Improvement of Strength Parameters of Cement Matrix with the Addition of Siliceous Fly Ash by Using Nanometric C-S-H Seeds

Abstract

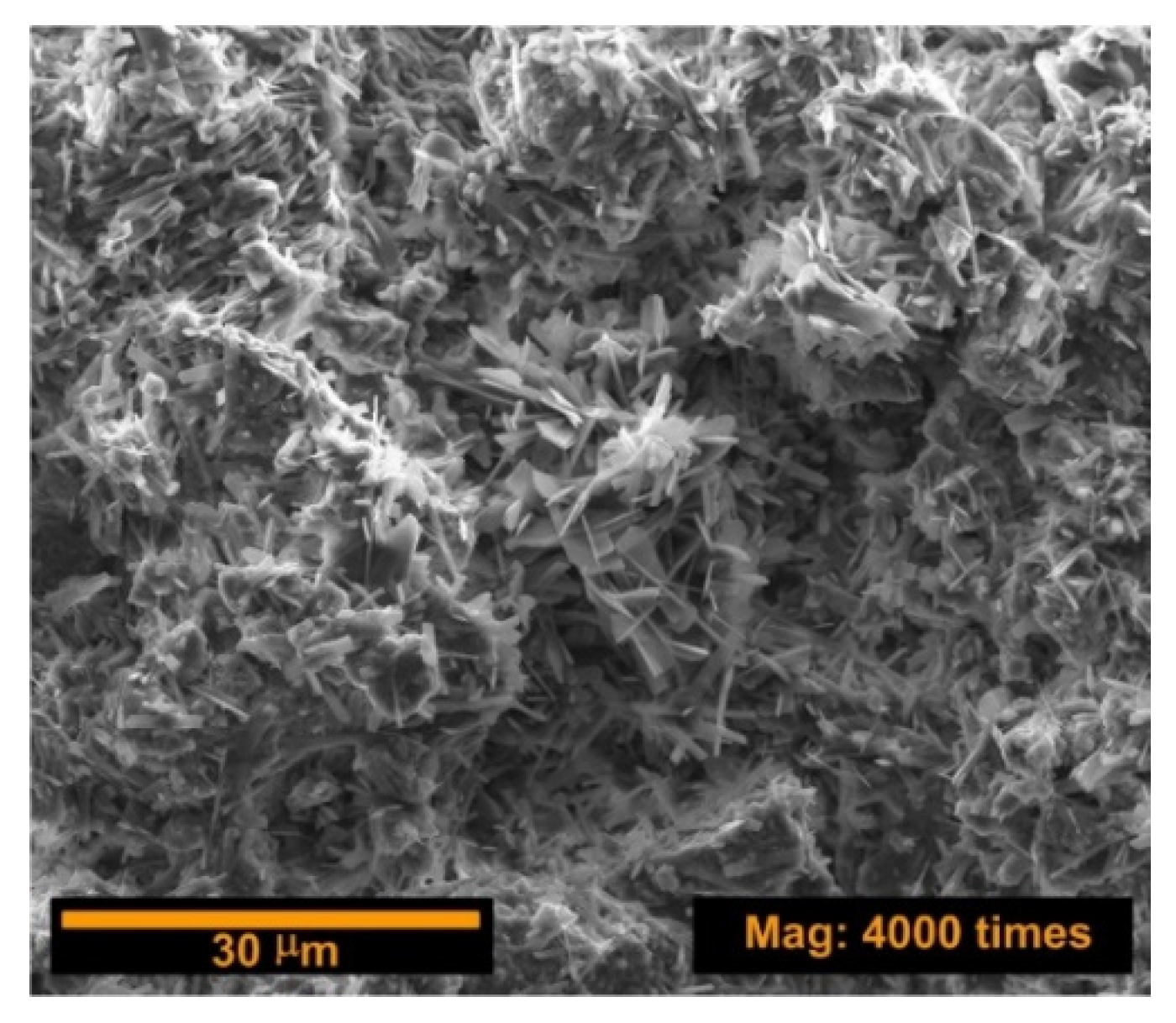

:1. Introduction

- clearly no negative influence of the preparation on reinforcement in reinforced concrete structures;

- no adverse interaction with organic aggregates.

2. Experimental Program

2.1. General Assumptions

2.2. Materials

2.3. Scope of the Experiments

- the compressive strength—fc;

- the tensile strength—fcf;

- the hydration heat.

