3.1. Test Verification

To validate the numerical simulation method used in this study, the original model was tested. As shown in

Figure 5, the test rig is an open-type system, which is composed of two parts, namely, the data acquisition system and the water circulation system. The DN100 electromagnetic flowmeter whose maximum allowable error is ±0.5% was used to measure the flow rate

Q. The valve of the pump inlet pipeline was fully opened during the test and the flow condition points were collected through the pump outlet pipeline valve. To secure a smooth external characteristic curve during the collection process, recording was performed at an interval of 5 m

3/h from the shutoff point to the large flow condition point for a total of 17 operating points.

Table 4 shows the pump performance test results. As the rotational speed of the pump was not constant at 2850 r/min during actual operation, for an effective comparison against the numerical calculation results, the external characteristic data of the pump was converted to a rated speed of 2850 r/min according to the rules of similarity theory.

Figure 6 shows a comparison between the test-based and simulated pump performance indicators. To completely reflect the external characteristic variation curve from the shutoff point to the maximum flow condition during the pump test, eight flow condition points were simulated from 0.1

Q to 1.4

Q. The numerical simulation results accurately predicted the external characteristic curve of the pump within the whole range of operating conditions as observed in the test. The relative errors in the head, efficiency, and power of the rated operating points were 4.4%, 2.95%, and 4%, respectively. All were smaller than 5%, which indicates that the numerical simulation method was accurate. Further, these results suggest that the orthogonal design case accurately reflects slotting effects numerically.

3.2. Direct Analysis of Orthogonal Design Case

Sixteen sets of orthogonal design cases were used in this study. Prototyping all of them would be costly and time-consuming, so considering the accuracy of the numerical calculation method, the full flow field numerical simulation method was selected as the research tool for this orthogonal design. To observe the effects of slotting on the performance of the medium specific speed centrifugal pump, full flow field numerical simulations were conducted at four operating condition points: 0.6Q, 0.8Q, 1.0Q, 1.2Q, and 1.4Q for 16 sets of slotted impellers in conjunction with the volutes.

This study centers on the effects of different slotting cases on pump performance.

Table 5,

Table 6 and

Table 7 show the numerical simulation results of 0.6

Q, 1.0

Q, and 1.4

Q, respectively. The orthogonal test data was processed to assess the main factors influencing the pump head and efficiency in the slotted blade case [

18]. The range analysis method was used to observe the effects of the levels of the factors at 0.6

Q, 1.0

Q, and 1.4

Q operating conditions on the pump’s performance.

In the case of a greater range, different levels of a given factor lead to a larger amplitude of variations in the test indicators. To this effect, the factor corresponding to the maximum range was the most important factor.

Ki(

i = 1,2,3,4) denotes the sum of the tests of the same level in any of the columns in

Table 3, where

i corresponds to different levels of the same factor,

ki =

Ki/

n denotes the arithmetic mean value of different levels of the same factor,

n denotes the number of occurrence of the same level in any of the columns in the table, and

R = max(k1,

k2,

k3,

k4) −

min(k1,

k2,

k3,

k4) denotes the range. A range analysis of 0.6Q are shown in

Table 8 and

Table 9.

The primary and secondary geometric parameters of slots influencing the pump performance at 0.6

Q were obtained as shown in

Table 10.

The primary and secondary geometric parameters of slots influencing the pump performance at 1.0

Q were obtained as shown in

Table 13.

The primary and secondary geometric parameters of slots influencing the pump performance at 1.4

Q were obtained as shown in

Table 16.

Range analyses of the operating condition points, 0.6Q, 1.0Q, and 1.4Q indicated that the slot width and depth under the small flow conditions and rated conditions have the greatest effects on the pump head and efficiency among the parameters tested. The slot position appeared to have little effect on the performance of the pump under small flow conditions. In the case of large flow conditions, however, the slot position had a greater effect on pump performance than any other parameter.

To analyze the effects of the changes in factor levels on the pump performance more intuitively, a trend variation chart was plotted with the head and efficiency of the pump as indicators. As shown in

Figure 7, the head

h0.6Q was the largest when the blade slotting position

p was close to the outlet side and the slot deflection angle

β was the smallest under the small flow condition 0.6

Q. The head

h0.6Q decreased progressively as slot width

b1 and the slot depth

h increased, and an inflection point emerged on the curve of the head

h0.6Q as slot position

p varied. Based on the steepness of the curve variation trend, the primary and secondary factors influencing the head

h0.6Q were slot width

b1, slot deflection angle

β, slot depth

h, and slot position

p, respectively. This result was consistent with the range analysis results. The efficiency

η0.6Q also increased as

b1 and

h decreased. The efficiency

η0.6Q curve trend also presented an inflection point with the changes in the slot position. Based on the trend graph, in order of intensity, the factors influencing the efficiency

η0.6Q were slot depth

h, slot width

b1, slot deflection angle

β, and slot position

p.

As shown in

Figure 8 and

Figure 9, under the conditions of 1.0

Q and 1.4

Q, the heads of

h1.0Q and

h1.4Q were the largest when the blade slot position

p was in the vicinity of the inlet edge of the blade. Like 0.6

Q, the heads of

h1.0Q and

h1.4Q and the efficiencies of

η1.0Q and

η1.4Q decreased progressively as slot width

b1 and the slot depth

h increased.

h1.0Q,

h1.4Q,

η1.0Q, and

η1.4Q also increased progressively as slot deflection angle

β increased.

