1. Introduction

Productivity in detecting and predicting the failure processes of thermal power plants has developed substantially over the years, improving proactive maintenance techniques (predictive and detective) based on the condition and automation control systems. Detection action, combined with rapid resource planning and execution of preventive and corrective activities, is fundamental to guarantee the failure rate and availability index of a generating unit within the regulatory agency’s limits. These indicators are not the only ones that make it possible to check the “quality” of a plant’s operation. However, they represent, in a simplified way, the number of hours that a device remained able to perform its function (when external resources are provided) and how many times this device had its operation compromised by an internal failure in a given period.

Adopting a predominantly corrective and unplanned maintenance policy implies high costs, with the impacts of the failure, whether catastrophic or not, only observed after the same. On the other hand, a planned, proactive maintenance program based on the condition will enable the operation and maintenance teams to monitor, analyze, and diagnose failures in their initial stage, resulting in high operational reliability of systems and equipment, reducing maintenance costs. According to [

1], the advantage of planned work over unplanned work is that it is always cheaper, faster, safer, and higher quality.

Because of the considerable complexity scenario of operation, with the auxiliary equipment of a thermal power plant, the operator’s technical capacity is essential to ensure critical decisions involving the safe, reliable, and economic operation of an installation. Operators must know the system, hierarchy, and work in routine, urgent, and emergencies. The development of technical skills (such as knowledge of operation) and behavioral skills (such as the ability to make decisions under time pressure) is an essential requirement for the adequate performance of the procedure [

2,

3,

4].

Decision-making about prioritizing criticality for operational monitoring of an asset’s components, from the perspective of operation and maintenance planning based on reliability-centered maintenance (RCM) concepts, can be considered a complex task. The risk profile associated with a component failure mode can have several consequences: a threat to occupational safety, environmental impact, damage to assets, loss of production costs, and the maintenance management strategy adopted.

In this sense, the proposition of a methodology addressing the concepts of reliability-centered maintenance can contribute to the optimization of the operation and the maintenance of thermal power plants. Through a multi-criteria model whose objective is to improve prioritizing routes, operational inspection based on the definition of an order based on criteria established by managers and technical teams has broad technical and academic relevance, contributing to efficiency, optimization, and sustainability of energy generation processes.

Still, in compliance with [

5], the evaluation should not be complicated since the differences observed are much more related to the diversity of results than contradictions. Some criteria allow the chosen method to be validated. In the problem in question, the MACBETH method’s application came from accepting the decision-maker’s method, which meant that the questions presented to the decision-maker made sense to them, and they had confidence in answering them. In addition, the need to assess the acceptance of data, its properties used by the method, and whether the result supported the decision-making process was highlighted.

From the authors’ point of view, the choice of a multi-criteria method among those available, applied to a given context, should be adapted to the problem’s characteristics in question. An important point will be assessing the situation, the decision objects, and the information available. According to [

6], the method’s choice must be the result of evaluating the chosen parameters, the type and precision of the data, the decision maker’s way of thinking, and their knowledge of the problem. It is also noteworthy that the direct consequence of the possibility of choosing between different methods is that the results can be discordant and even contradictory.

Secondary issues such as the existence of tools such as M-MACBETH [

6] and HIVIEW were also observed, as they allowed for greater integration with the problem addressed. Still under the opinion of these authors, who agree with [

7], who assessed that multi-criteria decision support methodology has several methods applied in the most diverse problems.

In this context, the present work targets to answer the following question comprehensively:

How to optimize operational inspection routes of a thermal power plant using a multi-criteria assessment model for ordering equipment and systems, structured in the concepts of reliability-centered maintenance (RCM) [

8]?

This paper presents the stages of structuring the multi-criteria model for decision-making, where through brainstorming methodologies reconciled to Web-Delphi research, it can achieve the goal of the study, identifying the main criteria and subcriteria, in ordering the criticality of systems in operational inspection routes of thermal plants from the perspective of operation and maintenance specialists.

The remainder of the paper is structured as follows.

