Laser Scanner-Based 3D Digitization for the Reflective Shape Measurement of a Parabolic Trough Collector

Abstract

:1. Introduction

2. Methodology

2.2. Data Acquisition and Comparison Strategy

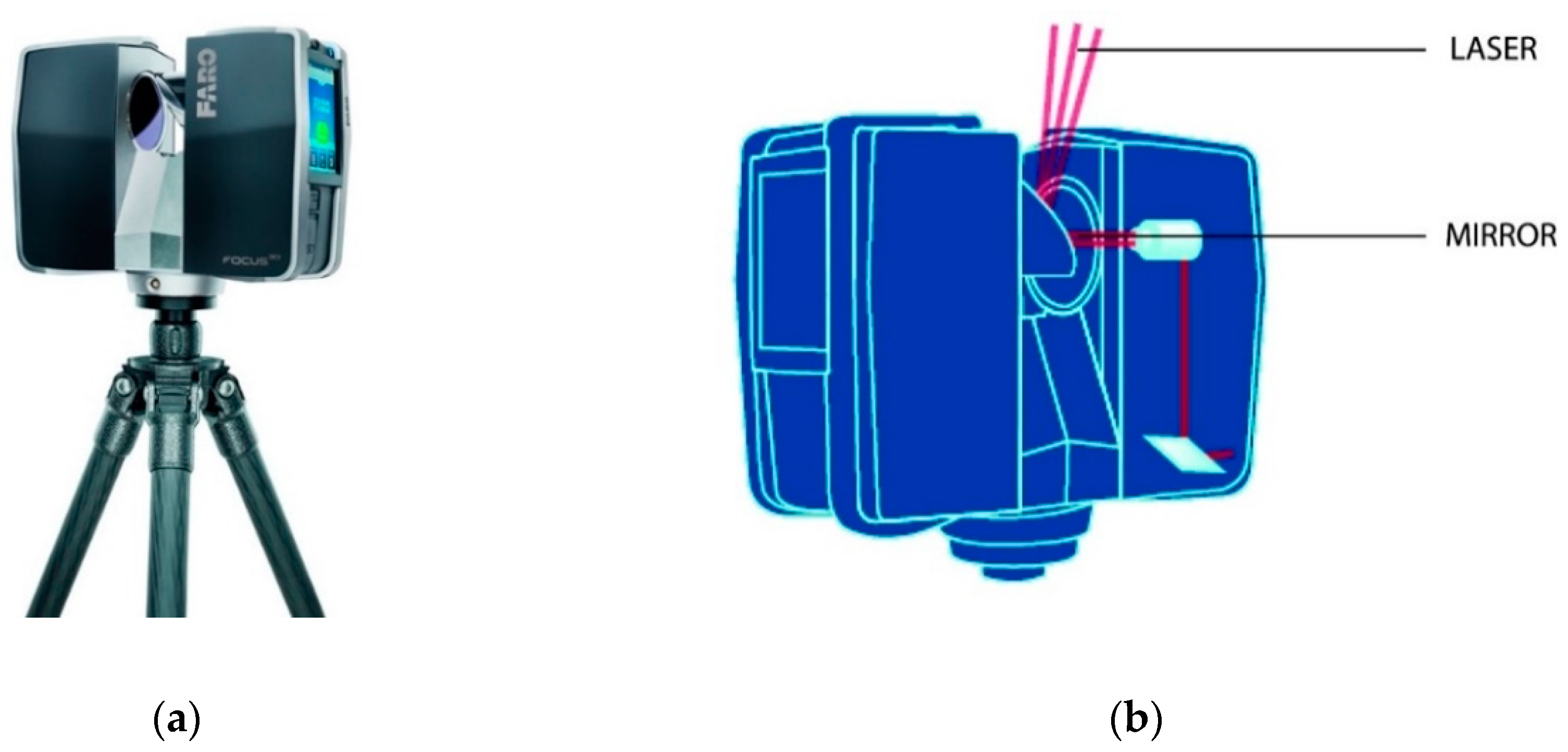

2.3. Features of the 3D Device Used

3. Test Procedure

3.1. 3D Scanner Measurements

3.1.1. Instrument Placement

3.1.2. Instrument Settings

3.2. Post-Processing Analyses

3.2.1. 3D Data Alignment

3.2.2. Finite Element Analyses

4. Results

4.1. Gravity Load Only

4.1.1. Data Comparison

- considering points in a range of ±20 cm around the reference object;

- without subsampling of the available cloud of 3D data (1/1);

- without fixing any limit in the number of iterations.

