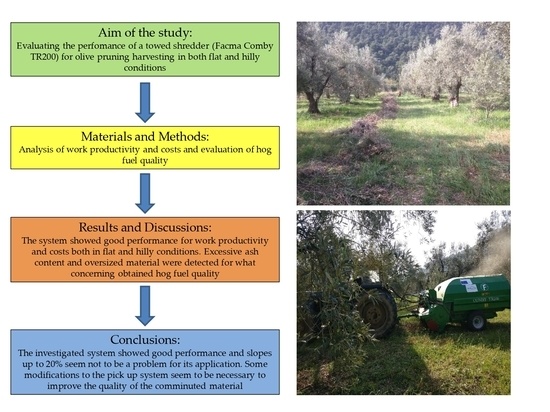

Machine Performance and Hog Fuel Quality Evaluation in Olive Tree Pruning Harvesting Conducted Using a Towed Shredder on Flat and Hilly Fields

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Area

2.2. Harvesting System Description

2.3. Data Collection

2.3.1. Field Work Evaluation

2.3.2. Post Harvest Measurements and Data Analysis

2.4. Cost Analysis

3. Results

3.1. Machine Performance and Quality of the Woody Comminuted Product

3.2. Cost Analysis

4. Discussion

4.1. Machine Performance and Quality of the Work and Woody Comminuted Product

4.2. Cost Analysis

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations:

| IBLC | Integrated biomass logistics center |

| NUTS | Nomenclature of Territorial Units for Statistics in Greece |

| FL | Flat slope experimental field |

| HL | Hilly slope experimental field |

| TFC | Theoretical field capacity (ha·h−1) |

| EFC | Effective field capacity (ha·h–1) |

| OT | Operating time (h) |

| MC | Material capacity (t·h−1) |

| PSD | Particle size distribution |

| HHV | Higher heating value (MJ·kg−1) |

| CRPA | Centro Ricerca per le Produzioni Animali |

| CERTH | The Centre for Research & Technology, Hellas |

| CPERI | Chemical Process Engineering Research Institute |

| FM | Fresh matter |

| DM | Dry matter |

| INASO-PASEGES | Institouto Agrotikis kai Sinetairistikis Oikonomias |

| NUTRIA | NUTRIA S.A., Agios Kostantinos, Fthiotida, Greece |

References

- Talbert, R.J.A. Atlas of Classical History; Routledge: Milton Park, UK, 2002; ISBN 1134966539. [Google Scholar]

- Lu, L.; Tang, Y.; Xie, J.; Yuan, Y. The role of marginal agricultural land-based mulberry planting in biomass energy production. Renew. Energy 2009, 34, 1789–1794. [Google Scholar] [CrossRef]

- Torquati, B.; Marino, D.; Venanzi, S.; Porceddu, P.; Chiorri, M. Using tree crop pruning residues for energy purposes: A spatial analysis and an evaluation of the economic and environmental sustainability. Biomass Bioenergy 2016, 95, 124–131. [Google Scholar] [CrossRef]

- Akhmedov, S.; Ivanova, T.; Abdulloeva, S.; Muntean, A.; Krepl, V. Contribution to the Energy Situation in Tajikistan by Using Residual Apricot Branches after Pruning as an Alternative Fuel. Energies 2019, 12, 3169. [Google Scholar] [CrossRef] [Green Version]

- Alatzas, S.; Moustakas, K.; Malamis, D.; Vakalis, S. Biomass Potential from Agricultural Waste for Energetic Utilization in Greece. Energies 2019, 12, 1095. [Google Scholar] [CrossRef] [Green Version]

- García-Galindo, D.; Dyjakon, A.; Cay Villa-Ceballos, F. Building Variable Productivity Ratios for Improving Large Scale Spatially Explicit Pruning Biomass Assessments. Energies 2019, 12, 957. [Google Scholar] [CrossRef] [Green Version]

- Dyjakon, A. The influence of apple orchard management on energy performance and pruned biomass harvesting for energetic applications. Energies 2019, 12, 632. [Google Scholar] [CrossRef] [Green Version]