Section 2 presents a literature review with the main concepts, definitions, and approaches regarding the Brazilian electric sector, thermoelectric power generation, reliability-centered maintenance (MCC). Moreover,

Section 3 focuses on research methodology and its characterization and the structuring and application phases necessary for the classification and prioritization of monitored points in the operational inspection routes. In addition,

Section 4 shows the evaluation model’s structuring, containing the definition of criteria and parameters for monitored points classification and prioritization. Finally,

Section 5 concludes with results and discussions of this application, followed by a conclusion.

2. Brazilian Electrical System

According to [

9], Brazil’s electric energy production and transmission system (SIN) is a sizeable hydro-thermal-wind system, with a predominance of hydroelectric plants and with multiple owners. The National Interconnected System consists of four subsystems: South, Southeast/Midwest, Northeast, and most of the North region.

The SIN covers all regions of the country, concentrating approximately 170,115 MW of installed capacity, being hydroelectric (63.9% of the total installed capacity), gas and LNG thermal power plants (8.9%), wind (10.9%), oil and diesel thermal power plants (2.5%), coal thermal (1.8%), biomass (8.3%), solar (2.2% of installed capacity), nuclear (1.2%), and others (0.4%) comprising 900 transmission lines that add up to 145.7 thousand kilometers in the voltages of 230, 345, 440, 500, and 750 kV, composing the primary network together with the connection assets of the plants and interconnections of international standards. It also houses 96.6% of the country’s total electricity production capacity [

9].

The need to attend to an increasing load, associated with the gradual reduction of the storage capacity on SIN and the tendency of abundant hydroelectric supply only in the rainy season (for example, the offer from the Amazon, with accentuated seasonality), obliges the complementation of hydroelectric generation in the dry period of each year, either by conventional thermal plants and/or by wind/biomass/solar sources. Thus, the thermal park and renewable sources increasingly play the SIN’s “virtual reservoir” [

9].

According to

Table 1, the Generation Information Bank of Electricity Regulatory Agency (ANEEL), the thermoelectric power generations of fossil origin in Brazil is guaranteed by 2504 plants and is distributed in the following sources:

3. Reliability-Centered Maintenance

A perfect system is one that always remains operational and maintains its function without failure during its useful life. Given this statement’s economic and technological unfeasibility, it is concluded that the systems and equipment of an installation are not perfect and fail. A failure is the alteration or cessation of the ability of an asset to perform a requested function [

10].

Still, according to [

10], reliability is the characteristic of a device expressed by the probability that that device has to fulfill a required function under conditions of use and for a determined period of time. This probability is defined as the ratio of the number of favorable cases to the number of possible cases (always less than 1). The required function of an equipment or system, on the other hand, means a level of admissibility below which the function is no longer satisfied.

