Experimental Research on a Heat Pump Applying a Ball-Circulating Type Automatic Fouling Cleaning System for Fish Farms

Abstract

:1. Introduction

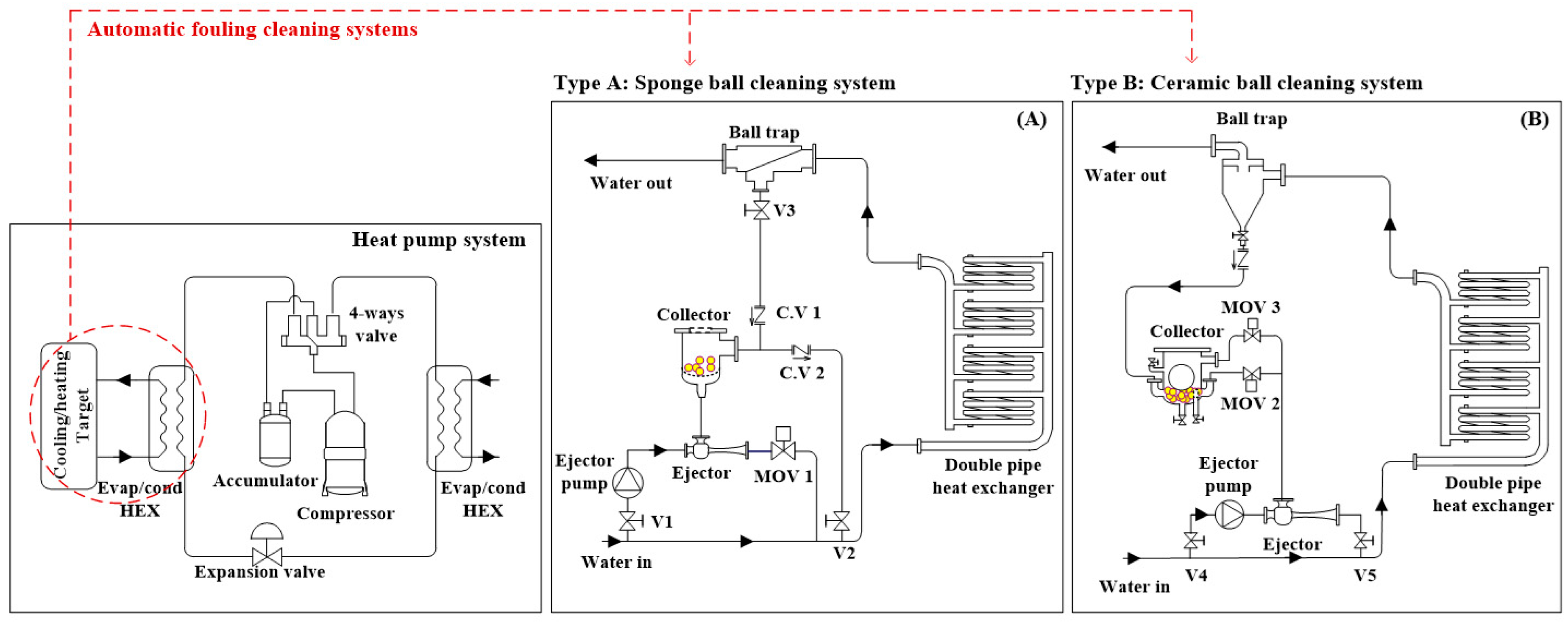

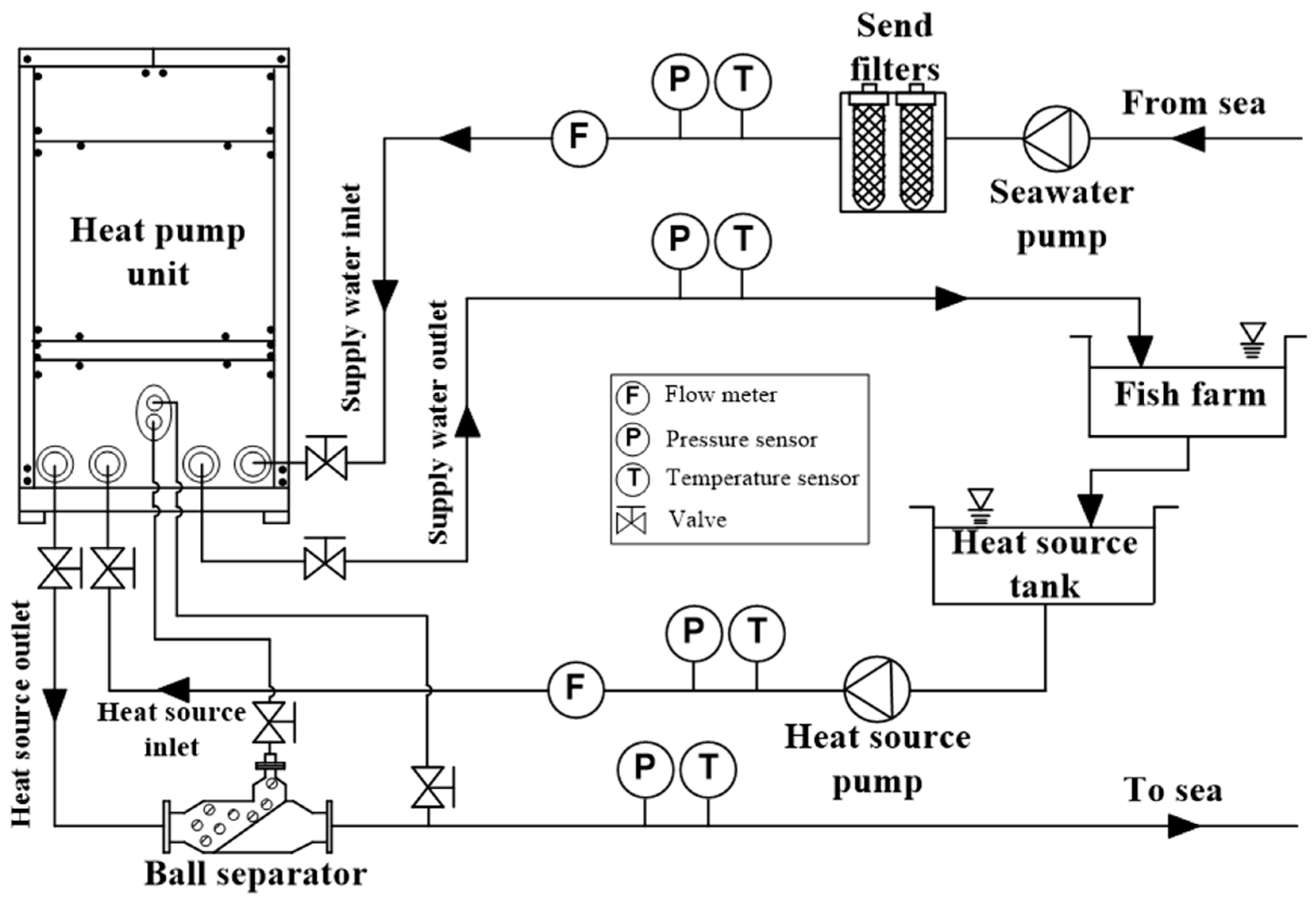

2. Heat Pump Applying Automatic Cleaning System

2.1. System Description

2.2. Working Principle of Automatic Fouling Cleaning Sstem

