Overview of the Development and Application of the Twin Screw Expander

Abstract

1. Introduction

2. The Current Research Status of Screw Expander

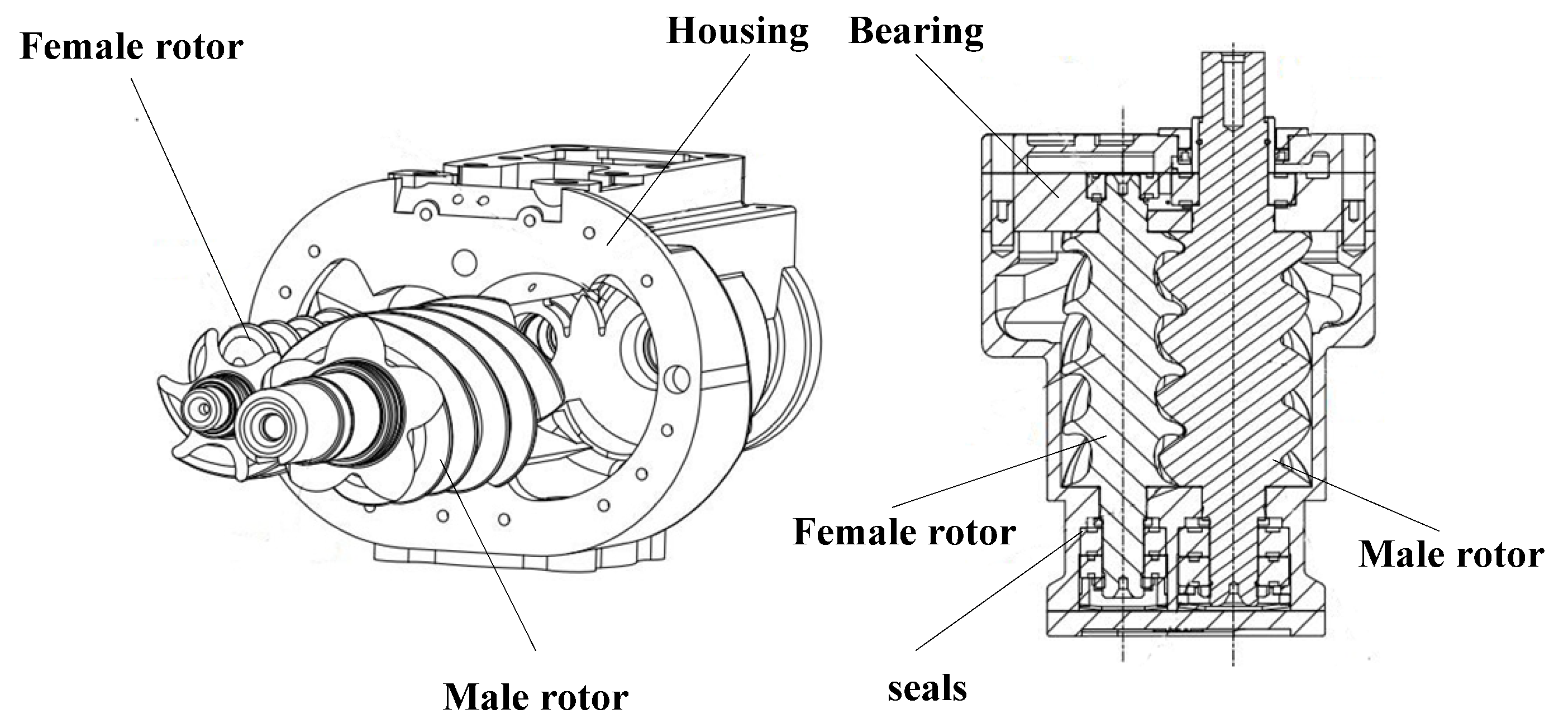

2.1. The Basic Structure and Operating Principle of the Screw Expander

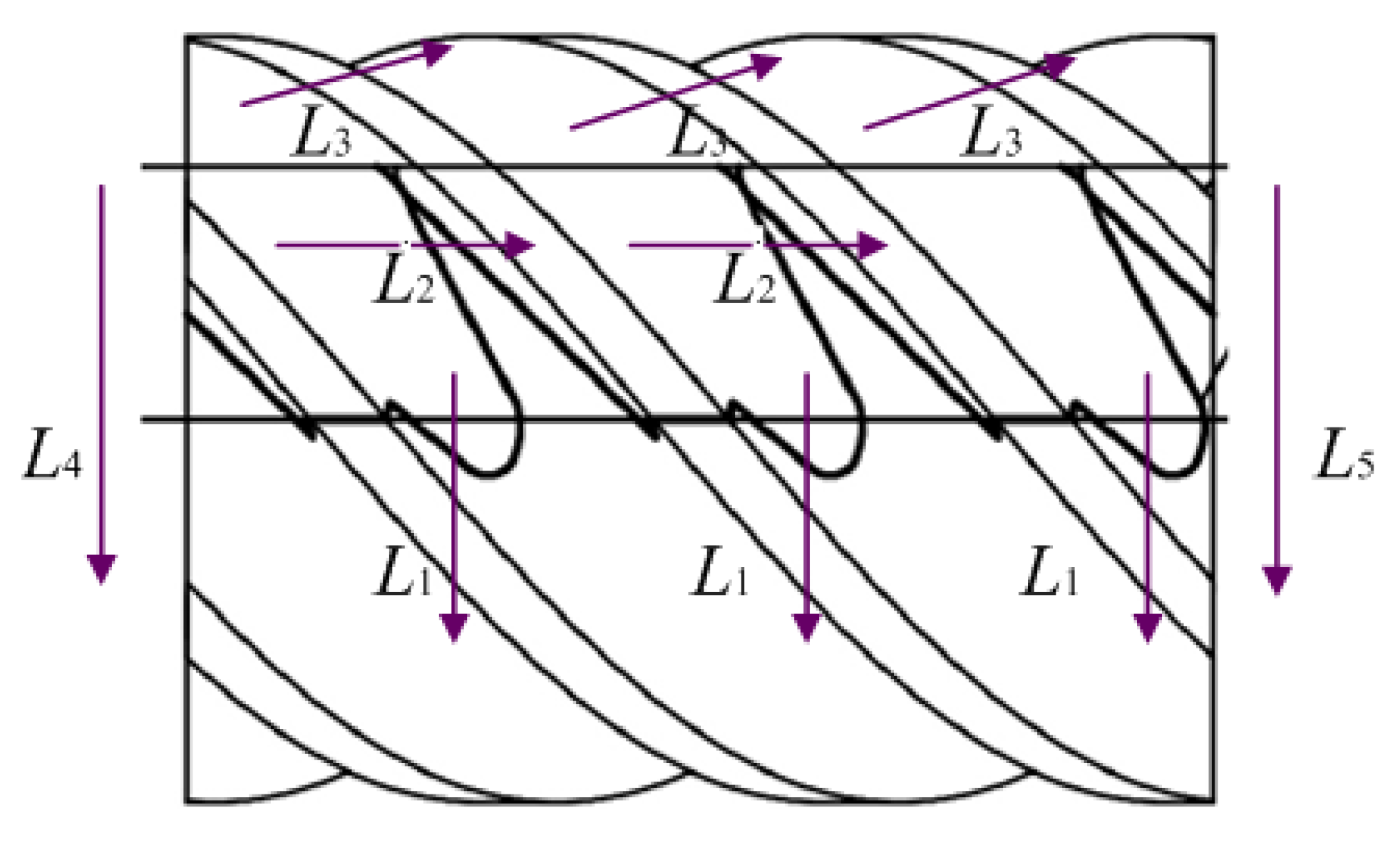

2.2. Research on Leakage of Screw Expander

2.2.1. Research on Screw Mechanical Leakage

2.2.2. Computer-Assisted Application in Leakage Research

2.2.3. Research on the Leakage of Working Fluid Condition

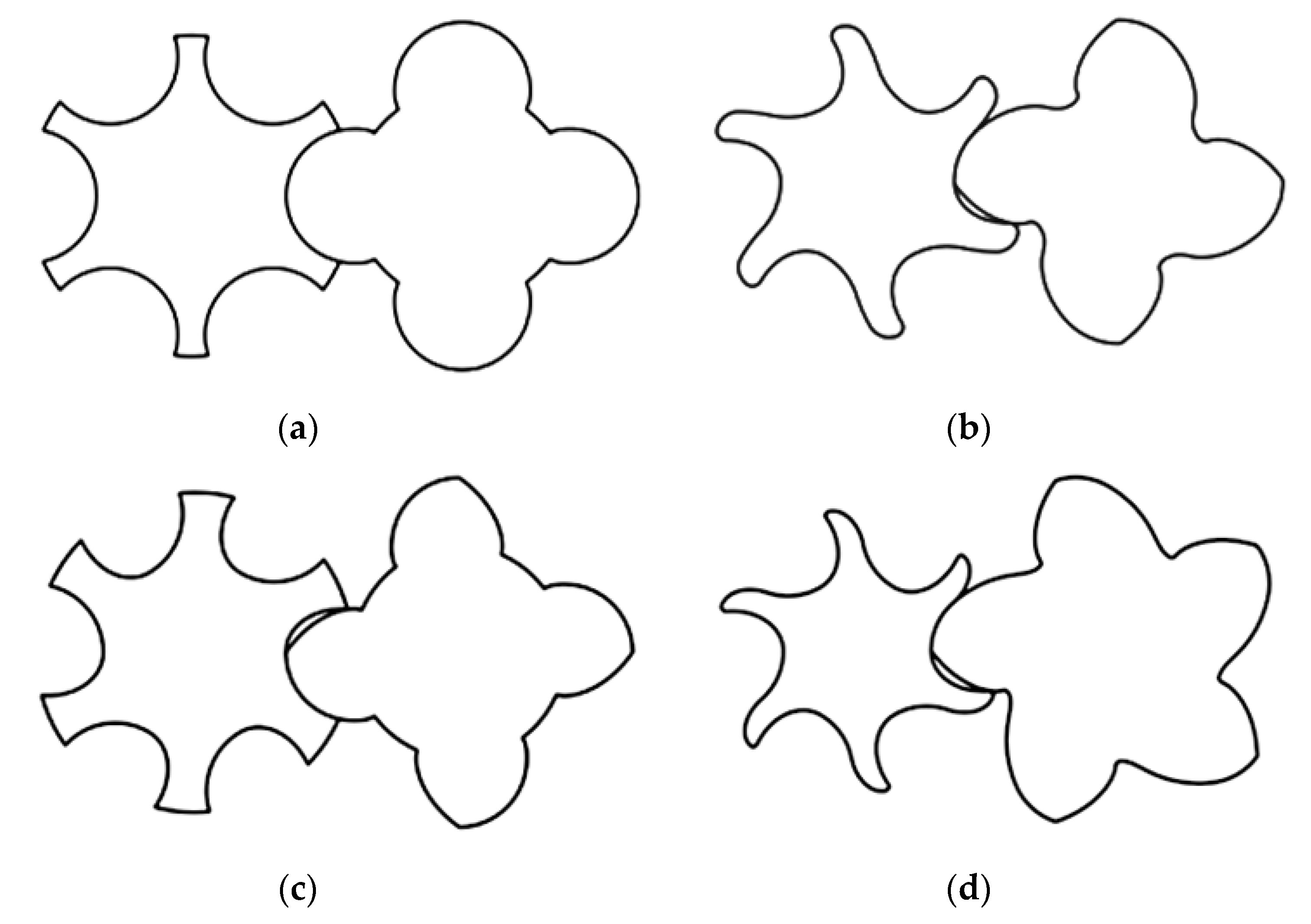

2.3. Research Status of Rotor Profile of Screw Expander

2.3.1. Development of the Rotor Profile of Screw Machine

2.3.2. Research on the Rotor Profile of Screw Machine

- (1)

- The application of the new method to the study of rotor profile

- (2)

- The application of computer-aided design in the design of profile

- (3)

- The reverse design of rotor profile

2.4. Research Status of the Machining of the Screw Rotor

2.4.1. Machining Method of the Screw Rotor

2.4.2. Profiler Design of Rotor Machining Tool

2.4.3. Advanced Professional Screw Rotor Processing Equipment

2.5. Research on Seal of Screw Expander

- Four sealing systems of the United States I-R (Ingersoll Rand) company

- (1)

- Standard labyrinth seal: The standard labyrinth seal is largely applicable to dry air, nitrogen and dry vacuum conditions. It can also apply to any dry gas that is not dangerous and can be allowed for a small amount of leakage.

- (2)