2.4. Testing Procedures

2.4.1. Tensile and Compressive Strength Tests

- fcf—tensile strength (MPa);

- F—destructive force (N);

- l—spacing of supports (mm);

- d1, d2—dimensions of the sample (width and height) (mm).

- fc—compressive strength (MPa);

- F—destructive force (N);

- —the surface area of the sample to be tested—40 × 40 mm (mm2).

2.4.2. Hydration Heat Test

- —thermoelectric power of semiconductor thermoelectric cells of the microcalorimeter;

- —appropriate heat transfer coefficients and the calorimeter time constant determined in the reference measurement.

3. Results and Discussion

3.1. Strength Tests Results

3.2. Hydration Heat Test Results

4. Summary and Conclusions

- in the concrete prefabrication technology;

- in concretes used in active repairs;

- in sprayed concretes;

- in a modern technology of printing buildings in 3D.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Giergiczny, Z. Fly ash and slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- Golewski, G.L.; Sadowski, T. A study of mode III fracture toughness in young and mature concrete with fly ash additive. Solid State Phenom. 2016, 254, 120–125. [Google Scholar] [CrossRef]

- Golewski, G.L. Studies of natural radioactivity of concrete with siliceous fly ash addition. Cem. Wapno Beton 2015, 2, 106–114. [Google Scholar]

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.; Hu, S.; Ling, Y. Properties of fresh and hardened fly ash/slag based geopolymer concrete: A review. J. Clean. Prod. 2020, 270, 122389. [Google Scholar] [CrossRef]

- Zhang, R.; Guo, F.; Xia, Y.; Tan, J.; Xing, Y.; Gui, X. Recovering unburned carbon from gasification fly ash using saline water. Waste Manag. 2019, 98, 29–36. [Google Scholar] [CrossRef]

- Bicer, A. Effect of production temperature on thermal and mechanical properties of polystyrene-fly ash composites. Adv. Compos. Lett. 2020, 29, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Kovacik, J.; Marsavina, L.; Linul, E. Poisson’s ratio of closed-cell aluminum foams. Materials 2018, 11, 1904. [Google Scholar] [CrossRef] [Green Version]

- Golewski, G.L. A novel specific requirements for materials used in reinforced concrete composites subjected to dynamic loads. Compos. Struct. 2019, 223, 110939. [Google Scholar] [CrossRef]

- Golewski, G.L. A new principles for implementation and operation of foundations for machines: A review of recent advances. Struct. Eng. Mech. 2019, 71, 317–327. [Google Scholar]

- Raheel, M.; Rahman, F.; Ali, Q. A stoichiometric approach to find optimum amount of fly ash needed in cement concrete. SN Appl. Sci. 2020, 2, 1100. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rukzon, S. Strength, porosity and corrosion resistance of ternary blend Portland cement, rice husk ash and fly ash mortar. Constr. Build. Mater. 2008, 22, 1601–1606. [Google Scholar] [CrossRef]

- Candamano, S.; Crea, F.; Iorfida, A. Mechanical characterization of basalt fabric-reinforced alkali-activated matrix composite: A preliminary investigation. Appl. Sci. 2020, 10, 2865. [Google Scholar] [CrossRef] [Green Version]

- Zhang, P.; Han, S.; Golewski, G.L.; Wang, X. Nanoparticle-reinforced building materials with applications in civil engineering. Adv. Mech. Eng. 2020, 12, 1–4. [Google Scholar] [CrossRef]

- Cai, X.; He, Z.; Tang, S.; Chen, X. Abrasion erosion characteristics of concrete made with moderate heat Portland cement, fly ash and siliceous fume using sandblasting test. Constr. Build. Mater. 2016, 127, 804–814. [Google Scholar] [CrossRef]

- Golewski, G.L. Changes in the fracture toughness under mode II loading of low calcium fly ash (LCFA) concrete depending on ages. Materials 2020, 13, 5241. [Google Scholar] [CrossRef] [PubMed]

- Golewski, G.L. Determination of fracture toughness in concretes containing siliceous fly ash during mode III loading. Struct. Eng. Mech. 2017, 62, 1–9. [Google Scholar] [CrossRef]

- Hu, X.; Shi, C.; Shi, Z.; Tong, B.; Wang, D. Early age shrinkage and heat of hydration of cement-fly ash-slag ternary blends. Constr. Build. Mater. 2017, 153, 857–865. [Google Scholar] [CrossRef]

