BioLPG for Clean Cooking in Sub-Saharan Africa: Present and Future Feasibility of Technologies, Feedstocks, Enabling Conditions and Financing

Abstract

:1. Introduction

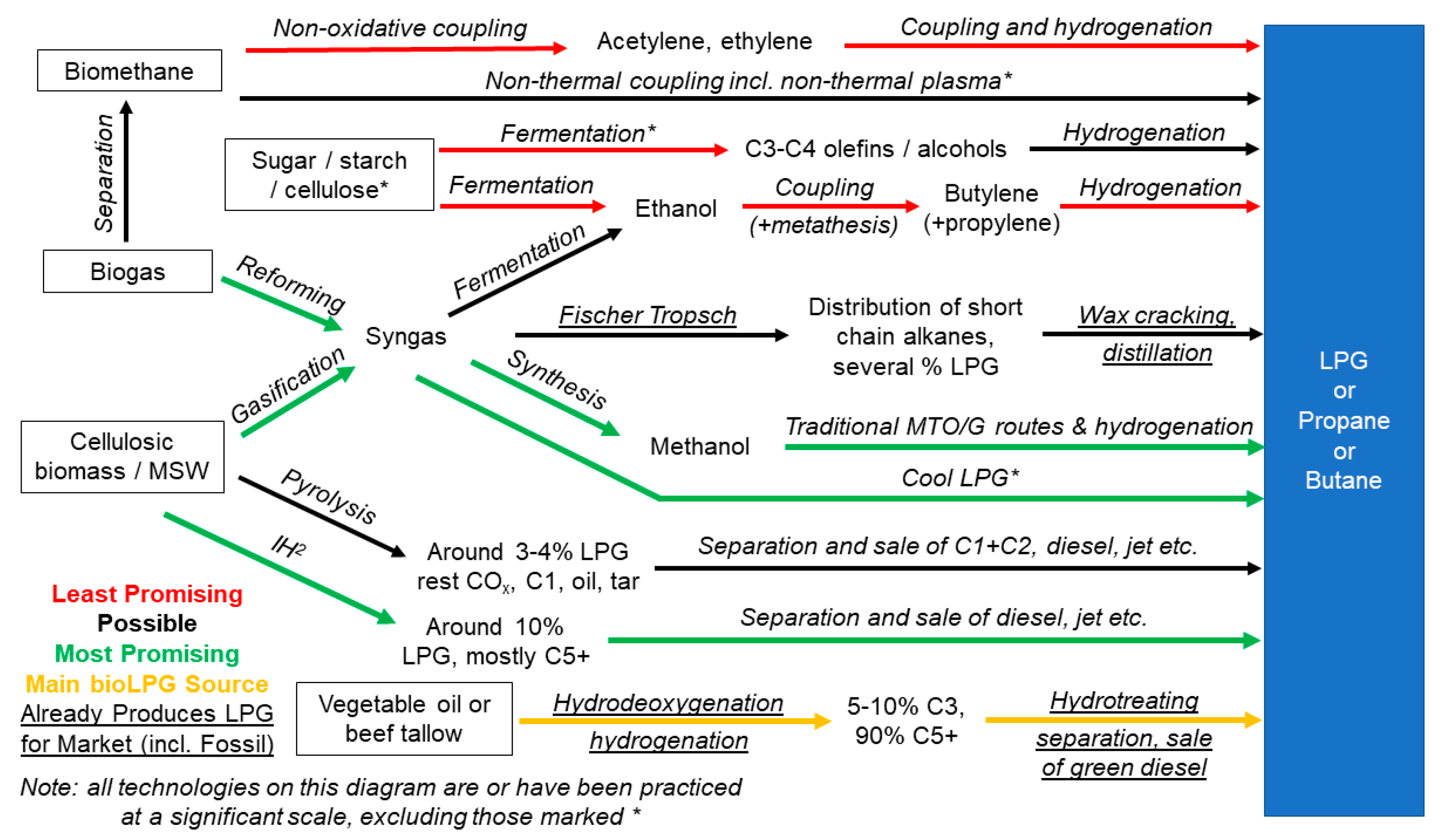

1.1. How LPG Is Produced and How It Could Be Produced Renewably

1.2. Aims and Significance of This Paper

2. Materials and Methods

2.1. Country Screening and Project Identification

Triage Process to Identify Focus Countries and Candidate bioLPG Projects

- First triage: National intentionality and action to develop the LPG sector. Evidence of (a) national need for clean cooking, (b) stated intentions to scale up the national LPG sectors, and (c) planning and implementation steps to accomplish LPG sector scale-up. Application of these screens to SSA (see Table 1) identified six countries as candidates for deeper investigation of bioLPG project potential: Cameroon, Ghana, Kenya, Rwanda, Senegal and Tanzania.

