Core Stress Analysis of Amorphous Alloy Transformer for Rail Transit under Different Working Conditions

Abstract

:1. Introduction

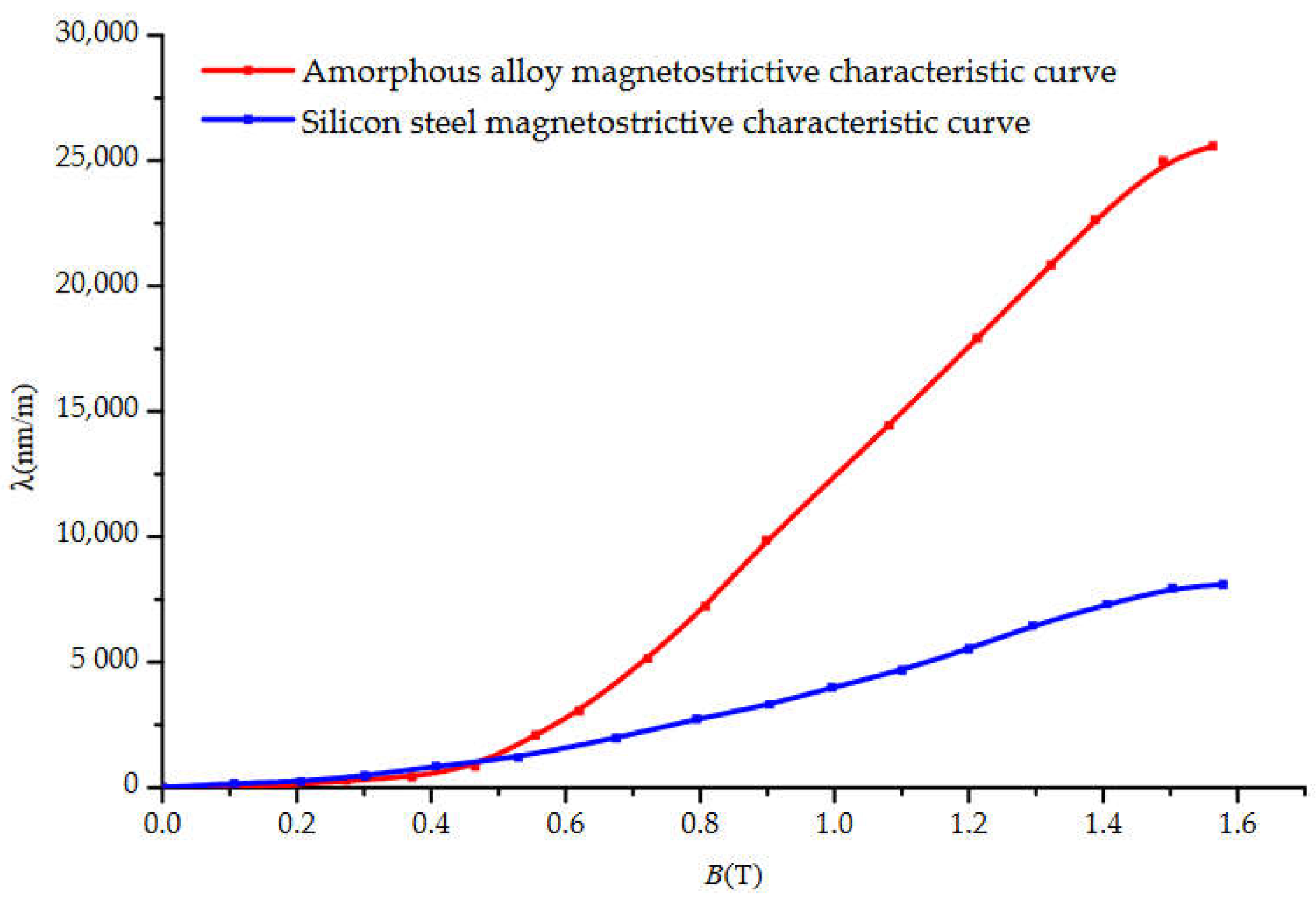

2. Mathematical Model of Stress and Strain Induced by Magnetostriction

2.1. Fully Coupled Model

2.2. Actual Calculation Model

3. Modeling

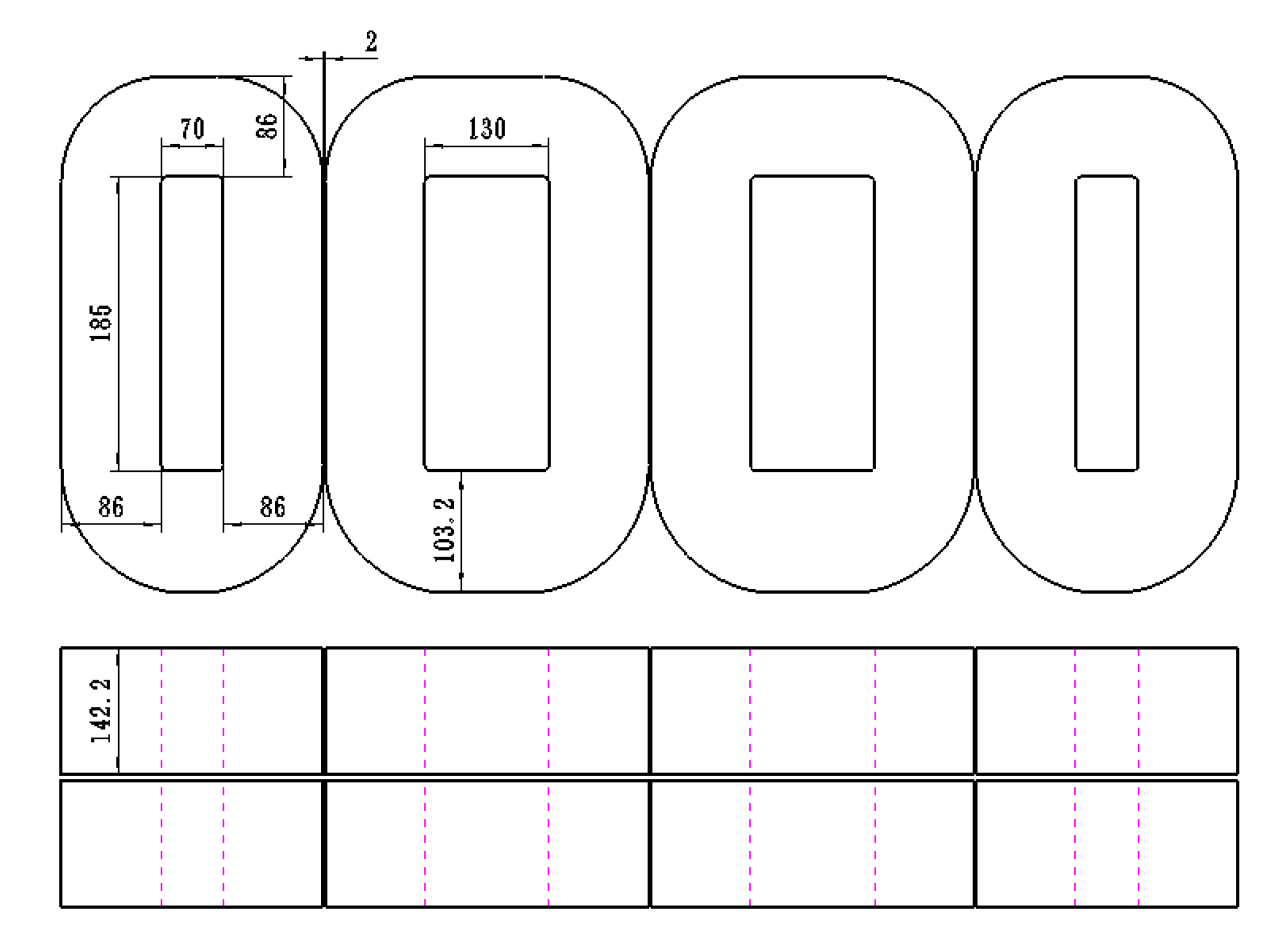

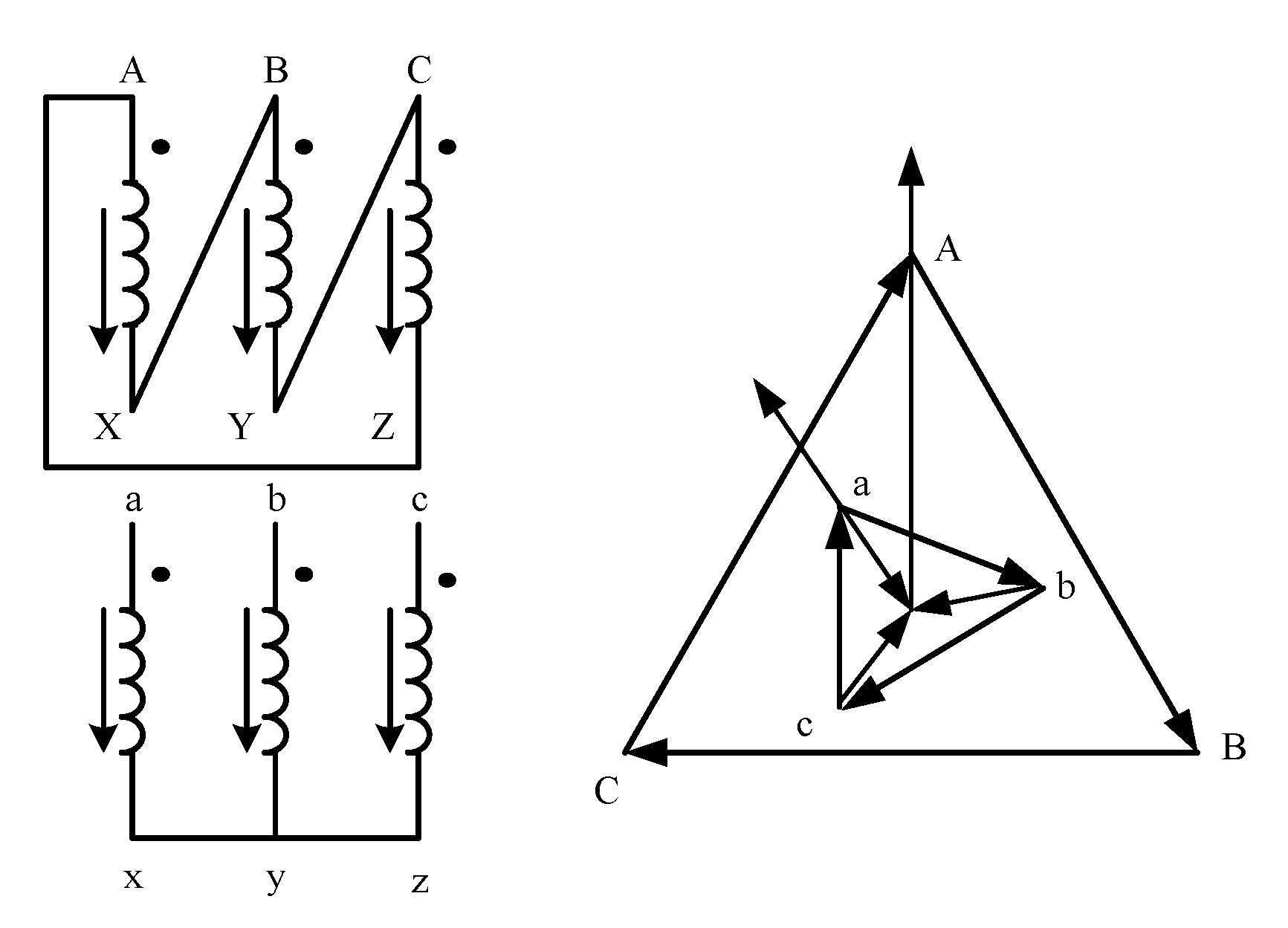

3.1. Transformer

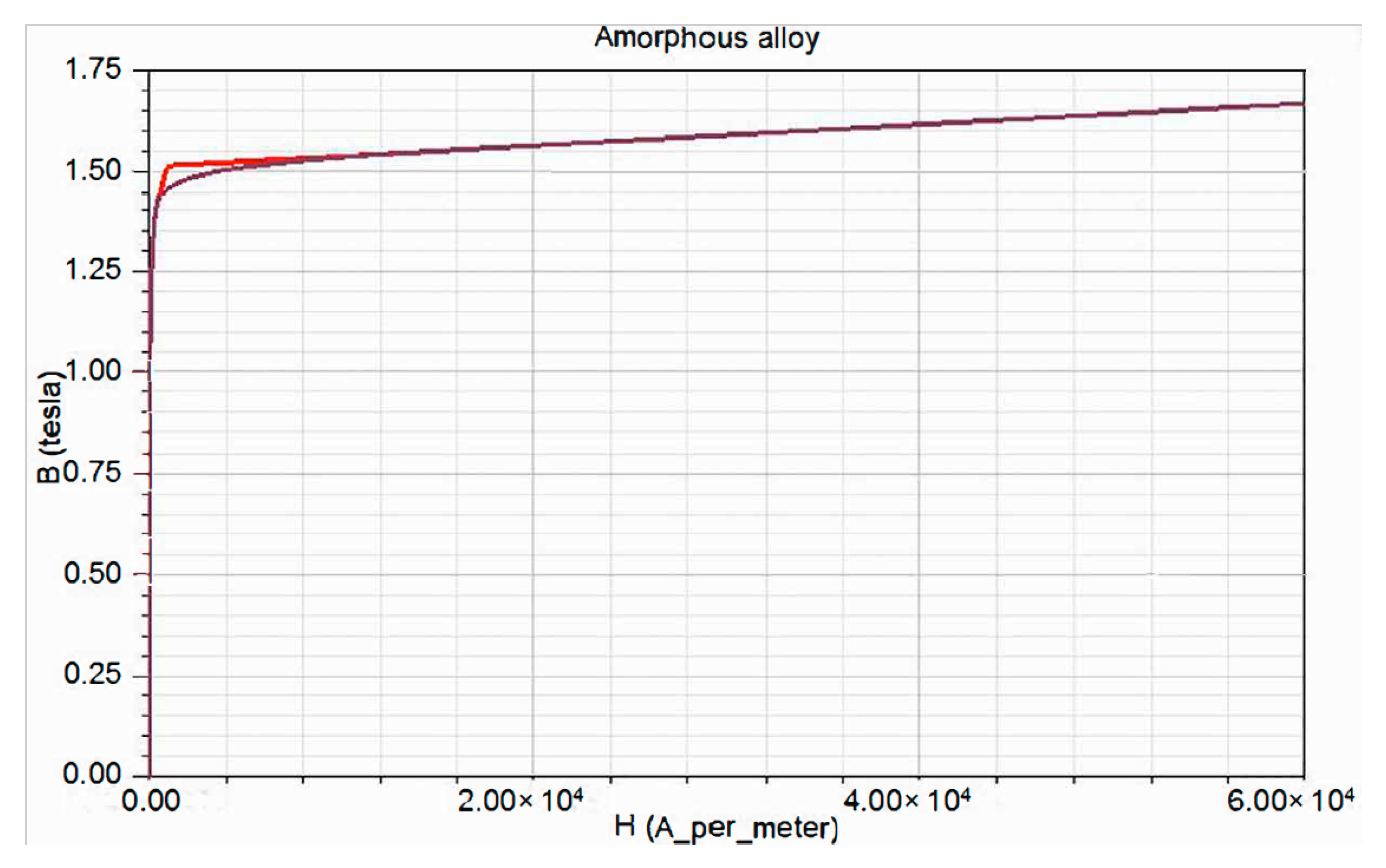

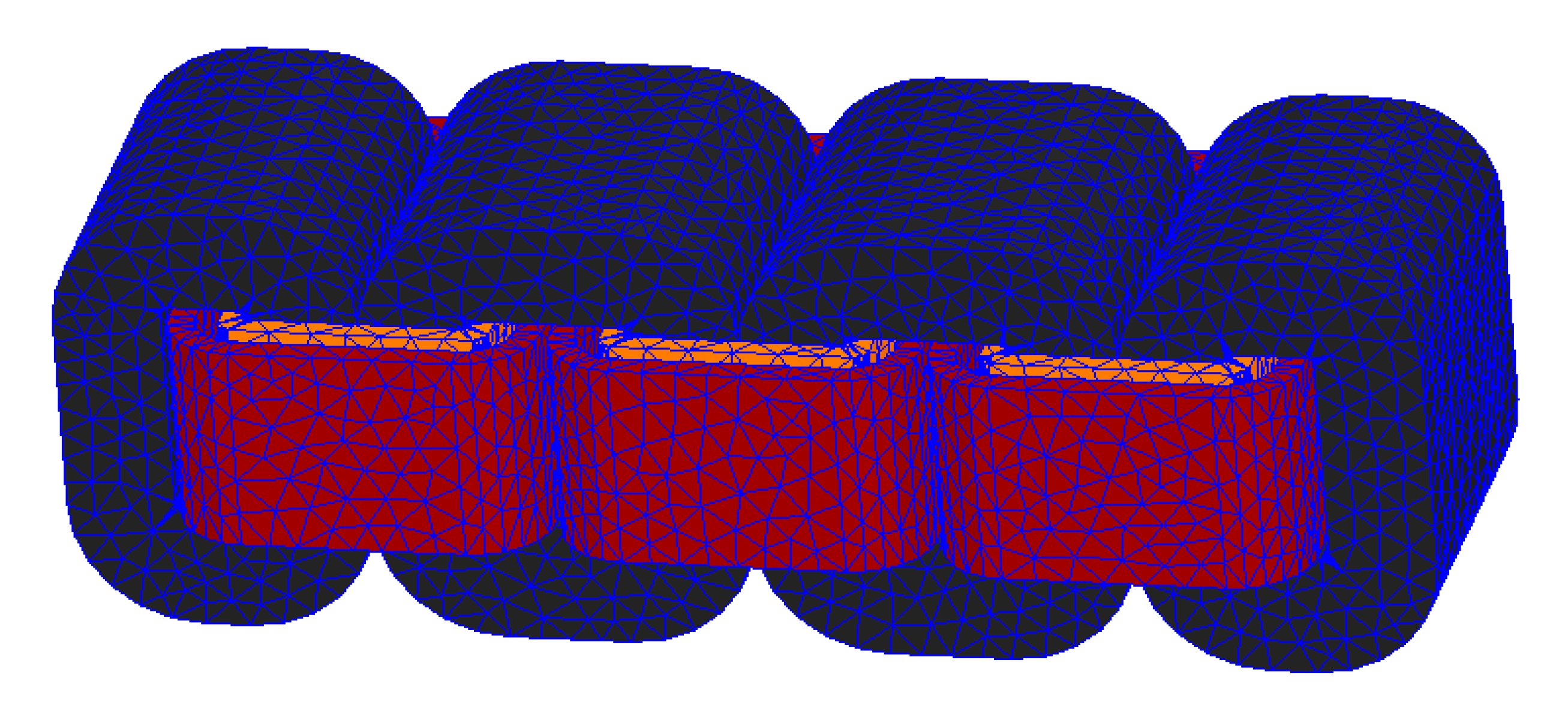

3.2. Core

3.3. Winding

3.4. Meshing

