Life Cycle Assessment of Bioethanol Production: A Review of Feedstock, Technology and Methodology

Abstract

:1. Introduction

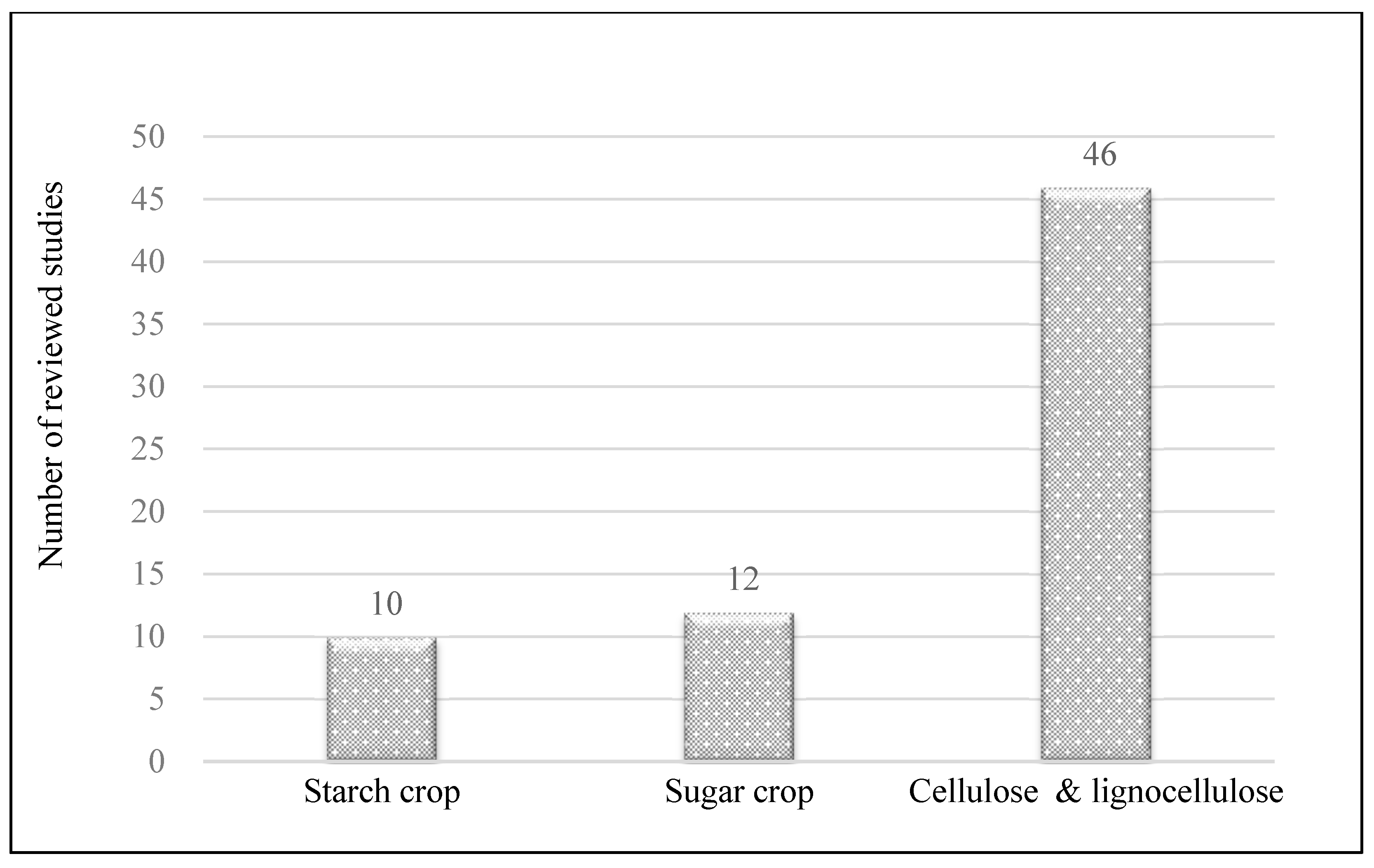

- Starch based bioethanol

- Sugar based bioethanol

- Lignocellulose based bioethanol

2. Method

2.1. Approach of Review

2.2. Data Description

3. Results and Discussion

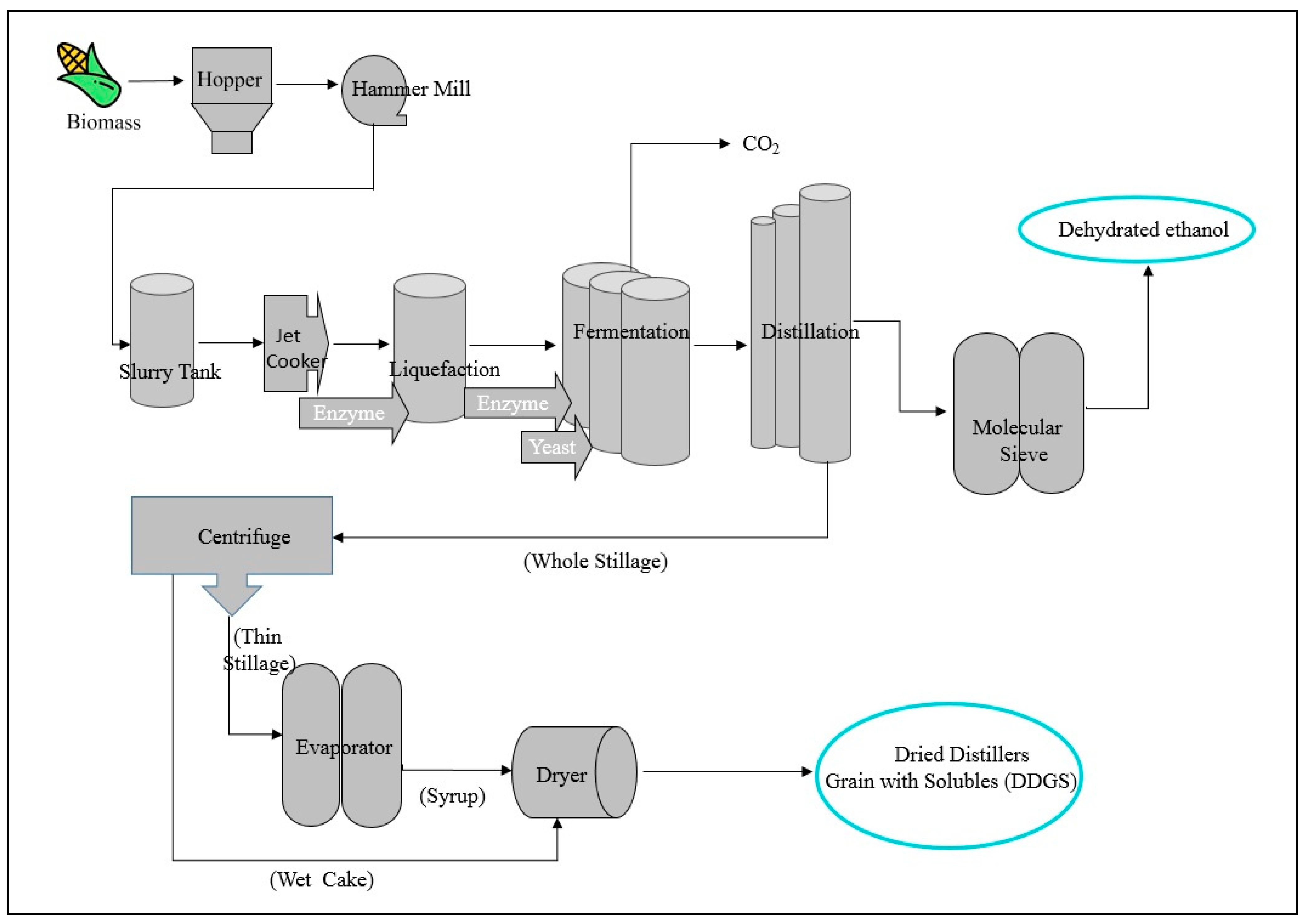

3.1. Technical Aspects

- Feedstock handling and pre-treatment;

