Rock Breaking and Dynamic Response Characteristics of Carbon Dioxide Phase Transition Fracturing Considering the Gathering Energy Effect

Abstract

:1. Introduction

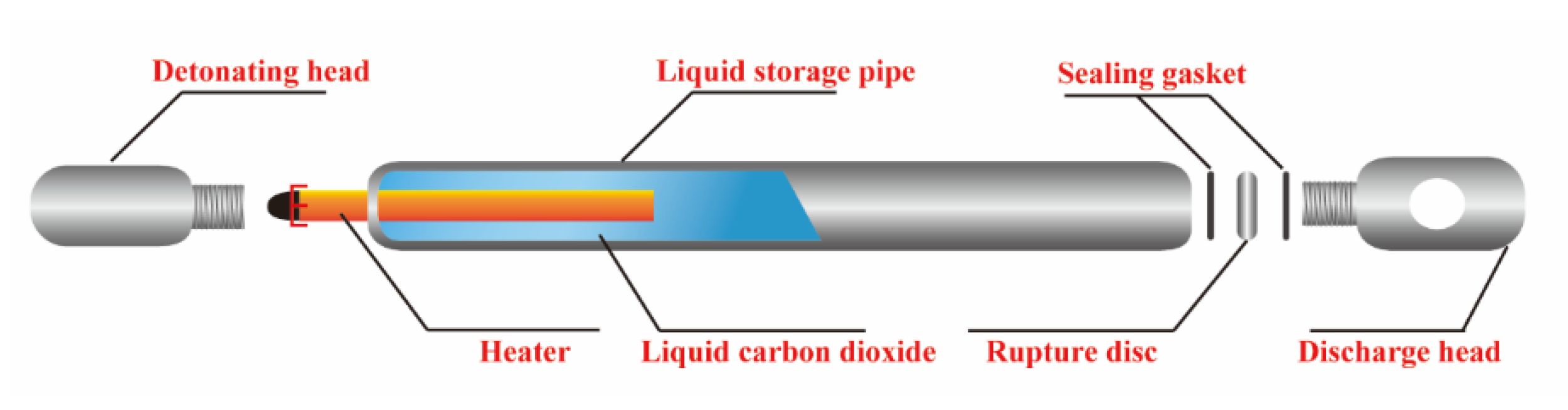

2. The Principle of Carbon Dioxide Phase Transition Fracturing

2.1. Procedure of Carbon Dioxide Phase Transition Fracturing

2.2. Gathering Energy Characteristics of Carbon Dioxide Phase Transition Fracturing

3. Carbon Dioxide Phase Transition Fracturing Tests

3.1. Field Tests of Carbon Dioxide Phase Transition Fracturing

3.2. Acquisition of Rock Mass Mechanical Parameters

4. Numerical Simulation of Carbon Dioxide Phase Transition Fracturing

4.1. Establishment of the Numerical Model

4.2. Selection of Load and Model Parameter

4.3. Determination of Impact Reduction Coefficient

5. Characteristics of Carbon Dioxide Phase Transition Fracturing

5.1. Crack Propagation Characteristics

5.2. Characteristics of Displacement

5.3. Characteristics of Vibration Velocity

5.4. Characteristics of Effective Stress

6. Conclusion

Author Contributions

Funding

Conflicts of Interest

References

- Li, Q.Y.; Luo, D.Y.; Feng, G.W.; Ma, H.P.; Wei, X.A.; Chen, G. Dynamic characteristics of liquid CO2 phase change fracturing, using experimental technique. Geotech. Geol. Eng. 2019, 37, 3387–3398. [Google Scholar] [CrossRef]

- Tao, M.; Zhao, H.T.; Li, X.B.; Ma, A. Comprehensive comparative analysis of liquid CO2 phase change fracturing and explosive rock fracturing. Blasting 2018, 35, 41–49. [Google Scholar]

- Singh, S.P. Non-explosive application of the PCF concept for underground excavation. Tunn. Undergr. Space Tech. 1998, 13, 305–311. [Google Scholar] [CrossRef]

- Li, Q.Y.; Liu, X.X.; Wu, Z.Y.; Xie, X.F. Application of liquid CO2 phase change rock breaking technology in metro foundation pit excavation. J. Rail Sci. Eng. 2018, 15, 163–169. [Google Scholar]

- Xie, X.F.; Li, X.B.; Li, Q.Y.; Ma, H.P.; Liu, X.X. Liquid CO2 phase-transforming rock fracturing technology in pile-well excavation. J. Cent. South Univ. 2018, 49, 2031–2038. [Google Scholar]

