Transient Simulation of Underground Pumped Storage Hydropower Plants Operating in Pumping Mode

Abstract

:1. Introduction

2. Methodology

2.1. Problem Statement

2.2. Mathematical Formulation

2.3. Numerical Model

2.3.1. Mesh Description

2.3.2. Mesh Grid Sensitivity

2.3.3. Solution Setup and Boundary Conditions

3. Results and Discussion

3.1. Analytical Model Results

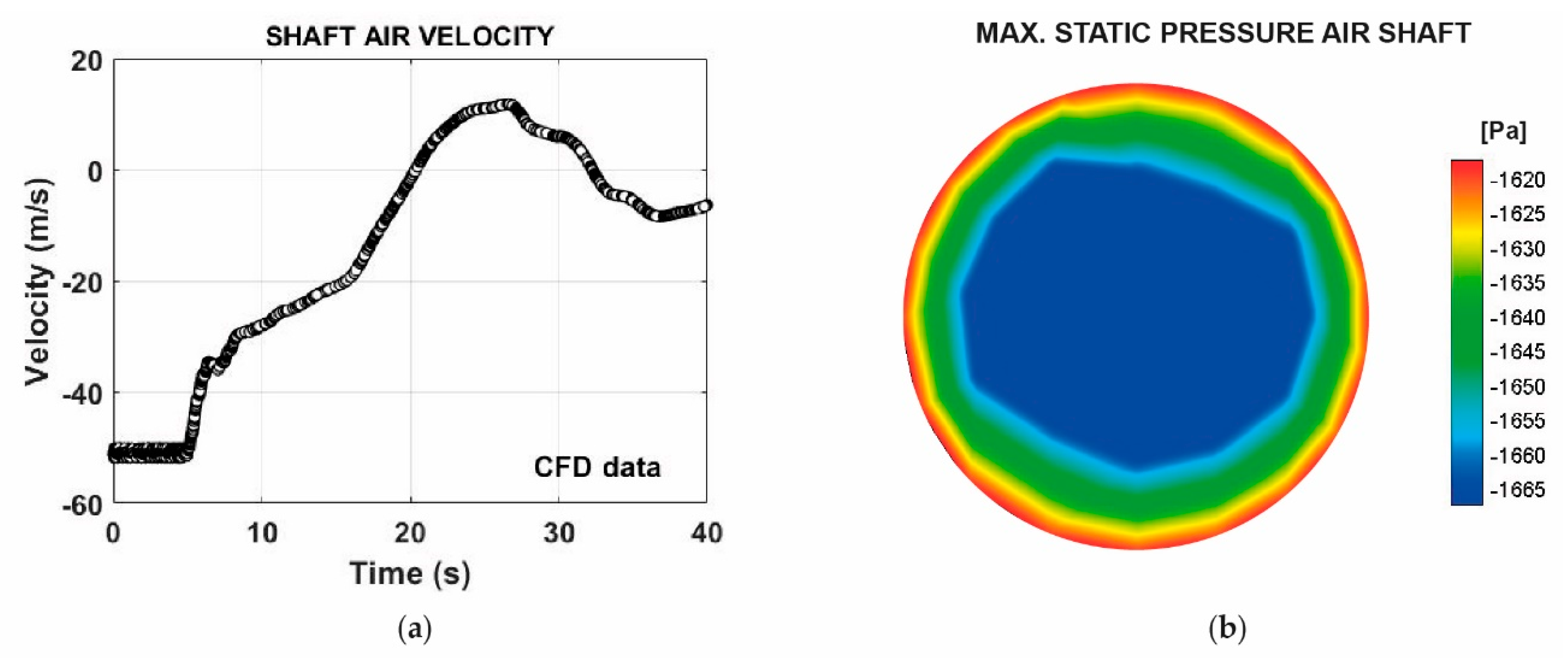

3.2. Numerical Results

3.3. Comparison of Analytial and CFD Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Cp | Specific heat (J kg−1 K−1) |