- Second triage: Enabling environment and capability of political system. Government commitment and support are of the utmost importance in order to induce the financing and implementation of an infrastructure system for biofuels. The literature is replete with emphasis on the importance and primacy of state policies and institutions. In Europe, studies note that the main barriers to renewable energy production in agriculture are frequent changes in policies, complicated legislatures, and a general perception of unpredictable national policy instruments [29,30].

- Third triage: Selection of technical process options. Choice of technical options required simultaneous and interactive consideration of process feedstock needs and availability of suitable feedstocks in adequate quantity. The technical options and their triaging are described in more detail in Section 2.2.

- Fourth triage: Feedstock selection and identification of project possibilities. Scanning of feedstock potential (viable quantities, siting, and notional economics of MSW or agricultural waste) was conducted in order to identify promising project types in Ghana, Kenya and Rwanda; this final triage yielded the results and five project choices analysed in detail in Section 2.3.

2.2. Triaging Technical Pathways to bioLPG Production

2.2.1. Fermentation

2.2.2. Hydrolysis and Hydrodeoxygenation of Triglycerides

2.2.3. Direct Thermochemical Conversion of MSW

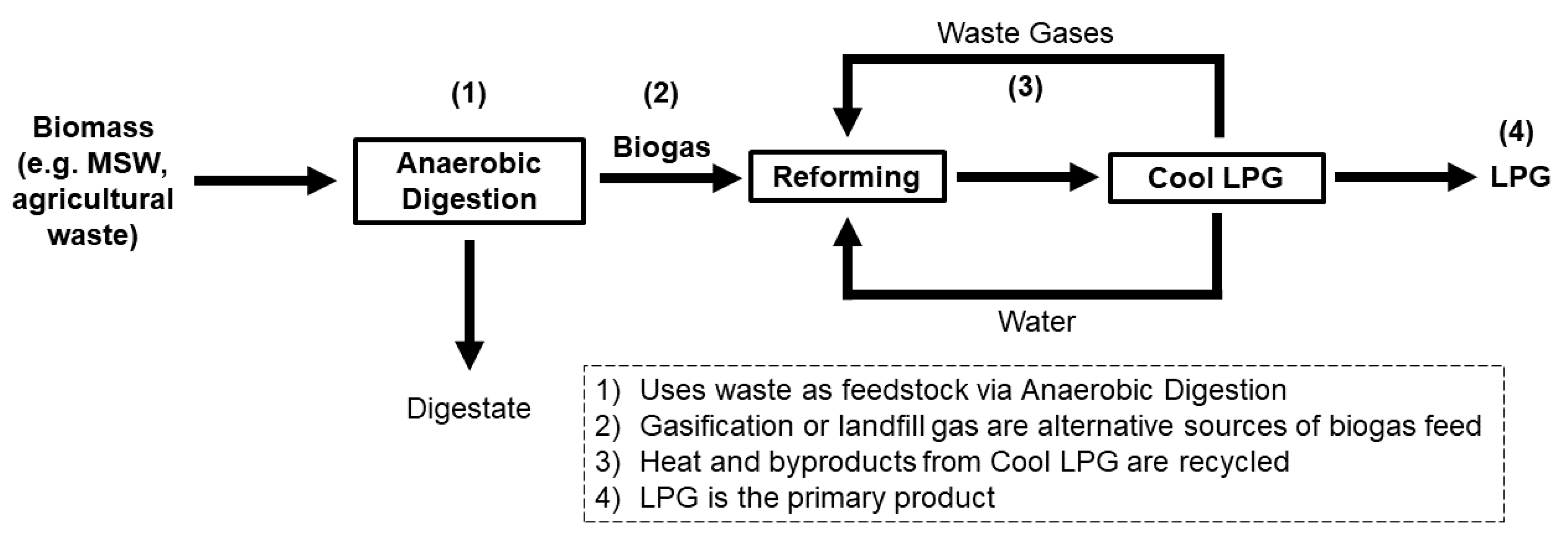

2.2.4. Waste to Biogas and Biogas Conversion

2.3. Availability of Appropriate Feedstocks in Triaged Countries

2.3.1. Feedstock Evaluation Criteria

2.3.2. Results of Feedstock Analyses for Ghana, Kenya and Rwanda

2.4. The ‘Enabling Environment’ in Ghana, Kenya and Rwanda

3. Results

3.1. Cost Estimates and Financial Feasibility Considerations for the Identified bioLPG Plant Projects

3.1.1. General Framework for Cost Estimation

3.1.2. Capital and Operating Costs (Not Including Feedstock) of IH2 and Cool LPG Plants in Ghana or Rwanda

3.1.3. MSW for IH2 or Cool LPG in Ghana and Rwanda

3.1.4. Agro-Residues for Cool LPG in Kenya

3.2. Candidate Project Financial Models and Their Results

- A bioLPG plant capacity of 10,000 tpa is modelled for AD + Cool LPG. A bioLPG plant capacity of 25,000 tpa (the preferred size for IH2′ economies of scale) is modelled for IH2.