- Labyrinth water ring seal: this seal combines with the stainless-steel rotary tooth groove and the babbitt metal stationary bushing. On this basis, a water ring is added to prevent working fluid from leaking along the axis.

- (3)

- Drive gas labyrinth seal: the seal can arrange injection air or inert gas, which is slightly higher than the screw mechanical exhaust pressure, to prevent leakage. This seal is suitable for harmful and combustible materials, which are not allowed to leak into the atmosphere.

- (4)

- Mechanical seal: this seal is suitable for a place where the working medium is toxic or expensive or the drive gas labyrinth seal that cannot be used. The mechanical seal is applied to a rotating sealing ring that is in perpendicular contact to the fixed surface, and an independent lubricating oil system for pressurizing and cooling seals, which includes a motor-driven oil pump, filter, cooler and fuel tank.

- 2

- Two kinds of sealing systems of the Japanese’s Kobelco company

- (1)

- Bearing oil film seal: the seal depends on the oil film to prevent gas leakage, and it is used to buffer the gas that does not spoil the oil.

- (2)

- Mechanical sea: this sealing system applied in this situation that the buffer gas cannot be used or the oil is not allowed to enter the working chamber. The mechanical seal takes lubricating oil as the sealing liquid, and the material of the sliding parts is usually made of graphite carbide. Due to the excellent sliding member material, even in case of high-speed operation, it also shows its good stability.

