Dynamic Mechanical Compression Impulse of Lithium-Ion Pouch Cells

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Quasi-Static Compression

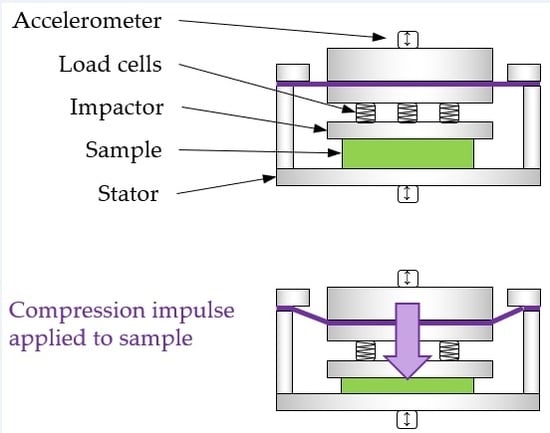

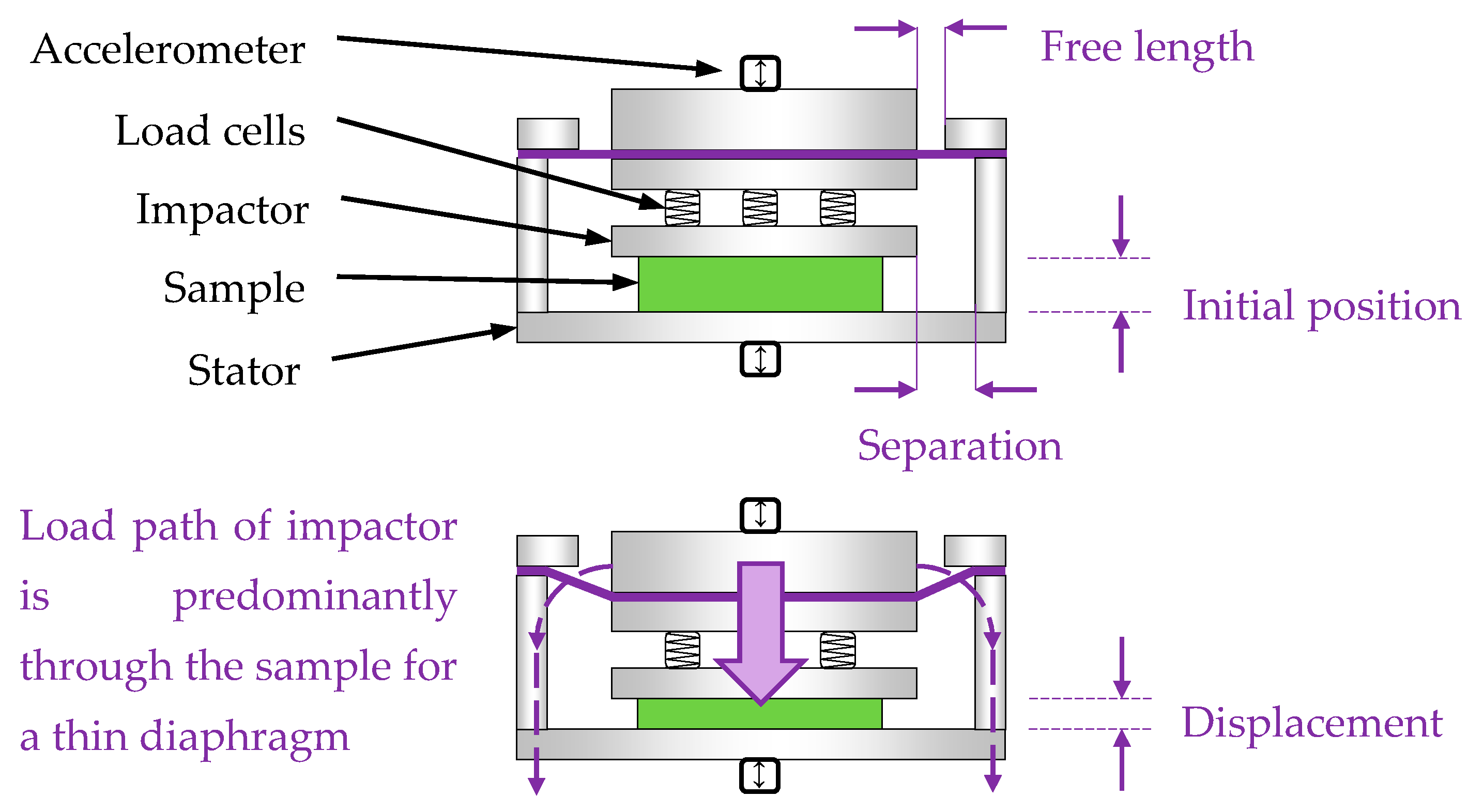