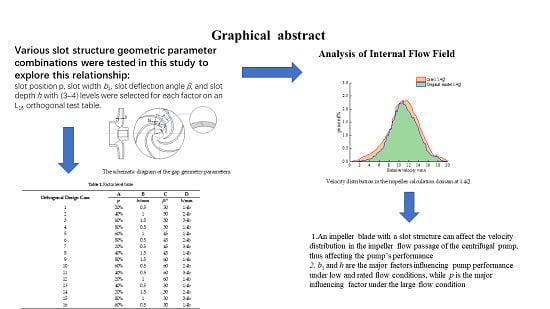

3.3. Analysis of Internal Flow Field

The orthogonal test results suggest that blade slotting improved the head at small flow condition points and the efficiency at large flow condition points, which is consistent with previously published results. Under the working condition of 0.6

Q, the head of Case 1 was 39.3 m; in the original case the head was 38.5 m. The head and efficiency in Case 1 for the 1.4

Q condition were 30.15 m and 77.86%, respectively, and in the original case were 30.05 m and 77.09%. To further explore the effects of the geometric slot parameters on pump performance, the distributions of performance curves of the original model and Case 1 were compared as shown in

Figure 10.

Figure 11 and

Figure 12 show cloud diagrams of the static pressure distribution of the blade unfolding at the section of the pump impeller flow passage (the section value Span was 0.9) in the original model and Case 1 of slotted blades under the conditions of 0.6

Q and 1.4

Q, respectively. As shown in

Figure 11, under the 0.6

Q condition, the static pressure distributions of the blade unfolding in Case 1 and the original model differed significantly. The distribution of pressure in the impeller flow passage from the blade inlet to the outlet was characterized by a low-pressure region in the first half-section of the impeller flow passage and a high-pressure region in the second half-section of the passage. The pressure gradient in the second half-section of the impeller flow passage was large because the flow passage diffusion was severe, which might have created a secondary back flow at the outlet of the impeller under small flow conditions. This is also likely a cause of the low efficiency of the medium-low specific speed centrifugal pump at the small flow condition point.

A significant low-pressure region was also observed in the position close to the inlet edge of the original model. Due to slotting in the position close to the inlet edge of the impeller, the distribution of blade unfolding static pressure disappears in the low-pressure region close to the inlet position of the blade in Case 1 and the pressure distribution is significantly more uniform than that in the original model. Vortexes and back flows are unlikely to form in the inlet position of the blade in this case, which is also one of the reasons why the head of the model in Case 1 is larger than that of the original model under the 0.6Q condition.

Under the 1.4Q large-flow condition, the diagram for the blade unfolding static pressure distribution in the case of the original model was similar to that in Case 1, however, the original model had a significant low-pressure region with considerable variations in the pressure gradient in the first half-section of the impeller flow passage inlet. This is mainly because the fluid flow angle of the incoming liquid increases with the flow rate while the inlet setting angle of the blade remains unchanged. As a result, the inlet setting angle is smaller than the liquid flow angle; a flow cutoff forms at the working surface in the position of the blade inlet creating a low-pressure region. Similarly, the changes in pressure gradient in the static pressure distribution diagram of blade unfolding in Case 1 are smaller than those of the original model due to the fact that the blade is slotted near the inlet.

As shown in

Figure 13, the pressure distribution is shown on the blade surface at the mean circumferential flow surface. Under 0.6

Q, the pressure distribution of the original model and the Case 1 model were quite different (

Figure 13). At the position near the inlet side, the pressure of the pressure surface and the suction surface of the Case 1 model were larger than the original model. This further illustrates that the Case 1 model improved the pressure distribution at the inlet edge of the blade due to slotting. The pressure near the inlet edge of the blade was higher than that of the original model under the 1.4Q large-flow condition.

Figure 14 and

Figure 15 show the distribution of pressure clouds in the middle plane of the blade flow channel. The pressure gradient distribution of the Case 1 model is more uniform than the original model under the 0.6

Q condition (

Figure 14); the original model shows a lower pressure than the Case 1 model near the blade inlet as well, which is consistent with the findings shown in

Figure 11 and

Figure 12. The enlarged view in the figure shows where, due to the existence of a gap, the local low-pressure gradient distribution was more uniform in the original model. This gap jet made the streamline in the inlet low-pressure area closer to the profile of the blade airfoil, thereby improving the local flow field.

Figure 15 shows that under the large flow rate of 1.4

Q, the impact of the gap on the local area was relatively small. The local enlarged view did not show similar phenomena to the small flow conditions. Generally speaking, the gap improved the local flow field under small flow conditions.

Figure 16 shows a diagram of the relative velocity distribution under the 1.4

Q operating condition in the impeller calculation domain. This distribution was normal; the average velocity of the impeller calculation domain was basically 11 m/s. The velocity distribution amplitude of velocity in Case 1 was larger than that of the original model, which indicates that the velocity within the impeller was concentrated near the desired value and was uniform throughout the impeller calculation domain. This was also one of the reasons why the efficiency and head of Case 1 were larger than those of the original model.