Thermal Characterization of Recycled Materials for Building Insulation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Materials

2.2. Sample Preparation and Conditioning

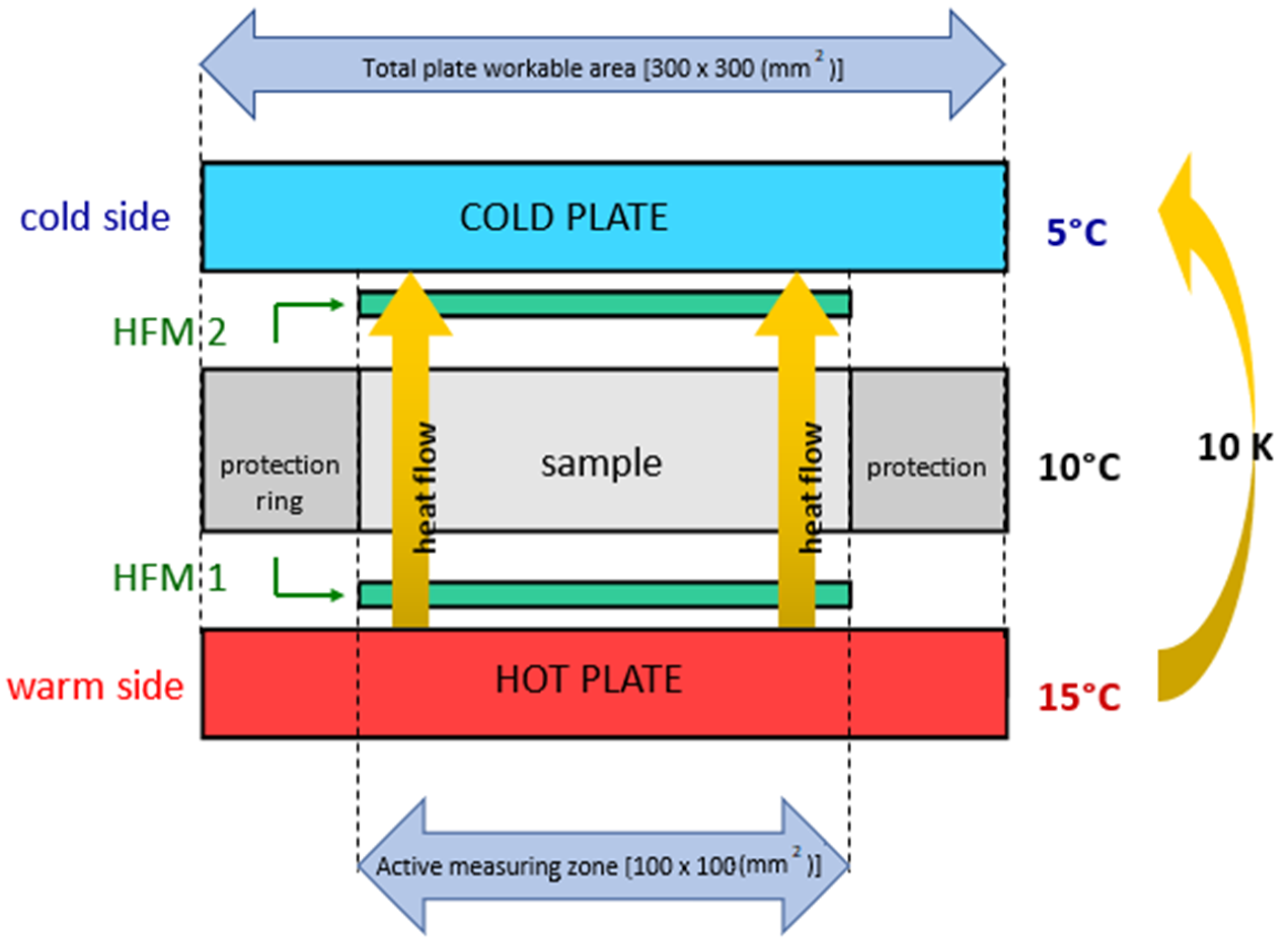

2.3. Thermal Conductance Measurement

3. The Case-Study Building

4. Results and Discussion

4.1. Thermal Characterization of the Analyzed Material

4.2. Influence of the Moisture Content

4.3. Energy Performance Analysis Applied to the Case Study

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Moussa, T.; Maalouf, C.; Ingrao, C.; Scrucca, F.; Costantine, G.; Asdrubali, F. Bio-based and recycled-waste materials in buildings: A study of energy performance of hemp-lime concrete and recycled-polyethylene terephthalate façades for office facilities in France and Italy. Sci. Technol. Built Environ. 2018, 24, 492–501. [Google Scholar] [CrossRef]