- Saccharification to reach fermentable sugars;

- Fermentation process to convert sugars to ethanol;

- Ethanol recovery.

3.2. Feedstock Provision

3.3. LCA Methodology Components

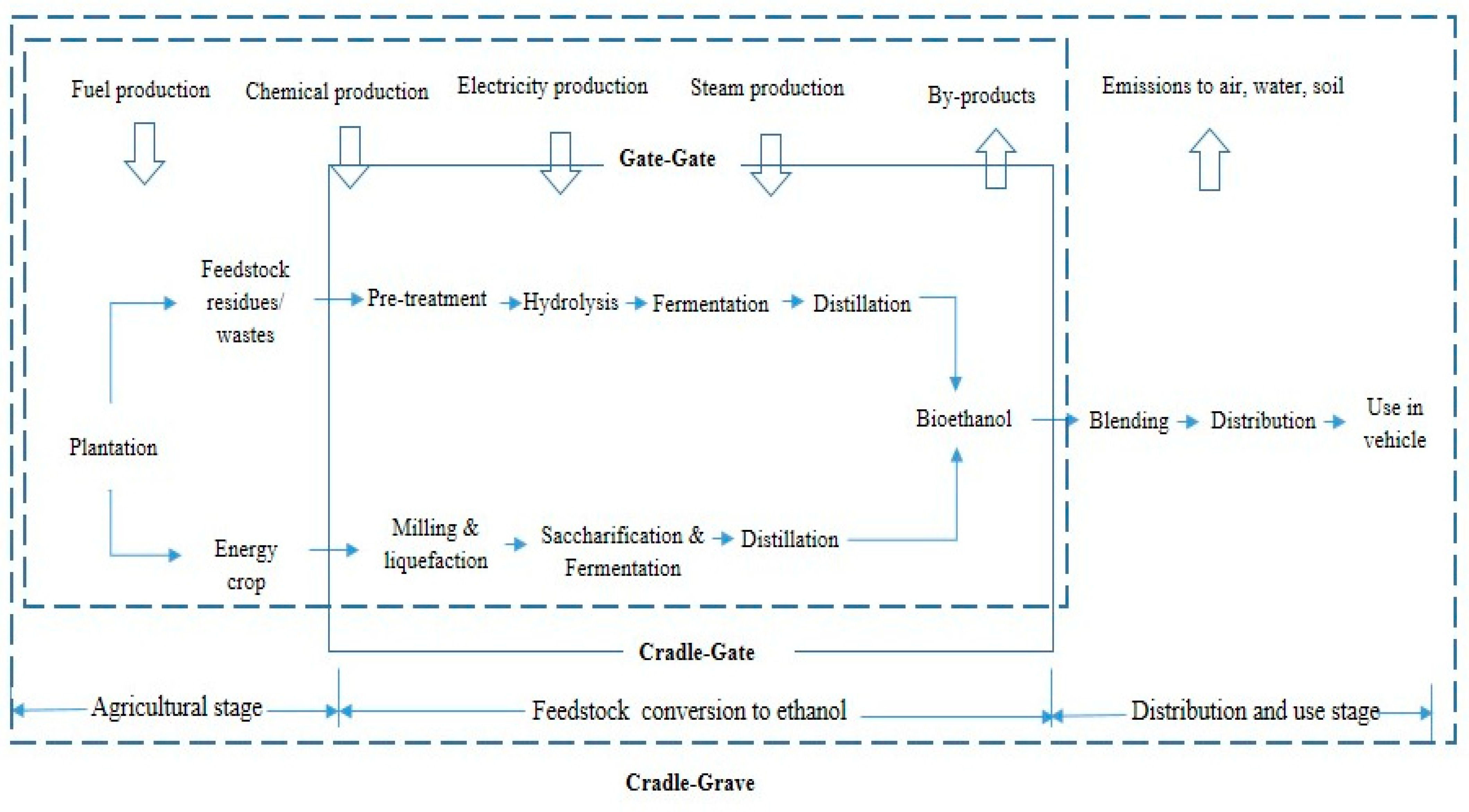

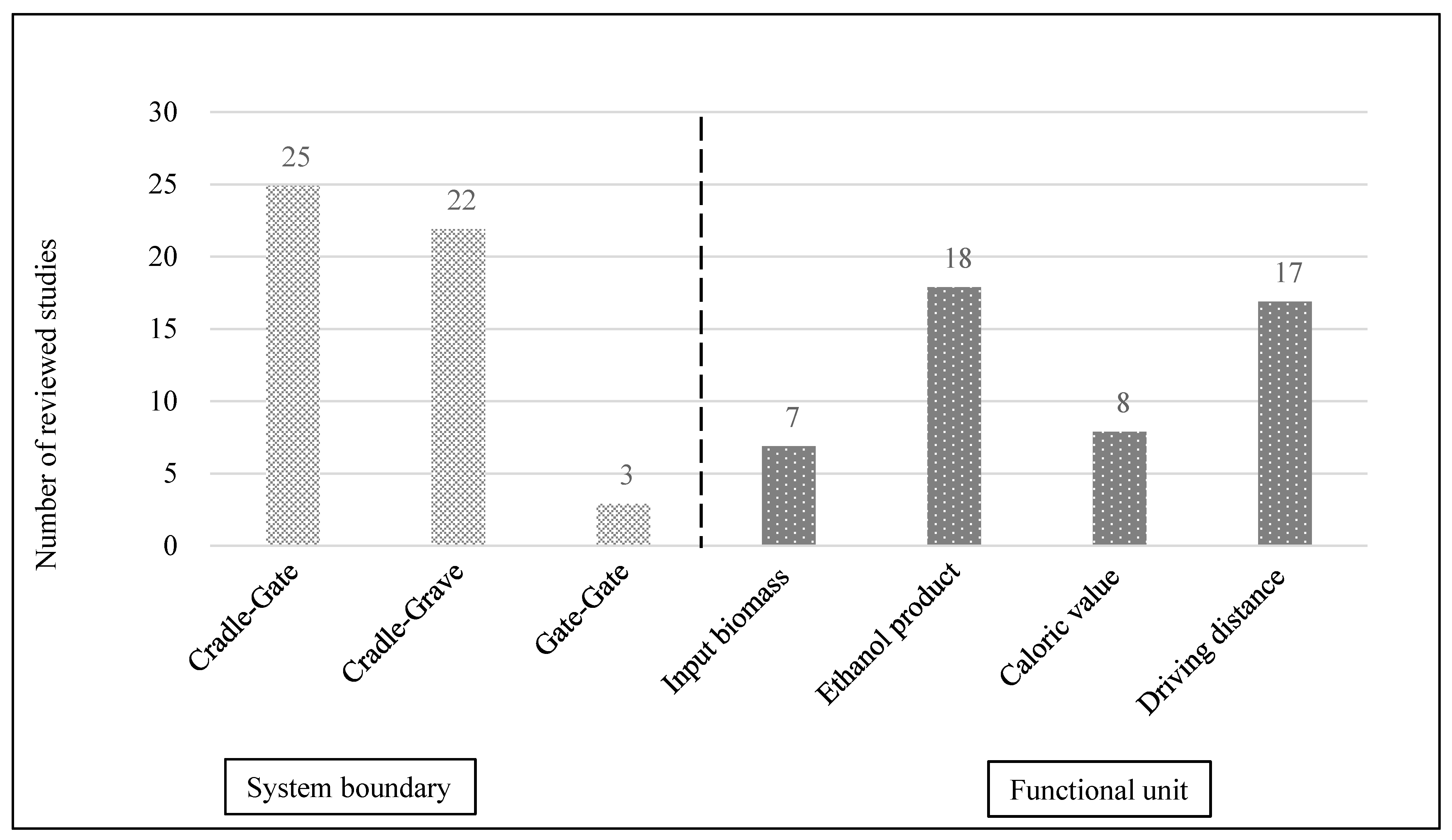

3.3.1. System Boundary and Functional Unit

3.3.2. Life Cycle Inventory

Data Source

3.3.3. Software Use

3.3.4. By-Product Credit and Allocation

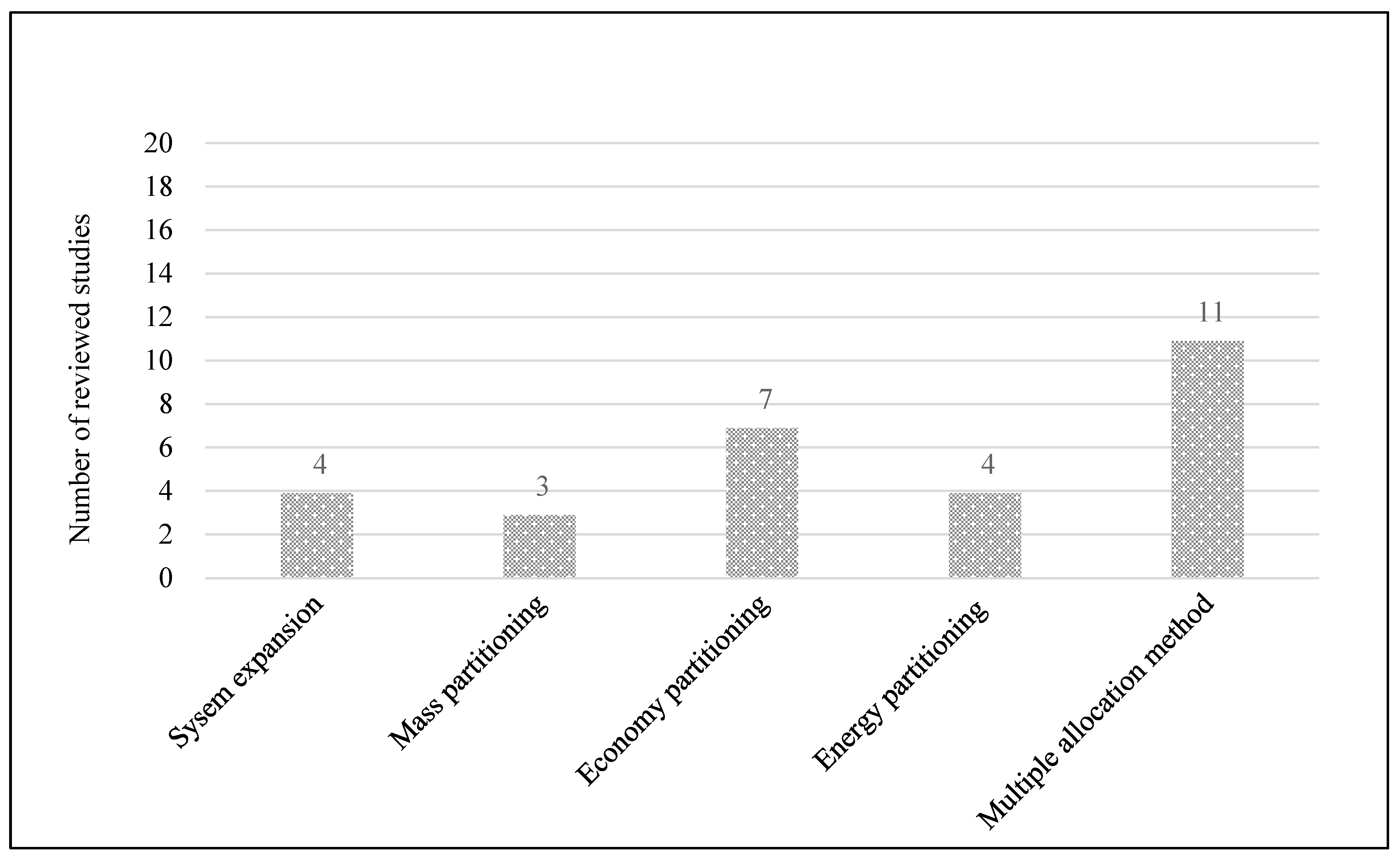

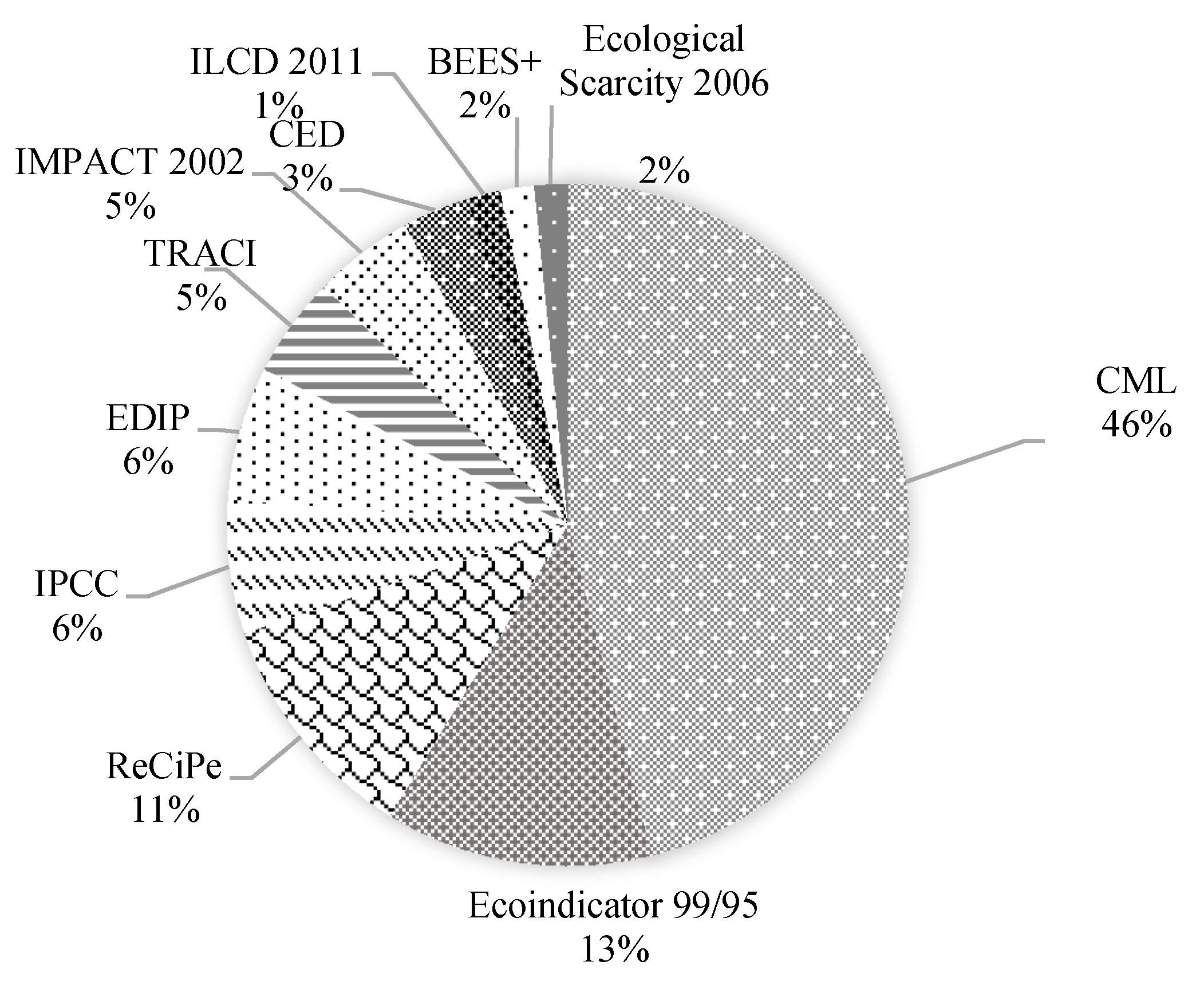