2.6. Study on Thermodynamic Model and Simulation Analysis of Screw Expander

2.6.1. Research on the Thermodynamic Model of Screw Expander

2.6.2. Research on Simulation Analysis of Screw Expander

3. The Application of Screw Expander

3.1. The Application of Screw Expander in the Low-Temperature Generation System

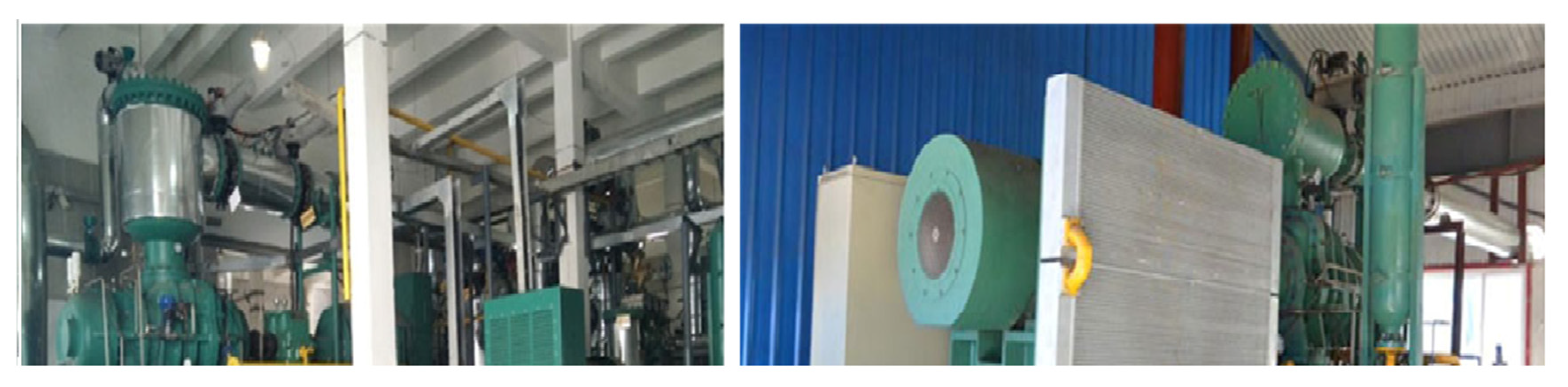

3.1.1. The Application of Screw Expander in Industrial Residual Pressure Power Generation

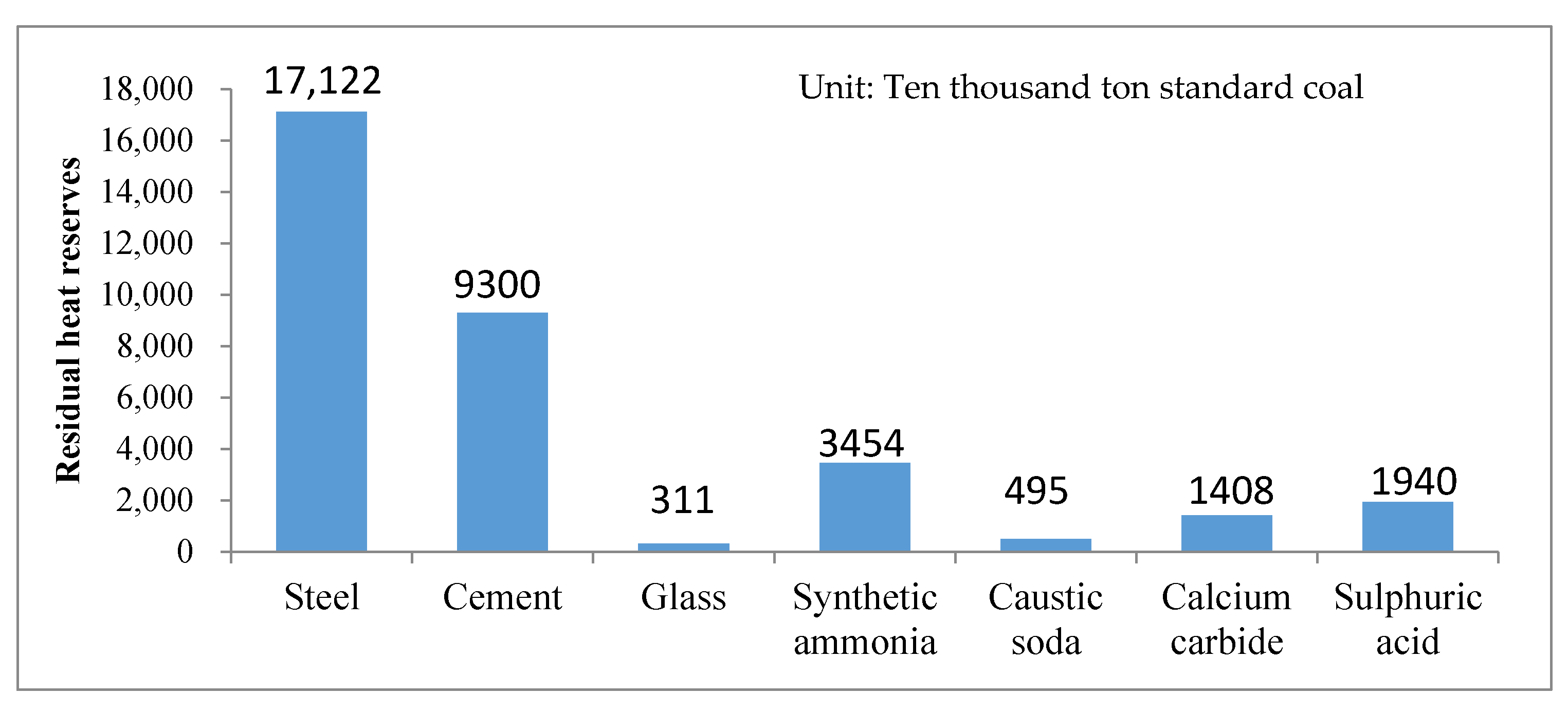

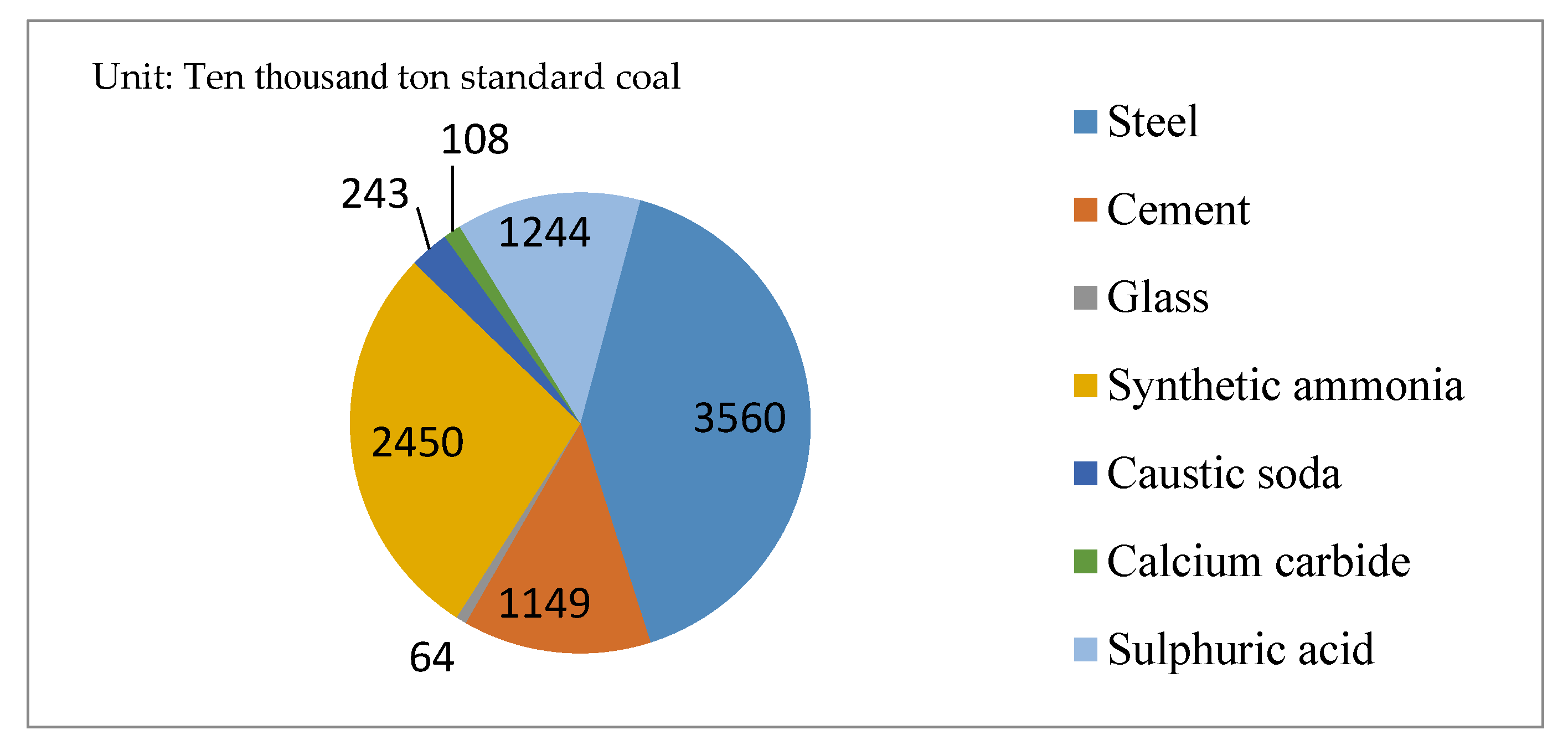

3.1.2. The Application of Screw Expander in Industrial Waste Heat Recovery

3.1.3. The Application of Screw Expander in Renewable Energy Generation

- (1)

- The Application in the Geothermal Power Generation

- (2)

