A Geothermal-Solar Hybrid Power Plant with Thermal Energy Storage

Abstract

:1. Introduction

- (a)

- A purely ORC geothermal mode during the hours of lower electric power demand.

- (b)

- A hybrid ORC geothermal-solar mode with thermal energy storage, which is converted to electricity during the higher electric power demand of the late afternoon hours.

- The proposed unit generates renewable power that may be contracted and dispatched and avoids the adverse effects of the duck curve.

- The power of the unit is significantly augmented at times of peak power demand, a very attractive feature for any renewable energy unit.

- The addition of superheat in the supercritical cycle avoids the two-phase turbine expansion.

- The thermal efficiency of the superheat cycle is significantly higher than the efficiencies of comparable solar thermal units and geothermal subcritical ORC units.

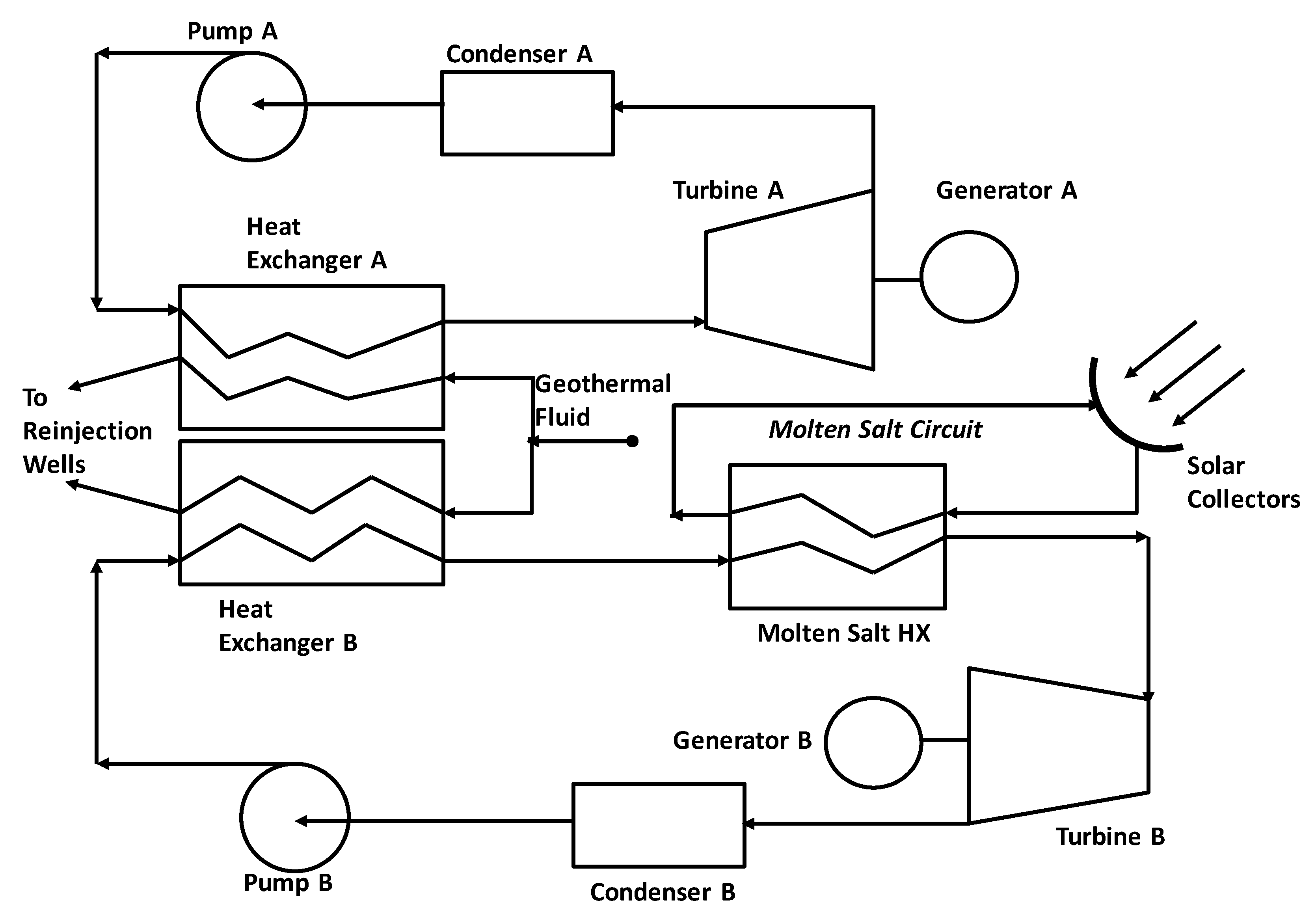

2. System Description and Operation

- A.

