Equipping a Combine Harvester with Turbine Technology Increases the Recovery of Residual Biomass from Cereal Crops via the Collection of Chaff

Abstract

:1. Introduction

2. Materials and Methods

2.1. Field Test and Crop Characteristics

2.2. Thievin System Description

2.3. Experimental Design and Pre-Harvest Sampling

2.4. Harvesting Tests

2.4.1. Machines Performance

2.4.2. Biomass Yield and Characterization

2.5. Post-Harvest Measurements

2.6. Statistical Analysis

3. Results and Discussion

3.1. Combine Performance

3.2. Baler Performance

3.3. Biomass Assessment

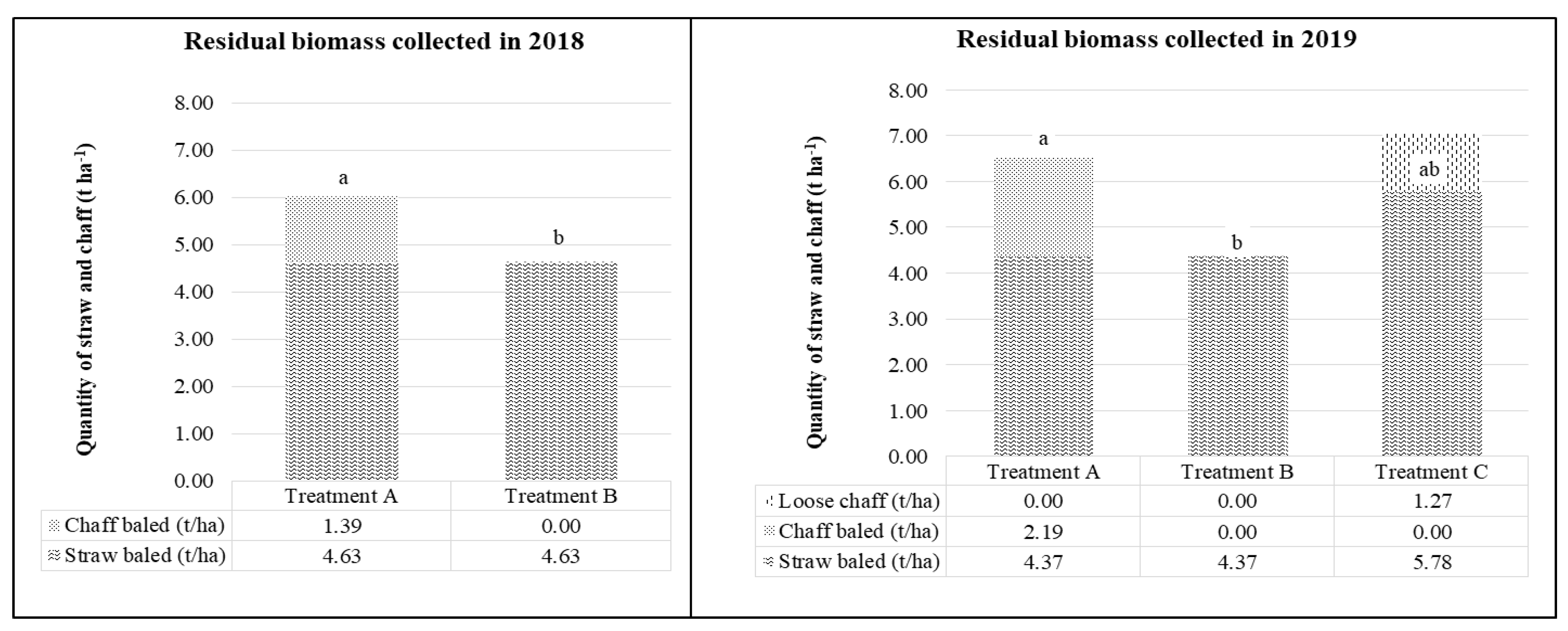

3.3.1. Yield

3.3.2. Bulk Density and Humidity

3.3.3. Biomass Losses

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Scarlat, N.; Dallemand, J.F.; Monforti-Ferrario, F.; Nita, V. The role of biomass and bioenergy in a future bioeconomy: Policies and facts. Environ. Dev. 2015, 15, 3–34. [Google Scholar] [CrossRef]

- European Parliament DIRECTIVE (EU) 2015/1513 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 9 September 2015 amending Directive 98/70/EC relating to the quality of petrol and diesel fuels and amending Directive 2009/28/EC on the promotion of the use of energy from renewabl. Off. J. Eur. Union 2015, L239/1, 20–30. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32015L1513&from=EN (accessed on 25 February 2020).