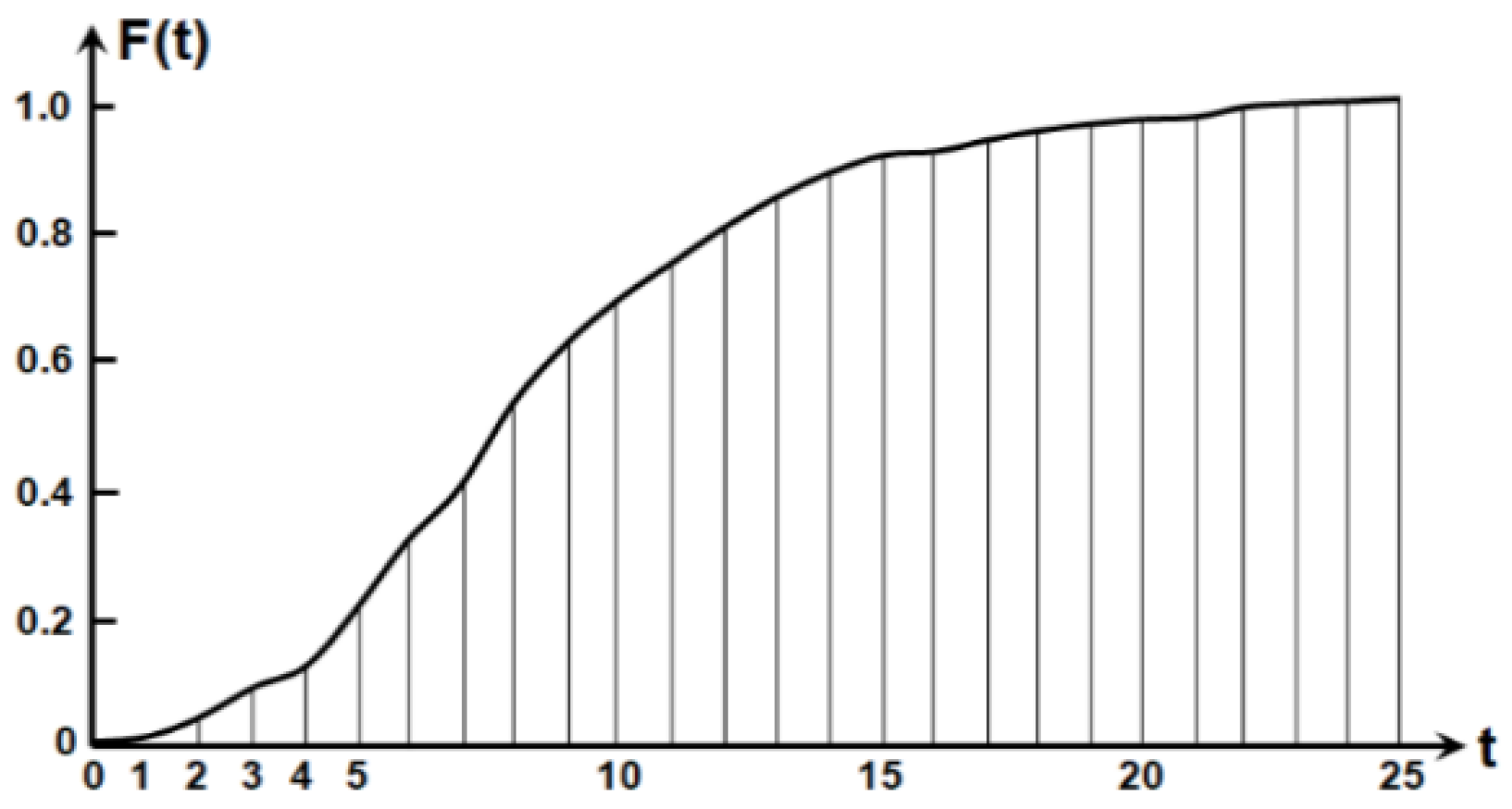

On the other hand, the authors [

11] expressed this conceptualization in terms of the random variable t, the time until the failure occurs, and the corresponding probability density function of failure occurrence f(t), the probability of failure in a specific time interval, can be defined by the relationship:

Since F(t) is the accumulated probability function, it comes:

That is, F(t) expresses the probability of failure occurring up to a time t.

This function F(t) increases with time, reaching a unit value when t → ∞, as shown in

Figure 1.

From the point of view of the logic of its operation, in

Figure 2, a component or equipment is either operating properly, as foreseen in the project, or is in a state of failure and, therefore, are mutually exclusive events, and reliability can be probabilistically expressed by the relationship:

In this sense, reliability-centered maintenance (RCM) is a methodology that identifies which practices are most suitable, within an operation, for the preservation of the functions contained therein. That is, it identifies and measures the reliability of a system (equipment, machines, and processes) and aims at the maximum utilization of the available resources, as long as they are feasible, to guarantee the reliability of the operation. In addition, due to the high level of information it generates, it allows the company to improve its operational performance, increases the useful life of the equipment, improves the decision-making regarding maintenance (when, where, what, and why to do it).

According to [

12], a broader definition of RCM could be “a process that is used to determine what must be done to ensure that a physical element continues to perform the desired functions in its present operational context”. Following [

13] is a methodology that identifies which practices are most suitable within an operation to preserve its functions. That is, it identifies and measures the reliability of a system (equipment, machines, and processes) and scientifically proposes ways to increase that reliability.