| D | Tunnel diameter (m) |

| f | Friction factor (-) |

| g | Gravity acceleration (9.8 m s−2) |

| H | Water level in the surge tank (m) |

| H’ | Water level in the underground reservoir (m) |

| HST | Water level of the surge tank (m) |

| L | Tunnel length (m) |

| le | Connection tunnel-surge tank (m) |

| P | Surge tank air pressure (Pa) |

| Patm | Atmospheric pressure (101,325 Pa) |

| Pr | Reservoir pressure (Pa) |

| QB | Pump flow rate (m3 s−1) |

| Se | Surge tank connection cross section (m2) |

| SST | Surge tank cross section (m2) |

| ST | Tunnel cross section (m2) |

| t | Time (s) |

| ϒ | Polytropic exponent value (-) |

| T | Temperature (K) |

| tc | Guide vanes closure time (s) |

| U | Internal energy (J kg−1 K−1) |

| v | Water velocity (m s−1) |

| vR | Reservoir velocity (m s−1) |

| ZR | Reservoir water level (m) |

| ZS | Surge tank water level (m) |

| Δhls | Hydraulic losses (Pa) |

| λ | Thermal conductivity (W m−1 K−1) |

| ξ90 | Loss coefficient in the elbow (-) |

| ξe | Loss coefficient in the surge tank expansion (-) |

| 1D | One dimensional (-) |

| 3D | Three-dimensional (-) |

| BK | Bulk Modulus (Pa) |

| CFD | Computational fluid dynamics (-) |

| ESS | Energy storage systems (-) |

| PISO | Pressure-Implicit with Splitting of Operators (-) |

| PRESTO | Pressure Staggering Option (-) |

| PSH | Pumped-storage hydropower (-) |

| PV | Photovoltaic |

| RES | Renewable energy sources (-) |

| RNG | Re-Normalisation Group (-) |

| UDF | User defined function (-) |

| UPSH | Underground pumped-storage hydropower (-) |

| URANS | Unsteady Reynolds-Averaged Navier-Stokes |

| VOF | Volume of fluid (-) |

| VRE | Variable renewable energies (-) |

References

- Energiewende, A. The European Power Sector in 2019. Available online: http://www.agora-energiewende.de (accessed on 10 February 2020).

- Winde, F.; Kaiser, F.; Erasmus, E. Exploring the use of deep level gold mines in South Africa for underground pumped hydroelectric energy storage schemes. Renew. Sustain. Energy Rev. 2016, 78, 668–682. [Google Scholar] [CrossRef]

- Gallo, A.B.; Simões-Moreira, J.R.; Costa, H.; Santos, M.M.; dos Santos, E.M. Energy storage in the energy transition context: A technology review. Renew. Sustain. Energy Rev. 2016, 65, 800–822. [Google Scholar] [CrossRef]

- Perez-Díaz, J.I.; Chazarra, M.; García-González, J.; Cavazzini, G.; Stoppato, A. Trends and challenges in the operation of pumped-storage hydropower plants. Renew. Sustain. Energy Rev. 2015, 44, 767–784. [Google Scholar] [CrossRef]

- Rehman, S.; Al-Hadhrami, L.M.; Alam, M.M. Pumped hydro energy storage system: A technological review. Renew. Sustain. Energy Rev. 2015, 44, 586–598. [Google Scholar] [CrossRef]

- Wong, I.H. An underground pumped storage scheme in the bukit Timah granite of Singapore. Tunn. Undergr. Space Technol. 1996, 11, 485–489. [Google Scholar] [CrossRef]

- Kucukali, S. Finding the most suitable existing hydropower reservoirs for the development of pumped-storage schemes: An integrated approach. Renew. Sustain. Energy Rev. 2014, 37, 502–508. [Google Scholar] [CrossRef]

- Fessenden, R.A. System of Storing Power. U.S. Patent 1,247,520, 20 November 1917. Application Filed 7 June 1907. [Google Scholar]

- Menendez, J.; Loredo, J.; Galdo, M.; Fernandez-Oro, J.M. Energy storage in underground coal mines in NW Spain: Assessment of an underground lower water reservoir and preliminary energy balance. Renew. Energy 2019, 134, 1381–1391. [Google Scholar] [CrossRef]

- Uddin, N. Preliminary design of an underground reservoir for pumped storage. Geotech. Geol. Eng. 2003, 21, 331–355. [Google Scholar] [CrossRef]

- Braat, K.B.; Van Lohuizen, H.P.S.; De Haan, J.F. Underground pumped hydro-storage project for the Netherlands. Tunn. Tunn. 1985, 17, 19–22. [Google Scholar]

- Alvarado, R.; Niemann, A.; Wortberg, T. Underground pumped-storage hydroelectricity using existing coal mining infrastructure. In Proceedings of the 36th IAHR world congress, The Hague, The Netherlands, 28 June–3 July 2015. [Google Scholar]

- Sorensen, K.E. Underground reservoirs: Pumped storage of the future? Civ. Eng. 1969, 39, 66. [Google Scholar]

- Tam, S.W.; Blomquist, C.A.; Kartsounes, G.T. Underground pumped hydro storage—An overview. In Proceedings of the First Annual Conference on Mechanical and Magnetic Energy Storage Contractors’ Information-exchange, Luray, VA, USA, 24–26 October 1978. [Google Scholar]

