Thermo-Chemical Instability and Energy Analysis of Absorption Heat Pumps

Abstract

:1. Introduction

2. Theoretical Background

3. Results

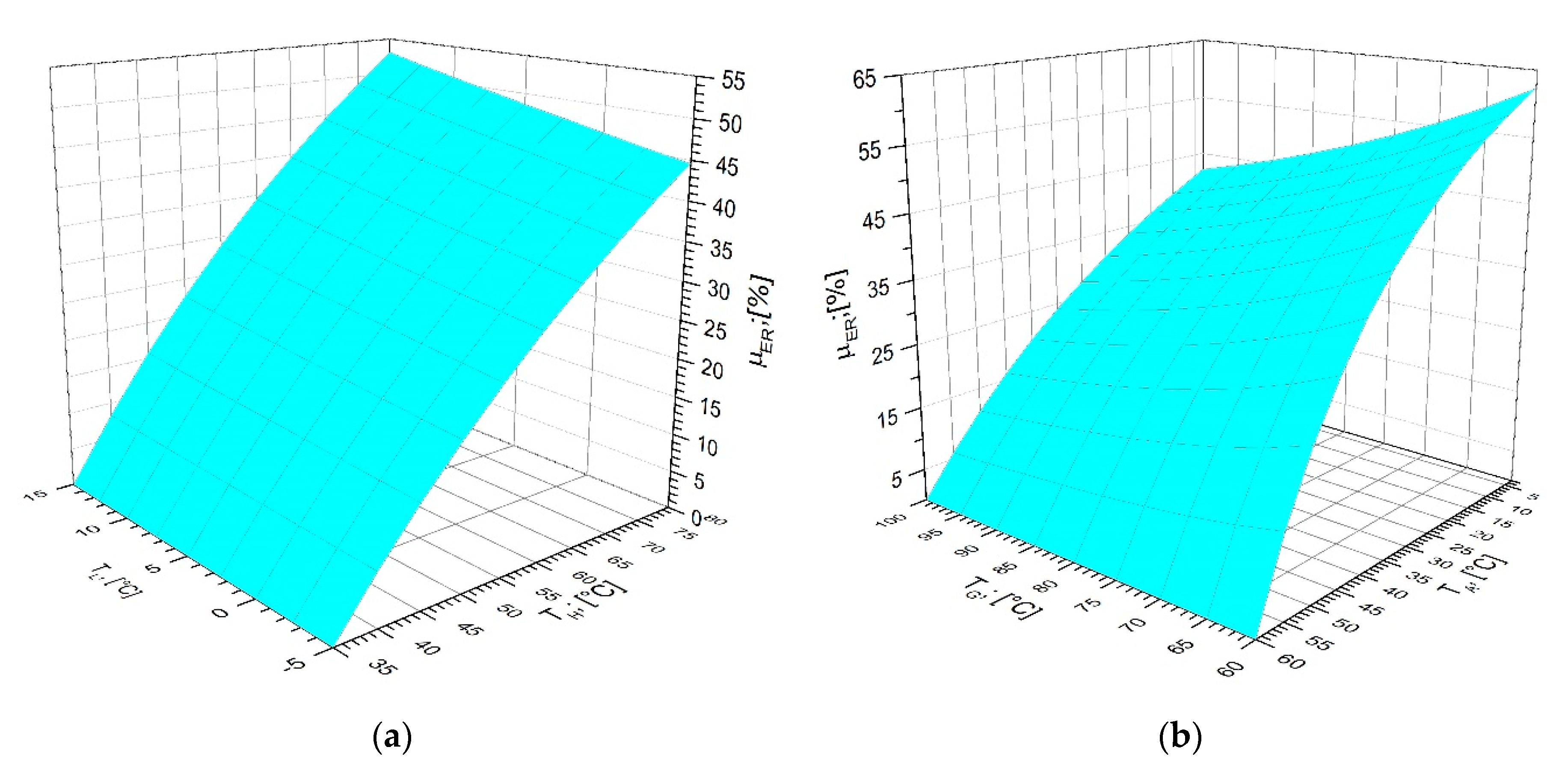

