Thermoformed Containers Based on Starch and Starch/Coffee Waste Biochar Composites

Abstract

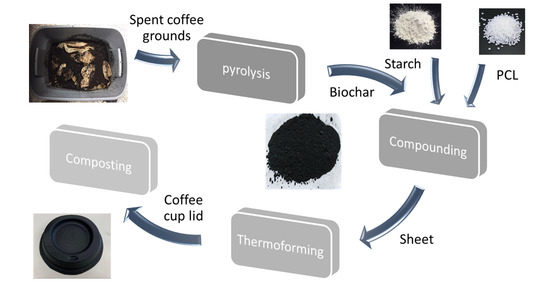

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Mechanical Properties Characterization

2.4. Soil Burial Test/Aerobic Biodegradation

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lu, D.R.; Xiao, C.M.; Xu, S.J. Starch-based completely biodegradable polymer materials. Express Polym. Lett. 2009, 3, 366–375. [Google Scholar] [CrossRef]

- Nunziato, R.; Hedge, S.; Dell, E.; Trabold, T.; Lewis, C.; Diaz, C. Mechanical Properties and Anaerobic Biodegradation of Thermoplastic Starch/Polycaprolactone Blends. In Proceedings of the 21th IAPRI World Conference on Packaging, Zhuhai, China, 19–22 June 2018; pp. 722–729. [Google Scholar]

- Averous, L.; Moro, L.; Dole, P.; Fringant, C. Properties of thermoplastic blends: Starch–polycaprolactone. Polymer 2000, 41, 4157–4167. [Google Scholar] [CrossRef]

- Lopez, O.; Garcia, M.A.; Villar, M.A.; Gentili, A.; Rodriguez, M.S.; Albertengo, L. Thermo-compression of biodegradable thermoplastic corn starch films containing chitin and chitosan. LWT Food Sci. Technol. 2014, 57, 106–115. [Google Scholar] [CrossRef]

- Zabaniotou, A.; Rovas, D.; Libutti, A.; Monteleone, M. Boosting circular economy and closing the loop in agriculture: Case study of a small-scale pyrolysis-biochar based system integrated in an olive farm in symbiosis with an olive mill. Environ. Dev. 2015, 14, 22–36. [Google Scholar] [CrossRef]

- Chen, W.; Meng, J.; Han, X.; Lan, Y.; Zhang, W. Past, present, and future of biochar. Biochar 2019, 1, 75–87. [Google Scholar] [CrossRef]

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Guran, S. Sustainable waste-to-energy technologies: Gasification and pyrolysis. In Sustainable Food Waste-to-Energy Systems; Elsevier: Amsterdam, The Netherlands, 2018; pp. 141–158. ISBN 9780128111574. [Google Scholar]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. A novel approach in organic waste utilization through biochar addition in wood/polypropylene composites. Waste Manag. 2015, 38, 132–140. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. Biocomposites from waste derived biochars: Mechanical, thermal, chemical, and morphological properties. Waste Manag. 2016, 49, 560–570. [Google Scholar] [CrossRef]

- Das, O.; Bhattacharyya, D.; Sarmah, A.K. Sustainable eco-composites obtained from waste derived biochar: A consideration in performance properties, production costs, and environmental impact. J. Clean. Prod. 2016, 129, 159–168. [Google Scholar] [CrossRef]

- Li, S.; Li, X.; Chen, C.; Wang, H.; Deng, Q.; Gong, M.; Li, D. Development of electrically conductive nano bamboo charcoal/ultra-high molecular weight polyethylene composites with a segregated network. Compos. Sci. Technol. 2016, 132, 31–37. [Google Scholar] [CrossRef]

- Moustafa, H.; Guizani, C.; Dufresne, A. Sustainable biodegradable coffee grounds filler and its effect on the hydrophobicity, mechanical and thermal properties of biodegradable PBAT composites. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Qian, S.; Yan, W.; Zhu, S.; Fontanillo Lopez, C.A.; Sheng, K. Surface modification of bamboo-char and its reinforcement in PLA biocomposites. Polym. Compos. 2018, 39, E633–E639. [Google Scholar] [CrossRef]

- Abdelwahab, M.A.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Injection Molded Novel Biocomposites from Polypropylene and Sustainable Biocarbon. Molecules 2019, 24, 4026. [Google Scholar] [CrossRef] [PubMed]

- Arrigo, R.; Jagdale, P.; Bartoli, M.; Tagliaferro, A.; Malucelli, G. Structure-property relationships in polyethylene-based composites filled with biochar derived from waste coffee grounds. Polymers 2019, 11, 1336. [Google Scholar] [CrossRef]

- Bartoli, M.; Giorcelli, M.; Rosso, C.; Rovere, M.; Jagdale, P.; Tagliaferro, A. Influence of Commercial Biochar Fillers on Brittleness/Ductility of Epoxy Resin Composites. Appl. Sci. 2019, 9, 3109. [Google Scholar] [CrossRef]