- Filippín, C. Benchmarking the Energy Efficiency and Greenhouse Gases Emissions of School Buildings in Central Argentina. Build Environ. 2000, 35, 407–414. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Pardo, N.; Thiel, C. Evaluation of several measures to improve the energy efficiency and CO2 emission in the European single-family houses. Energy Build. 2012, 49, 619–630. [Google Scholar] [CrossRef]

- Hadded, A.; Benltoufa, S.; Fayala, F.; Jemni, A. Thermo physical characterisation of recycled textile materials used for building insulating. J. Build. Eng. 2015, 5, 34–40. [Google Scholar] [CrossRef]

- Zhan, J.; Liu, W.; Wu, F.; Li, Z.; Wang, C. Life cycle energy consumption and greenhouse gas emissions of urban residential buildings in Guangzhou city. J. Clean. Prod. 2018, 194, 318–326. [Google Scholar] [CrossRef]

- World Resource Institute. Green House Protocol, Policy and Action Standard Commercial and Residential Buildings Sector Guidance Draft. 2015. Available online: https://ghgprotocol.org/sites/default/files/standards_supporting/Buildings%20-%20Additional%20Guidance.pdf (accessed on 25 April 2021).

- Pohoryles, D.A.; Maduta, C.; Bournas, D.A.; Kouris, L.A. Energy Performance of Existing Residential Buildings in Europe: A Novel Approach Combining Energy with Seismic Retrofitting. Energy Build. 2020, 223, 110024. [Google Scholar] [CrossRef]

- Junnila, S. The Environmental Impact of an Office Building throughout Its Life Cycle; Helsinki University of Technology: Espoo, Finland, 2004; ISBN 951-22-7285-7. [Google Scholar]

- Suzuki, M.; Oka, T. Estimation of life cycle energy consumption and CO2 emission of office buildings in Japan. Energy Build. 1998, 28, 33–41. [Google Scholar] [CrossRef]

- European Commission. Nearly Zero-Energy Buildings. 2014. Available online: https://ec.europa.eu/energy/topics/energy-efficiency/energy-efficient-buildings/nearly-zero-energy-buildings_en (accessed on 25 April 2021).

- Blom, I.; Itard, L.; Meijer, A. LCA-based environmental assessment of the use and maintenance of heating and ventilation systems in Dutch dwellings. Build Environ. 2010, 45, 2362–2372. [Google Scholar] [CrossRef]

- Joelsson, A.; Gustavsson, L. District Heating and Energy Efficiency in Detached Houses of Differing Size and Construction. Appl. Energy 2009, 86, 126–134. [Google Scholar] [CrossRef]

- Nemry, F.; Uihlein, A.; Colodel, C.M.; Wetzel, C.; Braune, A.; Wittstock, B.; Hasan, I.; Kreißig, J.; Gallon, N.; Niemeier, S.; et al. Options to reduce the environmental impacts of residential buildings in the European Union—Potential and costs. Energy Build. 2010, 42, 976–984. [Google Scholar] [CrossRef]

- Widén, J.; Nilsson, A.M.; Wäckelgård, E. A combined Markov-chain and bottom-up approach to modelling of domestic lighting demand. Energy Build. 2009, 41, 1001–1012. [Google Scholar] [CrossRef]

- Majumder, A.; Stochino, F.; Fraternali, F.; Martinelli, E. Seismic and Thermal Retrofitting of Masonry Buildings with Fiber Reinforced Composite Systems: A State of the Art Review. Int. J. Struct. Glass Adv. 2021, 5, 41–67. [Google Scholar] [CrossRef]

- Saba, N.; Paridah, T.; Mohammad, J. A Review on Potentiality of Nano Filler/Natural Fiber Filled Polymer Hybrid Composites. Polymers 2014, 6, 2247–2273. [Google Scholar] [CrossRef]

- Schiavoni, S.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Italian National Unification. UNI 10351: 2015 Building Materials and Products—Thermo Hygrometric Properties—Procedure for Choosing Project Values; UNI: Milan, Italy, 2015. (In Italian) [Google Scholar]

- European Commission—Renovation Wave: Doubling the Renovation Rate to cut Emissions, Boost Recovery and Reduce Energy Poverty. 14 October 2020. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_20_1835 (accessed on 25 April 2021).