- Application in biomass power generation

3.2. Potential Utilization Field of Screw Expander

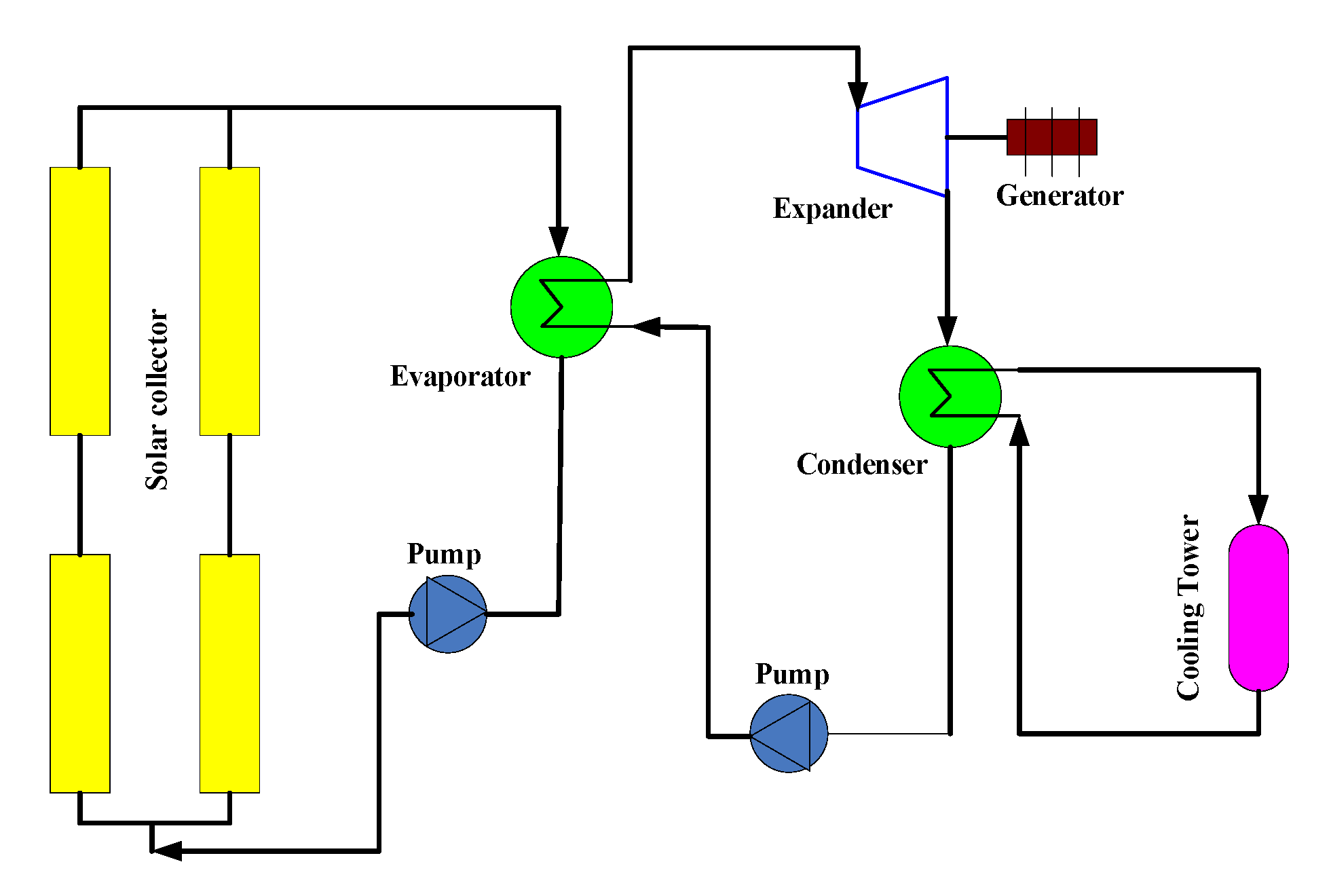

3.2.1. The Field of Solar Power Generation

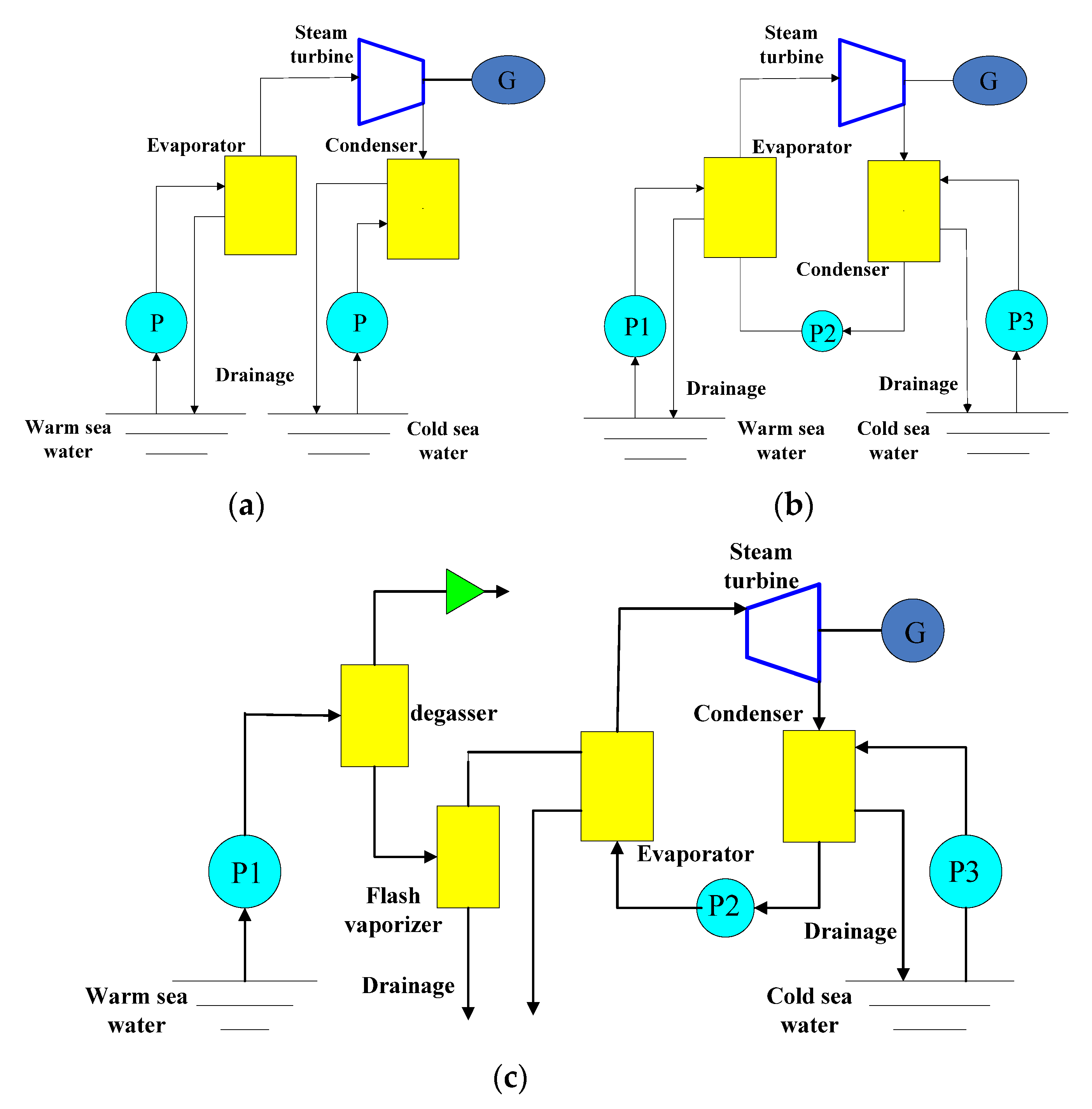

3.2.2. The Field of Ocean Thermal Energy Conversion

3.2.3. Liquefied Natural Gas (LNG) Cold Energy Generation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| ORC | Organic Rankine Cycle |

| ICCD | Iso-clearance Contour Diagram |

| TCA | Tooth Contact Analysis |

| ASR | Average-state Region |

| SCCAD | screw rotor design and calculation software |

| PROE | Pro/Engineer |

| CFD | Computational Fluid Dynamics |

| NURBS | Non-Uniform Rational B-Splines |

| MFC | Microsoft Foundation Classes |

| OpenGL | Open Graphics Library |

| TSD | Twin-screw compressor yin-yang rotor type line design system |

| CNC | Computer Numerical Control |

| CBN | Cubic Boron Nitride |

| CAD/CAM | Computer Aided Design/Computer Aided Manufacturing |

| MATLAB | Matrix&Laboratory |

| AutoLISP | Autodesk List Processor |

| OTEC | Ocean Thermal Energy Conversion |

| IGU | International Natural Gas Union |

| LNG | Liquefied Natural Gas |

References

- Zhe, L.U. Analysis on Current Situation of Industrial Waste Heat Recovery in China. Equip. Manuf. Technol. 2019, 12, 204–206. [Google Scholar]

- Xiong, H. The Survey Report on Utilization of Industrial Waste Heat Resources. 2017. Available online: http://www.doc88.com/p-1788513706822.html (accessed on 13 December 2003).