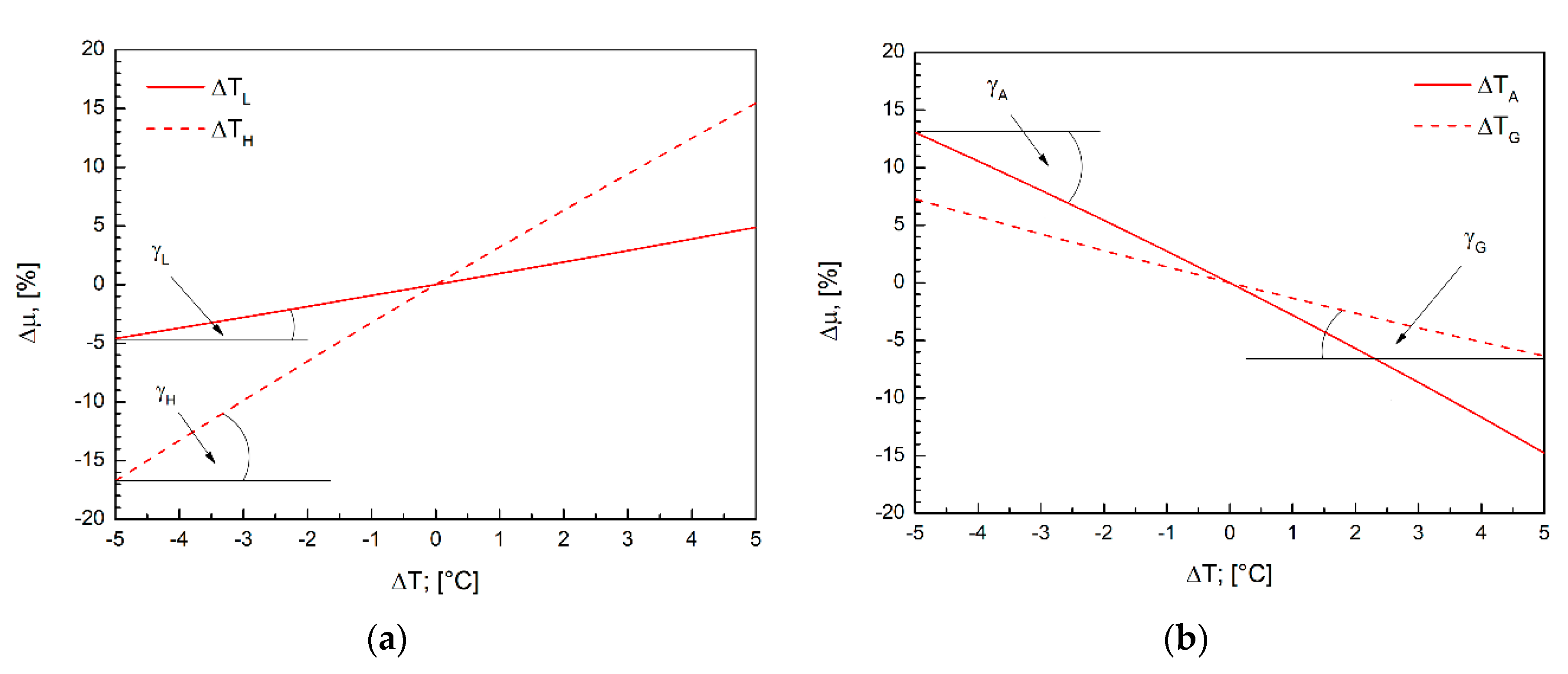

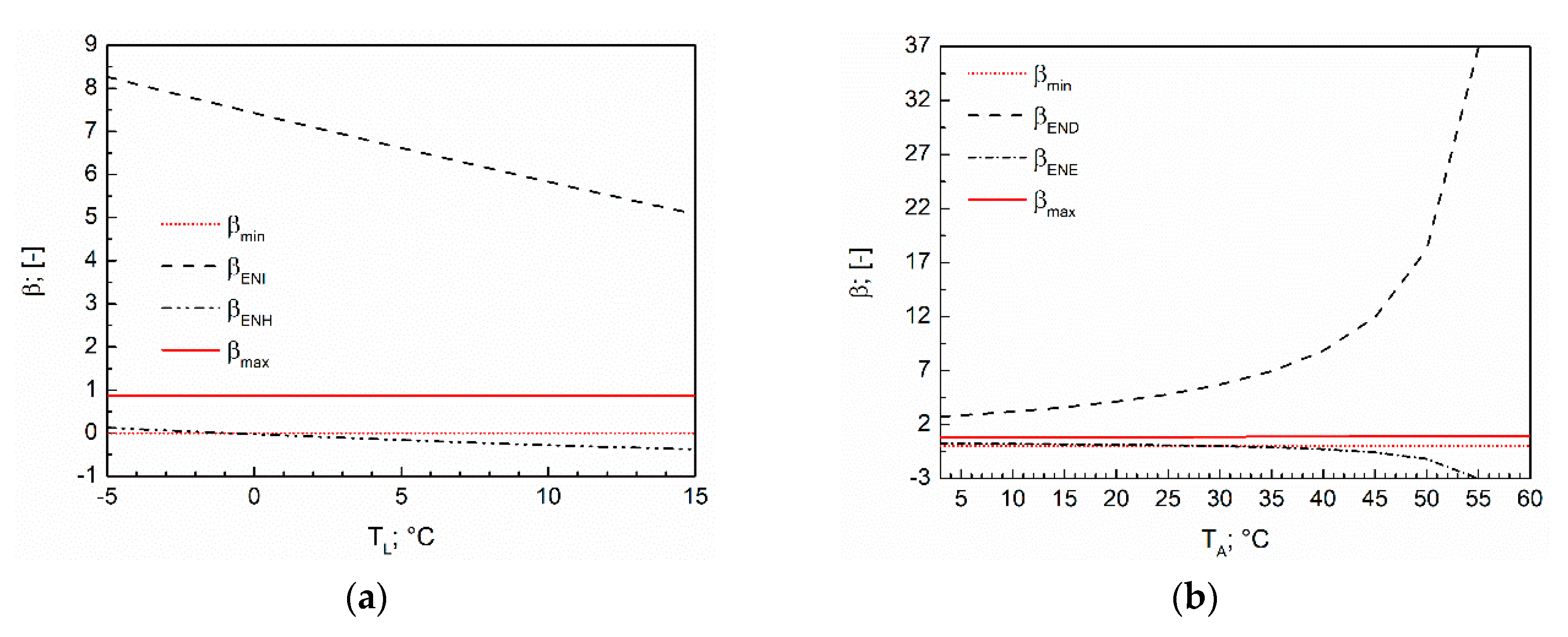

3.1. Instability of Absorption Heat Pumps

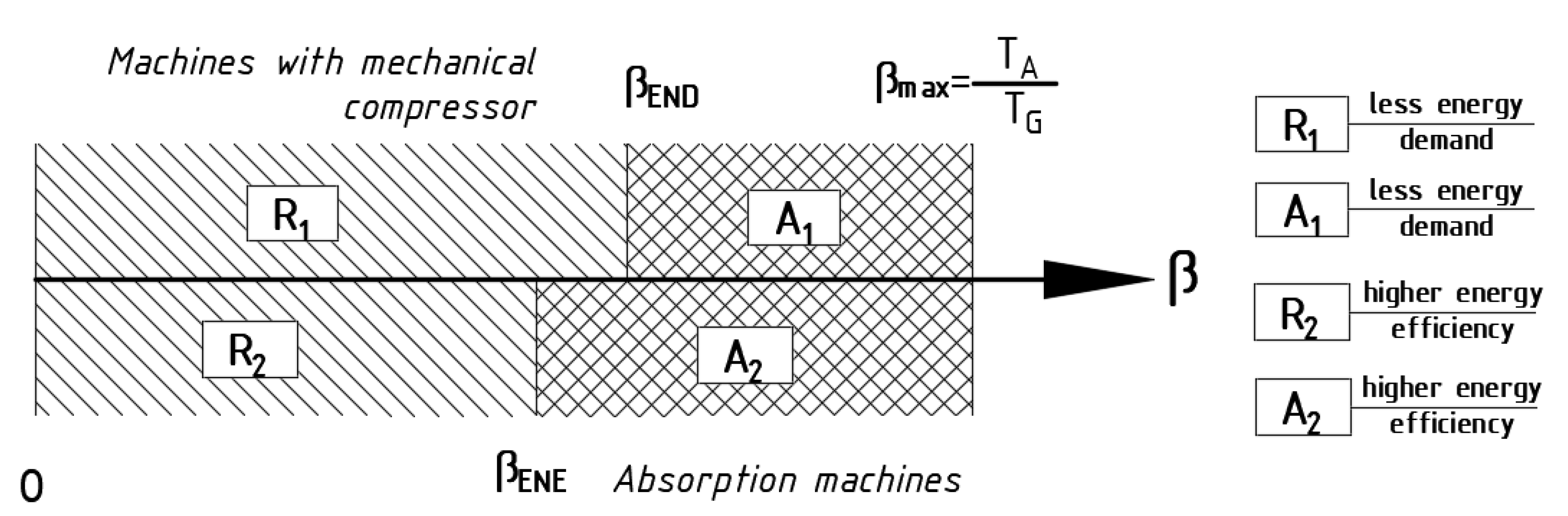