- You, L.; Jin, D.; Guo, S.; Wang, J.; Dai, Q.; You, Z. Leaching evaluation and performance assessments of asphalt mixtures with recycled cathode ray tube glass: A preliminary study. J. Clean. Prod. 2021, 279, 123716. [Google Scholar] [CrossRef]

- Asadi, S.; Hassan, M.; Beheshti, A.; Berryman, C. Quantification of residential energy consumption reduction using glass-modified asphalt shingle. J. Archit. Eng. 2015, 21, B4015003. [Google Scholar] [CrossRef]

- Ferrandez-García, M.T.; Ferrandez-Garcia, C.E.; Garcia-Ortuño, T.; Ferrandez-Garcia, A.; Ferrandez-Villena, M. Study of Waste Jute Fiber Panels (Corchorus capsularis L.) Agglomerated with Portland cement and Starch. Polymers 2020, 12, 599. [Google Scholar] [CrossRef] [Green Version]

- Liu, K.; Fu, C.; Xu, P.; Li, S.; Huang, M. An eco-friendliness inductive asphalt mixture comprising waste steel shavings and waste ferrites. J. Clean. Prod. 2021, 283, 124639. [Google Scholar] [CrossRef]

- El Azhary, K.; Chihab, Y.; Mansour, M.; Laaroussi, N.; Garoum, M. Energy efficiency and thermal properties of the composite material clay-straw. Energy Procedia 2017, 141, 160–164. [Google Scholar] [CrossRef]

- Benmansour, N.; Boudjemaa, A.; Abdelkader, G.; Abdelhak, K.; Aberrahim, B. Thermal and Mechanical Performance of Natural Mortar Reinforced with Date Palm Fibers for Use as Insulating Materials in Building. Energy Build. 2014, 81, 98–104. [Google Scholar] [CrossRef]

- Elfordy, S.; Lucas, F.; Tancret, F.; Scudeller, Y.; Goudet, L. Mechanical and Thermal Properties of Lime and Hemp Concrete (‘hempcrete’) Manufactured by a Projection Process. Constr. Build Mater. 2008, 22, 2116–2123. [Google Scholar] [CrossRef]

- Valenza, A.; Fiore, V.; Nicolosi, A.; Rizzo, G.; Scaccianoce, G.; Di Bella, G. Effect of sheep wool fibers on thermal-insulation and mechanical properties of cement matrix. Acad. J. Civ. Eng. 2015, 33, 40–45. [Google Scholar] [CrossRef]

- Raut, A.N.; Gomez, C.P. Thermal and Mechanical Performance of Oil Palm Fiber Reinforced Mortar Utilizing Palm Oil Fly Ash as a Complementary Binder. Constr. Build Mater. 2016, 126, 476–483. [Google Scholar] [CrossRef]

- Zakaria, M.; Ahmed, M.; Hoque, M.M.; Islam, S. Scope of using jute fiber for the reinforcement of concrete material. Text. Cloth. Sustain. 2017, 2, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Mazhoud, B.; Viel, M.; Collet, F.; Phelipot-Mardelé, A.; Lanos, C.; Prétot, S. Is Hemp Lime Concrete a Mix of Hemp and Lime? Acad. J. Civ. Eng. 2017, 35, 422–431. [Google Scholar] [CrossRef]

- Collet, F.; Sylvie, P. Thermal Conductivity of Hemp Concretes: Variation with Formulation, Density and Water Content. Constr. Build Mater. 2014, 65, 612–619. [Google Scholar] [CrossRef] [Green Version]

- Prétot, S.; Collet, F.; Garnier, C. Life cycle assessment of a hemp concrete wall: Impact of thickness and coating. Build. Environ. 2014, 72, 223–231. [Google Scholar] [CrossRef] [Green Version]

- Arnaud, L.; Gourlay, E. Experimental Study of Parameters Influencing Mechanical Properties of Hemp Concretes. Constr. Build Mater. 2012, 28, 50–56. [Google Scholar] [CrossRef]

