CO2 Injection and Enhanced Oil Recovery in Ohio Oil Reservoirs—An Experimental Approach to Process Understanding

Abstract

:1. Introduction

2. Materials and Methods

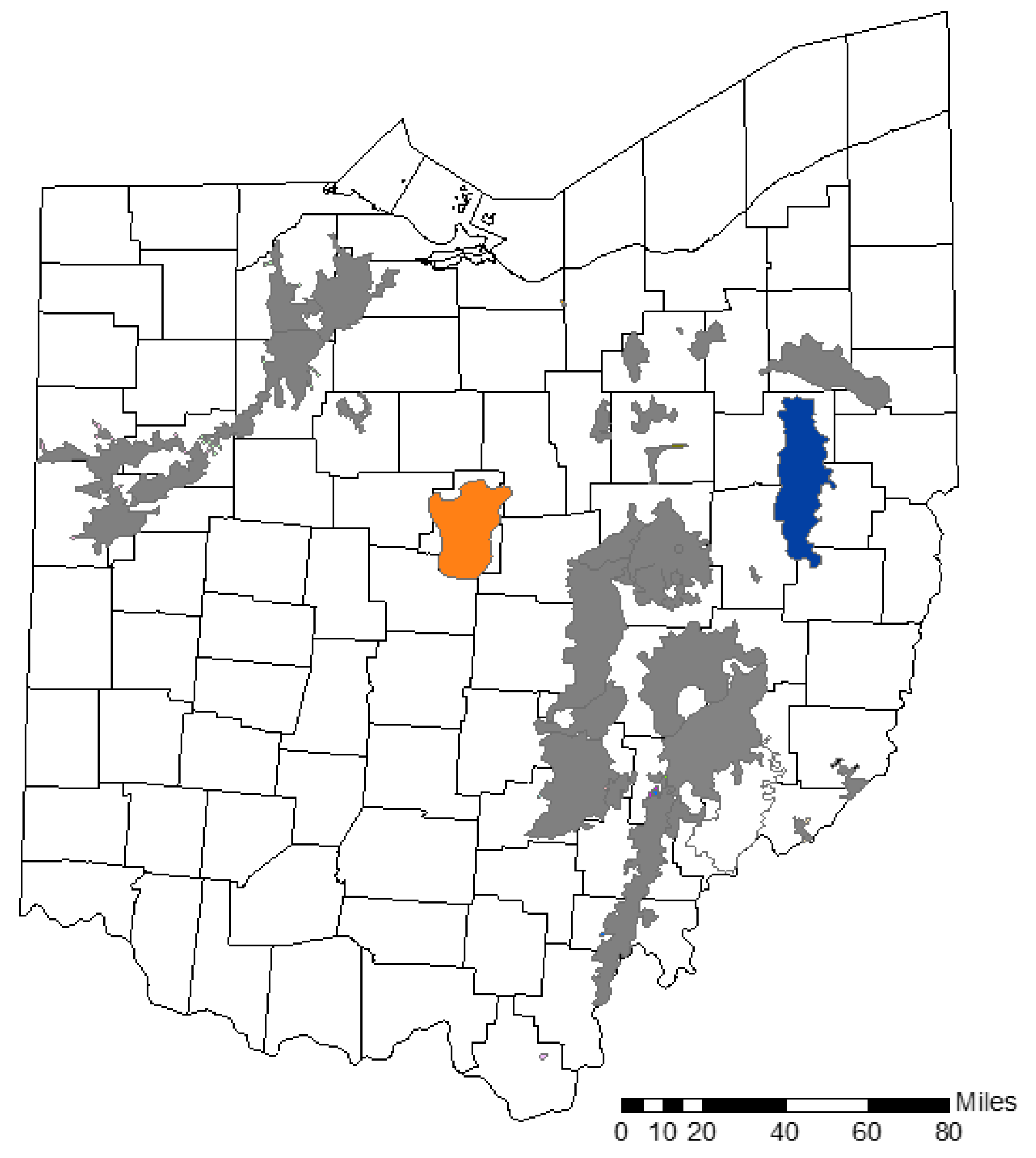

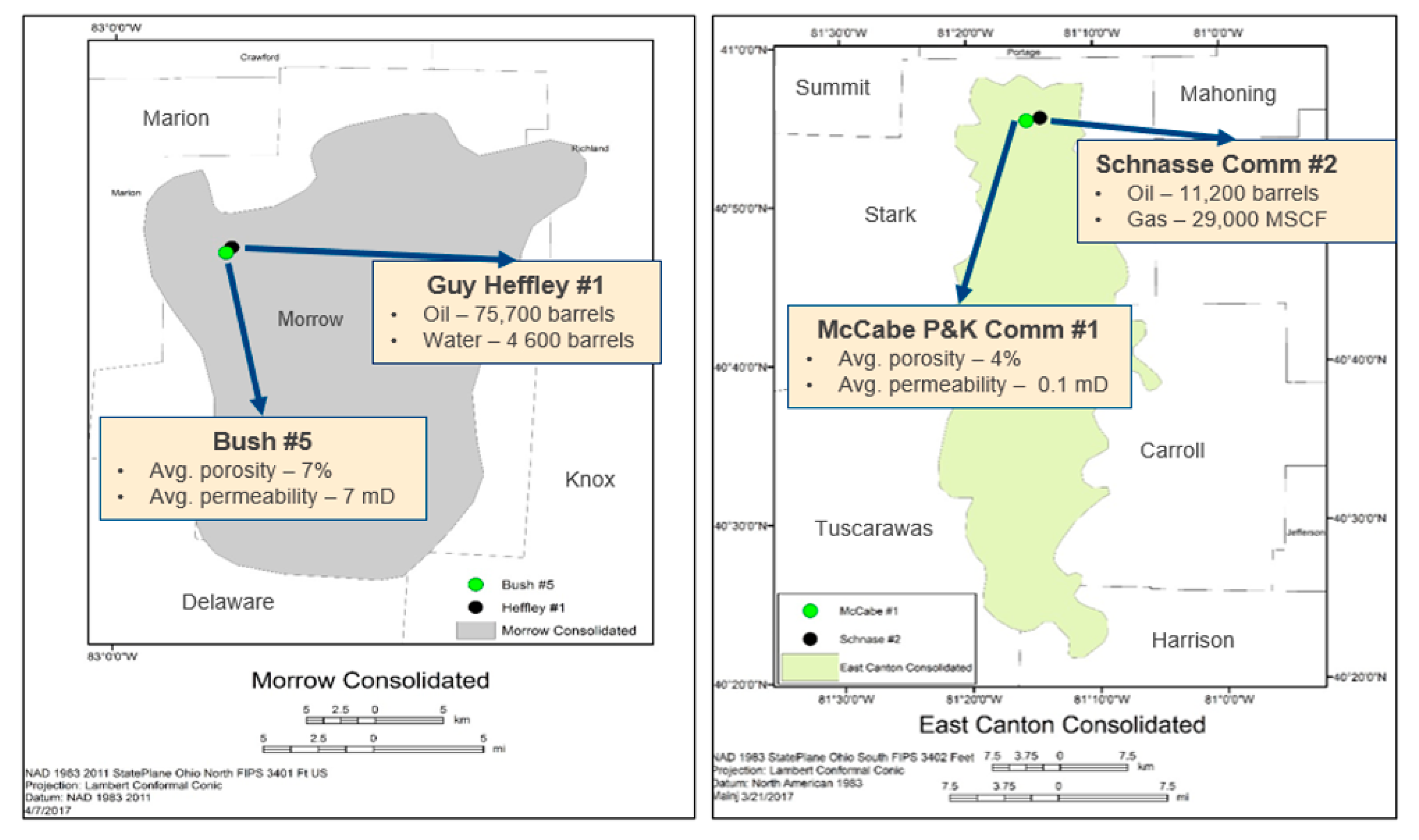

2.1. Study Areas and Sample Acquisition

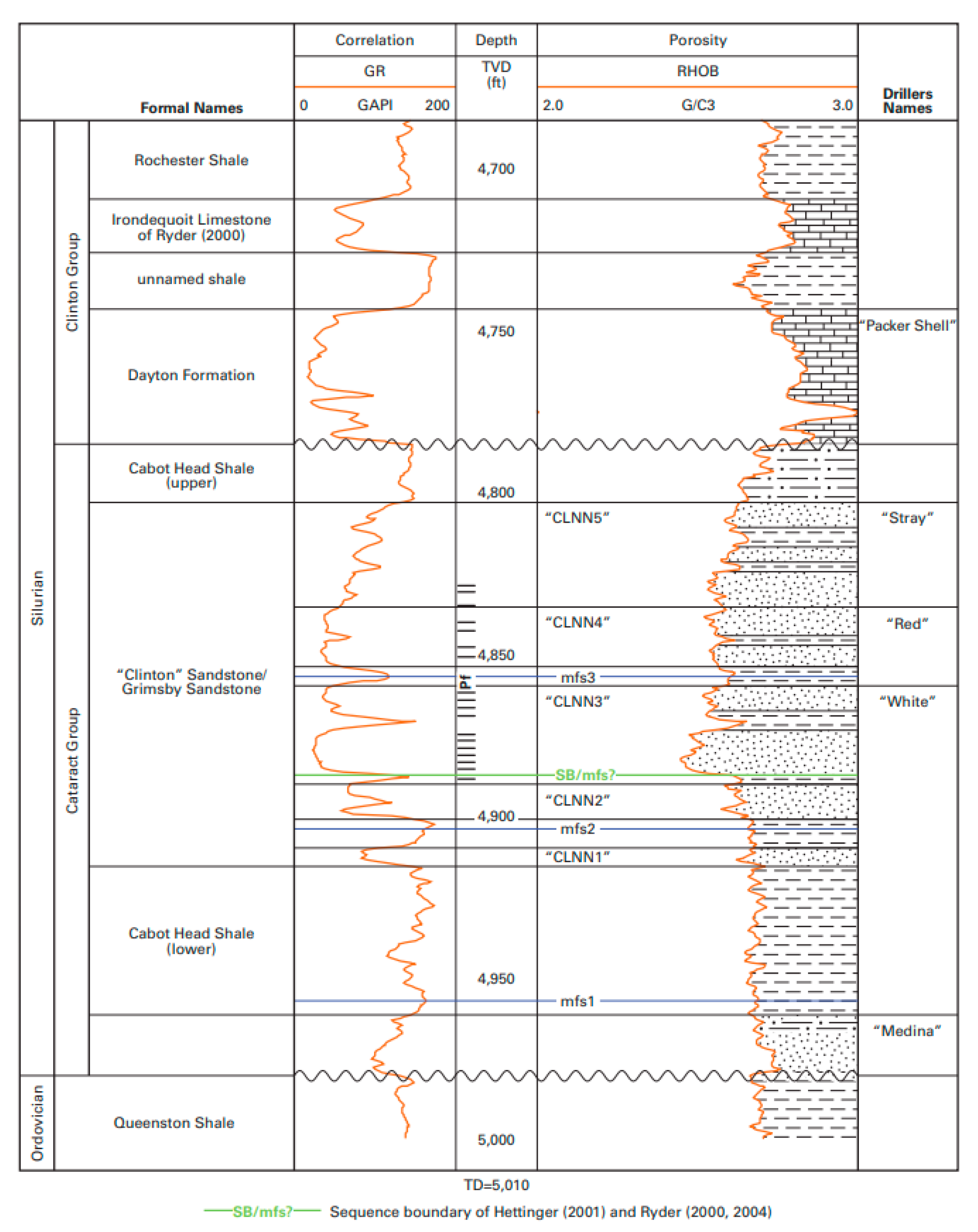

2.1.1. Reservoirs of Interest

2.1.2. Sample Collection

COPPER RIDGE DOLOMITE

LINTON SANDSTONE

2.2. Methods

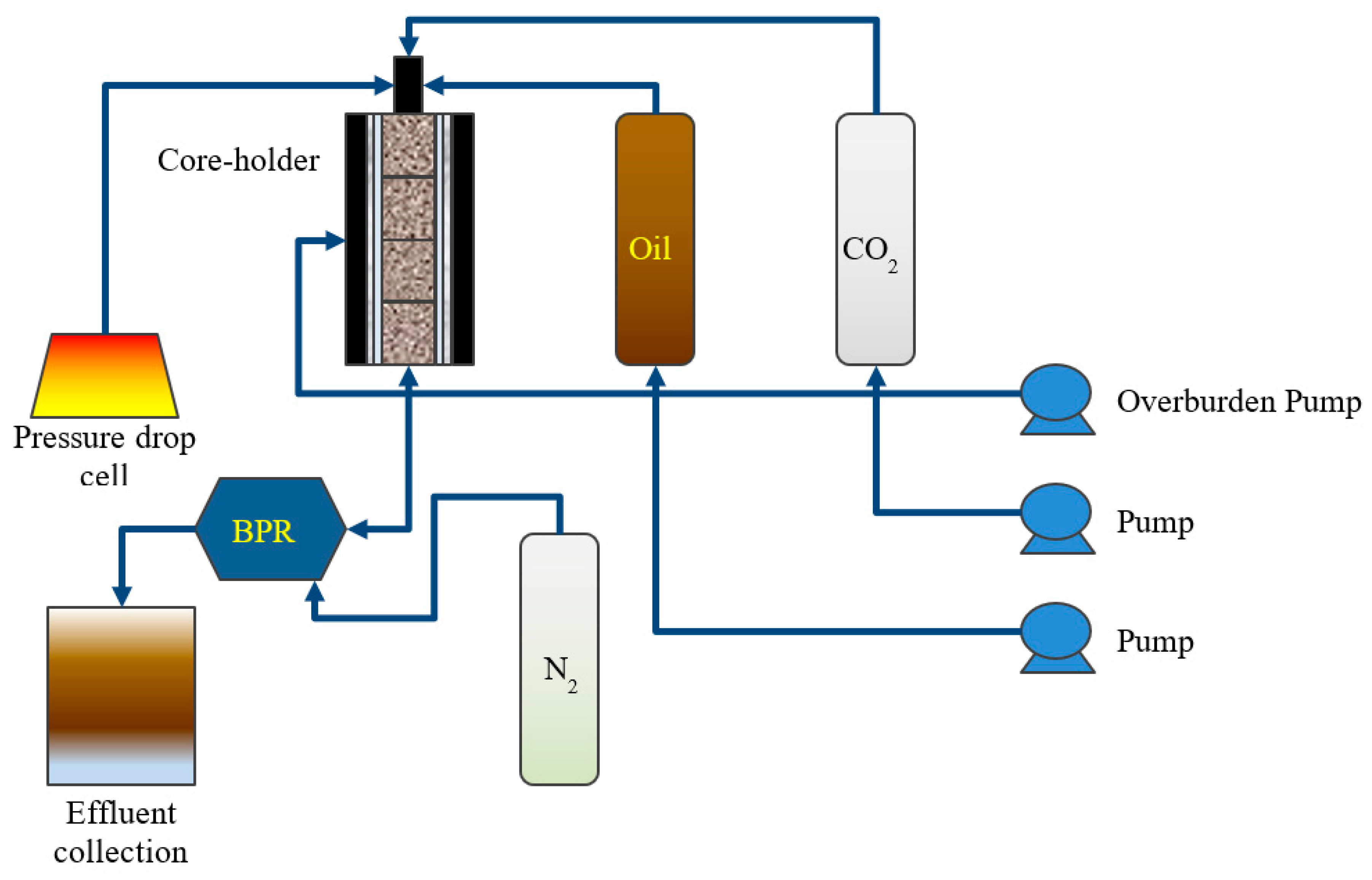

2.2.1. Experimental Setup