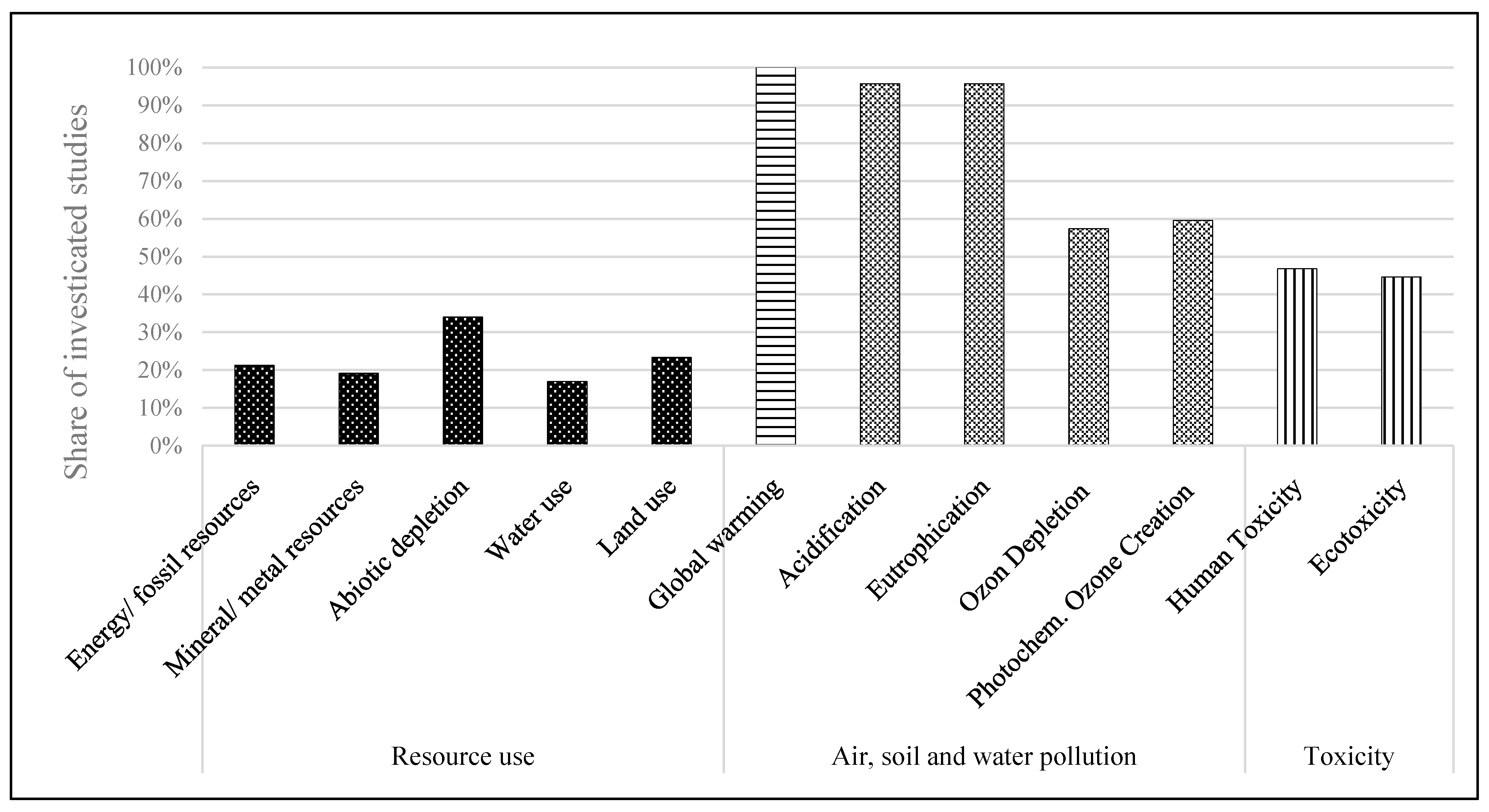

3.3.5. Applied Assessment Methods and Impact Categories

3.3.6. Uncertainties

4. Conclusions

- Reviewed papers show that studies results depend greatly on LCA methodology choices. Selection of allocation method, the definition of assessment method, system boundary and functional unit besides choosing effective impact categories change the results.

- Although most authors added the feedstock production and processing into the system boundary, less than half of them considered agrochemicals’ production. Given the important role of chemicals, such as fertilizers, pesticides in increasing acidification, eutrophication, land-use change and carcinogens, it seems necessary to include the production of those chemicals in LCA studies. Moreover, carrying out LCA analysis on the bioethanol from new generation of feedstock with less chemicals requirements or less agricultural practices would be useful to estimate and compare the relevant impacts with conventional feedstock.

