Experimental and CFD Investigation on the Application for Aerogel Insulation in Buildings

Abstract

1. Introduction

2. Properties of Aerogel

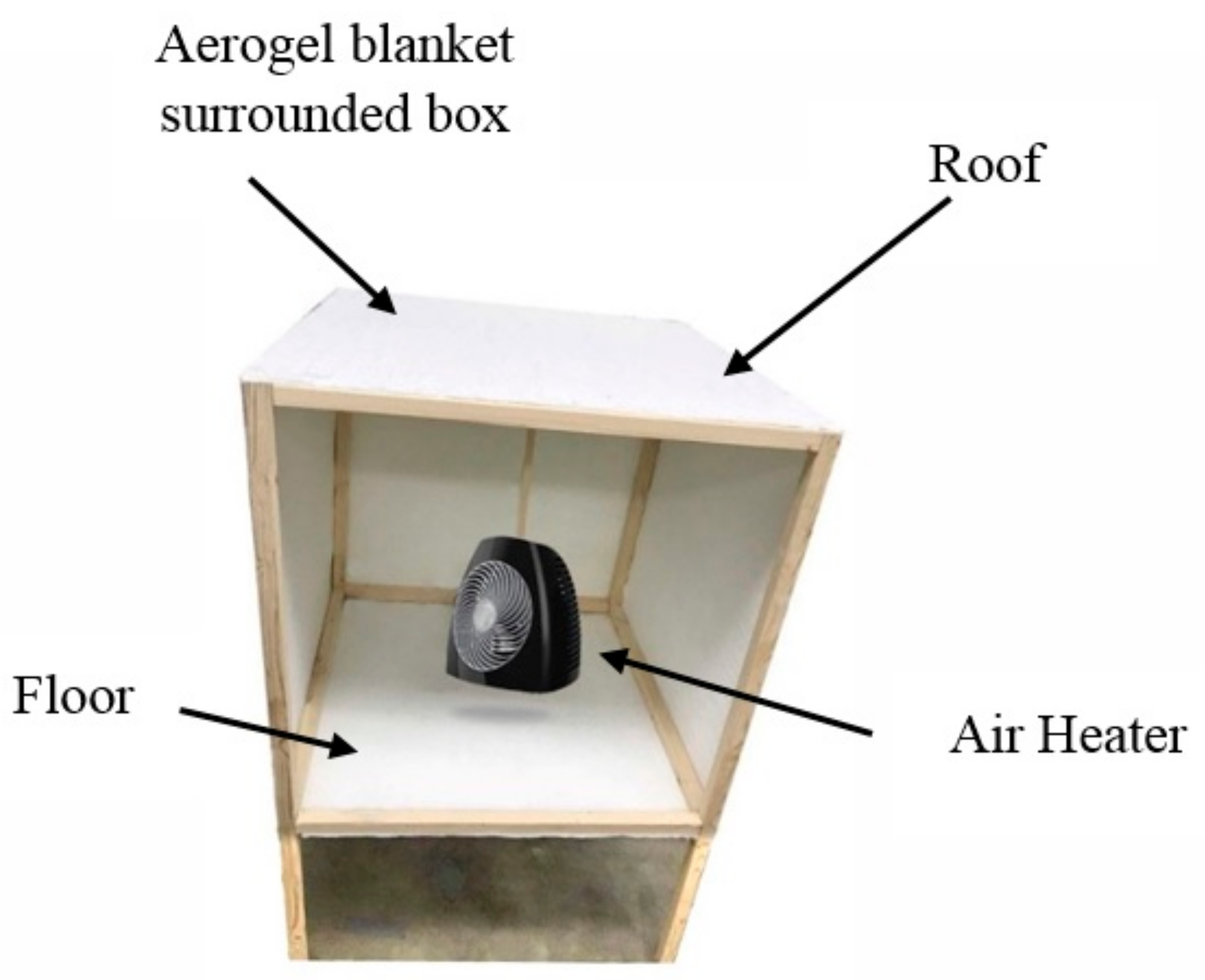

- Temperature deterioration of the inside wall of an aerogel-surrounded box.