- Joshaghani, A. The effect of trass and fly ash in minimizing alkali-carbonate reaction in concrete. Constr. Build. Mater. 2017, 150, 583–590. [Google Scholar] [CrossRef]

- Golewski, G.; Sadowski, T. Fracture toughness at shear (mode II) of concretes made of natural and broken aggregates. Brittle Matrix Compos. 2006, 8, 537–546. [Google Scholar]

- Bandura, L.; Panek, R.; Madej, J.; Franus, W. Synthesis of zeolite-carbon composites using high-carbon fly ash and their adsorption abilities towards petroleum substances. Fuel 2021, 283, 119173. [Google Scholar] [CrossRef]

- Szcześniak, A.; Zychowicz, J.; Stolarski, A. Influence of fly ash additive on the properties of concrete with slag cement. Materials 2020, 13, 3265. [Google Scholar] [CrossRef] [PubMed]

- Gil, D.M.; Golewski, G.L. Potential of siliceous fly ash and silica fume as a substitute of binder in cementitious concrete. E3S Web Conf. 2018, 49, 00030. [Google Scholar] [CrossRef] [Green Version]

- Gil, D.M.; Golewski, G.L. Effect of silica fume and siliceous fly ash addition on the fracture toughness of plain concrete in mode I. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012065. [Google Scholar] [CrossRef]

- Golewski, G.L. The influence of microcrack width on the mechanical parameters in concrete with the addition of fly ash: Consideration of technological and economical benefits. Constr. Build. Mater. 2019, 197, 849–861. [Google Scholar] [CrossRef]

- Suchorab, Z.; Franus, M.; Barnat-Hunek, D. Properties of fibrous concrete made with plastic fibers from E-Waste. Materials 2020, 13, 2414. [Google Scholar] [CrossRef]

- Gastaldini, A.L.G.; Isaia, G.C.; Saciloto, A.P.; Missau, F.; Hoppe, T.F. Influence of curing time on the chloride resistance of concrete containing rice husk ash: A technical and economical feasibility study. Cem. Concr. Compos. 2010, 32, 783–793. [Google Scholar] [CrossRef]

- Golewski, G.L. Energy savings associated with the use of fly ash and nanoadditives in the cement composition. Energies 2020, 13, 2184. [Google Scholar] [CrossRef]

- Ye, J.; Zubair, M.; Wang, S.; Cai, Y.; Zhang, P. Power production waste. Water Environ. Res. 2019, 91, 858–868. [Google Scholar] [CrossRef] [Green Version]

- Chalangaran, N.; Farzampour, A.; Paslar, N. Nano silica and metakaolin effects on the behaviour of concrete containing rubber crumbs. Civ. Eng. 2020, 1, 264–274. [Google Scholar]

- Golewski, G.L.; Sadowski, T. The fracture toughness the KIIIc of concretes with fly ash (FA) additive. Constr. Build. Mater. 2017, 143, 444–454. [Google Scholar] [CrossRef]

- Papadakis, V.G. Effect of fly ash of Portland cement systems. Part I. Low-calcium fly ash. Cem. Concr. Res. 1999, 29, 1727–1736. [Google Scholar] [CrossRef]

- Golewski, G.L. An analysis of fracture toughness in concrete with fly ash addition, considering all models of cracking. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012029. [Google Scholar] [CrossRef] [Green Version]

- Siddique, R. Effect of fine aggregate replacement with Class F fly ash on the mechanical properties of concrete. Cem. Concr. Res. 2003, 33, 539–547. [Google Scholar] [CrossRef]

- Sadowski, T.; Golewski, G.L. A failure analysis of concrete composites incorporating fly ash during torsional loading. Compos. Struct. 2018, 183, 527–535. [Google Scholar] [CrossRef]

- Dragas, J.; Tosic, N.; Ignatovic, S.; Marinkovic, S. Mechanical and time-dependent properties of high-volume fly ash concrete for structural use. Mag. Concr. Res. 2016, 68, 632–645. [Google Scholar] [CrossRef]

- Golewski, G.L. Effect of curing time on the fracture toughness of fly ash concrete composites. Compos. Struct. 2018, 185, 105–112. [Google Scholar] [CrossRef]

