Nanoparticle Emission and Characterization from Pre-Dried Lignite and Bituminous Coal Co-Combustion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fuel Samples

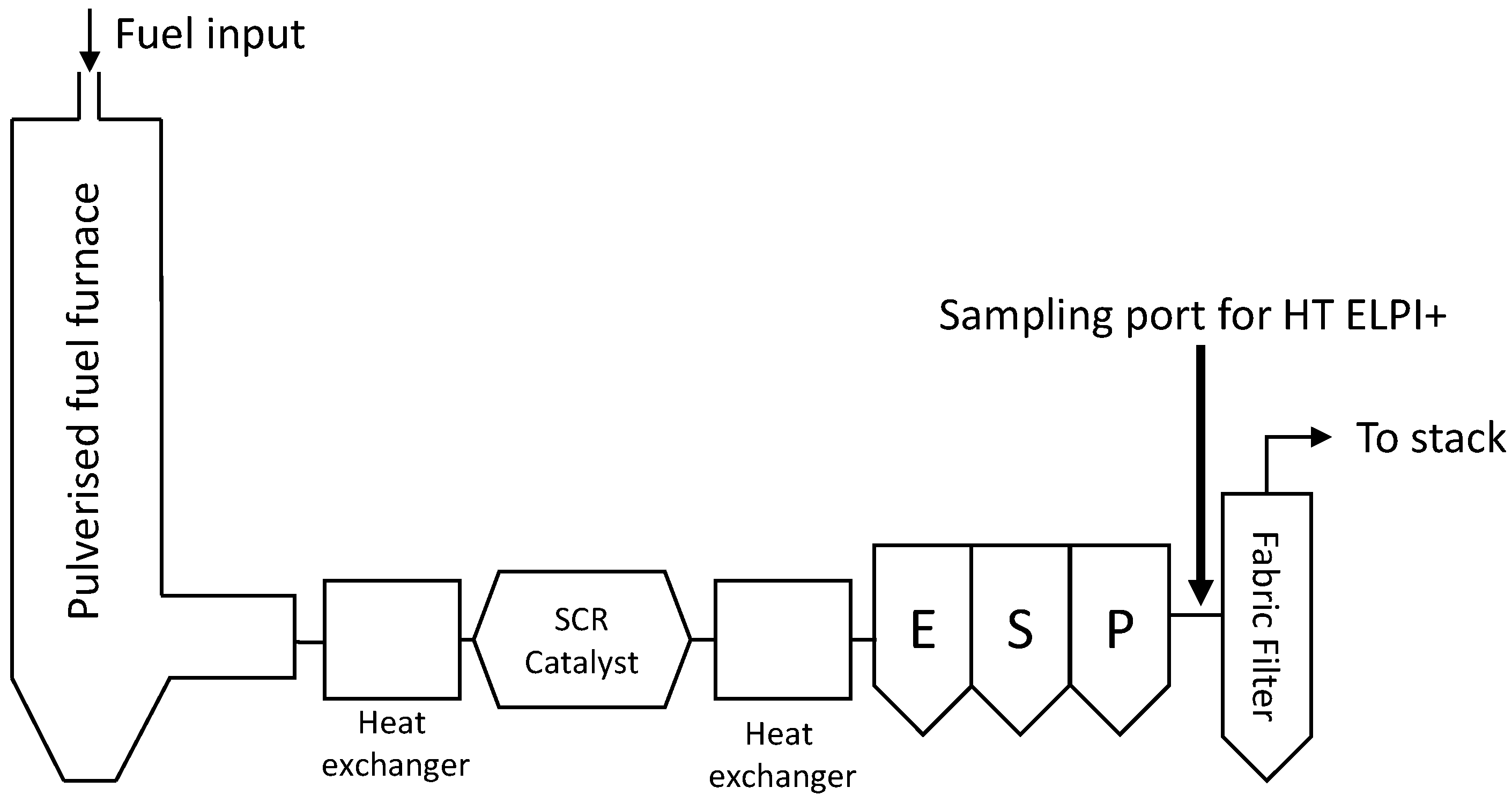

2.2. Unit Overview-Experimental Matrix

2.3. Sample System and Analysis Method

3. Results and Discussion

3.1. Skeletal Density

3.2. Fine PM Concentrations

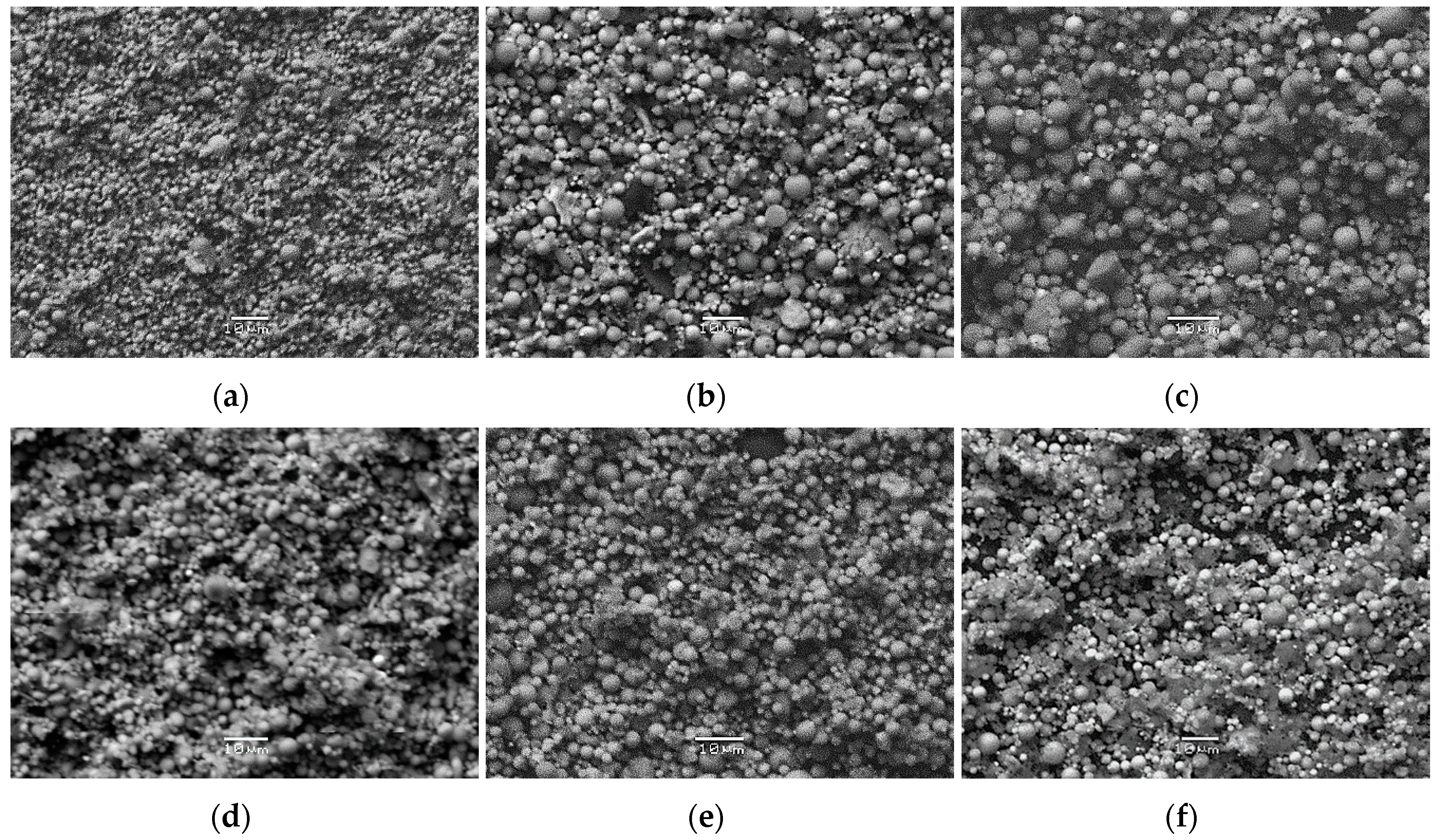

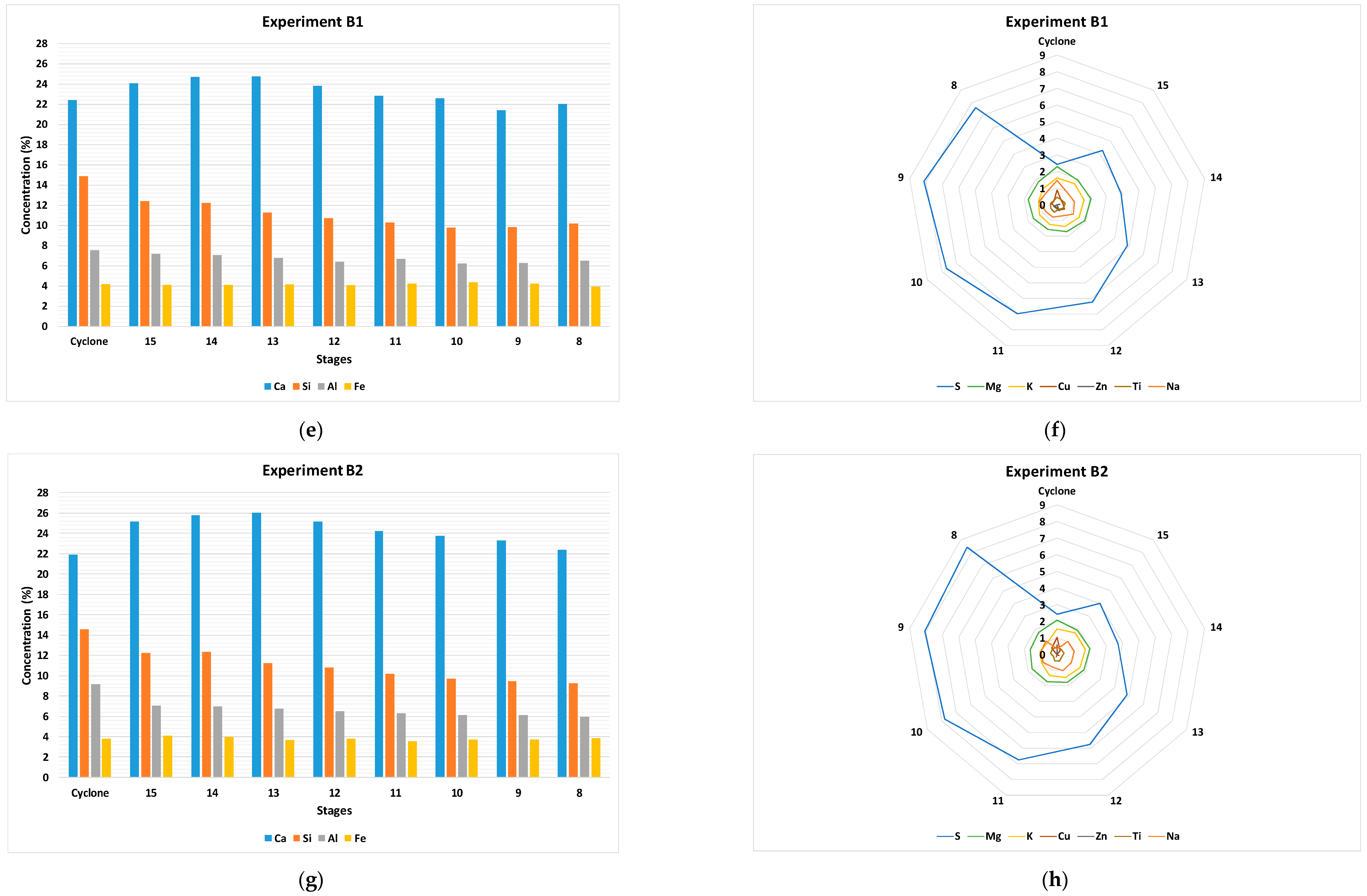

3.3. Scanning Electron Microscopy with Energy Dispersive Spectroscopy (SEM/EDS) Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- European Parliament & Council. Decision No 406/2009/EC of the European Parliament and of the Council of 23 April 2009 on the Effort of Member States to Reduce Their Greenhouse Gas Emissions to Meet the Community’s Greenhouse Gas Emission Reduction Commitments up to 2020; European Parliament & Council: Brussels, Belgium, 2009; pp. 136–148. [Google Scholar]

- International Energy Agency. Statistics-Total Primary Energy Supply (PES) by Source. Available online: https://www.iea.org/statistics/?country=WORLD&year=2008&category=Key%20indicators&indicator=TPESbySource&mode=chart&categoryBrowse=false&dataTable=BALANCES&showDataTable=true (accessed on 26 April 2020).

- International Energy Agency. Statistics-Electricity Generation by Fuel. Available online: https://www.iea.org/statistics/?country=WORLD&year=2007&category=Key%20indicators&indicator=ElecGenByFuel&mode=chart&categoryBrowse=false&dataTable=ELECTRICITYANDHEAT&showDataTable=true (accessed on 10 October 2018).

