Energy Utilization of Spent Coffee Grounds in the Form of Pellets

Abstract

1. Introduction

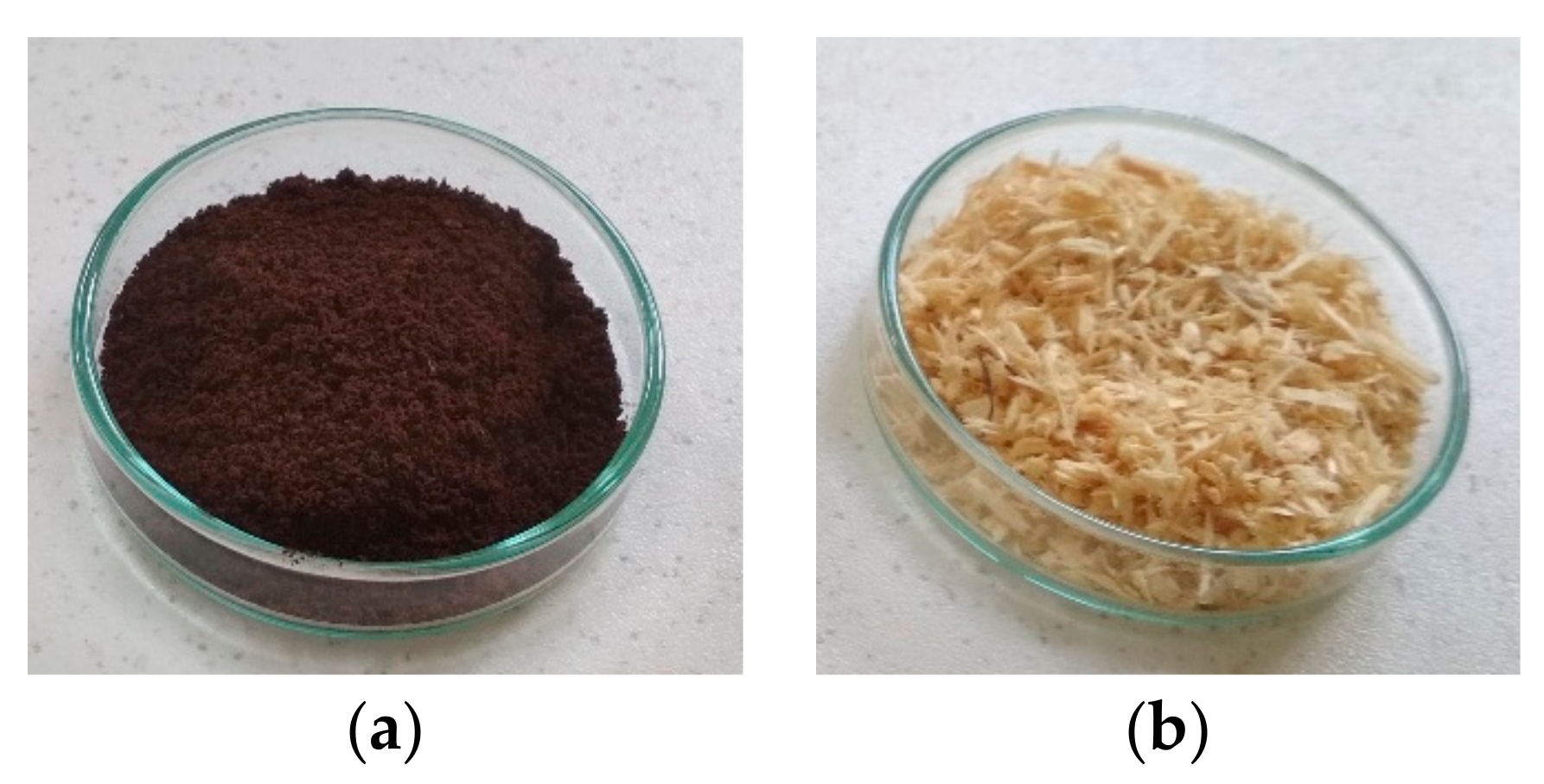

2. Materials and Methods

3. Experimental Research and Results

3.1. Calorific Values

3.2. The Boiler Measurements

3.3. The Analyses of Results

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Atabani, A.E.; Ala’a, H.; Kumar, G.; Saratale, G.D.; Aslam, M.; Khan, H.A.; Said, Z.; Mahmoud, E. Valorization of spent coffee grounds into biofuels and value-added products: Pathway towards integrated bio-refinery. Fuel 2019, 254, 115640. [Google Scholar] [CrossRef]

- Tun, M.M.; Juchelková, D.; Raclavská, H.; Sassmanová, V. Utilization of biodegradable wastes as a clean energy source in the developing countries: A case study in Myanmar. Energies 2018, 11, 3183. [Google Scholar] [CrossRef]

- Kang, S.B.; Oh, H.Y.; Kim, J.J.; Choi, K.S. Characteristics of spent coffee ground as a fuel and combustion test in a small boiler (6.5 kW). Renew. Energy 2017, 113, 1208–1214. [Google Scholar] [CrossRef]

- Karmee, S.K. A spent coffee grounds based biorefinery for the production of biofuels, biopolymers, antioxidants and biocomposites. Waste Manag. 2018, 72, 240–254. [Google Scholar] [CrossRef] [PubMed]

- Zuorro, A.; Lavecchia, R. Spent coffee grounds as a valuable source of phenolic compounds and bioenergy. J. Clean. Prod. 2012, 34, 49–56. [Google Scholar] [CrossRef]

- Burniol-Figols, A.; Cenian, K.; Skiadas, I.V.; Gavala, H.N. Integration of chlorogenic acid recovery and bioethanol production from spent coffee grounds. Biochem. Eng. J. 2016, 116, 54–64. [Google Scholar] [CrossRef]

