Laboratory Measurements of the Relative Permeability of Coal: A Review

Abstract

1. Introduction

2. Relative Permeability Measurement of Coal

2.1. Preparation Work

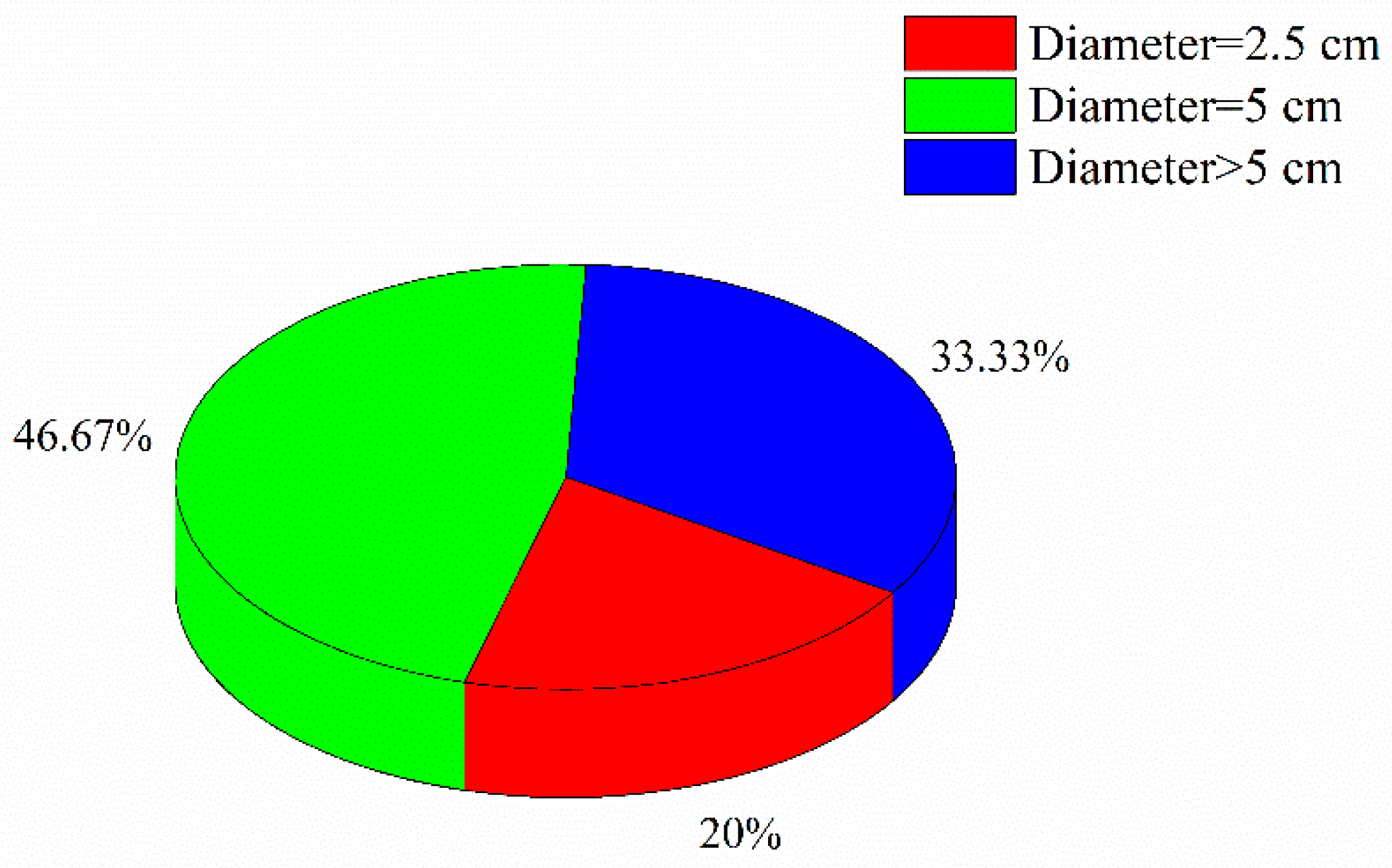

2.1.1. Sample Selection

2.1.2. Test Fluid Selection

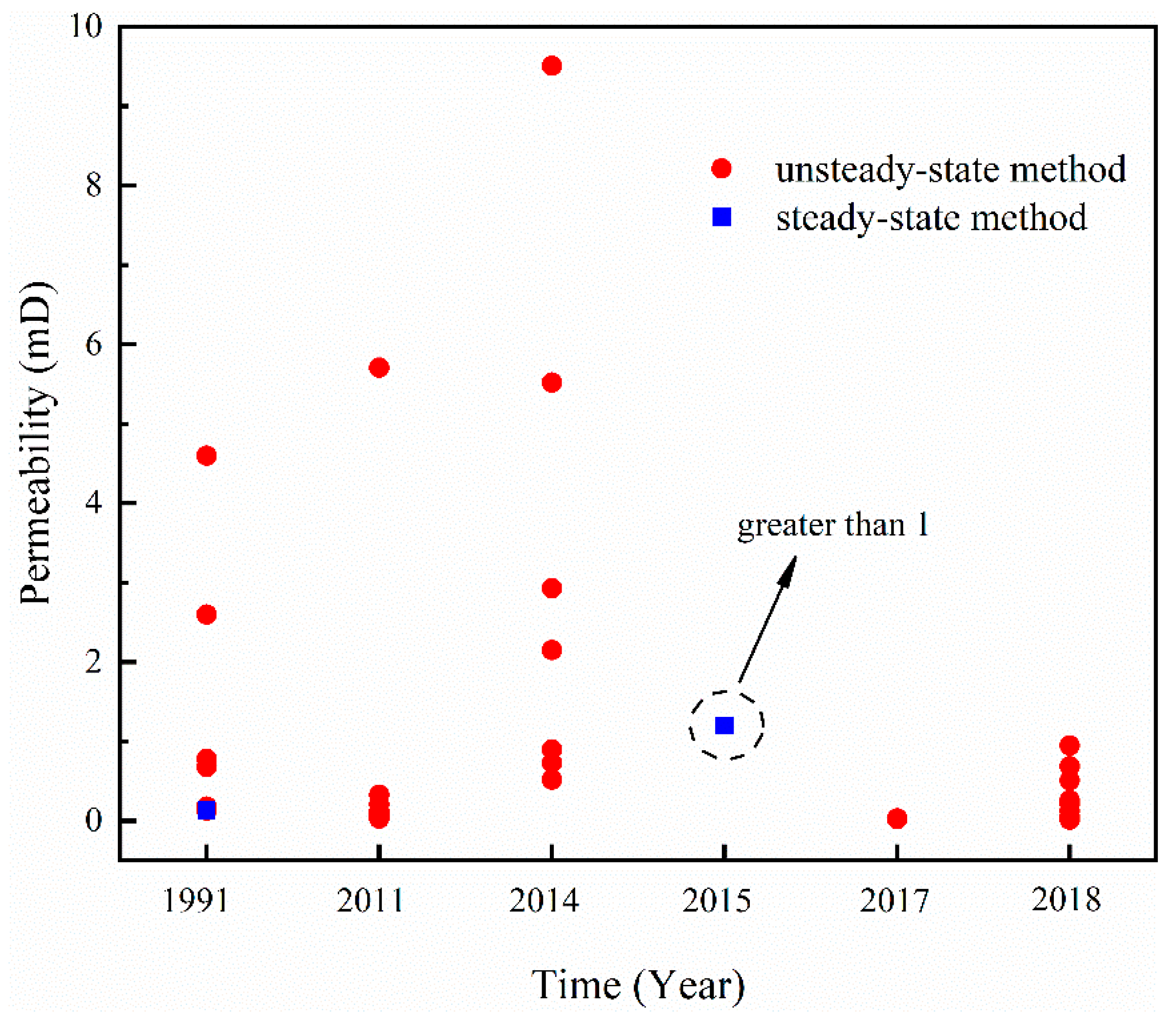

2.1.3. Absolute Permeability Test

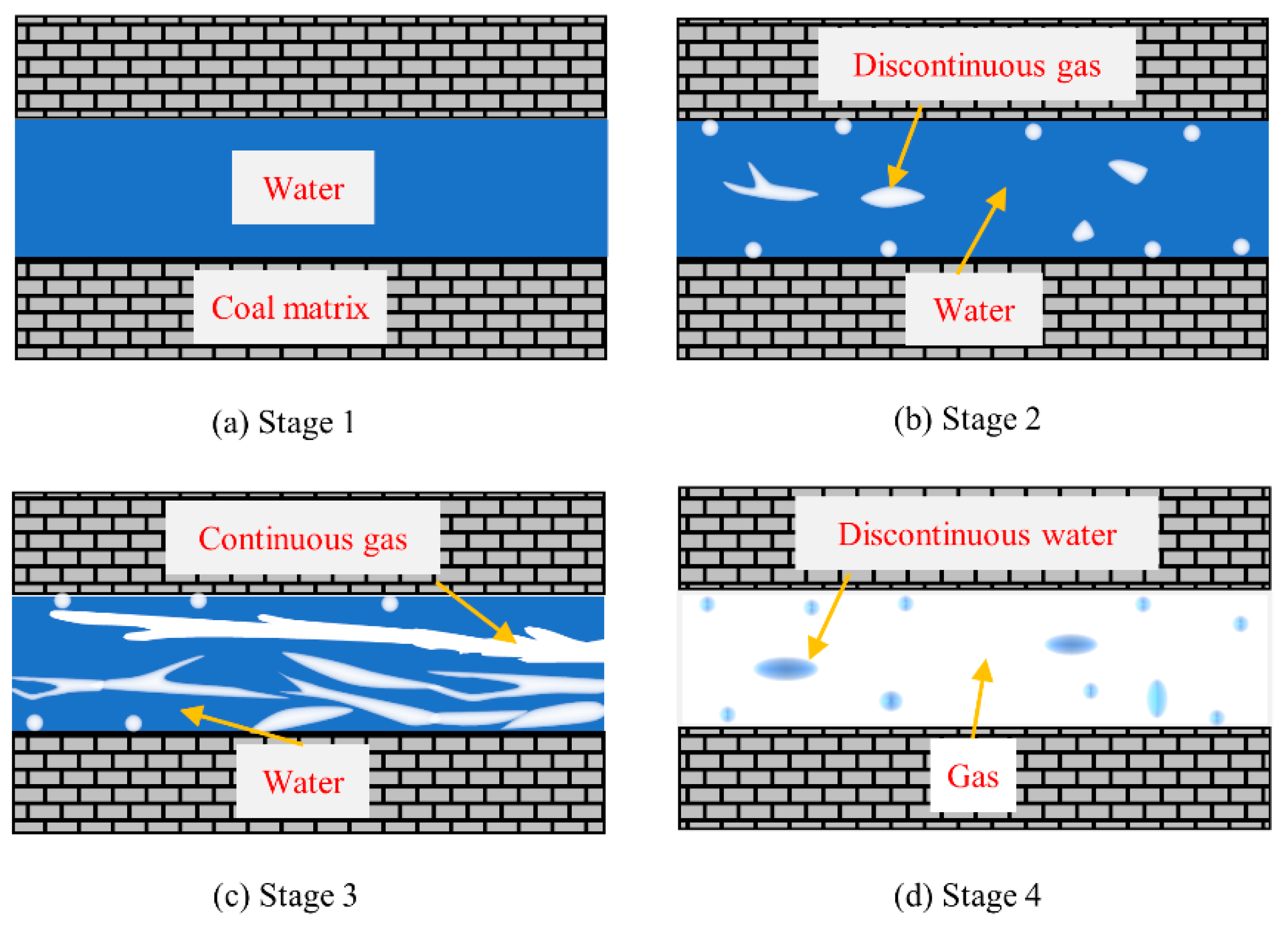

2.2. Methods to Measure the Coal Relative Permeability in Laboratories

2.2.1. Steady-State Method

2.2.2. Unsteady-State Method

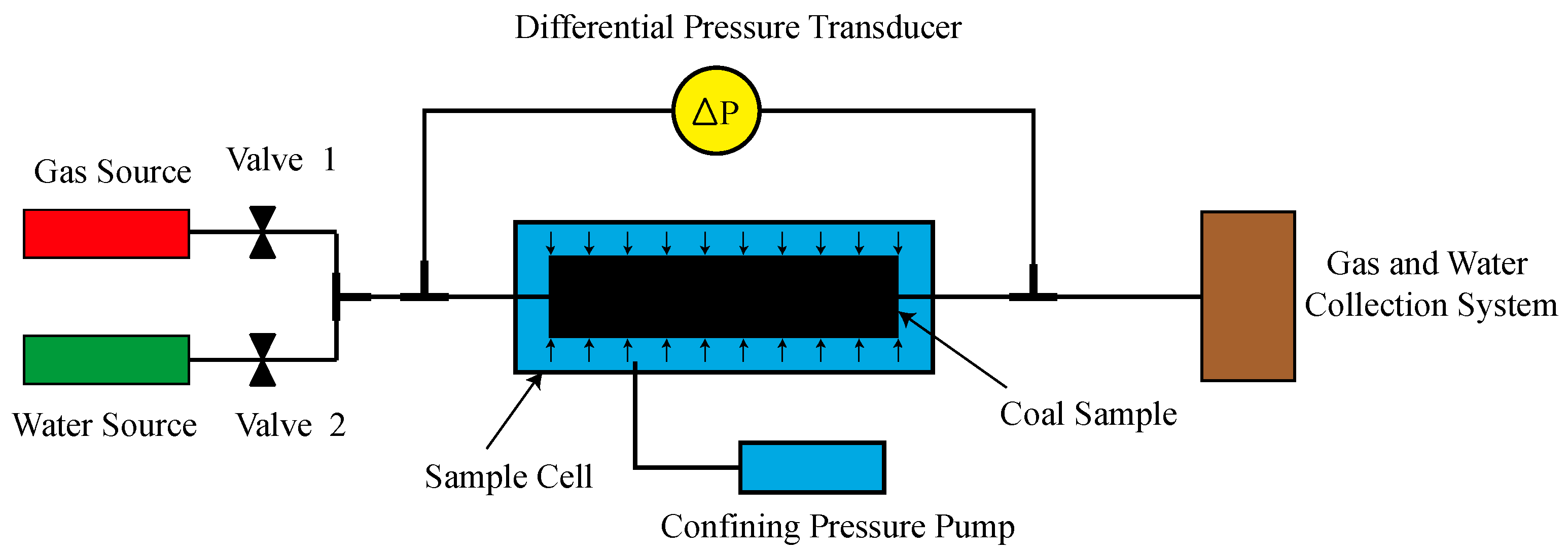

2.3. Devices to Measure Relative Permeability in Laboratories

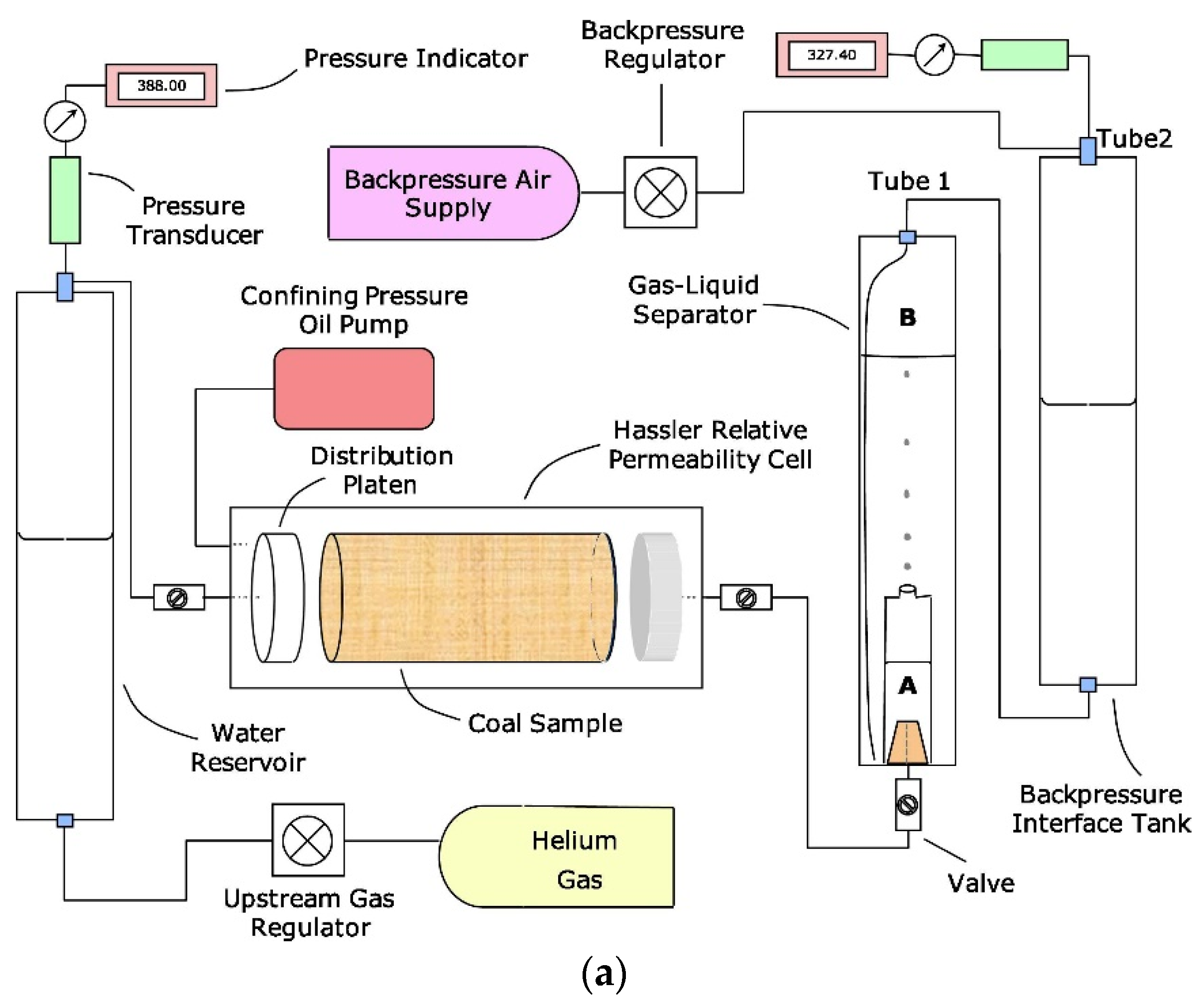

2.3.1. Volumetric Technique

2.3.2. Gravimetric Technique

2.3.3. Acoustic Technique

2.3.4. X-ray CT Scanning Technique

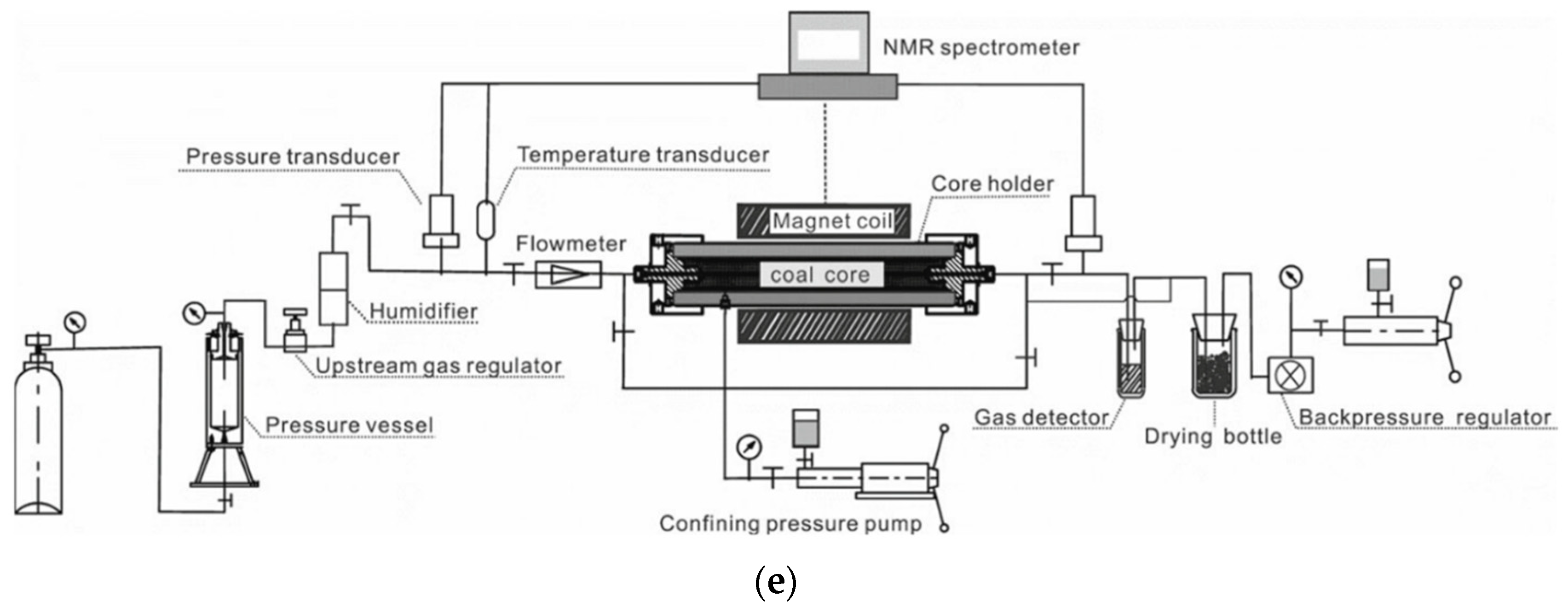

2.3.5. NMR Technique

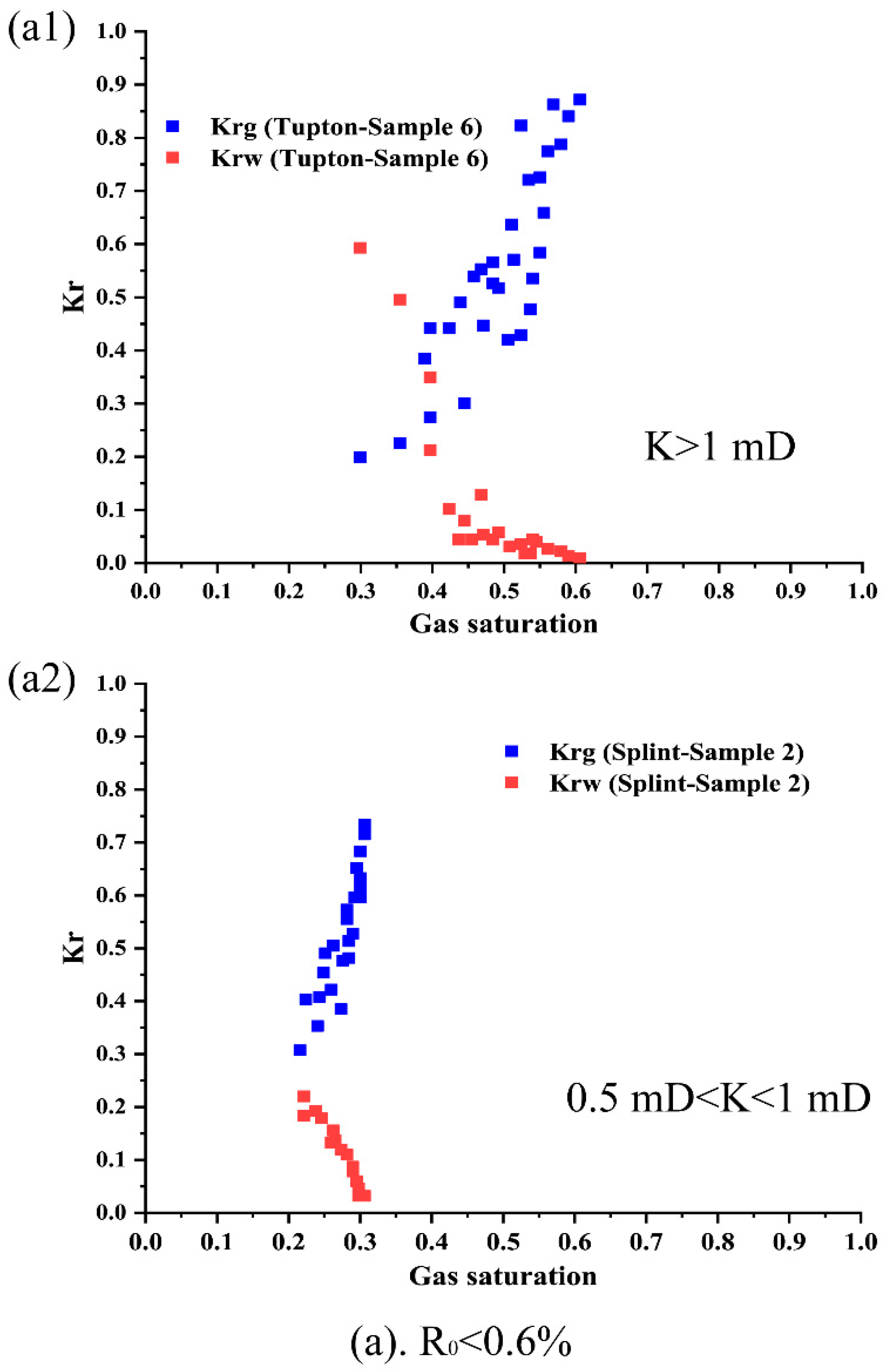

