Analysis on Double Quench and Instantaneous Power of SFCL Using Two Magnetically Coupled Windings According to Winding Direction

Abstract

:1. Introduction

2. Experimental Methods

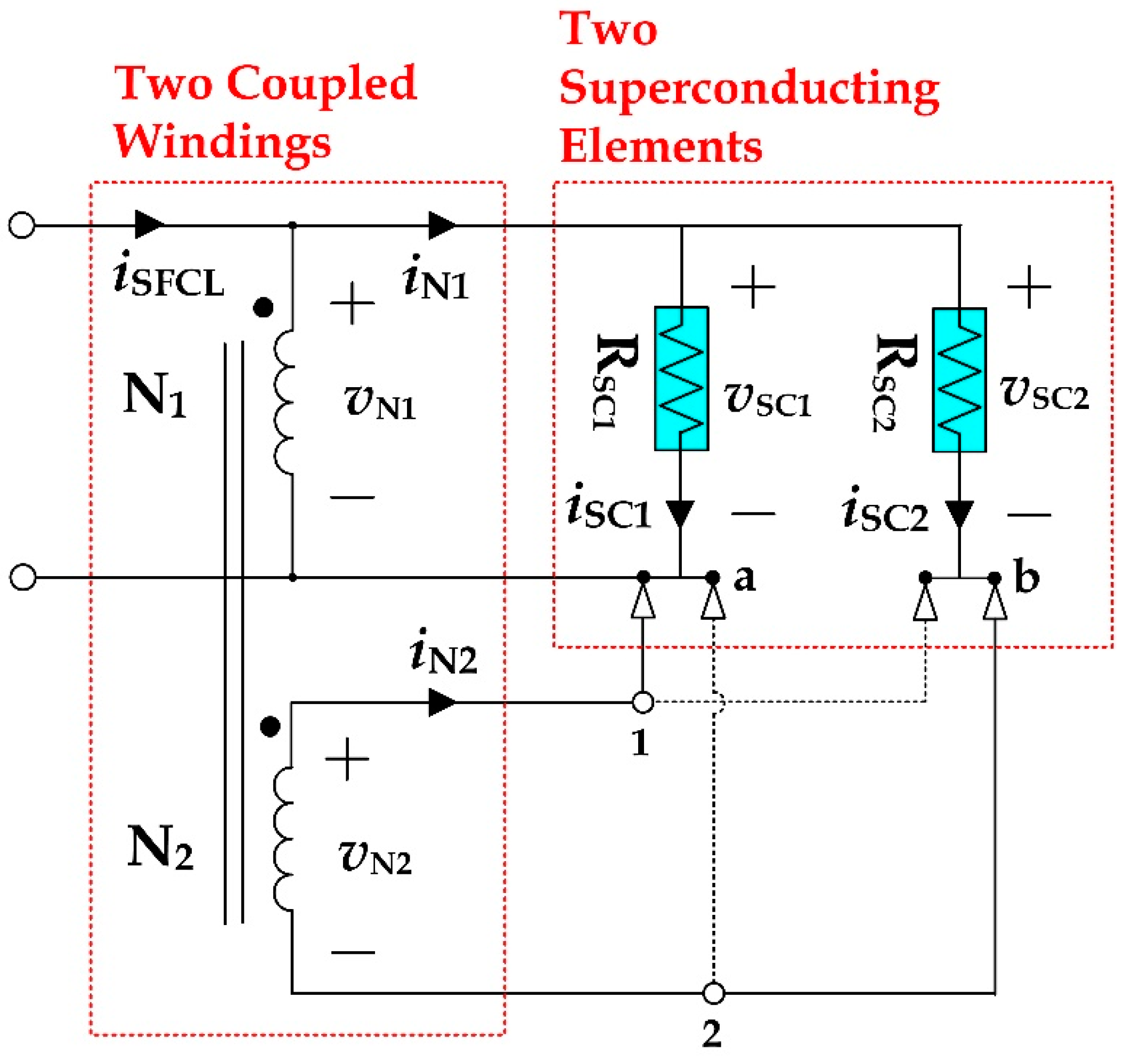

2.1. Structure and Operational Principle

2.2. Experimental Design and Methods

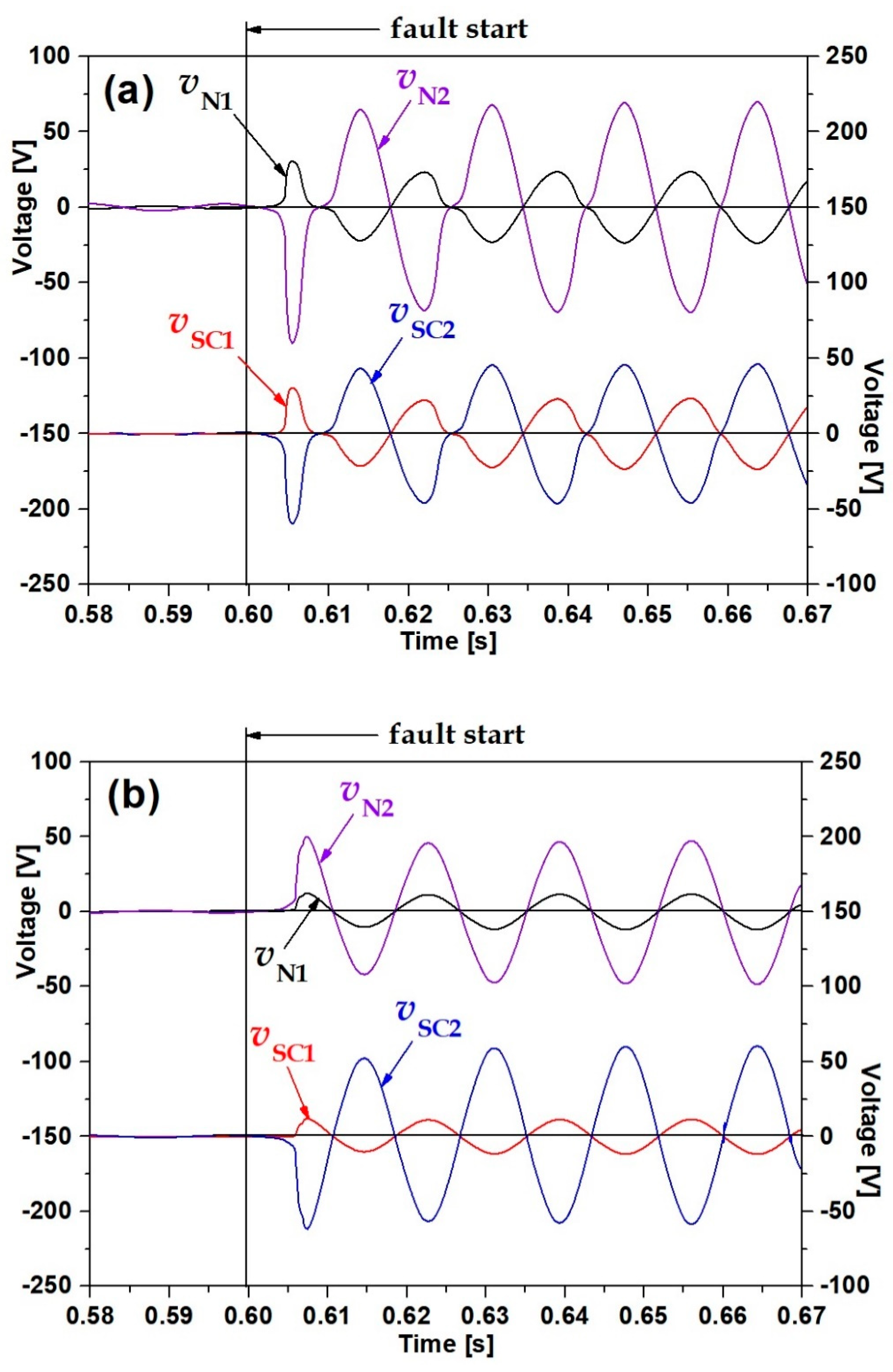

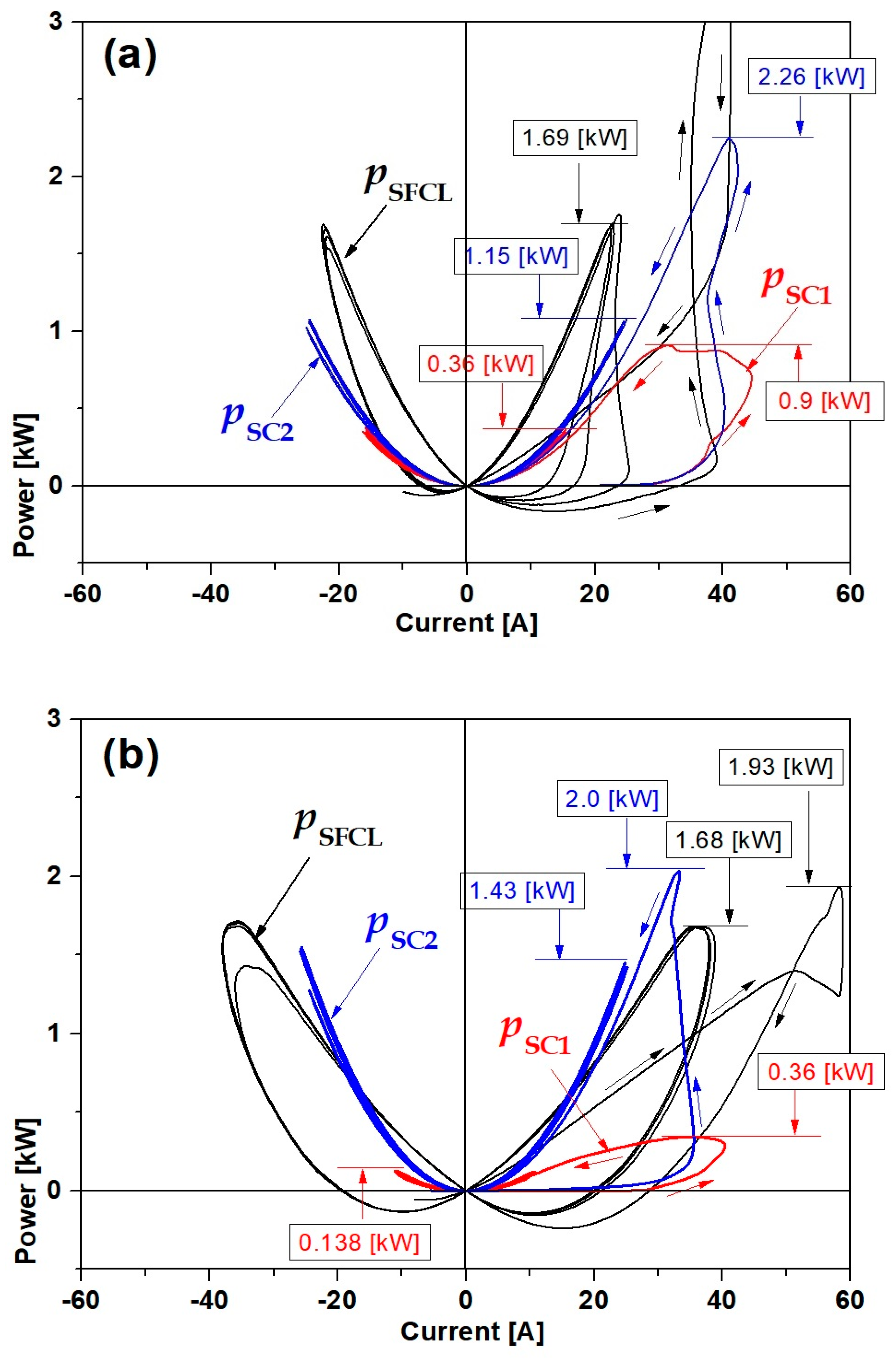

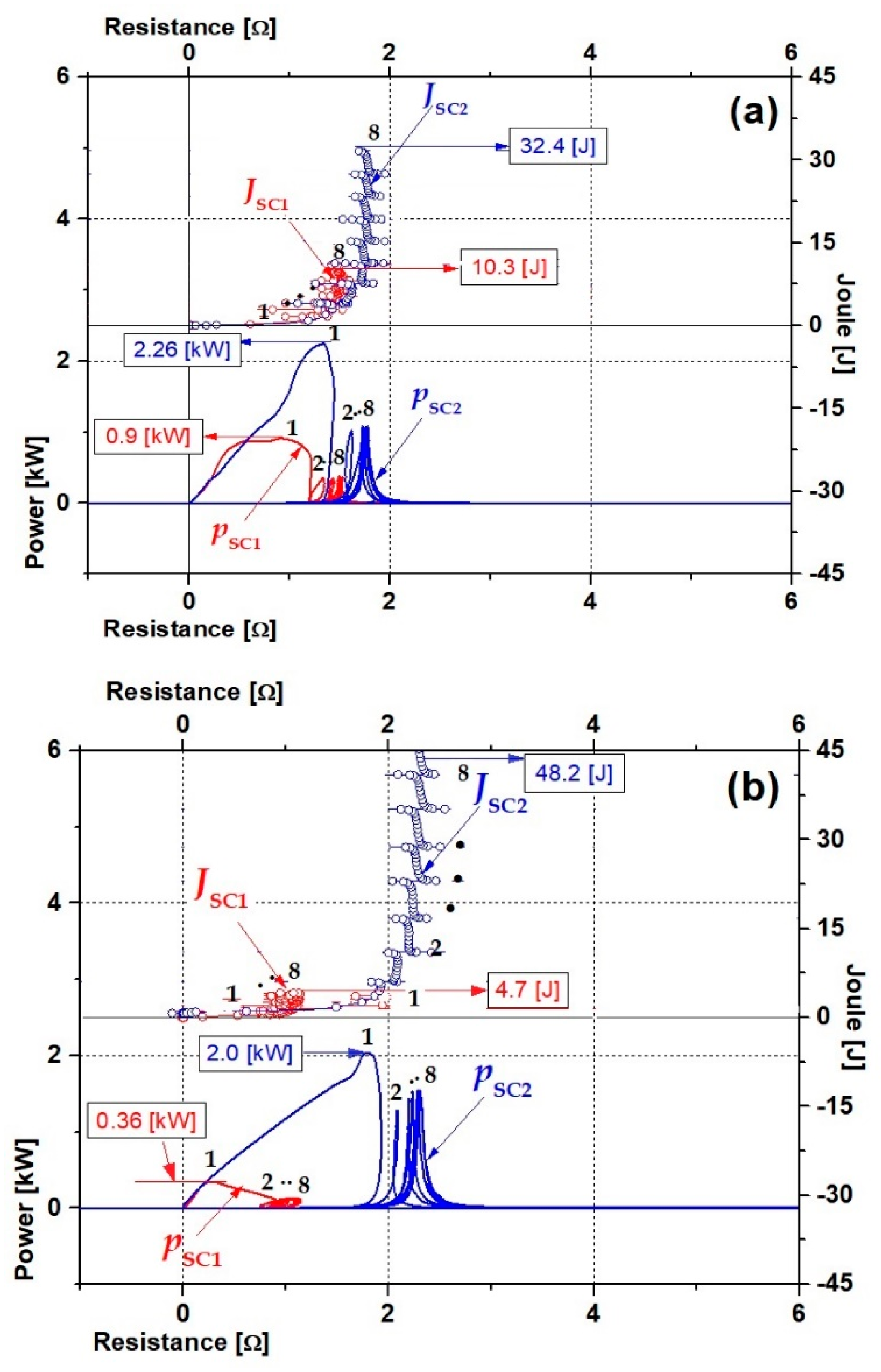

3. Experimental Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| SFCL | the superconducting fault current limiter |

