Dependability Impact in the Smart Solar Power Systems: An Analysis of Smart Buildings

Abstract

1. Introduction

- an SPN availability model for the smart photovoltaic management system;

- the comparison between the implementation cost of the grid-tie and hybrid solar.

2. Related Works

2.1. Dependability in IoT Systems

2.2. Dependability in Solar Power System

3. Background

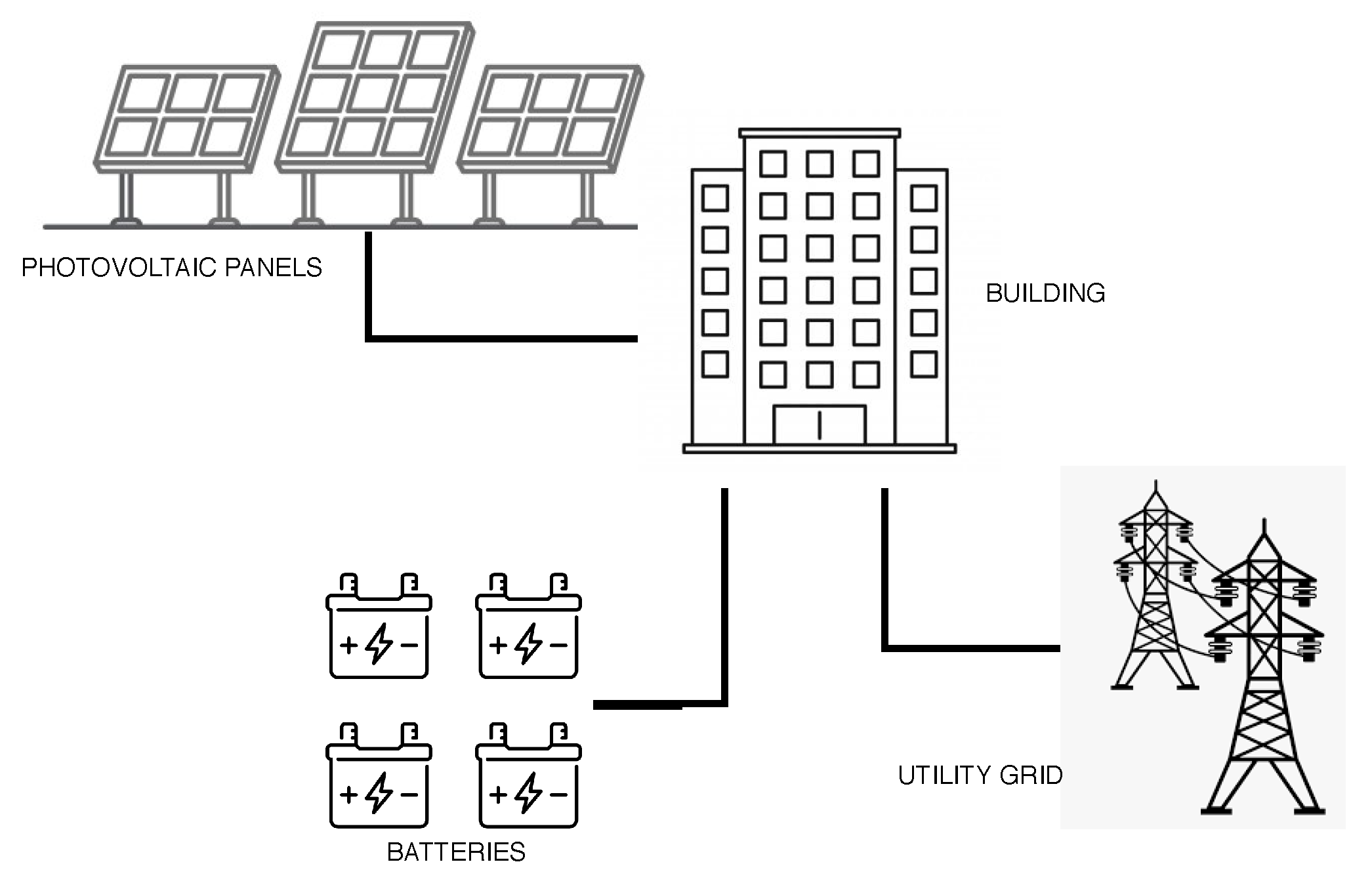

3.1. Solar Power System

3.2. Reliability and Availability

3.3. Stochastic Petri Nets

4. Photovoltaic System

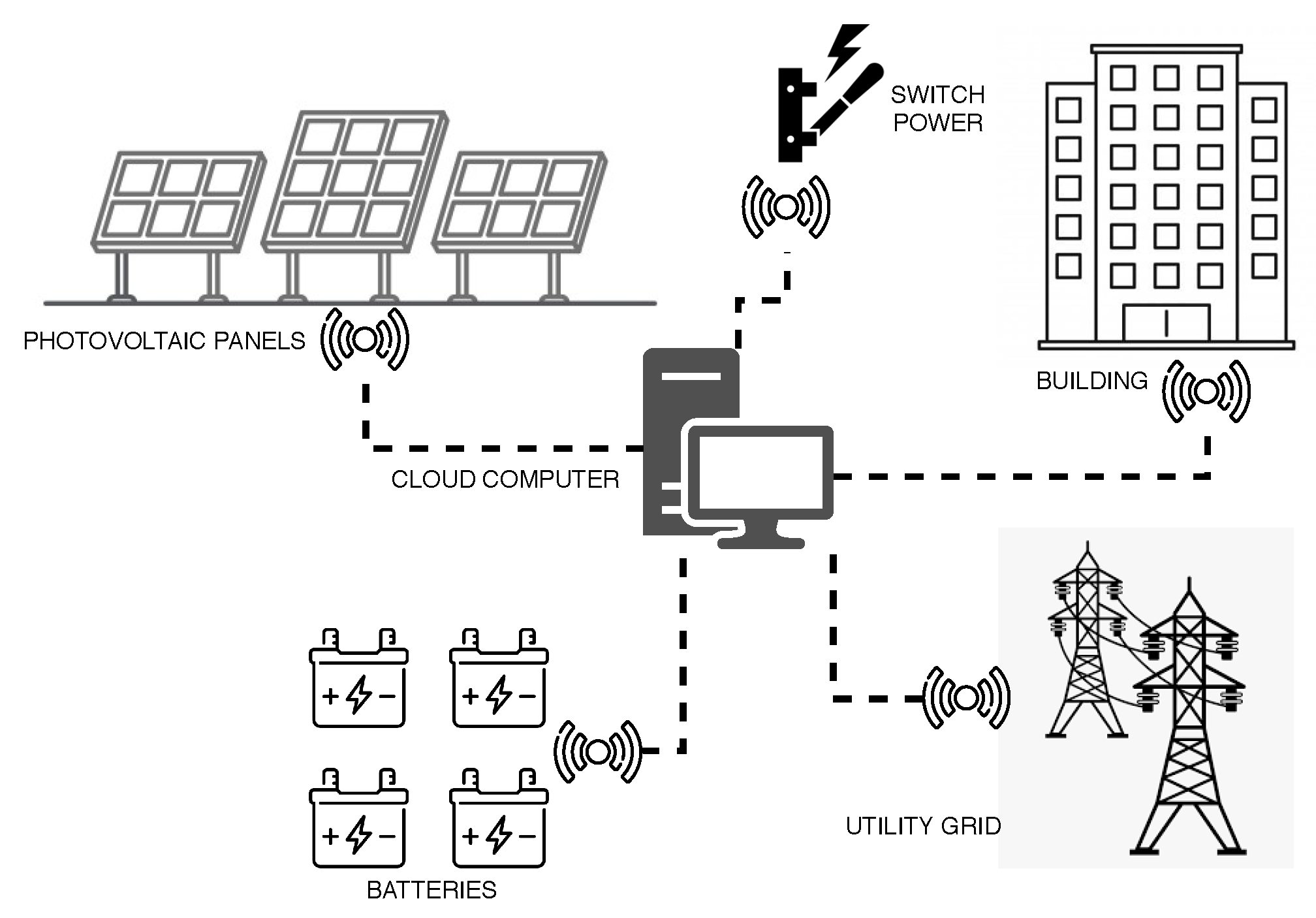