- Menendez, J.; Fernández-Oro, J.M.; Galdo, M.; Loredo, J. Efficiency analysis of underground pumped storage hydropower plants. J. Energy Storage 2020, 28, 101234. [Google Scholar] [CrossRef]

- Menendez, J.; Fernandez-Oro, J.M.; Galdo, M.; Loredo, J. Pumped storage hydropower plants with underground reservoir: Influence of air pressure on the efficiency of the Francis turbine and energy production. Renew. Energy 2019, 143, 1427–1438. [Google Scholar] [CrossRef]

- Pummer, E.; Schüttrumpf, H. Reflection phenomena in underground pumped storage reservoirs. Water 2018, 10, 504. [Google Scholar] [CrossRef] [Green Version]

- Ye, J.; Zeng, W.; Zhao, Z.; Yang, J.; Yang, J. Optimization of Pump Turbine Closing Operation to Minimize Water Hammer and Pulsating Pressures During Load Rejection. Energies 2020, 13, 1000. [Google Scholar] [CrossRef] [Green Version]

- Tanaka, H. Vibration Behavior and Dynamic Stress of Runners of Very High Head Reversible Pumpturbines. Int. J. Fluid Mach. Syst. 2011, 4, 289–306. [Google Scholar] [CrossRef]

- Zuo, Z.; Fan, H.; Liu, S.; Wu, Y. S-shaped characteristics on the performance curves of pump-turbines in turbine mode—A review. Renew. Sustain. Energy Rev. 2016, 60, 836–851. [Google Scholar] [CrossRef]

- Vakil, A.; Firoozabadi, B. Investigation of Valve-Closing Law on the Maximum Head Rise of a Hydropower Plant. Sci. Iran. Trans. B Mech. Eng. 2009, 16, 2222–2228. [Google Scholar]

- Zeng, W.; Yang, J.; Hu, J.; Yang, J. Guide-Vane Closing Schemes for Pump-Turbines Based on Transient Characteristics in S-shaped Region. J. Fluids Eng. 2016, 138, 051302. [Google Scholar] [CrossRef]

- Wylie, E.B.; Streeter, V.L. Book Fluid Transient in Systems; Prentice Hall: New York, NY, USA, 1993; p. 463. [Google Scholar]

- Shin, Y.G. Estimation of instantaneous exhaust gas flow rate based on the assumption of a polytropic process. J. Automob. Eng. 2001, 25, 637–643. [Google Scholar] [CrossRef]

- Najm, H.; Azoury, P.H.; Piasecki, M. Hydraulic ram analysis: A new look at an old problem. J. Power Energy 1999, 213, 127–141. [Google Scholar] [CrossRef]

- Filipan, V.; Virag, Z.; Bergant, A. Mathematical modelling of a hydraulic ram pump system. J. Mech. Eng. 2003, 49, 137–149. [Google Scholar]

- Vereide, K.; Tekle, T.; Nielsen, T.K. Thermodynamic Behavior and Heat Transfer in Closed Surge Tanks for Hydropower Plants. J. Hydraul. Eng. 2015, 141, 06015002. [Google Scholar] [CrossRef] [Green Version]

- Ni, W.; Zhang, J.; Shi, L.; Wang, T.; Zhang, X.; Chen, S. Mathematical Model of Small-Volume Air Vessel Based on Real Gas Equation. Water 2020, 12, 530. [Google Scholar] [CrossRef] [Green Version]

- Svee, R. Surge chamber with enclosed compressed air cushion. In Proceedings of the 1st International Conference on Pressure Surges, BHRA Fluid Engineering, Cranfield, UK, 6–8 September 1972; pp. 15–24. [Google Scholar]

- Zhou, L.; Liu, D.; Karney, B. Investigation of hydraulic transients in two entrapped air pockets in a water pipeline. J. Hydraul. Eng. 2013, 139, 949–959. [Google Scholar] [CrossRef]

- Vereide, K.; Lia, L.; Nielsen, T.K. Hydraulic scale modelling and thermodynamics of mass oscillations in closed surge tank. J. Hydraul. Res. 2015, 53, 519–524. [Google Scholar] [CrossRef] [Green Version]

- Zhou, D.; Chen, H.; Zhang, L. Investigation of pumped storage hydropower power-off transient process using 3D numerical simulation based on SP-VOF hybrid model. Energies 2018, 11, 1020. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, H.; Ilinca, A.; Perron, J. Energy storage systems: Characteristics and comparisons. Renew. Sustain. Energy Rev. 2008, 12, 1221–1250. [Google Scholar] [CrossRef]

- Yang, C.J.; Jackson, R.B. Opportunities and barriers to pumped-hydro energy storage in the United States. Renew. Sustain. Energy Rev. 2011, 15, 839–844. [Google Scholar] [CrossRef]