- From the technical point of view, pre-treatment was the most considered process in the studies with a high potential for changing LCA results. As reviewed papers showed that the modified pre-treatment methods lead to environmental savings, because pre-treatment plays an important role in the next processes. However, advanced pre-treatment technologies with optimization of inputs and outputs in the bioethanol production can decrease the environmental impacts; the other processes of production also need to be considered. Furthermore, in most circumstances, studies neglected the production, transportation and use of the chemicals, nutrients, enzymes, which are the inputs for bioethanol production processes. This aspect needs to be investigated more by future studies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Acronyms

| LCA | Life Cycle Assessment |

| FU | Functional Unit |

| FFVs | Flex Fuel Vehicles |

| 1G | First generation |

| 2G | Second generation |

| CED | Cumulative Energy Demand |

| CMLCA | Chain Management by Life Cycle Assessment |

| LUC | Land Use Change |

| GHG | Greenhouse Gases |

| E10 | Mixture of 10% ethanol and 90% gasoline by volume |

| E85 | Mixture of 85% ethanol and 15% gasoline by volume |

| ISO | International Standards Organization |

| BES | Biodiversity and Ecosystem Services |

| GWP | Global Warming Potential |

| IPCC | Intergovernmental Panel on Climate Change |

| EDIP | Environmental Design of Industrial Products |

| CML | Institute of Environmental Sciences of the Faculty of Science of Leiden University |

| BEES+ | Building for Environmental and Economic Sustainability |

| ILCD | The International Reference Life Cycle Data System |

| TRACI | Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts |

| LCIA | Life Cycle Impact Assessment |

References

- Edenhofer, O.; Pichs-Madru, R.; Sokona, Y.; Seyboth, K.; Matschoss, P.; Kadner, S.; Zwickel, T.; Eickemeier, P.; Hansen, G.; Schloemer, S.; et al. IPCC Special Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: New York, NY, USA, 2012. [Google Scholar]

- Directive (EU) 2018/2001 of the European Parliment and of the Council. 2018. Available online: https://eur-lex.europa.eu (accessed on 28 February 2021).

- Renewable Energy Prospects for the European Union. 2018. Available online: https://www.irena.org/ (accessed on 28 February 2021).

- U.S. Department of Energy. Available online: https://afdc.energy.gov/data/ (accessed on 28 February 2021).

- ePURE. European Renewable Ethanol—Key Figures. 2017. Available online: https://www.epure.org/ (accessed on 28 February 2021).

- Vohra, M.; Manwar, J.; Manmode, R.; Padgilwar, S.; Patil, S. Bioethanol production: Feedstock and current technologies. J. Environ. Chem. Eng. 2014, 2, 573–584. [Google Scholar] [CrossRef]

- Luo, L.; van der Voet, E.; Huppes, G.; Udo de Haes, H.A. Allocation issues in LCA methodology: A case study of corn stover-based fuel ethanol. Int J. Life Cycle Assess. 2009, 14, 529–539. [Google Scholar] [CrossRef]

- González-García, S.; Moreira, M.T.; Feijoo, G. Comparative environmental performance of lignocellulosic ethanol from different feedstocks. Renew. Sustain. Energy Rev. 2010, 14, 2077–2085. [Google Scholar] [CrossRef]

- ISO (International Organization for Standardization). Environmental Management—Life Cycle Assessment—Principles and Framework; Standard ISO14040; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO (International Organization for Standardization). Environmental Management—Life Cycle Assessment—Requirements and Guidelines; Standard ISO 14044; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. Life Cycle Assessment: Theory and Practice; Springer: Cham, Switzerland, 2018. [Google Scholar]

- da Costa Sousa, L.; Chundawat, S.P.S.; Balan, V.; Dale, B.E. ‘Cradle-to-grave’ assessment of existing lignocellulose pretreatment technologies. Curr. Opin. Biotechnol. 2009, 20, 339–347. [Google Scholar] [CrossRef]

- Shadbahr, J.; Zhang, Y.; Khan, F. Life cycle assessment of bioethanol production from woodchips with modifications in the pretreatment process. Appl. Biochem. Biotechnol. 2015, 175, 1080–1091. [Google Scholar] [CrossRef]

- Guo, M.; Littlewood, J.; Joyce, J.; Murphy, R. The environmental profile of bioethanol produced from current and potential future poplar feedstocks in the EU. Green Chem. 2014, 16, 4680–4695. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Littlewood, J.; Murphy, R.J. Environmental sustainability of bioethanol production from wheat straw in the UK. Renew. Susaint. Energy Rev. 2013, 28, 715–725. [Google Scholar] [CrossRef] [Green Version]

- Ntihuga, J.N.; Senn, T.; Gschwind, P.; Kohlus, R. Estimating energy and eco-balances for continuous bio-ethanol production using a Blenke cascade system. Energies 2013, 6, 2065–2083. [Google Scholar] [CrossRef] [Green Version]

- Falano, T.; Jeswani, H.K.; Azapagic, A. Assessing the environmental sustainability of ethanol from integrated biorefineries. Biotechnol. J. 2014, 9, 753–765. [Google Scholar] [CrossRef] [Green Version]

- González-García, S.; Moreira, M.T.; Feijoo, G.; Murphy, R.J. Comparative life cycle assessment of ethanol production from fast-growing wood crops (black locust, eucalyptus and poplar). Biomass Bioenergy 2012, 39, 378–388. [Google Scholar] [CrossRef]

- Pieragostini, C.; Aguirre, P.; Mussati, M.C. Life cycle assessment of corn-based ethanol production in Argentina. Sci. Total Environ. 2014, 472, 212–225. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Jia, C.; Wu, Y.; Xia, X.; Xi, B.; Wang, L.; Zhai, Y. Life cycle energy efficiency and environmental impact assessment of bioethanol production from sweet potato based on different production modes. PLoS ONE 2017, 12, e0180685. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mayer, F.D.; Brondani, M.; Aita, B.C.; Hoffmann, R.; Lora, E.S. Environmental and energy assessment of small scale ethanol fuel production. Energy Fuels 2015, 29, 6704–6716. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. Life cycle assessment of fuel ethanol derived from corn grain via dry milling. Bioresour. Technol. 2008, 99, 5250–5260. [Google Scholar] [CrossRef]

- Cavalett, O.; Chagas, M.F. Comparative LCA of ethanol versus gasoline in Brazil using different LCIA methods. Int. J. Life Cycle Assess. 2013, 647–658. [Google Scholar] [CrossRef]

- Buchspies, B.; Kaltschmitt, M. Life cycle assessment of bioethanol from wheat and sugar beet discussing environmental impacts of multiple concepts of co-product processing in the context of the European Renewable Energy Directive context of the European Renewable Energy Directive. Biofuels 2016, 7, 141–153. [Google Scholar] [CrossRef]

- Ometto, A.R.; Hauschild, M.Z. Lifecycle assessment of fuel ethanol from sugarcane in Brazil. Int. J. Life Cycle Assess. 2009, 236–247. [Google Scholar] [CrossRef]