| N1 | the primary winding of the two coupled windings |

| N2 | the secondary winding of the two coupled windings |

| SC1 | the superconducting element 1 |

| SC2 | the superconducting element 2 |

| IC | the critical current of superconducting element |

| Ein | the AC power supply voltage |

| Zln | the line impedance |

| RL | the load resistance |

| iN1 | the current of the primary winding |

| iN2 | the current of the secondary winding |

| iSC1 | the current of the superconducting element 1 |

| iSC2 | the current of the superconducting element 2 |

| VN1 | the voltage of the primary winding |

| VN2 | the voltage of the secondary winding |

| VSC1 | the voltage of the superconducting element 1 |

| VSC2 | the voltage of the superconducting element 2 |

| SW1 | the switch 1 of SFCL |

| SW2 | the switch 2 of SFCL |

| RSC1 | the resistance of the superconducting element 1 |

| RSC2 | the resistance of the superconducting element 2 |

| PSFCL | the instantaneous power of the superconducting fault current limiter |

| PSC1 | the instantaneous power of the superconducting element 1 |

| PSC2 | the instantaneous power of the superconducting element 2 |

References

- Hars, T.; Okuma, T.; Yamamoto, T.; Ito, D.; Tasaki, K.; Tsurunaga, K. Development of a new 6.6kV-1500A class superconducting fault current limiter for electric power system. IEEE Trans. Power Deliv. 1993, 8, 181–192. [Google Scholar]