- Spinelli, R.; Magagnotti, N.; Nati, C.; Cantini, C.; Sani, G.; Picchi, G.; Biocca, M. Integrating olive grove maintenance and energy biomass recovery with a single-pass pruning and harvesting machine. Biomass Bioenergy 2011, 35, 808–813. [Google Scholar] [CrossRef]

- Gasol, C.M.; Gabarrell, X.; Rigola, M.; González-García, S.; Rieradevall, J. Environmental assessment:(LCA) and spatial modelling (GIS) of energy crop implementation on local scale. Biomass Bioenergy 2011, 35, 2975–2985. [Google Scholar] [CrossRef]

- Dyjakon, A.; García-Galindo, D. Implementing agricultural pruning to energy in europe: Technical, economic and implementation potentials. Energies 2019, 12, 1513. [Google Scholar] [CrossRef] [Green Version]

- Pari, L.; Suardi, A.; Frąckowak, P.; Adamczyk, F.; Szaroleta, M.; Santangelo, E.; Bergonzoli, S.; Del Giudice, A.; Dyjakon, A. Two innovative prototypes for collecting pruning biomass: Early performance tests and assessment of the work quality. Biomass Bioenergy 2018, 117, 96–101. [Google Scholar] [CrossRef]

- Ghaderi, H.; Pishvaee, M.S.; Moini, A. Biomass supply chain network design: An optimization-oriented review and analysis. Ind. Crop. Prod. 2016, 94, 972–1000. [Google Scholar] [CrossRef]

- Pari, L.; Suardi, A.; Santangelo, E.; García-Galindo, D.; Scarfone, A.; Alfano, V. Current and innovative technologies for pruning harvesting: A review. Biomass Bioenergy 2017, 107, 398–410. [Google Scholar] [CrossRef]

- Agroinlog Integrated Biomass Logistic Centres for the Agro-industry. EU Horizon 2020 Research and Innovation Programme—Grant Agreement No 727961. Available online: http://agroinlog-h2020.eu/en/home/ (accessed on 14 February 2020).

- Annevelink, B.; Van Gogh, B.; Nogués, F.S.; Espatolero, S.; De La Cruz, T.; Luzzini, D.; Karampinis, M.; Kougioumtzis, M.; Olsson, J. Conceptual description of an integrated biomass logistics centre (IBLC). In Proceedings of the European Biomass Conference and Exhibition Proceedings, Stockholm, Sweden, 12–15 June 2017; Volume 2017, pp. 200–203. [Google Scholar]

- Picchi, G.; Spinelli, R. Industrial harvester biomass procurement of olive trees residues. In Proceedings of the 19th Europian Biomass Conference and Exhibition, Berlin, Germany, 6–10 June 2011; pp. 6–10. [Google Scholar]

- Manzone, M.; Gioelli, F.; Balsari, P. Effects of Different Storage Techniques on Round-Baled Orchard-Pruning Residues. Energies 2019, 12, 1044. [Google Scholar] [CrossRef] [Green Version]

- Dyjakon, A. The influence of the use of windrowers in baler machinery on the energy balance during pruned biomass harvesting in the apple orchard. Energies 2018, 11, 3236. [Google Scholar] [CrossRef] [Green Version]

- Acampora, A.; Croce, S.; Assirelli, A.; Del Giudice, A.; Spinelli, R.; Suardi, A.; Pari, L. Product contamination and harvesting losses from mechanized recovery of olive tree pruning residues for energy use. Renew. Energy 2013, 53, 350–353. [Google Scholar] [CrossRef]

- Civitarese, V.; Del Giudice, A.; Suardi, A.; Santangelo, E.; Pari, L. Study on the effect of a new rotor designed for chipping short rotation woody crops. Croat. J. For. Eng. J. Theory Appl. For. Eng. 2015, 36, 101–108. [Google Scholar]