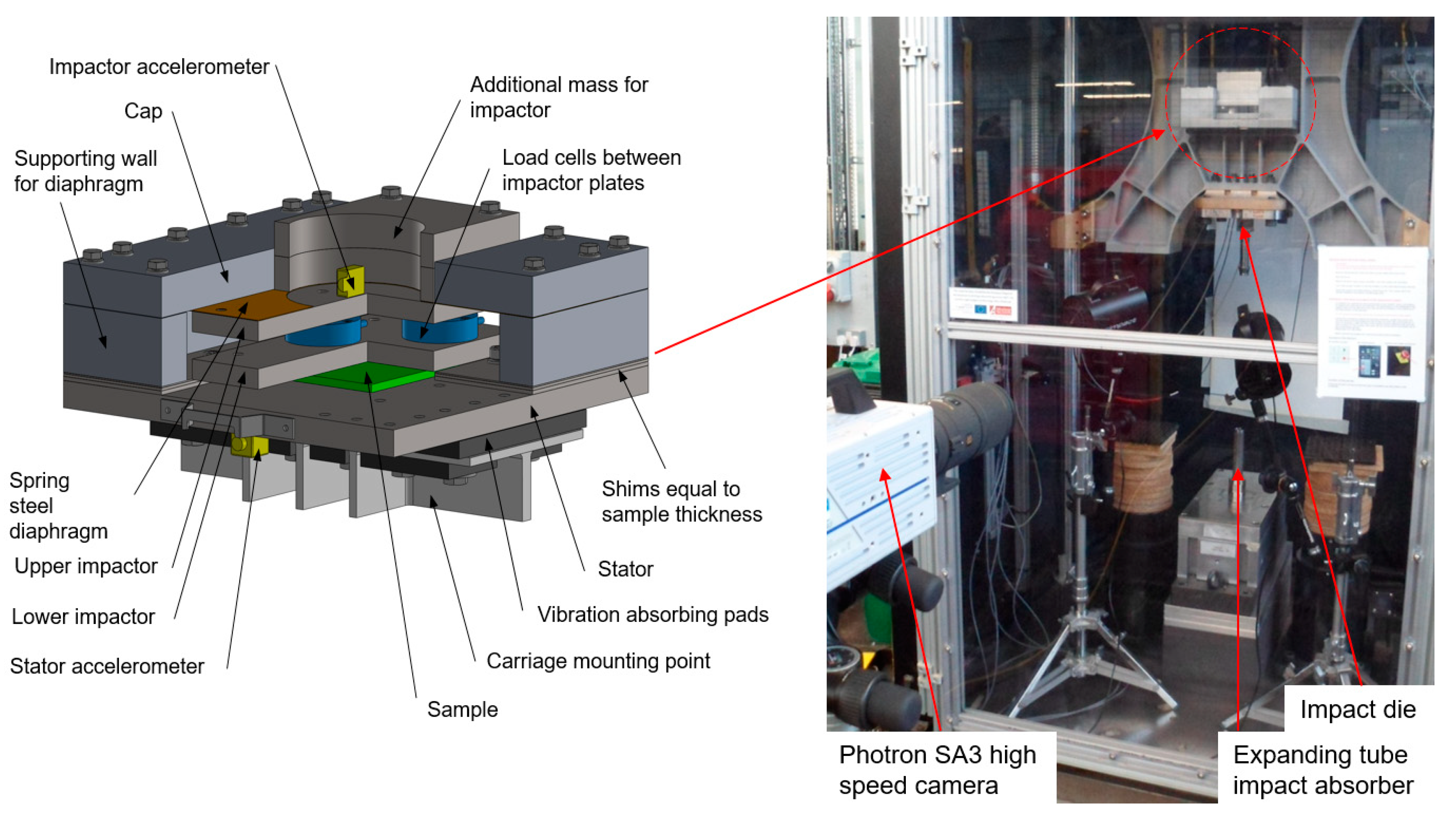

2.3. Compression Impulse with Diaphragm Method Development

2.4. Compression Impulse Methodology

3. Results and Discussion

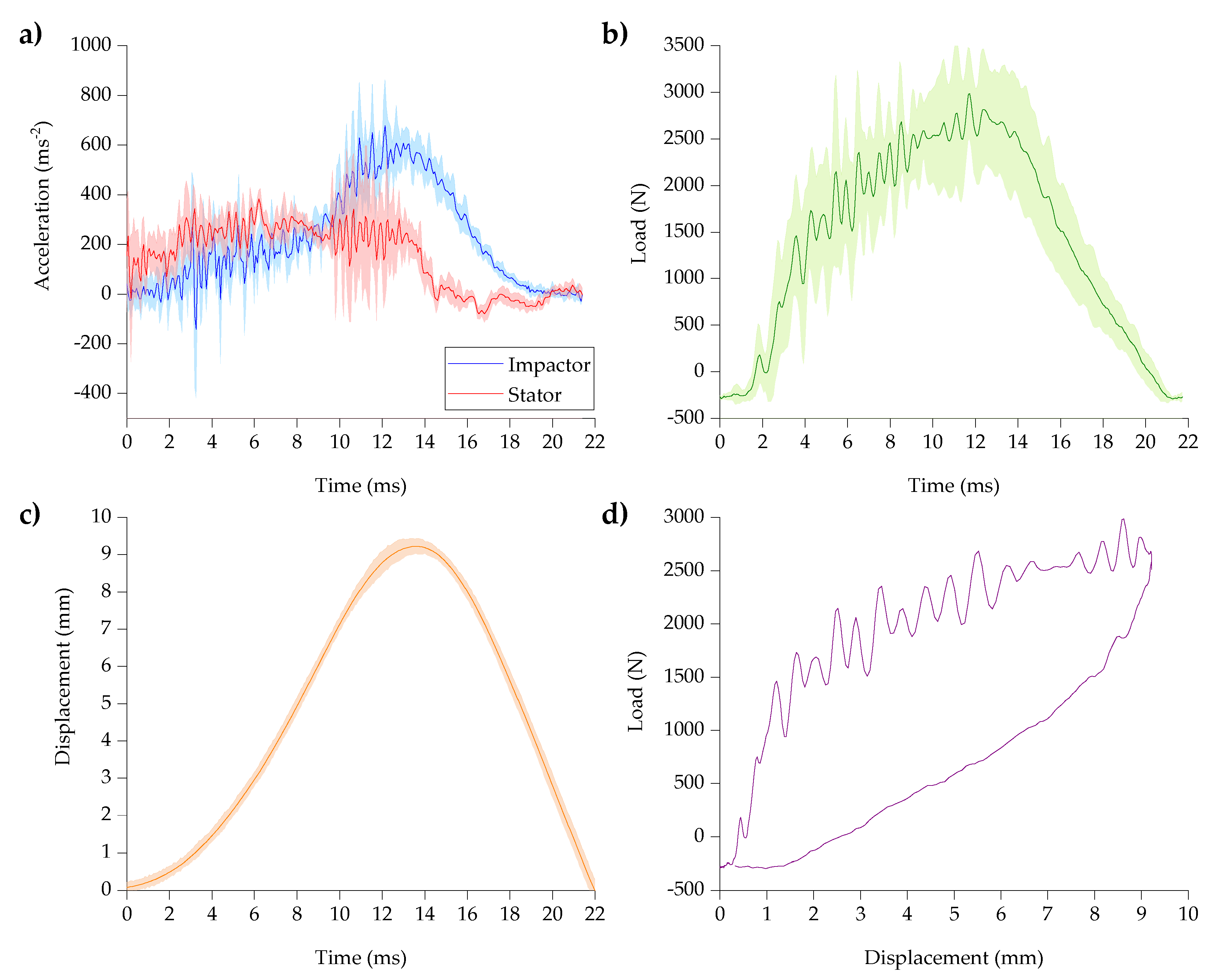