- When there is no solar energy (nighttime) and when the electricity demand is not high (winter), the plant operates as an optimized geothermal binary plant, using butane as the working fluid, with subcritical butane vapor produced in a counter-current heat exchanger. While it is well-known that the working fluid of the ORC may be optimized [23], this type of optimization is not in the focus of this study. The working fluid selection through optimization is beyond a conceptual study and, for brevity we decided to only present results for butane, because its critical temperature is close to the type of geothermal energy resources (140–170 °C) that will be utilized in the next generation of power plants [4]. At these resource temperatures, butane is the most suitable working fluid to be used in a Rankine cycle [23]. It must be noted that geothermal resources at these lower temperatures exist in several countries and regions with geothermal potential including the USA, Mexico, the countries of Central America, East Africa, the Mediterranean Countries, Japan, Philippines, and P.R. China.

- B.

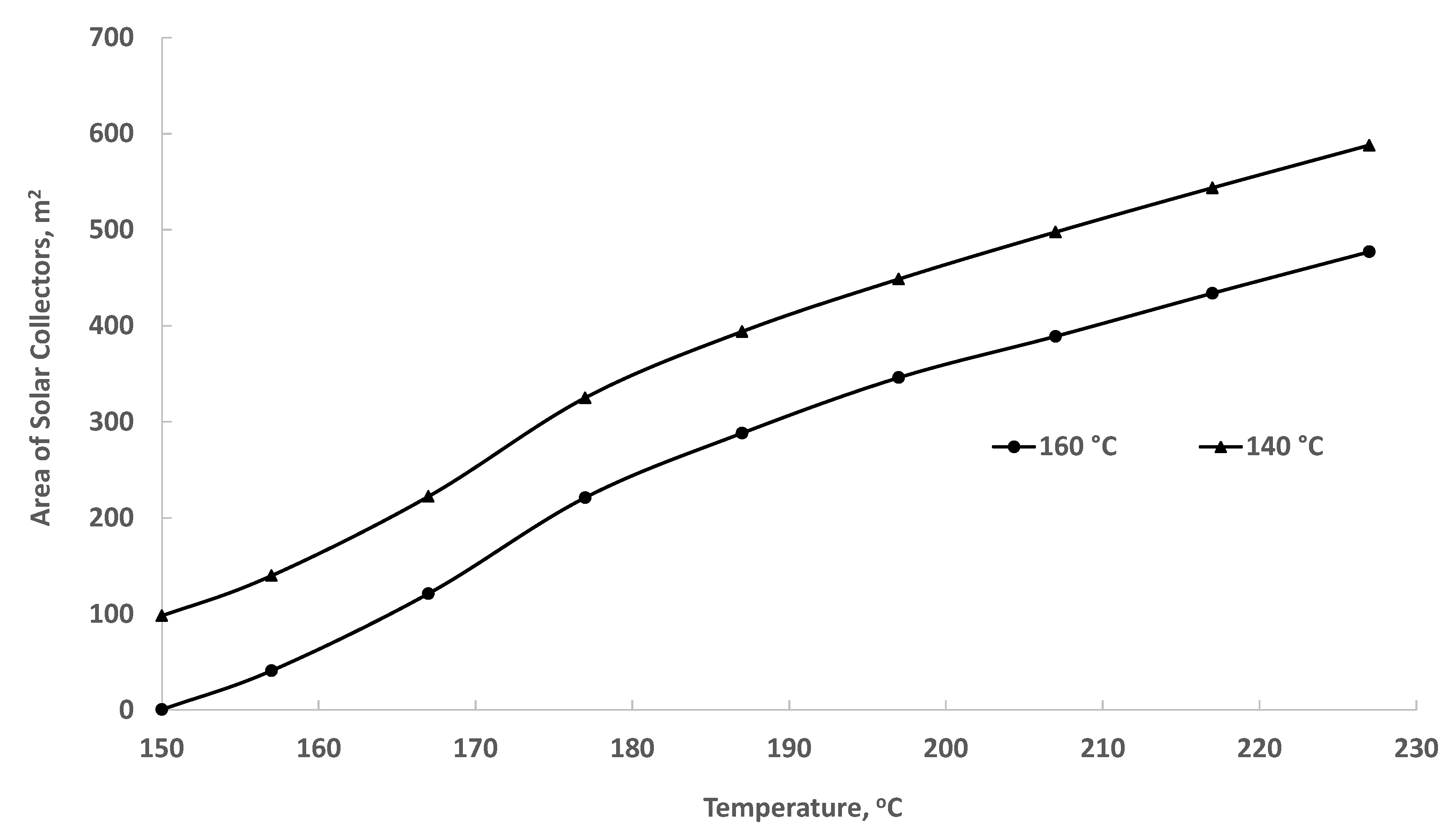

- At the peak electricity demand hours, the unit operates at supercritical pressures. Heat is supplied to the working fluid, first by the geothermal fluid in a counter-current heat exchanger and secondly by irradiance. The latter is collected in parabolic collectors, similar to those suggested in [10], and stored as heat in a tank of molten salts. Heat storage enables the unit to operate steadily for several hours in the afternoon and early evening and to supply significantly higher electric power when the electricity demand is high.

- The power system may operate in mode 2 even after sundown during the early evening hours, when the electricity demand is still high.

- The energy storage system makes the ORC immune from diurnal fluctuations of irradiance resulting from the position of the sun and possible cloudiness. The geothermal fluid is supplied at steady-state for the entire duration of the plant’s operation.

