1. Introduction

As compared with the traditional lighting sources, like the incandescent lights, fluorescent lights, and halogen lights, etc., the high-brightness lighting-emitting diodes (LEDs) have become promising due to their long life, compact size, and eco-friendly characteristics [

1]. The LED lights are widely used in the indoor lighting, outdoor lighting, and display backlighting. In these applications, multiple LEDs are connected to increase the luminous flux. The LEDs can be connected in series and parallel, depending on the output voltage and current of the LED driver. In general, multiple LEDs are connected in series to form an LED string, and then the LED strings are connected in parallel with each other. Since each LED has different voltage and current characteristics, the constant current control is required to equalize each LED string current. Therefore, LED current sharing technique is necessary. The LED current sharing can be classified into two methods. One is the active method [

2,

3,

4,

5,

6,

7,

8,

9], and the other is the passive method [

10,

11,

12,

13,

14,

15].

Generally, the active method uses semiconductor devices and integrated circuits to achieve LED current sharing. The active method has some disadvantages, such as complexity and high cost. The passive method, which features low cost and simplicity, is developed as another LED current sharing method. The passive method can be subdivided into inductive and capacitive methods. The inductive method usually uses the current-sharing transformers. For the current-sharing transformer method, the differential transformer with a 1:1 turns ratio is used to balance the LED current. On the other hand, the capacitive method uses the capacitors to achieve LED current balance. The current sharing is achieved based on the capacitor ampere-second balance. In

Figure 1, the literatures [

14] and [

15] display the low-power two-channel LED drivers using the capacitor to achieve LED current balance. They are suitable for low-input voltage and low-power applications. These two LED drivers are based on step-up converters. The output voltage of the two-channel LED driver is the sum of the voltages across two LED strings, and this is different from the parallel connection. Thus, these kinds of LED drivers are called pseudo multi-string LED drivers. However, if the resonance behavior is taken into account, then the soft switching of the switch and diode will happen, causing the overall efficiency can be upgraded. Consequently, the non-isolated boost resonant LED driver shown in [

16] is presented. In this circuit, only the diode in the resonant path can have zero-current-switching (ZCS) turn-off. In addition, if the resonance behavior as well as galvanic isolation taking into consideration, then the isolated voltage-bucking resonant LED driver as displayed in [

17] is proposed. In this circuit, only all the diodes on the secondary side have ZCS.

Therefore, an isolated LED driver based on the LLC resonant converter is proposed herein. Both switches have zero-voltage-switching (ZVS) turn-on and both the diodes on the secondary side have ZCS turn-off except at light load. The proposed LED driver is based on the current-sharing capacitor with a quite low voltage stress. In this paper, the basic operating principles, steady-state analyses, and experimental results will be given in the following sections.