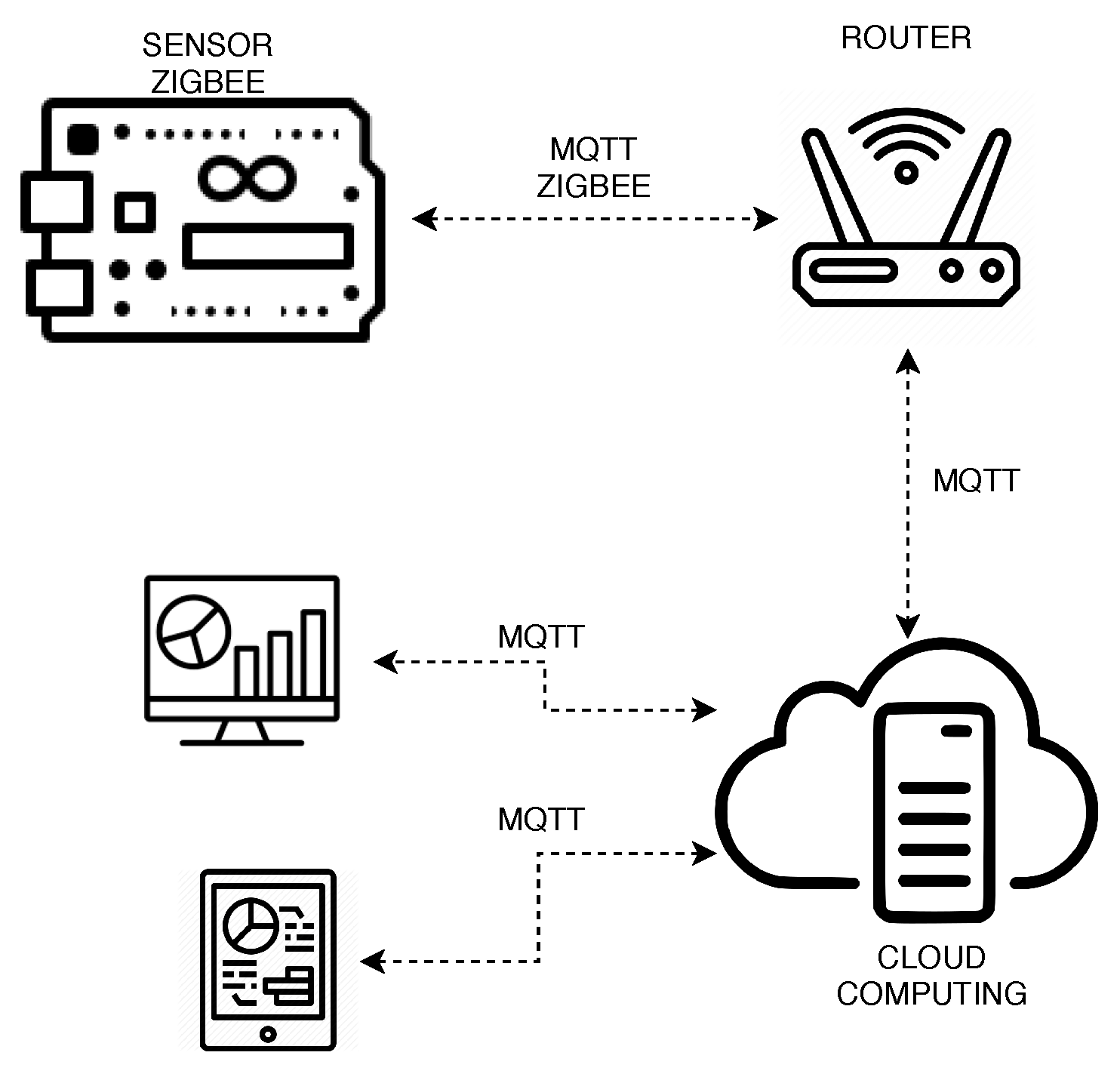

5. Autonomous Photovoltaic Management System

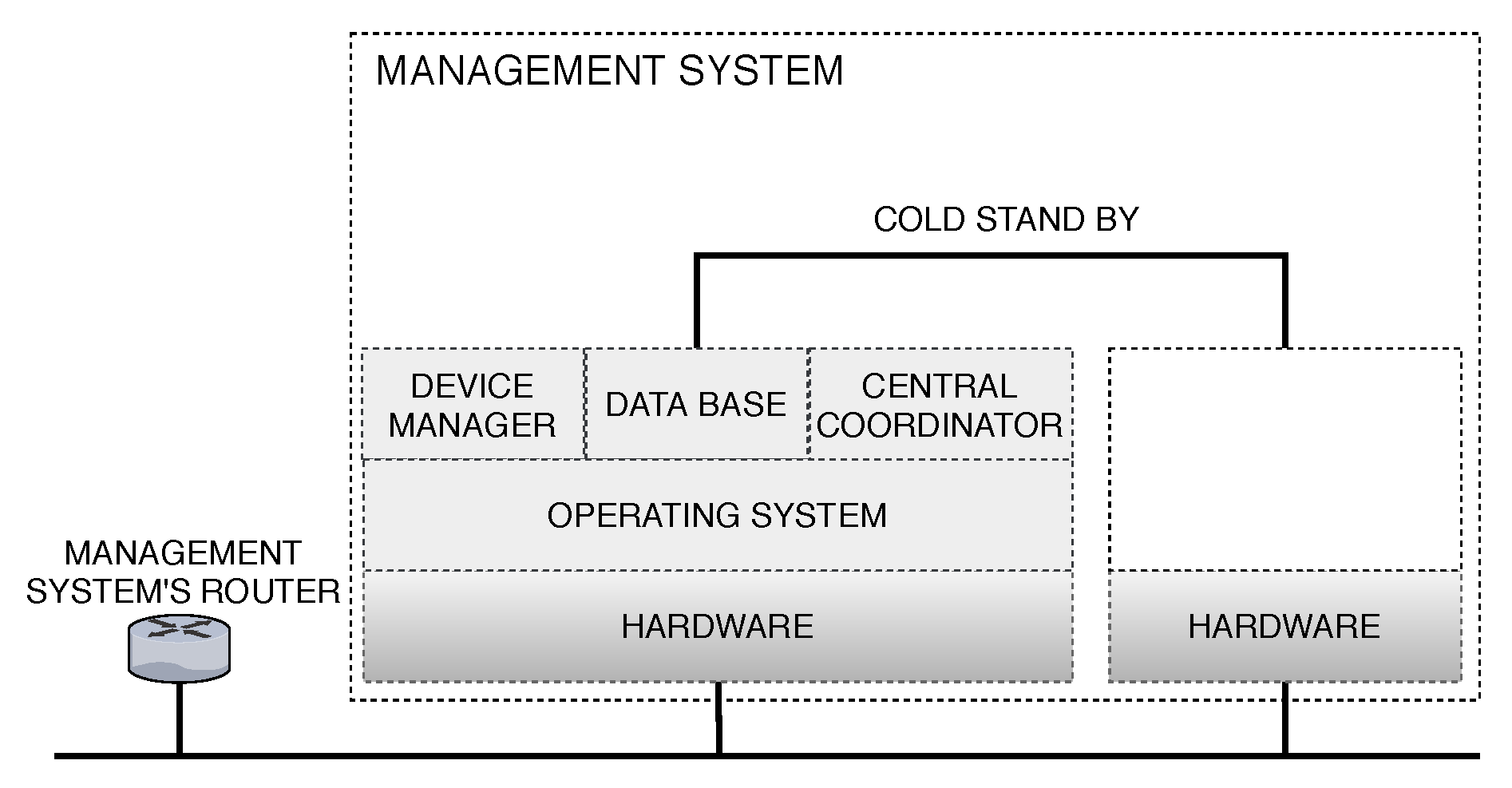

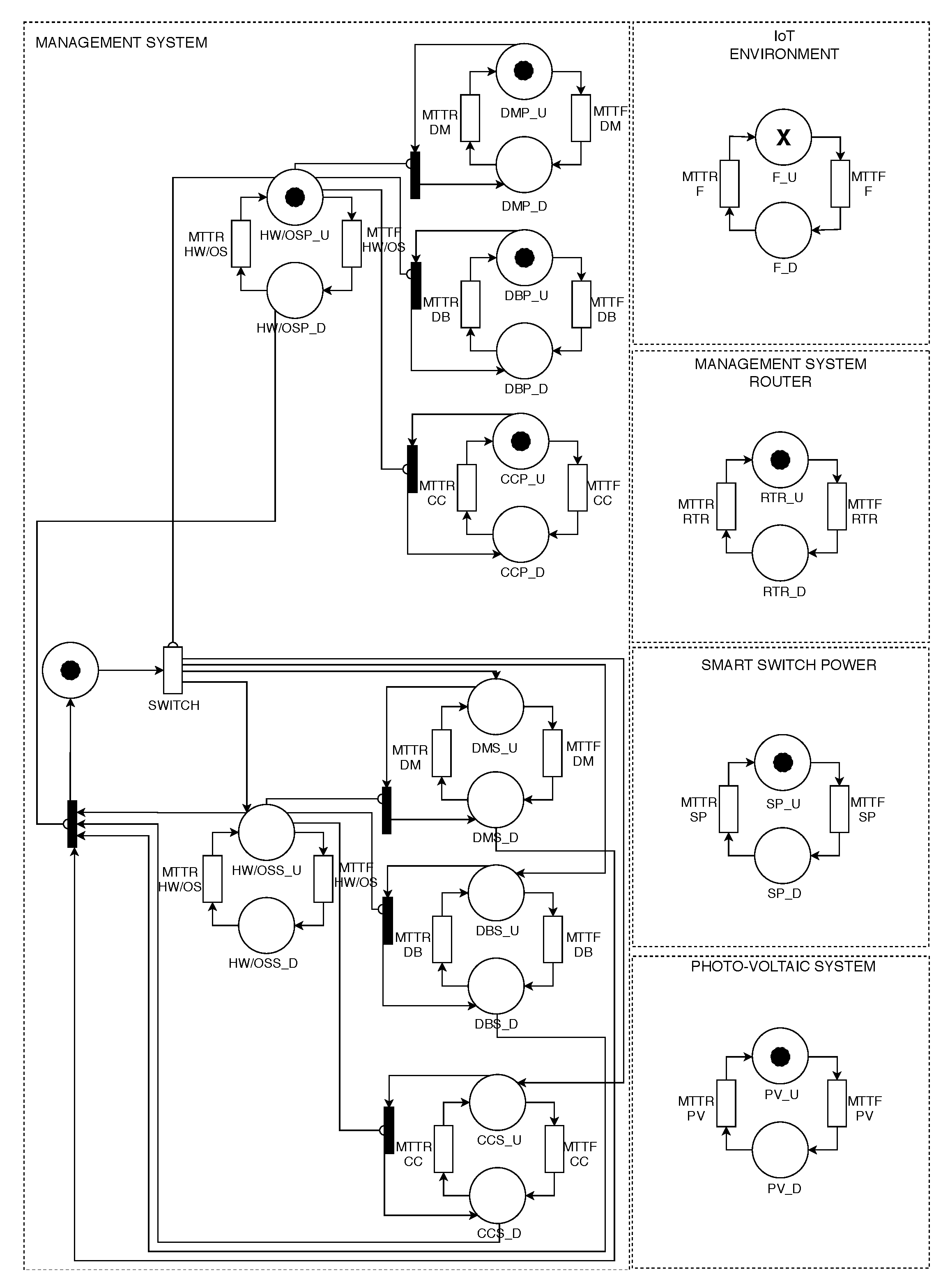

6. Dependability Models

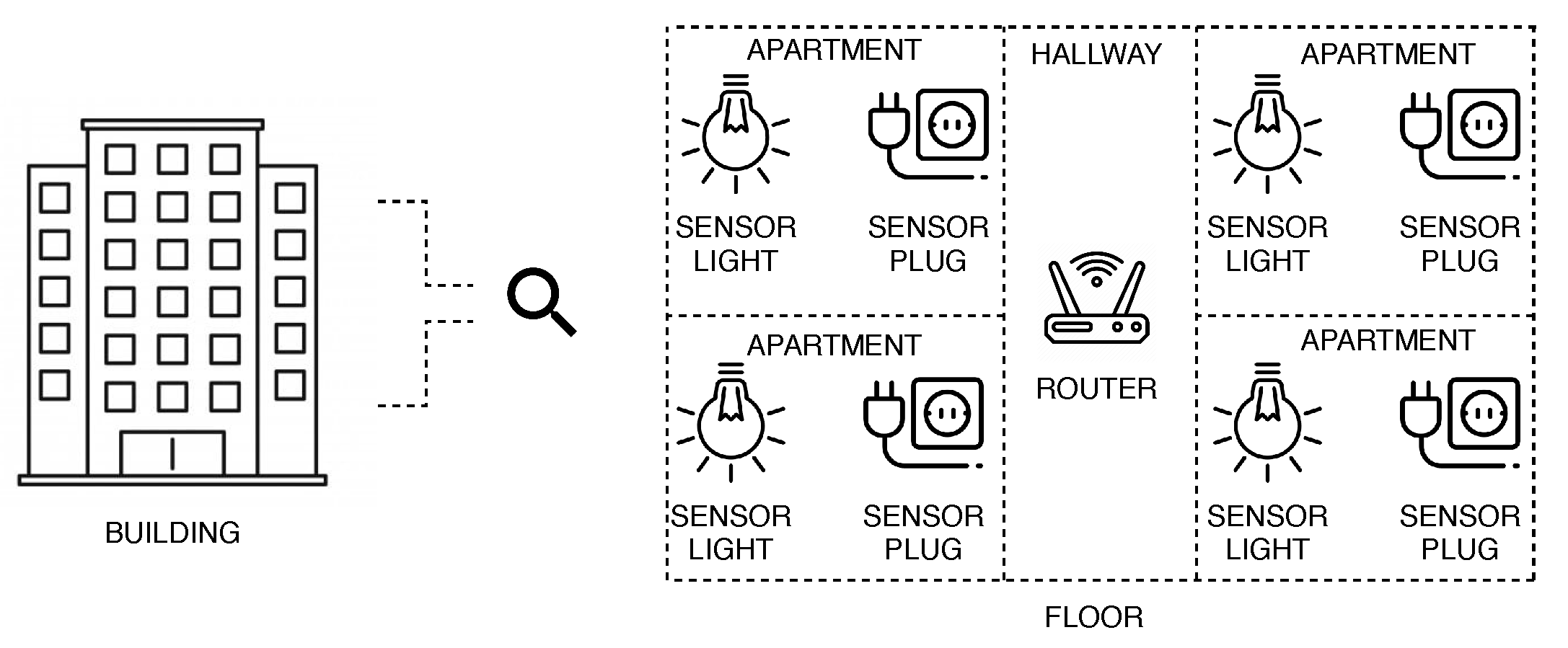

6.1. Model of the Building