2.2.2. Core Floods

3. Results

3.1. Core Characterization

3.2. CO2 Injection Schemes

4. Discussion

5. Conclusions

- In-situ capillary pressure and relative permeability curves have been obtained, which can serve as useful inputs for dynamic reservoir simulations conducted in carbonate and sandstone reservoirs in the Appalachian region.

- Near-miscible CO2 injections are capable of recovering additional oil from Ohio reservoirs. Incremental recoveries ranged from 20% to 50% OOIP, which amounted to a 50% to 180% increase over primary recoveries (calculated as the ratio incremental to primary recovery). Primary recoveries ranged from 20% to 30% in Ohio’s carbonate and sandstone reservoirs implying there is still some additional primary production left in Ohio’s oil fields.

- In tight reservoirs, WAG injection lowers and delays incremental oil recovery. Continuous CO2 injection is preferred over WAG injection.

- Miscible injection is beneficial in medium-high permeability (1–100 mD)—e.g., in reservoirs such as the Copper Ridge dolomite. Injecting above the MMP seemed to reduce the incremental oil recovery in the tighter Clinton sandstone alluding to a dependance on capillary forces for increasing oil recovery.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Global CCS Institute; Policy Priorities to Incentivise Large Scale Deployment of CCS; Global CCS Institute. Available online: https://www.globalccsinstitute.com/resources/publications-reports-research/policy-priorities-to-incentivise-large-scale-deployment-of-ccs/. (accessed on 23 November 2019).

