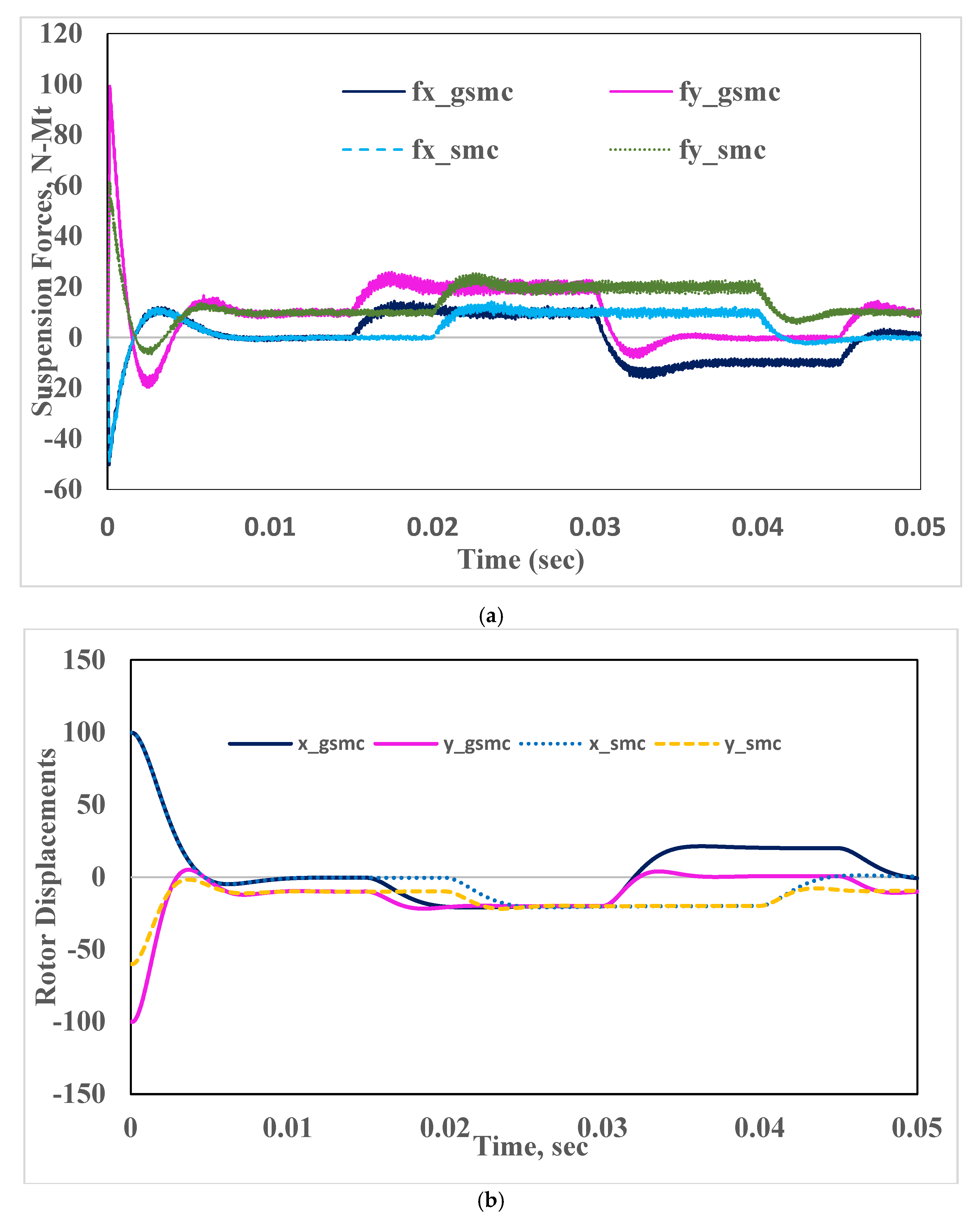

4.3.2. Change of Input Reference Displacements

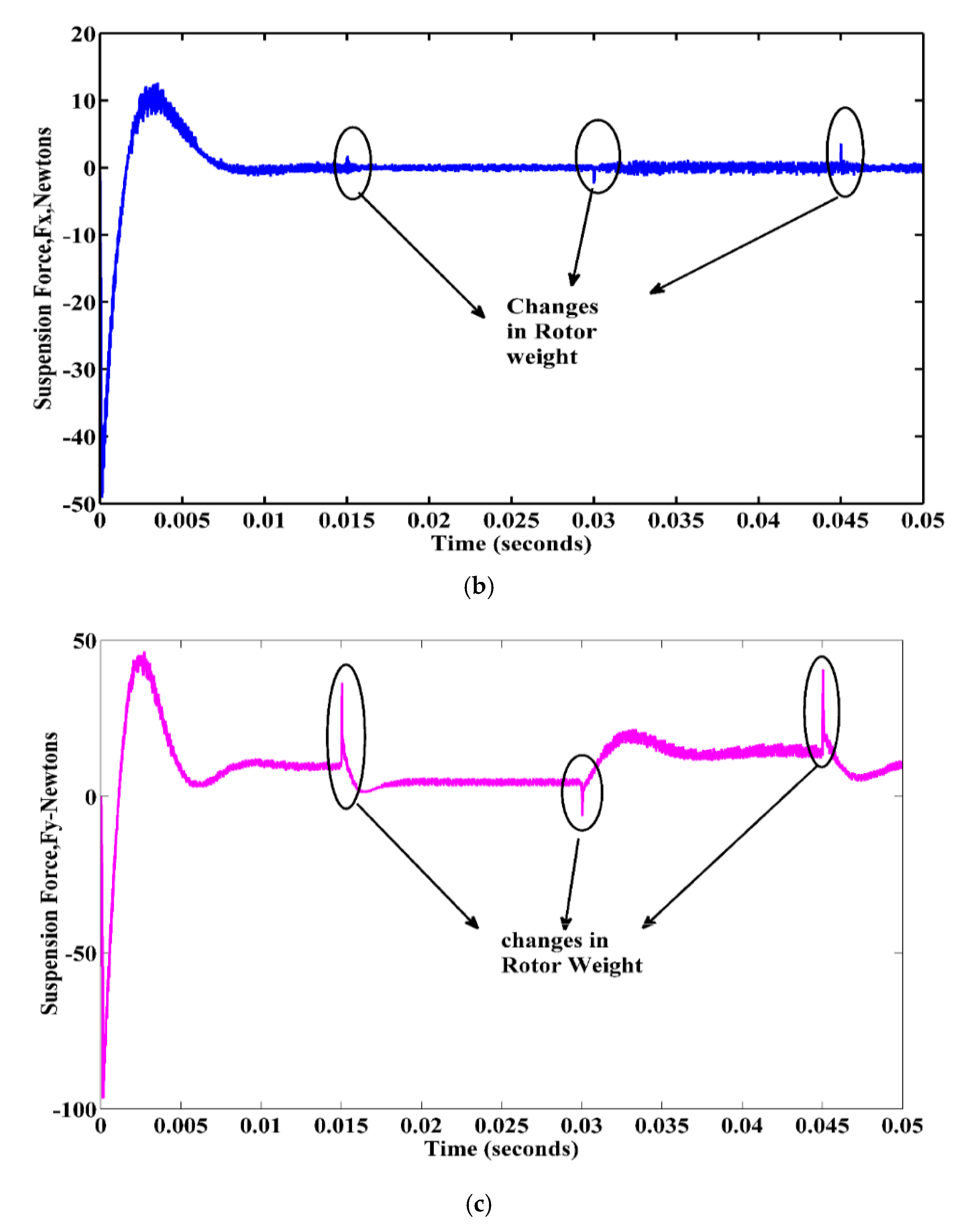

4.3.3. Rotor Weight Is Changed

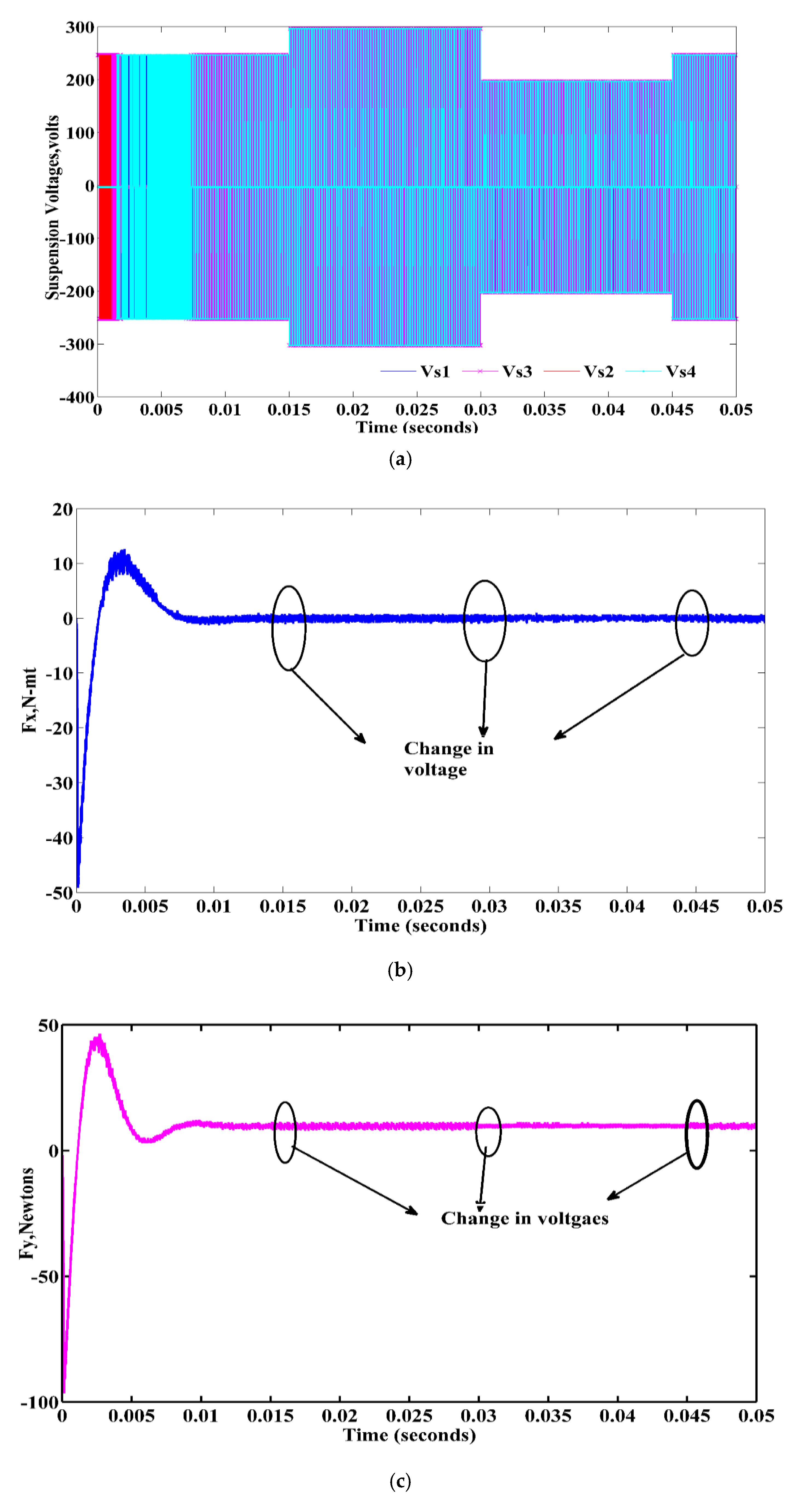

4.3.4. Change in Input Voltages

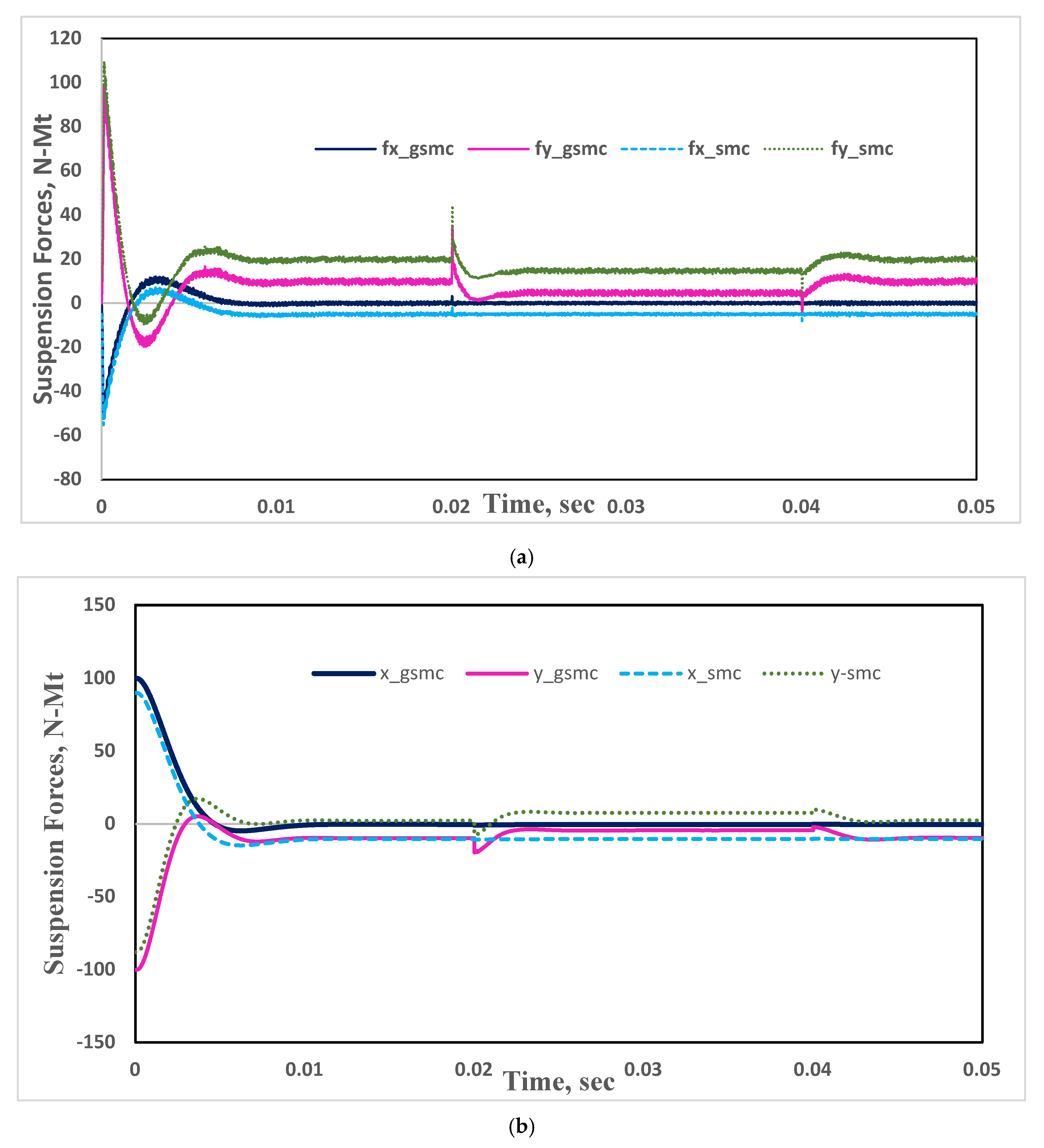

5. Comparisons of Suspension Forces and Displacements with Conventional SMC

6. Conclusions

- First, the operating principle and mathematical modeling of BSRM is discussed.

- When the suspension load is applied in the opposite direction, i.e., in the negative, the rotor eccentric direction is also in the opposite, and finally, the rotor dragged back to the center position with the proposed controller.