- International Energy Agency. Coal 2017 Analysis and Forecasts to 2022—Executive Summary; International Energy Agency: Paris, France, 2017. [Google Scholar]

- European Commission. EU Energy in Figures—Statistical Pocketbook 2017; Publications Office of the European Union: Luxembourg, 2017. [Google Scholar]

- Sivek, M.; Jirásek, J.; Sedláčková, L.; Čáslavský, M. Variation of moisture content of the bituminous coals with depth: A case study from the Czech part of the Upper Silesian Coal Basin. Int. J. Coal Geol. 2010, 84, 16–24. [Google Scholar] [CrossRef]

- Sivek, M.; Čáslavský, M.; Jirásek, J. Applicability of Hilt’s law to the Czech part of the Upper Silesian Coal Basin (Czech Republic). Int. J. Coal Geol. 2008, 73, 185–195. [Google Scholar] [CrossRef]

- Michels, A. Dry lignite Increases Flexibility. Available online: http://www.bine.info/fileadmin/content/Publikationen/Projekt-Infos/2016/Projekt_072–016/ProjektInfo_0716_engl_internetx.pdf (accessed on 10 January 2018).

- European Parliament & Council. Directive 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on Industrial Emissions (Integrated Pollution Prevention and Control); European Parliament & Council: Brussels, Belgium, 2010; pp. 17–119. [Google Scholar]

- European Parliament & Council. Directive 2008/50/EC of the European Parliament and of the Council of 21 May 2008 on Ambient Air Quality and Cleaner Air for Europe; European Parliament & Council: Brussels, Belgium, 2008; pp. 1–44. [Google Scholar]

- World Health Organization regional office for Europe. Health Effects of Particulate Matter; World Health Organization regional office for Europe: Copenhagen, Denmark, 2013. [Google Scholar]