- The capital cost of the 10,000 tpa AD + Cool LPG plant is projected at US$ 32 million, which is the US$ 40 million capital cost for a 10,000 tpa plant presented in Table 5, with the US$ 24 million Cool LPG component adjusted downward by the 65% adjustment factor described in Section 3.1.2. The capital cost of the 25,000 tpa IH2 plant is projected at US$ 188 million, as presented in Table 4, Capacity 1.

- The imported fossil LPG prices against which bioLPG must compete are analysed for LPG delivered in bulk to filling plants (a) located in/near Nairobi, Kenya, US$ 779/tonne; (b) in/near Accra, Ghana, US$ 796/tonne; and (c) in/near Kigali, Rwanda, US$ 903/tonne (higher fossil LPG logistics costs due to Rwanda being landlocked). These costs (as of mid 2020) includes, (i) for Kenya and Rwanda, the average historical Saudi Aramco Contract Price for butane and, (ii) for Ghana, the average historical ex-refinery and import parity price for LPG, ocean transportation, terminal and handling charges at the port, land transport; miscellaneous costs, duties and levies.

- Gasoline is the main product produced by the IH2 process and gasoline revenue is assumed at US$ 800/tonne.

- Gating/tipping fees might be received or be paid for MSW feedstock. Table 6 shows results from modelling gating fees ranging from receipt of US$ 10/tonne to payment of US$ 10/tonne.

- A conservative capital structure with 35% bank/commercial debt @ a 10% interest rate (sovereign debt information on Bloomberg + risk premium), 40% concessional debt from multilateral financial institutions (MFIs) and development banks @ 8% (conservative, based on conversations with DFIs, such as USDFC (formerly OPIC), FMO, and Swedfund using LIBOR + 400–600 basis point premium, depending on country risks and project risks), and 25% equity @ a 20% required internal rate of return (IRR). The blended interest rate is 8.93%, and the blended cost of capital is 11.7%.

- An exit value of five times earnings before interest, tax, depreciation and amortization (EBITDA) was used to reflect the value of the bioLPG plant’s income generating capacity in outer years.

- Borrowings starting in the first year, with only interest paid in the first year, and then principal and interest starting at the end of the second year.

3.3. Financing Issues and Projected LPG Supply Infrastructure and Fuel Costs

- (a)

- The capacity of local commercial financial institutions to lend is often constrained by national regulatory limits, and when faced with attractive local, lower risk investment alternatives (such as government securities). Risk mitigation assistance then becomes critical to induce local capital to flow.

- (b)

- The consensus need of potential major local funders (Ghana Infrastructure Fund, the Development Bank of Rwanda, Stanbic, Ecobank, Kenya Commercial Bank, and Databank in Ghana, Kenya, and Rwanda) was for development finance institutions (DFIs) to assist in various forms: grants, technical assistance (TA) for capacity building, investment capital (debt and equity), first-loss guarantees, investment insurance and other risk mitigation facilities.

- (c)

- The mobilization of international blended financing can be used to “crowd in” meaningful amounts of local funding (OECD: Blended Finance Funds and Facilities), as detailed in LPG Master Plans developed for Kenya, Rwanda, and Ghana [26,27,28]. The specific focus and needs of funding sources must be identified and targeted [78,79].

- (d)

- DFIs are often the most important early money and risk mitigation sources because they are willing to accept less certainty than the private sector due to their development mandates and offer longer tenors (up to 20 years). Additionally, through their TA, guarantees and first-loss protection, DFIs often enhance the expected economic performance and de-risk investments.

- (e)

- There is a wide range of potential public sector financial support for LPG projects. These include development/aid agencies (e.g., FCDO/UKAID, USAID, SIDA) for grants and TA; DFIs (e.g., FMO, IFC, KfW, PROPARCO, Swedfund, and USDFC) for capital and risk products; and development banks (e.g., AfDB and local development banks) for capital and risk products.

- (f)

- Leading DFIs (AfDB, FMO, IFC, Swedfund, and USDFC) have indicated preliminary interest in funding bio-related LPG value chains and LPG-related infrastructure.