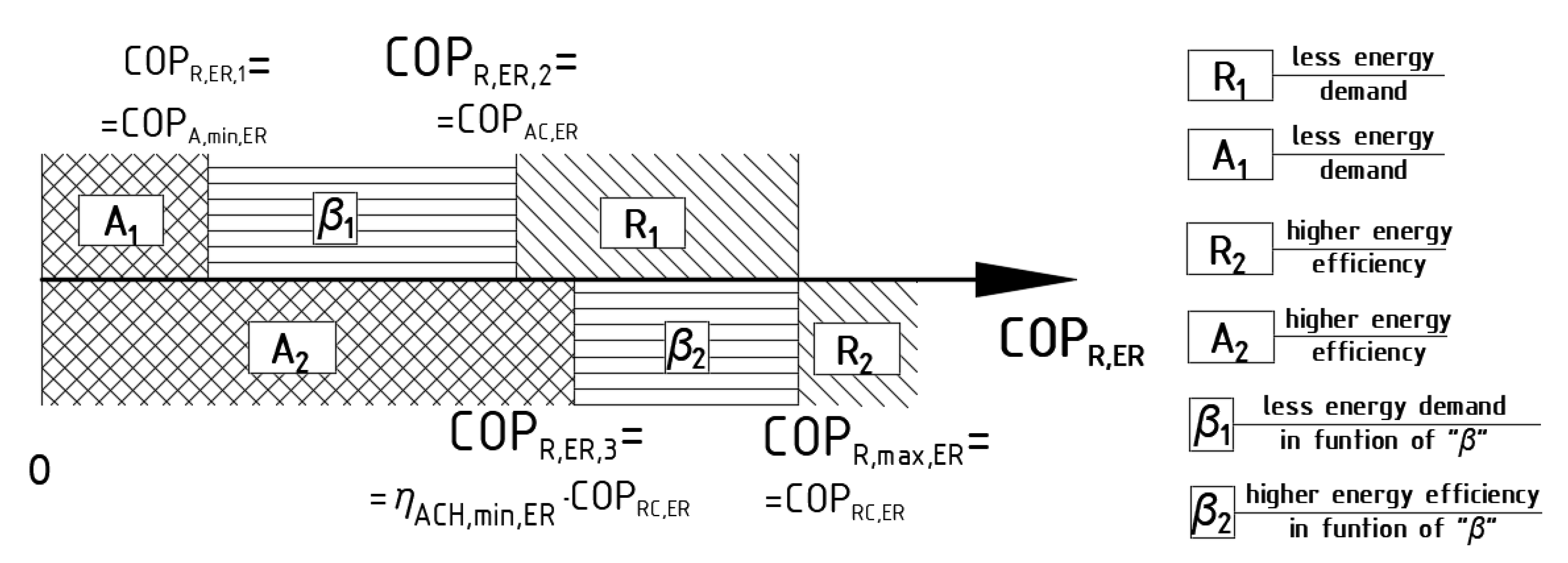

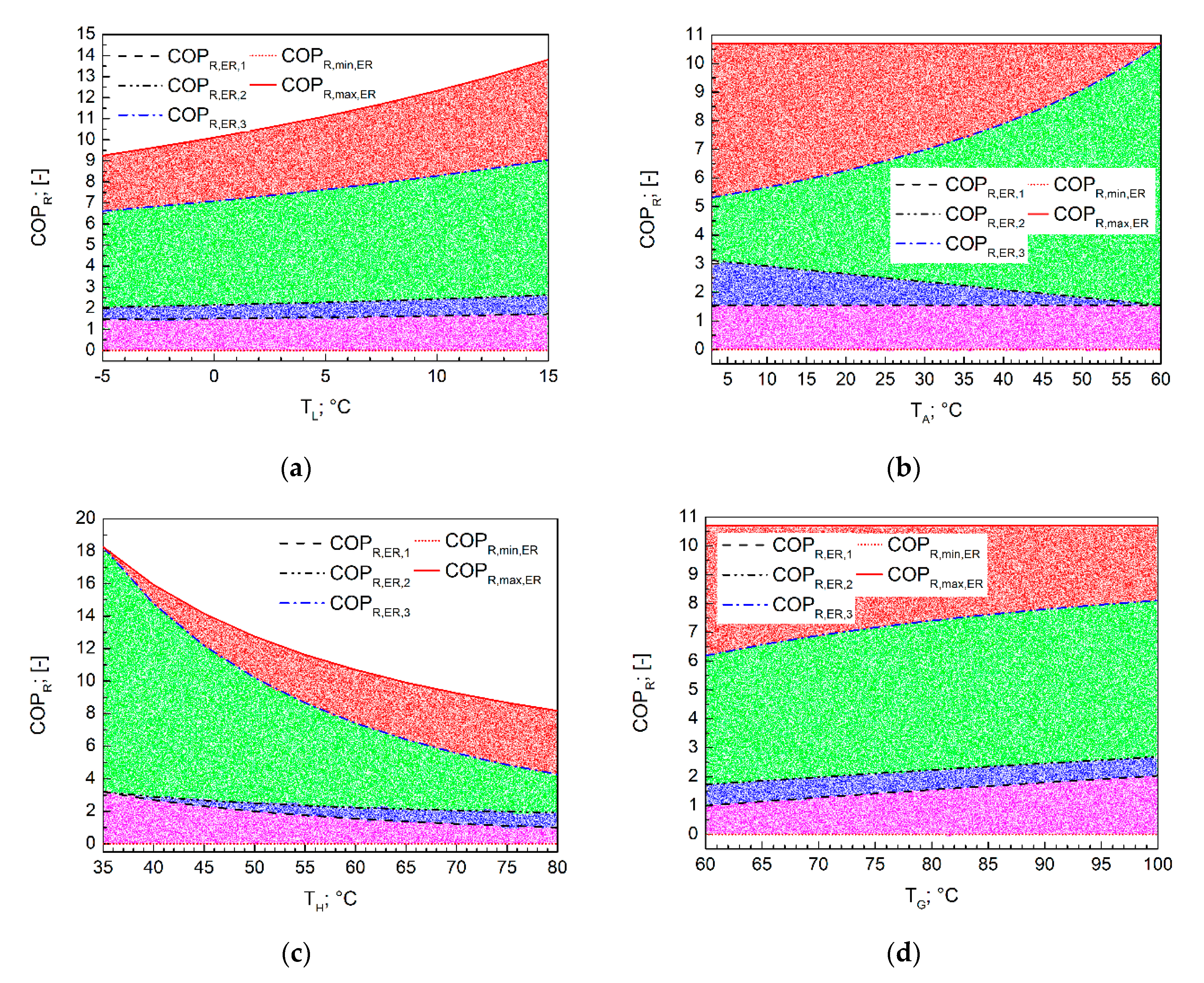

3.2. Energy Comparison of Machines Having Mechanical and Thermo-Chemical Compressors

4. Case Study

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Coefficient of performance. | |

| Coefficient of performance (cooling, absorption machine). | |

| Coefficient of performance (heating, absorption machine). | |

| Coefficient of performance in double-use operation mode (absorption machine). | |