- Fierro, J.J.; Escudero-Atehortúa, A.; Nieto-Londoño, C.; Giraldo, M.; Jouhara, H.; Wrobel, L.C. Evaluation of Waste Heat Recovery Technologies for the Cement Industry. Int. J. 2020, 100040. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, L.; Dong, H. Review of Research on Industrial Waste Heat Recovery Based on Organic Rankine Cycle. In Proceedings of the 10th National Energy and Thermal Engineering Academic Annual Conference, Hangzhou, Zhejiang Province, China, 14 August 2019; pp. 392–396. [Google Scholar]

- Dibazar, S.Y.; Salehi, G.; Davarpanah, A. Comparison of Exergy and Advanced Exergy Analysis in Three Different Organic Rankine Cycles. Processes 2020, 8, 586. [Google Scholar] [CrossRef]

- Feng, Y.-Q.; Wang, X.; Niaz, H.; Hung, T.-C.; He, Z.-X.; Zeb, A.J.; Xi, H. Experimental comparison of the performance of basic and regenerative organic Rankine cycles. Energy Convers. Manag. 2020, 223, 113459. [Google Scholar] [CrossRef]

- Ehyaei, M.A.; Ahmadi, A.; Rosen, M.A.; Davarpanah, A. Thermodynamic Optimization of a Geothermal Power Plant with a Genetic Algorithm in Two Stages. Processes 2020, 8, 1277. [Google Scholar] [CrossRef]

- Alizadeh, S.M.; Ghazanfari, A.; Ehyaei, M.A.; Ahmadi, A.; Jamali, D.H.; Nedaei, N.; Davarpanah, A. Investigation the Integration of Heliostat Solar Receiver to Gas and Combined Cycles by Energy, Exergy, and Economic Point of Views. Appl. Sci. 2020, 10, 5307. [Google Scholar] [CrossRef]

- Di Cairano, L.; Nader, W.B.; Nemer, M. Assessing fuel consumption reduction in Revercycle, a reversible mobile air conditioning/organic Rankine cycle system. Energy 2020, 118588. [Google Scholar] [CrossRef]

- Usman, M.; Imran, M.; Haglind, F.; Pesyridis, A.; Park, B.-S. Experimental analysis of a micro-scale organic Rankine cycle system retrofitted to operate in grid-connected mode. Appl. Eng. 2020, 180, 115889. [Google Scholar] [CrossRef]