- Sui, Z.; Zhang, Y.; Peng, Y.; Norris, P.; Cao, Y.; Pan, W.-P. Fine particulate matter emission and size distribution characteristics in an ultra-low emission power plant. Fuel 2016, 185, 863–871. [Google Scholar] [CrossRef]

- Zeng, G.; Sun, S.; Dong, H.; Zhao, Y.; Ye, Z.; Wei, L. Effects of combustion conditions on formation characteristics of particulate matter from pulverized coal bias ignition. Energy Fuels 2016, 30, 8691–8700. [Google Scholar] [CrossRef]

- Yao, Z.T.; Ji, X.S.; Sarker, P.K.; Tang, J.H.; Ge, L.Q.; Xia, M.S.; Xi, Y.Q. A comprehensive review on the applications of coal fly ash. Earth Sci. Rev. 2015, 141, 105–121. [Google Scholar] [CrossRef] [Green Version]

- Skodras, G.; Grammelis, P.; Kakaras, E.; Karangelos, D.; Anagnostakis, M.; Hinis, E. Quality characteristics of Greek fly ashes and potential uses. Fuel Process. Technol. 2007, 88, 77–85. [Google Scholar] [CrossRef]

- Sarkar, A.; Rano, R.; Udaybhanu, G.; Basu, A.K. A comprehensive characterisation of fly ash from a thermal power plant in Eastern India. Fuel Process. Technol. 2006, 87, 259–277. [Google Scholar] [CrossRef]

- Xu, M.; Yu, D.; Yao, H.; Liu, X.; Qiao, Y. Coal combustion-generated aerosols: Formation and properties. Proc. Combust. Inst. 2011, 33, 1681–1697. [Google Scholar] [CrossRef]

- Linak, W.P.; Miller, C.A.; Seames, W.S.; Wendt, J.O.L.; Ishinomori, T.; Endo, Y.; Miyamae, S. On trimodal particle size distributions in fly ash from pulverized-coal combustion. Proc. Combust. Inst. 2002, 29, 441–447. [Google Scholar] [CrossRef] [Green Version]