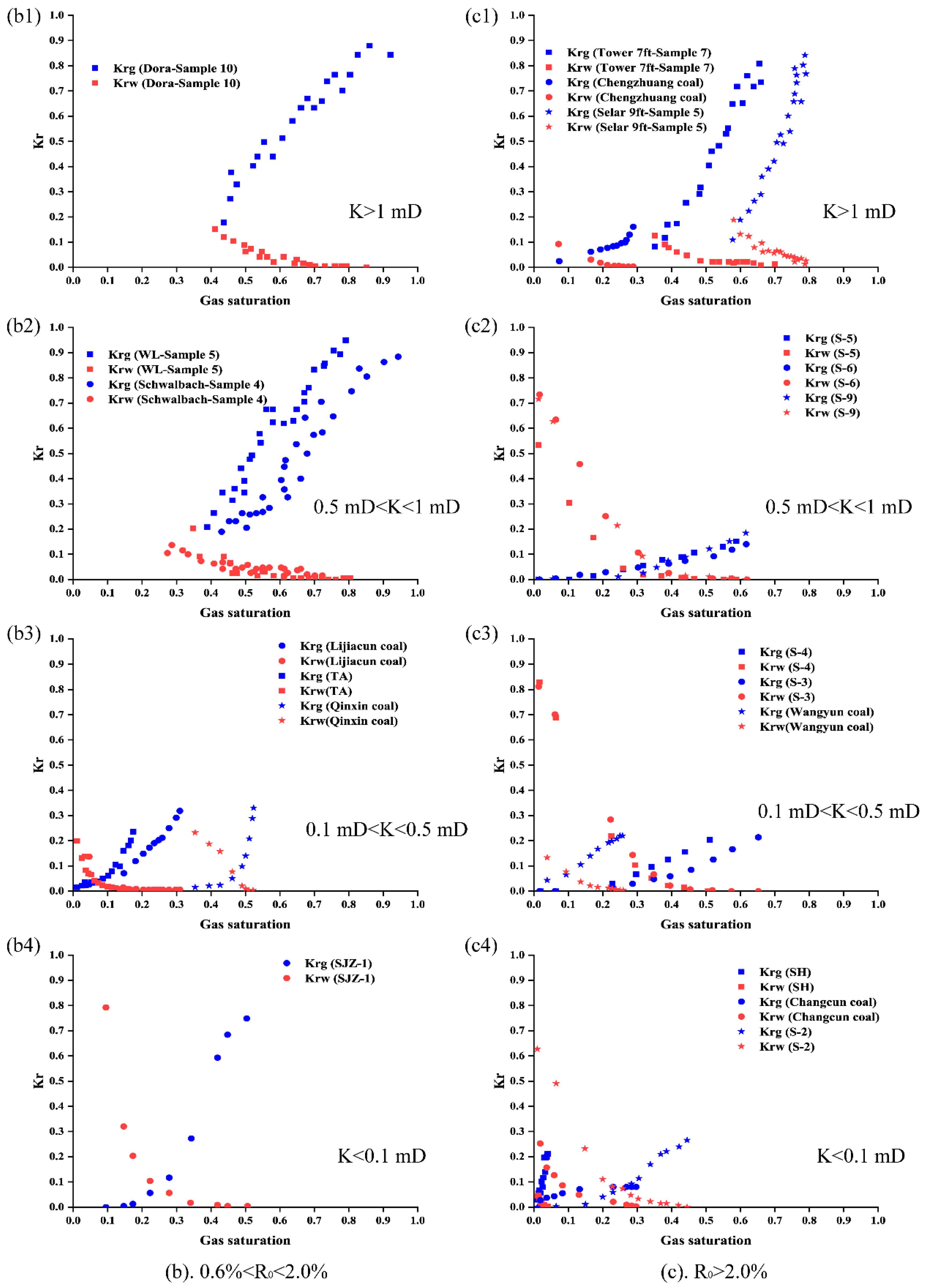

2.4. Summary of Relative Permeability Curves

3. Discussion

3.1. Determination of Absolute Permeability

3.2. Measurement Method

3.3. Measurement Devices

3.4. Measurement Results

4. Conclusions and Future Work

- Standardize the measurement process to make the experimental results more comparable and reliable. To make the results more comparable, the routine operations in the experiment (such as sample size selection, test fluid selection, and absolute permeability treatment) should be as consistent as possible, which will help to summarize the characteristics of the relative permeability of coals of different rank.

- Improve the measurement accuracy. The use of a high-precision differential pressure gauge may be an effective technique to monitor water production during the experiment and improve measurement accuracy. In addition, methods