- Golewski, G.L.; Sadowski, T. Experimental investigation and numerical modeling fracture processes in fly ash concrete at early age. Solid State Phenom. 2012, 188, 158–163. [Google Scholar] [CrossRef]

- Szeląg, M. Development of cracking patterns in modified cement matrix with microsilica. Materials 2018, 11, 1928. [Google Scholar] [CrossRef] [Green Version]

- Plank, J.; Sakai, E.; Miao, C.W.; Yu, C.; Hong, J.X. Chemical admixtures—Chemistry, applications and their impact on concrete microstructure and durability. Cem. Concr. Res. 2015, 78, 81–99. [Google Scholar] [CrossRef]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete—A review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Sobolev, K.; Gutierrez, M.F. How nanotechnology can change the concrete world. Am. Cer. Soc. Bull. 2005, 10, 14–18. [Google Scholar]

- Szostak, B.; Golewski, G.L. Effect of nano admixture of CSH on selected strength parameters of concrete including fly ash. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012105. [Google Scholar] [CrossRef]

- Sadowski, L.; Hola, J.; Czarnecki, L.; Mathia, T.G. New paradigm in the metrology of concrete surface morphology: Methods, parameters and applications. Measurement 2020, 169, 108497. [Google Scholar] [CrossRef]

- Zou, F.; Shen, K.; Hu, C.; Wang, F.; Yang, L.; Hu, S. Effect of sodium sulfate and C-S-H seeds on the reaction of fly ash with different amorphous alumina contents. ACS Sustain. Chem. Eng. 2020, 8, 1659–1670. [Google Scholar] [CrossRef]

- Zhang, P.; Wan, J.; Wang, K.; Li, Q. Influence of nano-SiO2 on properties of fresh and hardened high performance concrete: A state of the art review. Constr. Build. Mater. 2017, 148, 648–658. [Google Scholar] [CrossRef]

- Thomas, J.J.; Jennings, H.M.; Chen, J.J. Influence of Nucleation seeding on the hydration mechanisms of tricalcium silicate and cement. J. Phys. Chem. C 2009, 113, 4327–4334. [Google Scholar] [CrossRef] [Green Version]

- Antonovic, V.; Pundiene, I.; Stpnys, R.; Cesniene, J.; Kariene, J. A review of the possible applications of nanotechnology in refractory concrete. J. Civ. Eng. Manag. 2010, 16, 595–602. [Google Scholar] [CrossRef]

- John, E.; Matschei, T.; Stephan, D. Nucleation seeding with calcium silicate hydrate—A review. Cem. Concr. Res. 2018, 113, 74–85. [Google Scholar] [CrossRef]

- Land, G.; Stephan, D. The effect of synthesis conditions on the efficiency of C-S-H seeds to accelerate cement hydration. Cem. Concr. Compos. 2018, 87, 73–78. [Google Scholar] [CrossRef]

- Wang, B.; Yao, W.; Stephan, D. Preparation of calcium silicate hydrate seeds by means of mechanochemical method and its effect on the early hydration of cement. Adv. Mech. Eng. 2019, 11, 1–7. [Google Scholar] [CrossRef]

- Zou, F.; Hu, C.; Wang, F.; Ruan, Y.; Hu, S. Enhancement of early-age strength of the high content fly ash blended cement paste by sodium sulfate and C-S-H seeds towards a greener binder. J. Clean. Prod. 2020, 244, 118566. [Google Scholar] [CrossRef]

- Wang, F.; Kong, X.; Jiang, L.; Wang, D. The acceleration mechanism of nano C-S-H particles on OPC hydration. Constr. Build. Mater. 2020, 249, 118734. [Google Scholar] [CrossRef]

- Pużak, T. Nanotechnologia—Przyszłość prefabrykacji betonowej. Mater. Bud. 2010, 11, 16–18. (In Polish) [Google Scholar]

- Li, H.; Sun, H.; Tian, J.; Yang, Q.; Wan, Q. Mechanical and ultraconic testing of self-compacting concrete. Energies 2019, 12, 2187. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Sun, H.; Zhang, W.; Gou, H.; Yang, Q. Study on mechanical properties of self-compacting concrete and its filled in-line multi-cavity steel tube bundle shear wall. Energies 2019, 12, 3466. [Google Scholar] [CrossRef] [Green Version]