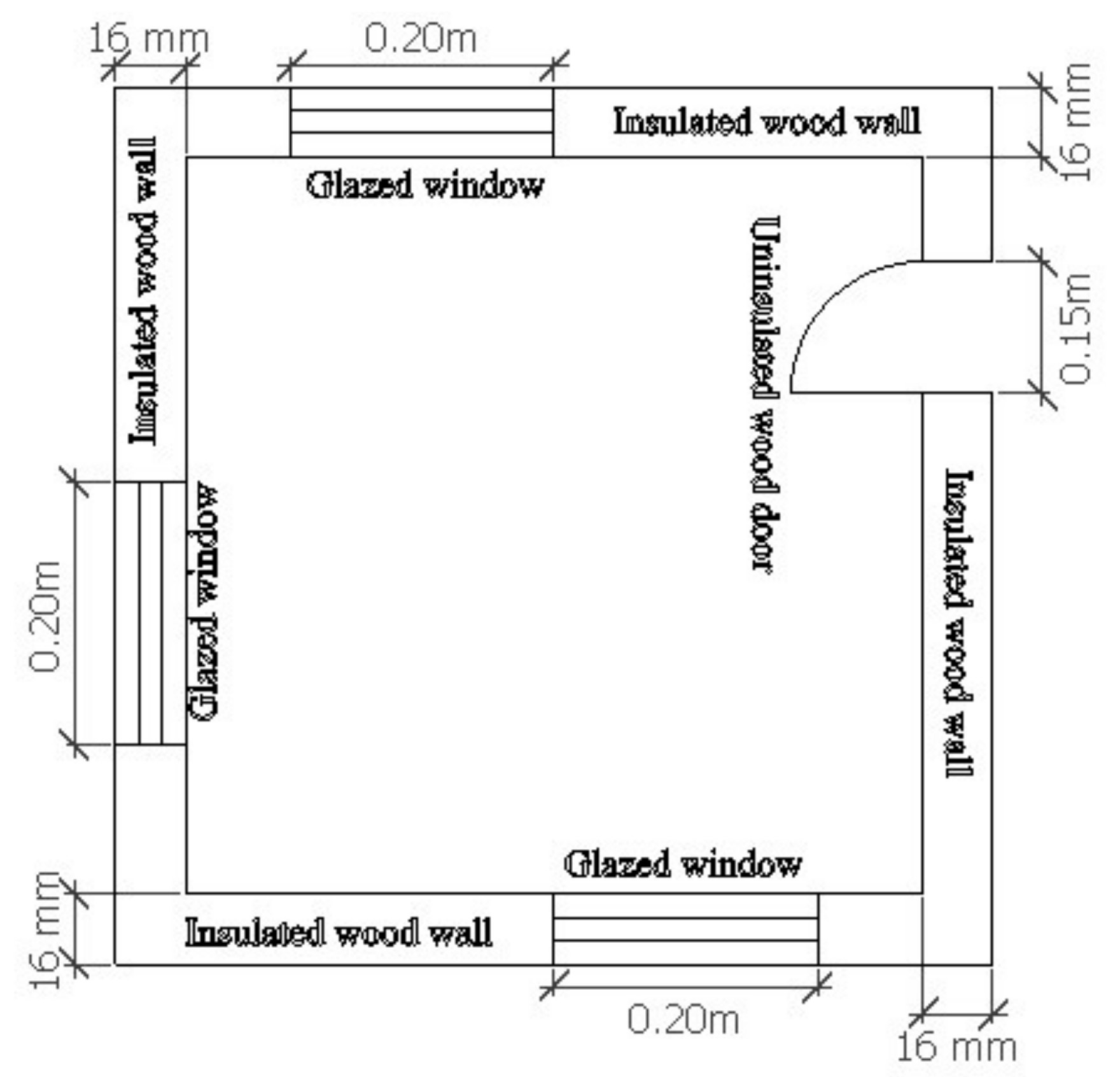

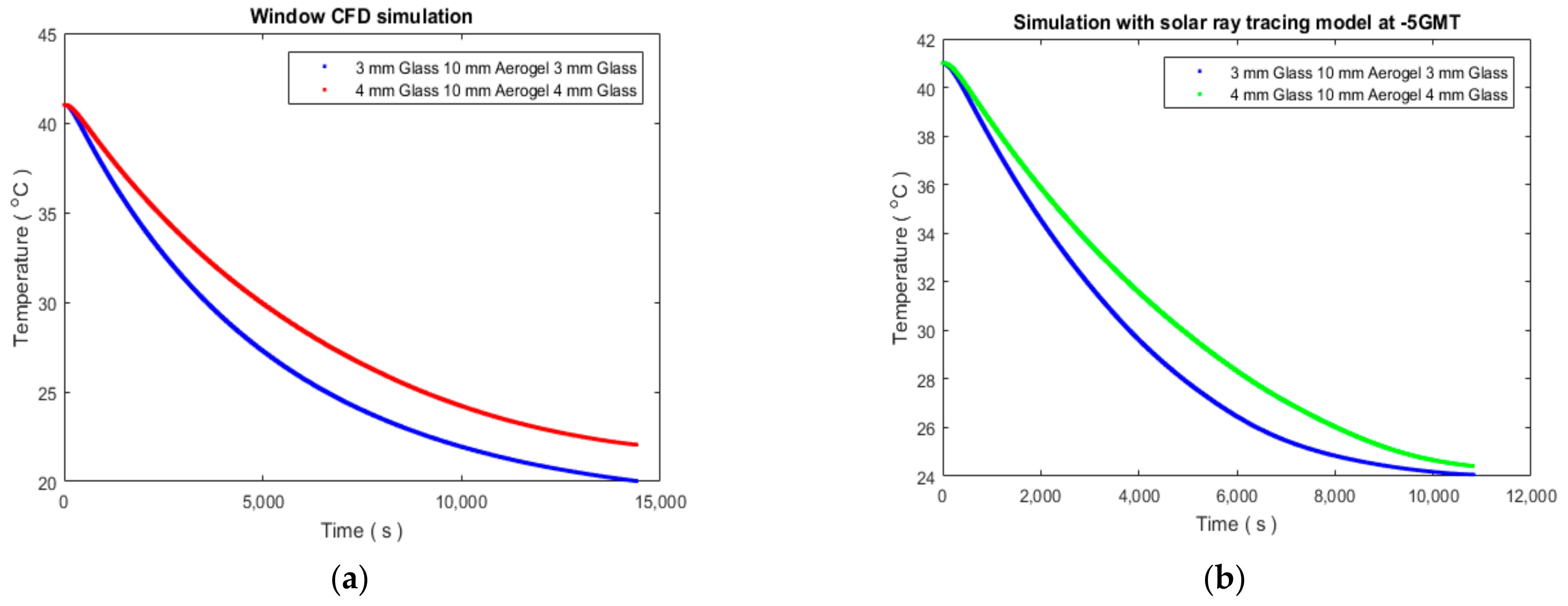

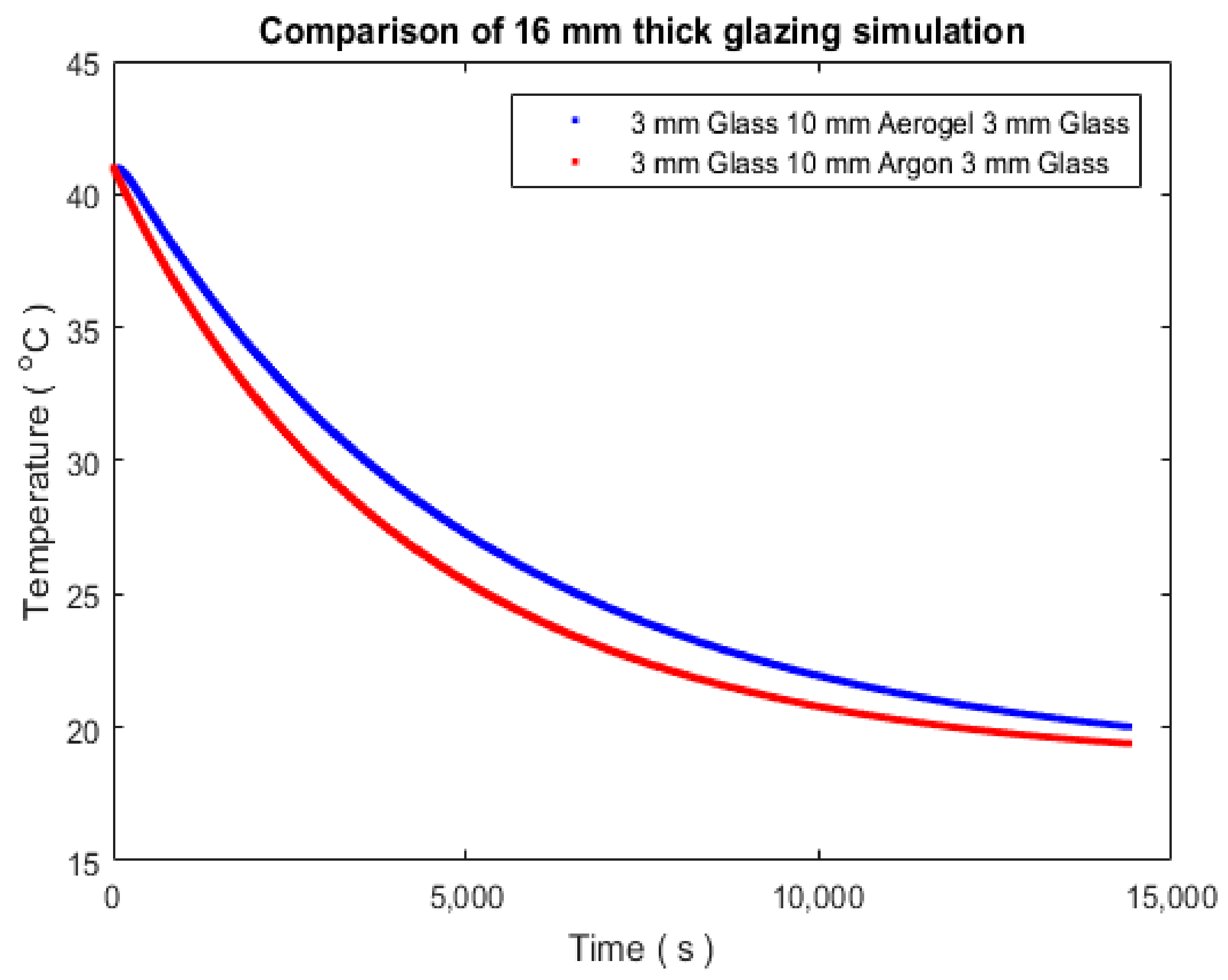

- Temperature decay of the inside wall of an aerogel-glazed window.

- Temperature degradation of the aerogel-insulated wall with an aerogel-glazed room.