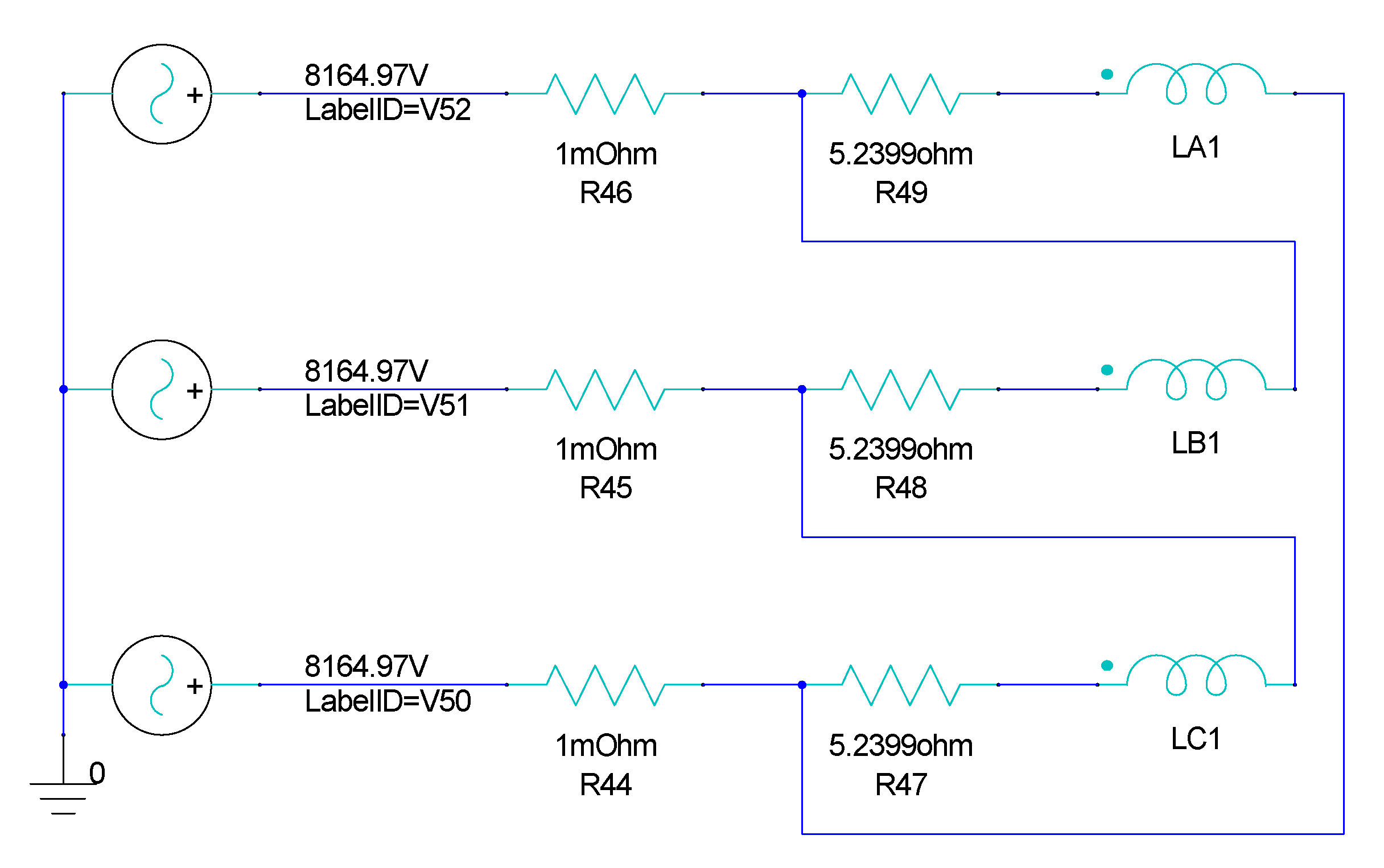

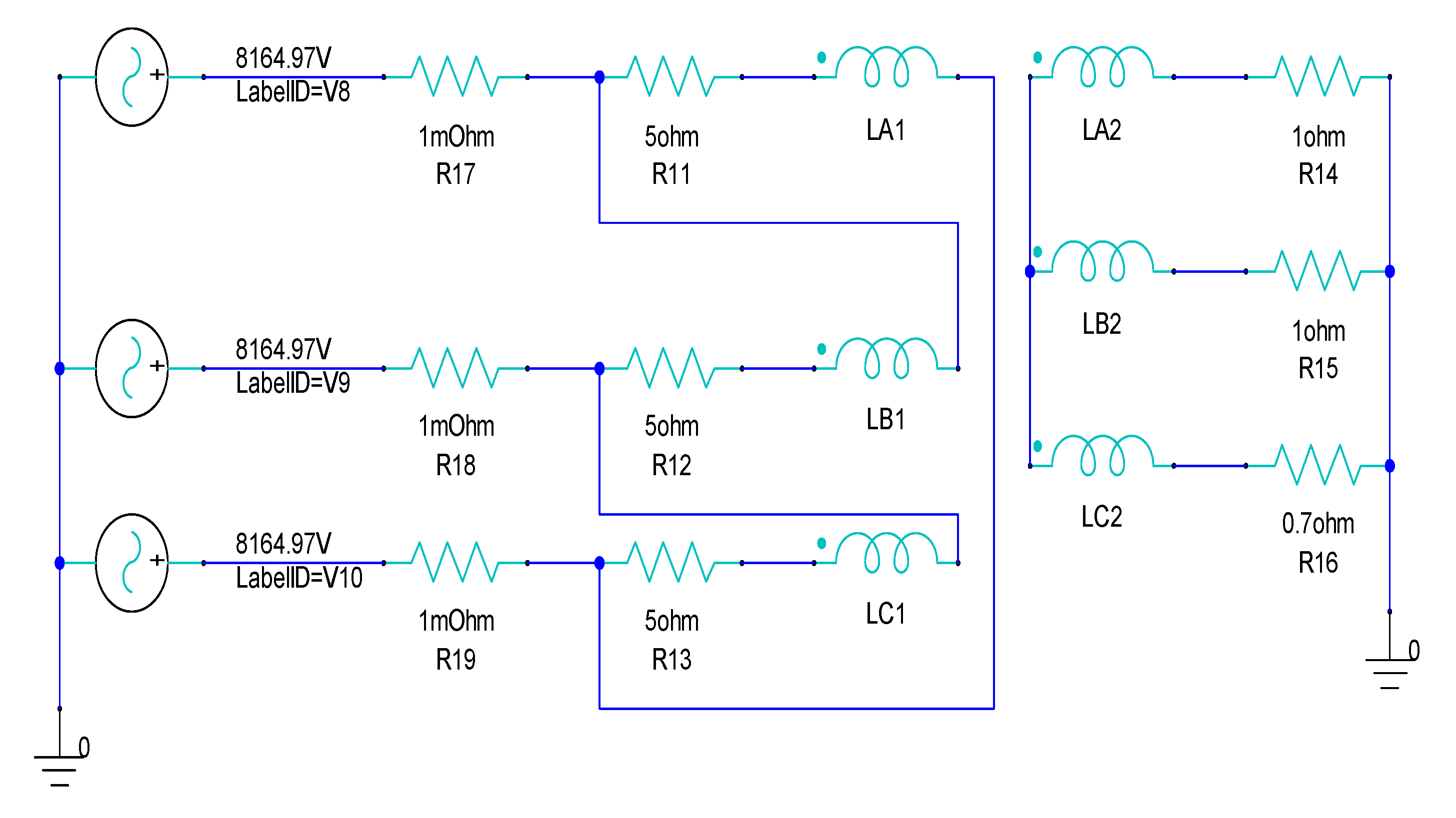

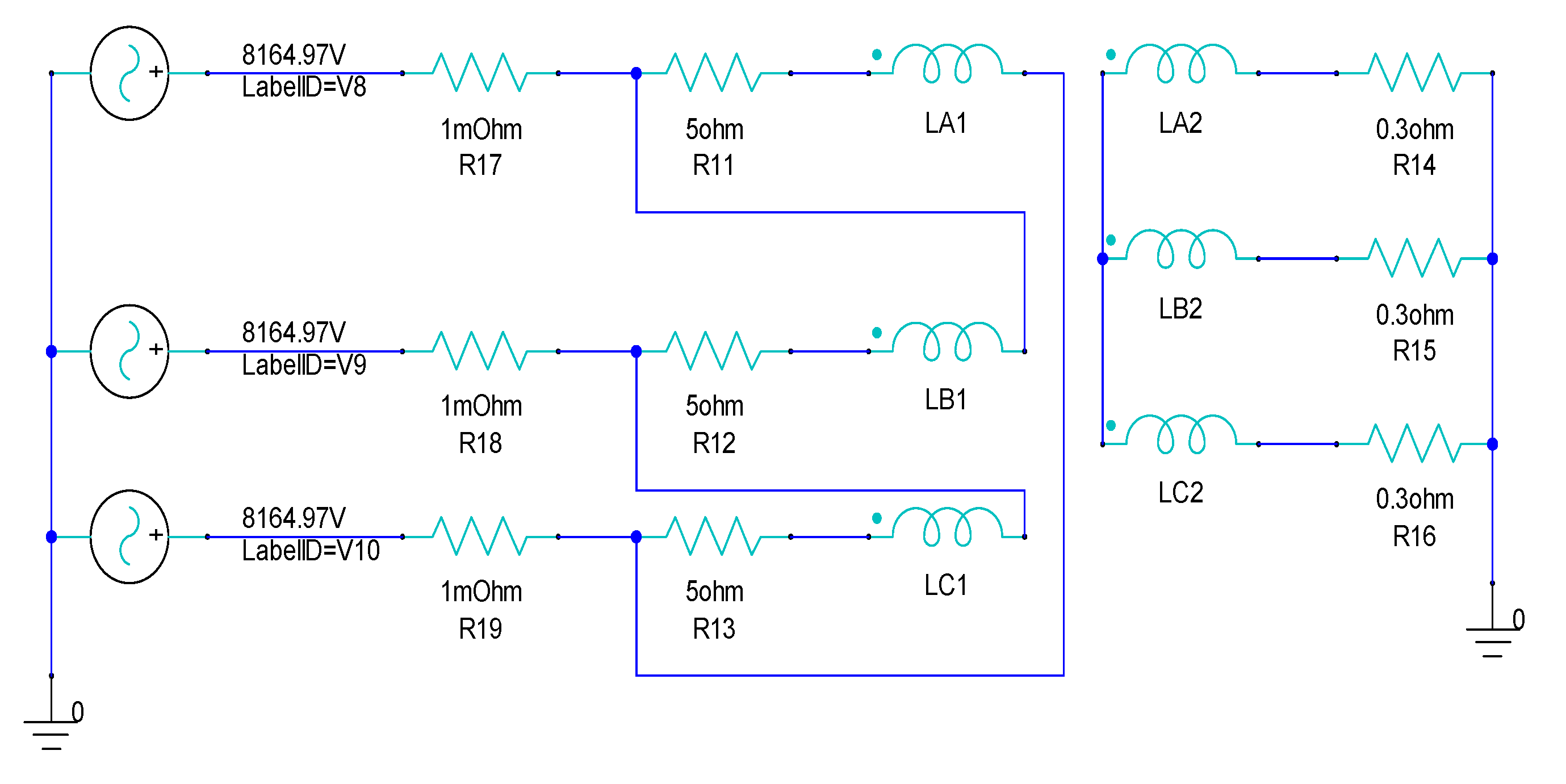

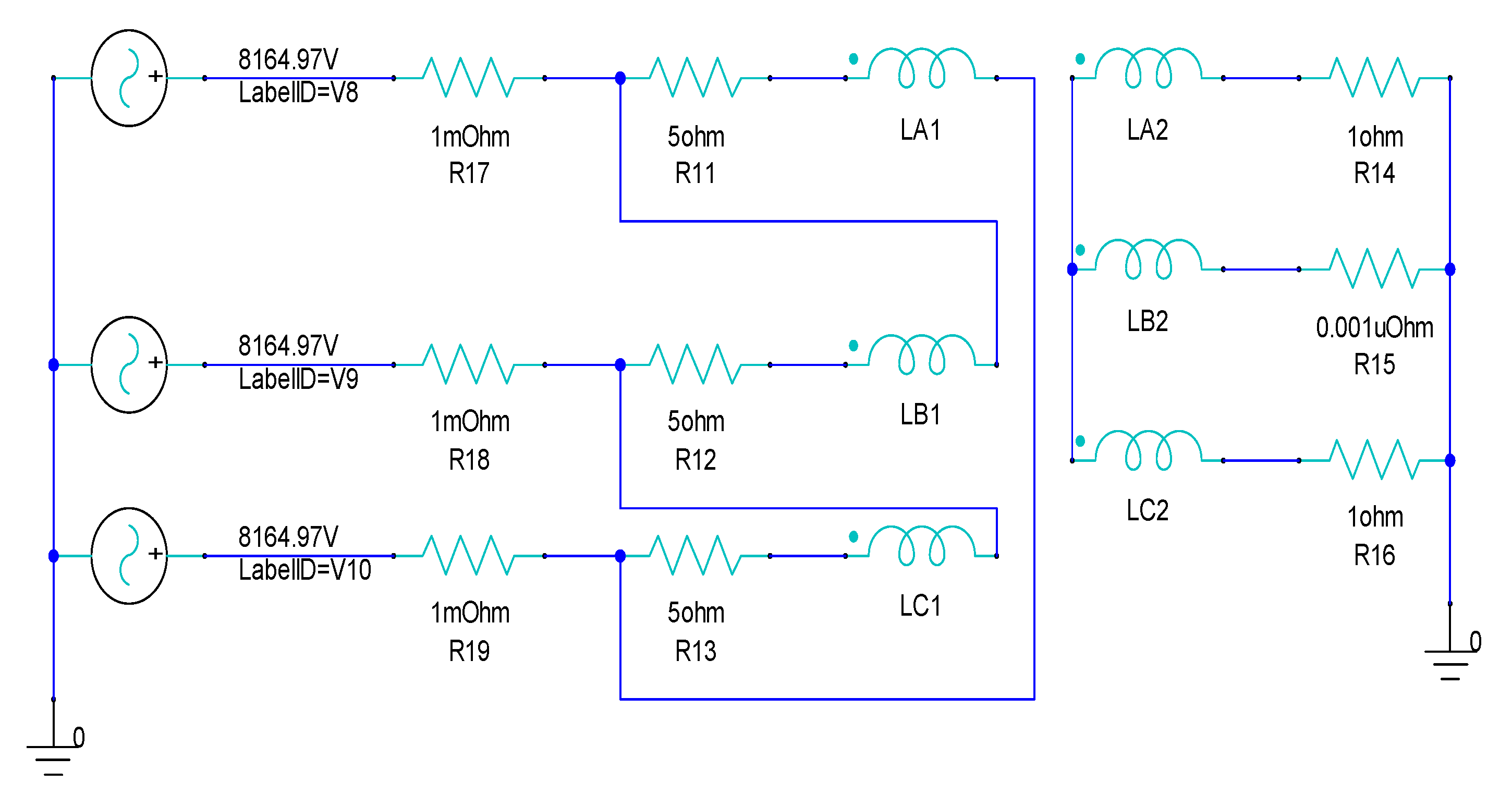

3.5. Electromagnetic-Circuit Coupling

- 1.

- Normal loadConsidering that amorphous alloy transformers are mostly used in the distribution network, the load rate is generally 30~60%. In this study, a 1 Ω load being added (η = 50%), the transformer windings and the load are connected to the three-phase power supply.

- 2.

- Load imbalancePhase A and Phase B add 1 Ω load, and Phase C adds 0.7 Ω load. Pa = 53.3 kVA, Pb = 53.3 kVA, Pc = 76.2 kVA. With the gradual decrease of phase C resistance, phase C active power gradually increases, and the load becomes more unbalanced. When the resistance drops to 0, a short circuit occurs.

- 3.

- Overload0.3 Ω loads have been added to simulate the overload situation of the transformer during operation (η = 169%).

- 4.

- Short circuitSetting the three-phase loads to 1 Ω, 1 × 10−9 Ω, and 1 Ω, respectively, a single-phase short circuit occurs. The very small resistance of phase B is equivalent to short-circuit.