2. Basic Analysis of the Proposed LED Driver

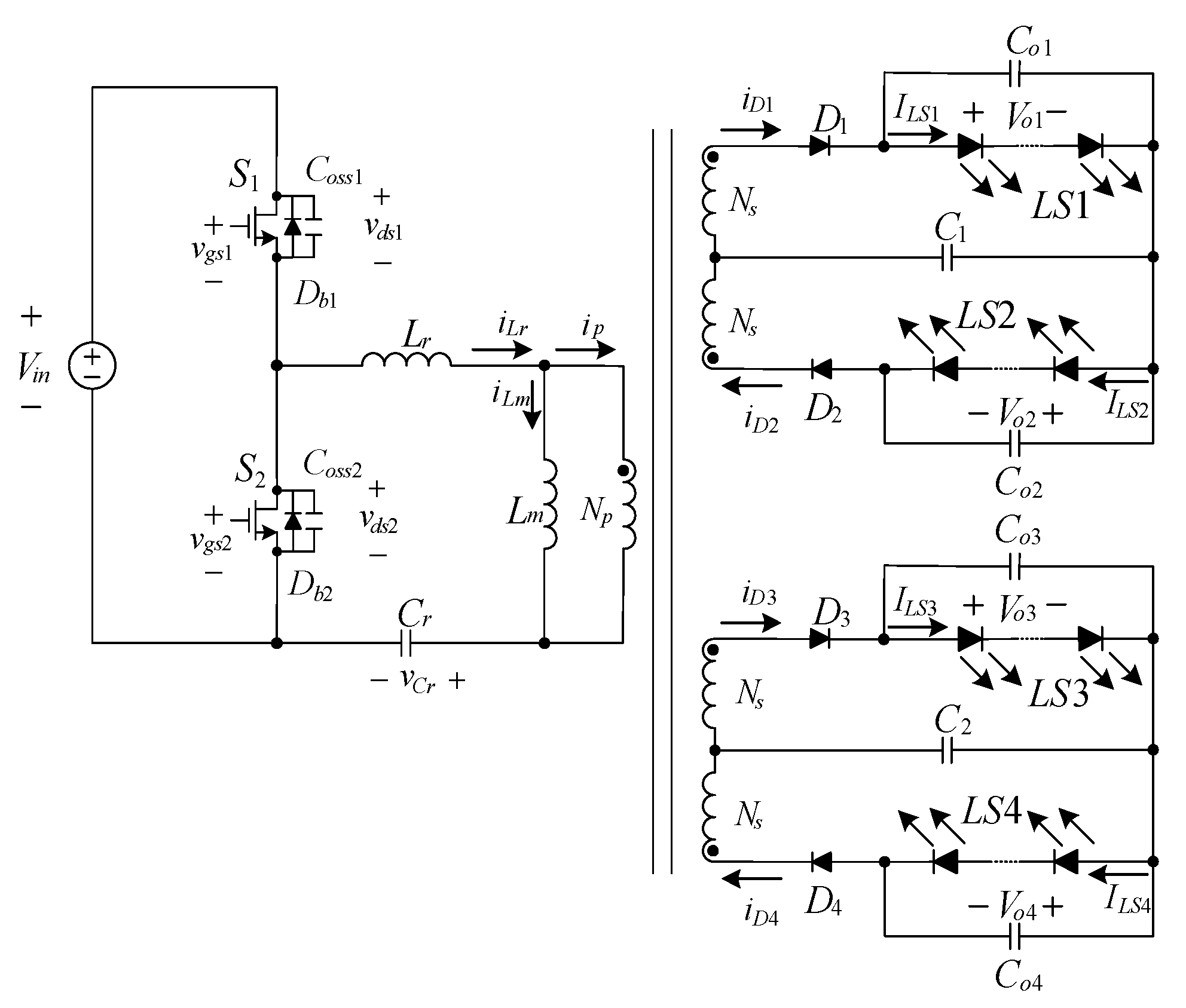

Figure 2 shows the proposed two-channel LED driver. For analysis convenience, there are some assumptions to be made as follows.

- (1)

The switches and components are ideal except for the metal-oxide-semiconductor field-effect transistor (MOSFET) switches and the transformer.

- (2)

The values of all the capacitors are large enough. Thus, the voltages across them are regarded as constant.

- (3)

The two output voltages are identical, namely, Vo1 = Vo2.

The following analyses contain the (a) operating principles; (b) LED modeling; (c) LED load characteristics; (d) voltage gain characteristics; and (e) extension of the proposed LED driver.