- Zhan, Z.; Fry, A.; Zhang, Y.; Wendt, J.O.L. Ash aerosol formation from oxy-coal combustion and its relation to ash deposit chemistry. Proc. Combust. Inst. 2015, 35, 2373–2380. [Google Scholar] [CrossRef] [Green Version]

- Helble, J.J.; Sarofim, A.F. Influence of char fragmentation on ash particle size distributions. Combust. Flame 1989, 76, 183–196. [Google Scholar] [CrossRef]

- Yoshiie, R.; Tsuzuki, T.; Ueki, Y.; Nunome, Y.; Naruse, I.; Sato, N.; Ito, T.; Matsuzawa, Y.; Suda, T. Effects of coal types on ash fragmentation and coalescence behaviors in pulverized coal combustion. Proc. Combust. Inst. 2013, 34, 2895–2902. [Google Scholar] [CrossRef]

- Zhang, L.; Ninomiya, Y. Emission of suspended PM 10 from laboratory-scale coal combustion and its correlation with coal mineral properties. Fuel 2006, 85, 194–203. [Google Scholar] [CrossRef]

- Gao, X.; Rahim, M.U.; Chen, X.; Wu, H. Significant contribution of organically-bound Mg, Ca, and Fe to inorganic PM 10 emission during the combustion of pulverized Victorian brown coal. Fuel 2014, 117, 825–832. [Google Scholar] [CrossRef]

- Seames, W.S. An initial study of the fine fragmentation fly ash particle mode generated during pulverized coal combustion. Fuel Process. Technol. 2003, 81, 109–125. [Google Scholar] [CrossRef]

- Furuya, K.; Miyajima, Y.; Chiba, T.; Kikuchi, T. Elemental characterization of particle size-density separated coal fly ash by spectrophotometry, ICP (inductively coupled plasma emission spectrometry), and scanning electron microscopy-energy dispersive X-ray analysis. Environ. Sci. Technol. 1987, 21, 898–903. [Google Scholar] [CrossRef]

- Zhao, G.; Zhao, Z.; Guo, X.; Du, Q.; Gao, J.; Dong, H.; Cao, Y.; Han, Q.; Su, L. Emission and morphological characteristics and elemental compositions of fine particulate matter from an industrial pulverized coal boiler equipped with a fabric filter in China. Energy Fuels 2016, 30, 4307–4317. [Google Scholar] [CrossRef]

- Lanzerstorfer, C. Fly ash from coal combustion: Dependence of the concentration of various elements on the particle size. Fuel 2018, 228, 263–271. [Google Scholar] [CrossRef]

- Zhang, X. Emission Standards and Control of PM2.5 from Coal-Fired Power Plants; CCC/267; IEA Clean Coal Centre: London, UK, 2016. [Google Scholar]

- Kazanc, F.; Levendis, Y.A. Physical properties of particulate matter emitted from combustion of coals of various ranks in O2/N2 and O2/CO2 environments. Energy Fuels 2012, 26, 7127–7139. [Google Scholar] [CrossRef]

- Krpec, K.; Horák, J.; Laciok, V.; Hopan, F.; Kubesa, P.; Lamberg, H.; Jokiniemi, J.; Tomšejová, Š. Impact of boiler type, heat output, and combusted fuel on emission factors for gaseous and particulate pollutants. Energy Fuels 2016, 30, 8448–8456. [Google Scholar] [CrossRef]

- Cao, D.-Z.; Selic, E.; Herbell, J.-D. Utilization of fly ash from coal-fired power plants in China. J. Zhejiang Univ. Sci. A 2008, 9, 681–687. [Google Scholar] [CrossRef]

- Wang, A.; Song, Q.; Tu, G.; Wang, H.; Yue, Y.; Yao, Q. Influence of flue gas cleaning system on characteristics of PM2.5 emission from coal-fired power plants. Int. J. Coal Sci. Technol. 2014, 1, 4–12. [Google Scholar] [CrossRef] [Green Version]

- Fay, J.A.; Golomb, D. Energy and the Environment; Oxford University Press: Oxford, UK, 2002. [Google Scholar]

- Argyropoulos, G.; Grigoratos, T.; Voutsinas, M.; Samara, C. Concentrations and source apportionment of PM10 and associated elemental and ionic species in a lignite-burning power generation area of southern Greece. Environ. Sci. Pollut. Res. 2013, 20, 7214–7230. [Google Scholar] [CrossRef] [PubMed]

- Vallero, D. Modeling applications. In Fundamentals of Air Pollution, 5th ed.; Vallero, D., Ed.; Academic Press: Boston, MA, USA, 2014; Chapter 27; pp. 6837–6853. [Google Scholar]

- Smith, R.D.; Campbell, J.A.; Nielson, K.K. Characterization and formation of submicron particles in coal-fired plants. Atmos. Environ. 1979, 13, 607–617. [Google Scholar] [CrossRef]

- Neville, M.; Sarofim, A.F. The stratified composition of inorganic submicron particles produced during coal combustion. Symp. Int. Combust. 1982, 19, 1441–1449. [Google Scholar] [CrossRef]

- Chen, R.; Hu, B.; Liu, Y.; Xu, J.; Yang, G.; Xu, D.; Chen, C. Beyond PM2.5: The role of ultrafine particles on adverse health effects of air pollution. Biochim. Biophys. Acta BBA Gen. Subj. 2016, 1860, 2844–2855. [Google Scholar] [CrossRef]

- Heinzerling, A.; Hsu, J.; Yip, F. Respiratory health effects of ultrafine particles in children: A literature review. Water Air Soil Pollut. 2016, 227, 32. [Google Scholar] [CrossRef] [Green Version]