- Madlener, R.; Specht, J.M. An Exploratory Economic Analysis of Underground Pumped-Storage Hydro Power Plants in Abandoned Coal Mines; FCN Working Paper No. 2/2013; FCN: Aachen, Germany, 2013. [Google Scholar]

- Menendez, J. Underground Energy Storage and Adjustment of the Spanish Electrical System. Ph.D. Thesis, University of Oviedo, Oviedo, Spain, 2018. [Google Scholar]

- Lin, A.; Sun, Y.; Zhang, H.; Lin, X.; Yang, L.; Zheng, Q. Fluctuating characteristics of air-mist mixture flow with conjugate wall-film motion in a compressor of gas turbine. Appl. Therm. Eng. 2018, 142, 779–792. [Google Scholar] [CrossRef]

- Lin, A.; Zheng, Q.; Jiang, Y.; Lin, X.; Zhang, H. Sensitivity of air/mist non-equilibrium phase transition cooling to transient characteristics in a compressor of gas turbine. Int. J. Heat Mass Transf. 2019, 137, 882–894. [Google Scholar] [CrossRef]

- Jabbari, M.; Bulatova, R.; Hattel, J.; Bahl, C. An Evaluation of Interface Capturing Methods in a VOF Based Model for Multiphase Flow of a Non-Newtonian Ceramic in Tape Casting. Appl. Math. Model. 2014, 38, 3222–3232. [Google Scholar] [CrossRef]

- Hirt, C.; Nichols, B. Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- Langevin, C.D.; Thorne, D.T.; Drausman, A.M.; Sukop, M.C.; Guo, W. SEAWAT Version 4: A Computer Program for Simulation of Multi-Species Solute and Heat Transport; Techniques and Methods Book 6, Chapter A22 (TM6A22); U.S. Geological Survey: Reston, VA, USA, 2008; p. 9.

| UPSH Plant | |

|---|---|

| Lower reservoir volume (m3) | 10,800 |

| Reservoir height (m) | 12 |

| Tunnel cross-section (m2) | 30 |

| Air duct cross-section (m2) | 0.78 |

| Surge tank height (m) | 50 |

| Surge tank cross-section (m2) | 19.63 |

| Surge tank initial water level (m) | 24.8 |

| Water flow rate – pumping mode (m3 s−1) | 40 |

| Max. gross pressure (MPa) | 4.41 |

| Max. net pressure in pump mode (MPa) | 4.74 |

| Max. pump input (MW) | 199.76 |

| Mesh Cells ×106 | Static Pressure (kPa) | Error (%) | Computational Time (h) |

|---|---|---|---|

| 1.28 | −1.54 | 7.8 | 125 |

| 1.92 | −1.59 | 4.8 | 166 |

| 2.74 | −1.66 | 0.6 | 249 |

| 3,83 | −1.67 | - | 330 |

| Properties | Water | Air |

|---|---|---|

| Specific heat Cp (J kg−1 K−1) | 4,182 | 1,006.4 |

| Thermal conductivity λ (W m−1 K−1) | 0.60 | 0.0242 |

| Viscosity (kg m−1 s−1) | 0.001 | 1.789 × 10−5 |

| Molecular weight (kg mol−1) | 18.01 × 10−3 | 28.96 × 10−3 |

| Temperature (K) | 293 | 298 |

| Closing Scheme | tc = 1 s | tc = 10 s | tc = 15 s | |||

|---|---|---|---|---|---|---|

| Parameter | Analytical | CFD | Analytical | CFD | Analytical | CFD |

| Max. static pressure (kPa) | 112.8 | 103.7 | 92.1 | 87.7 | 73.4 | 79.2 |

| Max. water level (m) | 6.5 | 6.0 | 5.0 | 4.79 | 3.5 | 2.92 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Menéndez, J.; Fernández-Oro, J.M.; Galdo, M.; Loredo, J. Transient Simulation of Underground Pumped Storage Hydropower Plants Operating in Pumping Mode. Energies 2020, 13, 1781. https://doi.org/10.3390/en13071781

Menéndez J, Fernández-Oro JM, Galdo M, Loredo J. Transient Simulation of Underground Pumped Storage Hydropower Plants Operating in Pumping Mode. Energies. 2020; 13(7):1781. https://doi.org/10.3390/en13071781

Chicago/Turabian StyleMenéndez, Javier, Jesús M. Fernández-Oro, Mónica Galdo, and Jorge Loredo. 2020. "Transient Simulation of Underground Pumped Storage Hydropower Plants Operating in Pumping Mode" Energies 13, no. 7: 1781. https://doi.org/10.3390/en13071781