6.2. Model of the Hybrid Solar System

6.3. Model of Grid-Tie Solar System

6.4. SPN Availability Model of the Entire System

7. Results

7.1. Photovoltaic Systems

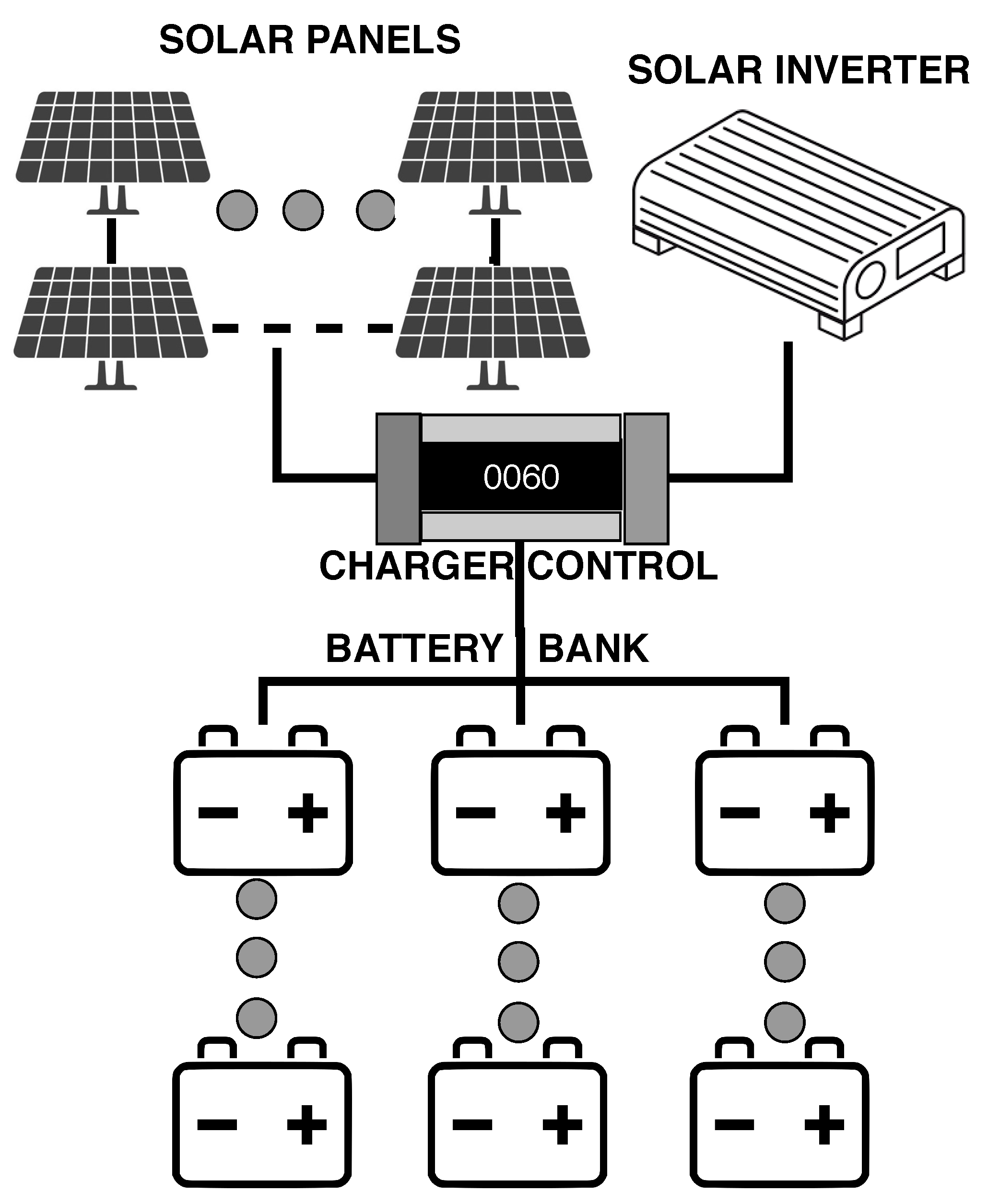

7.1.1. Hybrid Solar System

- 9 panels photovoltaic;

- 12 batteries;

- 1 charge controller;