- Carbone, F.; Beretta, F.; D’Anna, A. Factors influencing ultrafine particulate matter (PM0.1) formation under pulverized coal combustion and oxyfiring conditions. Energy Fuels 2010, 24, 6248–6256. [Google Scholar] [CrossRef]

- Wen, C.; Gao, X.; Yu, Y.; Wu, J.; Xu, M.; Wu, H. Emission of inorganic PM10 from included mineral matter during the combustion of pulverized coals of various ranks. Fuel 2015, 140, 526–530. [Google Scholar] [CrossRef]

- Zhuo, J.K.; Li, S.Q.; Yao, Q.; Song, Q. The progressive formation of submicron particulate matter in a quasi one-dimensional pulverized coal combustor. Proc. Combust. Inst. 2009, 32, 2059–2066. [Google Scholar] [CrossRef]

- Ruan, R.; Tan, H.; Wang, X.; Li, Y.; Li, S.; Hu, Z.; Wei, B.; Yang, T. Characteristics of fine particulate matter formation during combustion of lignite riched in AAEM (alkali and alkaline earth metals) and sulfur. Fuel 2018, 211, 206–213. [Google Scholar] [CrossRef]

- Li, G.; Li, S.; Huang, Q.; Yao, Q. Fine particulate formation and ash deposition during pulverized coal combustion of high-sodium lignite in a down-fired furnace. Fuel 2015, 143, 430–437. [Google Scholar] [CrossRef]

- Fix, G.; Seames, W.; Mann, M.; Benson, S.; Miller, D. The effect of combustion temperature on coal ash fine-fragmentation mode formation mechanisms. Fuel 2013, 113, 140–147. [Google Scholar] [CrossRef]

- Zhang, L.; Ninomiya, Y.; Yamashita, T. Formation of submicron particulate matter (PM1) during coal combustion and influence of reaction temperature. Fuel 2006, 85, 1446–1457. [Google Scholar] [CrossRef]

- Li, G.; Li, S.; Dong, M.; Yao, Q.; Guo, C.Y.; Axelbaum, R.L. Comparison of particulate formation and ash deposition under oxy-fuel and conventional pulverized coal combustions. Fuel 2013, 106, 544–551. [Google Scholar] [CrossRef]

- Fryda, L.; Sobrino, C.; Glazer, M.; Bertrand, C.; Cieplik, M. Study of ash deposition during coal combustion under oxyfuel conditions. Fuel 2012, 92, 308–317. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.W. Source profiles of particulate matter emissions from a pilot-scale boiler burning North American coal blends. J. Air Waste Manag. Assoc. 2001, 51, 1568–1578. [Google Scholar] [CrossRef] [Green Version]

- Yelverton, T.L.B.; Brashear, A.T.; Nash, D.G.; Brown, J.E.; Singer, C.F.; Kariher, P.H.; Ryan, J.V. Comparison of gaseous and particulate emissions from a pilot-scale combustor using three varieties of coal. Fuel 2018, 215, 572–579. [Google Scholar] [CrossRef]

- Papandreou, I.; Babat, S.; Maier, J.; Georgiou, C.; Karampinis, E.; Avagianos, I.; Vounatsos, P.; Grammelis, P.; Kakaras, E. Large technical scale parametric investigation of co-firing of hard coal and pre dried lignite under under- and over stoichiometric conditions in the scope of enhancing the flexibility of hard coal fired power stations. In Proceedings of the 43rd Clearwater Clean Energy Conference, Clearwater, FL, USA, 3–8 June 2018. [Google Scholar]

- Zhu, Q. Coal Sampling and Analysis Standards; CCC/235; IEA Clean Coal Centre: London, UK, 2014. [Google Scholar]

- Badin, E.J. Coal Combustion Chemistry: Correlation Aspects; Elsevier: Amsterdam, The Netherlands, 1984. [Google Scholar]

- Helble, J.J. A model for the air emissions of trace metallic elements from coal combustors equipped with electrostatic precipitators. Fuel Process. Technol. 2000, 63, 125–147. [Google Scholar] [CrossRef]

- Chen, T.-M.; Tsai, C.-J.; Yan, S.-Y.; Li, S.-N. An efficient wet electrostatic precipitator for removing nanoparticles, submicron and micron-sized particles. Sep. Purif. Technol. 2014, 136, 27–35. [Google Scholar] [CrossRef]

- Halliburton, W.B.; Carras, J.N.; Nelson, P.F. Fine Particle Emissions from Power Stations; Cooperative Research Centre for Coal in Sustainable Development: Pullenvale, Australia, 2018. [Google Scholar]

- Wang, C.; Liu, X.; Li, D.; Si, J.; Zhao, B.; Xu, M. Measurement of particulate matter and trace elements from a coal-fired power plant with electrostatic precipitators equipped the low temperature economizer. Proc. Combust. Inst. 2015, 35, 2793–2800. [Google Scholar] [CrossRef]

- Parker, K.R. Applied Electrostatic Precipitation; Blackie Academic & Professional: London, UK, 1997. [Google Scholar]

- Yu, D.; Xu, M.; Yao, H.; Liu, X.; Zhou, K. A new method for identifying the modes of particulate matter from pulverized coal combustion. Powder Technol. 2008, 183, 105–114. [Google Scholar] [CrossRef]