2.1. Operating Principles

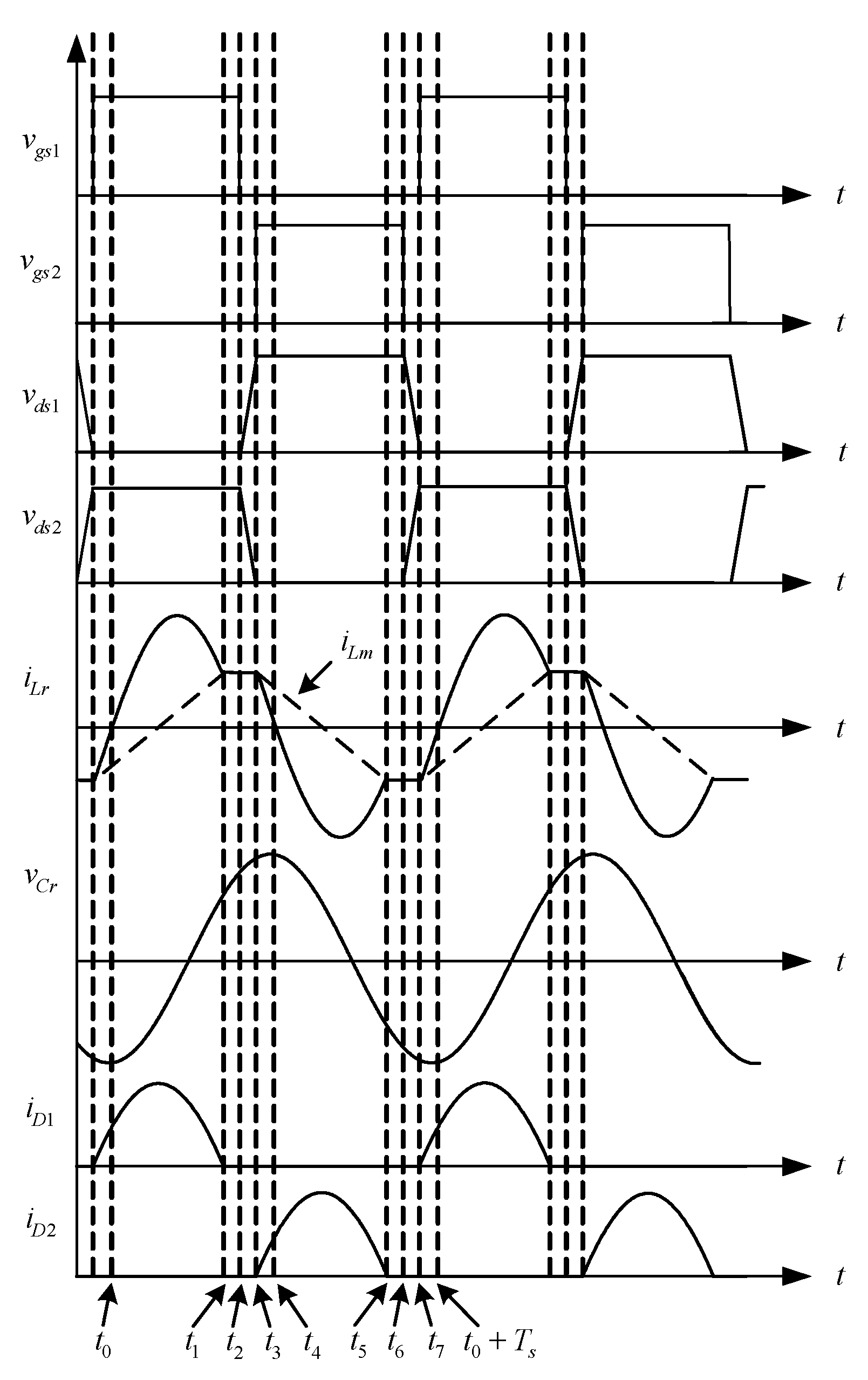

There are 8 operating states in the proposed LED driver.

Figure 3 shows the key waveforms over one switching period.

2.1.1. State 1 (t0, t1)

As shown in

Figure 4a,

S1 is ON, but

S2 is OFF. Thus,

Lr and

Cr resonate with each other and

iLr increases from zero. During this state,

iLr is larger than

iLm. Therefore, the current

ip is transferred from the primary side to the secondary side, thus making

D1 forward biased and hence providing energy to

Co1 and

LS1. As for

LS2, it is powered by

Co2. At the same time, the voltage

nVo1 is across

Lm, thus causing

iLm to be increased linearly. This state ends when

iLr equals

iLm at

t1.

2.1.2. State 2 (t1, t2)

As shown in

Figure 4b,

S1 is still ON, but

S2 is still OFF. During this state, since

iLr is equal to

iLm, there is no current flowing through the secondary side, thereby causing the energy required by

LS1 and

LS2 to be provided by

Co1 and

Co2, respectively. At the same time,

Cr,

Lr, and

Lm resonate together, thus causing

iLr to be increased quite slowly. This state ends when

S1 turns off at

t2.