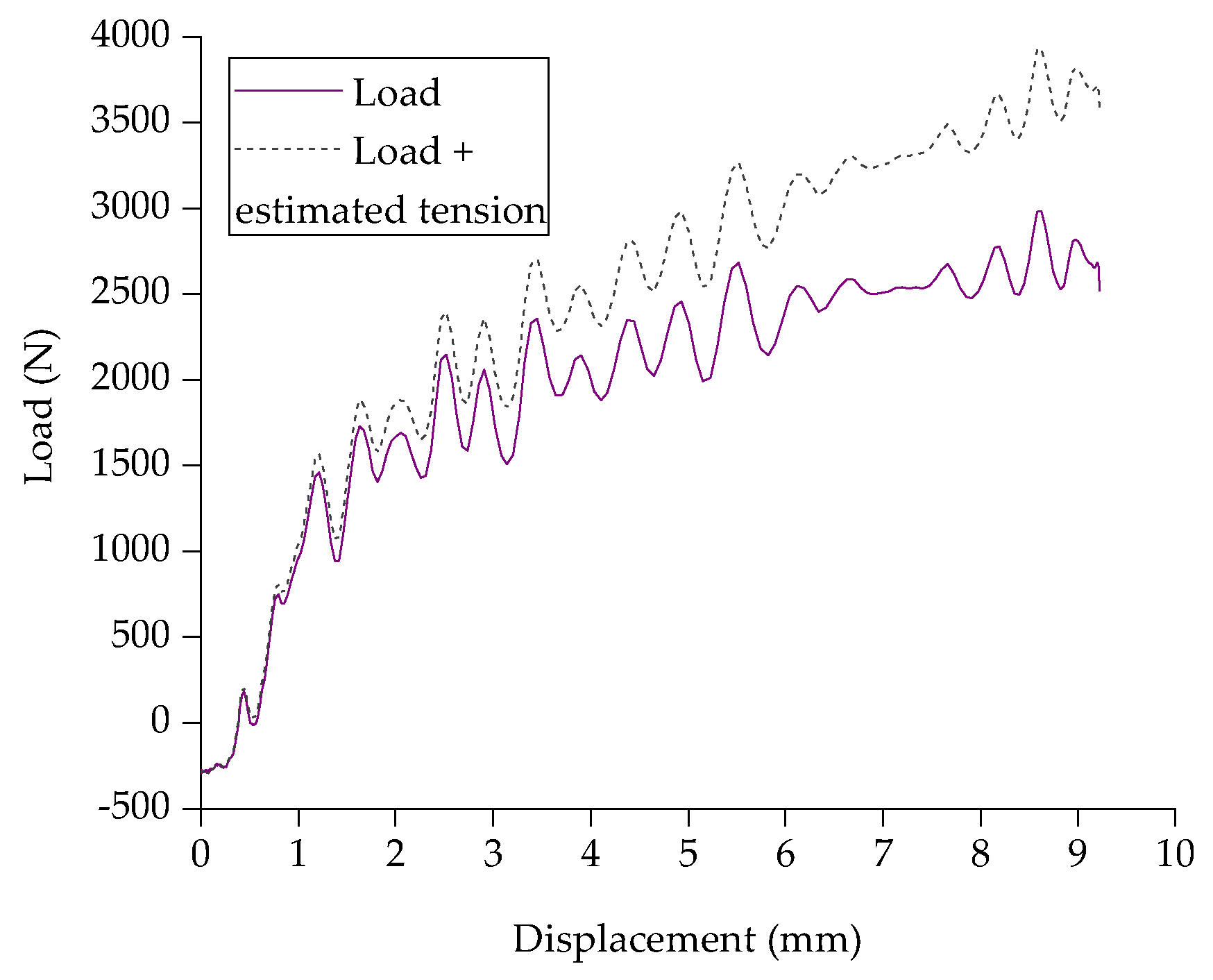

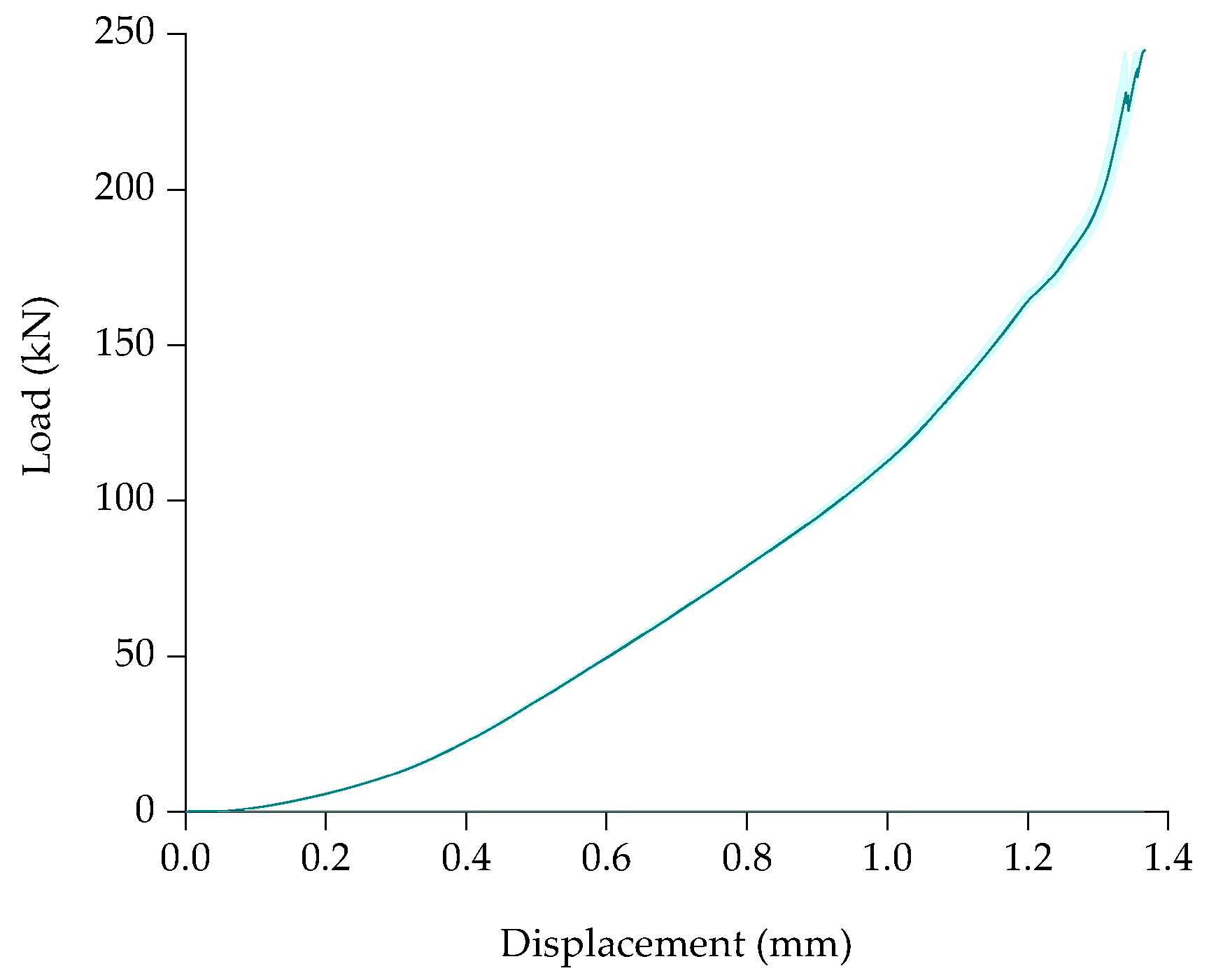

3.1. Arpro 5130 EPP Foam

3.2. Inert Pouch Cells

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Christensen, J.; Bastien, C. Chapter | two-Numerical Techniques for Structural Assessment of Vehicle Architectures. In Nonlinear Optimization of Vehicle Safety Structures; Christensen, J., Bastien, C., Eds.; Butterworth-Heinemann: Oxford, UK, 2016; pp. 51–105. [Google Scholar] [CrossRef]