should be identified to reduce water retention in the pipe and minimize the system error; for example, vertically placing the pipeline between the sample and the separator and performing hydrophobic treatment on the inner surface of the pipeline will improve measurement accuracy.

- Fill the research gaps. The relative permeability of supercritical carbon dioxide–water and mixed gas (methane and carbon dioxide)–water in coal as not yet been investigated and must be the next focus of study.

Author Contributions

Funding

Conflicts of Interest

References

- Zou, C.; Yang, Z.; Zhu, R.; Zhang, G.; Hou, L.; Wu, S.; Tao, S.; Yuan, X.; Dong, D.; Wang, Y.; et al. Progress in China’s Unconventional Oil & Gas Exploration and Development and Theoretical Technologies. Acta Geol. Sin. Engl. Ed. 2015, 89, 938–971. [Google Scholar]

- McGlade, C.; Speirs, J.; Sorrell, S. Unconventional gas—A review of regional and global resource estimates. Energy 2013, 55, 571–584. [Google Scholar] [CrossRef]

- Xia, X.G.; Yang, Y.F. Attribute Synthetic Evaluation Model for the CBM Recoverability and Its Application. Math. Probl. Eng. 2015, 2015, 434583. [Google Scholar] [CrossRef]

- Lau, H.C.; Li, H.Y.; Huang, S. Challenges and Opportunities of Coalbed Methane Development in China. Energy Fuels 2017, 31, 4588–4602. [Google Scholar] [CrossRef]

- Hein, F.J.; Ambrose, W.A.; Hackley, P.; Mead, J.S.; American Association of Petroleum Geologists, Energy Minerals Division. Unconventional Energy Resources: 2017 Review. Nat. Resour. Res. 2019, 28, 1661–1751. [Google Scholar]

- Thakur, P. Chapter 1—Global Reserves of Coal Bed Methane and Prominent Coal Basins. In Advanced Reservoir and Production Engineering for Coal Bed Methane; Thakur, P., Ed.; Gulf Professional Publishing: Houston, TX, USA, 2017; pp. 1–15. [Google Scholar]

- Zhang, M.; Fu, X.H. Characterization of pore structure and its impact on methane adsorption capacity for semi-anthracite in Shizhuangnan Block, Qinshui Basin. J. Nat. Gas Sci. Eng. 2018, 60, 49–62. [Google Scholar] [CrossRef]

- Lu, M.; Connell, L.D. A dual-porosity model for gas reservoir flow incorporating adsorption behaviour—Part I. Theoretical development and asymptotic analyses. Transp. Porous Media 2007, 68, 153–173. [Google Scholar] [CrossRef]

- Warren, J.E.; Root, P.J. The behavior of naturally fractured reservoirs. Soc. Pet. Eng. J. 1963, 3, 245–255. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Bustin, R.M. The effect of pore structure and gas pressure upon the transport properties of coal: A laboratory and modeling study. 1. Isotherms and pore volume distributions. Fuel 1999, 78, 1333–1344. [Google Scholar] [CrossRef]