| Minimum value of coefficient of performance (cooling, absorption machine). | |

| Minimum value of coefficient of performance (heating, absorption machine). | |

| Minimum value of coefficient of performance in double-use operation mode (absorption machine). | |

| Maximum value of coefficient of performance (cooling, absorption machine). | |

| Maximum value of coefficient of performance (heating, absorption machine). | |

| Maximum value of coefficient of performance in double-use operation mode (absorption machine). | |

| Coefficient of performance (cooling, machine with mechanical compressor). | |

| Coefficient of performance (heating, machine with mechanical compressor). | |

| Resultant coefficient of performance (machine with mechanical compressor). | |

| Maximum value of coefficient of performance (cooling, machine with mechanical compressor). | |

| Maximum value of coefficient of performance (heating, machine with mechanical compressor). | |

| Maximum value of resultant coefficient of performance (machine with mechanical compressor). | |

| Cooling capacity, in W. | |

| Heat released in the absorber, in W. | |

| Heat released in the condenser, in W. | |

| Heat consumed in the generator, in W. | |

| Evaporation temperature, in °C. | |

| Temperature in the absorber, in °C. | |

| Condensing temperature, in °C. | |

| Temperature in the generator, in °C. | |

| Electric power consumed by the machine, in W. | |

| Thermo-chemical performance index. | |

| Maximum value of thermo-chemical performance index. | |

| Minimum value of thermo-chemical performance index. | |

| The second law efficiency, in %. | |

| Thermo-chemical efficiency (in the cooling mode), in %. | |

| Thermo-chemical efficiency (in the heating and cooling mode), in %. | |

| Thermo-chemical efficiency (in the heating mode), in %. | |

| Maximum value of the thermo-chemical efficiency (in the cooling mode), in %. | |

| Maximum value of the thermo-chemical efficiency (in the heating and cooling mode), in %. | |

| Maximum value of the thermo-chemical efficiency (in the heating mode), in %. | |

| Minimum value of the thermo-chemical efficiency (in the cooling mode), in %. | |

| Minimum value of the thermo-chemical efficiency (in the heating and cooling mode) in %. | |

| Minimum value of the thermo-chemical efficiency (in the heating mode), in %. | |

| Energy efficiency of a machine with a mechanical compressor, in %. | |

| Thermo-chemical instability index, in %. | |

| Thermo-chemical instability index (cooling), in %. | |

| Thermo-chemical instability index (double-use operation mode), in %. | |

| Thermo-chemical instability index (heating), in %. |

Subscripts

| Machine with a mechanical compressor/absorption machine. | |

| The heat pump (machine with a mechanical compressor/absorption machine) working on a reversed Carnot cycle. | |

| Minimum/maximum value. | |

| Cooling/heating/double-use operation mode. |

References

- The European Parliament and of the Council. Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on energy efficiency. J. Eur. Union 2012, 315, 1–56. [Google Scholar]

- The European Parliament and of the Council. Directive 2010/31/EU of the European Parliament and of the Council. J. Eur. Union 2010, 153, 13–35. [Google Scholar]

- Bodó, B.; Kalmár, F. Analysis of primary energy use of typical buildings in Hungary. Environ. Eng. Manag. J. 2014, 13, 2725–2731. [Google Scholar] [CrossRef]

- Santamouris, M. Cooling the buildings—past, present and future. Energy Build. 2016, 128, 617–638. [Google Scholar] [CrossRef]

- Aste, N.; Leonforte, F.; Manfren, M.; Mazzon, M. Thermal inertia and energy efficiency—Parametric simulation assessment on a calibrated case study. Appl. Energy 2015, 145, 111–123. [Google Scholar] [CrossRef]

- Csáky, I.; Kalmár, F. Investigation of the relationship between the allowable transparent area, thermal mass and air change rate in buildings. J. Build. Eng. 2017, 12, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Kalmár, F.; Szabó, G.L. Analysis of thermal compressor efficiency in case of geothermal energy sources. Build. Serv. Eng. Res. Technol. 2014, 35, 237–243. [Google Scholar] [CrossRef]