- (g)

- Based on all the above, it is concluded that there is financial institutional interest and capability to explore the funding of Cool LPG projects in Ghana, Kenya and Rwanda at a commercial scale, assuming adequate evidence from well-conducted project feasibility studies.

Indicative Estimates of Capital Expenditures (CapEx) Required to Create Physical LPG Capability for an Additional 500 Million New Users in Sub-Saharan Africa

4. Discussion

Next Phases of bioLPG Development

- Fund next steps of technical process development and refinement, which is a general need and not site-specific.

- Fund and carry out detailed feasibility studies for bioLPG demonstration plants in carefully selected sites.

- Finance and build demonstration bioLPG plants, incorporate learnings into commercialization planning.

- Develop and put into service commercially viable bioLPG plants across SSA.

- Stimulation of SSA governments to explore bioLPG as a solution, with coordination across relevant ministries and agencies and complementary stimulation of TA funding.

- Stimulation of international development organizations and funding sources to support bioLPG as a solution and to engage with SSA governments to assess and develop bioLPG production capacity and related feedstock projects.

- Stimulation of finance institutions to build human capacity and decision-maker interest in serving a bioLPG project market and reducing risk premiums included in finance pricing.

- Stimulation of planning and funding of urban MSW capacity, as feedstock for bioLPG.

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ESMAP. The State of Access to Modern Energy Cooking Services. Available online: https://www.worldbank.org/en/topic/energy/publication/the-state-of-access-to-modern-energy-cooking-services (accessed on 19 May 2021).

- IEA. World Energy Outlook 2020-Analysis. Available online: https://www.iea.org/reports/world-energy-outlook-2020 (accessed on 19 May 2021).

- Van Leeuwen, R.; Evans, A. Hyseni Increasing the Use of Liquefied Petroleum Gas in Cooking in Developing Countries. Available online: https://openknowledge.worldbank.org/handle/10986/26569 (accessed on 19 May 2021).

- IEA. SDG7: Data and Projections-Analysis-IEA. Available online: https://www.iea.org/reports/sdg7-data-and-projections (accessed on 19 May 2021).

- Puzzolo, E.; Zerriffi, H.; Carter, E.; Stokes, H. Supply Considerations for Scaling Up Clean Cooking Fuels for Household Energy in Low- and Middle-Income Countries-Puzzolo-2019-GeoHealth-Wiley Online Library. Available online: https://agupubs.onlinelibrary.wiley.com/doi/full/10.1029/2019GH000208 (accessed on 19 May 2021).

- WHO. Burning Opportunity: Clean Household Energy for Health, Sustainable Development, and Wellbeing of Women and Children. Available online: http://www.who.int/airpollution/publications/burning-opportunities/en/ (accessed on 19 May 2021).

- Puzzolo, E.; Cloke, J.; Evans, A.; Pope, D. National Scaling Up of LPG to Achieve SDG 7: Implications for Policy, Implementation, Public Health and Environment. Available online: https://www.mecs.org.uk/wp-content/uploads/2020/2002/MECS-LPG-Briefing-Paper_Jan-2020.pdf (accessed on 19 May 2021).

- WLPGA; GLPGP. Sustainable Development Goals: Contributions of LPG. Paris and New York: World LP Gas Association and Global LPG Partnership. Available online: https://www.wlpga.org/wp-content/uploads/2019/02/Sustainable-Development-Goals-Contributions-of-LPG.pdf (accessed on 19 May 2021).

- Mani, S.; Jain, A.; Tripathi, S.; Gould, C.F. The drivers of sustained use of liquified petroleum gas in India. Nat. Energy 2020, 5, 450–457. [Google Scholar] [CrossRef]

- Thoday, K.; Benjamin, P.; Gan, M.; Puzzolo, E. The Mega Conversion Program from kerosene to LPG in Indonesia: Lessons learned and recommendations for future clean cooking energy expansion. Energy Sustain. Dev. 2018, 46, 71–81. [Google Scholar] [CrossRef]

- WLPGA. Guidelines for Good Safety Practices in the LPG Industry. Available online: https://online.fliphtml5.com/addge/mysq/#p=1 (accessed on 19 May 2021).

- IEA. Energy Access Outlook: From Poverty to Prosperity WEO-2017 Special Report. Available online: https://www.iea.org/reports/energy-access-outlook-2017 (accessed on 19 May 2021).

- WLPGA. Statistical Review of Global LPG 2020; World LP Gas Association: Paris, France, 2020. [Google Scholar]

- GLPGP. Assessing Potential for BioLPG Production and Use within the Cooking Energy Sector in Africa. Available online: https://www.ccacoalition.org/en/resources/assessing-potential-biolpg-production-and-use-within-cooking-energy-sector-africa (accessed on 19 May 2021).