- 1-2

- Heating by the geothermal resource

- 2-3

- Additional heating by solar irradiance.

- 3-4

- Turbine expansion

- 4-5

- Condensation

- 5-1

- Pressurization

3. Governing Equations

3.1. Mode 1, Non-Peak Hours

3.2. Mode 2, Peak Hours

4. Results and Discussion

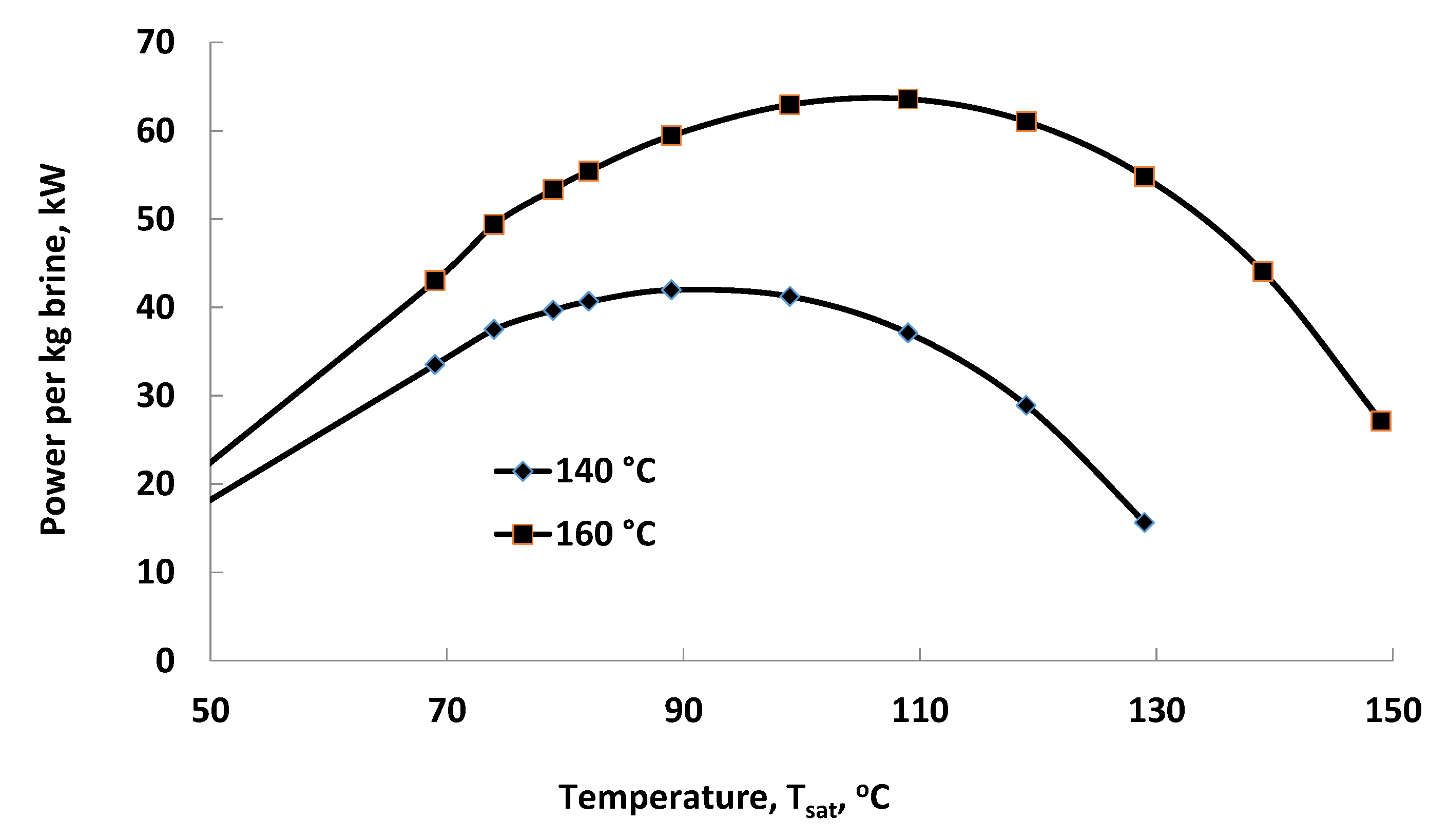

4.1. Operation in Mode 1

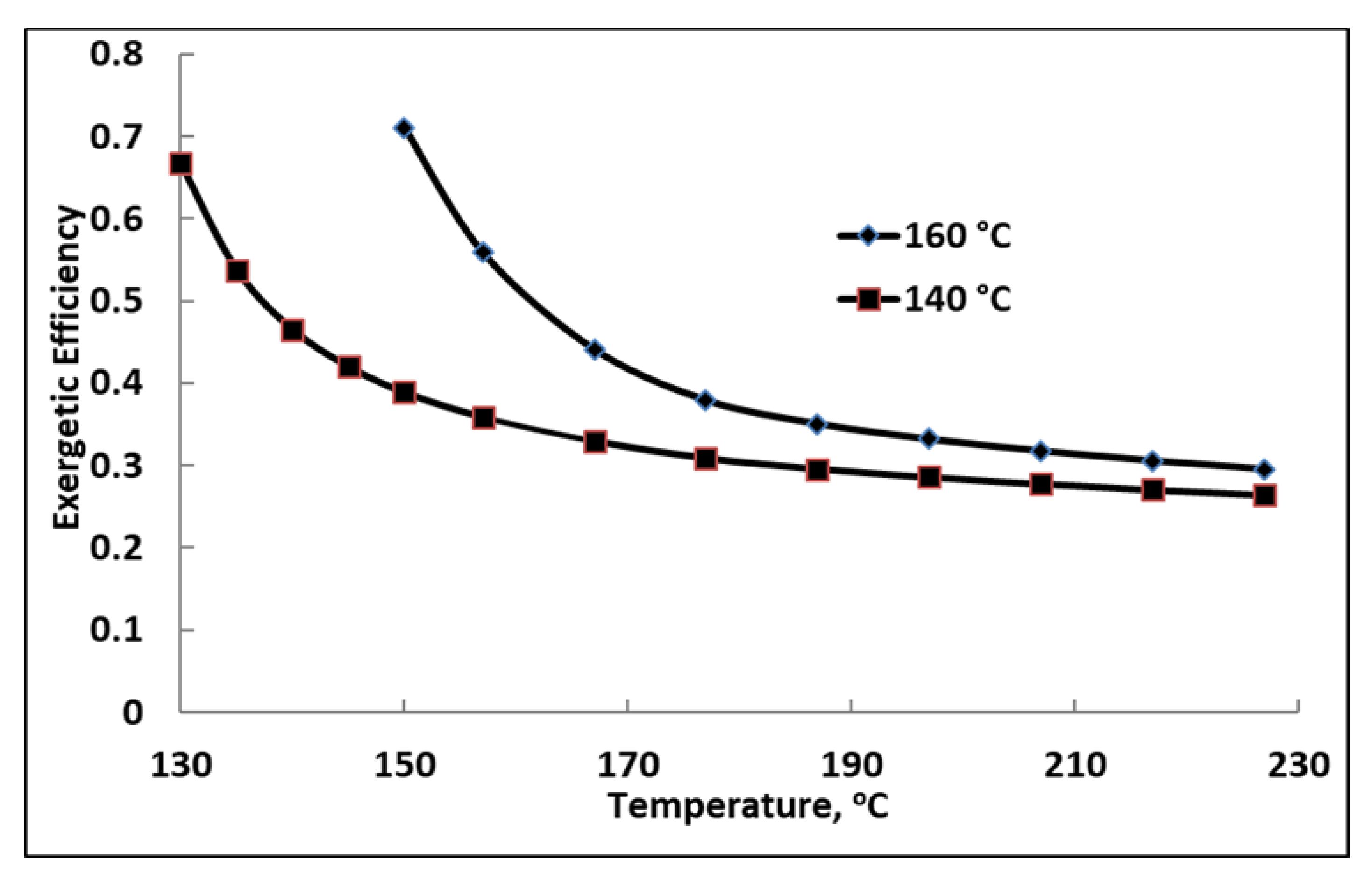

4.2. Operation in Mode 2

- The power produced per unit mass flow rate of the brine may be significantly increased by the addition of solar heat.

- The rates of heat supplied by the solar irradiance and the geothermal fluid, and , are of the same order of magnitude, almost equal in a few cases.

- The significantly higher power produced by the cycle would be very welcome by the electric power grid, when it is produced during the peak hours of late afternoon and early evening.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| List of Symbols | |

| c | specific heat capacity |

| h | enthalpy |

| e | exergy |

| m | mass |

| P | pressure |

| Q | heat |

| s | entropy |

| S | irradiance |

| t | time |

| T | temperature |

| w | specific work |

| η | efficiency |

| Subscripts | |

| 0 | pertains to the environment |