- The rotor displacements, positions, and suspension forces are changed slightly at the instant of change of references, and immediately those reached the steady state according to the command signal.

- When the rotor weight is varied suddenly, there is no significant change in rotor displacement and its suspension force. However, in very little time, the rotor reaches a stable position and maintains steady operation due to the proposed control action.

- When the suspension system is subjected to a variation of voltages, there is no significant change in rotor X- and Y-directional displacements, and its suspension forces because of the disturbance rejection property of the control action.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Variable Name | Description |

| Rotor mass, kg | |

| Gravity (9.8) | |

| and | X- and Y-directional suspension forces respectively |

| and | Suspension Force constant matrices |

| Kxxp, Kyyp Kxyp, Kyxp and Kxxn, Kyyn, Kxyn and Kyxn | Corresponding Suspension force constants in both positive and negative directions |

| and | X- and Y-directional suspension current matrices respectively |

| ixp,iyp,ixn,iyn | Suspension currents, amp |

| Flux linkage of torque winding | |

| Resistance of windings, ohms | |

| Phase inductance reversal matrix | |

| Position of the rotor per phase, deg | |

| Phase voltage vector, volts | |

| Speed of the rotor, rpm | |

| and | Total electromagnetic torque developed and external applied load torque |

| Damping coefficient, actual moment of inertia of rotor and , | |

| Phase current vector, amp | |

| , and , | X- and Y-directional rotor reference and desired displacements, respectively |

| , | Actual rotor displacements in X and Y directions |

| Rotor X and Y displacement and speed error equations, respectively | |

| Rotor X and Y displacement and speed switching function positive constants, respectively | |

| Rotor X and Y displacement and speed switching exponential term constants, respectively | |

| Rotor X and Y displacement and speed switching equations, respectively | |

| Rotor X and Y displacement and speed control equations, respectively |

References

- Chaibet, A.; Moussa, B.; Ouddah, N.; Monmasson, E. Experimental Sensorless Control of Switched Reluctance Motor for Electrical Powertrain System. Energies 2020, 13, 3081. [Google Scholar] [CrossRef]