- European Committee for Standardization. Building lime. In Definitions, Specifications and Conformity Criteria; EN 459-1:2015; CEN: Brussels, Belgium, 2015. [Google Scholar]

- Italian National Unification. Methods of Test for Mortar for Masonry—Part 2: Bulk Sampling of Mortars and Preparation of Test Mortars; UNI EN 1015-2:2007; UNI: Milan, Italy, 2007. [Google Scholar]

- Italian National Unification. Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table); UNI EN 1015-3:2007; UNI: Milan, Italy, 2007. [Google Scholar]

- Italian National Unification. Thermal Performance of Building Materials and Products-Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods-Products of High and Medium Thermal Resistance; UNI EN 12667: 2002; UNI: Milan, Italy, 2002. [Google Scholar]

- International Organization for Standardization. Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus; ISO 8301:1991; ISO: Geneva, Switzerland, 1991. [Google Scholar]

- European Committee for Standardization. Thermal Performance of Building Products and Components—Specific Criteria for the Assessment of Laboratories Measuring Heat Transfer Properties—Part 3: Measurements by the Guarded Heat Flow Meter Method; EN 1946-3; CEN: Brussels, Belgium, 1999. [Google Scholar]

- European Committee for Standardization. Thermal Performance of Building Products and Components—Specific Criteria for the Assessment of Laboratories Measuring Heat Transfer Properties—Part 2: Measurements by Guarded Hot Plate Method; EN 1946-2:1999; CEN: Brussels, Belgium, 1999. [Google Scholar]

- Italian National Unification. Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of the Hot Plate with Guard Ring and the Heat Flow Meter Method—Thick Products with High and Medium Thermal Resistance; UNI EN 12939:2002; UNI: Milan, Italy, 2002. [Google Scholar]

- Italian National Unification. Energy Performance of Buildings—Energy Needs for Heating and Cooling, Internal Temperatures and Sensible and Latent Heat Loads—Part 1: Calculation Procedures; UNI EN ISO 52016-1:2018; UNI: Milan, Italy, 2018. [Google Scholar]

- Interministerial Decree—Application of the Methodologies for Calculating Energy Performance and Defining the Prescriptions and Minimum Requirements for Buildings; Italian Ministry of Economic Development: Rome, Italy, 2015.

| Binding Elements | Aggregating Material | Strengthening and Insulating Materials | |

|---|---|---|---|

| Lime | Sand | Sheep wool fibre | 3 cm (±2 mm) long |

| Opus signinum | Thistle fibre | 1 cm (±2 mm) long | |

| Clay | Hemp shives | 1 cm (±2 mm) long | |

| Jute fibre | 1 cm (±2 mm) long | ||

| Group | Sample Id. Number and Dimensions | Samples | Materials Used | Sample Composition Dry Weight [%] | Water to Binder Ratio [%] | Density [kg/m3] |