- Kwon, E.E.; Yi, H.; Jeon, Y.J. Sequential co-production of biodiesel and bioethanol with spent coffee grounds. Bioresour. Technol. 2013, 136, 475–480. [Google Scholar] [CrossRef] [PubMed]

- Somnuk, K.; Eawlex, P.; Prateepchaikul, G. Optimization of coffee oil extraction from spent coffee grounds using four solvents and prototype-scale extraction using circulation process. Agric. Nat. Resour. 2017, 51, 181–189. [Google Scholar] [CrossRef]

- Kristanto, G.A.; Wijaya, H. Assessment of spent coffee ground (SCG) and coffee silverskin (CS) as refuse derived fuel (RDF). IOP Conf. Ser. Earth Environ. Sci. 2018, 195, 012056. [Google Scholar] [CrossRef]

- Kansai, N.; Chaisuwan, N.; Supakata, N. Carbonized Briquettes as a Tool for Adding Value to Waste from Rain tree (Samanea Saman) and Coffee Ground/Tea Waste. Eng. J. 2018, 22, 47–63. [Google Scholar] [CrossRef]

- Patcharee, P.; Naruephat, T. A Study on How to Utilize Waste Paper and Coffee Residue for Briquettes Production. Int. J. Environ. Sci. Dev. 2015, 6, 201. [Google Scholar] [CrossRef]

- Pilusa, T.J.; Huberts, R.; Muzenda, E. Emissions analysis from combustion of eco-fuel briquettes for domestic applications. J. Energy South. Afr. 2013, 24, 30–36. [Google Scholar] [CrossRef]

- Limousy, L.; Jeguirim, M.; Dutournie, P.; Kraiem, N.; Lajili, M.; Said, R. Gaseous products and particulate matter emissions of biomass residential boiler fired with spent coffee grounds pellets. Fuel 2013, 107, 323–329. [Google Scholar] [CrossRef]

- Arce, M.E.; Saavedra, Á.; Míguez, J.L.; Granada, E.; Cacabelos, A. Biomass fuel and combustion conditions selection in a fixed bed combustor. Energies 2013, 6, 5973–5989. [Google Scholar] [CrossRef]

- Moradian, F.; Pettersson, A.; Svärd, S.H.; Richards, T. Co-combustion of animal waste in a commercial waste-to-energy BFB boiler. Energies 2013, 6, 6170–6187. [Google Scholar] [CrossRef]

- Lisowski, A.; Olendzki, D.; Swietochowski, A.; Dabrowska, M.; Mieszkalski, L.; Ostrowska-Ligeza, E.; Stasiak, M.; Klonowski, J.; Piatek, M. Spent coffee grounds compaction process: Its effects on the strength properties of biofuel pellets. Renew. Energy 2019, 142, 173–183. [Google Scholar] [CrossRef]

- Jeguirim, M.; Limousy, L.; Dutournie, P. Pyrolysis kinetics and physicochemical properties of agropellets produced from spent ground coffee blended with conventional biomass. Chem. Eng. Res. Des. 2014, 92, 1876–1882. [Google Scholar] [CrossRef]

- Kantová, N.; Holubčík, M.; Jandačka, J.; Čaja, A. Comparison of Particulate Matters Properties from Combustion of Wood Biomass and Brown Coal. Procedia Eng. 2017, 192, 416–420. [Google Scholar] [CrossRef]

- Palacka, M.; Vician, P.; Holubčík, M.; Jandačka, J. The Energy Characteristics of Different Parts of the Tree. Procedia Eng. 2017, 192, 654–658. [Google Scholar] [CrossRef]

- Recycling Coffee Grounds into Biomass Pellets for Home Heating. Available online: https://wood-pellet-line.com/recycling-coffee-grounds-into-biomass-pellets-for-home-heating/ (accessed on 2 February 2020).

- Sołowiej, P.; Neugebauer, M. Impact of coffee grounds addition on the calorific value of the selected biological materials. Agric. Eng. 2018, 20, 177–183. [Google Scholar] [CrossRef][Green Version]

| Parameter | 100% of SCG | 50/50 SCG/Sawdust | 40/60 SCG/Sawdust | 30/70 SCG/Sawdust |

|---|---|---|---|---|

| Total Carbon (%) | 54.56 | 52.69 | 52.13 | 51.29 |

| Total Nitrogen (%) | 17.78 | 46.87 | 50.64 | 61.66 |

| Total Hydrogen (%) | 7.44 | 6.99 | 6.89 | 6.74 |

| C (%) | H (%) | N (%) | |

|---|---|---|---|

| SCG | 46.42–71.6 | 6.04–8.99 | 2.03–15.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nosek, R.; Tun, M.M.; Juchelkova, D. Energy Utilization of Spent Coffee Grounds in the Form of Pellets. Energies 2020, 13, 1235. https://doi.org/10.3390/en13051235

Nosek R, Tun MM, Juchelkova D. Energy Utilization of Spent Coffee Grounds in the Form of Pellets. Energies. 2020; 13(5):1235. https://doi.org/10.3390/en13051235

Chicago/Turabian StyleNosek, Radovan, Maw Maw Tun, and Dagmar Juchelkova. 2020. "Energy Utilization of Spent Coffee Grounds in the Form of Pellets" Energies 13, no. 5: 1235. https://doi.org/10.3390/en13051235

APA StyleNosek, R., Tun, M. M., & Juchelkova, D. (2020). Energy Utilization of Spent Coffee Grounds in the Form of Pellets. Energies, 13(5), 1235. https://doi.org/10.3390/en13051235