- Cai, H.; Wang, H.; Li, M.; Shen, S.; Feng, A.Y.; Zheng, J. Torque Ripple Reduction for Switched Reluctance Motor with Optimized PWM Control Strategy. Energies 2018, 11, 3215. [Google Scholar] [CrossRef]

- Tchakoua, P.; Benini, E.; Ouhrouche, M.; Slaoui-Hasnaoui, F.; Tameghe, T.A.; Ekemb, G. Wind Turbine Condition Monitoring: State-of-the-Art Review, New Trends, and Future Challenges. Energies 2014, 7, 2595–2630. [Google Scholar] [CrossRef]

- Hossain, L.; Hasan, M.; Muyeen, S.M. Methods for Advanced Wind Turbine Condition Monitoring and Early Diagnosis: A Literature Review. Energies 2018, 11, 1309. [Google Scholar] [CrossRef]

- Pérez, J.M.P.; Márquez, F.P.G.; Tobias, A.; Papaelias, M. Wind turbine reliability analysis. Renew. Sustain. Energy Rev. 2013, 23, 463–472. [Google Scholar] [CrossRef]

- Bichsel, J. The Bearingless Electrical Machine. In Proceedings of the International Symposium on Magnetic Suspension Technology, NASA Langley Research Center, Hampton, VA, USA, 19–23 August 1991; Part 2. pp. 561–573, SEE N92-27788 18-18. [Google Scholar]

- Rahaman, M.A.; Fukao, T.; Ohishi, T. Principles and Developments of Bearingless AC Motors; IPEC: Yokohama, Japan, 1995. [Google Scholar]

- Takemoto, M.; Shimada, K.; Chiba, A. A Design and Characteristics of Switched Reluctance Type Bearingless Motors. In Proceedings of the 4th International Symposium on Magnetic Suspension Technology, Gifu City, Japan, 30 October–1 November 1997; NASA/CP-1998-207654. pp. 49–63. [Google Scholar]

- Takemoto, M.; Chiba, A.; Fukao, T. A new control method of bearingless switched reluctance motors using square-wave currents. In Proceedings of the 2000 IEEE Power Engineering Society Winter Meeting. Conference Proceedings (Cat. No.00CH37077), Singapore, 23–27 January 2000; Institute of Electrical and Electronics Engineers (IEEE): Piscatvey, NJ, USA; Volume 1, pp. 375–380. [Google Scholar]

- Takemoto, M.; Chiba, A.; Fukao, T. A Feed-forward Compensator for Vibration Reduction Considering Magnetic Attraction Force in Bearingless Switched Reluctance Motors. In Proceedings of the 7th International Symposium on Magnetic Bearings, Zurich, Switzerland, 23–25 August 2000; pp. 395–400. [Google Scholar]

- Takemoto, M.; Suzuki, H.; Chiba, A.; Fukao, T.; Rahman, M. Improved analysis of a bearingless switched reluctance motor. IEEE Trans. Ind. Appl. 2001, 37, 26–34. [Google Scholar] [CrossRef]

- Takemoto, M.; Chiba, A.; Fukao, T. A method of determining advanced angle of square-wave currents in bearingless switched reluctance motors. In Conference Record of the 2000 IEEE Industry Applications Conference, Proceedings of the Thirty-Fifth IAS Annual Meeting and World Conference on Industrial Applications of Electrical Energy (Cat. No.00CH37129), Rome, Italy, 8–12 August 2000; IEEE: Piscatvey, NJ, USA, 2001; Volume 37, pp. 1702–1709. [Google Scholar] [CrossRef]

- Takemoto, M.; Chiba, A.; Akagi, H.; Fukao, T. Suspending force and Torque of a Bearingless Switched Reluctance Motor Operating in a Region of Magnetic Saturation. In Conference Record of the 2002 IEEE Industry Applications Conference, Proceedings of the 37th IAS Annual Meeting (Cat. No. 02CH37344), Pittsburgh, PA, USA, 13–18 October 2002; IEEE: Piscatvey, NJ, USA, 2002; Volume 1, pp. 35–42. [Google Scholar]