- Sui, Z.; Zhang, Y.; Yao, J.; Norris, P.; Cao, Y.; Pan, W.-P. The influence of NaCl and Na2CO3 on fine particulate emission and size distribution during coal combustion. Fuel 2016, 184, 718–724. [Google Scholar] [CrossRef]

| Analysis | Czech Bituminous Coal (BC) | Greek Pre-Dried Lignite (GL) |

|---|---|---|

| Net Calorific Value (kJ/kg) (a.r.) | 25971 | 9567 |

| Proximate (% w.t.) | ||

| Moisture | 0.94 | 15.1 |

| Volatile matter (dry) | 23.62 | 43.46 |

| Fixed Carbon (dry) | 54.17 | 18.85 |

| Ash (dry) | 22.21 | 37.69 |

| Ultimate (% w.t. daf) | ||

| Carbon | 85.52 | 56.52 |

| Hydrogen | 5.11 | 4.40 |

| Nitrogen | 1.48 | 1.55 |

| Sulfur | 0.57 | 1.29 |

| Chlorine | 0.07 | 0.04 |

| Oxygen | 7.25 | 36.20 |

| Ash analysis (% w.t.) | ||

| Si | 25.45 | 14.67 |

| Al | 11.60 | 7.43 |

| Fe | 5.76 | 3.30 |

| Mg | 1.75 | 2.26 |

| Ca | 3.09 | 26.93 |

| Na | 0.33 | 0.24 |

| K | 2.20 | 0.88 |

| Ti | 0.58 | 0.32 |

| P | 0.06 | 0.14 |

| Ba | 0.08 | 0.04 |

| Mn | 0.13 | 0.03 |

| Sr | 0.03 | 0.04 |

| S | 1.48 | 2.42 |

| O | 47.47 | 41.29 |

| Experiment | Pre-Dried Lignite Thermal Share | Hard Coal Thermal Share | Conditions | Air Ratio (Burner) | Total Air Ratio |

|---|---|---|---|---|---|

| A1 | 10% | 90% | Un-staged | 1.15 | 1.15 |

| A2 | 10% | 90% | Staged | 0.8 | 1.15 |

| B1 | 50% | 50% | Un-staged | 1.15 | 1.15 |

| B2 | 50% | 50% | Staged | 0.8 | 1.15 |

| C1 | 100% | 0% | Un-staged | 1.15 | 1.15 |

| C2 | 100% | 0% | Staged | 0.8 | 1.15 |

| Stage | Number of Jets | Pressure (kPa) | Calculated Aerodynamic D50 (μm) @ 180 °C | Calculated Stage Midpoints Di (μm) @ 180 °C |

|---|---|---|---|---|

| Inlet | - | 101.33 | - | - |

| 15 | 1 | 101.32 | 10.34 | - |

| 14 | 1 | 101.30 | 6.95 | 8.477 |

| 13 | 3 | 101.25 | 4.13 | 5.361 |

| 12 | 14 | 101.18 | 2.45 | 3.185 |

| 11 | 17 | 101.01 | 1.62 | 1.996 |

| 10 | 20 | 100.49 | 0.944 | 1.238 |

| 9 | 48 | 99.63 | 0.594 | 0.749 |

| 8 | 50 | 97.20 | 0.353 | 0.458 |

| 7 | 27 | 89.05 | 0.228 | 0.284 |

| 6 | 19 | 68.70 | 0.123 | 0.168 |

| 5 | 21 | 38.33 | 0.0668 | 0.091 |

| 4 | 58 | 21.67 | 0.0362 | 0.049 |

| 3 | 69 | 9.77 | 0.0199 | 0.027 |

| 2 | 174 | 4.26 | 0.0111 | 0.015 |

| 1 | filter | 4.00 | 0.0060 | 0.008 |

| Experiment | Skeletal Density | ± | Bituminous Coal | Pre-Dried Lignite | Conditions |

|---|---|---|---|---|---|

| gr/cm3 | gr/cm3 | Thermal Share | |||

| A1 | 2.3854 | 0.0744 | 90% | 10% | Un-staged |

| A2 | 2.4045 | 0.0836 | 90% | 10% | Staged |

| B1 | 2.5605 | 0.0664 | 50% | 50% | Un-staged |

| B2 | 2.4717 | 0.1003 | 50% | 50% | Staged |

| C1 | 2.6425 | 0.0355 | 0% | 100% | Un-staged |

| C2 | 2.6480 | 0.0519 | 0% | 100% | Staged |

| Experiment | PM0.1 | PM1 | PM2.5 |

|---|---|---|---|

| Mass Fraction | Mass Fraction | Mass Fraction | |

| A1 | 0.052% | 5.445% | 31.212% |

| A2 | 0.058% | 4.102% | 25.081% |

| B1 | 0.011% | 2.745% | 20.191% |

| B2 | 0.022% | 3.323% | 25.837% |

| C1 | 0.002% | 2.184% | 15.280% |

| C2 | 0.002% | 2.450% | 14.780% |

| Experiment | C2 | B2 | A2 | C2 | B2 | A2 | C2 | B2 | A2 | C2 | B2 | A2 | C2 | B2 | A2 | C2 | B2 | A2 | C2 | B2 | A2 | C2 | B2 | A2 | C2 | B2 | A2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stage | Stage | Stage | Stage | Stage | Stage | Stage | Stage | Stage | |||||||||||||||||||

| Element | Cyclone 1 | Cyclone | Cyclone 3 | 15 | 15 | 15 | 14 | 14 | 14 1 | 13 | 13 | 13 | 12 | 12 | 12 | 11 | 11 4 | 11 | 10 | 10 | 10 | 9 | 9 1,2 | 9 | 8 | 8 2 | 8 |

| Na | 0.89 | 0.33 | - | 0.97 | 1.02 | 1.30 | 0.67 | 1.06 | 0.78 | 1.03 | 0.99 | 1.07 | 0.91 | 1.04 | 0.70 | 0.84 | 0.81 | 0.47 | 0.72 | 0.96 | 0.68 | 0.75 | 0.98 | 0.59 | 0.79 | 1.06 | 0.88 |