|---|---|---|---|---|---|---|

| Plaster with Recycled Materials | S13 |  | Lime putty | 44% | 32% | 1684.46 |

| (300 × 300 mm2) | Sand | 45% | ||||

| Calcium carbonate | 11% | |||||

| S10 |  | Lime putty & Opus signinum | 44% | 32% | 1793.1 | |

| (300 × 300 mm2) | Sand | 45% | ||||

| Calcium carbonate | 11% | |||||

| S12 |  | Lime putty | 41.50% | 33% | 1793.1 | |

| (300 × 300 mm2) | Opus signinum | 18.50% | ||||

| Sand | 40% | |||||

| S09 |  | Opus signinum | 44% | 32% | 1659.58 | |

| (300 × 300 mm2) | Sand | 45% | ||||

| Calcium carbonate | 11% | |||||

| Plaster with Natural Fibres | S14 |  | Sheep wool fibre | 3% | 39% | 1390.91 |

| Lime putty | 16% | |||||

| (300 × 300 mm2) | Opus signinum | 36% | ||||

| Sand | 35% | |||||

| Calcium carbonate | 9% | |||||

| S11 |  | Sheep wool fibre | 4% | 39% | 1114.61 | |

| Lime putty | 43% | |||||

| (300 × 300 mm2) | Sand | 42% | ||||

| Calcium carbonate | 11% | |||||

| S06 |  | Sheep Wool & Thistle fibres | 3% | 39% | 1101.48 | |

| Lime putty | 16% | |||||

| Opus signinum | 36% | |||||

| (100 × 100 mm2) | Sand | 35% | ||||

| Calcium carbonate | 9% | |||||

| S05 |  | Sheep Wool & Thistle fibres | 4% | 36% | 1206.06 | |

| Lime putty | 43% | |||||

| (100 × 100 mm2) | Sand | 42% | ||||

| Calcium Carbonate | 11% | |||||

| Building Insulation Materials with Natural Fibres | S08 |  | Hemp shives | 50.50% | 39% | 489.94 |

| (300 × 300 mm2) | Lime putty | 42.20% | ||||

| Opus signinum | 7.30% | |||||

| S07 |  | Hemp shives | 55% | 39% | 459.06 | |

| (300 × 300 mm2) | Lime putty | 45% | ||||

| C02 |  | Hemp shives | 30% | 39% | 436.6 | |

| (100 × 100 mm2) | Clay | 70% | ||||

| C01 (100 × 100 mm2) |  | Jute fibre Clay | 21% 79% | 39% | 807.41 |

| Sample Id. Number and Dimensions | Samples | Materials Used |

|---|---|---|

| S04 |  | Sheep wool and Lime putty |

| (100 × 100 mm2) | ||

| S03 |  | Hemp shives and Lime putty |

| (100 × 100 mm2) | ||

| S02 |  | Hemp shives, lime putty and opus signinum |

| (100 × 100 mm2) | ||

| S01 |  | Sheep wool, lime putty and opus signinum |

| (100 × 100 mm2) |

| Description | Thickness (cm) | |

|---|---|---|

| Case 1 | Opaque building envelope dispersing towards the outside with traditional plaster (lime and cement plaster) | 1.5 |

| Case 2 | Replacement of traditional plaster, using plaster with recycled materials (Opus signinum and lime putty), same specification as samples S9, S10, S12 and S13 (Table 2) | 1.5 |

| Case 3 | Replacement of traditional plaster, using plaster made up with natural fibres (sheep’s wool fibres, lime putty and opus signinum), same specification as samples S11 and S14 (Table 2) | 1.5 |

| Case 4 | Replacement of traditional plaster, using plaster made up with natural fibres (sheep wool and thistle fibres), lime putty and opus signum), same specification as samples S5 and S6 (Table 2) | 1.5 |

| Case 5 | Replacement of traditional plaster with building materials with natural fibres (hemp shives and clay), same specification as of samples C01 and C02 (Table 2) + 1.5 cm of clay plaster | 1.5 + 3 |

| Case 6 | Adding thermal insulation panel in sintered expanded polystyrene (EPS) in order to meet strict national regulations on the opaque building envelope | variable |

| Samples Tested | Reference Values in the Literature | ||||||

|---|---|---|---|---|---|---|---|

| Sample | Composition | Thermal Conductivity [W/(m·K)] | Materials Used | Thermal Conductivity [W/(m·K)] | Ref. | ||

| @10 °C | @20 °C | @30 °C | @20 °C | ||||

| Thermo-Insulating Natural Plaster with Recycled Materials | Traditional Plasters | ||||||

| S09 | Opus signinum paste | 0.458 | 0.464 | 0.471 | Pure gypsum plaster | 0.70 | [19] |

| S10 | Lime putty and Opus signinum | 0.463 | 0.469 | 0.476 | |||

| S13 | Lime putty | 0.470 | 0.475 | 0.479 | Lime & gypsum plaster | 0.90 | [19] |

| S12 | Lime putty and Opus signinum | 0.425 | 0.430 | 0.436 | |||

| Thermo-Insulating Retrofitting Plaster with Natural Fibres | Plasters and Mortars with Natural Fibres | ||||||

| S05 | Sheep Wool + Thistle fibres and Lime putty | 0.172 | 0.180 | 0.188 | Sicilian sheep wool (washed and unwashed) + Cement | 0.09–0.11 (with 46% wool 1–20 mm) | [28] |

| S06 | Sheep Wool + Thistle fibres, Lime putty and Opus signinum | 0.139 | 0.146 | 0.153 | |||