3. Comparison of Finned/Twisted Tubes

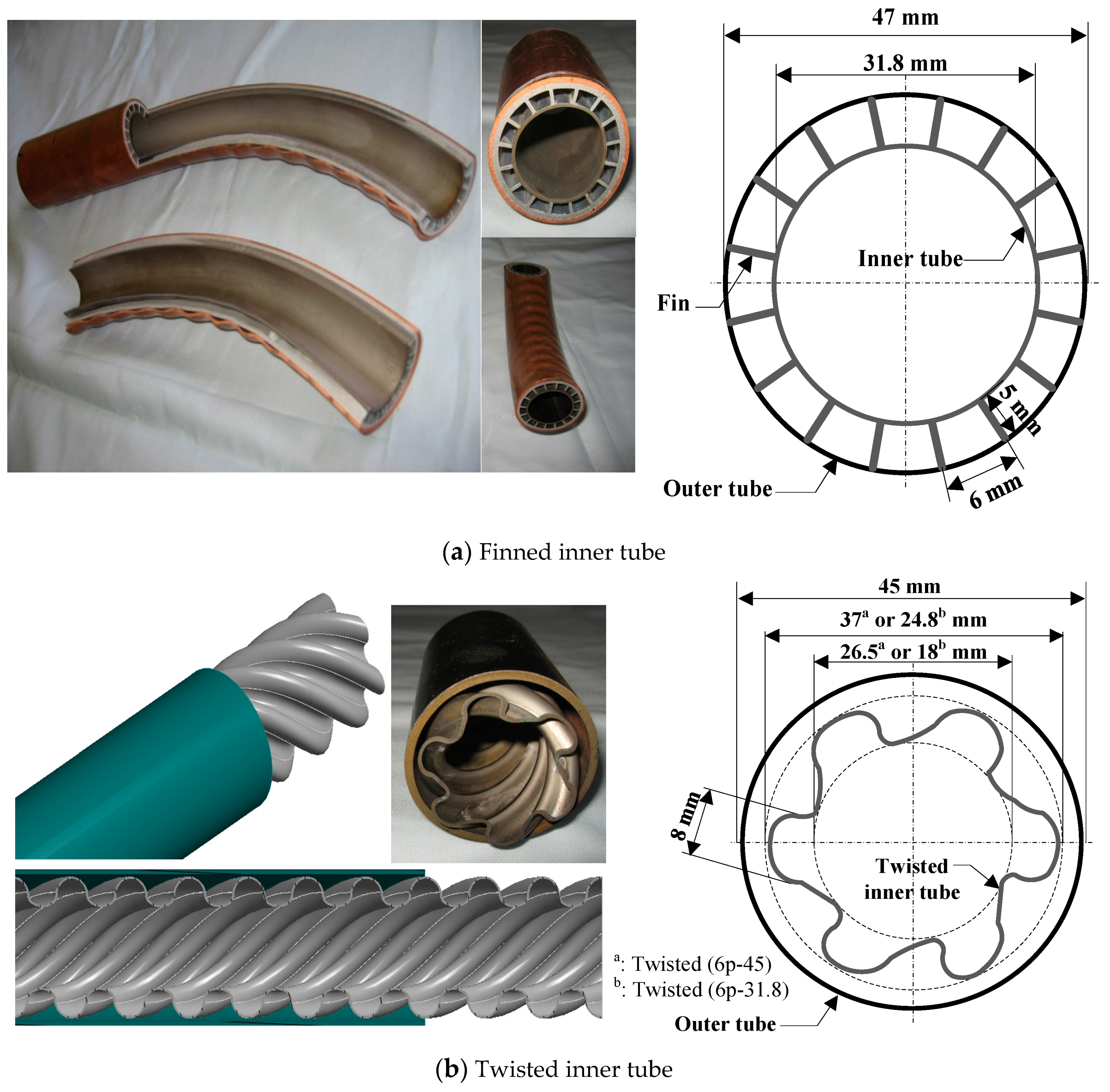

3.1. Geometric Shape of Finned/Twisted Tubes

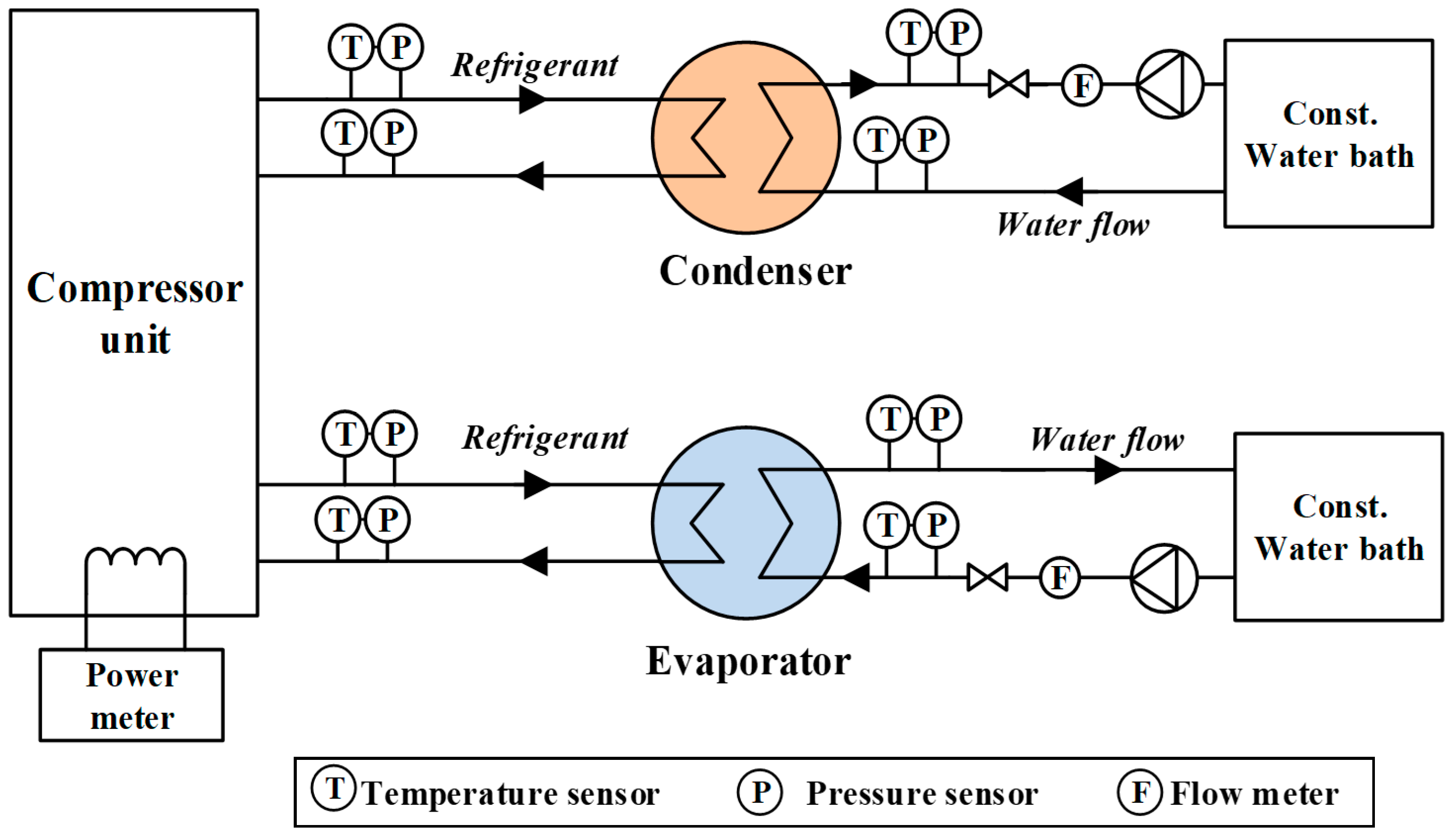

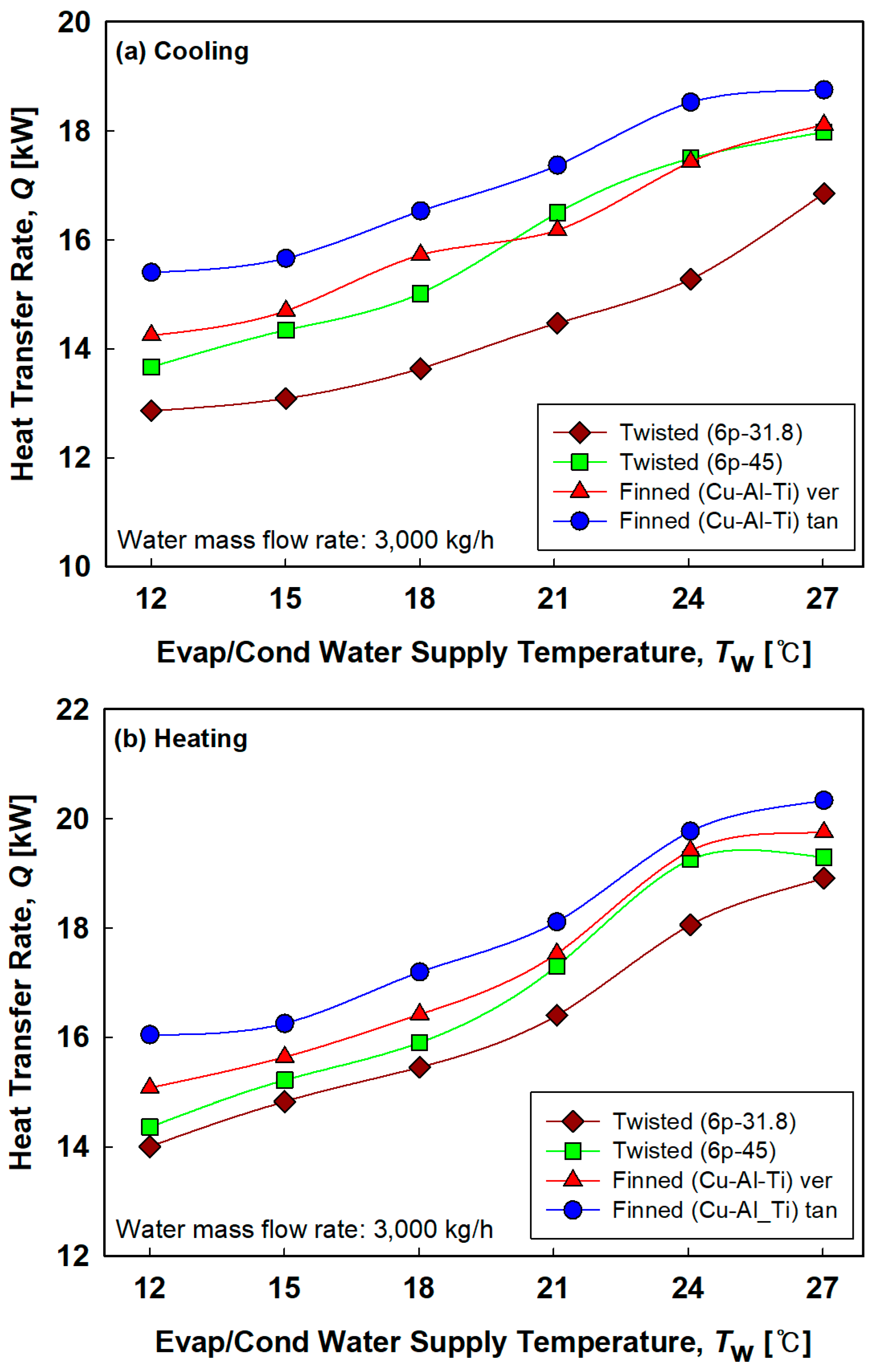

3.2. Performance Comparison of HEX (Heat Exchanger) Using Finned/Twisted Tubes