- Takemoto, M.; Chiba, A.; Akagi, H.; Fukao, T. Radial Force and Torque of a Bearingless Switched Reluctance Motor Operating in a Region of Magnetic Saturation. IEEE Trans. Ind. Appl. 2004, 40, 103–112. [Google Scholar] [CrossRef]

- Morrison, C.R. Bearingless Switched Reluctance Motor. U.S. Patent 6,727,618, 27 April 2004. [Google Scholar]

- Chen, L.; Hofman, W. Analytically Computing Winding Currents to Generate Torque and Levitation Force of a New Bearingless Switched Reluctance Motor. In Proceedings of the 12th International Power Electronics and Motion Control Conference, Portoroz, Slovenia, 30 August–1 September 2006; pp. 1058–1063. [Google Scholar]

- Chen, L.; Hofmann, W. Performance Characteristics of one Novel Switched Reluctance Bearingless Motor Drive. In Proceedings of the 2007 Power Conversion Conference, Nagoya, Japan, 2–5 April 2007; Institute of Electrical and Electronics Engineers (IEEE): Piscatvey, NJ, USA, 2007; pp. 608–613. [Google Scholar]

- Morrison, C.; Siebert, M.; Ho, E. Electromagnetic Forces in a Hybrid Magnetic-Bearing Switched-Reluctance Motor. IEEE Trans. Magn. 2008, 44, 4626–4638. [Google Scholar] [CrossRef]

- Chen, L.; Hofmann, W. Analysis of radial forces based on rotor eccentricity of bearingless switched reluctance motors. In Proceedings of the XIX International Conference on Electrical Machines—ICEM, Rome, Italy, 6–8 September 2010; pp. 1–6. [Google Scholar]

- Chen, L.; Hofmann, W. Design procedure of bearingless high-speed switched reluctance motors. In Proceedings of the Power Electronics Electrical Drives Automation and Motion (SPEEDAM), Pisa, Italy, 14–16 June 2010; pp. 1442–1447. [Google Scholar] [CrossRef]

- Wang, H.J.; Lee, D.H.; Ahn, J.W. Novel Bearingless Switched Reluctance Motor with Hybrid Stator Poles, Concept, Analysis, Design and Experimental Verification. In Proceedings of the The Eleventh International Conference on Electrical Machines and Systems, Wuhan, China, 17–20 October 2008; pp. 3358–3363. [Google Scholar]

- Yang, G.; Deng, Z.; Cao, X.; Wang, X. Optimal Winding Arrangements of a Bearingless Switched Reluctance Motor. IEEE Trans. Power Electron. 2008, 23, 3056–3066. [Google Scholar] [CrossRef]

- Wang, H.J. Design and Control of a Novel Bearingless Switched Reluctance Motor. Ph.D. Thesis, Industrial System Engineering of the Kyungsung University, Busan, Korea, 2009. [Google Scholar]

- Lee, D.-H.; Ahn, J.-W. Design and Analysis of Hybrid Stator Bearingless SRM. J. Electr. Eng. Technol. 2011, 6, 94–103. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Y.; Liu, X.; Ahn, J.-W. Design of novel bearingless switched reluctance motor. IET Electr. Power Appl. 2012, 6, 73. [Google Scholar] [CrossRef]

- Yang, Y.; Deng, Z.; Yang, G.; Cao, X.; Zhang, Q. A Control Strategy for Bearingless Switched-Reluctance Motors. IEEE Trans. Power Electron. 2010, 25, 2807–2819. [Google Scholar] [CrossRef]

- Cao, X.; Deng, Z.; Yang, G.; Wang, X. Independent Control of Average Torque and Radial Force in Bearingless Switched-Reluctance Motors With Hybrid Excitations. IEEE Trans. Power Electron. 2009, 24, 1376–1385. [Google Scholar] [CrossRef]

- Ortega, R.; Sarr, A.; Bobtsov, A.A.; Bahri, I.; Diallo, D. Adaptive state observers for sensorless control of switched reluctance motors. Int. J. Robust Nonlinear Control. 2018, 29, 990–1006. [Google Scholar] [CrossRef]

- Derdiyok, A.; Inanç, N.; Özbulur, V.; Bilgiç, M.O. Improving performance of switched reluctance motor by fuzzy logic controller. Int. J. Robust Nonlinear Control. 1999, 9, 307–317. [Google Scholar] [CrossRef]