- Johnson, E. Process Technologies and Projects for BioLPG. Energies 2019, 12, 250. [Google Scholar] [CrossRef] [Green Version]

- WLPGA. The Role of LPG & bioLPG in Europe; World LP Gas Association: Paris, France, 2019. [Google Scholar]

- UNEP. Africa Waste Management Outlook. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/25514/Africa_WMO.pdf (accessed on 19 May 2021).

- DECC. RHI Evidence Report: Biopropane for Grid Injection; Department of Energy and Climate Change: London, UK, 2014.

- Goldemberg, J.; Martinez-Gomez, J.; Sagar, A.; Smith, K. Household Air Pollution, Health, and Climate Change-Clearing the Air. Available online: http://www.kirkrsmith.org/publications/2018/1/2/household-air-pollution-health-and-climate-change-clearing-the-air (accessed on 19 May 2021).

- Kypridemos, C.; Puzzolo, E.; Aamaas, B.; Hyseni, L.; Shupler, M.; Aunan, K. Pope Daniel Health and Climate Impacts of Scaling Adoption of Liquefied Petroleum Gas (LPG) for Clean Household Cooking in Cameroon: A Modeling Study. Environ. Health Perspect. 2020, 128, 047001. [Google Scholar] [CrossRef] [Green Version]

- Singh, D.; Pachauri, S.; Zerriffi, H. Environmental payoffs of LPG cooking in India. Environ. Res. Lett. 2017, 12, 115003. [Google Scholar] [CrossRef] [Green Version]

- Bruce, N.; de Cuevas, R.A.; Cooper, J.; Enonchong, B.; Ronzi, S.; Puzzolo, E.; MBatchou, B.; Pope, D. The Government-led initiative for LPG scale-up in Cameroon: Programme development and initial evaluation. Energy Sustain. Dev. 2018, 46, 103–110. [Google Scholar] [CrossRef]

- Climate Justice Alliance. Just Transition—A Framework for Change. Available online: https://climatejusticealliance.org/just-transition/ (accessed on 20 May 2021).

- Gustafsson, M.; Anderberg, S. Dimensions and characteristics of biogas policies—Modelling the European policy landscape. Renew. Sustain. Energy Rev. 2021, 135, 110200. [Google Scholar] [CrossRef]

- Torrijos, M. State of Development of Biogas Production in Europe. Procedia Environ. Sci. 2016, 35, 881–889. [Google Scholar] [CrossRef]

- WHO. WHO Household Energy Database. Available online: https://www.who.int/data/gho/data/indicators/indicator-details/GHO/gho-phe-primary-reliance-on-clean-fuels-and-technologies-proportion (accessed on 20 May 2021).

- GLPGP. National Feasibility Study: LPG for Clean Cooking in Cameroon. Available online: http://glpgp.org/country-feasibility-and-investment-reports (accessed on 19 May 2021).

- GLPGP. National Feasibility Study: LPG for Clean Cooking in Ghana. Available online: http://glpgp.org/country-feasibility-and-investment-reports (accessed on 19 May 2021).

- GLPGP. National Feasibility Study: LPG for Clean Cooking in Kenya. Available online: http://glpgp.org/country-feasibility-and-investment-reports (accessed on 19 May 2021).

- GLPGP; MININFRA. National Feasibility Study: LPG for Clean Cooking in Rwanda; Global LPG Partnership: New York, NY, USA, 2021. [Google Scholar]

- Kemausuor, F.; Adaramola, M.S.; Morken, J. A Review of Commercial Biogas Systems and Lessons for Africa. Energies 2018, 11, 2984. [Google Scholar] [CrossRef] [Green Version]

- Kidmo, D.K.; Deli, K.; Bogno, B. Status of renewable energy in Cameroon. Renew. Energy Environ. Sustain. 2021, 6, 2. [Google Scholar] [CrossRef]

- Faye, C.M.; Mbera, B.; Kaberia, C.; Deng, C. Solid Waste Management and Risks to Health in Urban Africa: A Study of Dakar City, Senegal. Available online: https://www.urbanark.org/solid-waste-management-and-risks-health-urban-africa-study-dakar-city-senegal (accessed on 19 May 2021).

- Multiconsult, N. Final Report Study on the Potential of Increased Use of LPG for Cooking in Developing Countries. Available online: https://www.multiconsultgroup.com/assets/LPG-for-Cooking-in-Developing-Countries_Report-by-Multiconsult.pdf (accessed on 19 May 2021).