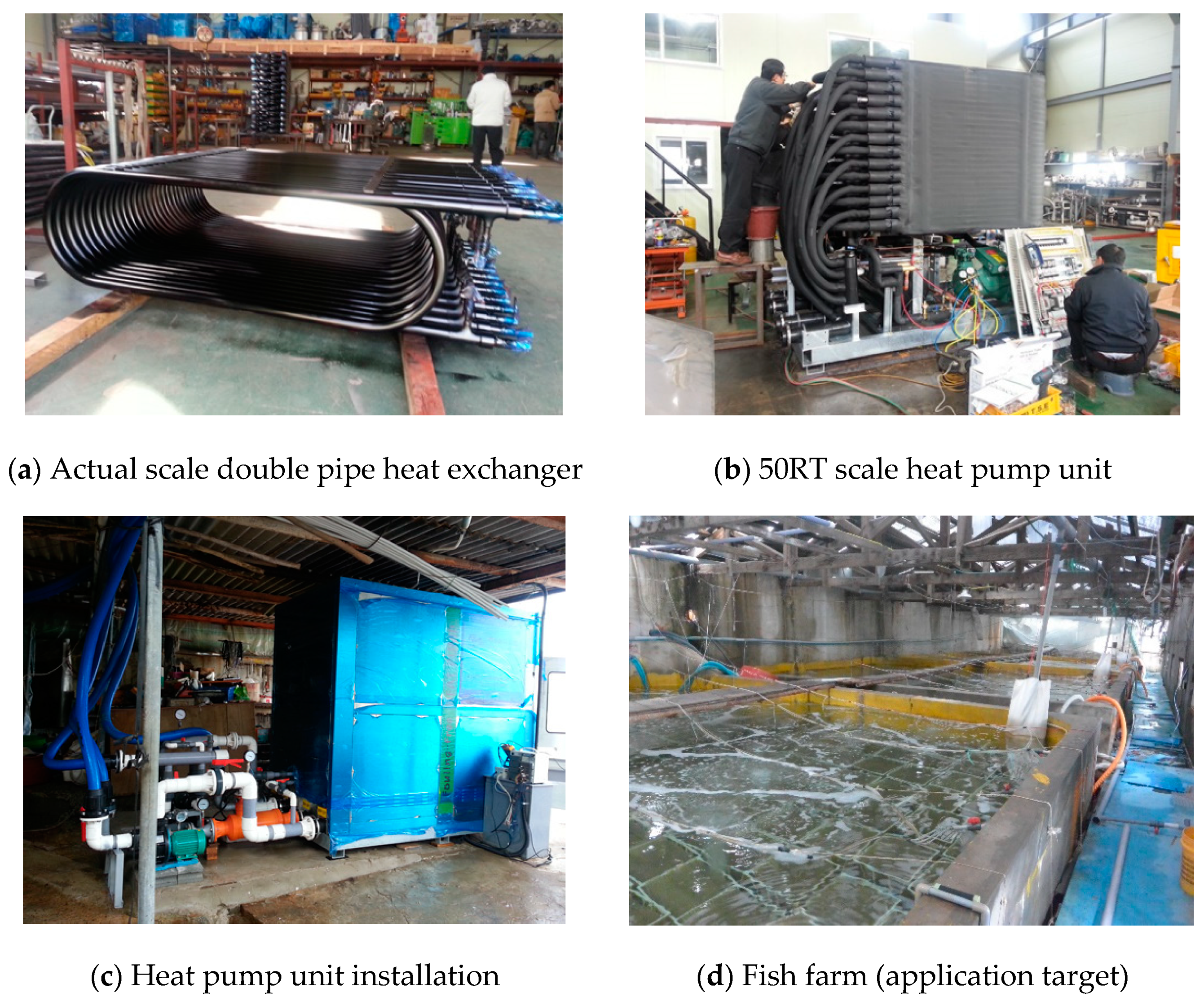

4. 50 RT-Scale Field Test Targeting Fish Farms

4.1. General Description of Field Test

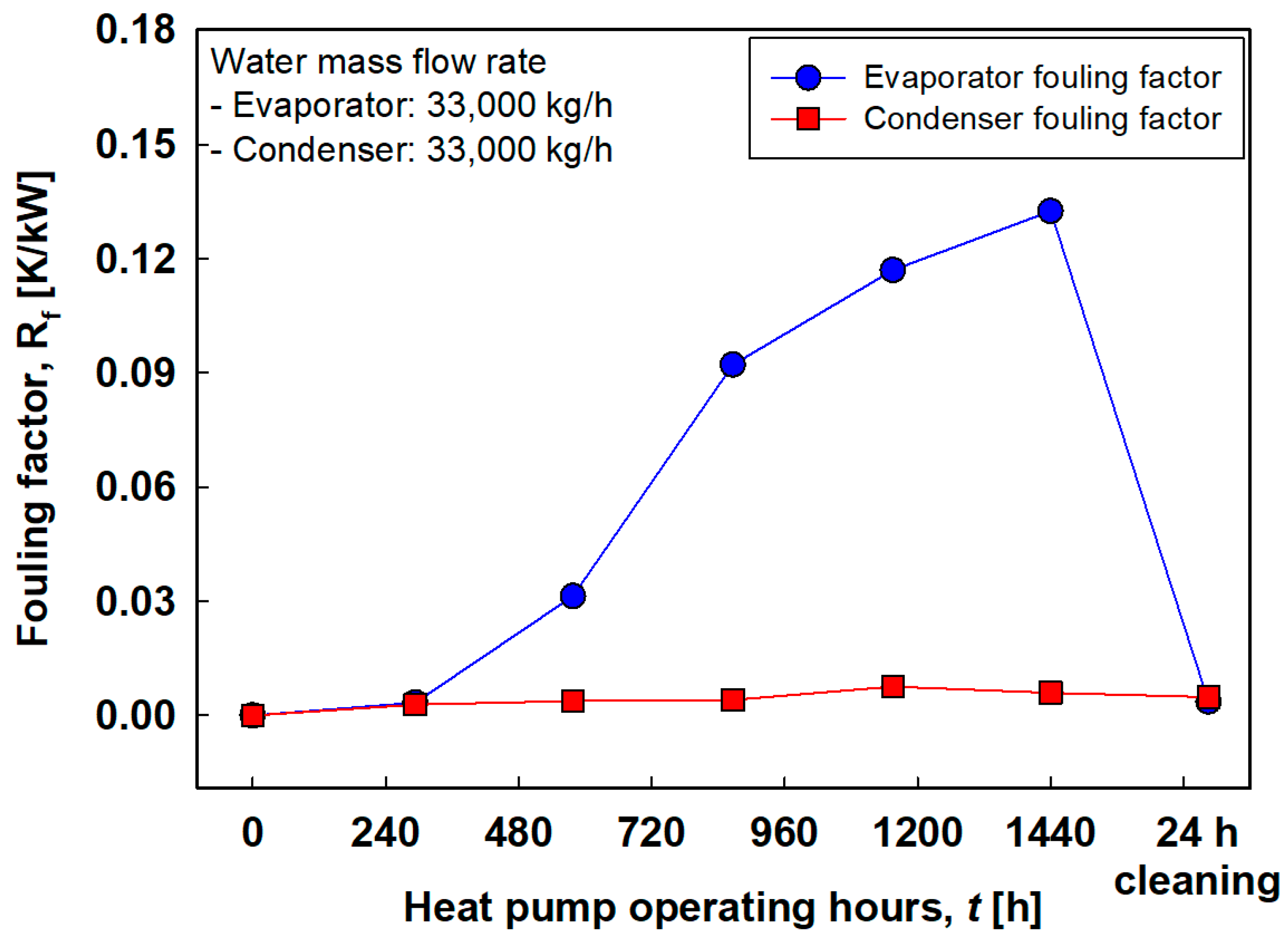

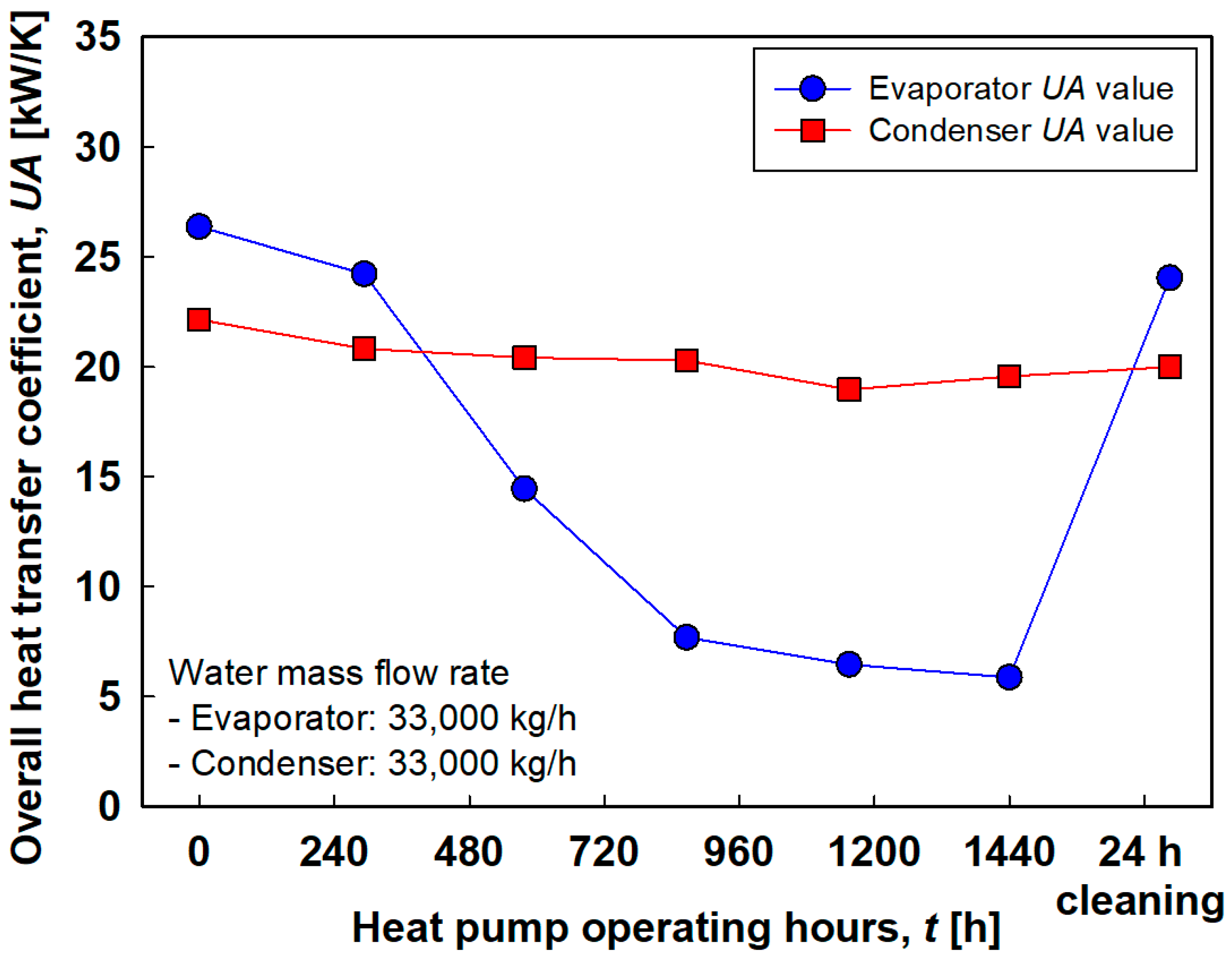

4.2. Results of Filed Test at Fouling Condition

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rakib, M.I.; Saidur, R.; Mohamad, E.N.; Afifi, A.M. Waste-heat utilization—The sustainable technologies to minimize energy consumption in Bangladesh textile sector. J. Clean. Prod. 2017, 142, 1867–1876. [Google Scholar] [CrossRef]

- Baek, N.C.; Shin, U.C.; Yoon, J.H. A study on the design and analysis of a heat pump heating system using wastewater as a heat source. Sol. Energy 2005, 78, 427–440. [Google Scholar] [CrossRef]

- Oon, C.S.; Kazi, S.N.; Hakimin, M.A.; Abdelrazek, A.H.; Mallah, A.R.; Low, F.W.; Tiong, S.K.; Badruddin, I.A.; Kamanger, S. Heat transfer and fouling deposition investigation on the titanium coated heat exchanger surface. Powder Technol. 2020, 373, 671–680. [Google Scholar] [CrossRef]