- Ye, L.; Lin, L.Z.; Juengst, K.P. Application Studies of superconducting Fault Current Limiters in Electric Power Systems. IEEE Trans. Appl. Supercond. 2002, 12, 900–903. [Google Scholar] [CrossRef]

- Antonio, M. State of the art of SFCL and their application to the electric power system. Phys. C Supercond. Appl. 2013, 484, 242–247. [Google Scholar]

- Schettino, H.J.; Andrade, R., Jr.; Polasek, A.; Kottonau, D.; Sousa, W.T.B. A strategy for protection of high voltage systems using resistive superconducting fault current limiters. Phys. C Supercond. Appl. 2018, 544, 40–45. [Google Scholar] [CrossRef]

- Ye, L.; Campbell, A.M. Case study of HTS resistive superconducting fault current limiter in electrical distribution systems. Electr. Power Syst. Res. 2007, 77, 534–539. [Google Scholar] [CrossRef]

- Lorenzo-Fernandez, J.A.; Osorio, M.R.; Veira, J.A.; Tello, M.J.; Vidal, F. Thermal behaviour of high-temperature superconducting fault current limiters; Application to microlimiters. J. Phys. Chem. Solids 2010, 71, 1105–1107. [Google Scholar] [CrossRef]

- Jiang, Y.; Dongyuan, S.; Xianzhong, D.; Yuejin, T.; Shijie, C. Comparison of Superconducting Fault Current Limiter in Power System. Power Eng. Soc. Summer Meet. 2001, 3, 43–47. [Google Scholar]

- Joo, M.S. Reduction of fault current peak in an inductive high-Tc superconducting fault current limiter. Cryogenics 2005, 45, 343–347. [Google Scholar] [CrossRef]

- Xin, Y.; Gong, W.Z.; Niu, X.Y.; Gao, Y.Q.; Guo, Q.Q.; Xiao, L.X.; Cao, Z.J.; Hong, H.; Wu, A.G.; Li, Z.H.; et al. Manufacturing and test of a 35 kV/90 MVA saturated iron-core type superconductive fault current limiter for live-grid operation. IEEE Trans. Appl. Supercond. 2009, 19, 1934–1937. [Google Scholar] [CrossRef]

- Lim, S.H.; Kang, H.G.; Han, B.S.; Song, J.J. Analysis of new bridge-type superconducting fault current limiter applying modified magnetic shielding model. Mater. Sci. Eng. B 2003, 102, 348–351. [Google Scholar] [CrossRef]

- Hu, Y.; Jianxun, J. Characteristic Analysis of a Fully Controlled Bridge type Superconducting Fault Current Limiter. IEEE Trans. Appl. Supercond. 2016, 26, 5603706. [Google Scholar]

- Matsui, H.; Kondo, W.; Tsukada, K.; Sohma, M.; Yamaguchi, I.; Kumagai, T.; Manabe, T.; Arai, K.; Yamasaki, H. Environment-resistive coating for the thin-film-based SFCL Ag/Au–Ag/YBa2Cu3O7/CeO2/Al2O3. Phys. C Supercond. Appl. 2010, 470, 221–224. [Google Scholar] [CrossRef]

- Noe, M.; Juengst, K.P.; Werfel, F.N.; Elschner, S.; Bock, J.; Wolf, A.; Breuer, F. Measurements and tests of HTS bulk material in resistive fault current limiters. Phys. C Supercond. Appl. 2002, 372–376, 1626–1630. [Google Scholar] [CrossRef]

- Rhee, S.B.; Lee, B.W. Investigation of real field application issues for resistive type SFCLs for distribution electric power networks. Phys. C Supercond. Appl. 2010, 470, 1641–1645. [Google Scholar] [CrossRef]

- Matsumura, T.; Shimizu, H.; Yokomizu, Y. Design guideline of flux-lock type HTS fault current limiter for power system application. IEEE Trans. Appl. Supercond. 2001, 11, 1956–1959. [Google Scholar] [CrossRef]