| C | collector |

| e | exit/outlet |

| gf | geothermal fluid |

| H | highest |

| i | inlet |

| max | maximum |

| P | pump |

| s | isentropic |

| sat | saturated |

| sol | solar |

| sal | salts |

| st | storage |

| T | turbine |

| wf | working fluid |

| Superscript | |

| . (dot) | denotes time rate |

| Abbreviations | |

| GCC | Global Climate Change |

| ORC | Organic Rankine Cycle |

| PV | Photovoltaic |

References

- Michaelides, E.E. Energy, the Environment, and Sustainability; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Di Pippo, R. Geothermal Power Plants—Principles, Applications, Case Studies and Environmental Impact, 3rd ed.; Elsevier: Oxford, UK, 2012. [Google Scholar]

- Bertani, R. Geothermal Power Generation in the World 2005–2010 Update Report. Geothermics 2012, 41, 1–29. [Google Scholar] [CrossRef]

- Michaelides, E.E. Future Directions and Cycles for Electricity Production from Geothermal Resources. Energy Convers. Manag. 2016, 107, 3–9. [Google Scholar] [CrossRef]

- Manfrida, G.; Tempesti, D.; Fiaschi, D.; Bruscoli, L. Improving the Environmental Sustainability of Flash Geothermal Power Plants—A Case Study. Sustainability 2015, 7, 15262–15283. [Google Scholar]