- Rosales-Calderon, O.; Arantes, V. A review on commercial-scale high-value products that can be produced alongside cellulosic ethanol. Biotechnol. Biofuels 2019, 12, 240. [Google Scholar] [CrossRef] [Green Version]

- Pandey, A.; Larroche, C.; Ricke, S.C. Biofuels: Alternative Feedstocks and Conversion Processes; Academic Press: Cambridge, MA, USA, 2011; ISBN 978-0-12-385099-7. [Google Scholar]

- GTI. Expert Analysis of the Concept of Synthetic and/or Bio-LPG. Available online: https://propane.com/wp-content/uploads/2020/01/15866_PERC_BioPropane.pdf (accessed on 20 May 2021).

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; Urban Development; The World Bank: Washington, DC, USA, 2018; ISBN 978-1-4648-1329-0. [Google Scholar]

- Arthur, R.; Baidoo, M.F.; Antwi, E. Biogas as a potential renewable energy source: A Ghanaian case study. Renew. Energy 2011, 36, 1510–1516. [Google Scholar] [CrossRef]

- Kemausuor, F.; Kamp, A.; Thomsen, S.T.; Bensah, E.C.; Østergård, H. Assessment of biomass residue availability and bioenergy yields in Ghana. Resour. Conserv. Recycl. 2014, 86, 28–37. [Google Scholar] [CrossRef]

- Nelson, N.; Darkwa, J.; Calautit, J.; Worall, M.; Mokaya, R.; Adjei, E.; Kemausuor, F.; Ahiekpor, J. Potential of Bioenergy in Rural Ghana. Sustainability 2021, 13, 381. [Google Scholar] [CrossRef]

- Arthur, R.; Baidoo, M.F.; Brew-Hammond, A.; Bensah, E.C. Biogas generation from sewage in four public universities in Ghana: A solution to potential health risk. Biomass Bioenergy 2011, 35, 3086–3093. [Google Scholar] [CrossRef]

- Miezah, K.; Obiri-Danso, K.; Kádár, Z.; Fei-Baffoe, B.; Mensah, M.Y. Municipal solid waste characterization and quantification as a measure towards effective waste management in Ghana. Waste Manag. 2015, 46, 15–27. [Google Scholar] [CrossRef] [Green Version]

- Mohammed, M.; Egyir, I.S.; Donkor, A.K.; Amoah, P.; Nyarko, S.; Boateng, K.K.; Ziwu, C. Feasibility study for biogas integration into waste treatment plants in Ghana. Egypt. J. Pet. 2017, 26, 695–703. [Google Scholar] [CrossRef] [Green Version]

- UNEP. Sustainability of Sugarcane Bagasse Briquettes and Charcoal Value Chains in Kenya: Results and Recommendations from Implementation of the Global Bioenergy Partnership (GBEP) Indicators. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/31122/GBEPKs.pdf?sequence=1&isAllowed=y (accessed on 19 May 2021).

- Mugodo, K.; Magama, P.P.; Dhavu, K. Biogas Production Potential from Agricultural and Agro-Processing Waste in South Africa. Waste Biomass Valorization 2017, 8, 2383–2392. [Google Scholar] [CrossRef]

- Fischer, E.; Schmidt, T.; Hora, S.; Giersdorf, J.; Stinner, W.; Scholwin, F. Agro-industrial biogas in Kenya, Potentials, Estimates for Tariffs, Policy and Business Recommendations. Available online: http://digicollection.org/eebea/documents/s20341en/s20341en.pdf (accessed on 19 May 2021).

- MINICOM. Industrial Master Plan for the AgroProcessing Subsector (2014–2020). Available online: https://rwandatrade.rw/media/2014-20%20MINICOM%20Agro-Processing%20Industrial%20Masterplan.pdf (accessed on 19 May 2021).

- Alice, U.; Ming, Y.; Nestor, U.; Donath, N.; Narcisse, N. Liquid Wastes Treatment and Disposal in Rwanda. J. Pollut. Eff. Control 2017, 5, 1–5. [Google Scholar]

- MININFRA. National Sanitation Policy. Available online: https://www.rura.rw/fileadmin/Documents/Water/Laws/NATIONAL_SANITATION_POLICY__DECEMBER_2016.pdf (accessed on 19 May 2021).

- Government of Ghana. Ghana’s Intended Nationally Determined Contribution (INDC) and Accompanying Explanatory Note. Accra, Ghana. 2015. Available online: https://www4.unfccc.int/sites/ndcstaging/PublishedDocuments/Ghana%20First/GH_INDC_2392015.pdf (accessed on 28 June 2021).

- Government of Ghana. Mainstreaming Climate Change and Green Economy Sustainable Development Goals (SDGs) into the Development Plans of MMDAs. Accra, Ghana. 2017. Available online: https://www.un-page.org/files/public/mainstreaming_climate_change_and_green_economy.pdf (accessed on 28 June 2021).