- Del Giudice, A.; Assirelli, A.; Gallucci, F.; Bellacima, R.; Pari, L.; Santangelo, E. Production of energy feedstock from the riparian vegetation of Arundo donax (L.): Suitability of the chopping systems. Ecol. Eng. 2017, 102, 459–467. [Google Scholar] [CrossRef]

- Spinelli, R.; Cavallo, E.; Eliasson, L.; Facello, A. Comparing the efficiency of drum and disc chippers. Silva Fenn. 2013, 47, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Abdallah, R.; Auchet, S.; Méausoone, P.J. Experimental study about the effects of disc chipper settings on the distribution of wood chip size. Biomass Bioenergy 2011, 35, 843–852. [Google Scholar] [CrossRef]

- Barontini, M.; Scarfone, A.; Spinelli, R.; Gallucci, F.; Santangelo, E.; Acampora, A.; Jirjis, R.; Civitarese, V.; Pari, L. Storage dynamics and fuel quality of poplar chips. Biomass Bioenergy 2014, 62, 17–25. [Google Scholar] [CrossRef]

- Nati, C.; Boschiero, M.; Picchi, G.; Mastrolonardo, G.; Kelderer, M.; Zerbe, S. Energy performance of a new biomass harvester for recovery of orchard wood wastes as alternative to mulching. Renew. Energy 2018, 124, 121–128. [Google Scholar] [CrossRef]

- Nati, C.; Spinelli, R.; Fabbri, P. Wood chips size distribution in relation to blade wear and screen use. Biomass Bioenergy 2010, 34, 583–587. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Nati, C.; Pari, L.; Vanneste, J.L. Recovering kiwifruit pruning residues for biomass production. Trans. ASABE 2012, 55, 21–28. [Google Scholar] [CrossRef]

- Jones, T.G.; Song, G.G.; Richardson, J.D. Effect of chipper setting on chip size distribution and mechanical pulp properties. Appita Technol. Innov. Manuf. Environ. 2005, 58, 56. [Google Scholar]

- Hellenic Statistical Authority (ELSTAT). Annual Agricultural Statistical Survey: 2015. Available online: www.statistics.gr (accessed on 10 January 2020).

- Kougioumtzis, M.-A.; Karampinis, E.; Grammelis, P.; Kakaras, E. Assessment of biomass resources for an integrated biomass logistics center (IBLC) operating in the olive oil sector. In Proceedings of the European Biomass Conference and Exhibition Proceedings, Copenhagen, Denmark, 14–17 May 2018; Volume 2018, pp. 309–313. [Google Scholar]

- ASAE. ASAE S495 Uniform Terminology for Agricultural Machinery Management. Society 2000, 342–343. [Google Scholar]

- EN ISO 18134-2:2017. Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method. Available online: https://www.iso.org/standard/71536.html (accessed on 15 March 2020).

- ISO 17828:2015. Solid Biofuels—Determination of Bulk Density. 2015; Available online: https://www.iso.org/obp/ui/#iso:std:iso:17828:ed-1:v1:en (accessed on 15 March 2020).

- ISO 17225-4:2014. Solid Biofuels—Fuel Specifications and Classes—Part 4: Graded Wood Chips. Available online: https://www.iso.org/standard/59459.html (accessed on 15 March 2020).

- ISO 18122:2015. Solid Biofuels—Determination of Ash Content. Available online: https://www.iso.org/obp/ui/#iso:std:iso:18122:ed-1:v1:en (accessed on 15 March 2020).

- ISO 18125:2015. Solid Biofuels—Determination of the Gross Calorific Value.