- Falahi, M.; Salmasi, F.R. A sliding mode controller for switched-reluctance motor with iterative learning compensation. In Proceedings of the International Conference on Electrical Machines and Systems, ICEMS 2007, Seoul, Korea, 8–11 October 2007; pp. 631–635. [Google Scholar] [CrossRef]

- Edwards, C.; Spurgeon, S.K. Robust output tracking using a sliding-mode controller/observer scheme. Int. J. Control. 1996, 64, 967–983. [Google Scholar] [CrossRef]

- Chan, C.; Zhan, Y.; Chau, K.T. Stability analysis of fuzzy sliding mode controlled switched reluctance motor drives. In PESC 98 Record, Proceedings of the 29th Annual IEEE Power Electronics Specialists Conference (Cat. No.98CH36196), Fukuoka, Japan, 22 May 1998; IEEE: Piscatvey, NJ, USA, 2002; Volume 2, pp. 1283–1289. [Google Scholar] [CrossRef]

- Imine, H.; Madani, T. Sliding-mode control for automated lane guidance of heavy vehicle. Int. J. Robust Nonlinear Control. 2011, 23, 67–76. [Google Scholar] [CrossRef]

- Spurgeon, S. Sliding mode observers: A survey. Int. J. Syst. Sci. 2008, 39, 751–764. [Google Scholar] [CrossRef]

- Teixeira, L.R.; Oliveira, J.B.; Araujo, A.D. Smooth indirect adaptive sliding mode control. Int. J. Robust Nonlinear Control. 2013, 25, 775–790. [Google Scholar] [CrossRef]

- Cheng, Z.; Hou, C.; Wu, X. Global Sliding Mode Control for Brushless DC Motors by Neural Networks. In Proceedings of the 2009 International Conference on Artificial Intelligence and Computational Intelligence, Shanghai, China, 7–8 November 2009; Volume 4, pp. 3–6. [Google Scholar] [CrossRef]

- Liu, L.; Han, Z.; Li, W. Global sliding mode control and application in chaotic systems. Nonlinear Dyn. 2008, 56, 193–198. [Google Scholar] [CrossRef]

- Boukattaya, M.; Gassara, H.; Tarak, D. A global time-varying sliding-mode control for the tracking problem of uncertain dynamical systems. ISA Trans. 2020, 97, 155–170. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Wang, X. Advanced Sliding Mode Control for Mechanical Systems; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- Rao, P.N.; Rao, G.V.S.K.; Kumar, G.V.N. A Novel Technique for Controlling Speed and Position of Bearingless Switched Reluctance Motor Employing Sensorless Sliding Mode Observer. Arab. J. Sci. Eng. 2017, 43, 4327–4346. [Google Scholar] [CrossRef]

- Faiz, J.; Pakdelian, S. Diagnosis of Static Eccentricity in Switched Reluctance Motors Based on Mutually Induced Voltages. IEEE Trans. Magn. 2008, 44, 2029–2034. [Google Scholar] [CrossRef]

- Zhu, M.; Zhang, Y.; Xie, Z.; Zhao, B. Method of reducing noise and torque ripple of switched reluctance motor. In Proceedings of the 2017 Chinese Automation Congress (CAC), Jinan, China, 20–22 October 2017; pp. 2761–2765. [Google Scholar] [CrossRef]

- Torkaman, H.; Afjei, E. Comprehensive Detection of Eccentricity Fault in Switched Reluctance Machines Using High-Frequency Pulse Injection. IEEE Trans. Power Electron. 2012, 28, 1382–1390. [Google Scholar] [CrossRef]

- Torkaman, H.; Afjei, E.; Yadegari, P. Static, Dynamic, and Mixed Eccentricity Faults Diagnosis in Switched Reluctance Motors Using Transient Finite Element Method and Experiments. IEEE Trans. Magn. 2012, 48, 2254–2264. [Google Scholar] [CrossRef]