| Mg | 2.17 | 2.07 | 1.55 | 2.10 | 1.90 | 1.94 | 1.96 | 2.01 | 1.83 | 1.94 | 1.87 | 1.93 | 1.80 | 1.79 | 1.71 | 1.71 | 1.75 | 1.75 | 1.68 | 1.73 | 1.69 | 1.59 | 1.64 | 1.68 | 1.68 | 1.73 | 1.84 |

| Al | 5.16 | 9.12 | 11.35 | 5.51 | 7.05 | 10.74 | 5.80 | 6.96 | 10.60 | 5.57 | 6.76 | 10.99 | 5.40 | 6.49 | 10.93 | 5.01 | 6.31 | 10.73 | 4.93 | 6.15 | 10.84 | 5.16 | 6.11 | 10.27 | 5.01 | 5.95 | 10.38 |

| Si | 10.85 | 14.55 | 19.21 | 9.77 | 12.19 | 17.63 | 10.26 | 12.33 | 17.67 | 9.53 | 11.25 | 17.18 | 8.82 | 10.77 | 16.78 | 8.34 | 10.16 | 16.25 | 8.25 | 9.68 | 15.78 | 7.88 | 9.43 | 15.16 | 7.78 | 9.25 | 15.56 |

| S | 2.75 | 2.42 | 1.08 | 5.10 | 4.01 | 1.58 | 4.31 | 3.72 | 1.46 | 5.60 | 4.86 | 2.01 | 6.44 | 5.77 | 2.67 | 7.29 | 6.75 | 3.34 | 7.89 | 7.79 | 3.71 | 8.80 | 8.08 | 4.26 | 9.14 | 8.42 | 4.53 |

| K | 1.06 | 1.54 | 2.39 | 1.12 | 1.70 | 2.61 | 1.28 | 1.73 | 2.74 | 1.17 | 1.59 | 2.68 | 1.04 | 1.47 | 2.66 | 0.92 | 1.34 | 2.45 | 0.89 | 1.06 | 2.24 | 0.78 | 1.05 | 2.28 | 0.73 | 0.92 | 2.22 |

| Ca | 32.88 | 21.90 | 12.74 | 30.45 | 25.16 | 13.28 | 30.68 | 25.78 | 13.31 | 29.90 | 26.00 | 12.82 | 29.51 | 25.17 | 12.51 | 29.28 | 24.25 | 12.41 | 28.39 | 23.71 | 12.14 | 27.26 | 23.32 | 12.39 | 26.31 | 22.36 | 12.25 |

| Ti | 0.38 | 0.46 | 0.62 | 0.23 | 0.40 | 0.80 | 0.31 | 0.43 | 0.78 | 0.24 | 0.32 | 0.70 | 0.32 | 0.42 | 0.67 | 0.18 | 0.41 | 0.57 | 0.22 | 0.25 | 0.72 | - | 0.39 | 0.76 | 0.14 | 0.43 | 0.74 |

| Fe | 3.94 | 3.77 | 6.05 | 3.02 | 4.08 | 6.23 | 3.25 | 4.00 | 6.64 | 2.82 | 3.65 | 6.17 | 3.04 | 3.76 | 6.22 | 3.19 | 3.53 | 6.25 | 3.14 | 3.72 | 6.27 | 3.01 | 3.73 | 6.39 | 3.19 | 3.84 | 4.62 |

| Cu | 0.33 | 1.03 | 0.37 | - | 0.29 | 0.33 | 0.15 | - | 0.58 | - | 0.13 | 0.39 | - | - | 0.43 | - | 0.15 | 0.43 | - | - | 0.54 | - | - | 0.91 | 0.17 | 0.50 | 0.87 |

| Zn | - | 0.58 | 0.22 | - | - | - | 0.19 | - | 0.22 | - | - | 0.19 | - | - | 0.43 | - | 0.16 | 0.62 | - | - | 0.39 | - | - | 0.24 | - | - | 0.55 |

| O | 39.52 | 42.23 | 43.95 | 41.73 | 42.20 | 43.56 | 41.14 | 41.98 | 43.32 | 42.20 | 42.58 | 43.87 | 42.72 | 43.32 | 44.29 | 43.24 | 44.22 | 44.73 | 43.89 | 44.95 | 45.00 | 44.77 | 44.59 | 45.07 | 45.06 | 45.24 | 45.56 |

| Experiment | C1 | B1 | A1 | C1 | B1 | A1 | C1 | B1 | A1 | C1 | B1 | A1 | C1 | B1 | A1 | C1 | B1 | A1 | C1 | B1 | A1 | C1 | B1 | A1 | C1 | B1 | A1 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stage | Stage | Stage | Stage | Stage | Stage | Stage | Stage | Stage | |||||||||||||||||||

| Element | Cyclone | Cyclone | Cyclone | 15 | 15 | 15 | 14 | 14 | 14 | 13 3 | 13 | 13 | 12 2 | 12 4 | 12 | 11 | 11 | 11 1 | 10 | 10 | 10 | 9 | 9 | 9 | 8 | 8 | 8 |

| Na | 0.26 | 1.46 | 1.02 | 0.97 | 0.96 | 1.43 | 0.63 | 1.07 | 1.37 | 0.95 | 1.14 | 1.27 | 0.70 | 0.72 | 1.47 | 0.95 | 0.79 | 0.96 | 0.89 | 0.79 | 0.96 | 1.00 | 1.09 | 1.05 | 0.93 | 0.98 | 1.08 |