- Marzougui, D.; Brown, D.; Park, H.K.; Kan, C.D.; Opiela, K.S. Development & Validation of a Finite Element Model for a Mid-Sized Passenger Sedan. In Proceedings of the 13th International LS-DYNA Users Conference, Dearborn, MI, USA, 8–10 June 2014. [Google Scholar]

- Léost, Y.; Boljen, M. Crash simulations of electric cars in the EVERSAFE project. In Proceedings of the LS-DYNA Forum, Bamberg, Germany, 6–8 October 2014. [Google Scholar]

- Sahraei, E.; Bosco, E.; Dixon, B.; Lai, B. Microscale failure mechanisms leading to internal short circuit in Li-ion batteries under complex loading scenarios. J. Power Sources 2016, 319, 56–65. [Google Scholar] [CrossRef]

- Lai, W.-J.; Ali, M.Y.; Pan, J. Mechanical behavior of representative volume elements of lithium-ion battery modules under various loading conditions. J. Power Sources 2014, 248, 789–808. [Google Scholar] [CrossRef]

- Zhang, C.; Santhanagopalan, S.; Sprague, M.A.; Pesaran, A.A. A representative-sandwich model for simultaneously coupled mechanical-electrical-thermal simulation of a lithium-ion cell under quasi-static indentation tests. J. Power Sources 2015, 298, 309–321. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Liu, B.; Wang, X.; Hu, D. Computational model of 18650 lithium-ion battery with coupled strain rate and SOC dependencies. Appl. Energy 2016, 172, 180–189. [Google Scholar] [CrossRef] [Green Version]

- Choi, H.Y.; Lee, I.; Lee, J.S.; Kim, Y.M.; Kim, H. A study on mechanical characteristics of lithium-polymer pouch cell battery for electric vehicle. In Proceedings of the 23rd International Technical Conference on the Enhanced Safety of Vehicles (ESV), Seoul, Korea, 27–30 May 2013. [Google Scholar]

- Breitfuss, C.; Sinz, W.; Feist, F.; Gstrein, G.; Lichtenegger, B.; Knauder, C.; Ellersdorfer, C.; Moser, J.; Steffan, H.; Stadler, M.; et al. A ‘Microscopic’ Structural Mechanics FE Model of a Lithium-Ion Pouch Cell for Quasi-Static Load Cases. Sae Int. J. Passeng. Cars - Mech. Syst. 2013, 6, 1044–1054. [Google Scholar] [CrossRef]

- Zhu, J.; Wierzbicki, T.; Li, W. A review of safety-focused mechanical modeling of commercial lithium-ion batteries. J. Power Sources 2018, 378, 153–168. [Google Scholar] [CrossRef]

- Pesaran, A.A.; Kim, G.-H.; Smith, K. Accelerating battery design using computer-aided engineering tools. In Proceedings of the 25th World Battery, Hybrid and Fuel Cell Electric Vehicle Symposium & Exhibition, Shenzhen, China, 11 May 2010. [Google Scholar]

- Pannala, S.; Turner, J.A.; Allu, S.; Elwasif, W.R.; Kalnaus, S.; Simunovic, S.; Kumar, A.; Billings, J.J.; Wang, H.; Nanda, J. Multiscale modeling and characterization for performance and safety of lithium-ion batteries. J. Appl. Phys. 2015, 118. [Google Scholar] [CrossRef]

- Grazioli, D.; Magri, M.; Salvadori, A. Computational modeling of Li-ion batteries. Comput. Mech. 2016, 58, 889–909. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Santhanagopalan, S.; Sprague, M.A.; Pesaran, A.A. Simultaneously coupled mechanical-electrochemical-thermal simulation of lithium-ion cells. ECS Trans. 2016, 72, 9–19. [Google Scholar] [CrossRef] [Green Version]

- Marcicki, J.; Zhu, M.; Bartlett, A.; Yang, X.G.; Chen, Y.; Miller, T.; L’Eplattenier, P.; Caldichoury, I. A Simulation Framework for Battery Cell Impact Safety Modeling Using LS-DYNA. J. Electrochem. Soc. 2017, 164, A6440–A6448. [Google Scholar] [CrossRef]

- Zhang, C.; Santhanagopalan, S.; Sprague, M.A.; Pesaran, A.A. Coupled mechanical-electrical-thermal modeling for short-circuit prediction in a lithium-ion cell under mechanical abuse. J. Power Sources 2015, 290, 102–113. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Ma, J.; Zhang, L. Finite Element Thermal Model and Simulation for a Cylindrical Li-ion Battery. IEEE Access 2017, 5, 15372–15379. [Google Scholar] [CrossRef]