- Luo, L.; Van Der Voet, E.; Huppes, G. Life cycle assessment and life cycle costing of bioethanol from sugarcane in Brazil. Renew. Sustain. Energy Rev. 2008, 13, 1613–1619. [Google Scholar] [CrossRef]

- Wang, M.; Shi, Y.; Xia, X.; Li, D.; Chen, Q. Life-cycle energy efficiency and environmental impacts of bioethanol production from sweet potato. Bioresour. Technol. 2013, 133, 285–292. [Google Scholar] [CrossRef]

- Foteinis, S.; Kouloumpis, V.; Tsoutsos, T. Life cycle analysis for bioethanol production from sugar beet crops in Greece. Energy Policy 2011, 39, 4834–4841. [Google Scholar] [CrossRef]

- Wang, M.; Chen, Y.; Xia, X.; Li, J.; Liu, J. Energy efficiency and environmental performance of bioethanol production from sweet sorghum stem based on life cycle analysis. Bioresour. Technol. 2014, 163, 74–81. [Google Scholar] [CrossRef] [PubMed]

- Borrion, A.L.; Mcmanus, M.C.; Hammond, G.P. Environmental life cycle assessment of bioethanol production from wheat straw. Biomass Bioenergy 2012, 47, 9–19. [Google Scholar] [CrossRef]

- Aguilar-Sánchez, P.; Navarro-Pineda, F.S.; Sacramento-Rivero, J.C.; Barahona-Pérez, L.F. Life-cycle assessment of bioethanol production from sweet sorghum stalks cultivated in the state of Yucatan, Mexico. Clean. Technol. Environ. 2018, 20, 1685–1696. [Google Scholar] [CrossRef]

- Daylan, B.; Ciliz, N. Life cycle assessment and environmental life cycle costing analysis of lignocellulosic bioethanol as an alternative transportation fuel. Renew. Energy 2016, 89, 578–587. [Google Scholar] [CrossRef]

- Budsberg, E.; Rastogi, M.; Puettmann, M.E.; Caputo, J.; Balogh, S.; Volk, T.A.; Gustafson, R.; Johnson, L. Life-cycle assessment for the production of bioethanol from willow biomass crops via biochemical conversion. For. Prod. J. 2012, 62, 305–313. [Google Scholar] [CrossRef] [Green Version]

- Cherubini, F.; Jungmeier, G. LCA of a biorefinery concept producing bioethanol, bioenergy, and chemicals from switchgrass. Int. J. Life Cycle Assess. 2010, 15, 53–66. [Google Scholar] [CrossRef]

- Murphy, C.W.; Kendall, A. Life cycle analysis of biochemical cellulosic ethanol under multiple scenarios. Glob. Chang. Biol. Bioenergy 2015, 7, 1019–1033. [Google Scholar] [CrossRef]

- Cherubini, F.; Ulgiati, S. Crop residues as raw materials for biorefinery systems—A LCA case study. Appl. Energy 2010, 87, 47–57. [Google Scholar] [CrossRef]

- González-García, S.; Gasol, C.M.; Gabarrell, X.; Rieradevall, J.; Moreira, M.T.; Feijoo, G. Environmental profile of ethanol from poplar biomass as transport fuel in Southern Europe. Renew. Energy 2010, 35, 1014–1023. [Google Scholar] [CrossRef]

- González-García, S.; Luo, L.; Moreira, M.T.; Feijoo, G.; Huppes, G. Life cycle assessment of hemp hurds use in second generation ethanol production. Biomass Bioenergy 2012, 36, 268–279. [Google Scholar] [CrossRef]

- Forte, A.; Zucaro, A.; Fagnano, M.; Fierro, A. Potential environmental impact of bioethanol production chain from fiber sorghum to be used in passenger cars. Sci. Total Environ. 2017, 598, 365–376. [Google Scholar] [CrossRef]

- Zucaro, A.; Forte, A.; Basosi, R.; Fagnano, M.; Fierro, A. Life Cycle Assessment of second generation bioethanol produced from low-input dedicated crops of Arundo donax L. Bioresour. Technol. 2016, 219, 589–599. [Google Scholar] [CrossRef] [PubMed]

- Papong, S.; Malakul, P. Life-cycle energy and environmental analysis of bioethanol production from cassava in Thailand. Bioresour. Technol. 2010, 101, S112–S118. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Luo, L.; van der Voet, E. Life cycle assessment of switchgrass-derived ethanol as transport fuel. Int. J. Life Cycle Assess. 2010, 15, 468–477. [Google Scholar] [CrossRef] [Green Version]

- González-García, S.; Luo, L.; Moreira, M.T.; Feijoo, G.; Huppes, G. Life cycle assessment of flax shives derived second generation ethanol fueled automobiles in Spain. Renew. Sustain. Energy Rev. 2009, 13, 1922–1933. [Google Scholar] [CrossRef]

- González-García, S.; Moreira, M.T.; Feijoo, G. Environmental performance of lignocellulosic bioethanol production from Alfalfa stems. Biofuel Bioprod. Biorefin. 2010, 4, 118–131. [Google Scholar] [CrossRef]

- Botha, T.; von Blottnitz, H. A comparison of the environmental benefits of bagasse-derived electricity and fuel ethanol on a life-cycle basis. Energy Policy 2006, 34, 2654–2661. [Google Scholar] [CrossRef]

- González-García, S.; Gasol, C.M.; Gabarrell, X.; Rieradevall, J.; Moreira, M.T.; Feijoo, G. Environmental aspects of ethanol-based fuels from Brassica carinata: A case study of second generation ethanol. Renew. Sustain. Energy Rev. 2009, 13, 2613–2620. [Google Scholar] [CrossRef]

- González-García, S.; Iribarren, D.; Susmozas, A.; Dufour, J.; Murphy, R.J. Life cycle assessment of two alternative bioenergy systems involving Salix spp. biomass: Bioethanol production and power generation. Appl. Energy 2012, 95, 111–122. [Google Scholar] [CrossRef]

- González-García, S.; Moreira, M.T.; Feijoo, G. Environmental aspects of eucalyptus based ethanol production and use. Sci. Total Environ. 2012, 438, 1–8. [Google Scholar] [CrossRef]

- Lyu, H.; Yang, S.; Zhang, J.; Feng, Y.; Geng, Z. Impacts of utilization patterns of cellulosic C5 sugar from cassava straw on bioethanol production through life cycle assessment. Bioresour. Technol. 2021, 323, 124586. [Google Scholar] [CrossRef] [PubMed]

- Kadam, K.L. Environmental benefits on a life cycle basis of using bagasse-derived ethanol as a gasoline oxygenate in India. Energy Policy 2002, 30, 371–384. [Google Scholar] [CrossRef]

- Dias, M.O.S.; Junqueira, T.L.; Cavalett, O.; Cunha, M.P.; Jesus, C.D.F.; Rossell, C.E.V.; Filho, R.M.; Bonomi, A. Integrated versus stand-alone second generation ethanol production from sugarcane bagasse and trash. Bioresour. Technol. 2012, 103, 152–161. [Google Scholar] [CrossRef] [Green Version]