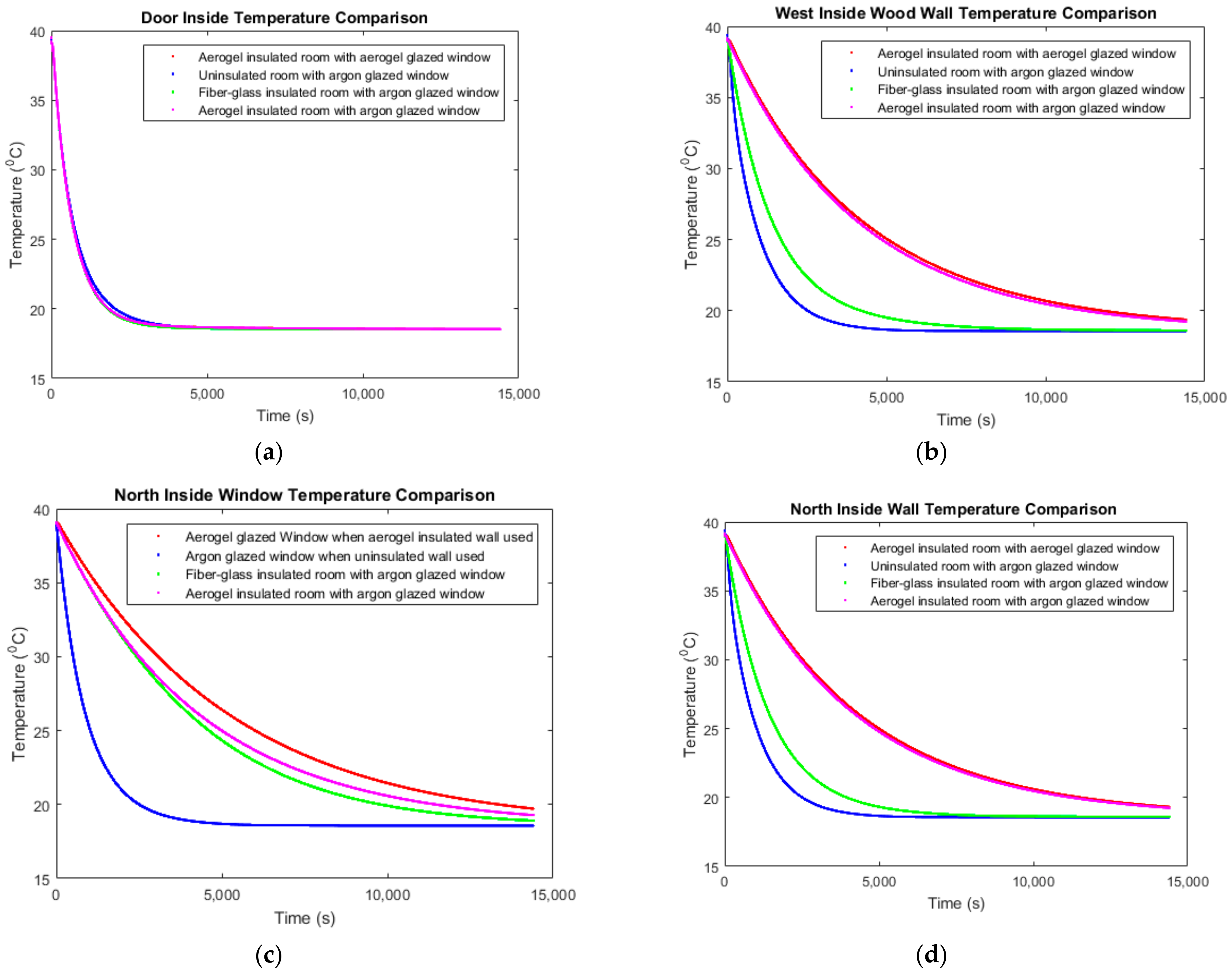

- Comparison between temperature deterioration of the aerogel insulated with aerogel-glazed room and argon-glazed with fiberglass-insulated room.

- Comparison of building energy consumption between aerogel- and fiberglass-insulated room.

3. Model Development

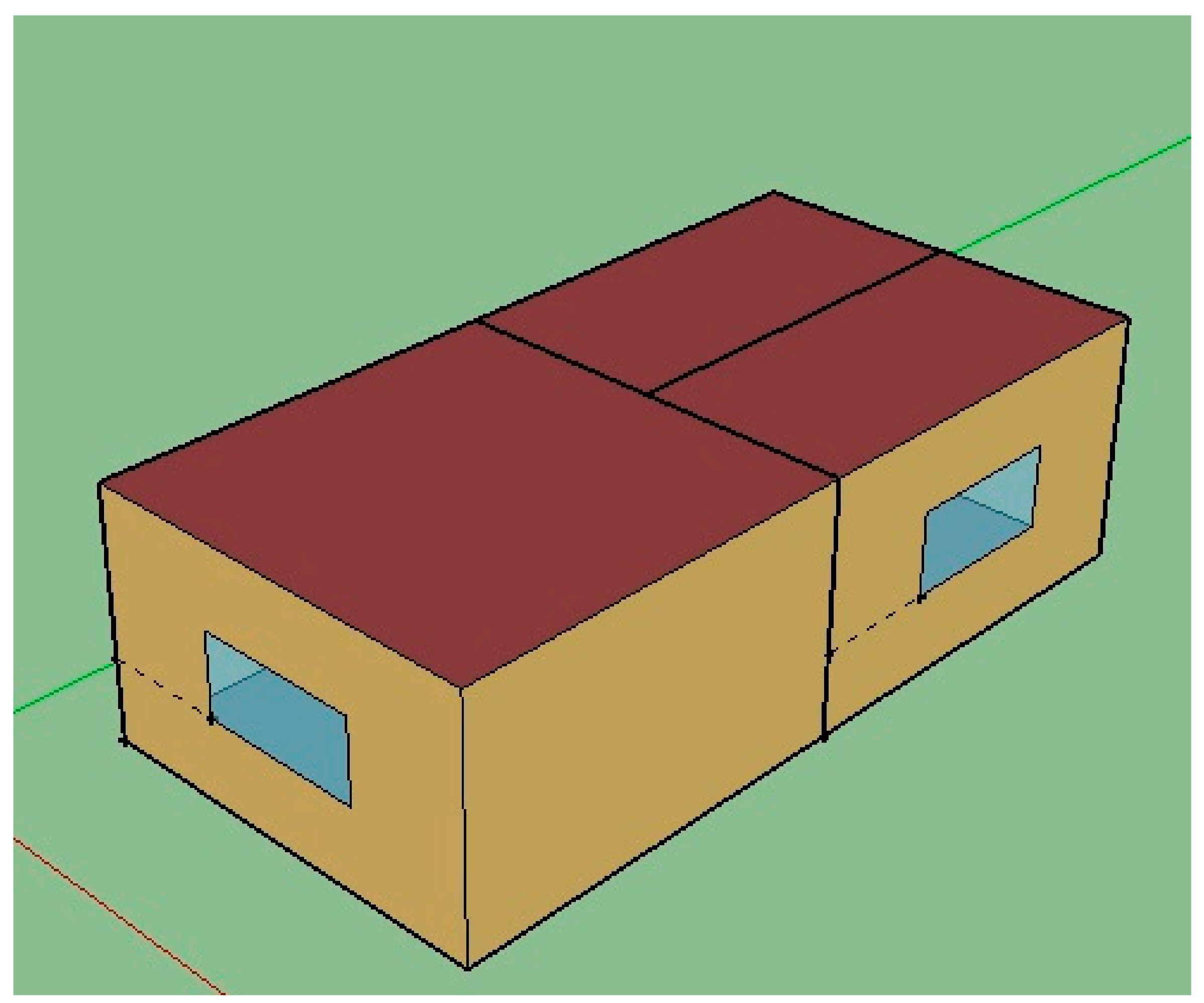

3.1. CFD Model

3.2. Auxiliary Equations for Radiation

3.3. Model Details and Boundary Conditions

- The laminar flow model is considered.

- The energy equation is used in the simulation.