2.1.3. State 3 (t2, t3)

As shown in

Figure 4c,

S1 is turned OFF and

S2 still keeps OFF. During this state,

Coss1 is charged and

Coss2 is discharged, thus causing the energy required by

LS1 and

LS2 to be still provided by

Co1 and

Co2, respectively. This state ends when

Coss1 is charged to

Vin, and

Coss2 is discharged to zero at

t3.

2.1.4. State 4 (t3, t4)

As shown in

Figure 4d,

S1 keeps OFF, but

S2 is turned ON with zero voltage switching (ZVS) due to

iLr flowing through

Db2. During this state,

iLr is smaller than

iLm. Therefore, the current -

ip is reflected from the secondary side to the primary side, thereby making

D2 forward biased and hence providing energy to

Co2 and

LS2. As for

LS1, it is powered by

Co1. At the same time, the voltage

−nVo2 is across

Lm, thereby causing

iLm to be decreased linearly. This state ends when

iLr reaches zero at

t4.

2.1.5. State 5 (t4, t5)

As shown in

Figure 4e,

S1 still keeps OFF, but

S2 keeps ON. During this state,

iLr changes the direction. The voltage -

nVo2 is still across

Lm. Thus,

iLm is still decreased linearly. This state ends when

iLr equals

iLm at

t5.

2.1.6. State 6 (t5, t6)

As shown in

Figure 4f,

S1 still keeps OFF, but

S2 still keeps ON. Since

iLr is equal to

iLm, there is no current flowing through the secondary side, thereby causing the energy required by

LS1 and

LS2 to be provided by

Co1 and

Co2, respectively. At the same time,

Cr,

Lr and

Lm resonate together, thus causing

iLr to be decreased quite slowly. This state ends when

S2 turns off at

t6.

2.1.7. State 7 (t6, t7)

As shown in

Figure 4g,

S1 still keeps OFF, and

S2 is turned OFF. During this state,

Coss1 is charged and

Coss2 is discharged, thus causing the energy required by

LS1 and

LS2 to be still provided by

Co1 and

Co2, respectively. This state ends when

Coss1 is discharged to zero, and

Coss2 is charged to

Vin at

t7.

2.1.8. State 8 (t7, t0 + Ts)

As shown in

Figure 4h,

S2 keeps OFF, but

S1 is turned ON with ZVS due to

iLr flowing through

Db1. During this state, −

iLr is smaller than −

iLm. Therefore, the current

ip is transferred from the primary side to the secondary side, thus making

D1 forward biased and hence providing energy to

Co1 and

LS1. As for

LS2 it is powered by

Co2. At the same time, the voltage

nVo1 is across

Lm, thus causing

iLm to be increased linearly. This state ends when

iLr reaches zero at

t =

t0 +

Ts.

2.2. LED Modeling

The LED string can be modeled as a piecewise linear model as shown in

Figure 5. The equivalent LED string model contains one ideal diode

Dideal, one equivalent on-resistance

RLED and one equivalent forward voltage

VF, with all the three connected in series. Also, the LED string current is defined as

ILED. Hence, the LED string voltage

VLED can be expressed as

2.3. LED Load Characteristics

The AC equivalent load can be modeled by using the fundamental harmonic approximation (FHA). The AC equivalent circuit of the proposed LLC resonant LED driver is shown in

Figure 6. The derivation is shown as follows.

The current

iac(fund) is defined as a fundamental sinusoidal wave on the secondary side. That is,

where

Ip is the maximum value of

iac(fund)(

t).

The expression of

VLED can be changed to

where

is the average current of

iD1 and equal to

ILED.Therefore,

can be expressed to be

By substituting (4) into (3),

VLED can be rewritten to be

In addition, the voltage on the secondary side,

vac(

t), can be expressed to be

Also, the voltage

vac(

t) can be represented by a Fourier series as follows:

Since

vac(

t) is an odd function waveform,

an is zero. Thus,

The fundamental waveform of

vac(

t), called

vac(fund)(

t), is

Based (4) and

Vo1 =

VLED, the effective resistive load

Ro,ac can be signified by

2.4. Voltage Gain Characteristics

Figure 7 shows the two-port model of the FHA resonant circuit. The output load resistor

Rout can be regarded as the equivalent static resistance of the LED string at a given forward current, that is,

VLED divided by

ILED. In addition, the voltage gain is

where

is the fundamental component of the input voltage in the phasor domain and

is the fundamental component of the output voltage in the phasor domain.