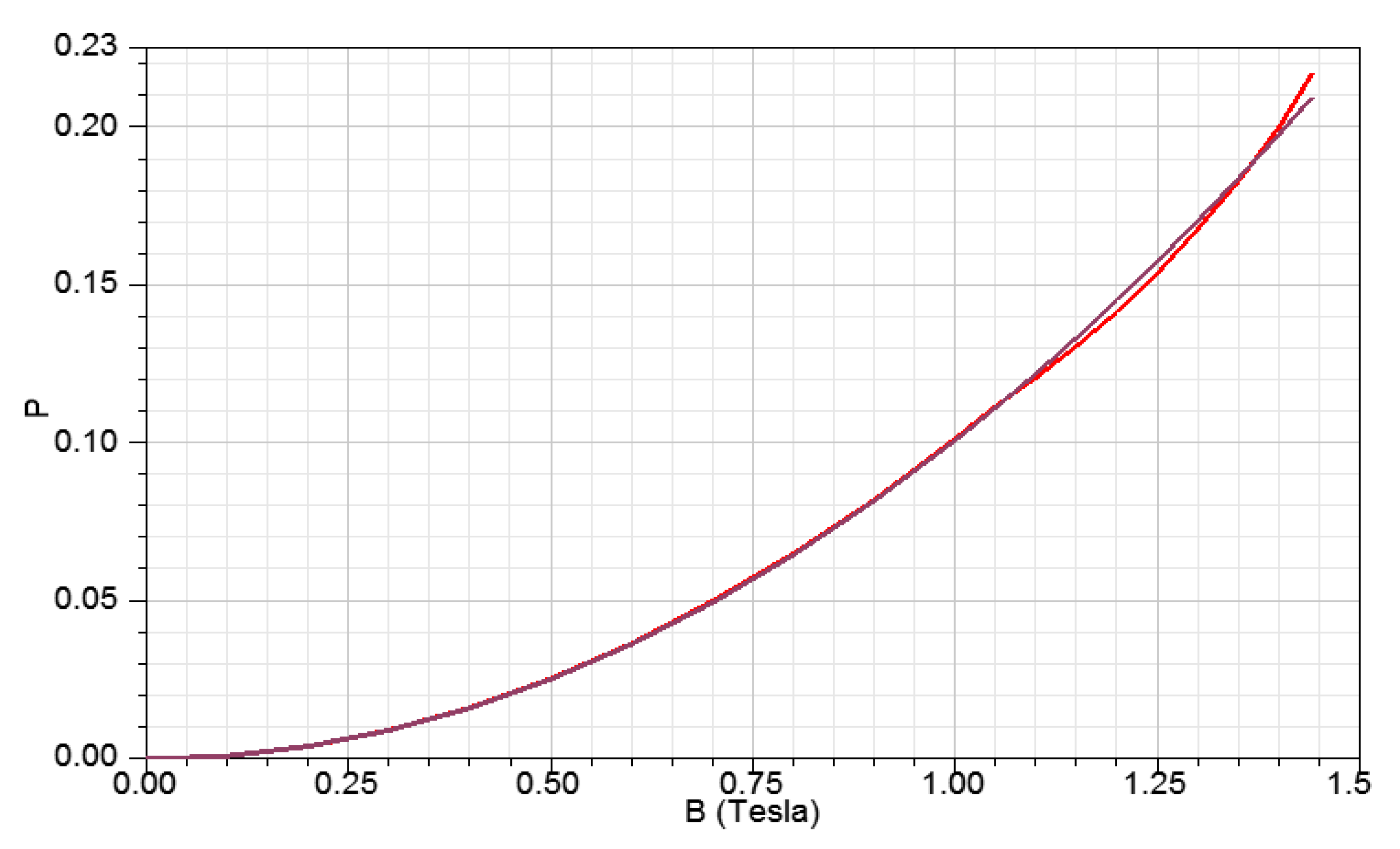

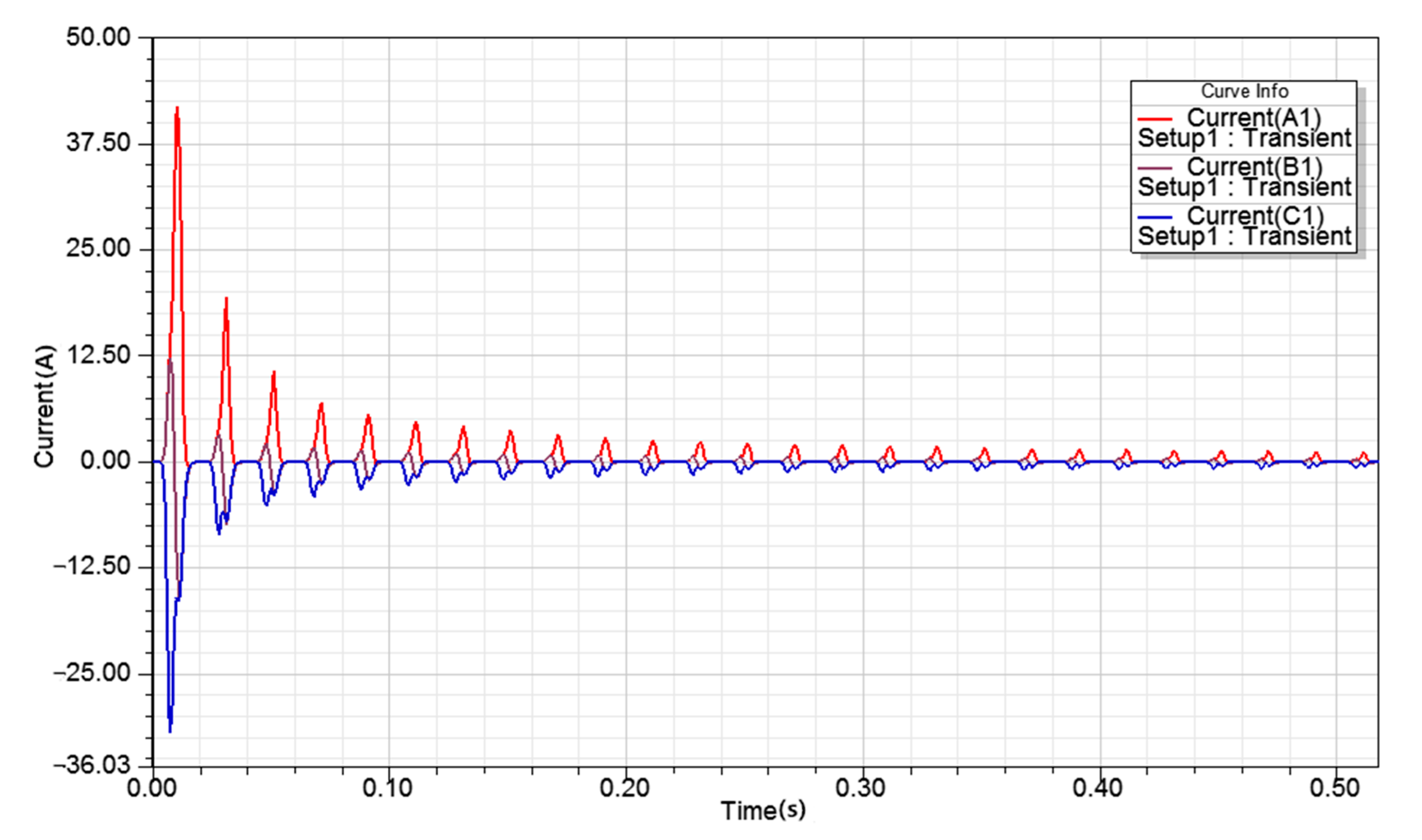

4. Verification of Transformer Model

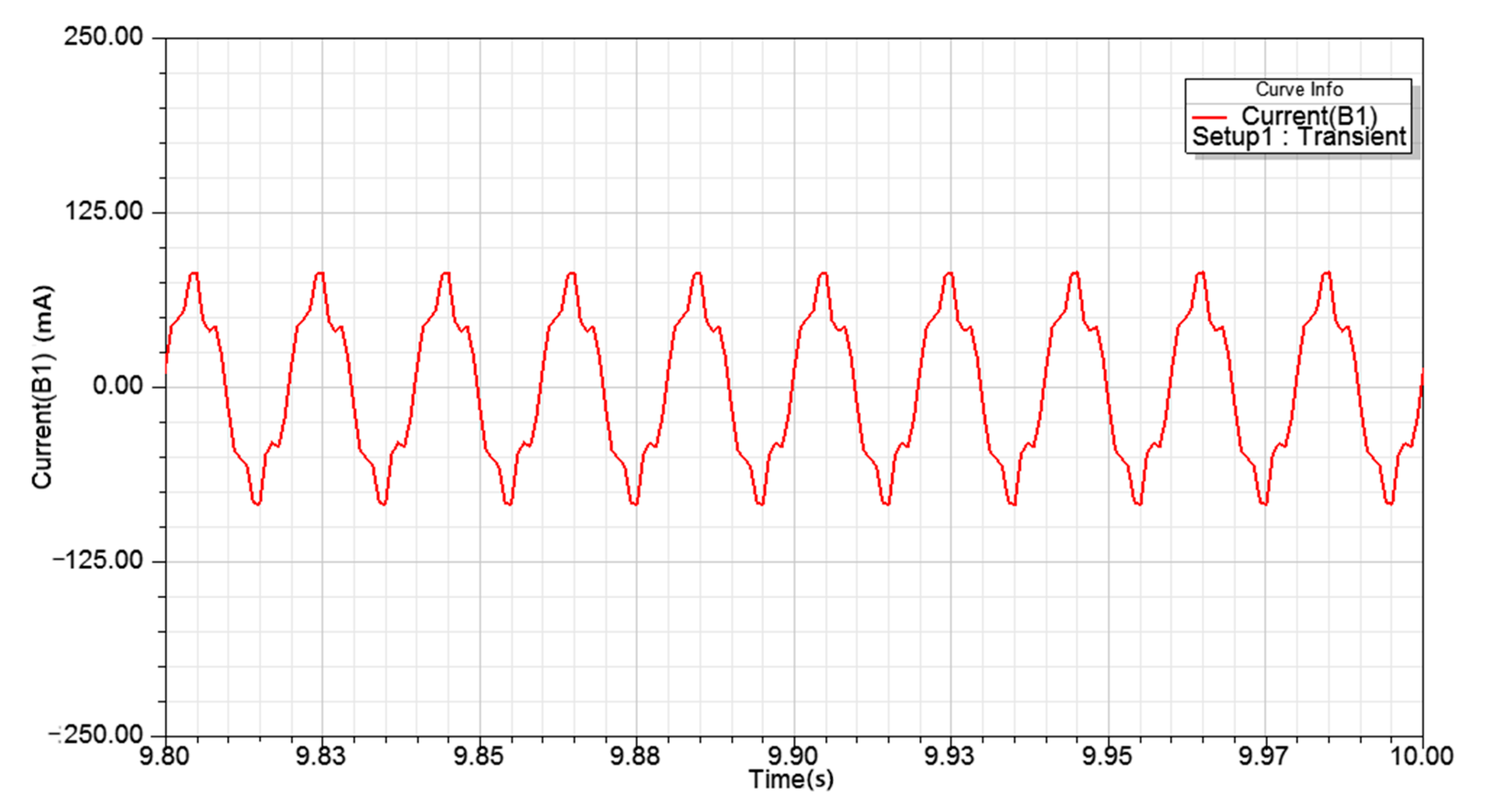

4.1. No-Load Current

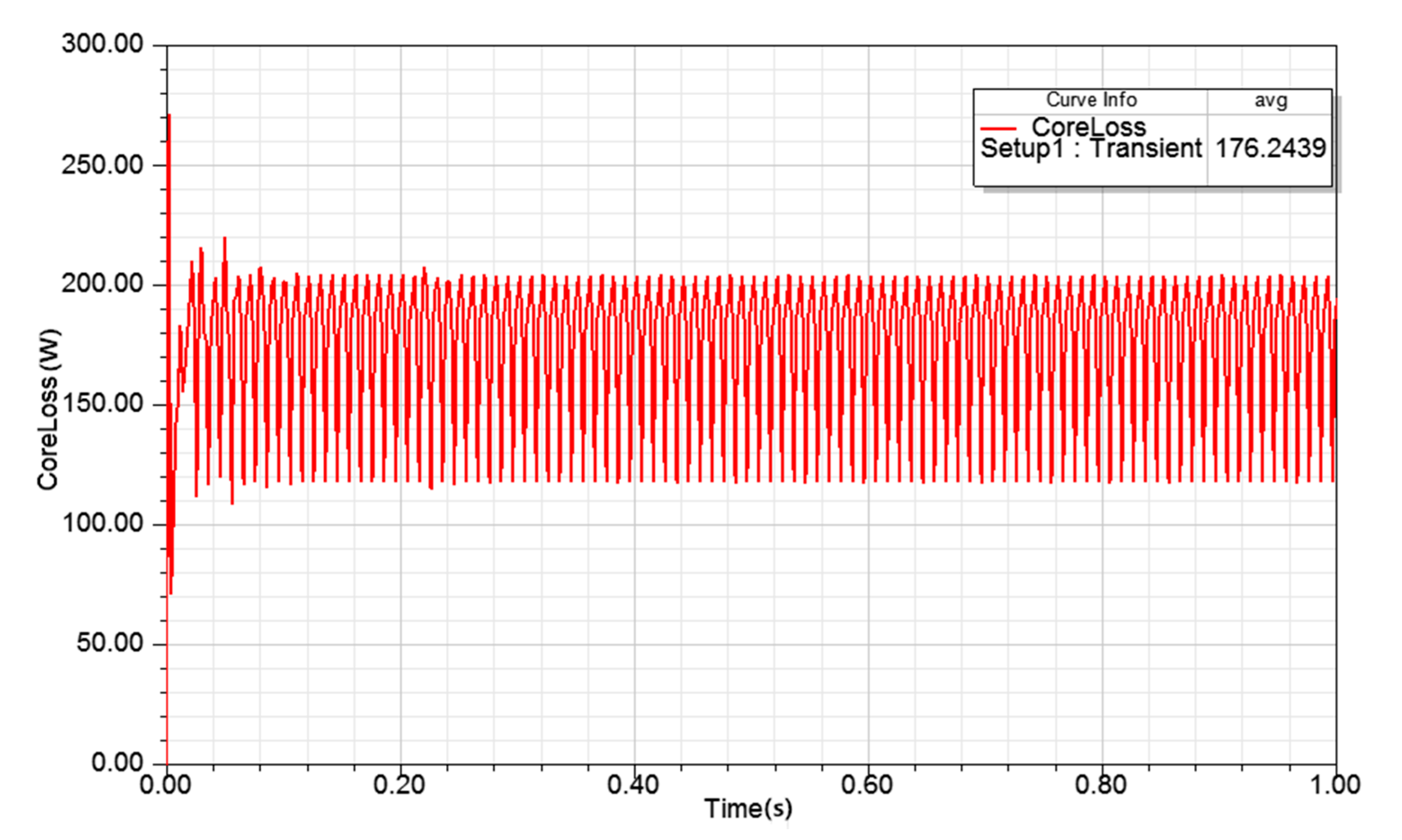

4.2. No-Load Loss

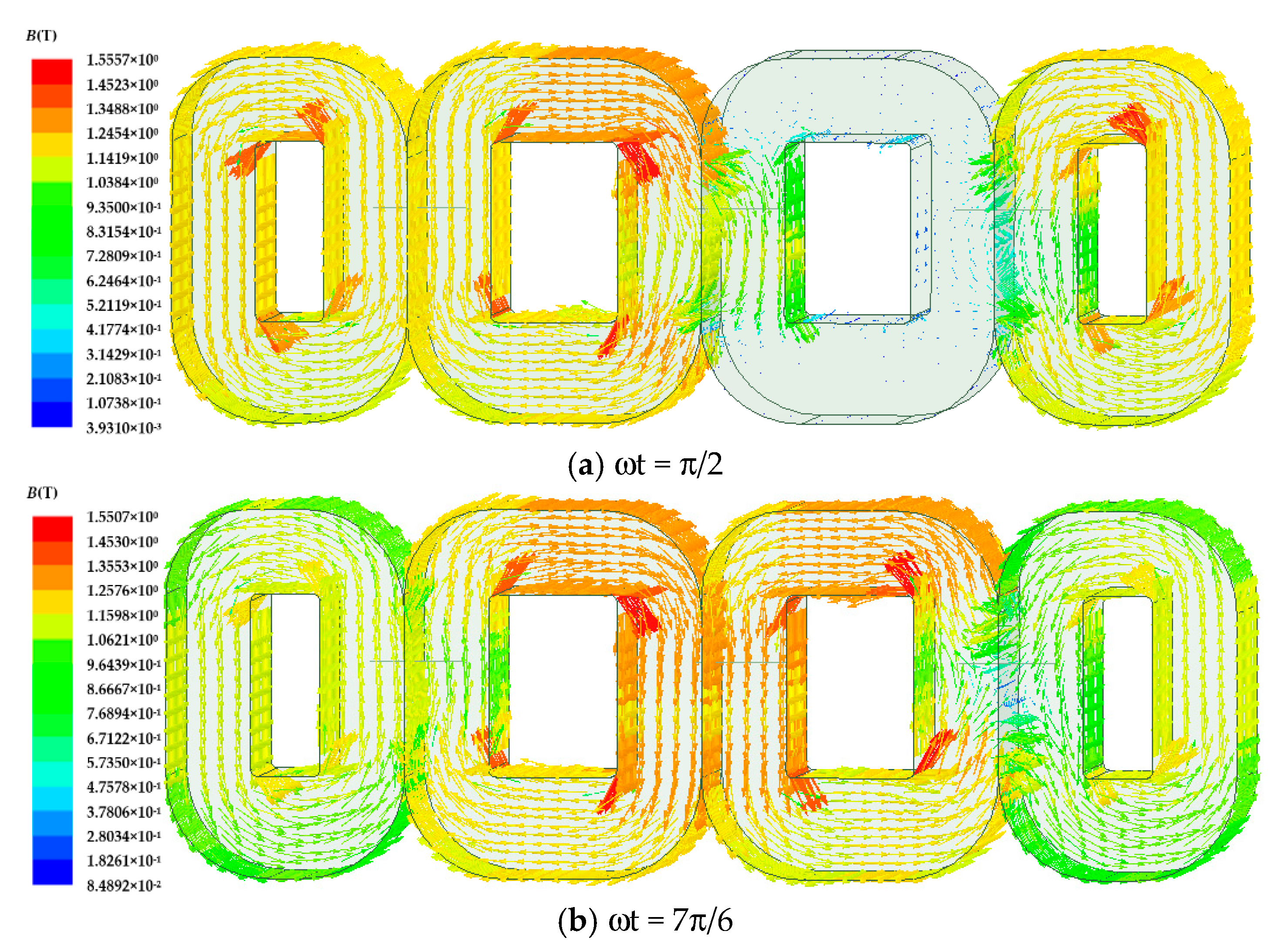

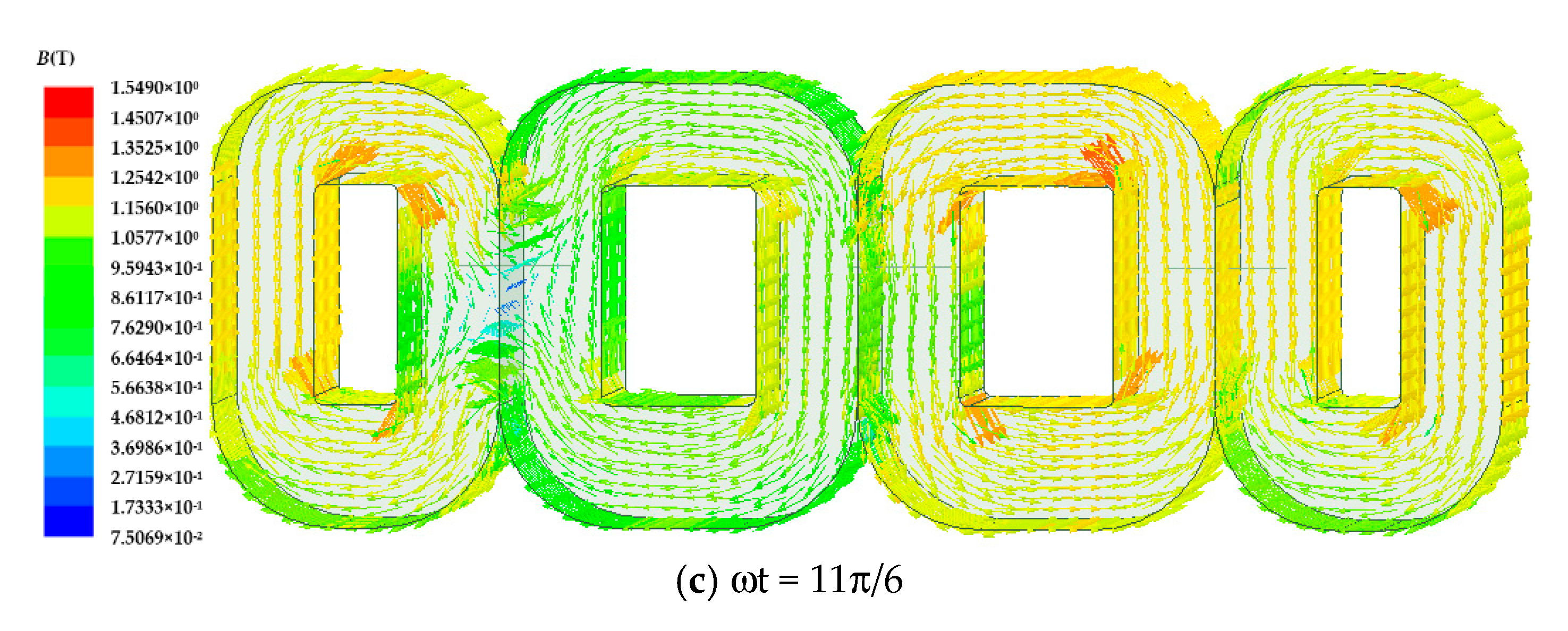