- Mostaghimi, P.; Armstrong, R.T.; Gerami, A.; Hu, Y.B.; Jing, Y.; Kamali, F.; Liu, M.; Liu, Z.S.; Lu, X.; Ramandi, H.L.; et al. Cleat-scale characterisation of coal: An overview. J. Nat. Gas Sci. Eng. 2017, 39, 143–160. [Google Scholar] [CrossRef]

- Gray, I. Reservoir Engineering in Coal Seams: Part 1-The Physical Process of Gas Storage and Movement in Coal Seams. SPE Reserv. Eng. 1987, 2, 28–34. [Google Scholar] [CrossRef]

- Aminian, K.; Ameri, S. Predicting production performance of CBM reservoirs. J. Nat. Gas Sci. Eng. 2009, 1, 25–30. [Google Scholar] [CrossRef]

- De Silva, P.N.K.; Ranjith, P.G.; Choi, S.K. A study of methodologies for CO2 storage capacity estimation of coal. Fuel 2012, 91, 1–15. [Google Scholar] [CrossRef]

- Packham, R.; Cinar, Y.; Moreby, R. Simulation of an enhanced gas recovery field trial for coal mine gas management. Int. J. Coal Geol. 2011, 85, 247–256. [Google Scholar] [CrossRef]

- Liu, H.H.; Mou, J.H.; Cheng, Y.P. Impact of pore structure on gas adsorption and diffusion dynamics for long-flame coal. J. Nat. Gas Sci. Eng. 2015, 22, 203–213. [Google Scholar] [CrossRef]

- Fang, Z. Mechanisms and Experimental Study of Gas Mixture Enhanced Coalbed Methane Recovery Technology. Ph.D. Thesis, Institute of Rock and Soil Mechanics Chinese Academy of Sciences, Wuhan, China, 2009. [Google Scholar]

- Ma, T.; Rutqvist, J.; Oldenburg, C.M.; Liu, W.Q.; Chen, J.G. Fully coupled two-phase flow and poromechanics modeling of coalbed methane recovery: Impact of geomechanics on production rate. J. Nat. Gas Sci. Eng. 2017, 45, 474–486. [Google Scholar] [CrossRef]

- Teng, T.; Wang, J.G.; Gao, F.; Ju, Y.; Xia, T.Q. Impact of Water Film Evaporation on Gas Transport Property in Fractured Wet Coal Seams. Transp. Porous Media 2016, 113, 357–382. [Google Scholar] [CrossRef]

- Honarpour, M.; Mahmood, S.M. Relative-Permeability Measurements—An Overview. J. Petrol. Technol. 1988, 40, 963–966. [Google Scholar] [CrossRef]

- Nie, B.; Liu, X.; Yang, L.; Meng, J.; Li, X. Pore structure characterization of different rank coals using gas adsorption and scanning electron microscopy. Fuel 2015, 158, 908–917. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Kitano, K.; Vassileva, C.G. Some relationships between coal rank and chemical and mineral composition. Fuel 1996, 75, 1537–1542. [Google Scholar] [CrossRef]

- Shen, J.; Qin, Y.; Wang, G.X.; Fu, X.H.; Wei, C.T.; Lei, B. Relative permeabilities of gas and water for different rank coals. Int. J. Coal Geol. 2011, 86, 266–275. [Google Scholar] [CrossRef]

- Palmer, I.; Mansoori, J. How permeability depends on stress and pore pressure in coalbeds: A new model. In Proceedings of the SPE Annual Technical Conference and Exhibition of the Society of Petroleum Engineers, Denver, CO, USA, 6–9 October 1996. [Google Scholar]

- Pan, Z.J.; Connell, L.D.; Camilleri, M. Laboratory characterisation of coal reservoir permeability for primary and enhanced coalbed methane recovery. Int. J. Coal Geol. 2010, 82, 252–261. [Google Scholar] [CrossRef]

- Reznik, A.A.; Dabbous, M.K.; Fulton, P.F.; Taber, J.J. Air-Water Relative Permeability Studies of Pittsburgh and Pocahontas Coals. Soc. Pet. Eng. J. 1974, 14, 556–562. [Google Scholar] [CrossRef]

- Gash, B.W.; Volz, R.F.; Potter, G.; Corgan, J.M. The Effects of Cleat Orientation and Confining Pressure on Cleat Porosity, Permeability and Relative Permeability in Coal. In Proceedings of the SPWLA/SCA Symposium, Oklahoma City, OK, USA, 15–16 June 1992; pp. 15–16. [Google Scholar]

- Dabbous, M.K.; Reznik, A.A.; Mody, B.G.; Fulton, P.F.; Taber, J.J. Gas-Water Capillary Pressure in Coal at Various Overburden Pressures. Soc. Pet. Eng. J. 1976, 16, 261–268. [Google Scholar] [CrossRef]

- Durucan, S.; Ahsan, M.; Shi, J.Q.; Syed, A.; Korre, A. Two phase relative permeabilities for gas and water in selected European coals. Fuel 2014, 134, 226–236. [Google Scholar] [CrossRef]

- Alexis, D.A.; Karpyn, Z.T.; Ertekin, T.; Crandall, D. Fracture permeability and relative permeability of coal and their dependence on stress conditions. J. Unconv. Oil Gas Res. 2015, 10, 1–10. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Wu, C.F.; Liu, S.X. Characteristic analysis and fractal model of the gas-water relative permeability of coal under different confining pressures. J. Pet. Sci. Eng. 2017, 159, 488–496. [Google Scholar] [CrossRef]

- Sun, X.; Yao, Y.; Ripepi, N.; Liu, D. A Novel Method for Gas-Water Relative Permeability Measurement of Coal Using NMR Relaxation. Transp. Porous Media 2018, 124, 73–90. [Google Scholar] [CrossRef]

- Shen, J.; Qin, Y.; Li, Y.P.; Wang, G. Experimental investigation into the relative permeability of gas and water in low-rank coal. J. Pet. Sci. Eng. 2019, 175, 303–316. [Google Scholar] [CrossRef]

- Shaw, D.; Mostaghimi, P.; Armstrong, R.T. The dynamic behaviour of coal relative permeability curves. Fuel 2019, 253, 293–304. [Google Scholar] [CrossRef]

- Wang, J.M.; Zhao, Y.S.; Mao, R.B. Impact of temperature and pressure on the characteristics of two-phase flow in coal. Fuel 2019, 253, 1325–1332. [Google Scholar] [CrossRef]