- The surface-to-surface (S2S) radiation model is also considered in the simulation.

4. Results and Discussion

4.1. Experiment and Simulation Results for the Aerogel Blanket Surrounded Box

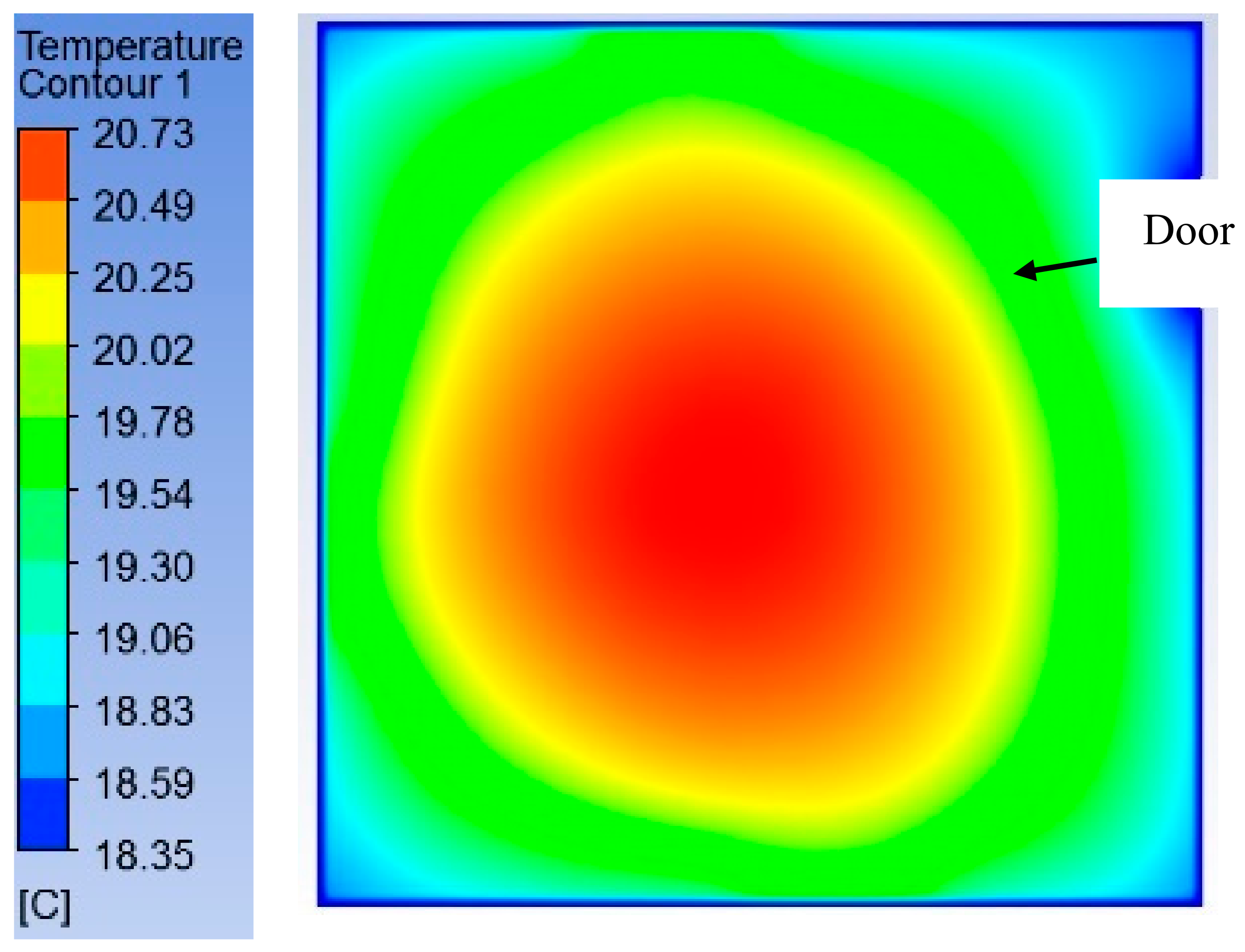

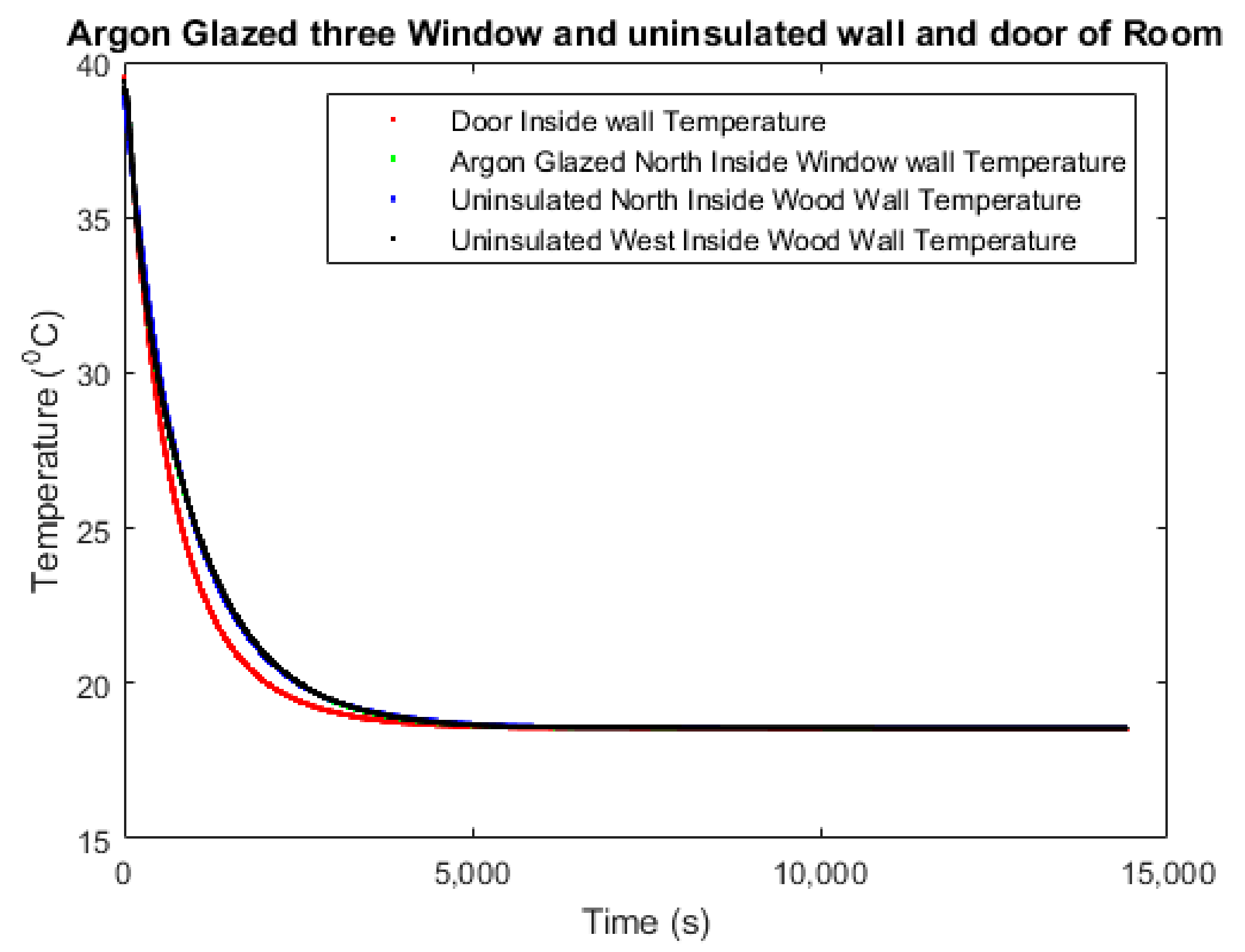

4.2. Simulation of a Room Considering Door and Window

4.3. EnergyPlus Simulation of an Office

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| U, V | Dimensional velocity component (m s−1) |

| Density (kg m−3) | |

| P | Dimensional pressure (Pa) |

| Kinematic viscosity (m2s−1) | |

| g | Acceleration due to gravity (9.81 ms−2) |

| Thermal diffusivity (m2s−1) | |

| Thermal expansion coefficient (Per kelvin (K−1) | |

| Temperature (Celsius/Kelvin/Fahrenheit) | |

| Reference temperature (Celsius/Kelvin/Fahrenheit) | |

| t | Time (Second/minute/hour) |

| x, y | Dimensional coordinates |

| Q | Heat Transfer (W) |

| A | Area (m2) |

| K | Thermal conductivity (Wm−1 K−1) |

| Energy flux that leaves from the surface (Wt) | |

| Emissivity | |

| Boltzmann constant (J K−1) | |

| Incident energy flux from surroundings (W) | |

| and | Solar irradiation |

| Ratio of sky diffuse radiation on a vertical surface | |

| Direct normal irradiation | |

| ϵ | Tilt angle |

| Ground reflectivity |

References

- Narayanan, R. Heat-driven cooling technologies. In Clean Energy for Sustainable Development; Academic Press: Cambridge, MA, USA, 2017; pp. 191–212. [Google Scholar] [CrossRef]

- Narayanan, R.; Halawa, E.; Jain, S. Performance characteristics of solid-desiccant evaporative cooling systems. Energies 2018, 11, 2574. [Google Scholar] [CrossRef]

- Uriarte, I.; Erkoreka, A.; Eguia, P.; Granada, E.; Martin-Escudero, K. Estimation of the heat loss coefficient of two occupied residential buildings through an average method. Energies 2020, 13, 5724. [Google Scholar] [CrossRef]