Moreover, the RCM aims to maximize the available resources to guarantee operational reliability as long as they are feasible. Again, due to the high level of information it generates, it allows the company to improve its operating performance, increases the equipment’s useful life, and enhances the decision-making regarding maintenance (when, where, what, and why to do it). Once the risks of failures have been raised, the company will be able to direct its efforts towards the machines that, if they fail, may generate some aggravation for the environment and/or its employees. Therefore, it improves security [

8].

4. Multi-Criteria Methodology

Concerning objectives, research is presented as descriptive and exploratory because, consistent with [

14], the descriptive involves using standard data collection techniques: questionnaires and systematic observation. Thus, lifting describes the characteristics of a specific phenomenon or establishing relationships between variables. Exploratory research involves literature review and interviews with people that have practical experience with the researched problem. As for the procedures, the research is bibliographical. Naturally, the study is often classified as applied because it will be developed directly with thermal power station operation and maintenance specialists to resolve the matter of evaluation. The brainstorming technique for lifting qualitative information may be a tool related to creativity and utilized in the research design phase, answering a problem question.

According to [

15], research can be qualitative regarding the approach to the problem, where there is an inseparable link between the target worlds. Therefore, the subjectivity of the topic that cannot be translated into numbers and/or quantitative, supported the very fact that everything is often quantified.

In this context, this research is qualitative and quantitative, with a group of specialists in thermoelectric plant operation. The research was of the participant case type, carried out in a coal-fired power plant with 2 × 360 MW generating units, where the operational teams work on relay scales in three shifts. An observational diagnosis of 60 days was performed in order to account for the average time for carrying out the operational inspection routes by systems. The results, which show a total of approximately 50 person-hours per day in carrying out the inspection routes, are detailed in

Table 2.

According to the results of the judgment matrix of the MACBETH approach, the ordering proposal will enable the review of the strategy of execution of the current operational routes, redefining criticality, periodicity, routing and resources applied, and maintaining the reliability of the plant.

To illustrate the stages of development of the criticality ordering methodology, in view of the proposal to review the current strategy of operational inspection routes in thermoelectric plants and the increase in the productivity of the operation team, a flowchart/algorithm was created, detailed in

Figure 3.

At first, categorizing the most relevant criteria and subcriteria in assessing equipment and systems criticality was undertaken. In a second step, the Delphi method was used as an investigation technique in two rounds, because of the complexity of the evaluation and the impacts of failures in the electricity generation process, where it will be possible to create a ranking of criteria and subcriteria and obtain a greater degree of consensus reached by specialists.

In [

16], the Delphi method is defined as “a method to structure a collective communication process so that it is effective by allowing a group of individuals, as a whole, to deal with a complex problem”. Thus, Delphi is considered a systematic technique to collect specialists’ scientifically valid opinions on a given subject [

17]. The authors of [

16] also emphasize another potential Delphi: identifying knowledge, skills, or abilities of a particular professional.

The implementation process of Delphi is accomplished in a few steps, as shown in

Figure 4.

According to the illustration, after the expert’s choice, implementation of the Delphi method takes place through construction and performance of the primary questionnaire. Following this, a quantitative and qualitative analysis of the responses is formed. Afterward, the second questionnaire, followed by a replacement reflection and being closer to consensus, continues the method.

4.1. Support Multi-Criteria Decision

In comparison with advanced decision support methods, the basis of decision theory supports the MCDA method (multi-criteria decision analysis). Making everyday decisions involving everyday life becomes more complicated, as it is necessary to solve the problem, taking into account different perspectives and evaluating according to the specific form of the problem and, thus, a set of alternative solutions can be considered multiple criteria conflicting with each other ([

18,

19]). This line of reasoning [

20,

21] confirms that before choosing two alternative actions, the choice of a multi-criteria decision problem is motivated by the desire to satisfy multiple, often conflicting objectives.