- Ogbonnaya, S.K.; Ajayi, O.O. Fouling phenomenon and its effect on heat exchanger: A review. Front. Heat Mass Transf. 2017, 9, 2007–2018. [Google Scholar] [CrossRef]

- Andritsos, N.; Karabelas, A.J. Calcium carbonate scaling in a plate heat exchanger in the presence of particles. Int. J. Heat Mass Transf. 2003, 46, 4613–4627. [Google Scholar] [CrossRef]

- Awad, M. Fouling of Heat Transfer Surfaces; InTech Open Access Publisher: Rijeka, Croatia, 2011; ISBN 978-953-307-226-5. [Google Scholar]

- Jamialahmadi, M.; Müller-Steinhagen, H. A new model for the effect of calcium sulfate scale formation on pool boiling heat transfer. J. Heat Transf. 2004, 126, 507–517. [Google Scholar] [CrossRef]

- Qureshi, B.A.; Zubair, S.M. Performance degradation of a vapor compression refrigeration system under fouled conditions. Int. J. Refrig. 2011, 34, 1016–1027. [Google Scholar] [CrossRef]

- Qureshi, B.A.; Zubair, S.M. The impact of fouling on performance of a vapor compression refrigeration system with integrated mechanical sub-cooling system. Appl. Energy 2012, 92, 750–762. [Google Scholar] [CrossRef]

- Hasan, B.O.; Jwair, E.A.; Craig, R.A. The effect of heat transfer enhancement on the crystallization fouling in a double pipe heat exchanger. Exp. Therm. Fluid Sci. 2017, 86, 272–280. [Google Scholar] [CrossRef]

- Esawy, M.; Malayeri, M.R.; Müller-Steinhagen, H. Crystallization fouling of finned tubes during pool boiling: Effect of fin density. Heat Mass Transf. Stoffuebertragung 2010, 46, 1167–1176. [Google Scholar] [CrossRef]

- Bai, X.; Luo, T.; Cheng, K.; Chai, F. Experimental study on fouling in the heat exchangers of surface water heat pumps. Appl. Therm. Eng. 2014, 70, 892–895. [Google Scholar] [CrossRef]

- Lestina, T. Heat Exchangers Fouling, Cleaning and Maintenance BT—Handbook of Thermal Science and Engineering; Kulacki, F.A., Ed.; Springer International Publishing: Cham, The Netherland, 2017; pp. 1–33. ISBN 978-3-319-32003-8. [Google Scholar]

- Jamialahmadi, M.; Müller-Steinhagen, H. Heat exchanger fouling and cleaning in the dihydrate process for the production of phosphoric acid. Chem. Eng. Res. Des. 2007, 85, 245–255. [Google Scholar] [CrossRef]

- Müller-Steinhagen, H.; Malayeri, M.R.; Watkinson, A.P. Heat exchanger fouling: Mitigation and cleaning strategies. Heat Transf. Eng. 2011, 32, 189–196. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, S.; Lai, Y.; Ma, C. Influence of ultrasound to convectional heat transfer with fouling of cooling water. Appl. Therm. Eng. 2016, 100, 340–347. [Google Scholar] [CrossRef]

- Fontdevila, A.L. Fouling of a Double Pipe Heat Exchanger. Ph.D. Thesis, Dublin City University, Dublin, Ireland, 2004. [Google Scholar]

- Awais, M.; Bhuiyan, A.A. Recent advancements in impedance of fouling resistance and particulate depositions in heat exchangers. Int. J. Heat Mass Transf. 2019, 141, 580–603. [Google Scholar] [CrossRef]

- Jalalirad, M.R.; Abd-Elhady, M.S.; Malayeri, M.R. Cleaning action of spherical projectiles in tubular heat exchangers. Int. J. Heat Mass Transf. 2013, 57, 491–499. [Google Scholar] [CrossRef]

- Abd-Elhady, M.S.; Malayeri, M.R.; Jalalirad, M.R. Intensification of the cleaning action of structurally different projectiles by multiple injections and changing injection rate. Desalination 2014, 337, 52–59. [Google Scholar] [CrossRef]

- Jalalirad, M.R.; Malayeri, M.R. A Criterion for the Selection of Projectiles for Cleaning Tubular Heat Exchangers. In Proceedings of the International Conference on Heat Exchanger Fouling and Cleaning, Budapest, Hungary, 9–14 June 2013; Volume 2013, pp. 332–338. [Google Scholar]

- Abd-Elhady, M.S.; Malayeri, M.R. Impact of hardness and surface texture on cleaning action of various projectiles. Chem. Eng. Res. Des. 2015, 94, 153–163. [Google Scholar] [CrossRef]

- Seol, S.H.; Nagano, K.; Togawa, J. Modeling of adsorption heat pump system based on experimental estimation of heat and mass transfer coefficients. Appl. Therm. Eng. 2020, 171, 115089. [Google Scholar] [CrossRef]

- Lee, S.-H.; Cha, D.-A.; Kwon, O.-K. Flow Characteristic with Distance of Inlet Port and Rotating Length of Fluid in the Double Heat Exchanger. J. Korea Soc. Power Syst. Eng. 2013, 17, 51–57. [Google Scholar] [CrossRef] [Green Version]

- Chae, H.-M.; Kwon, J.-T.; Cha, D.-A.; Kwon, O.-K. The Measurements of Ball Recovery Rate for the Cleaning Apparatus in Plate Heat Exchanger Using Ceramic Ball. J. Korea Soc. Power Syst. Eng. 2014, 18, 38–44. [Google Scholar] [CrossRef]

- Kwon, O.-K.; Seol, W.-S. Research and Development of Sea Water Heat Pump. J. Korea Soc. Power Syst. Eng. 2013, 17, 7–13. [Google Scholar] [CrossRef]

- Aquaculture Engineering; Lekang, O.-I. (Ed.) John Wiley & Sons: Hoboken, NJ, USA, 2013; ISBN 9781118496077. [Google Scholar]

- Bergamini, R.; Jensen, J.K.; Elmegaard, B. Thermodynamic competitiveness of high temperature vapor compression heat pumps for boiler substitution. Energy 2019, 182, 110–121. [Google Scholar] [CrossRef]