- Republic of Kenya. Kenya’s First National Determined Contributions (Updated Version). Available online: https://www4.unfccc.int/sites/ndcstaging/PublishedDocuments/Kenya%20First/Kenya%27s%20First%20%20NDC%20(updated%20version).pdf (accessed on 19 May 2021).

- Republic of Rwanda. Updated Nationally Determined Contribution. Available online: https://www4.unfccc.int/sites/ndcstaging/PublishedDocuments/Rwanda%20First/Rwanda_Updated_NDC_May_2020.pdf (accessed on 19 May 2021).

- Republic of Kenya. The Energy Act. Available online: https://kplc.co.ke/img/full/o8wccHsFPaZ3_ENERGY%20ACT%202019.pdf (accessed on 19 May 2021).

- Government of Ghana. National Energy Policy (Draft). Available online: Ttp://www.energycom.gov.gh/files/snep/MAIN%20REPORT%20final%20PD.pdf (accessed on 19 May 2021).

- Müller, F.; Claar, S.; Neumann, M.; Elsner, C. Is green a Pan-African colour? Mapping African renewable energy policies and transitions in 34 countries. Energy Res. Soc. Sci. 2020, 68, 101551. [Google Scholar] [CrossRef]

- Haregu, T.N.; Ziraba, A.K.; Aboderin, I.; Amugsi, D.; Muindi, K.; Mberu, B. An assessment of the evolution of Kenya’s solid waste management policies and their implementation in Nairobi and Mombasa: Analysis of policies and practices. Environ. Urban. 2017, 29, 515–532. [Google Scholar] [CrossRef] [Green Version]

- Aparcana, S. Approaches to formalization of the informal waste sector into municipal solid waste management systems in low- and middle-income countries: Review of barriers and success factors. Waste Manag. 2017, 61, 593–607. [Google Scholar] [CrossRef] [Green Version]

- Bello, I.; Ismail, M.; Kabbashi, N. Solid Waste Management in Africa: A Review. Int. J. Waste Resour. 2016, 6, 2. [Google Scholar]

- Kamp, L.M.; Bermúdez Forn, E. Ethiopia׳s emerging domestic biogas sector: Current status, bottlenecks and drivers. Renew. Sustain. Energy Rev. 2016, 60, 475–488. [Google Scholar] [CrossRef] [Green Version]

- African Development Bank. Private Sector Development Policy of the African Development Bank Group. Available online: https://www.afdb.org/sites/default/files/documents/policy-documents/private_sector_development_policy_of_the_afdb_group.pdf (accessed on 20 May 2021).

- Republic of Kenya. The Climate Change Act. Available online: http://kenyalaw.org/kl/fileadmin/pdfdownloads/Acts/ClimateChangeActNo11of2016.pdf (accessed on 20 May 2021).

- ADI Analytics Natural Gas Utilization via Small-Scale Methanol Technologies. Available online: http://www.sgicc.org/uploads/8/4/3/1/8431164/bftp_methanol_white_paper_vf.pdf (accessed on 23 May 2021).

- Stokes Consulting Group The Economics of Methanol Production in Nigeria Based on Large Low-Cost Gas Resources. Available online: https://www.projectgaia.com/documents/The%20Economics%20of%20Methanol%20Production%20in%20Nigeria%20Based%20on%20Large%20Low-Cost%20Gas.pdf (accessed on 23 May 2021).

- Rajasheker, A.; Bowers, A.; Gatoni, A.S. Assessing Waste Management Services in Kigali. Available online: https://www.theigc.org/wp-content/uploads/2019/11/Rajashekar-et-al-2019-paper.pdf (accessed on 19 May 2021).

- Kabera, T.; Wilson, D.C.; Nishimwe, H. Benchmarking performance of solid waste management and recycling systems in East Africa: Comparing Kigali Rwanda with other major cities. Waste Manag. Res. 2019, 37, 58–72. [Google Scholar] [CrossRef] [Green Version]

- Hogg, D. Costs for Municipal Waste Management in the EU. Available online: http://projects.mcrit.com/ceara/attachments/article/154/cost%20for%20municipal%20waste%20management%20UE.pdf (accessed on 19 May 2021).

- Wheeler, P.A.; Rome, L. Waste Pre-Treatment: A Review. UK Gov Environment Agency. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/290316/sp1-344-tr-e-e.pdf (accessed on 19 May 2021).