- Jingwen, Y.; Kefeng, Y.; Jia, H.; Ganghui, L.; Hongbin, G. Research progress and application status of organic Rankine cycle expanders. Therm. Power Gener. 2019, 48, 10–18. [Google Scholar]

- Yajing, S. Flow Field Analysis and Dynamic Performance Study of Twin Screw Expander. Ph.D. Thesis, Yangzhou University, Yangzhou, China, April 2019. [Google Scholar]

- Yuan, T. Application of screw expander in waste heat power generation project. Energy Res. Util. 2018, 3, 54–55. [Google Scholar]

- Fong, Z.; Huang, F.; Fang, H. Evaluating the inter-lobe clearance of twin-screw compressor by the iso-clearance contour diagram (ICCD). Mech. Mach. Theory 2001, 36, 725–742. [Google Scholar] [CrossRef]

- Prins, J.; Ferreira, C.A.I. Leakage Experiments on a Running Twin Screw Compressor. Arzneim. Forsch. 2002, 25, 975–976. [Google Scholar]

- Tian, Y.; Lu, J.; Shen, J.; Wu, H.; Xing, Z. Optimization on shaft seals for a twin-screw steam compressor based on a novel uniform property region (UPR) model on discharge end-face. Int. J. Refrig. 2018, 91, 167–176. [Google Scholar] [CrossRef]

- Xing, Z.; Fu, P. Study of Leakage Characteristics in Twin Screw Compressor with Refrigerant R134a. Refrig. J. 2000, 04, 23–28. [Google Scholar]

- Qi, Y.; Yu, Y. Numerical simulation and analysis of leakage process in twin screw expander. J. Shanghai Jiaotong Univ. 2016, 504, 496–501. [Google Scholar]

- Papes, I.; Degroote, J.; Vierendeels, J. 3D CFD Analysis of an Oil Injected Twin Screw Expander. In Proceedings of the ASME 2013 International Mechanical Engineering Congress and Exposition, San Diego, CA, USA, 15–21 November 2013. [Google Scholar]

- Hesse, J.; Spillekohoff, A.; Shorbagy, A.E. CFD simulation of a screw compressor including leakage flows and rotor heating. In Proceedings of the 9th International Conference on Compressors and Their Systems, London, UK, 7–9 September 2015. [Google Scholar]

- Li, H.; Jin, G.; Wu, Z. Leakage analysis and calculation of oil injection single screw compressor. Fluid Mach. 1993, 8, 14–18. [Google Scholar]

- Wang, Z.; Liu, Z.; Wu, W.; Feng, Q. Research of leakage characteristics of single screw refrigeration compressors with the Multicolumn Envelope Meshing Pair. Int. J. Refrig. 2015, 49, 1–10. [Google Scholar] [CrossRef]

- Bein, T.W.; Hamilton, J.F. Computer Modeling of an Oil Flooded Single Screw Air Compressor. 1982. Available online: https://docs.lib.purdue.edu/cgi/viewcontent.cgi?article=1382&context=icec (accessed on 11 December 2020).

- Jiang, S.G. Study on the Positive and Negative Configurations of Twin Screw Rotor Profile Based on NURBS. Ph.D. Thesis, Jiangnan University, Wuxi, China, June 2018. [Google Scholar]

- Hui, L. Research and Simulation of MWorks Based Screw Compression Machine Line. Ph.D. Thesis, Huazhong University of Technology, Wuhan, China, January 2013. [Google Scholar]

- Zaytsev, D.; Ferreira, C.A.I. Profile generation method for twin screw compressor rotors based on the meshing line. Int. J. Refrig. 2005, 28, 744–755. [Google Scholar] [CrossRef]

- Stosic, N. Profile Rotors. Available online: http://www.staff.city.ac.uk/~sj376/nrot.html (accessed on 13 December 2017).

- Litvin, F.L.; Feng, P.H. Computerized design, generation, and simulation of meshing of rotors of screw compressor. Mech. Mach. Theory 1997, 32, 137–160. [Google Scholar] [CrossRef]

- Xueming, H.; Guojiang, S.; Meiping, W.; Rong, Z.; Xiaogang, J. Application of B-spline in Reverse Design Method of Screw Rotor Profiles. Mech. Sci. Technol. 2018, 37, 43–54. [Google Scholar]

- SCCAD. Screw Compressor Design and Calculation Software. Scientific and Technological Achievements; Xi’an Jiaotong University: Xi’an, China, 2002. [Google Scholar]

- Xueming, H.; Zhengang, J.; Meiping, W.; Rong, Z.; Xiaogang, J. Research on Relationship between Rotor Profiles and Meshing Lines in Twin-screw Compressors. China Mech. Eng. 2017, 28, 763–770. [Google Scholar]

- Chunyang, J. Research on the Design of Double Helix Rotor Profile and Cutter Blade Shape. Ph.D. Thesis, Zhongnan University, Changsha, China, June 2013. [Google Scholar]

- Shi, G.-J.; He, X.-M.; Zhang, R. Research on Development of the Design System of Twin Screw Compressor Rotor Profiles. Compress. Technol. 2018, 5, 6–13. [Google Scholar]

- Jie, Z. Study on Machining Method of Screw Rotor in Oil-Free Screw Vacuum Pump. Ph.D. Thesis, Northeastern University, Shenyang, Liaoning, China, June 2015. [Google Scholar]

- Jia, Z. Research on the Segmented Grinding Technology of Large Screw Rotor. Ph.D. Thesis, Shaanxi Institute of Technology, Hanzhong, China, June 2015. [Google Scholar]

- Wang, H. Research on Inner Helical Surface Milling Processing Technology of Screw Drilling Tool Motor Stator. Ph.D. Thesis, Shenyang University of Technology University, Shenyang, China, January 2012. [Google Scholar]

- Song, R. Numerical Simulation Method for Profile Calculation of Disk Milling Cutter for Screw Machining. Ph.D. Thesis, Dalian Jiaotong University, Dalian, China, June 2015. [Google Scholar]

- Wang, K. Research for Milling with Non-Instantaneous-Pole Envelope Theory Applying Technology of Complex and Abnormal Helical Surface. Ph.D. Thesis, Tianjin University, Tianjin, China, June 2003. [Google Scholar]

- Sheth, D.S.; Malkin, S. CAD/CAM for Geometry and Process Analysis of Helical Groove Machining. CIRP Ann. Manuf. Technol. 1990, 41, 225–228. [Google Scholar] [CrossRef]

- Shan, J.; Jiang, X. Computer aided design of form milling cutter for helicodal surface. J. Zhejiang Univ. Technol. 2000, S1, 38–40. [Google Scholar]

- Yuchun, K.; Shu, F.; Longmei, W.; Haitao, R. Numerical Simulation Method of Forming Grinding Wheel Contour for Complex Spiral Curved Surfaces. J. Sichuan Univ. 2013, 2, 182–187. [Google Scholar]

- Liang, D.; Li-Min, D.; Ze-Wei, W.; Rui, W.; Liang, Y. Solution of grinding wheel machining drill bit with spiral groove based on Matlab. Heavy Mach. 2019, 6, 69–75. [Google Scholar]