- Zhang, C.; Santhanagopalan, S.; Stock, M.J.; Brunhart-Lupo, N.; Gruchalla, K. Interpretation of Simultaneous Mechanical-Electrical-Thermal Failure in a Lithium-Ion Battery Module: Preprint. In Proceedings of the SC16: International Conference for High Performance Computing, Networking, Storage and Analysis, Salt Lake City, UT, USA, 1 December 2016. [Google Scholar]

- Liu, B.; Zhao, H.; Yu, H.; Li, J.; Xu, J. Multiphysics computational framework for cylindrical lithium-ion batteries under mechanical abusive loading. Electrochim. Acta 2017. [Google Scholar] [CrossRef]

- Lai, W.-J.; Ali, M.Y.; Pan, J. Mechanical behavior of representative volume elements of lithium-ion battery cells under compressive loading conditions. J. Power Sources 2014, 245, 609–623. [Google Scholar] [CrossRef]

- Ali, M.Y.; Lai, W.-J.; Pan, J. Computational models for simulations of lithium-ion battery cells under constrained compression tests. J. Power Sources 2013, 242, 325–340. [Google Scholar] [CrossRef]

- Sahraei, E.; Wierzbicki, T.; Hill, R.; Luo, M. Crash Safety of Lithium-Ion Batteries towards Development of a Computational Model. In Proceedings of the SAE 2010 World Congress & Exhibition, Detroit, MI, USA, 13–15 April 2010. [Google Scholar]

- Sahraei, E.; Hill, R.; Wierzbicki, T. Calibration and finite element simulation of pouch lithium-ion batteries for mechanical integrity. J. Power Sources 2012, 201, 307–321. [Google Scholar] [CrossRef]

- Sahraei, E.; Campbell, J.; Wierzbicki, T. Modeling and short circuit detection of 18650 Li-ion cells under mechanical abuse conditions. J. Power Sources 2012, 220, 360–372. [Google Scholar] [CrossRef]

- Sahraei, E.; Meier, J.; Wierzbicki, T. Characterizing and modeling mechanical properties and onset of short circuit for three types of lithium-ion pouch cells. J. Power Sources 2014, 247, 503–516. [Google Scholar] [CrossRef]

- Wierzbicki, T.; Sahraei, E. Homogenized mechanical properties for the jellyroll of cylindrical Lithium-ion cells. J. Power Sources 2013, 241, 467–476. [Google Scholar] [CrossRef]

- Sahraei, E.; Kahn, M.; Meier, J.; Wierzbicki, T. Modelling of cracks developed in lithium-ion cells under mechanical loading. RSC Adv. 2015, 5, 80369–80380. [Google Scholar] [CrossRef]

- Xia, Y.; Wierzbicki, T.; Sahraei, E.; Zhang, X. Damage of cells and battery packs due to ground impact. J. Power Sources 2014, 267, 78–97. [Google Scholar] [CrossRef]

- Ali, M.Y.; Lai, W.-J.; Pan, J. Computational models for simulation of a lithium-ion battery module specimen under punch indentation. J. Power Sources 2015, 273, 448–459. [Google Scholar] [CrossRef]

- Amodeo, C.M.; Ali, M.Y.; Pan, J. Computational models for simulations of lithium-ion battery modules under quasi-static and dynamic constrained compression tests. Int. J. Crashworthiness 2017, 22, 1–14. [Google Scholar] [CrossRef]

- Kukreja, J.; Nguyen, T.; Siegmund, T.; Chen, W.; Tsutsui, W.; Balakrishnan, K.; Liao, H.; Parab, N. Crash analysis of a conceptual electric vehicle with a damage tolerant battery pack. Extrem. Mech. Lett. 2016, 9, 371–378. [Google Scholar] [CrossRef] [Green Version]

- Kumar, A.; Kalnaus, S.; Simunovic, S.; Gorti, S.; Allu, S.; Turner, J.A. Communication—Indentation of Li-Ion Pouch Cell: Effect of Material Homogenization on Prediction of Internal Short Circuit. J. Electrochem. Soc. 2016, 163, A2494–A2496. [Google Scholar] [CrossRef]

- Wang, H.; Kumar, A.; Simunovic, S.; Allu, S.; Kalnaus, S.; Turner, J.A.; Helmers, J.C.; Rules, E.T.; Winchester, C.S.; Gorney, P. Progressive mechanical indentation of large-format Li-ion cells. J. Power Sources 2017, 341, 156–164. [Google Scholar] [CrossRef] [Green Version]

- Avdeev, I.; Gilaki, M. Structural analysis and experimental characterization of cylindrical lithium-ion battery cells subject to lateral impact. J. Power Sources 2014, 271, 382–391. [Google Scholar] [CrossRef]

- Gilaki, M.; Avdeev, I. Impact modeling of cylindrical lithium-ion battery cells: A heterogeneous approach. J. Power Sources 2016, 328, 443–451. [Google Scholar] [CrossRef]

- Seulin, M.; Michel, C.; Lapoujade, V.; L’Eplattenier, P. Mechanical modeling Li-ion cell crush experiments using LS-DYNA. In Proceedings of the 11th European LS-DYNA Conference, Salzburg, Austria, 9–11 May 2017. [Google Scholar]