- Kozarcanin, S.; Hanna, R.; Staffell, I.; Gross, R.; Andresen, G.B. Impact of climate change on the cost-optimal mix of decentralised heat pump and gas boiler technologies in Europe. Energy Policy 2020, 140, 111386. [Google Scholar] [CrossRef] [Green Version]

- Ala, G.; Orioli, A.; Di Gangi, A. Energy and economic analysis of air-to-air heat pumps as an alternative to domestic gas boiler heating systems in the South of Italy. Energy 2019, 173, 59–74. [Google Scholar] [CrossRef]

- Luo, J.; Xue, W.; Shao, H. Thermo-economic comparison of coal-fired boiler-based and groundwater-heat-pump based heating and cooling solution—A case study on a greenhouse in Hubei, China. Energy Build. 2020, 223, 110214. [Google Scholar] [CrossRef]

- Chou, H.M.; Wong, K.L. Heat transfer characteristics of an insulated regular cubic box by using a solid wedge thermal resistance model. Energy Convers. Manag. 2003, 44, 1983–1997. [Google Scholar] [CrossRef]

- Qin, X.; Zhang, D.; Zhang, F.; Gao, Z.; Wei, X. Experimental and numerical study on heat transfer of gas cooler under the optimal discharge pressure. Int. J. Refrig. 2020, 112, 229–239. [Google Scholar] [CrossRef]