- 1 inverter

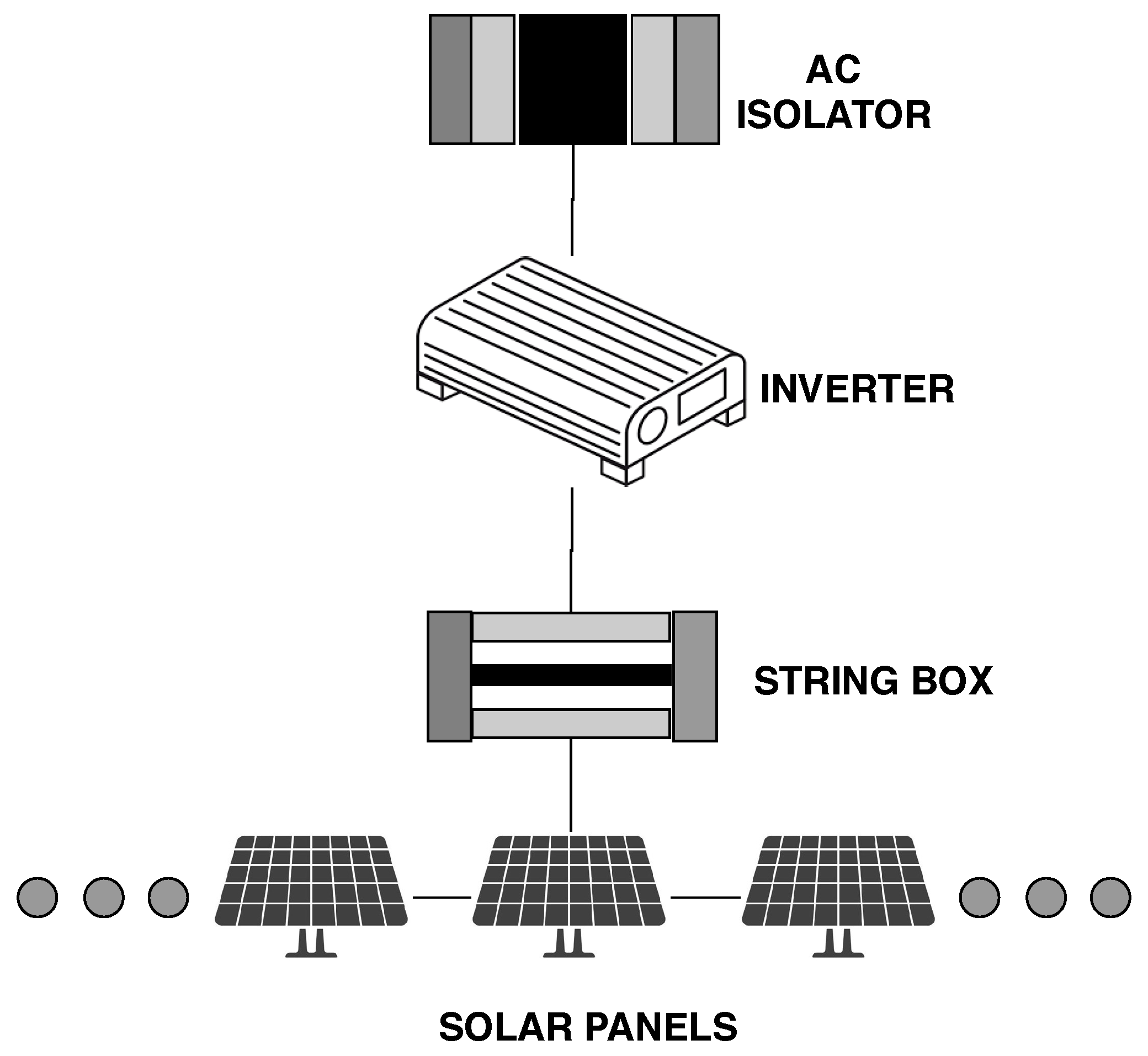

7.1.2. Grid-Tie Solar Power System

- 9 panels photovoltaic;

- 1 string boxes;

- 1 AC isolator;