- Kemppainen, A.J.; Shonnard, D.R. Comparative life-cycle assessments for biomass-to-ethanol production from different regional feedstocks. Biotechnol. Prog. 2005, 21, 1075–1084. [Google Scholar] [CrossRef] [PubMed]

- Fu, G.Z.; Chan, A.W.; Minns, D.E. Life cycle assessment of bio-ethanol derived from cellulose. Int. J. Life Cycle Assess. 2003, 8, 137–141. [Google Scholar] [CrossRef]

- Melamu, R.; von Blottnitz, H. 2nd Generation biofuels a sure bet? A life cycle assessment of how things could go wrong. J. Clean. Prod. 2011, 19, 138–144. [Google Scholar] [CrossRef]

- Stephenson, A.L.; Dupree, P.; Scott, S.A.; Dennis, J.S. The environmental and economic sustainability of potential bioethanol from willow in the UK. Bioresour. Technol. 2010, 101, 9612–9623. [Google Scholar] [CrossRef]

- Muñoz, I.; Flury, K.; Jungbluth, N.; Rigarlsford, G.; Milà i Canals, L.; King, H. Life cycle assessment of bio-based ethanol produced from different agricultural feedstocks. Int. J. Life Cycle Assess. 2014, 19, 109–119. [Google Scholar] [CrossRef]

- Olukoya, I.A.; Ramachandriya, K.D.; Wilkins, M.R.; Aichele, C.P. Life cycle assessment of the production of ethanol from eastern redcedar. Bioresour. Technol. 2014, 173, 239–244. [Google Scholar] [CrossRef]

- Maga, D.; Thonemann, N.; Hiebel, M.; Sebastião, D.; Lopes, T.F.; Fonseca, C.; Gírio, F. Comparative life cycle assessment of first- and second-generation ethanol from sugarcane in Brazil. Int. J. Life Cycle Assess. 2019, 24, 266–280. [Google Scholar] [CrossRef] [Green Version]

- Cherubini, F.; Strømman, A.H.; Ulgiati, S. Influence of allocation methods on the environmental performance of biorefinery products—A case study. Resour. Conserv. Recycl. 2011, 55, 1070–1077. [Google Scholar] [CrossRef]

- Boulay, A.M.; Bare, J.; Benini, L.; Berger, M.; Lathuillière, M.J.; Manzardo, A.; Margni, M.; Motoshita, M.; Núñez, M.; Pastor, A.V.; et al. The WULCA consensus characterization model for water scarcity footprints: Assessing impacts of water consumption based on available water remaining (AWARE). Int. J. Life Cycle Assess. 2018, 23, 368–378. [Google Scholar] [CrossRef] [Green Version]

- de Baan, L.; Alkemade, R.; Koellner, T. Land use impacts on biodiversity in LCA: A global approach. Int. J. Life Cycle Assess. 2013, 18, 1216–1230. [Google Scholar] [CrossRef]

- Müller-wenk, R.; Brandão, M. Climatic impact of land use in LCA—Carbon transfers between vegetation/soil and air. Int. J. Life Cycle Assess. 2010, 15, 172–182. [Google Scholar] [CrossRef]

- Brandão, M.; Milà i Canals, L. Global characterisation factors to assess land use impacts on biotic production. Int. J. Life Cycle Assess. 2013, 18, 1243–1252. [Google Scholar] [CrossRef]

- Saad, R.; Koellner, T.; Margni, M. Land use impacts on freshwater regulation, erosion regulation, and water purification: A spatial approach for a global scale level. Int. J. Life Cycle Assess. 2013, 18, 1253–1264. [Google Scholar] [CrossRef]

- Spatari, S.; Bagley, D.M.; MacLean, H.L. Life cycle evaluation of emerging lignocellulosic ethanol conversion technologies. Bioresour. Technol. 2010, 101, 654–667. [Google Scholar] [CrossRef] [PubMed]

| Reference/Authors and Reference Number as Required by Energies | Biomass Source | Location | System Boundary | Functional Unit | Data Source/Type of Collected Data | Software | LCIA Method/Type | Allocation Method |

|---|---|---|---|---|---|---|---|---|

| [20] | Sweet potato | China | Cradle-gate | Ethanol product | Industry, GREET | ND | CML | ND |

| [21] | Sugarcane | Brazil | Cradle-gate | Ethanol product | Industry | SimaPro | Ecoindicator | Mass, energy |

| [16] | Wheat | Germany | Cradle-gate | Ethanol product | Experimental data, Lean database | GaBi | CML | ND |

| [22] | Corn grain | USA | Cradle-grave | Ethanol product | GREET, NREL, DEAM database | ND | TRACI, IPCC | System expansion |

| [23] | Sugarcane | Brazil | Cradle-grave | Caloric value | Ecoinvent, process simulation | SimaPro | TRACI, EDIP, IMPACT 2002, Ecological scarcity 2006, ReCiPe, CML, Ecoindicator | Energy |

| [24] | Wheat, sugar beet | Germany | Cradle-gate | Caloric value | Industry, ecoinvent | Umberto | ReCiPe, CED | Energy |

| [19] | Corn grain | Argentina | Cradle-gate | Caloric value | Industry, ecoinvent, NREL | SimaPro | ReCiPe, Ecoindicator | Economic |

| [25] | Sugarcane | Brazil | Cradle-grave | Driving distance | PestLCI software, industry, simapro databases | SimaPro | EDIP | Energy |

| [26] | Sugarcane | Brazil | Cradle-grave | Driving distance | Ecoinvent, EIPRO database, | CMLCA | CML | Economic |

| [27] | Sweet potato | China | Cradle-gate | Ethanol product | GREET, on-site servey | ND | CML | Economic |

| [28] | Sugar beet | Greece | Cradle-gate | Caloric value | Industry, ecoinvent | SimaPro | CML | ND |

| [14] [29] | Poplar Sweet sorghum | Sweden, France, Italy, Spain, Slovakia China | Cradle-grave Cradle-gate | Driving distance Ethanol product | Aspen Plus GREET pilot plant | SimaPro ND | CML, Ecoindicator CML | System expansion, energy Energy, economic |

| [30] | Wheat straw | UK | Cradle-grave | Driving distance, ethanol product | Laboratory data, NREL | SimaPro | ReCiPe | Mass |

| [31] | Sweet sorghum | Mexico | Cradle-grave | Input biomass | Ecoinvent, Aspen Plus | SimaPro | CML | System expansion |

| [32] | Corn stover | Turkey | Cradle-grave | Driving distance | Ecoinvent, NREL | GaBi | IPCC, EDIP | ND |

| [33] | Willow | USA | Cradle-grave | Caloric value | GREET, Aspen Plus, NREL, ecoinvent | SimaPro | TRACI | Energy |

| [34] | Switchgrass | Austria | Gate-gate | Input biomass | Ecoinvent | SimaPro | CML, CED | ND |

| [13] | Woodchips | Canada | Gate-gate | Ethanol product | NREL, ecoinvent | SimaPro | Ecoindicator | ND |

| [35] | Corn stover, switchgrass | USA | Cradle-gate | Caloric value | GREET, ecoinvent, GaBi | ND | IPCC | ND |