| Tube | Diameter (mm) | Thickness (mm) | Length (mm) | |

|---|---|---|---|---|

| Finned type | Copper tube | 47 | 1.5 | 7600 |

| Aluminum fin | 45.5 | 1.2 | 7500 | |

| Titanium tube | 31.8 | 1.0 | 8000 | |

| Twisted type | Steel pipe | 45 | 2 | 6000 |

| Titanium tube | 37 a/24.8 b | 0.8 | 8000 | |

| Device/Parameter | Range | Uncertainty |

|---|---|---|

| Pt-100 sensor | −200~850 °C | ±0.25 °C |

| Pressure transmitter | 0~16 bar | ±0.5% F.S |

| Water flow meter | 0.6~6 m3/h (Lab-scale) 4~40 m3/h (Filed test) | ±0.5% F.S |

| Heat transfer rate | - | <2.77% |

| Component | Parameters | Information | |

|---|---|---|---|

| Compressor | Type | Bitzer Screw CHS6553-50 | |

| Displacement | 165 m3/h | ||

| Max. power input | 62.8 kW | ||

| Refrigerant | R-22 | ||

| Condenser/evaporator | Type | Double pipe heat exchanger | |

| Inner tube | Titanium 31.8 a 1.0T b | ||

| Outer tube | Copper 50.8 a 1.5T b | ||

| Fin | Aluminum 45.5 a 1.2T b | ||

| Piping system | Refrigerant | Liquid | 1 1/8” copper |

| Vapor (high and low pressure) | 1 5/8” and 2 1/8” copper | ||

| Water | 100A PVC | ||

| Automatic fouling cleaning system | Number of heat exchangers | 14 | |

| Type | Sponge ball type | ||

| Cleaning ball diameter | 30.5 mm | ||

| Material | Natural rubber | ||

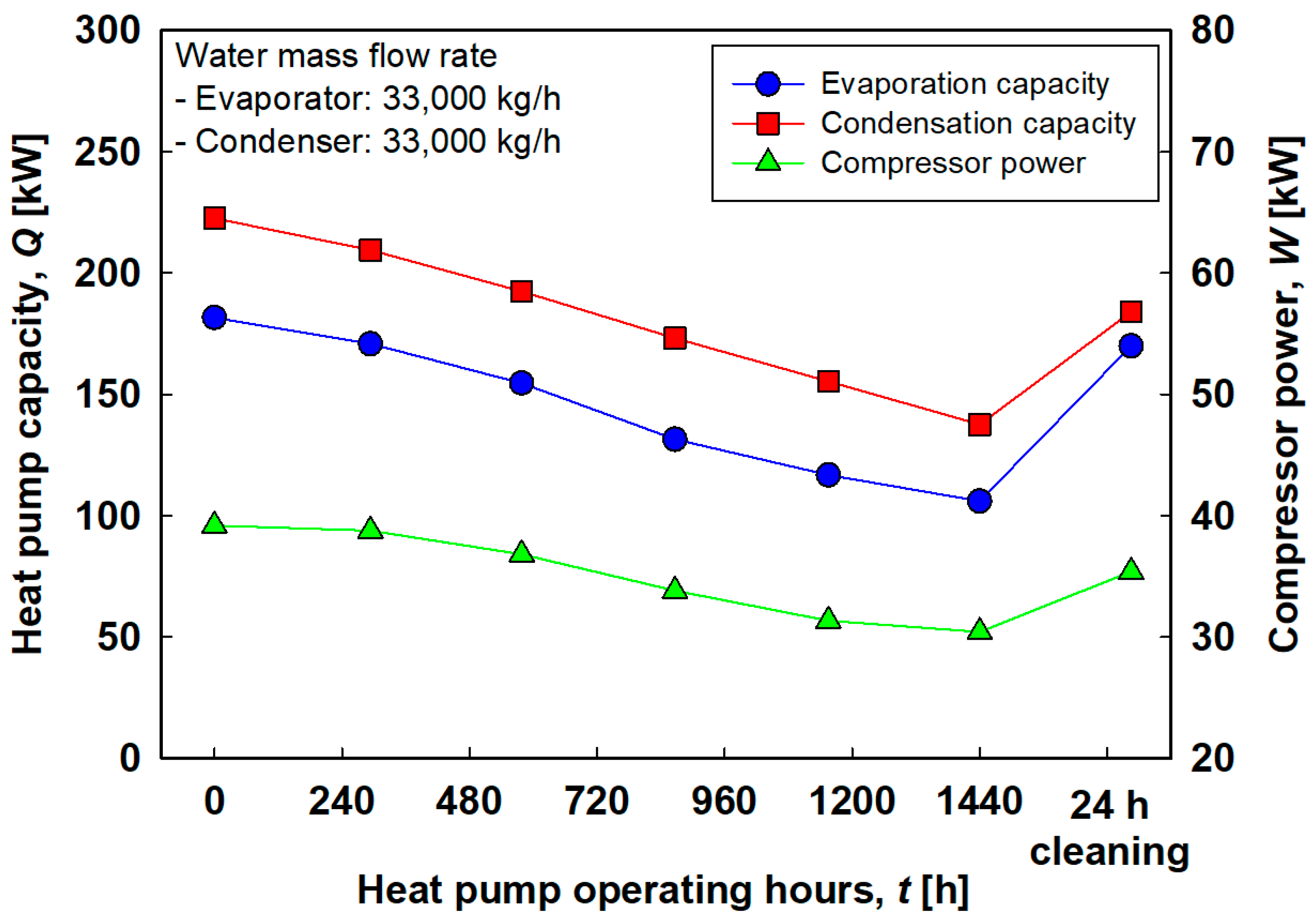

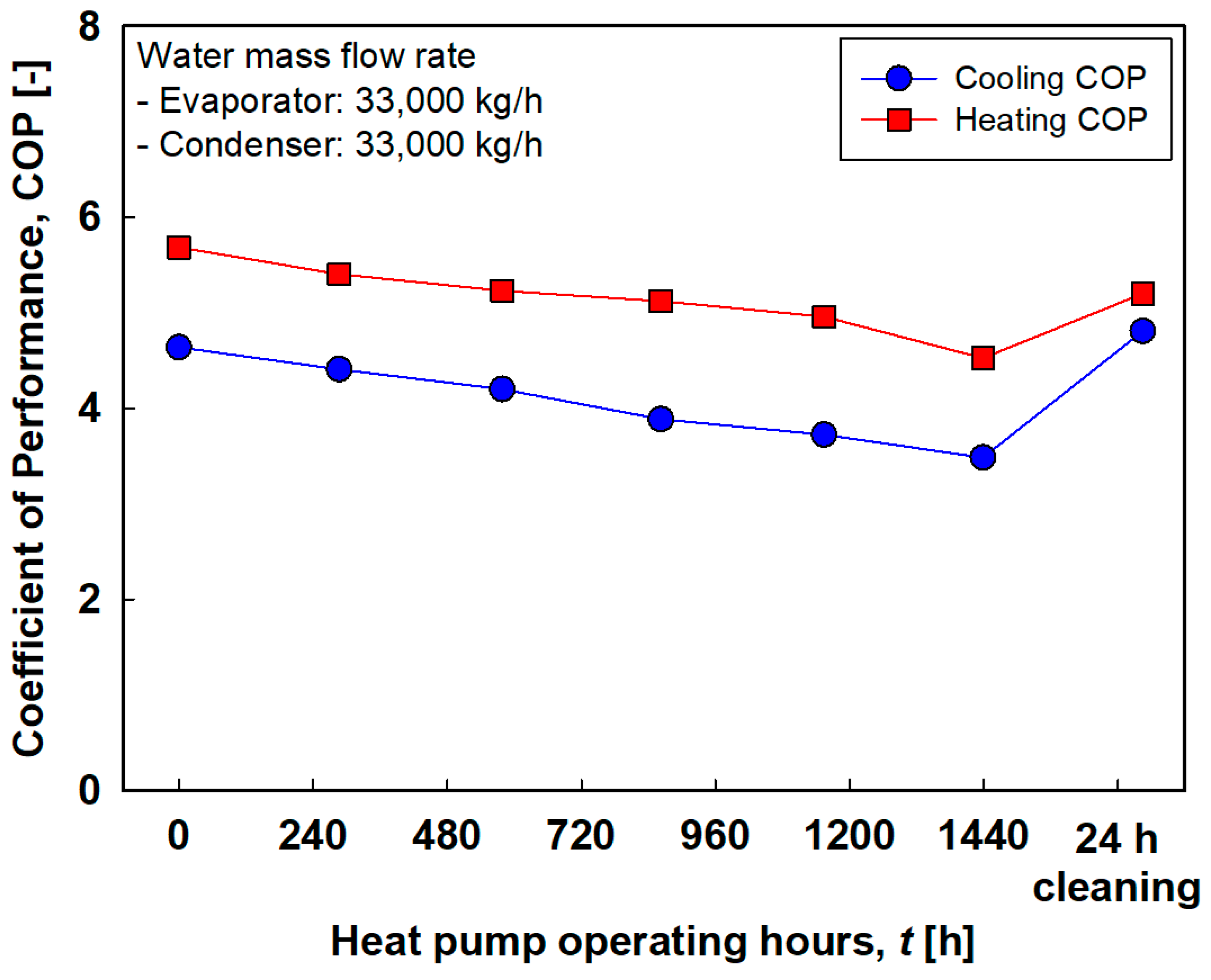

| Hours | Cooling Heat Transfer Rate [kW] | Heating Heat Transfer Rate [kW] | Compressor Power [kW] | COPc | COPh |

|---|---|---|---|---|---|

| 0 (22 August) | 181.70 | 222.68 | 39.17 | 4.64 | 5.68 |

| 240 | 170.87 | 209.53 | 38.76 | 4.41 | 5.41 |

| 576 | 154.63 | 192.52 | 36.80 | 4.20 | 5.23 |

| 864 | 131.44 | 173.19 | 33.81 | 3.89 | 5.12 |

| 1152 | 116.75 | 155.41 | 31.34 | 3.73 | 4.96 |

| 1440 (22 October) | 105.92 | 137.62 | 30.41 | 3.48 | 4.53 |

| 24 h cleaning | 170.10 | 184.02 | 35.38 | 4.81 | 5.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seol, S.-H.; Serageldin, A.A.; Kwon, O.K. Experimental Research on a Heat Pump Applying a Ball-Circulating Type Automatic Fouling Cleaning System for Fish Farms. Energies 2020, 13, 5856. https://doi.org/10.3390/en13225856

Seol S-H, Serageldin AA, Kwon OK. Experimental Research on a Heat Pump Applying a Ball-Circulating Type Automatic Fouling Cleaning System for Fish Farms. Energies. 2020; 13(22):5856. https://doi.org/10.3390/en13225856

Chicago/Turabian StyleSeol, Sung-Hoon, Ahmed A. Serageldin, and Oh Kyung Kwon. 2020. "Experimental Research on a Heat Pump Applying a Ball-Circulating Type Automatic Fouling Cleaning System for Fish Farms" Energies 13, no. 22: 5856. https://doi.org/10.3390/en13225856

APA StyleSeol, S.-H., Serageldin, A. A., & Kwon, O. K. (2020). Experimental Research on a Heat Pump Applying a Ball-Circulating Type Automatic Fouling Cleaning System for Fish Farms. Energies, 13(22), 5856. https://doi.org/10.3390/en13225856