- Freeman, E.; Occello, D.; Barnes, F. Energy Storage for Electrical Systems in the USA. AIMS Energy 2016, 4, 856–875. [Google Scholar] [CrossRef]

- Weber, M.E. Making Renewables Work. Mech. Eng. 2016, 138, 12–17. [Google Scholar]

- DeValeria, M.K.; Michaelides, E.E.; Michaelides, D.N. Energy and thermal storage in clusters of grid-independent buildings. Energy 2019, 190, 116440. [Google Scholar] [CrossRef]

- Michaelides, E.E. Making Texas Green. Mech. Eng. 2019, 141, 32–37. [Google Scholar] [CrossRef] [Green Version]

- Bronicki, L.Y. Hybrid Geothermal Power Plant. US Patent and Trademark Office; U.S. Patent #9,331,547, 3 May 2016. [Google Scholar]

- Kestin, J. (Ed.) A Sourcebook for the Production of Geothermal Electric Power; DOE: Washington, DC, USA, 1980. [Google Scholar]

- Lentz, A.; Almanza, R. Solar-geothermal hybrid system. Appl. Therm. Eng. 2006, 26, 1537–1544. [Google Scholar] [CrossRef]

- Greenhut, A.D.; Tester, J.W.; DiPippo, R.; Field, R.; Love, C.; Nichols, K.; Augustine, C.; Batini, F.; Price, W.; Gigliucci, G.; et al. Solar-Geothermal Hybrid Cycle Analysis for Low Enthalpy Solar and Geothermal Resources. In Proceedings of the World Geothermal Congress 2010, Bali, Indonesia, 25–29 April 2010. [Google Scholar]

- Zhou, C.; Doroodchi, E.; Moghtaderi, B. An in-depth assessment of hybrid solar-geothermal power generation. Energy Convers. Manag. 2013, 74, 88–101. [Google Scholar] [CrossRef]

- Yang, J.; Li, J.; Yang, Z.; Duan, Y. Thermodynamic analysis and optimization of a solar organic Rankine cycle operating with stable output. Energy Convers. Manag. 2019, 187, 459–471. [Google Scholar] [CrossRef]

- Kutlu, C.; Li, J.; Su, Y.; Pei, G.; Riffat, S. Off-design performance modeling of a solar organic Rankine cycle integrated with pressurized hot water storage unit for community level application. Energy Convers. Manag. 2018, 166, 132–145. [Google Scholar] [CrossRef] [Green Version]

- Manfrida, G.; Secchia, R.; Stańczyk, K. Modelling and simulation of phase change material latent heat storages applied to a solar-powered Organic Rankine Cycle. Appl. Energy 2016, 179, 378–388. [Google Scholar] [CrossRef] [Green Version]

- Ayub, M.; Mitsos, A.; Hadi, G. Thermo-economic analysis of a hybrid solar-binary geothermal power plant. Energy 2015, 87, 326–335. [Google Scholar] [CrossRef]

- Wang, Q.; Huang, Q. Research on integrated solar and geothermal energy engineering design in hot summer and cold winter area. Procedia Eng. 2011, 21, 648–655. [Google Scholar] [CrossRef] [Green Version]

- Al-Ali, M.; Dincer, I. Energetic and exergetic studies of a multigenerational solar-geothermal system. Appl. Therm. Eng. 2014, 71, 16–23. [Google Scholar] [CrossRef]

- McTigue, D.; Castro, J.; Mungas, J.; Kramer, N.; King, J.; Turchi, G.; Zhua, G. Hybridizing a geothermal power plant with concentrating solar power and thermal storage to increase power generation and dispatchability. Appl. Energy 2018, 228, 1837–1852. [Google Scholar] [CrossRef]