According to [

6], the decision-making in private and public organizations depends on human activity, where managers’ value judgment plays a crucial role. Thus, it is appropriate to answer how numerically representing this value judgment by integrating information technology into human decisions through techniques and decision support tools is warranted. Support for multi-criteria decision-making is a dynamic field of knowledge, and research aims to assist policymakers and negotiators, helping them to solve problems, making it possible to broaden their arguments and expand their ability to learn and understand [

22].

4.2. Multi-Criteria Decision Support Concepts

This method supports multi-criteria decision making to assess complex situations from a set of different quantitative and qualitative indicators, including finances, actual operations, inputs, processes, products, and results. It can be used as a set of analysis techniques to support decision making [

23]. In [

24], advanced decision-making methods are used to evaluate multiple possible choices among various decision-making criteria to select, classify, classify, and describe a set of more complex decision-making schemes.

Advanced methods of approved decision support tools are used to select, classify, and describe alternative details that will be based on decision making [

18], or can also analyze and evaluate living conditions as a basis for decisions to do. Overall, it is the result of past choices. Likewise, in [

18], due to the ability to deal with quantitative and qualitative aspects, advanced decision support methods can be used in different fields of knowledge.

4.3. Stages of the Decision Support Process

According to [

25], there are three main stages of the decision support process. (1) Structure: To deal with the problem and determine the objective, and to qualitatively analyze the alternatives and their impact; (2) Evaluation: Design to make a model decision, and define the number of standards based on the information collected in the design phase; (3) Recommendation: Use the recommended standard weight application model to support the decision in the evaluation phase, they are subsequently carried out sensitivity analyzes and robustness. The study of reference for later problems is necessary to structure the multi-criteria model to be used. According to [

17], there are four types of problems:

Description of the problem (P.δ)—a description is made of alternatives;

Problematic classification (P.β)— classification of alternatives is carried out.

Sorting (P.γ)—ordering of the alternatives is generated.

Problematics of choice (P.α)—the best alternative or alternatives are chosen.

Moreover, the author of [

15] confirms that the design phase is significant in constructing the decision support multi-criteria model. According to the author, we define the problem, the actors, identification, and implementation of the elements at this stage, whether they are less relevant or more impactful in the evaluation process.

4.4. Data Phase

The detailed planning of all the steps that will be used is part of the first phase of scientific research, which also involves the choice of the theme, the formulation of the problem, the specification of the objectives, the construction of the hypotheses, and the operationalization of the methods [

22].

4.5. Structure Phase

According to [

15], the purpose of the research through the interview aims to explore the experiences of the actors inserted in the organizational context. Thus, the structuring phase was initiated by conducting interviews with process specialists, through brainstorming, according to the steps below:

Step 1. Interviews with specialists: Interviews with a group of 4 specialists in operations of a thermal power plant (an operation manager, an utilities manager and 2 operation supervisors) to develop, through brainstorming technique, the categorization of criteria and subcriteria that, in the group’s opinion, is the most relevant in assessing the criticality of points monitored by an inspection route operational, taking into account the impacts that a failure can bring to an electric power generation process.

Step 2. Questionnaire—Web-Delphi (First round): Application of a questionnaire with a group of 5 specialists in operation and maintenance of thermal power plant (the four interviewed in the previous step, added to a maintenance engineer) to develop a ranking of criteria and subcriteria, considered by the group as the most important to assess the criticality of systems and points monitored in operational inspection routes.

Step 3. Questionnaire—Web-Delphi (Second round): In the second round of Web-Delphi, after the evaluation and analysis of the primary round answers consistent with the opinion of every participant and aiming at the closest search for consensus, an opportunity is provided for reclassification and ordering individually in compliance with the compiled responses group, which allows the definition of the most important criteria and subcriteria for the evaluation of criticality of systems and points monitored in operational inspection routes.