- Wang, J.; Santamouris, M.; Meng, Q.; He, B.J.; Zhang, L.; Zhang, Y. Predicting the solar evaporative cooling performance of pervious materials based on hygrothermal properties. Solar Energy 2019, 191, 311–322. [Google Scholar] [CrossRef]

- Zhang, L.; Deng, Z.; Liang, L.; Zhang, Y.; Meng, Q.; Wang, J.; Santamouris, M. Thermal behavior of a vertical green facade and its impact on the indoor and outdoor thermal environment. Energy Build. 2019, 204, 1–14. [Google Scholar] [CrossRef]

- Szodrai, F.; Lakatos, Á. Különböző éghajlati viszonyoknak kitett épületek fűtési energiafelhasználásának csökkentése hőszigeteléssel. Energiagazdálkodás 2016, 57, 26–29. [Google Scholar]

- Long, L.; Ye, H. The roles of thermal insulation and heat storage in the energy performance of the wall materials: A simulation study. Sci. Rep. 2016, 6, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Szodrai, F.; Lakatos, Á.; Kalmár, F. Analysis of the change of the specific heat loss coefficient of buildings resulted by the variation of the geometry and the moisture load. Energy 2016, 115, 820–829. [Google Scholar] [CrossRef] [Green Version]

- Kalmár, F. Investigation of thermal perceptions of subjects with diverse thermal histories in warm indoor environment. Build. Environ. 2016, 107, 254–262. [Google Scholar] [CrossRef]

- Verbeke, S.; Audenaert, A. Thermal inertia in buildings: A review of impacts across climate and building use. Renew. Sustain. Energy Rev. 2018, 82, 2300–2318. [Google Scholar] [CrossRef]

- Sakulpipatsin, P.; Itard, L.C.M.; van der Kooi, H.J.; Boelman, E.C.; Luscuere, P.G. An exergy application for analysis of buildings and HVAC systems. Energy Build. 2010, 42, 90–99. [Google Scholar] [CrossRef]

- Schellen, L.; Loomans, M.G.L.C.; de Wit, M.H.; Olesen, B.W.; van Marken Lichtenbelt, W.D. The influence of local effects on thermal sensation under non-uniform environmental conditions—Gender differences in thermophysiology, thermal comfort and productivity during convective and radiant cooling. Physiol. Behav. 2012, 107, 252–261. [Google Scholar] [CrossRef]

- Kalmár, F. Summer operative temperatures in free running existing buildings with high glazed ratio of the facades. J. Build. Eng. 2016, 6, 236–242. [Google Scholar] [CrossRef] [Green Version]

- Kalmár, F.; Kalmár, T. Interrelation between mean radiant temperature and room geometry. Energy Build. 2012, 55, 414–421. [Google Scholar] [CrossRef]

- Szabó, G.L.; Kalmár, F. Investigation of energy and exergy performances of radiant cooling systems in buildings—A design approach. Energy 2019, 185, 449–462. [Google Scholar] [CrossRef]

- Hepbasli, A. Low exergy (LowEx) heating and cooling systems for sustainable buildings and societies. Renew. Sustain. Energy Rev. 2012, 16, 73–104. [Google Scholar] [CrossRef]

- Torío, H.; Angelotti, A.; Schmidt, D. Exergy analysis of renewable energy-based climatisation systems for buildings: A critical view. Energy Build. 2009, 41, 248–271. [Google Scholar] [CrossRef]

- Meggers, F.; Ritter, V.; Goffin, P.; Baetschmann, M.; Leibundgut, H. Low exergy building systems implementation. Energy 2012, 41, 48–55. [Google Scholar] [CrossRef]

- Ma, G.; Zhang, Y.; Yue, M.; Shi, Y. Thermal Economy Study on the Waste Heat Utilization of a Double Reheat Unit under coupled Steam Turbine and Boiler. Appl. Therm. Eng. 2020, 174, 115112. [Google Scholar] [CrossRef]

- Jianbo, L.; Kai, L.; Xiaolong, H.; Chen, Z.; Fulin, C.; Xiangqiang, K. A novel absorption–compression combined refrigeration cycle activated by engine waste heat. Energy Convers. Manag. 2020, 205, 1–13. [Google Scholar] [CrossRef]