- Rasmussen, C.; Bacher, P.; Cali, D.; Nielsen, H.A.; Madsen, H. Method for scalable and automatized thermal building performance documentation and screening. Energies 2020, 13, 3866. [Google Scholar] [CrossRef]

- Narayanan, R.; Halawa, E.; Jain, S. Dehumidification potential of a solid desiccant based evaporative cooling system with an enthalpy exchanger operating in subtropical and tropical climates. Energies 2019, 12, 2704. [Google Scholar] [CrossRef]

- Rucinska, J.; Trzaski, A. Measurements and simulation study of daylight availability and its impact on the heating, cooling and lighting energy demand in an educational building. Energies 2020, 13, 2555. [Google Scholar] [CrossRef]

- GhaffarianHoseini, A.; Dahlan, N.; Berardi, U.; GhaffarianHoseini, A.; Makaremi, N. Sustainable energy performances of green buildings: A review of current theories, implementations and challenges. Renew. Sustain. Energy Rev. 2013, 25, 1–17. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, state-of-the-art and future and future thermal building insulation materials and solutions—Properties, requirements and possibilities. Energy Build. 2011, 4, 2549–2563. [Google Scholar] [CrossRef]

- Heinemann, U. Long-Term Performance of Super-Insulating Materials in Building Components and Systems; Energy in Building and Communities Program; International Energy Agency: Paris, France, 2020. [Google Scholar]

- Husing, N.; Schubert, U. Aerogels–airy materials: Chemistry, structure and properties. Angew. Chem. Int. Ed. 1998, 2, 22–45. [Google Scholar] [CrossRef]

- Jelle, B.; Hynd, A.; Gustavsen, A.; Arasteh, D.; Goudey, H.; Hart, R. Fenestration of today and tomorrow: A state–of–the–art review and future research opportunities. Sol. Energy Mater. Sol. Cells 2012, 96, 1–28. [Google Scholar] [CrossRef]