- Li, J.; He, W.; Gao, J. Simulation and verification of profile of milling cutter for forming compressor screw arbor. Tool Technol. 2007, 1, 72–74. [Google Scholar]

- Zhang, L.; Zhang, R.; Zhao, F. A New CAD Method to Generate Manufacturing Tool of Helicoids. Mech. Des. Res. 2011, 2, 83–86. [Google Scholar]

- Lee, Y.S. Rapid Design of Forming Milling Cutter for Screw of Compressor for Coal Mine. Coal Mine Mach. 2020, 41, 90–92. [Google Scholar]

- Jiang, L. Analysis of Dynamic Characteristics of Spiral Surface of Milling Rotor with Disk Milling Cutter. Ph.D. Thesis, Shenyang University of Technology, Shenyang, China, June 2019. [Google Scholar]

- Wang, G. Study on Error Control in Forming Grinding of Screw Rotor with Complex Section. Ph.D. Thesis, Shaanxi Institute of Technology, Hanzhong, China, June 2015. [Google Scholar]

- Zhao, Y.; Hou, H.; Li, Z.; Zhou, B.; Tian, G. Research on twin—Screw compressor rotor precision grinding method. Manuf. Technol. Mach. Tool 2014, 2, 28–32. [Google Scholar]

- Hou, H.; Zhao, Y. Accurate calculation of rotor grinding parameters of twin screw compressor. J. Mach. Des. 2014, 10, 72–76. [Google Scholar]

- Wang, K. Fluid-Solid Coupling Analysis of T-Groove Dry Gas Seal. Ph.D. Thesis, Anhui University of Science and Technology, Huainan, China, June 2018. [Google Scholar]

- Yin, Z. Application Study of the Day Gas Seal in the Gas Screw Compress of the Crude Distillation Units. Ph.D. Thesis, Beijing University of Technology, Beijing, China, May 2013. [Google Scholar]

- Zhou, W. The sealing structure of the screw compressor. Lubr. Eng. 1988, 3, 67–68. [Google Scholar]

- Smith, I.K.; Stošič, N.; Aldis, C.A. Development of the trilateral flash cycle system. Part 3: The design of high-efficiency two-phase screw expanders. J. Power Energy 1996, 210, 75–93. [Google Scholar] [CrossRef]

- Giuffrida, A. Improving the semi-empirical modelling of a single-screw expander for small organic Rankine cycles. Appl. Energy 2017, 193, 356–368. [Google Scholar] [CrossRef]

- Qi, Y.; Yu, Y.; Hooman, K. Thermodynamic Simulation on the Performance of Twin Screw Expander Applied in Geothermal Power Generation. Energies 2016, 9, 694. [Google Scholar] [CrossRef]

- Tang, H.; Wu, H.; Wang, X.; Xing, Z. Performance study of a twin-screw expander used in a geothermal organic rankine cycle power generator. Energy 2015, 90, 631–642. [Google Scholar] [CrossRef]

- Tian, Y.; Xing, Z.; He, Z.; Wu, H. Modeling and performance analysis of twin-screw steam expander under fluctuating operating conditions in steam pipeline pressure energy recovery applications. Energy 2017, 141, 692–701. [Google Scholar] [CrossRef]

- Guo, S.; Ying, Z.; Shi, B.; Zhu, Y.; Pan, L. Effect of inlet vent on screw expander efficiency. Sci. Technol. Innov. Her. 2015, 23, 1–4. [Google Scholar]

- Buckney, D.; Kovacevic, A.; Mujic, E.; Stosic, N. Some Aspects of Estimating Geometric Characteristics of Screw Compressors. In Proceedings of the International Compressor Engineering Conference, Purdue, IN, USA, 16–19 July 2012. [Google Scholar]

- Seshaiah, N.; Ghosh, S.K.; Sahoo, R.K.; Sarangi, S.K. Mathematical modeling of the working cycle of oil injected rotary twin screw compressor. Appl. Therm. Eng. 2006, 27, 145–155. [Google Scholar] [CrossRef]

- Papes, I.; Degroote, J.; Vierendeels, J. Development of a thermodynamic low order model for a twin screw expander with emphasis on pulsations in the inlet pipe. Appl. Therm. Eng. 2016, 103, 909–919. [Google Scholar] [CrossRef]

- Kovacevic, A.; Rane, S. 3D CFD analysis of a twin screw expander. In Proceedings of the 8th International Conference on Compressors and their Systems, San Diego, CA, USA, 9–10 September 2013; pp. 417–429. [Google Scholar]

- Nikolov, A.; Huck, C.; Brümmer, A. Influence of Thermal Deformation on the Characteristic Diagram of a Screw Expander in the Automotive Application of Exhaust Heat Recovery. In Proceedings of the International Compressor Engineering Conference, Purdue, IN, USA, 16–19 July 2012. [Google Scholar]

- Baidu Encyclopedia; “Screw Compressor” Baidu Encyclopedia Entry [EB/OL]. Available online: https://baike.so.com/doc/5734536-5947281.html (accessed on 8 July 2020).

- Kaishan Compressor Co. LTD. The Screw Swelling Machine Sends Electricity. [EB/OL]. Available online: http://www.kaishancomp.com/product.asp (accessed on 8 December 2019).

- Wenjuan, S.; Jiangxi Huadian Electric Power Co., Ltd. Has Successfully Developed the Summary of Screw Rod Expansion Power Machine. Available online: http://jxxy.jxnews.com.cn/system/2013/06/28/012490596.shtml (accessed on 8 December 2019).

- Yu, Y.; Hu, D.; Wu, F. Applications of the Screw Expander in Geothermal Power Generation in China. In Proceedings of the World Geothermal Congress 2015, Melbourne, Australia, 19–25 April 2015. [Google Scholar]

- Weng, Y. Conversion Process and Utilization of Low Grade Heat Energy; Xi’an Jiao Tong University Press: Xi’an, China, 2014; pp. 5–9. ISBN 978-7-313-12376-3. [Google Scholar]

- Chen, L. Performance Analysis and Matching Research of Expander for Solar Energy Multi-Feeder System. Ph.D. Thesis, North China Electric Power University, Beijing, China, March 2019. [Google Scholar]

- Iodice, P.; Langella, G.; Amoresano, A. Energy performance and numerical optimization of a screw expander–based solar thermal electricity system in a wide range of fluctuating operating conditions. Int. J. Energy Res. 2020, 44, 1858–1874. [Google Scholar] [CrossRef]

- Zhou, Y.; Lu, S.; Xie, K. Research of Organic Mediums Used in Rankin Cycle in Screw Expander. Chem. Equip. Pip. 2019, 56, 47–52. [Google Scholar]

- Zhang, Y.; Wu, Y.; Xia, G.; Ma, C.; Ji, W.; Liu, S.; Wang, J.; Guo, H. Performance Study on Single-screw Expander in Organic Rankine Cycle System. J. Mech. Eng. 2015, 51, 156–163. [Google Scholar] [CrossRef]

- Lanzhou da Cheng Screw Expansion Generator Solar Energy Collector Project. Available online: http://www.jxhdep.com/newsInfo.asp?id=284&pid=83 (accessed on 3 June 2020).