- Mazzotti, M.; Pini, R.; Storti, G. Enhanced coalbed methane recovery. J. Supercrit. Fluids 2009, 47, 619–627. [Google Scholar] [CrossRef]

- Mukherjee, M.; Misra, S. A review of experimental research on Enhanced Coal Bed Methane (ECBM) recovery via CO2 sequestration. Earth-Sci. Rev. 2018, 179, 392–410. [Google Scholar] [CrossRef]

- Puri, R.; Yee, D. Enhanced Coalbed Methane Recovery. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 23–26 September 1990; Society of Petroleum Engineers: Richardson, TX, USA, 1990. [Google Scholar]

- Gunter, W.; Gentzis, T.; Rottenfusser, B.; Richardson, R. Deep coalbed methane in Alberta, Canada: A fuel resource with the potential of zero greenhouse gas emissions. Energy Convers. Manag. 1997, 38, S217–S222. [Google Scholar] [CrossRef]

- Zhang, Y. Experimental Study on Gas-Water Two Phase Flow in Coalbed Media. Master’s Thesis, China University of Petroleum, Qingdao, China, 2011. [Google Scholar]

- Ham, Y. Measurement and Simulation of Relative Permeability of Coal to Gas and Water. Ph.D. Thesis, The University of Calgary, Calgary, AB, USA, 2011. [Google Scholar]

- Gao, G.; Bai, Y.; Hou, T.; Guan, T. Experimental on relative permeability of gas and water based on coal unsteady-state method. Saf. Coal Mines 2015, 46, 12–15. [Google Scholar]

- Zhang, J.Y.; Feng, Q.H.; Zhang, X.M.; Wen, S.M.; Zhai, Y.Y. Relative Permeability of Coal: A Review. Transp. Porous Media 2015, 106, 563–594. [Google Scholar] [CrossRef]

- Meaney, K.; Paterson, L. Relative Permeability in Coal. In Proceedings of the SPE Asia Pacific Oil and Gas Conference, Adelaide, Australia, 28–31 October 1996; Society of Petroleum Engineers: Adelaide, Australia, 1996; p. 6. [Google Scholar]

- Karacan, C.O. Swelling-induced volumetric strains internal to a stressed coal associated with CO2 sorption. Int. J. Coal Geol. 2007, 72, 209–220. [Google Scholar] [CrossRef]

- Zhou, D.; Feng, Z.C.; Zhao, D.; Zhao, Y.S.; Cai, T.T. Experimental study of meso-structural deformation of coal during methane adsorption-desorption cycles. J. Nat. Gas Sci. Eng. 2017, 42, 243–251. [Google Scholar] [CrossRef]

- Gash, B.W. Measurement of “Rock Properties” in Coal for Coalbed Methane Production. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 6–9 October 1991; Society of Petroleum Engineers: Richardson, TX, USA, 1991. [Google Scholar]

- Puri, R.; Evanoff, J.C.; Brugler, M.L. Measurement of coal cleat porosity and relative permeability characteristics. In Proceedings of the SPE Gas Technology Symposium, Houston, TX, USA, 22–24 January 1991. [Google Scholar]

- Zhang, Z.; Qin, Y.; Zhuang, X.G.; Li, G.Q.; Wang, X.M. Poroperm characteristics of high-rank coals from Southern Qinshui Basin by mercury intrusion, SEM-EDS, nuclear magnetic resonance and relative permeability analysis. J. Nat. Gas Sci. Eng. 2018, 51, 116–128. [Google Scholar] [CrossRef]

- Chen, G. Gas Slippage and Matrix Shrinkage Effects on Permeability of Coal. Ph.D. Thesis, The University of Arizona, Tucson, Arizona, 1994. [Google Scholar]

- Mazumder, S.; Plug, W.J.; Bruining, H. Capillary Pressure and Wettability Behavior of Coal-Water-Carbon dioxide System. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 5–8 October 2003; pp. 2467–2476. [Google Scholar]

- Leverett, M.C. Capillary behavior in porous solids. Trans. AIME 1941, 142, 152–169. [Google Scholar] [CrossRef]

- Buckley, S.E.; Leverett, M.C. Mechanism of fluid displacement in sands. Trans. AIME 1942, 146, 107–116. [Google Scholar] [CrossRef]

- Welge, H.J. A simplified method for computing oil recovery by gas or water drive. Trans. AIME 1952, 195, 91–98. [Google Scholar] [CrossRef]

- Johnson, E.F.; Bossler, D.P.; Naumann, V.O. Calculation of Relative Permeability from Displacement Experiments. Trans. AIME 1959, 216, 370–372. [Google Scholar] [CrossRef]

- Dabbous, M.K.; Reznik, A.A.; Taber, J.J.; Fulton, P.F. The Permeability of Coal to Gas and Water. Soc. Pet. Eng. J. 1974, 14, 563–572. [Google Scholar] [CrossRef]

- Laubach, S.E.; Marrett, R.A.; Olson, J.E.; Scott, A.R. Characteristics and origins of coal cleat: A review. Int. J. Coal Geol. 1998, 35, 175–207. [Google Scholar] [CrossRef]

- Cheng, Q. Research on determination of coalbed gas-water relative permeability. J. Jiaozuo Inst. Technol. 2001, 20, 199–201. [Google Scholar]

- Ge, L.; Soares, F.T.; Mahoney, S.; Hamilton, C.; Khan, C.; Steel, K.; Rufford, T.E.; Rudolph, V. Effect of oxidation and silane surface treatments of coal powders on relative permeability in packed coal beds. J. Nat. Gas Sci. Eng. 2019, 69, 102931. [Google Scholar] [CrossRef]

- Paterson, L.; Meaney, K.; Smyth, M. Measurements of relative permeability, absolute permeability and fracture geometry in coal. In Proceedings of the Coalbed Methane Symposium, Townsville, Australia, 19–21 November 1992. [Google Scholar]

- Brooks, R.H.; Corey, A.T. Properties of porous media affecting fluid flow. J. Irrig. Drain. Div. 1966, 92, 61–88. [Google Scholar]

- Chen, D.; Pan, Z.J.; Liu, J.S.; Connell, L.D. An improved relative permeability model for coal reservoirs. Int. J. Coal Geol. 2013, 109, 45–57. [Google Scholar] [CrossRef]

- Schembre, J.M.; Kovscek, A.R. A technique for measuring two-phase relative permeability in porous media via X-ray CT measurements. J. Pet. Sci. Eng. 2003, 39, 159–174. [Google Scholar] [CrossRef]

- Guo, Y.; Pan, B.; Zhang, L. A New Method to Identify Reservoirs in Tight Sandstones Based on the New Model of Transverse Relaxation Time and Relative Permeability. Geofluids 2017, 2017, 6787038. [Google Scholar] [CrossRef]

- Fang, Z.; Li, X. Device for Measuring Gas and Water Relative Permeability of Porous Media; China National Intellectual Property: Beijing, China, 2014.