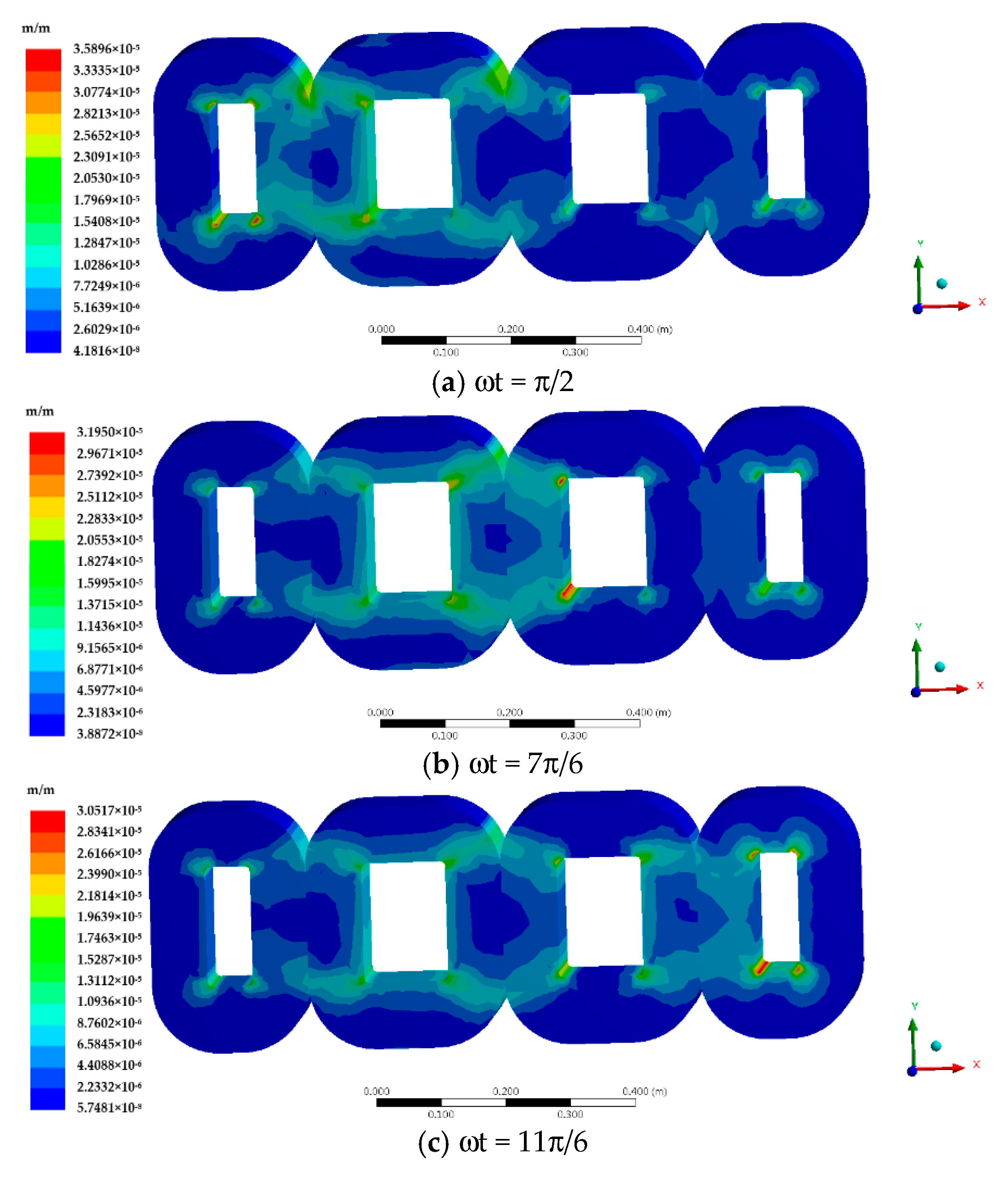

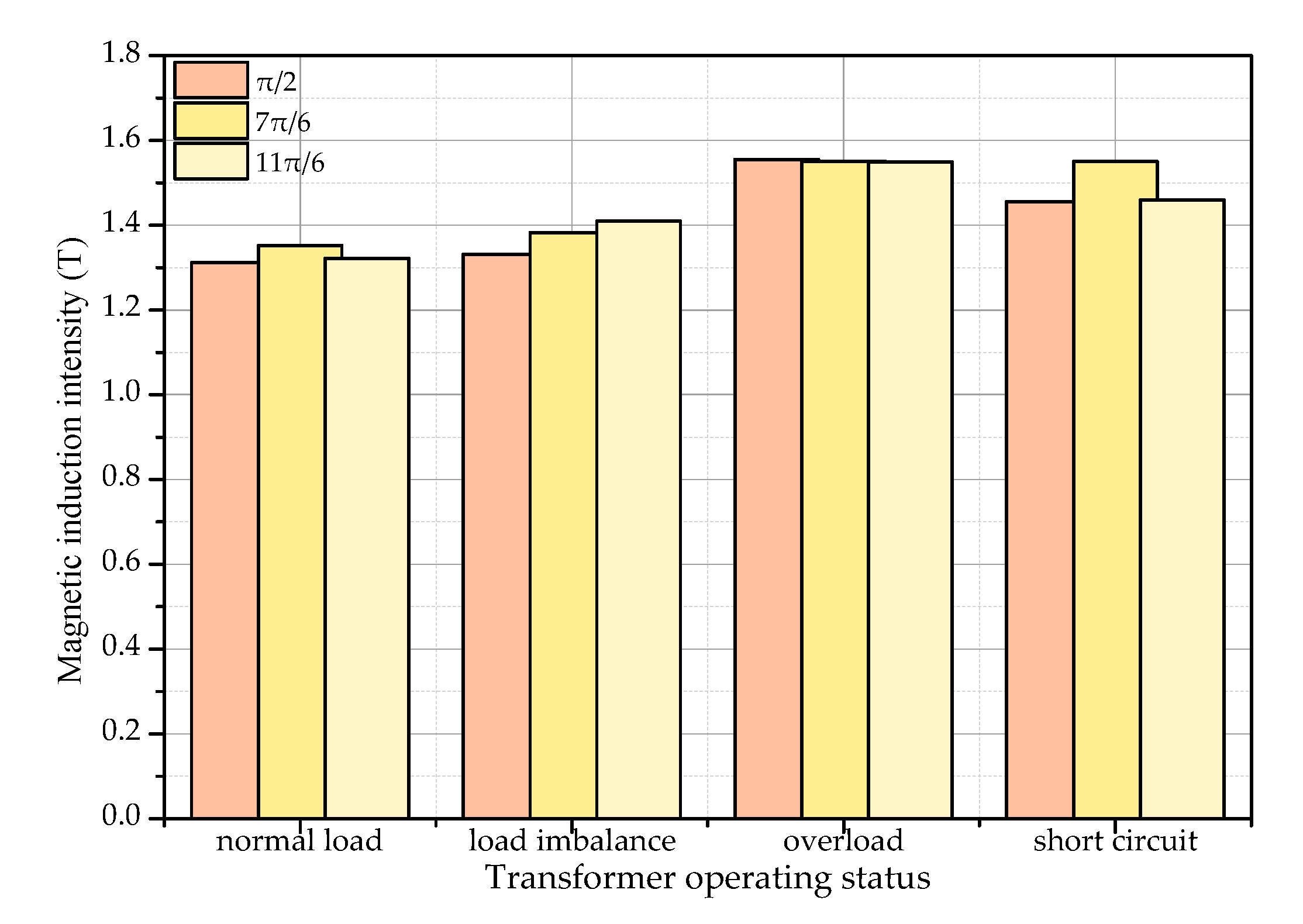

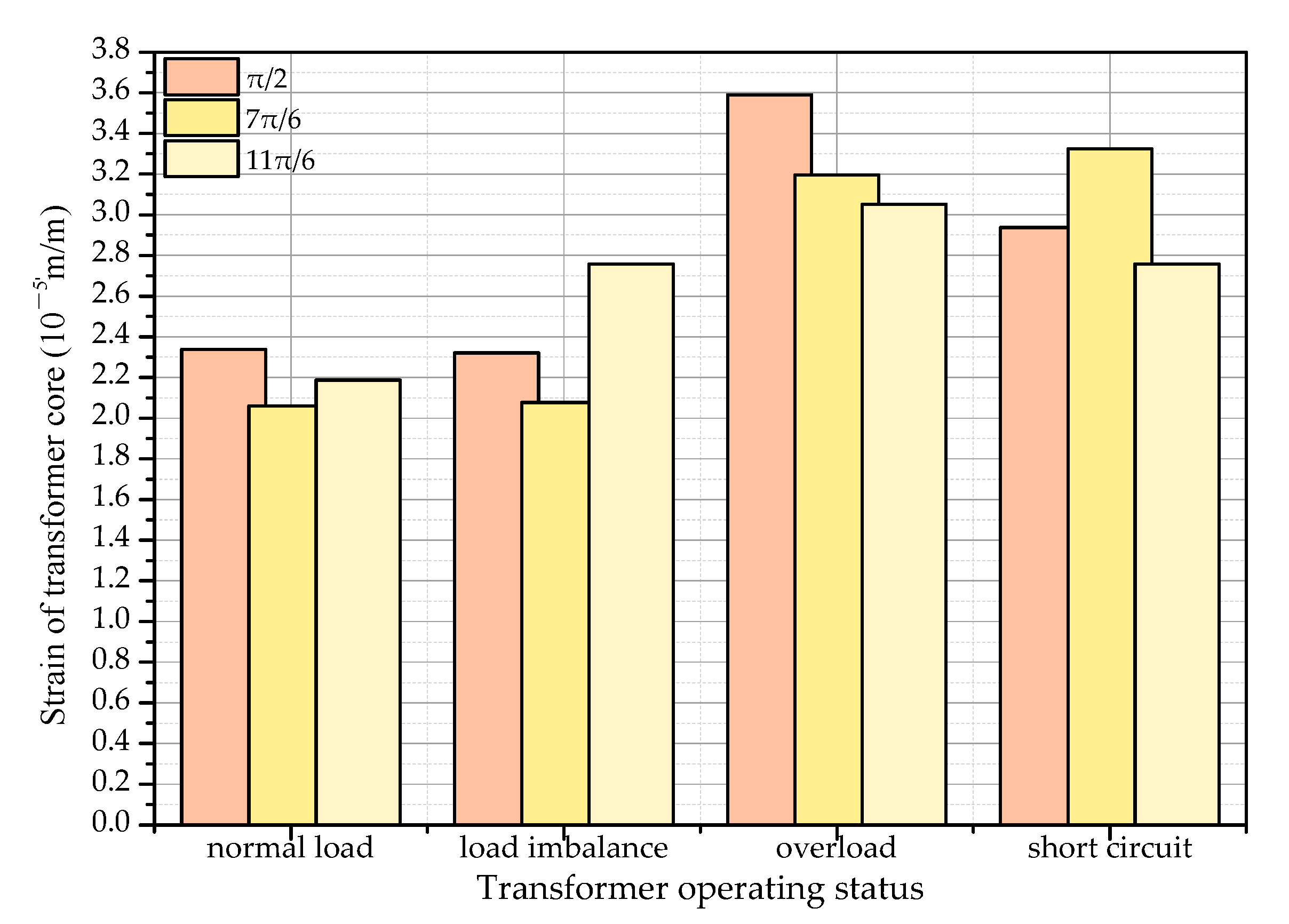

5. Simulation Analysis of Iron Core Electromagnetic Field and Strain under Different Working Conditions

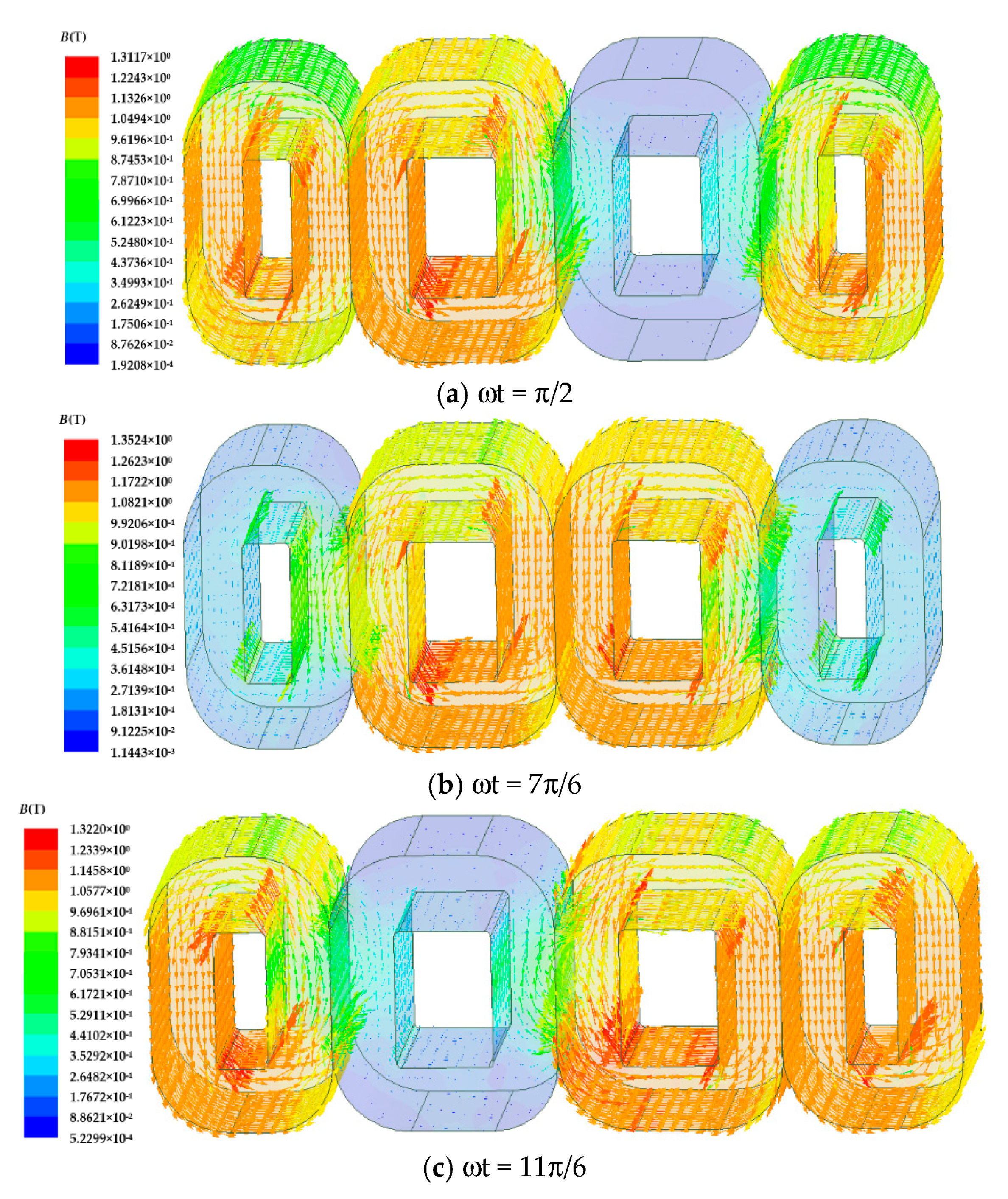

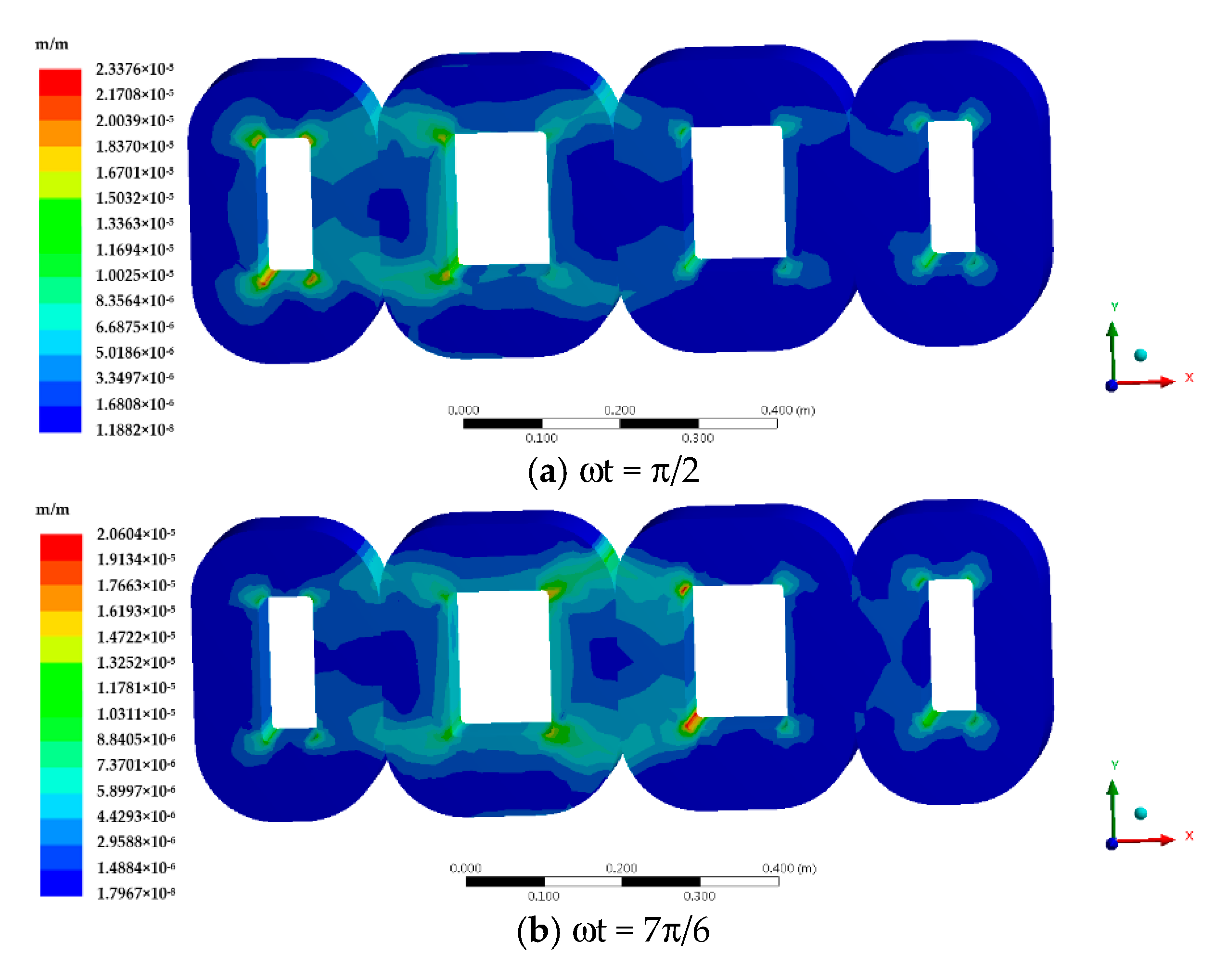