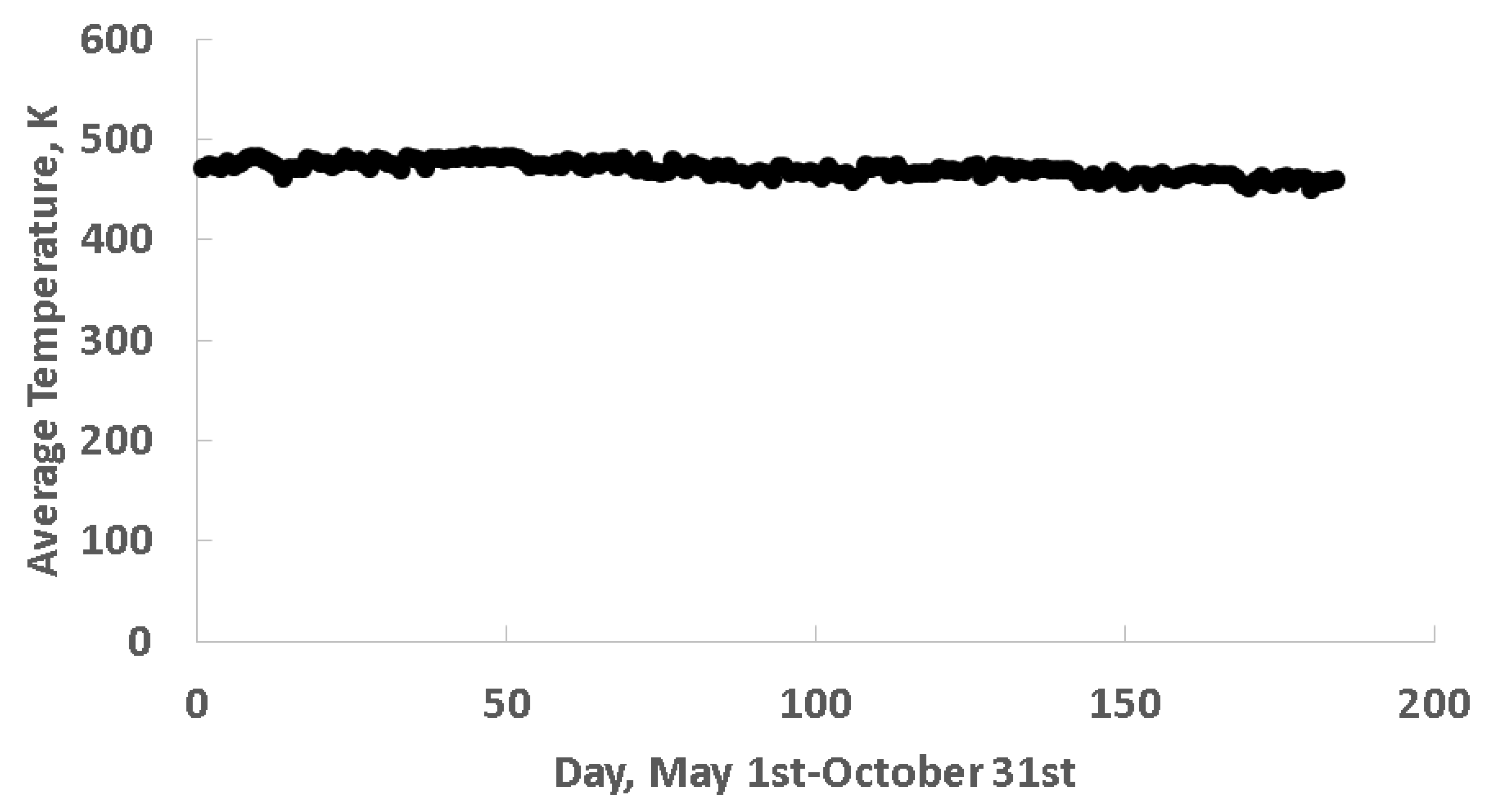

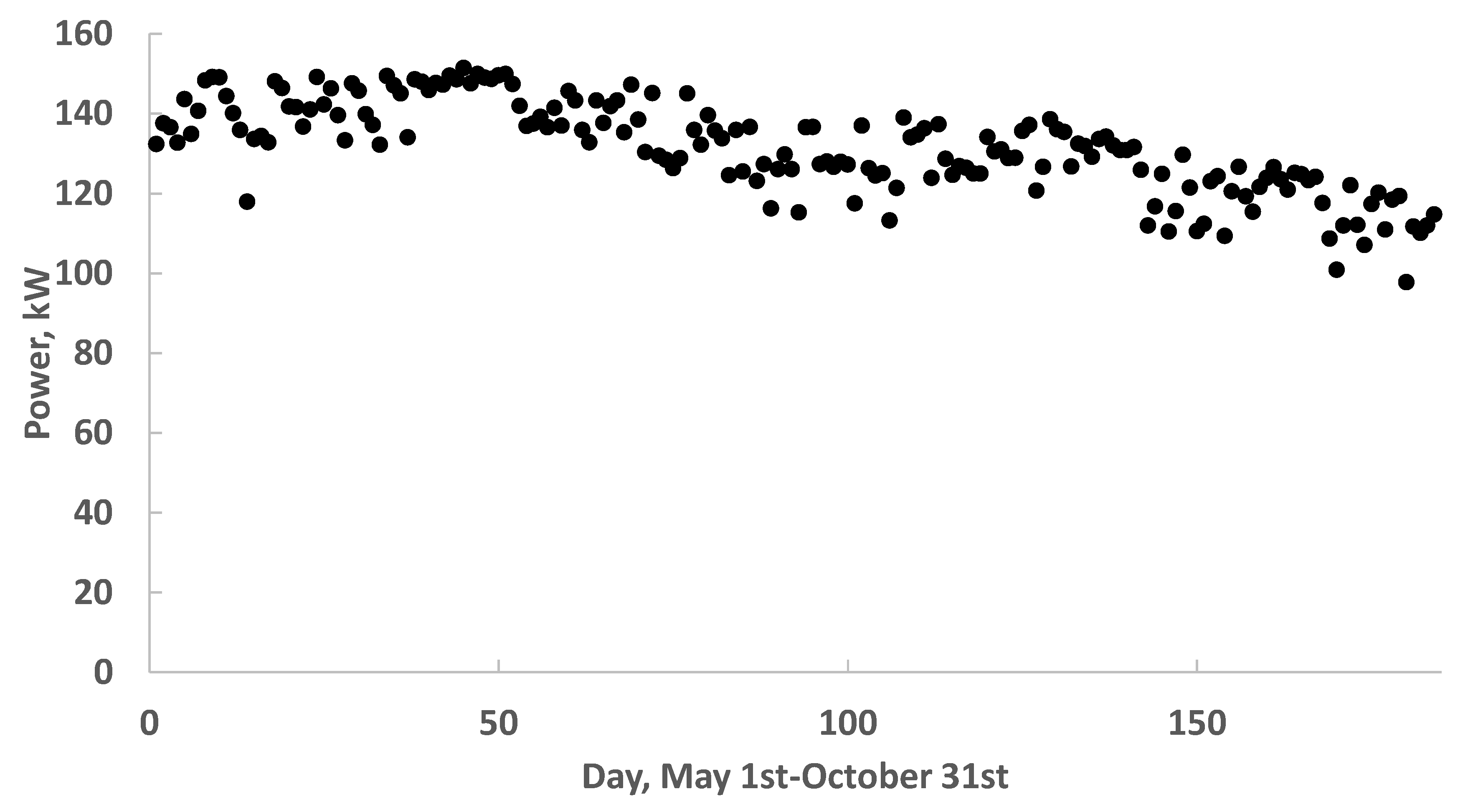

- Stillwater Facility, Annual, 2019, Electricity Data Browser, Energy Information Administration. Available online: https://www.eia.gov/electricity/data/ (accessed on 20 September 2019).

- Edrisi, B.; Michaelides, E.E. Effect of the working fluid on the optimum work of binary-flashing geothermal power plants. Energy 2013, 38, 389–394. [Google Scholar] [CrossRef]

- Wilcox, S. National Solar Radiation Database 1991–2010 Update: User’s Manual; Technical Report NREL/TP-5500-54824; National Renewable Energy Laboratory: Golden, CO, USA, 2012. [Google Scholar]

- Michaelides, E.E. Thermodynamic Properties of Geothermal Fluids. Trans. Geoth. Resour. Counc. 1981, 5, 361–364. [Google Scholar]

- REFPROP. Reference Thermodynamic and Fluid Transport Properties; National Institute of Standards and Technology: Boulder, CO, USA, 2013. [Google Scholar]

- Kutscher, C.; Burkholder, F.; Stynes, K. Generation of a Parabolic Trough Collector Efficiency Curve from Separate Measurements of Outdoor Optical Efficiency and Indoor Receiver Heat Loss; NREL/CP-5500-49304; National Renewable Energy Laboratory: Golden, CO, USA, 2010. [Google Scholar]

- Bejan, A. Unification of Three Different Theories concerning the Ideal Conversion of Enclosed Radiation. J. Solar Energy Eng. 1987, 109, 46–51. [Google Scholar] [CrossRef]

- Serrano-López, R.; Fradera, J.; Cuesta-López, S. Molten salts database for energy applications. Chem. Eng. Process. Process Intensif. 2013, 73, 87–102. [Google Scholar] [CrossRef] [Green Version]

| Working Fluid | Butane |

|---|---|

| Temperature of geothermal brine | 140–160 °C (liquid because of high pressure) |