| [36] | Corn stover, wheat straw | Austria | Cradle-gate | Input biomass | Ecoinvent, ETH-ESU 96 | SimaPro | CML | ND |

| [37] | Poplar | Spain | Cradle-grave | Driving distance | NREL, Experimental data | ND | CML | ND |

| [7] | Corn stover | Netherlands | Cradle-grave | Driving distance | NREL, EIPRO database, ecoinvent | CMLCA | CML | Energy, mass, economic |

| [18] | Black locust, eucalyptus and poplar | Spain, Italy | Cradle-grave | Driving distance | NREL, on-site survey, ecoinvent | CMLCA | CML | ND |

| [8] | Alfalfa, Ethiopian mustard, flax shive, hemp hurds and poplar | Spain | Cradle-grave | Driving distance | NREL, ecoinvent | ND | CML | Mass |

| [15] | Wheat straw | UK | Cradle-grave | Driving distance | NREL, EMEP-EEA Guidebook, Aspen Plus, ecoinvent, IPCC guidline | SimaPro | CML | Economic, system expansion |

| [38] | Hemp hurds | Spain | Cradle-grave | Driving distance | NREL, ecoinvent | ND | CML | Mass, economic |

| [39] | Fiber sorghum | Italy | Cradle-grave | Input biomass | Experimental data, ecoinvent, IPCC guidline | SimaPro | ReCiPe | ND |

| [40] | Arundo donax L. | Italy | Cradle-grave | Driving distance | Experimental data, ecoinvent, IPCC guidline | SimaPro | ReCiPe | Energy, economic |

| [17] | Wheat straw, forest residue, poplar, and miscanthus | UK | Cradle-gate | Ethanol product | NREL, Aspen Plus, ecoinvent, GEMIS model | GaBi | CML | Economic, system expansion |

| [41] | Cassava | Thailand | Cradle-gate | Ethanol product | Industry, ecoinvent | SimaPro | CML | Energy |

| [42] | Switchgrass | Netherlands | Cradle-gate | Driving distance | NREL, ecoinvent | CMLCA | CML | Energy, economic |

| [43] | Flax shives | Spain | Cradle-grave | Ethanol product | NREL, on-site survey, ecoinvent | CMLCA | CML | Mass, economic |

| [44] | Alfalfa stems | Spain | Cradle-grave | Driving distance | NREL, ecoinvent | CMLCA | CML | Mass |

| [45] | Bagasse | South Africa | Cradle-gate | Input biomass | Industry, TEAM database | TEAM | CML | ND |

| [46] | Brassica carinata | Spain | Cradle-grave | Driving distance, ethanol product | NREL, on-site survey, ecoinvent, EIPRO database | CMLCA | CML | not used |

| [47] | Willow | Sweden | Cradle-gate | Input biomass | NREL, ecoinvent, on-site survey, Aspen Plus | SimaPro | CML | Economic |

| [48] | Eucalyptus | Spain | Cradle-grave | Driving distance | NREL, ecoinvent, on-site survey | CMLCA | CML | ND |

| [49] | Cassava straw, cassava root | China | Cradle-gate | Ethanol product | NREL, Aspen Plus | GaBi | CML | ND |

| [50] | Bagasse | India | Gate-gate | Input biomass | EPA, NREL, Aspen Plus, TEAM databases | TEAM | CML, IPCC | ND |

| [51] | Bagasse, Sugarcane | Brazil | Cradle-gate | Ethanol product | Industry, NREL, Aspen Plus | SimaPro | CML | Economic |

| [52] | Timber, recycled newsprint | USA | Cradle-gate | Ethanol product | Boustead model, NREL, Aspen Plus, USDA Forest Service database | EFRAT | Ecoindicator | ND |

| [53] | Hay, agricultural and forest wood waste | Canada | Cradle-grave | Driving distance | Ecoinvent | SimaPro | Ecoindicator | not used |

| [54] | Bagasse | South Africa | Cradle-gate | Caloric value | Industry, ecoinvent | SimaPro | IMPACT 2002 | System expansion |

| [55] | Willow | UK | Cradle-grave | Ethanol product | NREL, GaBi databases, Aspen HYSYS | GaBi | EDIP | System expansion, energy |

| [56] | Maize grain, maize stover, sugarcane, sugar beet and wheat | USA, Brazil, France | Cradle-gate | Ethanol product | Ecoinvent | SimaPro | ReCiPe | Economic |

| [57] | Eastern redcedar, corn grain | USA | Cradle-gate | Caloric value | Ecoinvent, NREL, Aspen Plus | SimaPro | IMPACT 2002, BEES+ | System expansion |

| [58] | Sugarcane, bagasse | Brazil | Cradle-gate | Ethanol product | SuperPro Designer, CanaSoft model, ecoinvent, NREL | GaBi | ILCD 2011, Ecoindicator | Economic |

| Type of Collected Data | Data Source | Reference |

|---|---|---|

| Primary data for the agricultural activities | CanaSoft model | [58] |

| Emission data related to fossil fuel, combustion and auxiliary materials production | GREET model | [20,22,27,29,33,35] |

| Processes of bioethanol production | Aspen Plus, SuperPro Designer | [14,15,17,31,33,47,49,50,51,52,55,57,58] |

| Transportation, ethanol and electricity production, Agricultural data, facility and equipment design | NREL report | [7,8,13,15,17,18,19,22,30,32,33,37,38,42,43,44,46,47,48,49,50,51,52,55,57,58] |

| Emissions from capital goods production | EIPRO database | [7,26] |

| Emission from agricultural activities, fuel combustion and field operation | EMEP-EEA Guidebook | [15] |

| Emissions inventory | Boustead Model | [52] |

| Pesticide application emissions | PestLCI software | [25] |

| Software | Developer | Country |

|---|---|---|

| SimaPro | Pré-consultants | Netherland |

| GaBi | PE International | Germany |

| Umberto | Ifu Institute | Germany |

| TEAM | Ecobilan-PricewaterhouseCoopers | France |

| CMLCA | Institute of Environmental Sciences (CML), Leiden University | Netherland |

| EFRAT (Environmental Fate and Risk Assessment Tool) | Institute of Environmental Sciences (CML), Leiden University Department of Chemical Engineering and Department of Environmental Engineering at MichiganTech University | United States |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soleymani Angili, T.; Grzesik, K.; Rödl, A.; Kaltschmitt, M. Life Cycle Assessment of Bioethanol Production: A Review of Feedstock, Technology and Methodology. Energies 2021, 14, 2939. https://doi.org/10.3390/en14102939

Soleymani Angili T, Grzesik K, Rödl A, Kaltschmitt M. Life Cycle Assessment of Bioethanol Production: A Review of Feedstock, Technology and Methodology. Energies. 2021; 14(10):2939. https://doi.org/10.3390/en14102939

Chicago/Turabian StyleSoleymani Angili, Tahereh, Katarzyna Grzesik, Anne Rödl, and Martin Kaltschmitt. 2021. "Life Cycle Assessment of Bioethanol Production: A Review of Feedstock, Technology and Methodology" Energies 14, no. 10: 2939. https://doi.org/10.3390/en14102939