- Han, T.H.; Ko, S.C.; Lee, B.G.; Lim, S.H. Study on Current Limiting Characteristics of a Flux-lock type SFCL using Series Connected Two Coils with Twice Triggering Operation. J. Electr. Eng. Technol. 2014, 9, 777–781. [Google Scholar] [CrossRef] [Green Version]

- Badakhshan, M.; Mousavi, G.S.M. Flux-lock type of superconducting fault current limiters: A comprehensive review. Phys. C Supercond. Appl. 2018, 547, 51–54. [Google Scholar] [CrossRef]

- Han, T.H.; Ko, S.C.; Lim, S.H. Fault Current Limiting Characteristics of a Small-Scale Bridge Type SFCL with Single HTSC Element Using Flux-Coupling. Electonics 2020, 9, 569. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Xia, D.; Zhang, Z.; Qiu, Q.; Zhang, G. Analysis of a flux-coupling type superconductor fault current limiter with pancake coils. Cryogenics 2017, 87, 18–23. [Google Scholar] [CrossRef]

- Lim, S.H. Operational Characteristics of Flux-Lock Type SFCL With Series Connection of Two Coils. IEEE Trans. Appl. Supercond. 2007, 17, 1895–1898. [Google Scholar] [CrossRef]

- Lim, S.H.; Kim, J.C. Quench and Recovery Characteristics of Series-Connected Resistive Type SFCLs WITH Magnetically Coupled Shunt-Reactors. IEEE Trans. Appl. Supercond. 2008, 18, 729–732. [Google Scholar]

- Han, T.H.; Lim, S.H. Current limiting characteristics of transformer type SFCL with coupled secondary windings according to its winding direction. Prog. Supercon. Cryog. 2017, 19, 44–47. [Google Scholar]

- Kim, H.R.; Choi, H.S.; Lim, H.R.; Kim, I.S.; Hyun, O.B. Initial quench development in uniform Au/Y-Ba-Cu-O thin films. IEEE Trans. Appl. Supercond. 2001, 11, 2414–2417. [Google Scholar]

- Lim, S.H.; Choi, H.S.; Chung, D.C.; Ko, S.C.; Han, B.S. Impedance variation of a flux-lock type SFCL dependent on winding direction between coil 1 and coil 2. IEEE Trans. Appl. Supercond. 2005, 15, 2039–2042. [Google Scholar] [CrossRef]

- Han, T.H.; Lim, S.H. Magnetizing Characteristics of Transformer Type SFCL with additional secondary winding. IEEE Trans. Appl. Supercond. 2018, 28, 5602605. [Google Scholar]

- Lim, S.H.; You, L.K.; Kim, J.C. Study on Peak Current Limiting Characteristics of a Flux-Lock Type SFCL Using Its Third Winding. IEEE Trans. Appl. Supercond. 2011, 3, 1275–1279. [Google Scholar] [CrossRef]

| Experimental Circuit | Value | Unit | |

|---|---|---|---|

| Power source (EIn) | AC voltage | 120 | Vrms |

| Frequency | 60 | Hz | |

| Line impedance (ZIn) | Resistance | 0.42 | Ω |

| Reactance | 0.066 | Ω | |

| Load (RL) | Resistance | 5 | Ω |

| SFCL using two coupled windings | Value | Unit | |

| Two coupled windings | Primary winding (N1) | 15 | Turns |

| Secondary winding (N2) | 45 | Turns | |

| Two superconducting elements (SC1, SC2) | Material | YBCO | |

| Fabrication form | Thin film | ||

| Critical temperature (TC) | 87 | K | |

| Critical current (IC) | 27 | A | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ko, S.-C.; Han, T.-H.; Lim, S.-H. Analysis on Double Quench and Instantaneous Power of SFCL Using Two Magnetically Coupled Windings According to Winding Direction. Energies 2020, 13, 5533. https://doi.org/10.3390/en13215533

Ko S-C, Han T-H, Lim S-H. Analysis on Double Quench and Instantaneous Power of SFCL Using Two Magnetically Coupled Windings According to Winding Direction. Energies. 2020; 13(21):5533. https://doi.org/10.3390/en13215533

Chicago/Turabian StyleKo, Seok-Cheol, Tae-Hee Han, and Sung-Hun Lim. 2020. "Analysis on Double Quench and Instantaneous Power of SFCL Using Two Magnetically Coupled Windings According to Winding Direction" Energies 13, no. 21: 5533. https://doi.org/10.3390/en13215533