| Condenser Temperature, T0 | 35 °C |

| Turbine efficiency, ηT | 85% |

| Pump efficiency, ηP | 82% |

| Pinch point temperature difference (mode 1), ΔT | 10 °C |

| Minimum temperature difference (mode 2) | 10 °C |

| Fraction of heat lost in molten salts tank, ηst, | 10% |

| Solar collector efficiency, ηC | 75% |

| Daily hours of operation in mode 2 | 6 h (21,600 s) |

| Tgi, °C, (K) | 140 (413) | 160 (433) |

|---|---|---|

| Tsat, K | 362 | 382 |

| Psat, MPa | 1.17 | 1.74 |

| , kg/s | 0.70 | 0.8038 |

| , kW | 42.0 | 63.6 |

| ηex | 67% | 74% |

| Tgi, K, (°C) | 433, (160) | 413, (140) |

|---|---|---|

| , kg/s | 1.4542 | 1.4945 |

| , kW with TsH = 460 K | 135.5 | 139.7 |

| , kW | 312.8 | 427.6 |

| , kW | 481.2 | 418.4 |

| , kW TsH = 500 K | 172.6 | 177.7 |

| , kW | 517.7 | 638.2 |

| , kW | 481.2 | 418.4 |

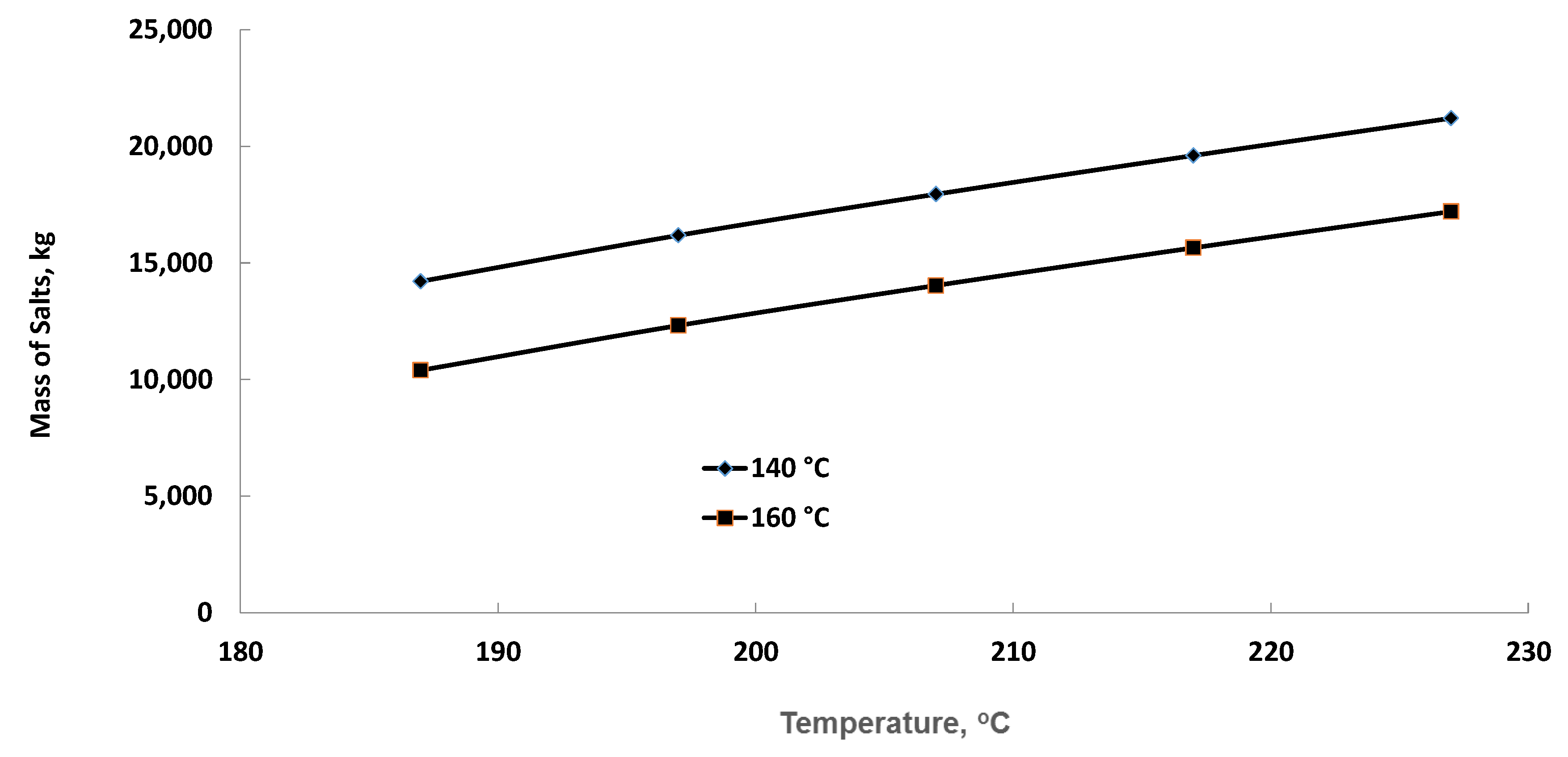

| T, °C | Tgi = 160 °C | Tgi = 140 °C | ||

|---|---|---|---|---|

| Additional Power, kW | Additional Heat, kW | Additional Power, kW | Additional Heat, kW | |

| 130 | - | 0 | 0 | |

| 135 | - | 4.7 | 24.3 | |

| 140 | - | 10.3 | 50.4 | |

| 145 | - | 16.3 | 77.7 | |

| 150 | 0 | 0 | 22.8 | 106.6 |

| 157 | 10.4 | 44.5 | 33.5 | 151.8 |

| 167 | 32.1 | 131.5 | 55.8 | 241.2 |

| 177 | 58.4 | 240.0 | 82.8 | 352.8 |

| 187 | 73.9 | 312.8 | 98.8 | 427.6 |

| 197 | 85.1 | 370.6 | 110.3 | 487.0 |

| 207 | 94.6 | 422.3 | 120.1 | 540.1 |

| 217 | 103.0 | 470.9 | 128.7 | 590.0 |

| 227 | 110.9 | 517.7 | 136.8 | 638.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bokelman, B.; Michaelides, E.E.; Michaelides, D.N. A Geothermal-Solar Hybrid Power Plant with Thermal Energy Storage. Energies 2020, 13, 1018. https://doi.org/10.3390/en13051018

Bokelman B, Michaelides EE, Michaelides DN. A Geothermal-Solar Hybrid Power Plant with Thermal Energy Storage. Energies. 2020; 13(5):1018. https://doi.org/10.3390/en13051018

Chicago/Turabian StyleBokelman, Brady, Efstathios E. Michaelides, and Dimitrios N. Michaelides. 2020. "A Geothermal-Solar Hybrid Power Plant with Thermal Energy Storage" Energies 13, no. 5: 1018. https://doi.org/10.3390/en13051018