- Yin, L. Marine low-carbon Energy: A new Generation of Offshore Energy. High Technol. Ind. 2020, 9, 39–41. [Google Scholar]

- Wang, C.; Yee, A.; Tay, H.K.Z.Y. Research and developments on ocean thermal energy conversion. IES J. Part A Civ. Struct. Eng. 2011, 4, 41–52. [Google Scholar] [CrossRef]

- Feng, G.; Zhong, S. Research status and prospect of ocean thermal energy conversion. J. Northeast Electr. Power Univ. 2011, 31, 72–77. [Google Scholar]

- Juan, Y.; Ting, Y.; Da-Shu, L.I.; Zhi-Chuan, L. Study on the Up-to-Date Progress and Suggestions for Ocean Thermal Energy Conversion Technologies. J. Oceanogr. Technol. 2017, 4, 82–87. [Google Scholar]

- Kang, J.M. IGU World LNG Report 2019; Technical Report; International Gas Union (IGU): Vevey, Switzerland, 2019. [Google Scholar]

- Liu, Z.; Karimi Iftekhar, A.; He, T. A novel inlet air cooling system based on liquefied natural gas cold energy utilization for improving power plant performance. Energy Convers Manag. 2019, 187, 41–52. [Google Scholar] [CrossRef]

- Wu, X.; Cai, L.; Li, T.; Yang, X.; Yu, P. Latest progress of LNG cold energy utilization technology. Oil Gas Storage Transp. 2017, 36, 624–635. [Google Scholar]

- Zhang, L. Research on Waste Heat Recovery and Utilization System Based on LNG Cold Energy. Ph.D. Thesis, Liaoning University of Petroleum and Chemical Technology, Fushun, China, June 2019. [Google Scholar]

- Chen, L.; Xu, P.; Sun, L.; Dong, W.; Ma, K. Analysis on the current situation of LNG cold power generation technology. Nat. Gas Oil 2013, 6. Available online: https://www.semanticscholar.org/paper/Analysis-on-Current-Situation-of-LNG-Cold-Energy-Lng/f5e8c005dc2703a7fcca1cc88e630efc1196c7c1#citing-papers (accessed on 9 December 2020).

| Industry | Source of Waste Heat Resources | Percentage of Fuel Consumption |

|---|---|---|

| Metallurgy | Rolling steel heating furnace, Soaking pit, Open hearth furnace, Blast furnace | above 33% |

| Chemical | Chemical reaction heat, Combustible chemical heat, etc. | above 15% |

| Building material | High-temperature flue gas, Kiln crow cooling and high temperature products, etc. | approx. 40% |

| Glass | Glass melter, enameling furnace, pot furnace, etc. | approx. 20% |

| Papermaking | Drying cylinder, steamer, waste gas, black liquor, etc. | approx. 15% |

| Textile | Dryer, slasher, digester, etc. | approx. 15% |

| Machinery | Forged reheating furnace, cupola furnace, heat treatment furnace, etc. | approx. 15% |

| Type | Power Range/kW | Advantages | Disadvantages | |

|---|---|---|---|---|

| velocity based (turbines) expanders | Radial flow | 50–1000 | High isentropic efficiency; Small losses of all kinds; Compact structure; Single stage expansion is relatively large; Good sealing; Manufacturing mature. | High speed; Price is high; Not suitable for small power units. |

| Axial flow | >250 | In large units, the entropy efficiency is higher; The power of the single machine can be maximized, and the expansion ratio of the multistage expansion is also very large; Long life. | The number of impellers is large and the manufacturing cost is high; High maintenance cost; The clearance loss and friction loss are larger in small units. | |

| positive displacement (volumetric) expanders | Scroll expander | 1–20 | No valve, less moving parts; Low speed; Easy to manufacture; The cost is low. | Lubrication system is required; Small power; The loss of power is large, mainly due to friction, suction and internal leakage. |

| Screw expander | 15–500 | Less moving parts, less loss; High volume efficiency; Suitable for two phase flow; High flexibility; Low speed. | Lubrication system is required; High machining accuracy requirement. | |

| Slide expander | 1–10 | Suitable for two phase flow; Simple structure; Low speed. | Sealing problem; Small power. | |

| Piston expander | 20–100 | Suitable for two phase flow; Compared with other positive displacement expander, the expansion is higher; Applicable to off-duty conditions; The cost is low. | Many moving parts, complex manufacturing, loss; The weight is big, heavy; Flow resistance exists in inlet and outlet valves; With other capacity, the product expander is less efficient than the product expander. | |

| Project | HOLROYD TG350E | KLINGELNBERH H35R | KAPP RJ59 | SK7032 |

|---|---|---|---|---|

| Maximum mounting diameter/mm | 350 | 350 | 320 | 320 |

| Maximum spiral angle/(°) | ±60 | ±60 | ±60 | ±60 |

| The maximum stroke/mm | 1160 | 660 | 500/1000 | 850 |

| Grinding wheel spindle maximum speed/(r/min) | 3000 | 3600 | 8000 | 2700 |

| Maximum grinding wheel diameter/mm | 500 | 500 | CNB | 500 |

| Maximum workpiece weight | 500 | 400 | 350 | |

| Degree of automation | high | high | high | high |

| Automatic feeding of grinding wheel dressing | + | + | + | + |

| On-line measurement function | + | + | + | − |

| On-line measurement function | + | + | + | − |

| Compensation for tooth profile error compensation | + | + | + | − |

| Powerful grinding function | + | + | + | − |

| Year | 1990 | 2000 | 2010 | 2020 | |

|---|---|---|---|---|---|

| Region | |||||

| North America | 3 | 6 | 24 | 85 | |

| Latin America | 1 | 2 | 8 | 33 | |

| Western Europe | 1 | 2 | 8 | 33 | |

| Russia and Eastern Europe | 1 | 2 | 9 | 26 | |

| Middle East/North Africa | 2 | 3 | 9 | 29 | |

| Sub-Saharan Africa | 1 | 2 | 6 | 18 | |

| Pacific Ocean/China | 1 | 1 | 6 | 23 | |

| Central Asia/South Asia | 1 | 3 | 17 | 77 | |

| Total | 2 | 3 | 14 | 64 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, J.; Hua, Q.; Wang, J.; Jiang, Z.; Wang, J.; Yuan, L. Overview of the Development and Application of the Twin Screw Expander. Energies 2020, 13, 6586. https://doi.org/10.3390/en13246586

Wei J, Hua Q, Wang J, Jiang Z, Wang J, Yuan L. Overview of the Development and Application of the Twin Screw Expander. Energies. 2020; 13(24):6586. https://doi.org/10.3390/en13246586

Chicago/Turabian StyleWei, Junying, Qi Hua, Jidai Wang, Zheng Jiang, Jihong Wang, and Liang Yuan. 2020. "Overview of the Development and Application of the Twin Screw Expander" Energies 13, no. 24: 6586. https://doi.org/10.3390/en13246586

APA StyleWei, J., Hua, Q., Wang, J., Jiang, Z., Wang, J., & Yuan, L. (2020). Overview of the Development and Application of the Twin Screw Expander. Energies, 13(24), 6586. https://doi.org/10.3390/en13246586