- EU A 2030 framework for climate and energy policies European. European Parliament resolution of 5 February 2014 on a 2030 framework for climate and energy policies (2013/2135(INI)). Off. J. Eur. Union. 24.3.2017 2014, C 93/79, 79–102. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52014IP0094&from=EN (accessed on 18 January 2020).

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass pelletization—A review. BioResources 2012, 7, 4451–4490. [Google Scholar]

- Paiano, A.; Lagioia, G. Energy potential from residual biomass towards meeting the EU renewable energy and climate targets. The Italian case. Energy Policy 2016, 91, 161–173. [Google Scholar] [CrossRef]

- Craessaerts, G.; Saeys, W.; Missotten, B.; De Baerdemaeker, J. Identification of the cleaning process on combine harvesters, Part II: A fuzzy model for prediction of the sieve losses. Biosyst. Eng. 2010, 106, 97–102. [Google Scholar]

- EC Eurostat Database. Eur. Comm. Cereal. Prod. Grain (Including Seed) by Area, Prod. Humidity 2019. Available online: https://ec.europa.eu/eurostat/databrowser/view/tag00027/default/table?lang=en (accessed on 18 January 2020).

- McCartney, D.H.; Block, H.C.; Dubeski, P.L.; Ohama, A.J. Review: The composition and availability of straw and chaff from small grain cereals for beef cattle in western Canada. Can. J. Anim. Sci. 2006, 86, 443–455. [Google Scholar] [CrossRef]

- Rönnbäck, M.; Lundin, G. Simultaneous Harvesting of Straw and Chaff for Energy Purposes-Influence on Bale Density, Yield, Field Drying Process and Combustion Characteristics. In Proceedings of the XVIIth World Congress of the International Commission of Agricultural and Biosystems Engineering (CIGR) Hosted by the Canadian Society for Bioengineering (CSBE/SCGAB), Québec City, QC, Canada, 13–17 June 2010. [Google Scholar]

- Weiß, B.D.; Glasner, C. Evaluation of the process steps of pretreatment, pellet production and combustion for an energetic utilization of wheat chaff. Front. Environ. Sci. 2018, 6, 1–10. Available online: https://www.frontiersin.org/articles/10.3389/fenvs.2018.00036/ful (accessed on 20 February 2020). [CrossRef]

- Zhang, H.; Lopez, P.C.; Holland, C.; Lunde, A.; Ambye-Jensen, M.; Felby, C.; Thomsen, S.T. The multi-feedstock biorefinery–Assessing the compatibility of alternative feedstocks in a 2G wheat straw biorefinery process. GCB Bioenergy 2018, 10, 946–959. [Google Scholar] [CrossRef]

- Mann, M.E.; Cohen, R.D.H.; Kernan, J.A.; Nicholson, H.H.; Christensen, D.A.; Smart, M.E. The feeding value of ammoniated flax straw, wheat straw and wheat chaff for beef cattle. Anim. Feed Sci. Technol. 1988, 21, 57–66. [Google Scholar] [CrossRef]

- Gerling, M.; Dickey, P.C. Absorbant Animal Bedding. US Patent No 5,878,696, 9 March 1999. Available online: https://patentimages.storage.googleapis.com/aa/1d/1d/5d9a9f2a556454/US5878696.pdf (accessed on 25 February 2020).