- Berardi, U. Development of glazing system with silica aerogel. Energy Procedia 2015, 78, 394–399. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Aerogel insulation for building applications: A state-of-the-art review. Energy Build. 2011, 43, 761–769. [Google Scholar] [CrossRef]

- Lucci, E.; Becherini, F.; Di Tuccio, M.C.; Troi, A.; Frick, J.; Roberti, F.; Hermann, C.; Fairnington, I.; Mezzasalma, G.; Pockelé, L.; et al. Thermal performance evaluation and comfort assessment of advanced aerogel as blown-in insulation for historic buildings. Build. Environ. 2017, 122, 258–268. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Wood, C.J.; Riffat, S.B. Optimizing insulation thickness and analyzing environmental impacts of aerogel-based thermal superinsulation in buildings. Energy Build. 2014, 77, 28–39. [Google Scholar] [CrossRef]

- Mujeebu, M.A.; Ashraf, N.; Alsuwayigh, A. Energy performance and economic viability of nano aerogel glazing and nano vacuum insulation panel in multi-story office building. Energy 2016, 113, 949–956. [Google Scholar] [CrossRef]

- Li, D.; Zhang, C.; Li, Q.; Liu, C.; Arici, M.; Wu, Y. Thermal performance evaluation of glass window combining silica aerogels and phase change materials for cold climate of China. Appl. Therm. Eng. 2020, 165, 114–547. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, H.; Yang, L.; Xu, T.; Ding, Y.; Fu, P. Thermal and day-lighting performance of aerogel glazing system in large atrium building under cooling-dominant climates. Energy Procedia 2019, 158, 6347–6357. [Google Scholar] [CrossRef]

- Zhao, X.; Mofid, S.A.; Al Hulayel, M.R. Reduced-scale hot box method for thermal characterization of window insulation materials. Appl. Therm. Eng. 2019, 160, 114026. [Google Scholar] [CrossRef]

- Paulos, J.; Berardi, U. Optimizing the thermal performance of window frames through aerogel enhancements. Appl. Energy 2020, 266, 114–776. [Google Scholar] [CrossRef]

- Leung, C.K.; Lu, L.; Liu, Y.; Cheng, H.S.; Tse, J.H. Optical and thermal performance analysis of aerogel glazing technology in a commercial building of Hong Kong. Energy Built Environ. 2020, 1, 215–223. [Google Scholar] [CrossRef]

- Berardi, U.; Kisilewicz, T.; Kim, S. Experimental and numerical investigation of the thermal transmittance of PVC window frames with silica aerogel. J. Build. Eng. 2020, 32, 101–665. [Google Scholar] [CrossRef]

- Lolli, N.; Andresen, I. Aerogel vs. Argon insulation in windows: A greenhouse gas emissions analysis. Build. Environ. 2016, 101, 64–76. [Google Scholar] [CrossRef]

- An, L.; Wang, J.; Petit, D.; Armstrong, J.N.; Li, C.; Hu, Y.; Huang, Y.; Shao, Z.; Ren, S. A scalable cross-linked fiberglass-aerogel thermal insulation composite. Appl. Mater. Today 2020, 21, 100843. [Google Scholar] [CrossRef]

- An, L.; Wang, J.; Petit, D.; Armstrong, J.N.; Li, C.; Hu, Y.; Huang, Y.; Shao, Z.; Ren, S. An all-ceramic, anisotropic and flexible aerogel insulation material. Nano Lett. 2020, 20, 3828–3835. [Google Scholar] [CrossRef]

- Yang, R.; Hu, F.; An, L.; Armstrong, J.H.; Hu, Y.; Li, C.; Huang, Y.; Ren, S. A hierarchical mesoporous insulation ceramic. Nano Lett. 2020, 20, 1110–1116. [Google Scholar] [CrossRef]

- Merli, F.; Anderson, A.M.; Carroll, M.K.; Buratti, C. Acoustic measurements on monolithic aerogel samples and application of the selected solutions to standard window system. Appl. Acoust. 2018, 142, 123–131. [Google Scholar] [CrossRef]

- Gopi, S.; Balakrishnan, P.; Geethamma, V.G.; Pius, A.; Thomas, S. Applications of cellulose nanofibrils in drug delivery. In Applications of Nanocomposite Materials in Drug Delivery; Woodhead Publishing Series in Biomaterials; Woodhead Publishing: Sawston, UK, 2018; pp. 75–95. [Google Scholar]

- Jensen, K.I.; Shultz, J.M.; Kristiansen, F.H. Development of windows based on highly inslating aerogel glazings. J. Non-Cryst. Solids 2004, 350, 351–357. [Google Scholar] [CrossRef]

- Buratii, C.; Merli, F.; Moretti, E. Aerogel-based materials for building applications: Influence of granule size on thermal and acoustic performance. Energy Build. 2017, 152, 472–482. [Google Scholar] [CrossRef]

- Spaceloft Insulation Technical Guide. Aspen Aerogels. Available online: http://www.aerogel.uk.com/Spaceloft_Technical_Guide_1%20.pdf (accessed on 4 January 2021).

- ANSYS, Inc. ANSYS Fluent Theory Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2020. [Google Scholar]

- Riffat, S.B.; Qiu, G. A review of state-of-art aerogel application in buildings. Int. J. Low-Carbon Technol. 2012, 8, 1–6. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Wood, C.J.; Riffat, S.B. Toward aerogel based thermal superinsulation in buildings: A comprehensive review. Renew. Sustain. Energy Rev. 2014, 34, 273–299. [Google Scholar] [CrossRef]

- Omer, S.A.; Riffat, S.B.; Qiu, G. Technical note: Thermal insulation for hot water cylinders: A review and a conceptual evaluation. Build. Serv. Eng. Res. Technol. 2007, 28, 275–293. [Google Scholar] [CrossRef]

- Buy Aerogel. Available online: http://www.buyaerogel.com/product/spaceloft/#:~:text=Great%20for%20home%20insulation%2C%20winter,69%20g%20per%20square%20foot (accessed on 4 January 2021).