- Assirelli, A.; Pignedoli, S. Costo di esercizio delle macchine agricole. Cent. Ric. Prod. Anim. 2005, 5, 1–10. [Google Scholar]

- Picchi, G.; Lombardini, C.; Pari, L.; Spinelli, R. Physical and chemical characteristics of renewable fuel obtained from pruning residues. J. Clean. Prod. 2018, 171, 457–463. [Google Scholar] [CrossRef]

- Spinelli, R.; Picchi, G. Industrial harvesting of olive tree pruning residue for energy biomass. Bioresour. Technol. 2010, 101, 730–735. [Google Scholar] [CrossRef]

- Velázquez-Martí, B.; Fernández-González, E. Analysis of the process of biomass harvesting with collecting-chippers fed by pick up headers in plantations of olive trees. Biosyst. Eng. 2009, 104, 184–190. [Google Scholar] [CrossRef]

- Assirelli, A.; Croce, S.; Acampora, A. Potature di olivo da energia le trinciacaricatrici più adatte. L’Informatore Agrario 2012, 25, 32–36. [Google Scholar]

- Recchia, L.; Daou, M.; Rimediotti, M.; Cini, E.; Vieri, M. New shredding machine for recycling pruning residuals. Biomass Bioenergy 2009, 33, 149–154. [Google Scholar] [CrossRef]

- Suardi, A.; Latterini, F.; Alfano, V.; Palmieri, N.; Bergonzli, S.; Pari, L. Analysis of the Work Productivity and Costs of a Stationary Chipper Applied to the Harvesting of Olive Tree Pruning for Bio-Energy Production. Energies 2020, 13, 1359. [Google Scholar] [CrossRef] [Green Version]

- Prislan, P.; Krajnc, N.; Jemec, T.; Piškur, M. Monitoring of wood fuel prices in Slovenia, Austria, Italy, Croatia, Romania, Germany, Spain and Ireland. In Biomass Trade Center II Project, Wood Fuel Prices Report; Findings of Biomass Trade Center II Project; Biomass Trade Center, 2014. [Google Scholar]

| Characteristic | Unit | Flat Slope (FL) | Hilly Slope (HL) |

|---|---|---|---|

| Surface | ha | 0.6 | 1.67 |

| Exposition | --- | Northwest | |

| Prevalent Slope | % | 2.50 | 19.70 |

| Minimum Slope | % | 1.50 | 15.80 |

| Maximum Slope | % | 3.60 | 21.80 |

| Layout (Width between rows × distance between trees) | m × m | 10 × 10 | 10 × 10 |

| Olive variety | Amfissis | Amfissis | |

| Number of olive trees | 76 | 175 | |

| Average pruning Ø | cm | 3 | 3 |

| Average pruning lenght | cm | 204 | 215 |

| Average windrow width | cm | 140 | 162 |

| Average windrow height | cm | 55 | 55 |

| Parameters | Unit | Facma Comby TR200 | Ford 4610 | Ebro Model 85 | Abimac Girolivo |

|---|---|---|---|---|---|

| Investment | € | 21,000.00 | 38,690.00 | 80,166.00 | 12,900.00 |

| Service life | yr | 10 | 10 | 10 | 10 |

| Usage | h·yr−1 | 460 | 460 | 460 | 460 |

| Labour cost | €·h−1 | 11.50 | 11.50 | ||

| Workers | n | 1 | 1 |

| Machine Performance | Unit | Pruning Rake (FL) | Pruning Rake (HL) | Facma Comby TR200 (FL) | Facma Comby TR200 (HL) |

|---|---|---|---|---|---|

| Theoretical Field capacity | ha·h−1 | 1.13 | 1.57 | 2.98 ± 0.39 * | 1.56 ± 0.10 * |

| Effective Field capacity | ha·h−1 | 0.60 | 0.88 | 1.57 ± 0.16 * | 0.79 ± 0.21 * |