- Vidanovic, N.; Ognjanovic, S.; Ilincic, N.; Llic, N.; Tokalic, R. Application of unconventional methods of underground premises construction in coal mines. Tech. Technol. Educ. Manag. 2011, 6, 861–865. [Google Scholar]

- Caldwell, T. A comparison of non-explosive rock breaking techniques. In Proceedings of the 12th Australian Tunnelling Conference 2005: Tunnelling towards Better Cities, Brisbane, Australia, 17–20 April 2005. [Google Scholar]

- He, W.R.; He, F.L.; Zhang, K.; Zhao, Y.Q.; Zhu, H.Z. Increasing permeability of coal seam and improving gas drainage using a liquid carbon dioxide phase transition explosive technology. Adv. Civ. Eng. 2018, 2018, 3976505. [Google Scholar] [CrossRef]

- Lu, T.K.; Wang, Z.F.; Yang, H.M.; Yuan, P.J.; Han, Y.B.; Sun, X.M. Improvement of coal seam gas drainage by under-panel cross-strata stimulation using highly pressurized gas. Int. J. Rock Mech. Min. Sci. 2015, 77, 300–312. [Google Scholar] [CrossRef]

- Chen, H.D.; Wang, Z.F.; Qi, L.L.; An, F.H. Effect of liquid carbon dioxide phase change fracturing technology on gas drainage. Arab. J. Geosci. 2017, 10, 314. [Google Scholar] [CrossRef]

- Dong, Q.X.; Wang, Z.F.; Han, Y.B.; Sun, X.M. Research on TNT equivalent of liquid CO2 phase-transition fracturing. China Saf. Sci. J. 2014, 24, 84–88. [Google Scholar]

- Sun, K.M.; Wang, J.Y.; Xin, L.W. Research on the law of secondary cracks propagation in coal and rock caused by gas wedging during supercritical CO2 explosion under different stress differences. Chin. J. Appl. Mech. 2019, 36, 466–472. [Google Scholar]

- Guo, Y.L. Fracturing Mechanisms and Functions of Improvement of Gas Drainage of Highly Pressurized Carbon Dioxide Gas System. Master’s Thesis, Henan Polytechnic University, Jiaozuo, China, 2017. [Google Scholar]

- Zhou, K.P.; Ke, B.; Li, J.L.; Zhang, Y.N.; Cheng, L. Pressure dynamic response and explosion energy of liquid carbon dioxide blasting system. Blasting 2017, 34, 7–13. [Google Scholar]

- Ke, B.; Zhou, K.P.; Xu, C.S.; Ren, G.F.; Jiang, T.T. Thermodynamic properties and explosion energy analysis of carbon dioxide blasting systems. Min. Technol. 2019, 128, 39–50. [Google Scholar] [CrossRef]

- Kang, J.H.; Zhou, F.B.; Qiang, Z.Y.; Zhu, S.J. Evaluation of gas drainage and coal permeability improvement with liquid CO2 gasification blasting. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef] [Green Version]

- Xie, X.F.; Li, X.B.; Li, Q.Y.; Ma, H.P.; Fang, Y.; Liu, X.X. Research and review about the liquid CO2 phase-transforming rock fracturing technology. J. Rail Sci. Technol. 2018, 15, 1406–1414. [Google Scholar]

- Lei, Y. A Theoretical and Experimental Study on Carbon Dioxide Phase Transition Induced Fracturing and Antireflection in Low-Permeability Coal Seams with Gas-Rich. Ph.D. Thesis, Southwest Petroleum University, Chengdu, China, 2018. [Google Scholar]

- Zhang, Y.N.; Deng, J.R.; Deng, H.W.; Ke, B. Peridynamics simulation of rock fracturing under liquid carbon dioxide blasting. Int. J. Damage Mech. 2019, 28, 1038–1052. [Google Scholar] [CrossRef]

- Chen, H.D.; Wang, Z.F.; Chen, X.E.; Chen, X.J.; Wang, L.G. Increasing permeability of coal seams using the phase energy of liquid carbon dioxide. J. CO2 Util. 2017, 19, 112–119. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Deng, J.R.; Ke, B.; Deng, H.W.; Li, J.L. Experimental study on explosion pressure and rock breaking characteristics under liquid carbon dioxide blasting. Adv. Civ. Eng. 2018, 2018, 7840125. [Google Scholar] [CrossRef]