4.1.2. Parabola Focus Displacement Due to Deformation

4.2. Gravity and Torsional Loads

5. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fend, T.; Qoaider, L. Chapter 1: Introduction. In enerMENA CSP Teaching Materials; German Aerospace Center (DLR): Cologne, Germany, 2011; pp. 1–6. [Google Scholar]

- Dinter, F.; Gonzalez, D.M. Operability, Reliability and Economic Benefits of CSP with Thermal Energy Storage: First Year of Operation of ANDASOL 3. Energy Procedia 2014, 49, 2472–2481. [Google Scholar] [CrossRef] [Green Version]

- Shortis, M.R.; Johnston, G.H.G. Photogrammetry: An Available Surface Characterization Tool for Solar Concentrators, Part I: Measurements of Surfaces. J. Sol. Energy Eng. 1996, 118, 146–150. [Google Scholar] [CrossRef]

- Shortis, M.; Johnston, G. Photogrammetry: An Available Surface Characterization Tool for Solar Concentrators, Part II: Assessment of Surfaces. J. Sol. Energy Eng. 1997, 119, 286–291. [Google Scholar] [CrossRef]

- Pottler, K.; Lüpfert, E.; Johnston, G.H.G.; Shortis, M.R. Photogrammetry: A Powerful Tool for Geometric Analysis of Solar Concentrators and Their Components. J. Sol. Energy Eng. 2005, 127, 94. [Google Scholar] [CrossRef]

- Jones, S.A.; Neal, D.R.; Gruetzner, J.K.; Houser, R.M.; Edgar, R.M.; Wendelin, T.J. VSHOT: A tool for characterizing large, imprecise reflectors. In Proceedings of the SPIE Annual International Symposium on Optical Science, Engineering, and Instrumentation, Denver, CO, USA, 4–9 August 1996; SPIE: Denver, CO, USA, 1996; pp. 1–11. [Google Scholar]

- Knauer, M.C.; Kaminski, J.; Hausler, G. Phase measuring deflectometry: A new approach to measure specular free-form surfaces. In Proceedings of the Optical Metrology in Production Engineering, Strasbourg, France, 27–30 April 2004; Osten, W., Takeda, M., Eds.; SPIE: Strasbourg, France, 2004; Volume 5457, pp. 366–376. [Google Scholar]

- Jones, S.A.; Gruetzner, J.K.; Houser, R.M.; Edgar, R.M.; Wendelin, T.J. VSHOT measurement uncertainty and experimental sensitivity study. In Proceedings of the IECEC-97 Thirty-Second Intersociety Energy Conversion Engineering Conference (Cat. No.97CH6203), Honolulu, HI, USA, 27 July–1 August 1997; IEEE: Honolulu, HI, USA, 1997; Volume 3, pp. 1877–1882. [Google Scholar]

- Moreno-Oliva, V.I.; Campos-García, M.; Román-Hernández, E.; Santiago-Alvarado, A. Design of a single flat null-screen for testing a parabolic trough solar collector. Opt. Eng. 2014, 53, 114108. [Google Scholar] [CrossRef]

- Xiao, J.; Wei, X.; Lu, Z.; Yu, W.; Wu, H. A review of available methods for surface shape measurement of solar concentrator in solar thermal power applications. Renew. Sustain. Energy Rev. 2012, 16, 2539–2544. [Google Scholar] [CrossRef]

- García-Cortés, S.; Bello-García, A.; Ordóñez, C. Estimating intercept factor of a parabolic solar trough collector with new supporting structure using off-the-shelf photogrammetric equipment. Appl. Energy 2012, 92, 815–821. [Google Scholar] [CrossRef]

- Röger, M.; Prahl, C.; Ulmer, S. Fast Determination of Heliostat Shape and Orientation by Edge Detection and Photogrammetry. In Proceedings of the 14th CSP SolarPACES Symposium, Las Vegas, NV, USA, 4–7 March 2008. [Google Scholar]

- De Asís López, F.; García-Cortés, S.; Roca-Pardiñas, J.; Ordóñez, C. Geometric optimization of trough collectors using terrestrial laser scanning: Feasibility analysis using a new statistical assessment method. Measurement 2014, 47, 92–99. [Google Scholar] [CrossRef]

- Lee, M.; Lee, S.; Kwon, S.; Chin, S. A study on scan data matching for reverse engineering of pipes in plant construction. KSCE J. Civ. Eng. 2017, 21, 2027–2036. [Google Scholar] [CrossRef]

- Yang, Y.; Fang, H.; Fang, Y.; Shi, S. Three-dimensional point cloud data subtle feature extraction algorithm for laser scanning measurement of large-scale irregular surface in reverse engineering. Measurement 2020, 151, 107220. [Google Scholar] [CrossRef]