| Field efficiency | % | 0.53 | 0.56 | 0.52 ± 0.70 | 0.51 ± 0.12 |

| Working speed | km·h−1 | --- | --- | 3.85 ± 0.57 * | 1.94 ± 0.13 * |

| Biomass yield | tfm·ha−1 | --- | --- | 2.29 ± 0.54 * | 5.01 ± 1.61 * |

| Biomass yield | tdm·ha−1 | 1.67 ± 0.38 * | 3.66 ± 1.13 * | ||

| Material capacity | tfm·h−1 | --- | --- | 3.56 ± 0.68 | 3.75 ± 0.44 |

| Material capacity | tdm·h−1 | --- | --- | 2.60 ± 0.50 | 2.74 ± 0.32 |

| Losses | % | --- | --- | 23 ± 12 | 27 ± 7 |

| Fuel consumption | L·ha−1 | 3.01 | 2.11 | 8.1 ± 0.3 | 18.5 ± 3.9 |

| Fuel consumption | L·tfm−1 | 0.74 | 0.75 | 3.7 ± 0.7 | 3.8 ± 0.8 |

| Fuel consumption | L·tdm−1 | 1.01 | 1.03 | 5.1 ± 1.0 | 5.2 ± 1.1 |

| Fuel consumption | L·h−1 | 1.81 | 1.85 | 12.7 ± 0.8 | 14.2 ± 1.7 |

| Hog Fuel Characteristics | Unit | Pruning Rake (FL) | Pruning Rake (HL) | Facma Comby TR200 (FL) | Facma Comby TR200 (HL) |

| Bulk density | kg·m−3 | --- | --- | 229 ± 8 | 224 ± 14 |

| Moisture content | %, w.b. | --- | --- | 27.3 ± 1.39 | 27.8 ± 1.42 |

| Ash content | %, d.b. | --- | --- | 4.00 ± 0.11 | 4.20 ± 0.19 |

| Higher heating value | MJ·kg−1, d.b. | --- | --- | 19.58 | 20.27 |

| Particle Size | PSD | Cumulative Distribution |

|---|---|---|

| [mm] | [%] | [%] |

| < 3.15 mm | 12 | 12.00 |

| 3–15–8 mm | 27.69 | 39.69 |

| 8–16 mm | 26.37 | 66.06 |

| 16–45 mm | 17.53 | 83.59 |

| 45–63 mm | 0.59 | 84.18 |

| > 63 mm | 15.82 | 100.00 |

| Cost Item | Measure Unit | Facma Comby TR200 | Ebro Model 85 | Ford 4610 | Abimac Girolivo | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| FL | HL | FL | HL | FL | HL | FL | HL | |||

| Fixed Costs | Reintegration quote | €·yr−1 | 1728.63 | 1728.63 | 5355.73 | 5355.73 | 2584.80 | 2584.80 | 1033.66 | 1033.66 |

| Interests | €·yr−1 | 370.71 | 370.71 | 1601.62 | 1601.62 | 772.98 | 772.98 | 231.95 | 231.95 | |

| Shelter | €·yr−1 | 17.11 | 17.11 | 15.06 | 15.06 | 13.66 | 13.66 | 4.00 | 4.00 | |

| Insurance | €·yr−1 | 52.50 | 52.50 | 200.42 | 200.42 | 96.73 | 96.73 | 32.25 | 32.25 | |

| Miscellaneous expenses | €·yr−1 | 69.61 | 69.61 | 215.47 | 215.47 | 110.38 | 110.38 | 36.25 | 36.25 | |

| Total fixed cost per year | €·yr−1 | 2168.95 | 2168.95 | 7172.82 | 7172.82 | 3468.16 | 3468.16 | 1301.86 | 1301.86 | |

| Total fixed cost per hour | €·h−1 | 4.72 | 4.72 | 15.59 | 15.59 | 7.54 | 7.54 | 2.83 | 2.83 | |

| Variable Costs | Maintenance | €·h−1 | 1.68 | 1.68 | 1.51 | 1.51 | 0.73 | 0.73 | 1.03 | 1.03 |

| Fuel | €·h−1 | --- | --- | 7.29 | 8.15 | 1.04 | 1.06 | --- | --- | |

| Lubricant | €·h−1 | --- | --- | 0.24 | 0.24 | 0.14 | 0.14 | --- | --- | |

| Manpower | €·h−1 | --- | --- | 11.50 | 11.50 | 11.50 | 11.50 | --- | --- | |

| Total variable cost per hour | €·h−1 | 1.68 | 1.68 | 20.53 | 21.39 | 13.41 | 13.43 | 1.03 | 1.03 | |

| Total cost per year | €·yr−1 | 2940.41 | 2940.41 | 16617.50 | 17013.56 | 9635.72 | 9646.28 | 1775.76 | 1775.76 | |