- Jagadesh, P.; Ramachandra Murthy, A.; Murugesan, R. Effect of processed sugar cane bagasse ash on mechanical and fracture properties of blended mortar. Constr. Build. Mater. 2020, 262, 120846. [Google Scholar] [CrossRef]

- Szeląg, M. Mechano-physical properties and microstructure of carbon nanotube reinforced cement paste after thermal load. Nanomaterials 2017, 7, 267. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.; Li, S.; Huang, H.; Li, J.; Kobayashi, N. Effect of carbon nanoadditives on lithium hydroxide monohydrate-based composite materials for low temperature chemical heat storage. Energies 2017, 10, 644. [Google Scholar] [CrossRef] [Green Version]

- Rahmani, E.; Kazem Sharbatdar, M.; Beygi, M.H.A. The effect of water -to-cement ratio on the fracture behaviors and ductility of Roller Compacted Concrete Pavement (RCCP). Theor. Appl. Fract. Mech. 2020, 109, 102753. [Google Scholar] [CrossRef]

- EN 196-1:2016. Methods of Testing Cement. Determination of Strength; NSAI Standards: Dublin, Ireland, 2016. [Google Scholar]

- Salvador, R.P.; Cavalaro, S.H.P.; Segura, I.; Figueiredo, A.D.; Pérez, J. Early age hydration of cement pastes with alkaline and alkali-free accelerators for sprayed concrete. Constr. Build. Mater. 2016, 111, 386–398. [Google Scholar] [CrossRef]

- Szostak, B.; Golewski, G.L. Modification of early strength parameters of concrete by the addition of fly ash and admixture of nano C-S-H for application in 3D printing. MATEC Web Conf. 2020, 323, 01016. [Google Scholar] [CrossRef]

- Golewski, G.L. Effect of fly ash addition on the fracture toughness of plain concrete at third model of fracture. J. Civ. Eng. Manag. 2017, 23, 613–620. [Google Scholar] [CrossRef] [Green Version]

- Zhou, S.; Zhang, Y.; Zhou, D.; Wang, W.; Li, D.; Ke, Z. Experimental study on mechanical properties of fly ash stabilized with cement. Adv. Civ. Eng. 2020, 2020, 6410246. [Google Scholar]

- Golewski, G.L.; Sadowski, T. Macroscopic evaluation of fracture processes in fly ash concrete. Solid State Phenom. 2016, 254, 188–193. [Google Scholar] [CrossRef]

- Golewski, G.L. Estimation of the optimum content of fly ash in concrete composite based on the analysis of fracture toughness tests using various measuring systems. Constr. Build. Mater. 2019, 213, 142–155. [Google Scholar] [CrossRef]

| Series Designation | OPC | FA | Water | NA—Master X-Seed 100 |

|---|---|---|---|---|

| F20C0 | 1046 | 262 | 392 | - |

| F20C4 | 1046 | 262 | 340 | 52 |

| Component | Content Expressed in (% by mass) | Share of Mineral Phases (% by mass) |

|---|---|---|

| SiO2 | 15.00% | C3S—61.0% |

| Al2O3 | 2.78% | C2S—12.5% |

| Fe2O3 | 2.72% | C3A—8.6% |

| CaO | 71.06% | C4AF—4.3% |

| MgO | 1.38% | - |

| SO3 | 4.56% | - |

| K2O | 1.213% | - |

| Cl | 0.08% | - |

| Insoluble Residue | 1.27% | - |

| Loss of Roasting | 3.64% | - |

| Component | SiO2 | Al2O3 | Fe2O3 | K2O | SO3 | MgO | CaO | P2O5 | Ag2O | BaO | TiO2 | SrO | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Content [% by mass] | 55.27 | 26.72 | 6.66 | 3.01 | 0.47 | 0.81 | 2.35 | 1.92 | 0.10 | 0.10 | 1.89 | 0.22 | 4.66 |