- Holman, J.P. Heat Transfer, 10th ed.; McGraw-Hill: New York, NY, USA, 2009. [Google Scholar]

- Young, H.D.; Freedman, R.A.; Ford, A.L.; Sandin, T.R. Sears and Zemansky’s University Physics, 10th ed.; Addison Wesley Longman: Boston, MA, USA, 1999. [Google Scholar]

- Aldawi, F.; Alam, F. Residential building wall systems: Energy efficiency and carbon footprint. In Thermofluid Modeling for Energy Efficiency Applications; Academic Press: Cambridge, MA, USA, 2016; pp. 169–196. [Google Scholar] [CrossRef]

- Gao, G.; Li, Y.; Jing, Z.; Yuan, S. Experimental investigation on thermal physical properties on an advanced glass fiber composite material. Phys. Procedia 2012, 25, 339–344. [Google Scholar] [CrossRef][Green Version]

- Holman, J.P. Heat Transfer, 9th ed.; McGraw-Hill: New York, NY, USA, 2002. [Google Scholar]

- Cushman, B.; Beckers, J.-M. Introduction to geophysical fluid dynamics. Int. Geophys. 2011, 101, 99–129. [Google Scholar]

- Lawrence Berkeley National Laboratory, EnergyPlus Engineering Reference, 30 September 2016, p. 149. Available online: https://energyplus.net/sites/all/modules/custom/nrel_custom/pdfs/pdfs_v8.6.0/EngineeringReference.pdf (accessed on 4 January 2021).

| Material/Gas | Density (kg m−3) | Specific Heat (J kg−1 K−1) | Thermal Conductivity (W m−1 K−1) |

|---|---|---|---|

| Space loft aerogel | 150 | 1000 | 0.014 |

| Glass | 2700 | 840 | 0.8 |

| Argon | 1.6228 | 520.64 | 0.0158 |

| Air | 1.225 | 1006.43 | 0.0242 |

| Wood | 700 | 2310 | 0.173 |

| Fiber Glass | 12 | 1620 | 0.04 |

| Description | U-Value (Wm−2K−1) | Solar Heat Gain Coefficient (SHGC) | Transmittance (Tvis) |

|---|---|---|---|

| Aerogel-glazing (1 mm aerogel particle with 16 mm filling-thickness) | 2.065 | 0.346 | 0.058 |

| 3 mm standard glass | 5.8 | 0.87 | 0.86 |

| Aspect | Aerogel-Insulated Office | Fiberglass-Insulated Office | Energy Reduction by Using Aerogel Insulation | Energy Consumption Reduction (%) |

|---|---|---|---|---|

| Cooling (kWh) | 4088.57 | 4344.67 | 256.1 | 6 |

| Interior light (kWh) | 1723.81 | 1723.81 | 0 | 0 |

| Interior Equipment (kWh) | 3126.92 | 3126.92 | 0 | 0 |

| Fans (kWh) | 157.26 | 165.37 | 8.11 | 5 |

| HVAC (kW m−2) | 84.92 | 90.20 | 5.28 | 6 |

| Aspect | Aerogel-Insulated Office | Fiberglass-Insulated Office | Energy Reduction by Using Aerogel Insulation | Energy Consumption Reduction (%) |

|---|---|---|---|---|

| Cooling (W) | 1754.88 | 2129.65 | 374.77 | 18 |

| Interior light (W) | 479.53 | 479.53 | 0 | 0 |

| Interior Equipment (W) | 493.91 | 493.91 | 0 | 0 |

| Fans (W) | 45.96 | 54.33 | 8.37 | 15 |

| Aspect | Aerogel-Insulated Office | Fiberglass-Insulated Office | Energy Reduction by Using Aerogel Insulation | Energy Consumption Reduction (%) |

|---|---|---|---|---|

| Cooling (kWh) | 12,948.51 | 13,759.58 | 811.07 | 6 |

| Interior light (kWh) | 5459.31 | 5459.31 | 0 | 0 |

| Interior Equipment (kWh) | 9902.97 | 9902.97 | 0 | 0 |

| Fans (kWh) | 498.04 | 523.74 | 25.7 | 5 |

| Aspect | Aerogel-Insulated Office | Fiberglass-Insulated Office | Energy Reduction by Using Aerogel Insulation (%) |

|---|---|---|---|

| Cooling (kWh) | 258.97 | 275.19 | 6 |

| Interior light (kWh) | 109.19 | 109.19 | 0 |

| Interior Equipment (kWh) | 198.06 | 198.06 | 0 |

| Fans (kWh) | 9.96 | 10.47 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golder, S.; Narayanan, R.; Hossain, M.R.; Islam, M.R. Experimental and CFD Investigation on the Application for Aerogel Insulation in Buildings. Energies 2021, 14, 3310. https://doi.org/10.3390/en14113310

Golder S, Narayanan R, Hossain MR, Islam MR. Experimental and CFD Investigation on the Application for Aerogel Insulation in Buildings. Energies. 2021; 14(11):3310. https://doi.org/10.3390/en14113310

Chicago/Turabian StyleGolder, Santu, Ramadas Narayanan, Md. Rashed Hossain, and Mohammad Rofiqul Islam. 2021. "Experimental and CFD Investigation on the Application for Aerogel Insulation in Buildings" Energies 14, no. 11: 3310. https://doi.org/10.3390/en14113310

APA StyleGolder, S., Narayanan, R., Hossain, M. R., & Islam, M. R. (2021). Experimental and CFD Investigation on the Application for Aerogel Insulation in Buildings. Energies, 14(11), 3310. https://doi.org/10.3390/en14113310