- Rush, C.M. Effects of Wheat Chaff and Tillage on Inoculum Density of Pythium ultimum in the Pacific Northwest. Phytopathology 1986, 76, 1330. [Google Scholar] [CrossRef]

- Shirtliffe, S.J.; Entz, M.H. Chaff collection reduces seed dispersal of wild oat (Avena fatua) by a combine harvester. Weed Sci. 2005, 53, 465–470. [Google Scholar] [CrossRef]

- Walsh, M.; Newman, P.; Powles, S. Targeting Weed Seeds In-Crop: A New Weed Control Paradigm for Global Agriculture. Weed Technol. 2013, 27, 431–436. [Google Scholar] [CrossRef] [Green Version]

- Jacobs, A.; Kingwell, R. The Harrington Seed Destructor: Its role and value in farming systems facing the challenge of herbicide-resistant weeds. Agric. Syst. 2016, 142, 33–40. [Google Scholar] [CrossRef]

- Walsh, M.J.; Harrington, R.B.; Powles, S.B. Harrington Seed Destructor: A new nonchemical weed control tool for global grain crops. Crop Sci. 2012, 52, 1343–1347. [Google Scholar] [CrossRef]

- Jakobsen, K.; Jensen, J.A.; Bitarafan, Z.; Andreasen, C. Killing weed seeds with exhaust gas from a combine harvester. Agronomy 2019, 9, 544. [Google Scholar] [CrossRef] [Green Version]

- Glasner, C.; Vieregge, C.; Robert, J.; Fenselau, J.; Bitarafan, Z.; Andreasen, C. Evaluation of new harvesting methods to reduce weeds on arable fields and collect a new feedstock. Energies 2019, 12, 1688. [Google Scholar] [CrossRef] [Green Version]

- Pari, L.; Alfano, V.; Scarfone, A.; Bergonzoli, S.; Suardi, A.; Lazar, S. Best available technologies to harvest cereal chaff. In Proceedings of the 26th European Biomass Conference and Exhibition (EUBCE), Copenhagen, Denmark, 2018; Available online: http://www.etaflorence.it/proceedings/?detail=15108 (accessed on 17 January 2020).

- EU Agroinlog—Integrated Biomass Logistic Centres fo the Agro-Industry. Available online: http://agroinlog-h2020.eu/en/home/ (accessed on 17 January 2020).

- Thievin Matériel Agricole, Travaux Publics & Environnement. Available online: https://www.thievin.fr/ (accessed on 17 January 2020).

- American Society of Agricultural Engineers. Agricultural Machinery Management; American Society of Agricultural Engineers: St. Joseph, MI, USA, 2000; pp. 344–349. [Google Scholar]

- NSAI. ISO 17828:2015, Solid Biofuels—Determination of Bulk Density; NSAI: Vernier, Geneva, Switzerland, December 2015; Available online: https://www.iso.org/standard/60687.html (accessed on 6 March 2020).

- NSAI. ISO 18134-2:2017, Solid Biofuels—Determination ofMoisture content—Oven Dry Method—Part 2: Total Moisture—Simplified Method; NSAI: Vernier, Geneva, Switzerland, September 2015; Available online: https://www.iso.org/standard/61539.html (accessed on 6 March 2020).

- R Development Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing, Vienna Austria 2010. Available online: http://www.r-project.org/ (accessed on 6 March 2020).

- Abdi, H.; Williams, L.J. Tukey’s Honestly Signiflcant Difierence (HSD) Test; Sage: Thousand Oaks, CA, USA, 2010. [Google Scholar]

- Unger, J.S.; Glasner, C. Cost analysis of chaff harvesting concepts in Germany. Agronomy 2019, 9, 579. [Google Scholar] [CrossRef] [Green Version]

- INRA. Recuperateur de Menues Pailles «turbo Paille de Thievin». Mignaloux-Beauvoir; 2011. Available online: https://geco.ecophytopic.fr/documents/20182/21720/upload_00011189_pdf (accessed on 6 March 2020).

- CUMA. Journée Technique: Récuperation des menues pailles. 2015. Available online: http://draaf.normandie.agriculture.gouv.fr/IMG/pdf/6_Powerpoint_journee_menues_pailles_FRCUMA_cle0bd622.pdf (accessed on 6 March 2020).

- Thiérart Etude, Conception et Réalisation de Machines Spéciales. Available online: https://www.thierart.fr/ (accessed on 17 January 2020).