- Benson, S.M.; Friedman, S.J. Carbon Dioxide Capture, Utilization and Storage: An Important Part of a Response to Climate Change; Spring Issue; The Bridge, National Academy of Engineering: Washington, DC, USA, 2014; pp. 42–50. [Google Scholar]

- Rodosta, T.; Bromhal, G.; Damiani, D. U.S. DOE/NETL carbon storage program: Advancing science and technology to support commercial deployment. Energy Procedia 2017, 114, 5933–5947. [Google Scholar] [CrossRef]

- Jarrell, P.M.; Fox, C.; Stein, M.; Webb, S. Practical Aspects of CO2 Flooding—Monograph Volume 22; Society of Petroleum Engineers: Richardson, TX, USA, 2002. [Google Scholar]

- Novak, K.; Malvić, T.; Simon, K. Increased hydrocarbon recovery and CO2 management, a Croatian example. Environ. Earth Sci. 2013, 68, 1187–1197. [Google Scholar] [CrossRef]

- Novak, K.; Malvić, T.; Velić, J.; Simon, K. Increased hydrocarbon recovery and CO2 storage in Neogene sandstones, a Croatian example: Part II. Environ. Earth Sci. 2014, 71, 3641–3653. [Google Scholar] [CrossRef]

- Energy Information Administration (EIA). U.S. Energy Related Carbon Dioxide Emissions. Report published September 2018. Available online: https://www.eia.gov/environment/emissions/carbon/. (accessed on 23 November 2019).

- Riley, R.A.; Janssens, A.; Baranoski, M. Cambrian-Ordovician Knox Production Patterns and Potential for Enhanced Oil Recovery in Ohio. In Proceedings of the Fourth Annual Technical Symposium of the Ohio Geological Society, Akron, OH, USA, 9 October 1996. [Google Scholar]

- Bank, G.; Riestenberg, D.; Koperna, G. CO2 enhanced oil recovery potential of the Appalachian basin. In Proceedings of the SPE Eastern Regional Meeting, Lexington, KY, USA, 17–19 October 2007. SPE 111282. [Google Scholar]

- Ryder, R.T. Stratigraphic framework of Cambrian and Ordovician rocks across Rome trough, central Appalachian basin. Am. Assoc. Pet. Geol. Bull. 1987, 71, 1110. [Google Scholar]

- Hawkins, J.; Mishra, S.; Stowe, R.; Makwana, K.; Main, J. A revised assessment of the CO2 storage capacity and enhanced oil recovery potential in the major oil fields of Ohio. Environ. Geosci. 2017, 24, 1–13. [Google Scholar] [CrossRef]

- Pepper, J.F.; De Witt, W., Jr.; Everhart, G.M. The “Clinton” Sands of Early Silurian Age in Canton, Dover, Massillon, and Navarre Quadrangles; U.S. Geological Survey Bulletin 1003-A; U.S. Geological Survey: Reston, VA, USA, 1953; p. 13. [Google Scholar]

- Battelle. Basic and Advanced Wireline Log Interpretation in Bush #5 Well in Morrow County, Ohio; Reported Submitted to the Ohio Coal Development Office under Grant Number OOE-CDO-D-13-24; Battelle: Columbus, OH, USA, 2015. [Google Scholar]

- Riley, R.A.; Wicks, J.L.; Perry, C.J. Silurian “Clinton” Sandstone Reservoir Characterization for Evaluation of CO2-EOR Potential in the East Canton Oil Field, Ohio. Final Report submitted to US DOE under agreement number DE-NT0005115. 2010. Available online: https://www.osti.gov/servlets/purl/983930 (accessed on 23 November 2019).

- Valluri, M.K.; Mishra, S.; Schuetter, J. An improved correlation to estimate the minimum miscibility pressure of CO2 in crude oils for carbon capture, utilization, and storage projects. J. Pet. Sci. Eng. 2017, 158, 408–415. [Google Scholar] [CrossRef]

- Breen, K.J.; Angelo, C.G.; Masters, R.W.; Sedam, A.C. Chemical and Isotopic Characteristics of Brines from Three Oil- and Gas-Producing Sandstones in Eastern Ohio, with Applications to the Geochemical Tracing of Brine Sources; U.S. Geological Survey Water-Resources Investigations Report WRI 84-4314. 1985. Available online: https://pubs.er.usgs.gov/publication/wri844314 (accessed on 23 November 2019).