| S11 | Sheep wool and Lime putty | 0.248 | 0.257 | 0.266 | 0.15–0.25 (with 13% wool 1–20 mm) | ||

| S14 | Sheep Wool, Lime putty and Opus signinum | 0.265 | 0.272 | 0.280 | |||

| Building Insulation Materials with Natural Fibres | Building Materials with Natural Fibres | ||||||

| S07 | Hemp shives and Lime putty | 0.096 | 0.109 | 0.122 | Lime and hemp concrete (‘‘hempcrete’’) | 0.179–0.485 | [27] |

| S08 | Hemp shives, Lime putty, and Opus signinum | 0.093 | 0.107 | 0.121 | |||

| C01 | Hemp shives and clay | 0.124 | 0.139 | 0.151 | Straw and clay | 0.260–0.508 | [25] |

| Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | Case 6 | |

|---|---|---|---|---|---|---|

| Htr [W/K] | 302.03 | 294.24 | 294.24 | 288.56 | 279.07 | 259.73 |

| (%) | −2.6% | −2.6% | −4.5% | −7.6% | −14.0% | |

| Cagliari | ||||||

| EPH,nd [kWh/m2] | 83.10 | 80.62 | 78.8 | 76.61 | 78.10 | 64.04 |

| (%) | −3.0% | −5.2% | −7.8% | −6.0% | −22.9% | |

| EPC,nd [kWh/m2] | 5.51 | 5.70 | 5.90 | 6.07 | 5.95 | 5.84 |

| (%) | 3.4% | 7.1% | 10.2% | 8.0% | 6.0% | |

| Bolzano | ||||||

| EPH,nd [kWh/m2] | 172.70 | 167.79 | 164.20 | 159.89 | 162.83 | 130.69 |

| (%) | −2.8% | −4.9% | −7.4% | −5.7% | −24.3% | |

| EPC,nd [kWh/m2] | - | - | - | - | - | 0.11 |

| (%) | - | - | - | - | - | |

| Palermo | ||||||

| EPH,nd [kWh/m2] | 54.27 | 52.53 | 51.26 | 49.73 | 50.77 | 41.15 |

| (%) | −3.2% | −5.5% | −8.4% | −6.4% | −24.2% | |

| EPC,nd [kWh/m2] | 22.53 | 22.48 | 22.44 | 22.41 | 22.43 | 22.30 |

| (%) | −0.2% | −0.4% | −0.5% | −0.4% | −1.0% |

| Reference Case | Case 2 | Case 3 | Case 4 | Case 5 | ||

|---|---|---|---|---|---|---|

| Cagliari | EPH,nd [kWh/m2] | 64.04 | 64 | 63.95 | 63.88 | 63.47 |

| (%) | −0.1% | −0.1% | −0.2% | −0.9% | ||

| Bolzano | EPH,nd [kWh/m2] | 130.38 | 131.53 | 130.36 | 130.29 | 129.82 |

| (%) | 0.90% | 0% | −0.1% | −0.4% | ||

| Palermo | EPH,nd [kWh/m2] | 41.21 | 41.19 | 41.15 | 41.09 | 40.93 |

| (%) | 0.00% | −0.1% | −0.3% | −0.7% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Majumder, A.; Canale, L.; Mastino, C.C.; Pacitto, A.; Frattolillo, A.; Dell’Isola, M. Thermal Characterization of Recycled Materials for Building Insulation. Energies 2021, 14, 3564. https://doi.org/10.3390/en14123564

Majumder A, Canale L, Mastino CC, Pacitto A, Frattolillo A, Dell’Isola M. Thermal Characterization of Recycled Materials for Building Insulation. Energies. 2021; 14(12):3564. https://doi.org/10.3390/en14123564

Chicago/Turabian StyleMajumder, Arnas, Laura Canale, Costantino Carlo Mastino, Antonio Pacitto, Andrea Frattolillo, and Marco Dell’Isola. 2021. "Thermal Characterization of Recycled Materials for Building Insulation" Energies 14, no. 12: 3564. https://doi.org/10.3390/en14123564

APA StyleMajumder, A., Canale, L., Mastino, C. C., Pacitto, A., Frattolillo, A., & Dell’Isola, M. (2021). Thermal Characterization of Recycled Materials for Building Insulation. Energies, 14(12), 3564. https://doi.org/10.3390/en14123564