- Decoopman PB. Le point sur la récupération des menues pailles. Terra. 2012:42-43. Available online: http://www.synagri.com/ca1/PJ.nsf/TECHPJPARCLEF/17252/$File/0042_328.pdf?OpenElement (accessed on 6 March 2020).

- Wiwart, M.; Bytner, M.; Graban, L.; Lajszner, W.; Suchowilska, E. Spelt (Triticum spelta) and emmer (T. dicoccon) chaffused as a renewable source of energy. BioResources 2017, 12, 3744–3750. [Google Scholar] [CrossRef] [Green Version]

- Pari, L.; Toscano, G.; Suardi, A.; Bergonzoli, S.; Lopez, E.; Scarfone, A.; Alfano, V. Maize cob and cereal chaff: Feedstocks for energy production. Eur. Biomass Conf. Exhib. Proc. 2018, 2018, 279–282. [Google Scholar]

| Harvesting Phase | 2018 | 2019 |

|---|---|---|

| Seed threshing | Combine: New Holland CX840 Thievin system: A and B mode | Combine: New Holland CX8.70 Thievin system: A, B and C mode |

| Biomass baling | Tractor: Deutz-Fahr Agrotron M620 Baler: Deutz-Fahr Varimaster 690 | Tractor: Deutz-Fahr Agrotron M620 Baler: Deutz-Fahr Varimaster 690 |

| Separate chaff collection | Not performed | Tractor: John Deere 8270R Trailer: Thievin Cortal 240 |

| Year | Block 1 | Block 2 | Block 3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Plot A1 chaff on swath | Plot B1 chaff spreading | Plot C1 chaff on trailer | Plot C2 chaff on trailer | Plot B2 chaff spreading | Plot A2 chaff on swath | Plot B3 chaff spreading | Plot A3 chaff on swath | Plot C3 chaff on trailer | |

| 2019 | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| 2018 | Y | Y | N | N | Y | Y | Y | Y | N |

| Treatment | Theoretical Field Capacity (ha h−1) | Effective Field Capacity (ha h−1) | Material Capacity (t FM h−1) | |||

|---|---|---|---|---|---|---|

| 2018 | 2019 | 2018 | 2019 | 2018 | 2019 | |

| A mode | 2.57 ± 0.13 | 2.56 ± 0.01 | 2.24 ± 0.11 | 1.98 ± 0.02 | 13.98 ± 0.13 | 17.27 ± 0.56 |

| B mode | 2.71 ± 0.09 | 2.61 ± 0.06 | 2.41 ± 0.10 | 2.04 ± 0.06 | 14.39 ± 0.13 | 17.25 ± 1.13 |

| C mode | np | 2.69 ± 0.12 | np | 2.03 ± 0.11 | np | 17.10 ± 0.77 |

| Treatment | Theoretical Field Capacity (ha h−1) | Effective Field Capacity (ha h−1) | Material Capacity (t FM h−1) | |||

|---|---|---|---|---|---|---|

| 2018 | 2019 | 2018 | 2019 | 2018 | 2019 | |

| A mode | 5.23 ± 0.65 | 4.64 ± 0.31 | 3.46 ± 0.28 b | 3.09 ± 0.13 b | 20.79 ± 0.7 a | 20.20 ± 2.0 a |

| B mode | 5.99 ± 0.16 | 4.82 ± 0.09 | 4.05 ± 0.16 a | 3.45 ± 0.10 a | 18.73 ± 0.7 b | 15.09 ± 0.7 b |

| C mode | np | 4.93 ± 0.13 | np | 3.33 ± 0.09 ab | np | 19.16 ± 2.5 ab |

| Treatment | Fuel Consumption (l ha−1) | Fuel Consumption (l h−1) | Fuel Consumption (l t−1) | |||

|---|---|---|---|---|---|---|

| 2018 | 2019 | 2018 | 2019 | 2018 | 2019 | |

| A mode | 4.65 ± 0.91 | 6.21 ± 1.5 a | 16.09 ± 3.36 | 19.13 ± 4.33 a | 0.77 ± 0.15 | 0.94 ± 0.12 a |