- Gómez-del Río, T.; Garrido, M.A.; Rodríguez, J.; Arencón, D.; Martínez, A.B. High strain rate behaviour of polypropylene microfoams. In Proceedings of the EPJ Web of Conferences. 2012. Available online: https://www.epj-conferences.org/articles/epjconf/abs/2012/08/epjconf_dymat2012_02006/epjconf_dymat2012_02006.html (accessed on 10 February 2020). [CrossRef] [Green Version]

- Ouellet, S.; Cronin, D.; Worswick, M. Compressive response of polymeric foams under quasi-static, medium and high strain rate conditions. Polym. Test. 2006, 25, 731–743. [Google Scholar] [CrossRef]

- Sun, Y.; Li, Q.M. Effect of entrapped gas on the dynamic compressive behaviour of cellular solids. Int. J. Solids Struct. 2015, 63, 50–67. [Google Scholar] [CrossRef]

- Koohbor, B.; Ravindran, S.; Kidane, A. Effects of cell-wall instability and local failure on the response of closed-cell polymeric foams subjected to dynamic loading. Mech. Mater. 2018, 116, 67–76. [Google Scholar] [CrossRef]

- Mane, J.V.; Chandra, S.; Sharma, S.; Ali, H.; Chavan, V.M.; Manjunath, B.S.; Patel, R.J. Mechanical Property Evaluation of Polyurethane Foam under Quasi-static and Dynamic Strain Rates- An Experimental Study. Procedia Eng. 2017, 173, 726–731. [Google Scholar] [CrossRef]

- Daniel, I.M.; Cho, J.-M.; Werner, B.T. Characterization and modeling of stain-rate-dependent behavior of polymeric foams. Compos. Part A Appl. Sci. Manuf. 2013, 45, 70–78. [Google Scholar] [CrossRef]

- Viot, P. Hydrostatic compression on polypropylene foam. Int. J. Impact Eng. 2009, 36, 975–989. [Google Scholar] [CrossRef] [Green Version]

- Croop, B.; Lobo, H. Selecting material models for the simulation of foams in LS-DYNA. In Proceedings of the 7th European LS-DYNA Conference, Salzburg, Austria, 14–15 May 2009. [Google Scholar]

- Bouix, R.; Viot, P.; Lataillade, J.-L. Polypropylene foam behaviour under dynamic loadings: Strain rate, density and microstructure effects. Int. J. Impact Eng. 2009, 36, 329–342. [Google Scholar] [CrossRef] [Green Version]

- Kisters, T.; Sahraei, E.; Wierzbicki, T. Dynamic impact tests on lithium-ion cells. Int. J. Impact Eng. 2017. [Google Scholar] [CrossRef]

- Dixon, B.; Mason, A.; Sahraei, E. Effects of electrolyte, loading rate and location of indentation on mechanical integrity of li-ion pouch cells. J. Power Sources 2018, 396, 412–420. [Google Scholar] [CrossRef]

- Chen, Y.; Santhanagopalan, S.; Babu, V.; Ding, Y. Dynamic mechanical behavior of lithium-ion pouch cells subjected to high-velocity impact. Compos. Struct. 2019, 218, 50–59. [Google Scholar] [CrossRef]

- Jia, Y.; Yin, S.; Liu, B.; Zhao, H.; Yu, H.; Li, J.; Xu, J. Unlocking the coupling mechanical-electrochemical behavior of lithium-ion battery upon dynamic mechanical loading. Energy 2019, 166, 951–960. [Google Scholar] [CrossRef]

- Cannarella, J.; Leng, C.Z.; Arnold, C.B. On the coupling between stress and voltage in lithium-ion pouch cells. In Proceedings of the Energy Harvesting and Storage: Materials, Devices, and Applications, Baltimore, MD, USA, 5 June 2014; pp. 91150K-1–91150K-8. [Google Scholar]

- Zhu, J.; Luo, H.; Li, W.; Gao, T.; Xia, Y.; Wierzbicki, T. Mechanism of strengthening of battery resistance under dynamic loading. Int. J. Impact Eng. 2019, 131, 78–84. [Google Scholar] [CrossRef]

- Kalnaus, S.; Wang, H.; Watkins, T.R.; Simunovic, S.; Sengupta, A. Features of mechanical behavior of EV battery modules under high deformation rate. Extrem. Mech. Lett. 2019, 32, 100550. [Google Scholar] [CrossRef]

- Ozturk, U.E.; Anlas, G. Finite element analysis of expanded polystyrene foam under multiple compressive loading and unloading. Mater. Des. 2011, 32, 773–780. [Google Scholar] [CrossRef]

- Zhang, L.; Gurao, M.; Yang, K.H.; King, A.I. Material characterization and computer model simulation of low density polyurethane foam used in a rodent traumatic brain injury model. J. Neurosci. Methods 2011, 198, 93–98. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maheo, L.; Viot, P. Impact on multi-layered polypropylene foams. Int. J. Impact Eng. 2013, 53, 84–93. [Google Scholar] [CrossRef] [Green Version]