- 1 inverter

7.2. Results Obtained with the Proposed Models

7.2.1. Autonomous Energy Management System: Availability

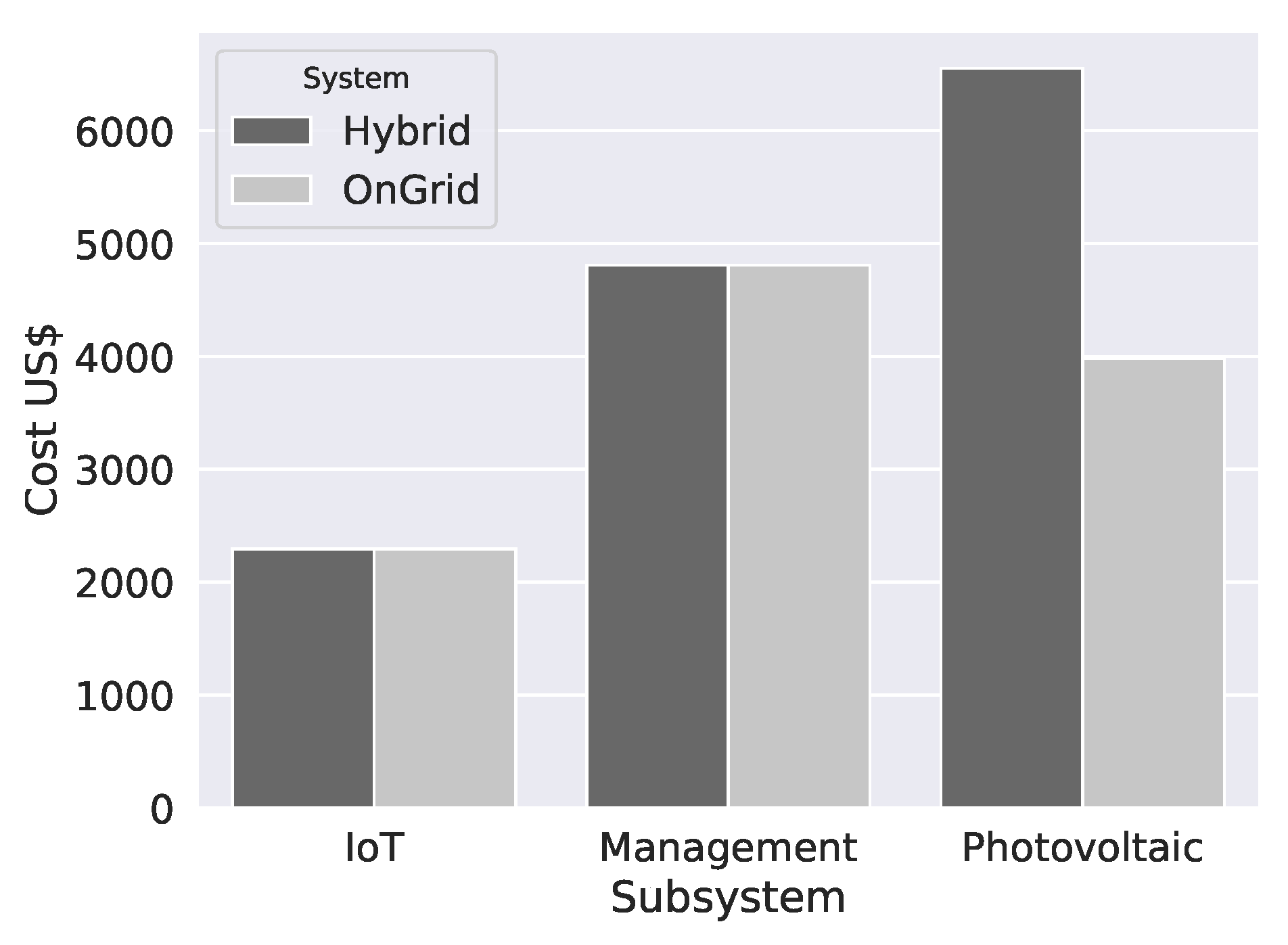

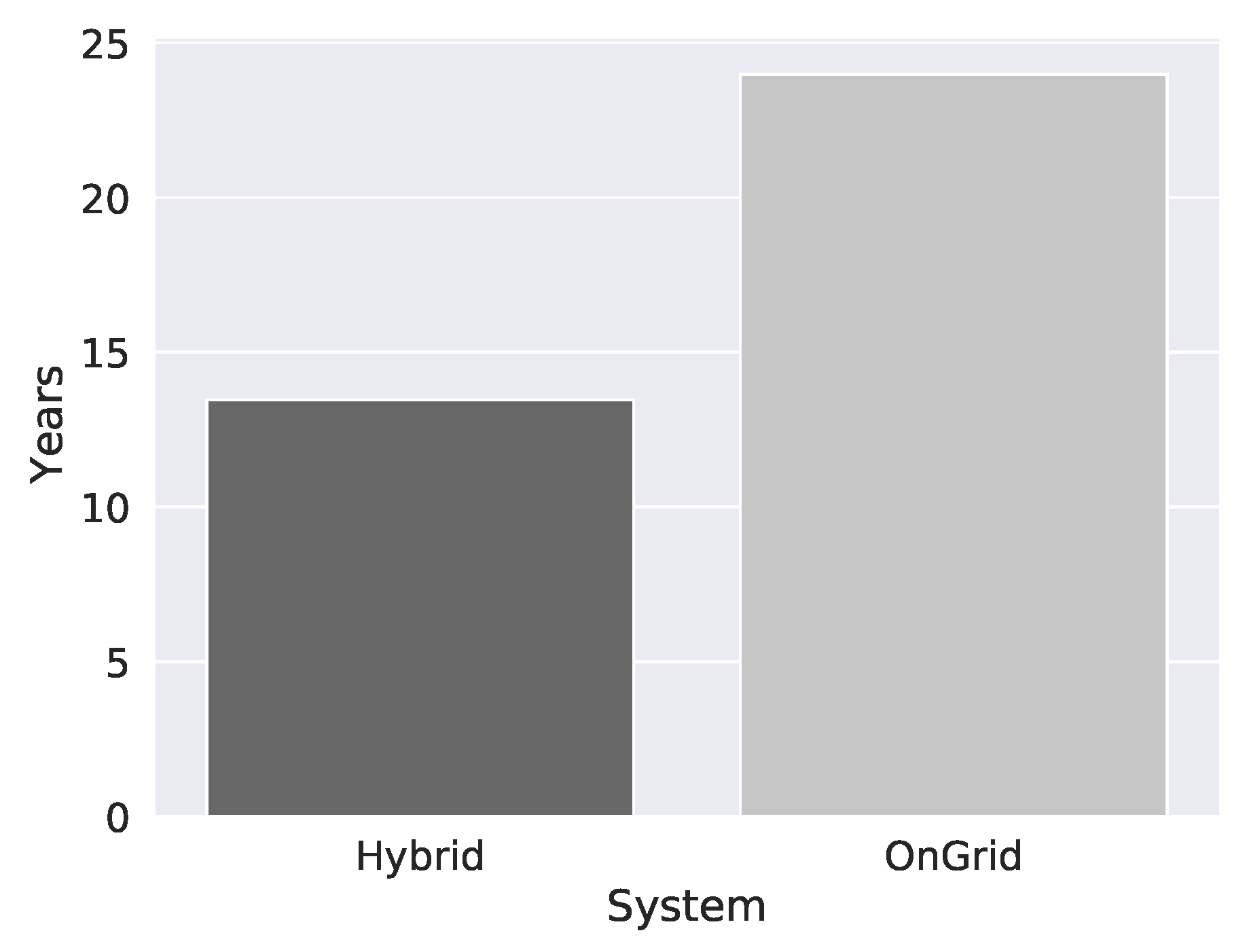

7.2.2. Autonomous Energy Management System: Deploying Cost

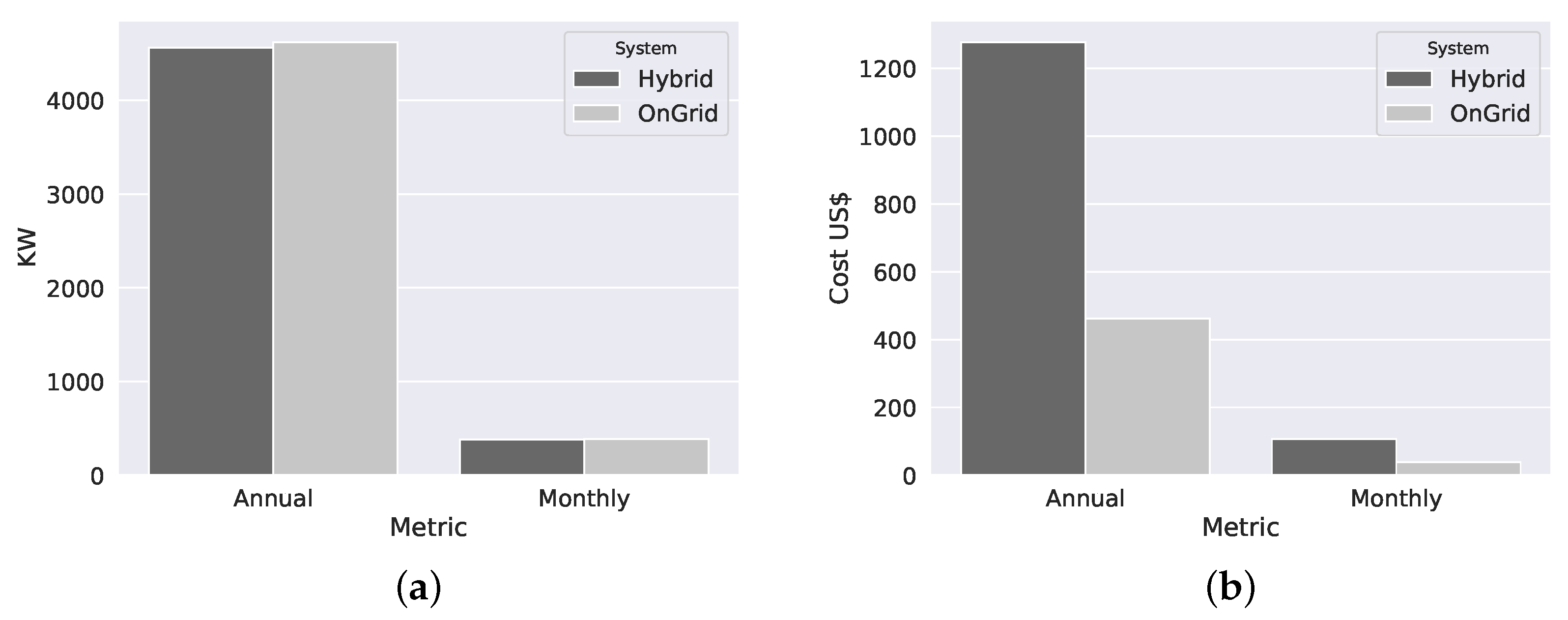

7.2.3. Autonomous Energy Management System: Cost Reduction

8. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Stojkoska, B.L.R.; Trivodaliev, K.V. A review of Internet of Things for smart home: Challenges and solutions. J. Clean. Prod. 2017, 140, 1454–1464. [Google Scholar] [CrossRef]

- Haller, S. Internet of Things: An Integral Part of the Future Internet, Future Internet Conference. Available online: http://services.future-internet.eu/images/1/16/A4_Things_Haller.pdf (accessed on 15 July 2018).