| Total cost per hour | €·h−1 | 6.39 | 6.39 | 36.13 | 36.99 | 20.95 | 20.97 | 3.86 | 3.86 | |

| Total cost per hectare | €·ha−1 | 4.07 | 8.09 | 23.01 | 46.82 | 34.91 | 23.83 | 6.43 | 4.39 | |

| Total cost per ton | €·tfm−1 | 1.78 | 1.62 | 10.05 | 9.34 | 15.25 | 4.76 | 2.81 | 0.88 | |

| Harvesting Cost | Unit | Harvesting Operation | Harvesting + Raking Operations | ||

|---|---|---|---|---|---|

| FL | HL | FL | HL | ||

| Hourly cost | €·h−1 | 42.52 | 43.38 | 67.32 | 68.21 |

| Cost per unit area | €·ha−1 | 27.08 | 54.91 | 68.43 | 83.13 |

| Cost per product unit (FM) | €·tfm−1 | 11.83 | 10.96 | 29.88 | 16.59 |

| Cost per product unit (DM) | €·tdm−1 | 16.27 | 15.18 | 41.10 | 22.98 |

| Machine | Reference | Field Capacity (ha·h−1) | Material Capacity (tfm·h−1) |

|---|---|---|---|

| Facma Comby TR200 FL | This study | 1.57 | 3.56 |

| Facma Comby TR200 HL | This study | 0.79 | 3.75 |

| Favaretto Speedy Cut | [8] | 0.39 | 0.72 |

| SAT-4 | [8] | 3.37 | 6.01 |

| Jordan | [8] | 0.60 | 6.70 |

| Serrat Olipack T1800 | [40] | 0.78 | 1.38 |

| Berti Picker C180 | [40] | 0.85 | 1.26 |

| Promagri 2000 | [40] | n.d. | 1.36 |

| Jounes Atila | [40] | n.d. | 0.69 |

| Tierre Plano | [41] | 0.85 | 11.00 |

| Nobili TRP-RT 145 | [42] | n.d. | 0.53 |

| Caravaggi BIO900 | [43] | 0.60 | 7.26 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suardi, A.; Latterini, F.; Alfano, V.; Palmieri, N.; Bergonzoli, S.; Karampinis, E.; Kougioumtzis, M.A.; Grammelis, P.; Pari, L. Machine Performance and Hog Fuel Quality Evaluation in Olive Tree Pruning Harvesting Conducted Using a Towed Shredder on Flat and Hilly Fields. Energies 2020, 13, 1713. https://doi.org/10.3390/en13071713

Suardi A, Latterini F, Alfano V, Palmieri N, Bergonzoli S, Karampinis E, Kougioumtzis MA, Grammelis P, Pari L. Machine Performance and Hog Fuel Quality Evaluation in Olive Tree Pruning Harvesting Conducted Using a Towed Shredder on Flat and Hilly Fields. Energies. 2020; 13(7):1713. https://doi.org/10.3390/en13071713

Chicago/Turabian StyleSuardi, Alessandro, Francesco Latterini, Vincenzo Alfano, Nadia Palmieri, Simone Bergonzoli, Emmanouil Karampinis, Michael Alexandros Kougioumtzis, Panagiotis Grammelis, and Luigi Pari. 2020. "Machine Performance and Hog Fuel Quality Evaluation in Olive Tree Pruning Harvesting Conducted Using a Towed Shredder on Flat and Hilly Fields" Energies 13, no. 7: 1713. https://doi.org/10.3390/en13071713

APA StyleSuardi, A., Latterini, F., Alfano, V., Palmieri, N., Bergonzoli, S., Karampinis, E., Kougioumtzis, M. A., Grammelis, P., & Pari, L. (2020). Machine Performance and Hog Fuel Quality Evaluation in Olive Tree Pruning Harvesting Conducted Using a Towed Shredder on Flat and Hilly Fields. Energies, 13(7), 1713. https://doi.org/10.3390/en13071713