4.6. MACBETH Approach

MACBETH is an acronym for “Measuring Attractiveness by a Categorical Based Evaluation Technique” of attractiveness, where the measurement of attractiveness is made by an assessment technique based on categories; that is, the method proposes the comparison of two options and the definition of the difference in attractiveness between them, according to the following options: null, very weak, moderate, strong, very strong or extreme [

25]. This approach applies to additive value models, so it can be used to define value functions and determine weights [

6].

Furthermore, it transforms ordinal scales into cardinal scales based on absolute judgments about the difference in attractiveness between ordinal scale levels [

26]. MACBETH’s characteristic allows the decision-maker to facilitate the process, who often has difficulty directly assigning a numerical value to the alternatives’ impact levels and the evaluation criteria [

27].

4.7. Application Phase

To create the optimization model of operational inspection routes with the ordering of the criticality of systems and equipment, the multiple criteria decision analysis (MCDA) methodology was adopted, allowing a more rational, justifiable, and explainable decision process able to deal with a set of mixed quantitative and qualitative data [

28].

With the criteria and subcriteria duly validated and ordered in the structuring phase and considered the most important by the specialists, a questionnaire was applied using reliability study techniques to define the trees and functional tables of the systems and points monitored in the process of producing electricity from a thermoelectric plant. In addition, the Google Forms tool was used with the participation of 25 (twenty-five) professionals in operation and maintenance of the plant, seeking a closer consensus and collective ordering of the criticality of the monitored systems and points.

The categorization of operation and maintenance professionals, in terms of department and position/function in the company, is shown in

Figure 5.

The survey results will be treated by applying the approach M-MACBETH, which allows the transformation of qualitative assessments into quantitative. The analysis will be the basis for setting the M-MACBETH software to make the judgment matrix for the studied criteria.

4.8. Identification Context Deciding

An energy generation system’s reliability is a critical success factor for organizations to guarantee the contractual commitments established in energy auctions. In this context, the operator has the function of evaluating the standard performance of systems, subsystems, and equipment to know if there is any change in each component’s characteristics, comparing the data and observations made with the part’s functioning standards, preferably with the expected result of each operation. That way, if there is any change, the operator will know that the machine needs intervention.

The early and quality detection of an anomaly plays a fundamental role in guaranteeing the availability and minimizing the electric power generation process’s failures. In this sense, in addition to supervision and control, the operator’s role is to develop proactive actions to ensure sufficient subsidies based on methods, techniques, plans, and equipment specifications and processes to plan and execute maintenance routines.

The criticality of the systems, subsystems, and monitored points must be defined with regard to the impacts that a failure can cause. The operators involved in the execution of the inspection route must know this information. Thus, given the complex definition of which systems should be monitored as a priority, with varying degrees of impact, urgency, and severity, the multi-criteria methodology to support the decision is introduced. It should be emphasized that for each category cited (impact, speed, and harshness), several criteria can be considered.

4.9. Construction of the Model

This first step will shape the decision problem and determine the options to be evaluated to play an essential role [

29]. For the construction of the evaluation model, the authors of [

30] highlight the following steps:

Definition of the problem label;

Identification of the actors involved in the evaluation process;

Identification of the evaluation elements (criteria);

Construction of the value tree;

Construction of descriptors;

Construction of value functions (PV); and

Determination of replacement rates (weight).

4.9.1. Definition of Label

As the objective of this research is to propose the optimization of operational inspection routes using a multi-criteria model to support the decision to evaluate the monitored components/systems of a coal-fired thermoelectric plant, the following label was defined:

4.9.2. Identification of Actors

Some actors involved directly and indirectly in decision-making were classified consistent with [

30], into two groups of acted and actors. The actors did not participating within the decision-making process. However, they are affected by the decisions and pressure the players. Stakeholders are constituted by three sorts of actors: policy makers, representatives, and facilitators. The basis of the evaluation process is supported by a series of steps to identify the evaluation elements.

4.9.3. Identification of the Evaluation Elements

The stages of identifying the primary elements of evaluation (EPAs) and elaborating the cognitive map took place by applying the Web-Delphi with the specialists who work in the coal-fired power plant’s operation and maintenance. It is observed that the evaluation process was divided into three main axes, defined in the research as being the fundamental points of view (PVFs). According to [

31], a family of PVFs is used as an initial pillar in structuring the multi-criteria assessment model.