- Zanella, A.; Bui, N.; Castellani, A.; Vangelista, L.; Zorzi, M. Internet of things for smart cities. IEEE Internet Things J. 2014, 1, 22–32. [Google Scholar] [CrossRef]

- Lin, K.; Chen, M.; Deng, J.; Hassan, M.M.; Fortino, G. Enhanced fingerprinting and trajectory prediction for IoT localization in smart buildings. IEEE Trans. Autom. Sci. Eng. 2016, 13, 1294–1307. [Google Scholar] [CrossRef]

- Khanda, K.; Salikhov, D.; Gusmanov, K.; Mazzara, M.; Mavridis, N. Microservice-based iot for smart buildings. In Proceedings of the 2017 31st International Conference on Advanced Information Networking and Applications Workshops (WAINA), Taipei, Taiwan, 27–29 March 2017; pp. 302–308. [Google Scholar]

- Arun, S.; Selvan, M. Intelligent residential energy management system for dynamic demand response in smart buildings. IEEE Syst. J. 2017, 12, 1329–1340. [Google Scholar] [CrossRef]

- Balaban, O.; de Oliveira, J.A.P. Sustainable buildings for healthier cities: Assessing the co-benefits of green buildings in Japan. J. Clean. Prod. 2017, 163, S68–S78. [Google Scholar] [CrossRef]

- Dwaikat, L.N.; Ali, K.N. Green buildings cost premium: A review of empirical evidence. Energy Build. 2016, 110, 396–403. [Google Scholar] [CrossRef]

- García, O.; Chamoso, P.; Prieto, J.; Rodríguez, S.; de la Prieta, F. A serious game to reduce consumption in smart buildings. In International Conference on Practical Applications of Agents and Multi-Agent Systems; Springer: Porto, Portugal, 2017; pp. 481–493. [Google Scholar]

- Macedo, D.; Guedes, L.A.; Silva, I. A dependability evaluation for Internet of Things incorporating redundancy aspects. In Proceedings of the 2014 IEEE 11th International Conference on Networking, Sensing and Control (ICNSC), Miami, FL, USA, 7–9 April 2014; pp. 417–422. [Google Scholar]

- Kamyod, C. End-to-end reliability analysis of an IoT based smart agriculture. In Proceedings of the 2018 International Conference on Digital Arts, Media and Technology (ICDAMT), Phayao, Thailand, 25–28 February 2018; pp. 258–261. [Google Scholar]

- Li, L.; Jin, Z.; Li, G.; Zheng, L.; Wei, Q. Modeling and analyzing the reliability and cost of service composition in the IoT: A probabilistic approach. In Proceedings of the 2012 IEEE 19th International Conference on Web Services (ICWS), Honolulu, HI, USA, 24–29 June 2012; pp. 584–591. [Google Scholar]

- Andrade, E.; Nogueira, B. Dependability evaluation of a disaster recovery solution for IoT infrastructures. J. Supercomput. 2018, 1–22. [Google Scholar] [CrossRef]

- Ştefan, V.K.; Otto, P.; Alexandrina, P.M. Considerations regarding the dependability of Internet of Things. In Proceedings of the 2017 14th International Conference on Engineering of Modern Electric Systems (EMES), Oradea, Romania, 1–2 June 2017; pp. 145–148. [Google Scholar]

- Diaz, P.; Egido, M.A.; Nieuwenhout, F. Dependability analysis of stand-alone photovoltaic systems. Prog. Photovolt. Res. Appl. 2007, 15, 245–264. [Google Scholar] [CrossRef]

- Collins, E.; Dvorack, M.; Mahn, J.; Mundt, M.; Quintana, M. Reliability and availability analysis of a fielded photovoltaic system. In Proceedings of the 2009 34th IEEE Photovoltaic Specialists Conference (PVSC), Philadelphia, PA, USA, 7–12 June 2009; pp. 002316–002321. [Google Scholar]

- Sayed, A.; El-Shimy, M.; El-Metwally, M.; Elshahed, M. Reliability, Availability and Maintainability Analysis for Grid-Connected Solar Photovoltaic Systems. Energies 2019, 12, 1213. [Google Scholar] [CrossRef]

- Cai, B.; Liu, Y.; Ma, Y.; Huang, L.; Liu, Z. A framework for the reliability evaluation of grid-connected photovoltaic systems in the presence of intermittent faults. Energy 2015, 93, 1308–1320. [Google Scholar] [CrossRef]

- Reinders, A.; Verlinden, P.; Van Sark, W.; Freundlich, A. Photovoltaic Solar Energy: From Fundamentals to Applications; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- O’Connor, J.P. Off Grid Solar: A Handbook for Photovoltaics with Lead-Acid or Lithium-Ion Batteries, 2nd ed.; Old Sequoia Publishing: Anchorage, AK, USA, 2019. [Google Scholar]

- Marcelo Gradella Villalva, J.R.G. Energia Solar Fotovoltaica-Conceitos e Aplicações; Saraiva Educação SA: São Paulo, Brazil, 2012. [Google Scholar]

- Avizienis, A.; Laprie, J.C.; Randell, B.; Landwehr, C. Basic Concepts and Taxonomy of Dependable and Secure Computing. IEEE Trans. Dependable Secur. Comput. 2004, 1, 11–33. [Google Scholar] [CrossRef]

- Trivedi, K.S. Probability and Statistics with Reliability, Queuing, and Computer Science Applications; Wiley Online Library: Hoboken, NJ, USA, 1982; Volume 13. [Google Scholar]

- Doyle, S.A.; Dugan, J.B. Dependability assessment using binary decision diagrams (BDDs). In Proceedings of the Twenty-Fifth International Symposium on Fault-Tolerant Computing, Pasadena, CA, USA, 27–30 June 1995; pp. 249–258. [Google Scholar]

- Bolch, G.; Greiner, S.; De Meer, H.; Trivedi, K.S. Queueing networks and Markov Chains: Modeling and Performance Evaluation with Computer Science Applications; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- German, R. Performance Analysis of Communication Systems with Non-Markovian Stochastic Petri Nets; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2000. [Google Scholar]