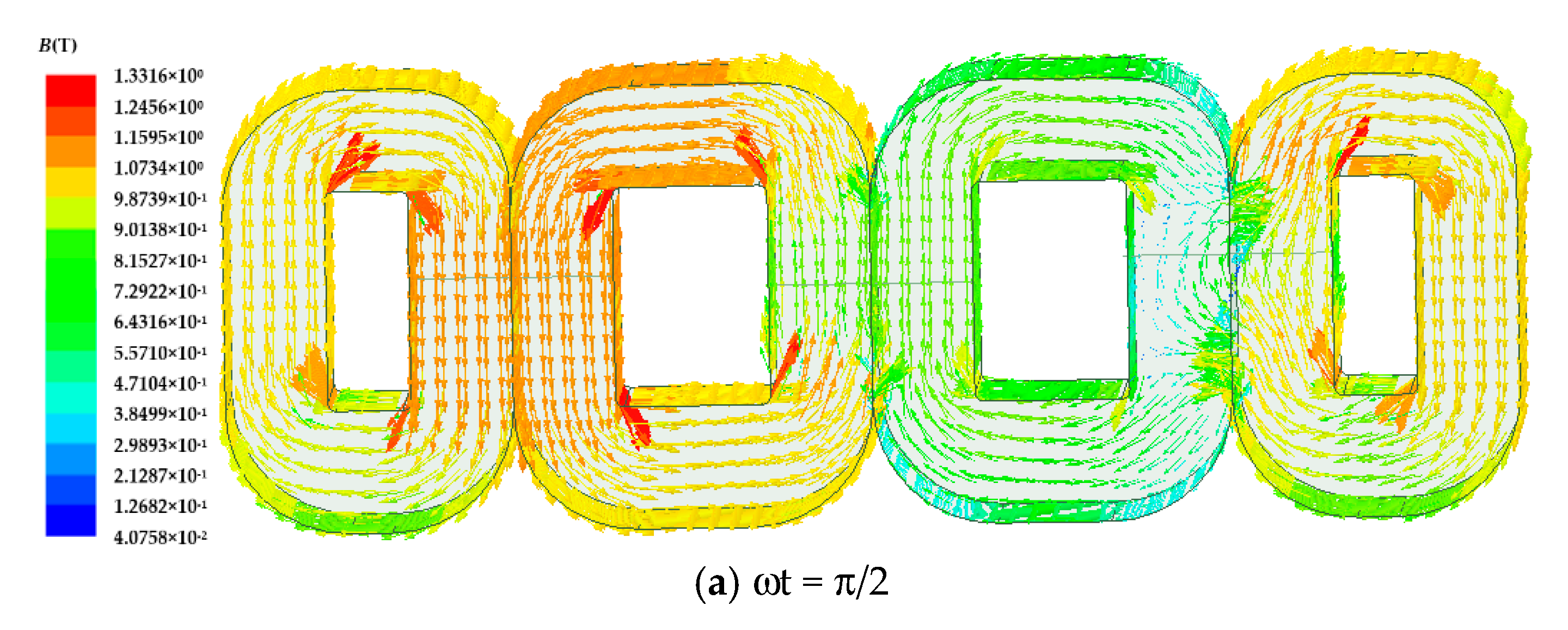

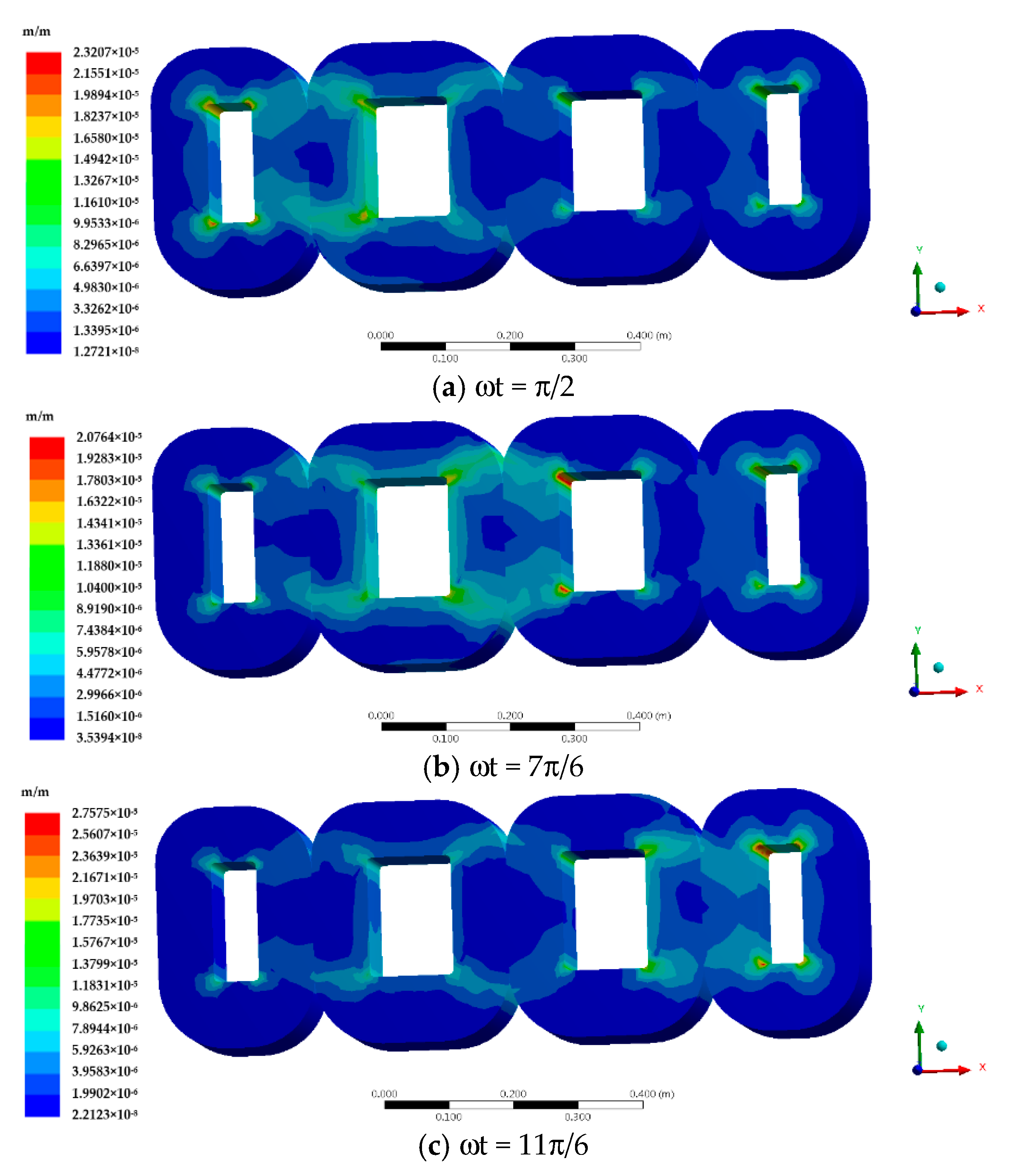

5.1. Normal Load

5.2. Load Imbalance

5.3. Overload

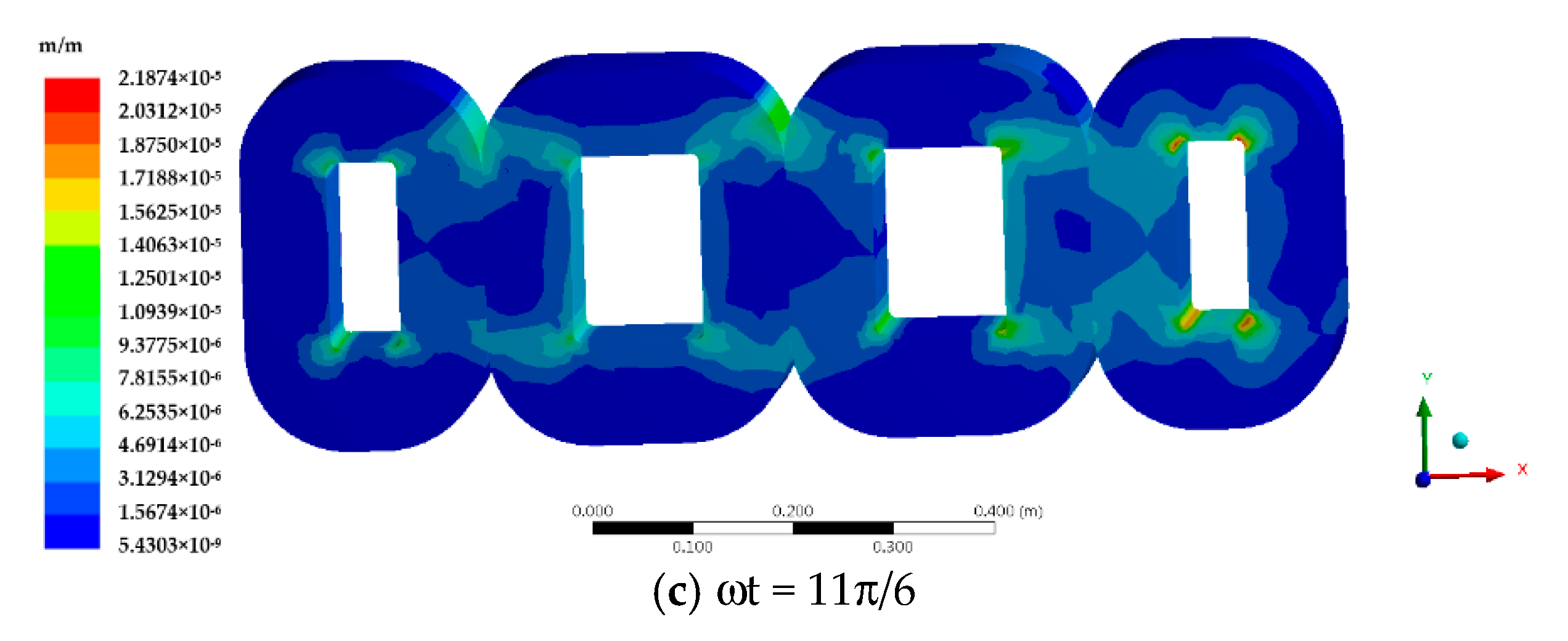

5.4. Short Circuit

6. Discussion

- Combining the simulation analysis results with the experiment and testing the stress of the iron core under different working conditions;

- Calculating the amount of amorphous debris generated under stress by simulation;

- Studying the flow trajectory and distribution of the amorphous debris in the transformer oil after generation;

- Studying detailed strain analysis under different overloads and load imbalance, and its effect during high-speed rail operation.