- Vishal, V.; Singh, T. A laboratory investigation of permeability of coal to supercritical CO2. Geotech. Geol. Eng. 2015, 33, 1009–1016. [Google Scholar] [CrossRef]

- Li, W.; Liu, Z.D.; Su, E.L.; Cheng, Y.P. Experimental Investigation on the Effects of Supercritical Carbon Dioxide on Coal Permeability: Implication for CO2 Injection Method. Energy Fuels 2019, 33, 503–512. [Google Scholar] [CrossRef]

- Du, Y.; Sang, S.; Pan, Z.; Wang, W.; Liu, S.; Fu, C.; Zhao, Y.; Zhang, J. Experimental study of supercritical CO2-H2O-coal interactions and the effect on coal permeability. Fuel 2019, 253, 369–382. [Google Scholar] [CrossRef]

- Salmachi, A.; Haghighi, M. Feasibility Study of Thermally Enhanced Gas Recovery of Coal Seam Gas Reservoirs Using Geothermal Resources. Energy Fuels 2012, 26, 5048–5059. [Google Scholar] [CrossRef]

- Luo, C.J.; Zhang, D.F.; Lun, Z.M.; Zhao, C.P.; Wang, H.T.; Pan, Z.J.; Li, Y.H.; Zhang, J.; Jia, S.Q. Displacement behaviors of adsorbed coalbed methane on coals by injection of SO2/CO2 binary mixture. Fuel 2019, 247, 356–367. [Google Scholar] [CrossRef]

| Author | Method | Sample Dimensions (cm) | Test Fluids | Absolute Permeability (mD) | Experimental Conditions | |||

|---|---|---|---|---|---|---|---|---|

| Confining Pressure (MPa) | Inlet Pressure (MPa) | Outlet Pressure (MPa) | Temperature (°C) | |||||

| Reznik, Dabbous, Fulton and Taber [26] | Steady-state method and Unsteady-state method | ng | air–distilled water | ng | 1.38/4.14/6.89 | ng | ng | ng |

| Gash [47] | Steady-state method and Unsteady-state method | D = 5.08–8.89 | helium–water | 0.04–4.6 | 3.1/6.89 | 2.55 | 2.07 | ng |

| Puri, Evanoff and Brugler [48] | Unsteady-state method | D = 8.89/6.35 L = 8.38/6.35 | helium–water | 0.18/ 0.68 | 7.45/ | 2.63 | 2.10 | ng |

| 2.79 * | ng | 2.07 | ||||||

| Paterson et al. [60] | Unsteady-state method | D = 5 L = 12 | methane–water | ng | ng | ng | ng | ng |

| Cheng [58] | Unsteady-state method | — | helium–water | ng | ng | ng | ng | ng |

| Ham [41] | Unsteady-state method | D = 7.62 L = 7.62 | helium–brine methane–brine carbon dioxide–brine | 0.0772/ 0.0784 | 5.52 | 1.38 | 0.69 | 22 |

| 2.76 | 2.07 | |||||||

| 3.45 | 2.76 | |||||||

| Shen, Qin, Wang, Fu, Wei and Lei [23] | Unsteady-state method | D = 5 L = 10 | methane–water | 0.03–5.71 | 2.5* | ng | ng | ng |

| Zhang [40] | Unsteady-state method | D = 7.69 L = 21 | methane–distilled water nitrogen–distilled water Carbon dioxide–distilled water | 375.2 | ng | ng | ng | ng |

| Durucan, Ahsan, Shi, Syed and Korre [29] | Unsteady-state method | D = 5 L = 6–10 | helium–water | 0.52–9.51 | 6.9/4.1 | 1.92 | 1.38 | ng |

| Alexis, Karpyn, Ertekin and Crandall [30] | Steady-state method | D = 5.08 | helium–brine carbon dioxide–brine | >1 | 2.1/2.25/ 3.8/4 | ng | ng | 20 ± 2 |

| Zhang, Wu and Liu [31] | Unsteady-state method | D = 4.85 L = 10.03 | helium–water | 0.022–0.031 | 2/4/6 | A + 1 | A | ng |

| Sun, Yao, Ripepi and Liu [32] | Unsteady-state method | D = 2.5 L = 6 | helium–brine | 0.015/ 0.128 | 4.3/8.3 | ng | ng | ng |

| Zhang, Qin, Zhuang, Li and Wang [49] | Unsteady-state method | D = 2.5 L = 5 | methane–brine | 0.052–0.95 | 2.5 * | ng | ng | 25 |

| Shaw, Mostaghimi and Armstrong [34] | Unsteady-state method | D = 6.10 L = 7.9 | helium–brine | ng | 5.52 | 4.41 | 4.34 | ng |

| 5.52 | 2.17 | 2.09 | ||||||

| 5.52 | 0.57 | 0.45 | ||||||

| Shen, Qin, Li and Wang [33] | Unsteady-state method | D = 2.50 | methane–water | 7.5 | 4.9 | 0.1 | 22 ± 1 | |

| ng | 8.5 | 4.9 | 0.1 | |||||

| 9.5 | 4.9 | 0.1 | ||||||

| 10.5 | 4.9 | 0.1 | ||||||

| 9 | 4.9 | 0.1 | ||||||

| 9.5 | 5.9 | 0.1 | ||||||

| 10 | 6.9 | 0.1 | ||||||

| 10.5 | 7.9 | 0.1 | ||||||

| Wang, Zhao and Mao [35] | Unsteady-state method | D = 5 L = 10–11 | nitrogen–water | ng | 4 | 3 | ng | 30/60/90/ 120/150/180 |

| 5 | 3 | ng | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, S.; Fang, Z.; Li, X. Laboratory Measurements of the Relative Permeability of Coal: A Review. Energies 2020, 13, 5568. https://doi.org/10.3390/en13215568

Shen S, Fang Z, Li X. Laboratory Measurements of the Relative Permeability of Coal: A Review. Energies. 2020; 13(21):5568. https://doi.org/10.3390/en13215568

Chicago/Turabian StyleShen, Shaicheng, Zhiming Fang, and Xiaochun Li. 2020. "Laboratory Measurements of the Relative Permeability of Coal: A Review" Energies 13, no. 21: 5568. https://doi.org/10.3390/en13215568

APA StyleShen, S., Fang, Z., & Li, X. (2020). Laboratory Measurements of the Relative Permeability of Coal: A Review. Energies, 13(21), 5568. https://doi.org/10.3390/en13215568