- Marsan, M.A.; Balbo, G.; Conte, G.; Donatelli, S.; Franceschinis, G. Modelling with Generalized Stochastic Petri Nets, 1st ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1994. [Google Scholar]

- Molloy, M.K. On the Integration of Delay and Throughput Measures in Distributed Processing Model. Ph.D. Thesis, University of California, Los Angeles, CA, USA, 1981. [Google Scholar]

- Silva, B.; Matos, R.; Callou, G.; Figueiredo, J.; Oliveira, D.; Ferreira, J.; Dantas, J.; Lobo, A.; Alves, V.; Maciel, P. Mercury: An integrated environment for performance and dependability evaluation of general systems. In Proceedings of the Industrial Track at 45th Dependable Systems and Networks Conference, DSN, Rio de Janeiro, RJ, Brazil, 22–25 June 2015. [Google Scholar]

- Guglielmetti, R.; Macumber, D.; Long, N. OpenStudio: An Open Source Integrated Analysis Platform; Technical Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2011.

- Dantas, J.; Matos, R.; Araujo, J.; Maciel, P. Models for Dependability Analysis of Cloud Computing Architectures for Eucalyptus Platform. Int. Trans. Syst. Sci. Appl. 2012, 8, 13–25. [Google Scholar]

- Cooper, T.; Farrell, R. Value-chain engineering of a tower-top cellular base station system. In Proceedings of the 2007 IEEE 65th Vehicular Technology Conference-VTC2007-Spring, Dublin, Ireland, 22–25 April 2007; pp. 3184–3188. [Google Scholar]

- Cisco Packet Tracer-Networking Simulation Tool. Available online: https://www.netacad.com/web/about-us/cisco-paket-tracer (accessed on 10 July 2019).

- Kim, D.S.; Machida, F.; Trivedi, K.S. Availability modeling and analysis of a virtualized system. In Proceedings of the 2009 15th IEEE Pacific Rim International Symposium on Dependable Computing, Shanghai, China, 16–18 November 2009; pp. 365–371. [Google Scholar]

- Rohouma, W.; Molokhia, I.; Esuri, A. Comparative study of different PV modules configuration reliability. Desalination 2007, 209, 122–128. [Google Scholar] [CrossRef]

- Zini, G.; Mangeant, C.; Merten, J. Reliability of large-scale grid-connected photovoltaic systems. Renew. Energy 2011, 36, 2334–2340. [Google Scholar] [CrossRef]

- Carrasco, L.M.; Narvarte, L.; Lorenzo, E. Operational costs of A 13,000 solar home systems rural electrification programme. Renew. Sustain. Energy Rev. 2013, 20, 1–7. [Google Scholar] [CrossRef]

- Zhao, Z.; Lee, W.C.; Shin, Y.; Song, K.B. An optimal power scheduling method for demand response in home energy management system. IEEE Trans. Smart Grid 2013, 4, 1391–1400. [Google Scholar] [CrossRef]

| Jan. | Feb. | Mar. | Apr. | May | Jun. | Jul. | Aug. | Sep. | Oct. | Nov. | Dec. | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling | 182.20 | 181.17 | 184.03 | 182.42 | 175.51 | 169.83 | 167.39 | 166.18 | 171.06 | 172.99 | 180.88 | 184.04 |

| Lighting | 117.91 | 117.91 | 117.91 | 117.91 | 117.91 | 117.91 | 117.91 | 117.91 | 117.91 | 117.91 | 117.91 | 117.91 |

| Equipment | 76.509 | 76.509 | 76.509 | 76.509 | 76.509 | 76.509 | 76.509 | 76.509 | 76.509 | 76.509 | 76.509 | 76.509 |

| Fans | 11.776 | 11.754 | 11.554 | 11.756 | 11.330 | 11.255 | 10.909 | 10.851 | 11.091 | 11.091 | 11.709 | 11.810 |

| Total | 388.40 | 387.35 | 390.01 | 388.60 | 381.26 | 375.51 | 372.73 | 371.45 | 376.58 | 378.61 | 387.02 | 390.31 |

| Month | [kWh/mDaily] |

|---|---|

| Jan. | 5.84 |

| Feb. | 5.94 |

| Mar. | 5.88 |

| Apr. | 5.15 |

| May. | 4.47 |

| Jun | 4.18 |

| Jul. | 4.30 |

| Aug. | 5.03 |

| Sep. | 5.45 |

| Oct. | 5.78 |

| Nov. | 6.05 |

| Dec. | 6.06 |

| Component | MTTF (Hours) | MTTR (Hours) |

|---|---|---|

| Hardware | 61,320 | 8 |

| Operating System | 1440 | 1 |

| Sensors/Actuators | 300,000 | 1 |

| Docker | 2900 | 1 |

| Controller Manager | 700 | 1 |

| Data Base | 1440 | 1 |

| Device Manager | 700 | 1 |

| Router | 26,000 | 8 |

| Inverter | 24,820 | 8 |

| Charge Controller | 70,080 | 8 |

| Solar Panel | 219,000 | 8 |

| Battery | 47,829 | 8 |

| Metric | Hybrid | Grid-Tie |

|---|---|---|

| Uptime | 8710.95 h | 8711.78 h |

| Downtime | 49.05 h | 48.21 h |

| Availability | 99.4494% | 99.4496% |

| Components | Hybrid US$ | Grid-Tie US$ |

|---|---|---|

| IoT components | 2293.46 | 2293.46 |

| Management infrastructure | 4808.50 | 4808.50 |

| solar components | 6554.28 | 3983.05 |

| Total | 13,656.24 | 11,085.01 |

| Hybrid | Grid-Tie | |||

|---|---|---|---|---|

| Metric | Average-KWh | US$ | Average-KWh | US$ |

| Annual | 4562.91 | 1277.61 | 4621.78 | 462.17 |

| Monthly | 380.24 | 106.46 | 385.14 | 38.51 |

| Daily | 12.67 | 3.54 | 12.83 | 1.28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Araujo, E.; Pereira, P.; Dantas, J.; Maciel, P. Dependability Impact in the Smart Solar Power Systems: An Analysis of Smart Buildings. Energies 2021, 14, 124. https://doi.org/10.3390/en14010124

Araujo E, Pereira P, Dantas J, Maciel P. Dependability Impact in the Smart Solar Power Systems: An Analysis of Smart Buildings. Energies. 2021; 14(1):124. https://doi.org/10.3390/en14010124

Chicago/Turabian StyleAraujo, Eltton, Paulo Pereira, Jamilson Dantas, and Paulo Maciel. 2021. "Dependability Impact in the Smart Solar Power Systems: An Analysis of Smart Buildings" Energies 14, no. 1: 124. https://doi.org/10.3390/en14010124

APA StyleAraujo, E., Pereira, P., Dantas, J., & Maciel, P. (2021). Dependability Impact in the Smart Solar Power Systems: An Analysis of Smart Buildings. Energies, 14(1), 124. https://doi.org/10.3390/en14010124