The input voltage waveform of the AC resonant tank is

From (12), it can be seen that the fundamental component of the input voltage is

As derived in (9), the output voltage fundamental component is

Based on (11), (13), and (14), the DC-DC input-to-output voltage conversion ratio can be derived as follows:

From (15), the DC-DC input-to-output voltage conversion ratio is

In

Figure 6, by transferring the time domain to the

s domain and let

, the magnitude of the voltage gain

, called

M, can be derived as follows:

where

,

,

, and

.

From (17), it can be seen that Q and K will affect the voltage gain.

The output resistance in

Figure 7 is replaced with the LED equivalent model as shown in

Figure 8. Based on (1),

Based on (16), Equation (19) can be rewritten as

From (19), it can be seen that the LED current can be regulated by changing the switching frequency

fs, and this means that the gain adjustment is made by frequency modulation. As seen in

Figure 9, by giving an LED current command

ILED_command, the frequency modulator will change the switching frequency

fs, and

vo,FHA will be varied to a corresponding value according to the designed voltage gain

M.

2.5. System Control

Figure 10 shows the control strategy of the proposed LED driver. From

Figure 10a, it can be seen that one of the LED strings is sensed and the current signal is transformed to the voltage signal and then sent to UCD3138, which contains an error ADC, a filter, and a digital PWM as shown in

Figure 10b. The sensed current signal will be sent to the error ADC and compared with the prescribed reference value. After this, the error signal will be sent to the filter, called the PID controller. Eventually, the calculated duty cycle and frequency will control the MOSFETs to regulate the LED string currents.

2.6. Effect of Variations in Equivalent forward Voltage on Current Sharing

As shown in

Figure 10a, since the voltages across the two central-tapped windings are the same, this means that

Assuming that the diodes

D1 and

D2 are two-in-one,

VD1 can be regarded as almost equal to

VD2. Therefore, (20) can be simplified to (21):

Based on (21), if the two LED strings are identical, then VC1 is zero; otherwise, VC1 is not zero. This means that the difference in equivalent forward voltage between the two LED strings can be absorbed by the current-sharing capacitor C1.

2.7. Circuit Extension

Figure 11 shows the four-channel LED driver, which can be derived from the proposed two-channel LED driver. However, in practice, the effective resistive load

Ro,ac will be changed. Consequently, the design of the associated parameters will be repeated if necessary.

3. Design Considerations

To verify the effectiveness of the proposed LED driver, a prototype is built up and tested.

Table 1 shows the system specifications of the proposed converter, whereas

Table 2 shows the component specifications used in the proposed converter. Moreover, the design procedures of (a) LED selection; (b) transformer turns ratio (

n); (c) maximum voltage conversion ratio (

Mmax) and minimum voltage conversion ratio (

Mmin); (d) effective resistive load reflected to the primary side of the transformer (

n2Ro,ac); (e) ratio of magnetizing inductance to resonant inductance ratio (

K) and quality factor (

Q); and (f) resonant capacitance (

Cr), resonant inductance (

Lr), and magnetizing inductance (

Lm).

3.1. Selection of LED String

The high-power LEDs, used as load for the proposed LED driver, are made by Everlight Electronics Ltd. The corresponding product name is EHP-AX08EL/GT01H-P01/5670/Y/K42. From the associated datasheet, it can be seen that the forward voltage is about 3.45 V if the constant current flowing through the LED is 350 mA. In the proposed two-channel LED driver, 12 pieces of LEDs are connected in series for each string. Also, the LED string can be constructed by as an approximately linear model as shown in

Figure 5. The equivalent forward voltage

VF is about 41.4 V (= 2.73·12), and the equivalent on-resistance

RLED is about 24.68 Ω (= 2.057·12).

3.2. Determination of Transformer Turns Ratio

The turns ratio of the transformer can be figured out under normal input voltage and unity voltage gain, namely,

Mnor = 1:

Based on the above calculation, the turns ratio n is selected to be 5. Via recalculation, the new voltage gain is 1.04.