- Hu, G.Z.; He, W.R.; Sun, M. Enhancing coal seam gas using liquid CO2 phase-transition blasting with cross measure borehole. J. Nat. Gas Sci. Eng. 2018, 60, 164–173. [Google Scholar] [CrossRef]

- Gao, F.; Tang, L.H.; Zhou, K.P.; Zhang, Y.N.; Ke, B. Mechanism analysis of liquid carbon dioxide phase transition for fracturing rock masses. Energies 2018, 11, 2909. [Google Scholar] [CrossRef] [Green Version]

- Chu, H.B.; Yang, X.L.; Hou, A.J.; Yu, Y.Q.; Liang, W.M. A simulation-based experimental study on explosion stress wave propagation and attenuation in coal. Explos. Shock Waves 2012, 32, 185–189. [Google Scholar]

- Sun, K.M.; Xin, L.W.; Wang, T.T.; Wang, J.Y. Simulation research on law of coal fracture caused by supercritical CO2 explosion. J. China Univ. Min. Technol. 2017, 46, 501–506. [Google Scholar]

- Zhu, W.C.; Gai, D.; Wei, C.H.; Li, S.G. High-pressure air blasting experiments on concrete and implications for enhanced coal gas drainage. J. Nat. Gas Sci. Eng. 2016, 36, 1253–1263. [Google Scholar] [CrossRef] [Green Version]

- Deng, K.; Chen, M.; Lu, W.B.; Yan, P.; Leng, Z.D. Investigation of influence of in-situ stress on presplitting induced fracture in abutment slot. Rock Soil Mech. 2019, 40, 1121–1128. [Google Scholar]

- Donze, F.V.; Bouchez, J.; Magnier, S.A. Modeling fractures in rock blasting. Int. J. Rock Mech. Min. Sci. 1997, 34, 1153–1163. [Google Scholar] [CrossRef]

- LS-DYNA. Key User’s Manual Volume II, 1st ed.; Livermore Software Technology Corporation: Livermore, CA, USA, 2007; pp. 38–40. [Google Scholar]

- Mott, N.F. Brittle fracture in mild steel plates. Engineering 1948, 165, 16–18. [Google Scholar]

- Stroh, A.N. A theory of the fracture of metals. Adv. Phys. 1957, 6, 418–465. [Google Scholar] [CrossRef]

- Park, C.B.; Miller, R.D.; Xia, J. Multichannel analysis of surface waves. Geophysics 1999, 64, 800–808. [Google Scholar] [CrossRef] [Green Version]

- Aki, K.; Richards, P.G. Quantitative Seismology, 2nd ed.; University Sciences Books: Sausalito, CA, USA, 2002. [Google Scholar]

- Wu, L.; Zhang, S.Z. The experimental study of velocity of crack spreading under explosion load. Blasting 1998, 15, 1–4. [Google Scholar]

- Kobayashi, A.S. Fracture Mechanics Test Technology, 1st ed.; China Railway Press: Beijing, China, 1983; pp. 30–80. [Google Scholar]

| Density (g/cm3) | UCS (MPa) | Uniaxial Tensile Strength (MPa) | Poisson’s Ratio | Elastic Modulus (GPa) | P-Wave Velocity (m/s) |

|---|---|---|---|---|---|

| 2.656 | 92 | 9.8 | 0.235 | 48.35 | 4197 |

| Density (g/cm3) | Elastic Modulus (GPa) | Poisson Ratio | Initial Yield Stress (MPa) | Tangent Modulus (GPa) | Hardening Coefficient | Failure Strain |

|---|---|---|---|---|---|---|

| 2.656 | 48.35 | 0.213 | 84 | 2 | 0.5 | 0.05 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, S.; Jiang, N.; He, X.; Luo, X. Rock Breaking and Dynamic Response Characteristics of Carbon Dioxide Phase Transition Fracturing Considering the Gathering Energy Effect. Energies 2020, 13, 1336. https://doi.org/10.3390/en13061336

Zhou S, Jiang N, He X, Luo X. Rock Breaking and Dynamic Response Characteristics of Carbon Dioxide Phase Transition Fracturing Considering the Gathering Energy Effect. Energies. 2020; 13(6):1336. https://doi.org/10.3390/en13061336

Chicago/Turabian StyleZhou, Shengtao, Nan Jiang, Xu He, and Xuedong Luo. 2020. "Rock Breaking and Dynamic Response Characteristics of Carbon Dioxide Phase Transition Fracturing Considering the Gathering Energy Effect" Energies 13, no. 6: 1336. https://doi.org/10.3390/en13061336