| Mg | 2.26 | 2.29 | 1.99 | 1.98 | 1.93 | 2.01 | 1.87 | 2.08 | 1.93 | 1.81 | 1.92 | 1.97 | 1.78 | 1.72 | 1.88 | 1.84 | 1.58 | 1.71 | 1.78 | 1.64 | 1.88 | 1.91 | 1.76 | 1.76 | 1.83 | 1.77 | 1.78 |

| Al | 5.64 | 7.55 | 10.37 | 5.42 | 7.19 | 11.20 | 5.69 | 7.07 | 11.78 | 5.32 | 6.79 | 11.96 | 5.34 | 6.41 | 12.39 | 5.03 | 6.67 | 12.16 | 5.15 | 6.24 | 12.34 | 6.28 | 6.27 | 12.07 | 5.56 | 6.51 | 11.72 |

| Si | 11.32 | 14.88 | 19.34 | 9.54 | 12.40 | 18.43 | 10.19 | 12.24 | 19.08 | 9.41 | 11.27 | 19.11 | 8.81 | 10.72 | 19.00 | 8.33 | 10.30 | 18.31 | 8.58 | 9.80 | 18.14 | 8.08 | 9.83 | 17.29 | 8.30 | 10.18 | 16.67 |

| S | 3.03 | 2.43 | 1.00 | 5.75 | 4.26 | 1.30 | 4.80 | 3.91 | 1.09 | 5.75 | 4.89 | 1.12 | 6.96 | 6.23 | 1.42 | 8.22 | 6.98 | 1.85 | 8.43 | 7.68 | 2.21 | 9.07 | 8.13 | 2.68 | 8.43 | 7.62 | 3.12 |

| K | 1.06 | 1.61 | 2.47 | 1.20 | 1.64 | 2.61 | 1.34 | 1.65 | 2.78 | 1.29 | 1.53 | 2.74 | 1.09 | 1.39 | 2.72 | 0.87 | 1.26 | 2.64 | 0.85 | 1.22 | 2.54 | 0.75 | 1.14 | 2.38 | 0.83 | 1.28 | 2.29 |

| Ca | 30.93 | 22.41 | 12.50 | 29.46 | 24.08 | 12.28 | 29.81 | 24.72 | 11.13 | 29.29 | 24.77 | 10.55 | 28.45 | 23.82 | 10.25 | 27.31 | 22.85 | 10.40 | 26.53 | 22.58 | 9.81 | 24.54 | 21.41 | 9.94 | 26.26 | 22.04 | 10.65 |

| Ti | 0.27 | 0.46 | 0.71 | 0.23 | 0.39 | 0.79 | 0.34 | 0.50 | 0.70 | 0.32 | 0.42 | 0.71 | 0.25 | 0.29 | 0.68 | 0.28 | 0.47 | 0.74 | 0.23 | 0.43 | 0.83 | 0.24 | 0.40 | 0.84 | 0.17 | 0.32 | 0.95 |

| Fe | 3.77 | 4.18 | 6.28 | 3.14 | 4.12 | 6.03 | 3.23 | 4.10 | 5.97 | 3.18 | 4.16 | 5.87 | 3.20 | 4.08 | 5.52 | 2.81 | 4.25 | 5.69 | 2.81 | 4.37 | 5.93 | 2.48 | 4.23 | 6.03 | 2.92 | 3.93 | 6.00 |

| Cu | 0.78 | 0.89 | 0.47 | - | 0.38 | - | 0.18 | 0.37 | - | 0.13 | 0.52 | 0.31 | 0.13 | 0.34 | - | - | 0.15 | 0.70 | - | 0.16 | - | - | 0.34 | 0.77 | - | 0.30 | 0.35 |

| Zn | 0.58 | - | 0.19 | - | - | - | 0.33 | 0.18 | - | - | - | 0.17 | - | 0.39 | - | - | 0.21 | 0.20 | - | 0.22 | 0.17 | - | - | 0.16 | - | - | 0.19 |

| O | 40.10 | 41.84 | 43.66 | 42.31 | 42.65 | 43.92 | 41.59 | 42.11 | 44.17 | 42.10 | 42.59 | 44.22 | 43.22 | 43.58 | 44.67 | 44.36 | 44.49 | 44.57 | 44.75 | 44.87 | 45.19 | 45.65 | 45.40 | 45.03 | 44.77 | 45.07 | 45.20 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Avagianos, I.; Vounatsos, P.; Papandreou, I.; Maier, J.; Grammelis, P.; Kakaras, E. Nanoparticle Emission and Characterization from Pre-Dried Lignite and Bituminous Coal Co-Combustion. Energies 2020, 13, 2373. https://doi.org/10.3390/en13092373

Avagianos I, Vounatsos P, Papandreou I, Maier J, Grammelis P, Kakaras E. Nanoparticle Emission and Characterization from Pre-Dried Lignite and Bituminous Coal Co-Combustion. Energies. 2020; 13(9):2373. https://doi.org/10.3390/en13092373

Chicago/Turabian StyleAvagianos, Ioannis, Panagiotis Vounatsos, Ioannis Papandreou, Joerg Maier, Panagiotis Grammelis, and Emmanuel Kakaras. 2020. "Nanoparticle Emission and Characterization from Pre-Dried Lignite and Bituminous Coal Co-Combustion" Energies 13, no. 9: 2373. https://doi.org/10.3390/en13092373

APA StyleAvagianos, I., Vounatsos, P., Papandreou, I., Maier, J., Grammelis, P., & Kakaras, E. (2020). Nanoparticle Emission and Characterization from Pre-Dried Lignite and Bituminous Coal Co-Combustion. Energies, 13(9), 2373. https://doi.org/10.3390/en13092373