After defining the PVFs, the necessary decompositions were performed, creating the elementary points of view (PVEs), both of which are the basic structure of the multi-criteria model of evaluation [

32]. It is noteworthy that the decomposition of PVFs (criteria) and PVEs (subcriteria) was validated by the group of 5 specialists in operation and maintenance of thermal power plants who participated in the Web-Delphi research.

4.9.4. Construction of the Value Tree

With the definition of the basic structure of the evaluation model, the value tree was created, composed of the elements indicated below, duly represented in

Figure 6:

a strategic objective (blue color);

three PVFs or criteria (green color);

nine PVEs or subcriteria (yellow).

4.9.5. Descriptors

After defining the PVFs (three) and PVEs (nine), to measure potential actions, it is necessary to build a criterion [

30], which consists of two tools: a descriptor and a value function. According to [

30], the descriptors promote understanding of what will be measured. The value function highlights the information related to the differences in attractiveness between the descriptors’ impact levels (IL) and reference level (RL). A descriptor corresponds to a set of impact levels that reports the performance of the potential actions of each PVF [

31]. For this study, four levels of impact were used, one for each descriptor.

In the present study, in

Table 3, each possible state of the descriptor was associated with an impact level Lj, where j corresponds to the decreasing order of the decision maker’s preference, that is:

L4—impact level with greater attractiveness (upper limit—U);

L3—impact level with immediately lower attractiveness;

L2—impact level with intermediate attractiveness;

L1—impact level with a lower level of attractiveness (lower limit—L).

4.9.6. Value Functions Definition

According to [

33], using the MACBETH approach, it is possible to define value functions that measure each performance level’s attractiveness. These numeric functions result from qualitative judgments on the differences in attractiveness reported by the decision-maker. During this process, the M-MACBETH software automatically verifies judgment consistency, remarking all the detected inconsistencies and suggesting ways to solve them. Once the matrix of judgments is filled, M-MACBETH can create the value functions.

4.9.7. Weight Determination

In addition, according to [

33], weight determination aims to define weights which will convert local evaluations (relative to each criterion) into global evaluations (relative to all criteria). Since additive value models are compensatory, weights play an important role because they reflect the importance of one criterion relative to others. The weight determination process is analogous to that followed by the definition of value functions.

During the weight determination process, judgment consistency is automatically verified as in the value functions definition. When judgments are inconsistent, the M-MACBETH software presents possible solutions. In the end, the decision-maker should check and validate the obtained weights to ensure that they reflect his opinion.

5. Evaluation Model

The case study illustrates a decision analysis process applied to scenarios in which, for optimizing resources and aiming at improving the productivity of the operation team, a strategy of operational monitoring of systems and subsystems of a thermoelectric plant is a set of maintenance interventions that must be implemented.

In this context, it is necessary to prioritize and select the systems, subsystems, and/or points monitored based on their criticality for the process and impact of failures to establish periodicity strategies and routes for operational inspection of the field. From this, the maximum benefit should be derived in terms of the decision maker’s preferences.

Moreover, to provide a practical demonstration of the approach proposed in this study, it was decided to use a reliability study and proactive maintenance techniques within reliability-centered maintenance (RCM) concepts. In this sense, the first step is to study the systems and subsystems that make up the energy generation’s thermal cycle in a coal-fired power plant.

In the second stage of the method, the functional tree of the systems and subsystems that make up the thermal cycle of energy generation of a coal-fired power plant (a graphical representation of the equipment’s functional relationships) is constructed [

34].

Figure 7 illustrates an example of a functional tree of a boiler system.

In the third stage, the monitored systems and subsystems (options) are selected and defined to evaluate criticality and ordering using the multi-criteria model, as shown in

Table 4.