- Elizondo, A.; Reinert, F. Limits and hurdles of Reverse Engineering for the replication of parts by Additive Manufacturing (Selective Laser Melting). Procedia Manuf. 2019, 41, 1009–1016. [Google Scholar] [CrossRef]

- Hawryluk, M.; Ziemba, J. Application of the 3D reverse scanning method in the analysis of tool wear and forging defects. Measurement 2018, 128, 204–213. [Google Scholar] [CrossRef]

- Popov, I.; Onuh, S.; Dotchev, K. Dimensional error analysis in point cloud-based inspection using a non-contact method for data acquisition. Meas. Sci. Technol. 2010, 21, 075303. [Google Scholar] [CrossRef]

- Brajlih, T.; Tasic, T.; Drstvensek, I.; Valentan, B.; Hadzistevic, M.; Pogacar, V.; Balic, J.; Acko, B. Possibilities of Using Three-Dimensional Optical Scanning in Complex Geometrical Inspection. Stroj. Vestn. J. Mech. Eng. 2011, 57, 826–833. [Google Scholar] [CrossRef] [Green Version]

- Kuş, A. Implementation of 3D Optical Scanning Technology for Automotive Applications. Sensors 2009, 9, 1967–1979. [Google Scholar] [CrossRef] [PubMed]

- Zaba, K.; Nowosielski, M.; Kita, P.; Nowak, S.; Kwiatkowski, M.; Sioma, A. Application of Non-Destructive Methods to Quality Assessment of Pattern Assembly and Ceramic Mould in the Investment Casting Elements of Aircraft Engines/Zastosowanie Nieniszczących Metod Do Oceny Jakości Woskowych Zestawów Modelowych Oraz Ceramicznych Form W Procesie Odlewania Precyzyjnego Elementów Silników Lotniczych. Arch. Metall. Mater. 2014. [Google Scholar] [CrossRef] [Green Version]

- Yao, A.W.L. Applications of 3D scanning and reverse engineering techniques for quality control of quick response products. Int. J. Adv. Manuf. Technol. 2005, 26, 1284–1288. [Google Scholar] [CrossRef]

- Li, B.; Li, F.; Liu, H.; Cai, H.; Mao, X.; Peng, F. A measurement strategy and an error-compensation model for the on-machine laser measurement of large-scale free-form surfaces. Meas. Sci. Technol. 2013, 25, 015204. [Google Scholar] [CrossRef]

- Bradley, C.; Currie, B. Advances in the Field of Reverse Engineering. Comput.-Aided Des. Appl. 2005, 2, 697–706. [Google Scholar] [CrossRef]

- FARO Technologies Inc. Faro Laser Scanner Focus 3D Manual. Available online: https://faro.app.box.com/s/kfpwjofogeegocr7mf2s866s2qalnaqw (accessed on 10 October 2020).

- Leica Geosystems AG. Cyclone 3D Point Cloud Processing Software. Available online: https://leica-geosystems.com/products/laser-scanners/software/leica-cyclone (accessed on 7 October 2020).

- Innovmetric Software Inc. Polyworks: The Smart 3D Metrology Digital Ecosystem. Available online: https://www.innovmetric.com/products/products-overview (accessed on 9 October 2020).

- Liu, K.; Shang, Y.; Ouyang, Q.; Widanage, W.D. A Data-driven Approach with Uncertainty Quantification for Predicting Future Capacities and Remaining Useful Life of Lithium-ion Battery. IEEE Trans. Ind. Electron. 2020. [Google Scholar] [CrossRef]

- Liu, K.; Hu, X.; Wei, Z.; Li, Y.; Jiang, Y. Modified Gaussian Process Regression Models for Cyclic Capacity Prediction of Lithium-Ion Batteries. IEEE Trans. Transp. Electrif. 2019, 5, 1225–1236. [Google Scholar] [CrossRef]

| Ranging Unit |

| |||

| Ranging noise | @10 m | @10 m—noise compressed | @25 m | @25 m—noise compressed |