- Ferreira, G.F.; Pierozzi, M.; Fingolo, A.C.; da Silva, W.P.; Strauss, M. Tuning Sugarcane Bagasse Biochar into a Potential Carbon Black Substitute for Polyethylene Composites. J. Polym. Environ. 2019, 27, 1735–1745. [Google Scholar] [CrossRef]

- George, J.; Azad, L.B.; Poulose, A.M.; An, Y.; Sarmah, A.K. Nano-mechanical behaviour of biochar-starch polymer composite: Investigation through advanced dynamic atomic force microscopy. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105486. [Google Scholar] [CrossRef]

- Giorcelli, M.; Khan, A.; Pugno, N.M.; Rosso, C.; Tagliaferro, A. Biochar as a cheap and environmental friendly filler able to improve polymer mechanical properties. Biomass Bioenergy 2019, 120, 219–223. [Google Scholar] [CrossRef]

- Giorcelli, M.; Bartoli, M. Development of Coffee Biochar Filler for the Production of Electrical Conductive Reinforced Plastic. Polymers 2019, 11, 1916. [Google Scholar] [CrossRef]

- Zhang, Q.; Khan, M.U.; Lin, X.; Cai, H.; Lei, H. Temperature varied biochar as a reinforcing filler for high-density polyethylene composites. Compos. Part B Eng. 2019, 175, 107151. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, D.; Xu, H.; Lu, W.; Ren, X.; Cai, H.; Lei, H.; Huo, E.; Zhao, Y.; Qian, M.; et al. Biochar filled high-density polyethylene composites with excellent properties: Towards maximizing the utilization of agricultural wastes. Ind. Crops Prod. 2020, 146, 112185. [Google Scholar] [CrossRef]

- Arrigo, R.; Bartoli, M.; Malucelli, G. Poly(lactic Acid)-biochar biocomposites: Effect of processing and filler content on rheological, thermal, and mechanical properties. Polymers 2020, 12, 892. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Reimer, C.; Wang, T.; Mohanty, A.K.; Misra, M. Thermal and Mechanical Properties of the Biocomposites of Miscanthus Biocarbon and Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate) (PHBV). Polymers 2020, 12, 1300. [Google Scholar] [CrossRef] [PubMed]

- Watt, E.; Abdelwahab, M.A.; Snowdon, M.R.; Mohanty, A.K.; Khalil, H.; Misra, M. Hybrid biocomposites from polypropylene, sustainable biocarbon and graphene nanoplatelets. Sci. Rep. 2020, 10, 10714. [Google Scholar] [CrossRef] [PubMed]

- Pudełko, A.; Postawa, P.; Stachowiak, T.; Malińska, K.; Dróżdż, D. Waste derived biochar as an alternative filler in biocomposites—Mechanical, thermal and morphological properties of biochar added biocomposites. J. Clean. Prod. 2021, 278, 123850. [Google Scholar] [CrossRef]

- Sarasini, F.; Luzi, F.; Dominici, F.; Maffei, G.; Iannone, A.; Zuorro, A.; Lavecchia, R.; Torre, L.; Carbonell-Verdu, A.; Balart, R.; et al. Effect of different compatibilizers on sustainable composites based on a PHBV/PBAT matrix filled with coffee silverskin. Polymers 2018, 10, 1256. [Google Scholar] [CrossRef]

- García-García, D.; Carbonell, A.; Samper, M.D.; García-Sanoguera, D.; Balart, R. Green composites based on polypropylene matrix and hydrophobized spend coffee ground (SCG) powder. Compos. Part B Eng. 2015, 78, 256–265. [Google Scholar] [CrossRef]

- Wu, C.S. Renewable resource-based green composites of surface-treated spent coffee grounds and polylactide: Characterisation and biodegradability. Polym. Degrad. Stab. 2015, 121, 51–59. [Google Scholar] [CrossRef]

- Zarrinbakhsh, N.; Wang, T.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Characterization of wastes and coproducts from the coffee industry for composite material production. BioResources 2016, 11, 7637–7653. [Google Scholar] [CrossRef]

- Quosai, P.; Anstey, A.; Mohanty, A.K.; Misra, M. Characterization of biocarbon generated by high- and low-temperature pyrolysis of soy hulls and coffee chaff: For polymer composite applications. R. Soc. Open Sci. 2018, 5. [Google Scholar] [CrossRef]

- Rodriguez Alberto, D.; Repa, K.; Hegde, S.; Miller, C.W.; Trabold, T.A. Novel Production of Magnetite Particles via Thermochemical Processing of Digestate from Manure and Food Waste. IEEE Magn. Lett. 2019. [Google Scholar] [CrossRef]