- Ramadan, M.; Murr, R.; Khaled, M.; Olabi, A.G. Air dryer using waste heat of HVAC systems—Code development and experimental validation. Appl. Therm. Eng. 2019, 147, 302–311. [Google Scholar] [CrossRef]

- Yildiz, A.; Güngör, A. Energy and exergy analyses of space heating in buildings. Appl. Energy 2009, 86, 1939–1948. [Google Scholar] [CrossRef]

- Lohani, S.P. Energy and exergy analysis of fossil plant and heat pump building heating system at two different dead-state temperatures. Energy 2010, 35, 3323–3331. [Google Scholar] [CrossRef]

- Lohani, S.P.; Schmidt, D. Comparison of energy and exergy analysis of fossil plant, ground and air source heat pump building heating system. Renew. Energy 2010, 35, 1275–1282. [Google Scholar] [CrossRef]

- Dincer, I.; Kanoglu, M. Refrigeration Systems and Applications, 2nd ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010; pp. 22–33, 187–189. ISBN 9780470747407. [Google Scholar]

- Arora, C.P. Refrigeration and Air Conditioning, 3rd ed.; Tata McGraw-Hill Education Pvt. Ltd.: New Delhi, India, 2009; pp. 67–86, 402–405. ISBN1 10: 9351340163. ISBN2 13: 9789351340164. [Google Scholar]

- Balmer, R.T. Modern Engineering Thermodynamics, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2011; pp. 542–590. ISBN 9780123749963. [Google Scholar]

- Szabó, G.L. Teljes energiahasznosítású abszorpciós gépek energetikai vizsgálata. Magyar Épületgépészet 2019, 68, 3–7. [Google Scholar]

- Szabó, G.L. Az abszorpciós gépek jelzőszámai és ezek kapcsolata. Energiagazdálkodás 2018, 59, 38–42. [Google Scholar]

| Denomination | Notation | Value | |

|---|---|---|---|

| Common data | Evaporation temperature | TL | 3 °C |

| Condensing temperature | TH | 60 °C | |

| Cooling capacity | 105 kW | ||

| Type unit | Single stage | ||

| Machine with a mechanical compressor | Coefficient of performance (cooling) | COPR,C | 3 |

| Coefficient of performance (heating) | COPR,H | 4 | |

| Resultant coefficient of performance | COPR,ER | 7 | |

| Heating capacity | 135 kW | ||

| Electric power consumed by the machine | P | 35 kW | |

| Working fluid | R410A | ||

| Absorption machine | Temperature in the absorber | TA | 35 °C |

| Temperature in the generator | TG | 80 °C | |

| Thermo-chemical performance index | β | 0.574 | |

| Maximum value of thermo-chemical performance index | TA/TG = βmax | 0.873 | |

| Coefficient of performance (cooling) | COPA,C | 0.5 | |

| Coefficient of performance (heating) | COPA,H | 1.5 | |

| Coefficient of performance in double-use operation mode | COPA,ER | 2 | |

| Thermo-chemical instability index (cooling) | μC | 55.6% | |

| Thermo-chemical instability index (heating) | μH | 21.2% | |

| Thermo-chemical instability index (double-use operation mode) | μER | 30.7% | |

| Heating capacity | 315 kW | ||

| Heat consumed in the generator | 210 kW | ||

| Working fluid | Water/Li-BR | ||

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

L. Szabó, G. Thermo-Chemical Instability and Energy Analysis of Absorption Heat Pumps. Energies 2020, 13, 1966. https://doi.org/10.3390/en13081966

L. Szabó G. Thermo-Chemical Instability and Energy Analysis of Absorption Heat Pumps. Energies. 2020; 13(8):1966. https://doi.org/10.3390/en13081966

Chicago/Turabian StyleL. Szabó, Gábor. 2020. "Thermo-Chemical Instability and Energy Analysis of Absorption Heat Pumps" Energies 13, no. 8: 1966. https://doi.org/10.3390/en13081966

APA StyleL. Szabó, G. (2020). Thermo-Chemical Instability and Energy Analysis of Absorption Heat Pumps. Energies, 13(8), 1966. https://doi.org/10.3390/en13081966