| @90% refl. | 0.6 mm | 0.3 mm | 0.95 mm | 0.5 mm |

| @10% refl. | 1.2 mm | 0.6 mm | 2.20 mm | 1.1 mm |

| Laser (Optical transmission) |

| |||

| Sampling Size | 1:1 | 1:2 | 1:4 | 1:5 | 1:8 |

|---|---|---|---|---|---|

| Δθ (degree) | 0.009 | 0.018 | 0.035 | 0.044 | 0.070 |

| Step @10m (mm) | 1.53 | 3.07 | 6.14 | 7.67 | 12.27 |

| Horizontal size (#3D pixels) | 40,960 | 20,480 | 10,240 | 8192 | 5120 |

| Vertical size (#3D pixels) | 17351 | 8676 | 4338 | 3470 | 2169 |

| 3D point cloud size (Mpoints) | 710.7 | 177.7 | 44.4 | 28.4 | 11.1 |

| Scan | Mean (mm) | σ (mm) |

|---|---|---|

| 1 | −0.029 | 2.98 |

| 3 | −0.034 | 2.97 |

| 4 | −0.027 | 3.02 |

| 5 | −0.015 | 3.08 |

| 6 | −0.025 | 3.17 |

| 7 | −0.037 | 3.01 |

| 8 | −0.047 | 2.90 |

| 9 | −0.025 | 3.02 |

| 10 | −0.002 | 2.95 |

| 11 | −0.099 | 3.01 |

| 12 | −0.011 | 2.95 |

| Mesh of the Model | Coarse | Refined |

|---|---|---|

| Total number of nodes | 186,945 | 4,841,985 |

| Total number of elements | 178,282 | 4,879,343 |

| Average element size [mm] | ~20 | ~100 |

| S4R quadrilateral linear elements | 152,722 | 4,058,061 |

| C3D8R hexahedral linear elements | 11,787 | 796,480 |

| S3 triangular linear elements | 9454 | 19,600 |

| B31 line linear elements | 4319 | 5202 |

| Analyzed 3D points | 8,888,962 |

| Mean deviation (mm) | 0.197 |

| σ (mm) | 4.615 |

| RMS deviation (mm) | 4.619 |

| Max Error (mm) | 20.00 |

| Min Error (mm) | −20.00 |

| Strip no. | x (mm) | y (mm) | z (m) | Metal Thickness (mm) | Film Thickness (mm) | Alignment Displacement (mm) | Focus to trough Distance (mm) | Focus Δx (mm) |

|---|---|---|---|---|---|---|---|---|

| Strip1 | 1720.35 | −0.24 | 5.8 | 1.5 | 0.1 | 0.197 | 1718.56 | 8.56 |

| Strip2 | 1718.28 | −0.20 | 5.0 | 1.5 | 0.1 | 0.197 | 1716.49 | 6.49 |

| Strip3 | 1719.39 | −0.09 | 3.0 | 1.5 | 0.1 | 0.197 | 1717.59 | 7.59 |

| Strip4 | 1720.60 | −0.11 | 1.0 | 1.5 | 0.1 | 0.197 | 1718.81 | 8.81 |

| Strip5 | 1720.55 | −0.17 | −1.0 | 1.5 | 0.1 | 0.197 | 1718.76 | 8.76 |

| Strip6 | 1716.96 | −0.22 | −3.0 | 1.5 | 0.1 | 0.197 | 1715.16 | 5.16 |

| Strip7 | 1714.27 | −0.34 | −5.0 | 1.5 | 0.1 | 0.197 | 1712.48 | 2.48 |

| Strip8 | 1724.28 | −0.38 | −5.8 | 1.5 | 0.1 | 0.197 | 1722.49 | 12.49 |

| Analyzed 3D points | 4,225,561 |

| Mean deviation (mm) | 0.413 |

| σ (mm) | 4.203 |

| RMS deviation (mm) | 4.225 |

| Max Error (mm) | 20.00 |

| Min Error (mm) | −20.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guidi, G.; Malik, U.S.; Manes, A.; Cardamone, S.; Fossati, M.; Lazzari, C.; Volpato, C.; Giglio, M. Laser Scanner-Based 3D Digitization for the Reflective Shape Measurement of a Parabolic Trough Collector. Energies 2020, 13, 5607. https://doi.org/10.3390/en13215607

Guidi G, Malik US, Manes A, Cardamone S, Fossati M, Lazzari C, Volpato C, Giglio M. Laser Scanner-Based 3D Digitization for the Reflective Shape Measurement of a Parabolic Trough Collector. Energies. 2020; 13(21):5607. https://doi.org/10.3390/en13215607

Chicago/Turabian StyleGuidi, Gabriele, Umair Shafqat Malik, Andrea Manes, Stefano Cardamone, Massimo Fossati, Carla Lazzari, Claudio Volpato, and Marco Giglio. 2020. "Laser Scanner-Based 3D Digitization for the Reflective Shape Measurement of a Parabolic Trough Collector" Energies 13, no. 21: 5607. https://doi.org/10.3390/en13215607