| SiO2 + Al2O3 + Fe2O3 = 88.65 ≥ 70.00% | |||||||||||||

| Particle Size (μm) | % Volume |

|---|---|

| 0.01−2 | 1.12 |

| 2−20 | 23.72 |

| 20−50 | 20 |

| 50−100 | 21.59 |

| 100−250 | 25.49 |

| 250−500 | 5.99 |

| 500−1000 | 1.09 |

| 1000−2000 | 0.93 |

| Sample Designation | Test Period | fc | s | V | fc,max | fc,min |

|---|---|---|---|---|---|---|

| F20C0 | 8 h | 1.19 | 0.07 | 5.81% | 1.26 | 1.06 |

| F20C4 | 8 h | 5.11 | 0.17 | 3.25% | 5.33 | 4.89 |

| F20C0 | 12 h | 3.32 | 0.12 | 3.62% | 3.50 | 3.13 |

| F20C4 | 12 h | 9.06 | 0.45 | 4.95% | 9.68 | 8.38 |

| F20C0 | 24 h | 18.87 | 0.73 | 3.87% | 20.07 | 18.01 |

| F20C4 | 24 h | 32.41 | 0.82 | 2.52% | 33.72 | 31.36 |

| F20C0 | 72 h | 49.81 | 0.93 | 1.87% | 50.98 | 48.84 |

| F20C4 | 72 h | 53.78 | 2.10 | 3.91% | 56.35 | 51.31 |

| F20C0 | 7 d | 55.33 | 2.28 | 4.13% | 58.59 | 51.59 |

| F20C4 | 7 d | 55.43 | 1.97 | 3.55% | 57.91 | 52.68 |

| F20C0 | 14 d | 55.45 | 2.10 | 3.78% | 58.01 | 51.32 |

| F20C4 | 14 d | 56.17 | 2.79 | 4.97% | 59.25 | 51.34 |

| F20C0 | 28 d | 104.65 | 3.56 | 3.40% | 109.91 | 97.88 |

| F20C4 | 28 d | 107.28 | 5.76 | 5.37% | 113.59 | 95.13 |

| Sample Designation | Test Period | fcf | s | V | fcf,max | fcf,min |

|---|---|---|---|---|---|---|

| FA20C0 | 8 h | 0.04 | 0.00 | 3.98% | 0.04 | 0.04 |

| FA20C4 | 8 h | 0.09 | 0.02 | 20.44% | 0.11 | 0.07 |

| FA20C0 | 12 h | 0.07 | 0.02 | 22.26% | 0.08 | 0.05 |

| FA20C4 | 12 h | 0.11 | 0.03 | 25.74% | 0.14 | 0.08 |

| FA20C0 | 24 h | 0.38 | 0.02 | 5.40% | 0.40 | 0.35 |

| FA20C4 | 24 h | 0.46 | 0.04 | 9.00% | 0.51 | 0.41 |

| FA20C0 | 72 h | 1.08 | 0.10 | 9.24% | 1.22 | 1.00 |

| FA20C4 | 72 h | 1.11 | 0.09 | 8.34% | 1.22 | 1.00 |

| FA20C0 | 7 d | 2.77 | 0.21 | 7.57% | 3.04 | 2.53 |

| FA20C4 | 7 d | 2.44 | 0.19 | 7.71% | 2.70 | 2.27 |

| FA20C0 | 14 d | 3.11 | 0.15 | 4.73% | 3.31 | 2.97 |

| FA20C4 | 14 d | 2.84 | 0.06 | 2.04% | 2.89 | 2.76 |

| FA20C0 | 28 d | 6.00 | 0.03 | 0.54% | 6.05 | 5.96 |

| FA20C4 | 28 d | 6.05 | 0.15 | 2.53% | 6.25 | 5.89 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szostak, B.; Golewski, G.L. Improvement of Strength Parameters of Cement Matrix with the Addition of Siliceous Fly Ash by Using Nanometric C-S-H Seeds. Energies 2020, 13, 6734. https://doi.org/10.3390/en13246734

Szostak B, Golewski GL. Improvement of Strength Parameters of Cement Matrix with the Addition of Siliceous Fly Ash by Using Nanometric C-S-H Seeds. Energies. 2020; 13(24):6734. https://doi.org/10.3390/en13246734

Chicago/Turabian StyleSzostak, Bartosz, and Grzegorz Ludwik Golewski. 2020. "Improvement of Strength Parameters of Cement Matrix with the Addition of Siliceous Fly Ash by Using Nanometric C-S-H Seeds" Energies 13, no. 24: 6734. https://doi.org/10.3390/en13246734

APA StyleSzostak, B., & Golewski, G. L. (2020). Improvement of Strength Parameters of Cement Matrix with the Addition of Siliceous Fly Ash by Using Nanometric C-S-H Seeds. Energies, 13(24), 6734. https://doi.org/10.3390/en13246734