3.3. Maximum and Minimum Voltage Gains

The maximum voltage gain and the minimum voltage gain are calculated as follows:

To prevent the operating point from going into the capacitive region, the maximum voltage gain should have a margin. The corresponding margin is 0.15 times

Mmax. Therefore, the value of

Mmax is changed to

3.4. Effective Resistive Load on the Primary Side

Based on (10), the effective resistive load on the primary side,

Rac, is calculated as follows:

3.5. Selection of K and Q and Determination of Switching Frequency Range

In the proposed LED driver, the value of

K is selected to be 5. From

Figure 12, it can be seen that the values of

M change with different values of

Q. In this paper,

Q is selected to be 0.48. The minimum switching frequency

fs_min and the maximum switching frequency

fs_max are shown below:

3.6. Resonant Capacitance, Resonant Inductance and Magnetizing Inductance

Based on the effective resistive load calculated in (26), the selected resonant frequency

fr = 100 kHz, and the selected quality factor

Q = 0.48, the resonant capacitance

Cr can be worked out from (29). Moreover, based on (29), the resonant inductance

Lr can be figured out from (30). Finally, based on the selected

K = 5, the magnetizing inductance can be found from (31):

4. Experimental Results

Figure 14 displays the resonant inductor current

iLr, and the resonant capacitor voltage

vCr. From this figure, it can be seen that the switching frequency

fs is smaller than the resonant frequency

fr. Also, when the resonant inductance current equals the magnetizing inductance current, there is no current transferring to the secondary side. During this period,

Cr,

Lr and

Lm resonate together, resulting in a slow increase of the resonant current.

Figure 15 shows the diode currents. From this figure, it can be seen that the diode currents reach zero before the MOSFET switches are turned on, and this means that the diodes are turned off with zero-current switching (ZCS).

Figure 16 shows the voltages on the two LED strings, named

Vo1 and

Vo2, and the currents in the two LED strings, named

ILS1 and

ILS2. From this figure, it can be seen that

Vo1 and

Vo2 are both about 41 V, and

ISL1 and

ISL2 are regulated to be 350 mA.

Figure 17 displays the voltage across

C1, named

VC1, and current flowing through

C1, named

iC1. From this figure, it can be seen that

VC1 is zero due to

Vo1 almost equal to

Vo2.

Figure 18 displays the efficiency. From this figure, it can be seen that the rated-load efficiency is around 94.8%, and the highest efficiency is around 96.6%.

Furthermore, in order to verify the current-sharing performance of variations in forward voltage due to the temperature and the LED current, the number of LEDs for

LS1 is 12 LEDs and the number of LEDs for

LS2 is 9 LEDs. From

Figure 19, it can be seen that two currents in

LS1 and

LS2 are almost the same, about 350 mA, but the difference in voltage between

LS1 and

LS2 is 10 V (=

Vo1 −

Vo2 = 40 V − 30 V = 10 V). From this result, it is obvious that if the forward voltage is varied due to the temperature and the LED current, the current sharing is still performed well.

In

Figure 20, it can be seen that the voltage across

C1 is not zero, equal to about 5 V, which can be obtained based on (21).

In addition, as shown in

Figure 18, the current consumed by the system can be calculated based on output power divided by efficiency and input voltage. Accordingly, the current consumed at 25% load current with 91.6% efficiency is 0.02047 A, the current consumed at 70% load current with 96.6% efficiency is 0.05435 A, and the current consumed at 100% load current with 94.8% efficiency is 0.07911 A.

6. Conclusions

An isolated LED driver based on the LLC resonant converter is presented herein. In the proposed LED driver, the current-sharing capacitor is used to balance the LED currents. Therefore, the active current sharing circuits are not required. From the experimental results, it can be seen that the currents in the two LED strings are identical without considering the difference in equivalent forward voltage between the two LED strings. Furthermore, the number of the LED channels can be increased. A detailed design of the proposed LED driver is shown in this paper, particularly for how to obtain the effective resistive load from the LED string. As for current control, only the current in one LED string is sensed and controlled by negative feedback control, and the current in the other LED string is determined by the current-sharing capacitor. By doing so, this makes the current control quite easy. Moreover, the measured efficiency shows that the efficiency at rated load is around 94.8%, and the efficiency can be up to 96.6%.