| B mode | 4.66 ± 0.11 | 2.81 ± 0.64 b | 19.02 ± 1.44 | 9.68 ± 3.87 b | 1.01 ± 0.13 | 0.64 ± 0.23 ab |

| C mode | np | 2.43 ± 0.94 b | np | 8.04 ± 2.90 b | np | 0.41 ± 0.09 b |

| Year | Theoretical Biomass (FM) | |

|---|---|---|

| 2018 | 2019 | |

| Total biomass (t ha−1) | 16.76 ± 1.44 | 18.69 ± 1.77 |

| Straw (t ha−1) | 7.39 ± 0.73 | 8.33 ± 0.75 |

| Wheat ears (t ha−1) | 9.37 ± 0.77 | 10.36 ± 1.34 |

| Seeds (t ha−1) | 7.32 ± 0.60 | 8.18 ± 1.06 |

| Chaff (t ha−1) | 2.04 ± 0.17 | 2.18 ± 0.28 |

| Treatment | Seed Harvested (t ha−1 FM) | |

|---|---|---|

| 2018 | 2019 | |

| A mode | 6.26 ± 0.19 | 8.15 ± 0.32 |

| B mode | 6.04 ± 0.06 | 7.85 ± 0.40 |

| C mode | np | 7.87 ± 0.10 |

| Mean | 6.17 ± 0.21 | 7.96 ± 0.30 |

| Moisture Content (%) | ||

|---|---|---|

| 2018 | 2019 | |

| Stems | 10.5 ± 0.6 | 11.9 ± 0.8 |

| Stubbles | np | 11.1 ± 1.3 |

| Ears | 10.0 ± 0.1 | 10.8 ± 0.5 |

| Chaff | 9.3 ± 0.2 | 9.2 ± 0.9 |

| Seeds | 10.3 ± 0.2 | 9.1 ± 0.1 |

| Bales | 9.78 ± 0.4 | 11.0 ± 0.7 |

| Seed Losses (t FM ha−1) | Chaff Losses (t FM ha−1) | Straw Losses (t FM ha−1) | ||||

|---|---|---|---|---|---|---|

| Treatment | 2018 | 2019 | 2018 | 2019 | 2018 | 2019 |

| A mode | 1.06 ± 0.24 | 0.04 ± 0.32 | 0.65 ± 0.59 | 0.00 ± 0.66 | 0.78 ± 0.36 | 2.26 ± 0.22 |

| B mode | 1.28 ± 0.06 | 0.33 ± 0.40 | 2.04 ± 0.0 | 2.18 ± 0.0 | 0.78 ± 0.36 | 2.25 ± 0.22 |

| C mode | np | 0.32 ± 0.10 | np | 0.90 ± 0.08 | np | 0.84 ± 0.93 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suardi, A.; Stefanoni, W.; Alfano, V.; Bergonzoli, S.; Pari, L. Equipping a Combine Harvester with Turbine Technology Increases the Recovery of Residual Biomass from Cereal Crops via the Collection of Chaff. Energies 2020, 13, 1572. https://doi.org/10.3390/en13071572

Suardi A, Stefanoni W, Alfano V, Bergonzoli S, Pari L. Equipping a Combine Harvester with Turbine Technology Increases the Recovery of Residual Biomass from Cereal Crops via the Collection of Chaff. Energies. 2020; 13(7):1572. https://doi.org/10.3390/en13071572

Chicago/Turabian StyleSuardi, Alessandro, Walter Stefanoni, Vincenzo Alfano, Simone Bergonzoli, and Luigi Pari. 2020. "Equipping a Combine Harvester with Turbine Technology Increases the Recovery of Residual Biomass from Cereal Crops via the Collection of Chaff" Energies 13, no. 7: 1572. https://doi.org/10.3390/en13071572

APA StyleSuardi, A., Stefanoni, W., Alfano, V., Bergonzoli, S., & Pari, L. (2020). Equipping a Combine Harvester with Turbine Technology Increases the Recovery of Residual Biomass from Cereal Crops via the Collection of Chaff. Energies, 13(7), 1572. https://doi.org/10.3390/en13071572