A simple additive value model was used to evaluate each intervention option. This model provides a measure for each possible intervention option of global attractiveness/benefit for further selection. Equation (1) defines the simple additive value model.

where

V(a)—is the global score of option a;

—is the weight of criterion i;

—is the partial score of option and in criterion i.

According to [

33], the MACBETH approach was used to build the value functions and determine the weights, which corresponds to the computation of the variables

(a) and

, respectively. An application of a resulting value function is provided in

Figure 8. Power generation impacts were defined as the criterion’s performance descriptor referring to a failure’s impact on load restriction or shutdown of generating units and non-compliance with contractual commitments (availability contract). More significant impact on power generation, incurring contractual penalties due to low availability, greater need for the use of reliability-centered maintenance techniques to anticipate failures and, consequently, greater priority for monitoring and attractiveness.

6. Results

The research was structured in three axes, attributed as the points of fundamental views. To obtain greater precision in the measurement, each axis was dismembered in three points of elementary views, totaling nine, according to the multi-criteria model of evaluation developed in the study.

Figure 9 shows the M-MACBETH window with the results obtained from applying the developed additive value model on the boiler system. The results show that considering the 25 operation and maintenance specialists (decision-makers) who participated in the survey and answered the questionnaire, the most attractive monitoring order for operational routes inspection are C14, C18, C17, C07, C03, C15, C02, C16, C06, C05, C08, C01, C09, C12, C13, C11, C10, and C04. This is a descending order with the overall benefit values, which means that they are the criticality perceived as more valuable.

For example, subsystem C14 corresponds to a case where there is a high impact in case of failure on:

Occupational safety (SSO);

Power generation impact (IMPACT);

Environmental impact (AMB);

Patrimonial impact (PATR).

These are the four criteria with higher weight (0.19, 0.18, 0.16, and 0.15, respectively, and according to the last line of

Figure 9), meaning that the decision-maker highly appreciates monitoring priority, leading to an increased probability of early detection of a failure.

Accordingly, the suggested monitoring order corresponds to what the decision-maker believes should be done to maintain plant reliability. As can be seen, the approach followed in this study incorporated the decision-maker’s objectives and identified which subsystems and monitored points are most attractive. The evaluation process allows for assessing the individual cumulative benefiting (global) from each subsystem or monitored point, as shown in

Figure 10.

7. Conclusions

A case study design was followed to show the application of the MACBETH approach for priority ordering on thermal power plant inspection routes decision-making at the operational level, which is a multi-criteria decision problem. A structured approach must consider the various criteria that matter to the decision process as a complex decision problem.

A sensitivity analysis was performed at the end of the method, were intended to verify the model’s susceptibility to changes in weights and the consequences of these changes. The sensitivity analysis was performed interactively through M-MACBETH software. Despite the analysis made, the decision-maker felt they did not need to make any changes.

This study achieved its initial objective because it had the essential participation of thermal power plant operation and maintenance experts through research methodologies, brainstorming, and Web-Delphi, and contributed positively to identifying the criteria and subcriteria, enabling the development of the value tree through a multi-criteria model, evaluating criticality and defining ordering of systems, subsystems, and points monitored. Through income generated by the research, it will be possible to apply well-founded management techniques and direct the particular expectations of the operation and maintenance team, which can provide conditions for significant gains.

According to the results of the judgment matrix of the MACBETH approach, the ordering proposal will enable the review of the strategy of execution of the current operational routes, redefining criticality, periodicity, routing, and resources applied, maintaining the reliability of the plant.

The research was limited to evaluate the criticality of subsystems and monitored points belonging to the boiler system because they are typical to thermoelectric plants classified within the Rankine thermodynamic cycle and represent a significant portion of the evaluation proposal.

As a suggestion for future work, it is considered pertinent to continue the research covering the other systems and subsystems of the typical thermoelectric power plant, developing customized management tools in this segment, addressing mainly the most critical points identified in the study as well as to integrate concepts of artificial intelligence and machine learning to collect requirements and dynamic judgment of criteria, integrating the model into maintenance planning in the prioritization of preventive maintenance routes.