- Yonezu, A.; Hirayama, K.; Kishida, H.; Chen, X. Characterization of the compressive deformation behavior with strain rate effect of low-density polymeric foams. Polym. Test. 2016, 50, 1–8. [Google Scholar] [CrossRef]

- Zhang, J.; Kikuchi, N.; Li, V.; Yee, A.; Nusholtz, G. Constitutive modeling of polymeric foam material subjected to dynamic crash loading. Int. J. Impact Eng. 1998, 21, 369–386. [Google Scholar] [CrossRef]

- Field, J.E.; Walley, S.M.; Proud, W.G.; Goldrein, H.T.; Siviour, C.R. Review of experimental techniques for high rate deformation and shock studies. Int. J. Impact Eng. 2004, 30, 725–775. [Google Scholar] [CrossRef]

- Hsiao, H.M.; Daniel, I.M.; Cordes, R.D. Dynamic compressive behavior of thick composite materials. Exp. Mech. 1998, 38, 172–180. [Google Scholar] [CrossRef]

- Cronin, D.S.; Ouellet, S. Low density polyethylene, expanded polystyrene and expanded polypropylene: Strain rate and size effects on mechanical properties. Polym. Test. 2016, 53, 40–50. [Google Scholar] [CrossRef]

- Viot, P.; Beani, F.; Lataillade, J.L. Polymeric foam behavior under dynamic compressive loading. J. Mater. Sci. 2005, 40, 5829–5837. [Google Scholar] [CrossRef]

- Zhu, F.; Lei, J.; Du, X.; Currier, P.; Gbaguidi, A.; Sypeck, D. Crushing Behavior of Vehicle Battery Pouch Cell and Module: A Combined Experimental and Theoretical Study. SAE Int. 2018. [Google Scholar] [CrossRef]

- Carnegie, C.R. Simulation of High Strain Rate Deformation in Structural Polymeric Foam; University of Warwick: Coventry, UK, 2016. [Google Scholar]

- Hsiao, H.M.; Daniel, I.M. Strain rate behavior of composite materials. Compos. Part B Eng. 1998, 29, 521–533. [Google Scholar] [CrossRef]

- Bouix, R.; Viot, P.; Lataillade, J.L. Phenomenological study of a cellular material behaviour under dynamic loadings. J. Phys. Iv Fr. 2006, 134, 109–116. [Google Scholar] [CrossRef]

- Froustey, C.; Lambert, M.; Charles, J.L.; Lataillade, J.L. Design of an Impact Loading Machine Based on a Flywheel Device: Application to the Fatigue Resistance of the High Rate Pre-straining Sensitivity of Aluminium Alloys. Exp. Mech. 2007, 47, 709–721. [Google Scholar] [CrossRef]

- Moreno, C. Identification, Test and Performance Prediction of A Novel Energy Absorbing Mechanism for Railway Vehicles; University of Warwick: Coventry, UK, 2015. [Google Scholar]

- Shakeri, M.; Salehghaffari, S.; Mirzaeifar, R. Expansion of circular tubes by rigid tubes as impact energy absorbers: Experimental and theoretical investigation. Int. J. Crashworthiness 2007, 12, 493–501. [Google Scholar] [CrossRef]

- Budynas, R.G.; Nisbett, J.K. Deflection and Stiffness. In Shigley’s Mechanical Engineering Design, 9th ed.; McGraw Hill: New York, NY, USA, 2011; p. 152. [Google Scholar]

- LS-DYNA Keyword User’s Manual; Livermore Software Technology Corporation; LSTC: Livermore, CA, USA, 2017; Volume 2.

- ABAQUS/Standard User’s Manual, Version 6.13; Dassault Systèmes Simulia Corp.: Providence, RI, USA, 2013.

| Material | Dimensions | Description |

|---|---|---|

| EPP foam | 200 × 100 × 50 mm | Arpro 5130, band saw finish |

| Inert pouch cell | Jellyroll length and width: 75 × 50 mm Approximate thickness of pouch cells: 4.5 mm | 14 repeating units: Cathode: FePO4 Separator: trilayer 20 μm Anode: graphite Electrolyte: DMC without lithium salt |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ratner, A.; Beaumont, R.; Masters, I. Dynamic Mechanical Compression Impulse of Lithium-Ion Pouch Cells. Energies 2020, 13, 2105. https://doi.org/10.3390/en13082105

Ratner A, Beaumont R, Masters I. Dynamic Mechanical Compression Impulse of Lithium-Ion Pouch Cells. Energies. 2020; 13(8):2105. https://doi.org/10.3390/en13082105

Chicago/Turabian StyleRatner, Alon, Richard Beaumont, and Iain Masters. 2020. "Dynamic Mechanical Compression Impulse of Lithium-Ion Pouch Cells" Energies 13, no. 8: 2105. https://doi.org/10.3390/en13082105

APA StyleRatner, A., Beaumont, R., & Masters, I. (2020). Dynamic Mechanical Compression Impulse of Lithium-Ion Pouch Cells. Energies, 13(8), 2105. https://doi.org/10.3390/en13082105