- Zribi, M.; Sira-Ramírez, H.; Ngai, A. Static and dynamic sliding mode control schemes for a permanent magnet stepper motor. Int. J. Control. 2001, 74, 103–117. [Google Scholar] [CrossRef]

| Ref. No. | Authors | Type of BSRM (Design) | Remarks |

|---|---|---|---|

| [8,9,10,11] | Masatsugu Takemoto et al. | 8/6 double layer, 3-ph BSRM. | Due to both windings on the stator pole, suspension force control and torque control regions are narrow. |

| [12,13,14] | Takemoto et al. | 8/6 double layer, 3-ph BSRM with square currents control methods. | The regions of generating torque and suspending force cannot be fully used, because the operating point must be selected to compromise between torque and suspending force. |

| [15,16,17,18,19,20] | Chen et al. and Hoffman et al. | hybrid rotor structure, called Morrison rotor. The Morrison rotor simplifies the stator design in that it contains only one type of winding. | Because of the increase in axial length, the critical speed of the rotor is reduced. Meanwhile, to maintain the rotor at the center, sometimes high reverse torque cannot be avoided. |

| [21,22,23] | Wang, Lee, and Ahn, | Proposed a method for bearingless SRM with 8/6 type, in which three windings are loaded with different currents in each commutating period. Consequently, three torques and three lateral forces are generated. | To satisfy suspended force, reverse torque is hard to avoid. This method restricts increase of rotor speed. At the same time, for the above two structures, control methods are very complicated to realize steady suspension. |

| [24,25] | Wang, Lee and Ahn, | Proposed a new BSRM with hybrid stator poles. In this structure, only half the stator poles are used for the torque. Therefore, power density is very low. | In this motor, long flux paths are taken, and flux reversal exists in the stator core, which may increase the magnetic motive force (MMF) requirements and have higher core losses. |

| [26,27,28] | Wang, Lee. and Ahn, | A proposed single winding design on 10/8 and 12/14 BSRM obtains a decoupled nature between suspended force and motor torque. | There are no windings on the rotor. Two self-regulated DC supplies are given to the suspension and torque coils to achieve the decoupled performance between net levitation force and motor torque of 12/14 BSRM. |

| Sno | Rated BSRM Details | Value |

|---|---|---|

| 1 | Total input power to the motor | 1000 W |

| 2 | Current/phase (maximum) | 4 A |

| 3 | Applied per phase voltage | 250 V |

| 4 | Net desired torque | 1 N.m |

| 5 | Rated desired speed | 9000 rpm |

| 6 | Main winding per phase resistance | 0.86 Ω |

| 7 | Levitation winding per phase resistance | 0.32 Ω |

| 8 | Suspension voltage | 250 V |

| 9 | Suspension current (maximum) | 4 amp |

| Desired Force | Suspending Force Poles Selection | Enable-Is1 | Enable-Is2 | Enable-Is3 | Enable-Is4 |

|---|---|---|---|---|---|

| If | Is1 and Is2 | 1 | 1 | 0 | 0 |

| If | Is2 and Is3 | 0 | 1 | 1 | 0 |

| If | Is3 and Is4 | 0 | 0 | 1 | 1 |

| If | Is4 and Is1 | 1 | 0 | 0 | 1 |

| Rotor Reference Displacements at 0 s | Reference Displacements at 0.02 s | Reference Displacements, at 0.04 s |

|---|---|---|

| (100, 100) | (50, 50) | (0, 0) |

| (−100, 100) | (−50, 50) | (0, 0) |

| (−100, −100) | (−50, −50) | (0, 0) |

| (100, −100) | (50, −50) | (0, 0) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rao, P.N.; Devarapalli, R.; García Márquez, F.P.; Malik, H. Global Sliding-Mode Suspension Control of Bearingless Switched Reluctance Motor under Eccentric Faults to Increase Reliability of Motor. Energies 2020, 13, 5485. https://doi.org/10.3390/en13205485

Rao PN, Devarapalli R, García Márquez FP, Malik H. Global Sliding-Mode Suspension Control of Bearingless Switched Reluctance Motor under Eccentric Faults to Increase Reliability of Motor. Energies. 2020; 13(20):5485. https://doi.org/10.3390/en13205485

Chicago/Turabian StyleRao, Pulivarthi Nageswara, Ramesh Devarapalli, Fausto Pedro García Márquez, and Hasmat Malik. 2020. "Global Sliding-Mode Suspension Control of Bearingless Switched Reluctance Motor under Eccentric Faults to Increase Reliability of Motor" Energies 13, no. 20: 5485. https://doi.org/10.3390/en13205485

APA StyleRao, P. N., Devarapalli, R., García Márquez, F. P., & Malik, H. (2020). Global Sliding-Mode Suspension Control of Bearingless Switched Reluctance Motor under Eccentric Faults to Increase Reliability of Motor. Energies, 13(20), 5485. https://doi.org/10.3390/en13205485