- Phetwarotai, W.; Potiyaraj, P.; Aht-Ong, D. Biodegradation of Polylactide and Gelatinized Starch Blend Films Under Controlled Soil Burial Conditions. J. Polym. Environ. 2013, 21, 95–107. [Google Scholar] [CrossRef]

- Weng, F.; Zhang, P.; Guo, D.; Koranteng, E.; Wu, Z.; Wu, Q. Preparation and Properties of Compatible Starch-PCL Composites: Effects of the NCO Functionality in Compatibilizer. Starch Stärke 2020, 72, 1900239. [Google Scholar] [CrossRef]

- Liang, J.Z.; Duan, D.R.; Tang, C.Y.; Tsui, C.P.; Chen, D.Z. Tensile properties of PLLA/PCL composites filled with nanometer calcium carbonate. Polym. Test. 2013, 32, 617–621. [Google Scholar] [CrossRef]

- Chaiwong, W.; Samoh, N.; Eksomtramage, T.; Kaewtatip, K. Surface-treated oil palm empty fruit bunch fiber improved tensile strength and water resistance of wheat gluten-based bioplastic. Compos. Part B Eng. 2019, 176, 107331. [Google Scholar] [CrossRef]

- Hegde, S.; Dell, E.; Lewis, C.; Trabold, T.A.; Diaz, C.A. Anaerobic Biodegradation of Bioplastic Packaging Materials. In Proceedings of the 21st IAPRI World Conference on Packaging, Zhuhai, China, 19–22 June 2018; DEStech Publications, Inc.: Lancaster, PA, USA, 2018; pp. 730–737. [Google Scholar]

- Hegde, S.; Dell, E.M.; Lewis, C.L.; Trabold, T.A.; Diaz, C.A. Development of a biodegradable thermoformed tray for food waste handling. In Proceedings of the 29th IAPRI, Enschede, The Netherlands, 11–14 June 2019; pp. 553–561. [Google Scholar]

| Publication Year | Biochar Feedstock | Base Polymer | Citation |

|---|---|---|---|

| 2015/2016 | waste wood (Pinus radiata), landfill pine sawdust, sewage sludge, and poultry litter | PP | [9,10,11] |

| 2016 | bamboo | PE | [12] |

| 2017 | waste coffee | PBAT | [13] |

| 2018 | bamboo | PLA | [14] |

| 2019 | NS | PP | [15] |

| 2019 | waste coffee | PE | [16] |

| 2019 | wheat straw, Miscanthus, oilseed rape, rice husk, and mixed softwoods | epoxy | [17] |

| 2019 | sugarcane bagasse | PE | [18] |

| 2019 | rice husk | starch | [19] |

| 2019 | maple wood, waste coffee | epoxy | [20,21] |

| 2019/2020 | rice husk, poplar wood | PE | [22,23] |

| 2020 | waste coffee | PLA | [24] |

| 2020 | Miscanthus | PHBV | [25] |

| 2020 | soyhull meal | PP | [26] |

| 2021 | wood, sewage sludge | PLA | [27] |

| Mixing | Compression Molding | Thermoforming | ||||

|---|---|---|---|---|---|---|

| Material Composition PCL:Starch | Equilibrium Torque (Nm) | Temp (°C) | Pressure (tons) | Time (min) | Forming Temp (°C) | Time (min) |

| 60:40 | 12 | 200 | 3 | 7 | 110 | 1.5 |

| 50:50 | 13 | 200 | 3.5 | 8 | 113 | 1 |

| 40:60 | 17 | 180 | 6.5 | 15 | 116 | 1 |

| 30:70 | 21 | 210 | 7 | 15 | 138 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diaz, C.A.; Shah, R.K.; Evans, T.; Trabold, T.A.; Draper, K. Thermoformed Containers Based on Starch and Starch/Coffee Waste Biochar Composites. Energies 2020, 13, 6034. https://doi.org/10.3390/en13226034

Diaz CA, Shah RK, Evans T, Trabold TA, Draper K. Thermoformed Containers Based on Starch and Starch/Coffee Waste Biochar Composites. Energies. 2020; 13(22):6034. https://doi.org/10.3390/en13226034

Chicago/Turabian StyleDiaz, Carlos A., Rahul Ketan Shah, Tyler Evans, Thomas A. Trabold, and Kathleen Draper. 2020. "Thermoformed Containers Based on Starch and Starch/Coffee Waste Biochar Composites" Energies 13, no. 22: 6034. https://doi.org/10.3390/en13226034

APA StyleDiaz, C. A., Shah, R. K., Evans, T., Trabold, T. A., & Draper, K. (2020). Thermoformed Containers Based on Starch and Starch/Coffee Waste Biochar Composites. Energies, 13(22), 6034. https://doi.org/10.3390/en13226034