7. Conclusions

- A strong coupling theory of electromagnetic field and mechanical field for magnetostriction of amorphous alloys and an actual calculation model of indirect coupling method using interpolation are proposed.

- The finite element model of the amorphous alloy transformer established has no-load current and no-load loss, similar to the field test data of the product when the secondary winding is in no-load operation, and the data error is relatively small.

- The normal operation of amorphous alloy transformers is simulated, and the characteristics of electric field, magnetic field, and eddy current field are analyzed. During normal operation, the electromagnetic characteristics of the transformer conform to the actual situation, which verifies the correctness of the simulation.

- As the load becomes more unbalanced, the strain of the iron core gradually increases. When a short circuit occurs, the strain of the iron core reaches the maximum. Under normal circumstances, as the load increases, the stress of the iron core increases. When the transformer is overloaded, the core stress increases faster and the maximum value is higher than the core stress during C-phase short circuit.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shao, J.; Wang, J.; Long, M.; Li, J.; Ma, Y. 5000 h Multi-Factor Accelerated Aging Test of FRP Made Transmission Tower: Characterization, Thermal Decomposition and Reaction Kinetics Study. Polymers 2017, 9, 170. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, J.; Shao, J.; Long, M.; Ma, Y.; Liu, K. Multifactor mechanical aging properties and electrical performance research on composite material tower and samples. IEEE Trans. Electr. Electron. Eng. 2018, 13, 13–26. [Google Scholar] [CrossRef]

- Zhao, Y.; Zheng, J.; Zhang, Z.; Shi, D.; Qin, X. Study on the influence of amorphous debris on the electric field of amorphous alloy transformer in urban rail transit. In 2017 2nd International Conference on Power and Renewable Energy (ICPRE), Proceedings of the 2017 2nd International Conference on Power and Renewable Energy (ICPRE), Chengdu, China, 20–23 September 2017; IEEE: Piscataway Township, NJ, USA, 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Sima, W.; Zou, M.; Yang, M.; Yang, Q.; Peng, D. Modeling of grain-oriented Si-steel and amorphous alloy iron core under ferroresonance using Jiles–Atherton hysteresis method. AIP Adv. 2018, 8, 056608. [Google Scholar] [CrossRef]

- Li, T.; Zhang, Y.; Liang, Y.; Ai, Q.; Dou, H. Multiphysics Analysis of an Axial-Flux In-Wheel Motor with an Amorphous Alloy Stator. IEEE Access 2020, 8, 27414–27425. [Google Scholar] [CrossRef]

- Alexandrov, N.; Schulz, R. Roberge Amorphous Alloys for Distribution Transformers: Design Considerations and Economic Impact. IEEE Trans. Power Deliv. 1987, 2, 420–424. [Google Scholar] [CrossRef]

- Bykovskaya, L.V.; Bykovskiyi, V. Simulation of a Voltage Transformer with a Magnetic Core Made of Amorphous Steels. In Proceedings of the 2020 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM); Institute of Electrical and Electronics Engineers (IEEE): Piscataway Township, NJ, USA, 2020; pp. 1–5. [Google Scholar]

- Zheng, J.; Zhao, Y.; Zhang, Z.; Shi, D.; Qin, X. Study on the influence of amorphous debris on the magnetic field distribution of amorphous alloy transformer. In Proceedings of the International Conference on Power and Renewable Energy (ICPRE), 2nd ed.; Institute of Electrical and Electronics Engineers (IEEE): Piscataway Township, NJ, USA, 2017; pp. 126–131. [Google Scholar]

- Liu, D.; Li, J.; Wang, S.; Yang, S.; Lin, Y.; Qi, Z.; Yan, M. Stability of Properties on Magnetic Ribbon and Cores with Domestic Fe-Based Amorphous Alloy for HTS AMDT. IEEE Trans. Appl. Supercon. 2019, 29, 1–5. [Google Scholar] [CrossRef]

- Takahashi, K.; Azuma, D.; Hasegawa, R. Acoustic and Soft Magnetic Properties in Amorphous Alloy-Based Distribution Transformer Cores. IEEE Trans. Magn. 2013, 49, 4001–4004. [Google Scholar] [CrossRef]

- Du, B.X.; Liu, D.S. Dynamic Behavior of Magnetostriction-Induced Vibration and Noise of Amorphous Alloy Cores. IEEE Trans. Magn. 2015, 51, 1–8. [Google Scholar] [CrossRef]

- Liu, D.; Du, B.; Yan, M.; Wang, S. Suppressing Noise for an HTS Amorphous Metal Core Transformer by Using Microperforated Panel Absorber. IEEE Trans. Appl. Supercon. 2016, 26, 1–5. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Y.; Zhu, J.; Guo, Y.; Lei, G.; Liu, C. Calculation of core loss and copper loss in amorphous/nanocrystalline core-based high-frequency transformer. AIP Adv. 2016, 6, 055927. [Google Scholar] [CrossRef] [Green Version]

- Haifeng, Z.; Wenhao, N.; Tao, L.; Dong, H.; Guoqiang, Z. The analysis of short-circuit withstanding ability for a 800 KVA/10 KV shell-form power transformer with amorphous alloy cores. In Proceedings of the 2012 China International Conference on Electricity Distribution; Institute of Electrical and Electronics Engineers (IEEE): Piscataway Township, NJ, USA, 2012; pp. 1–5. [Google Scholar]

- Guo, J.; Fang, S.; Zhang, Y.; Jin, Y. A novel method to check the axial tilt instability of the rectangular winding of the amorphous alloy transformer. IEEE Trans. Electr. Electron. Eng. 2018, 13, 92–97. [Google Scholar] [CrossRef] [Green Version]

- Xuan, M.; Du, X.; Xuan, L.; Hong, H. Analysis of production mechanism of amorphous debris in amorphous alloy transformer. Eng. J. Wuhan Univ. 2019, 52, 255–263. [Google Scholar]

- Xu, Y.; Wang, J.; Hou, H.; Shao, J. Simulation analysis of coupled magnetic-temperature fields in magnetic fluid hyperthermia. AIP Adv. 2019, 9, 105317. [Google Scholar] [CrossRef]

- Bahmani, M.A. Core Loss Calculation in Amorphous High Frequency High-Power Transformers with Different Topologies. Master’s Thesis, Chalmers University of Technology, Göteborg, Sweden, 2011. [Google Scholar]

- Chang, Y.-H.; Hsu, C.-H.; Chu, H.-L.; Tseng, C.-P. Magnetomechanical Vibrations of Three-Phase Three-Leg Transformer with Different Amorphous-Cored Structures. IEEE Trans. Magn. 2011, 47, 2780–2783. [Google Scholar] [CrossRef]

- Wu, S.; Tang, R.; Han, X.; Tong, W.; Zhao, S. Analytical Calculation and Influence Factors of Vibration in Amorphous Metal Cores. Trans. China Electrotech. Soc. 2016, 31, 73–82. [Google Scholar]

- Anderson, P.I.; Moses, A.J.; Stanbury, H.J. Assessment of the Stress Sensitivity of Magnetostriction in Grain-Oriented Silicon Steel. IEEE Trans. Magn. 2007, 43, 3467–3476. [Google Scholar] [CrossRef]

- Yan, R.G.; Yang, Q.X.; Yang, W.R.; Hou, S.P.; Yan, W.L. Giant Magnetostrictive Acceleration Sensors. Proc. Csee 2009, 29, 104–109. [Google Scholar]

- Besbes, M.; Ren, Z.; Razek, A. Finite element analysis of magneto-mechanical coupled phenomena in magnetostrictive materials. IEEE Trans. Magn. 1996, 32, 1058–1061. [Google Scholar] [CrossRef]

- Xue, X.; Cheng, K.W.E.; Bao, Y.J.; Leung, P.L.; Cheung, N.C. Switched Reluctance Generators with Hybrid Magnetic Paths for Wind Power Generation. IEEE Trans. Magn. 2012, 48, 3863–3866. [Google Scholar] [CrossRef]

- Cheng, K.W.E.; Evans, P.D. Calculation of winding losses in high frequency toroidal inductors using multi-strand conductors. IEE Proc. Electr. Power Appl. 1995, 142, 313–322. [Google Scholar] [CrossRef]

| Model Number | Phase Number | Rated Voltage (kV) | Join Groups | Rated Capacity (kVA) | Frequency (Hz) | Rated Current (A) | Tapping Range |

|---|---|---|---|---|---|---|---|

| SBH15-M | 3 | 10/0.4 | Dyn11 | 315 | 50 | 18.2/454.7 | 10 × (1 ± 2 × 2.5) |

| Parameters | Inner Frame Length (mm) | Inner Frame Height (mm) | Thickness (mm) | Width (mm) |

|---|---|---|---|---|

| Big frame iron core | 185 | 130 | 86 | 142.2 |

| Small frame iron core | 185 | 70 | 86 | 142.2 |

| Performance | Saturated Magnetic Induction (T) | Lamination Coefficient | Resistivity (μΩm) | Density (g/cm3) | Young’s Modulus (GPa) | Poisson Ratio | Vickers Degree (HV) | Thickness (m) |

|---|---|---|---|---|---|---|---|---|

| Size | 1.56 | 0.86 | 1.3 | 7.18- | 110 | 0.3 | 900 | 24 |

| Winding | High-Voltage Winding | Low-Voltage Winding |

|---|---|---|

| Turns | 818 | 18 |

| Sectional area (mm2) | 3.94 | 152 |

| Resistance (Ω) | 5.2399 | 0.002614 |

| Rated current (A) | 18.2 | 454.7 |

| Material | red copper | red copper |

| Winding connection mode | D | Y |

| Sinusoidal voltage (kV) | 10 | 0.4 |

| Phase C (Ω) | 0.6 | 0.5 | 0.4 | 0.3 | 0.2 | 0.1 | 10−9 |

|---|---|---|---|---|---|---|---|

| maximum values of strain at 11π/6 (10−5) | 2.78 | 2.81 | 2.85 | 2.90 | 2.93 | 2.95 | 2.99 |

| η | 50 | 70 | 90 | 110 | 130 | 160 |

|---|---|---|---|---|---|---|

| maximum values of strain at 11π/6 × (10−5) | 2.19 | 2.29 | 2.42 | 2.66 | 2.85 | 3.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, J.; Xu, C.; Cheng, K.W.E. Core Stress Analysis of Amorphous Alloy Transformer for Rail Transit under Different Working Conditions. Energies 2021, 14, 164. https://doi.org/10.3390/en14010164

Shao J, Xu C, Cheng KWE. Core Stress Analysis of Amorphous Alloy Transformer for Rail Transit under Different Working Conditions. Energies. 2021; 14(1):164. https://doi.org/10.3390/en14010164

Chicago/Turabian StyleShao, Jianwei, Cuidong Xu, and Ka Wai Eric Cheng. 2021. "Core Stress Analysis of Amorphous Alloy Transformer for Rail Transit under Different Working Conditions" Energies 14, no. 1: 164. https://doi.org/10.3390/en14010164

APA StyleShao, J., Xu, C., & Cheng, K. W. E. (2021). Core Stress Analysis of Amorphous Alloy Transformer for Rail Transit under Different Working Conditions. Energies, 14(1), 164. https://doi.org/10.3390/en14010164