- Jacot, R.H.; Hopkins, C.W.; Gonzalez, D.W.; Meyer, B.R. Improving Hydraulic Fracturing Results in the Clinton Sandstone of Ohio: A Case History. In Proceedings of the Society of Petroleum Engineers Eastern Regional Meeting, Pittsburgh, PA, USA, 2–4 November 1993. [Google Scholar] [CrossRef]

- Han, L.; Gong, Y. Optimization of miscible CO2 water-alternating-gas injection in the Bakken formation. Energy Fuels 2014, 28, 6811–6819. [Google Scholar] [CrossRef]

- Gong, Y.; Gu, Y. Miscible CO2 simultaneous water-and-gas (CO2-SWAG) injection in the Bakken formation. Energy Fuels 2015, 29, 5655–5665. [Google Scholar] [CrossRef]

- Yin, M. CO2 Miscible Flooding Application and Screening Criteria; Missouri University of Science and Technology: Rolla, MO, USA, 2015. [Google Scholar]

- Wang, X.; Gong, Y. Oil recovery and permeability reduction of a tight sandstone reservoir in immiscible and miscible CO2 flooding processes. Ind. Eng. Chem. 2011, 50, 2388–2399. [Google Scholar] [CrossRef]

- Robertson, E.P. Oil recovery increases by low-salinity flooding: Minnelusa and Green river formations. In Proceedings of the SPE Annual Technical Conference and Exhibition, Tuscany, Italy, 20–22 September 2010. Paper SPE 132154. [Google Scholar]

| Property | Morrow Consolidated (MCOF) | East Canton (ECOF) |

|---|---|---|

| Producing member | Copper Ridge dolomite | Clinton sandstone |

| Depth | 3000 ft | 5200 ft |

| Pay thickness (net) | ~166 feet | ~110 feet |

| Average permeability | 10 mD | 0.1 mD |

| Average discovery pressure | 1486 psi | 2136 psi |

| Average temperature | 91 °F | 104 °F |

| Typical peroration depths | 3000–3500 feet | 4500–5500 feet |

| Oil originally in place (OOIP) | 177 million barrels | 1537 million barrels |

| Average Porosity | 10% | 7% |

| Oil API Gravity | 41.9° API | 46.2° API |

| Property | Copper Ridge Dolomite | Clinton Sandstone |

|---|---|---|

| Permeability | 12.56 mD | 2.74 mD |

| Porosity | 12.7% | 7.5% |

| Initial oil saturation | 0.72 | 0.63 |

| Contact angle | >150° | 118° |

| Oil–water interfacial tension | 20.3 dynes/cm | 30.14 dynes/cm |

| Parameter | Copper Ridge Dolomite | Clinton Sandstone |

|---|---|---|

| Residual oil saturation (Sor) (kro = 0) | 0.6 | 0.58 |

| Irreducible water saturation (Swirr) (krw = 0) | 0.2 | 0.36 |

| Oil relative permeability at Swirr | 0.14 | 0.23 |

| Water relative permeability at Sor | 0.12 | 0.04 |

| Reservoir | Experiment | Average Oil Recovery (% OOIP) |

|---|---|---|

| Copper Ridge | Water Flood | 30% |

| Copper Ridge | Immiscible CO2 Flood | 16% |

| Copper Ridge | Miscible CO2 Flood | 26% |

| Copper Ridge | 1:1 WAG Flood | 20% |

| Copper Ridge | 2:1 WAG Flood | 18% |

| Clinton | Water Flood | 20% |

| Clinton | Immiscible CO2 Flood | 29% |

| Clinton | Miscible CO2 Flood | 26% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valluri, M.K.; Zhou, J.; Mishra, S.; Mohanty, K. CO2 Injection and Enhanced Oil Recovery in Ohio Oil Reservoirs—An Experimental Approach to Process Understanding. Energies 2020, 13, 6215. https://doi.org/10.3390/en13236215

Valluri MK, Zhou J, Mishra S, Mohanty K. CO2 Injection and Enhanced Oil Recovery in Ohio Oil Reservoirs—An Experimental Approach to Process Understanding. Energies. 2020; 13(23):6215. https://doi.org/10.3390/en13236215

Chicago/Turabian StyleValluri, Manoj Kumar, Jimin Zhou, Srikanta Mishra, and Kishore Mohanty. 2020. "CO2 Injection and Enhanced Oil Recovery in Ohio Oil Reservoirs—An Experimental Approach to Process Understanding" Energies 13, no. 23: 6215. https://doi.org/10.3390/en13236215

APA StyleValluri, M. K., Zhou, J., Mishra, S., & Mohanty, K. (2020). CO2 Injection and Enhanced Oil Recovery in Ohio Oil Reservoirs—An Experimental Approach to Process Understanding. Energies, 13(23), 6215. https://doi.org/10.3390/en13236215