- Pressley, P.N.; Levis, J.W.; Damgaard, A.; Barlaz, M.A.; DeCarolis, J.F. Analysis of material recovery facilities for use in life-cycle assessment. Waste Manag. 2015, 35, 307–317. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stapf, D.; Ceceri, G.; Johansson, I.; Whitty, K. Biomass Pre-Treatment for Bioenergy—Case Study 3: Pretreatment of Municipal Solid Waste (MSW) for Gasification. Available online: https://www.ieabioenergy.com/blog/publications/biomass-pre-treatment-for-bioenergy-case-study-3-pretreatment-of-municipal-solid-waste-msw-for-gasification/ (accessed on 19 May 2021).

- Kenya News Agency. Government to Establish Agro-Processing Hubs. Available online: https://www.kenyanews.go.ke/government-to-establish-agro-processing-hubs/ (accessed on 19 May 2021).

- Nielsen, C.F. Briquetting Solution for Agricultural Waste in Africa. Available online: https://cfnielsen.com/tapping-the-untapped/ (accessed on 19 May 2021).

- GIZ. Kenyan Flower Industry—Potential for Renewable Energy. Available online: https://www.german-energy-solutions.de/GES/Redaktion/DE/Publikationen/Marktanalysen/2015/studie_2015_subsector-flower-industry-kenya.pdf?__blob=publicationFile&v=6 (accessed on 19 May 2021).

- Kanyiri, G.; Waswa, F. Enhancing benefits from biomass wastes within small-medium scale coffee processing factories in Kiambu County, Kenya. Afr. J. Environ. Sci. Technol. 2017, 11, 198–206. [Google Scholar]

- Kioko, P.; Strathmore University, Nairobi, Kenya. Pineapple waste fraction from Delmonte Limited Kenya. Personal communication, 2020. [Google Scholar]

- Rajuai, C.; Naitex Developers LTD, Nairobi, Kenya. Transport data. Personal communication, 2020. [Google Scholar]

- Basile, I.; Dutra, J. Blended Finance Funds and Facilities: 2018 Survey Results; OECD Development Co-operation Working Papers; OECD Publishing: Paris, France, 2019. [Google Scholar]

- Convergence. The State of Blended Finance 2019–Convergence Resources. Available online: https://www.convergence.finance/resource/13VZmRUtiK96hqAvUPk4rt/view (accessed on 19 May 2021).

- Troncoso, K.; Soares da Silva, A. LPG fuel subsidies in Latin America and the use of solid fuels to cook. Energy Policy 2017, 107, 188–196. [Google Scholar] [CrossRef]

| Country Name | Has Major Clean Cooking Fuel Need 1 | Has 2030 Target for LPG Penetration 2 | Has LPG Master Plan or Plan-in-Process 3 |

|---|---|---|---|

| Angola | X | ||

| Benin | X | ||

| Burkina Faso | X | X | |

| Burundi | X | ||

| Cabo Verde | X | ||

| Cameroon | X | X | X |

| Central African Republic | X | ||

| Chad | X | ||

| Congo, Dem. Rep. | X | ||

| Congo, Rep. | X | ||

| Cote d’Ivoire | X | X | |

| Djibouti | X | ||

| Egypt, Arab Rep. | |||

| Equatorial Guinea | X | ||

| Eritrea | X | ||

| Eswatini | |||

| Ethiopia | X | ||

| Gabon | X | ||

| Gambia, The | X | ||

| Ghana | X | X | X |

| Guinea | X | ||

| Guinea-Bissau | X | X | |

| Kenya | X | X | X |

| Lesotho | X | ||

| Liberia | X | X | |

| Libya | |||

| Madagascar | X | ||

| Malawi | X | ||

| Mali | X | X | |

| Mauritania | |||

| Mauritius | |||

| Morocco | |||

| Mozambique | X | ||

| Namibia | X | ||

| Niger | X | X | |

| Nigeria | X | X | |

| Rwanda | X | X | X |

| Sao Tome and Principe | X | ||

| Senegal | X | X | X |

| Seychelles | |||

| Sierra Leone | X | ||

| Somalia | X | ||

| South Africa | |||

| South Sudan | X | ||

| Sudan | X | ||

| Tanzania | X | X | X * |

| Togo | X | ||

| Tunisia | |||

| Uganda | X | ||

| Zambia | X | ||

| Zimbabwe | X |

| Conversion Technology | Feedstock Characteristics | Potential Feedstocks | Volumes Required for 10,000 tpa bioLPG | Comments |

|---|---|---|---|---|

| Catalytic thermo-chemical conversion | Heterogeneous organic/biomass feedstock. Single input feedstock could be an option (with improved biochar output) but the process can manage mixed feedstock including mixed MSW. | Biomass/MSW | ~70,000 tpa feedstock | BioLPG is a minor volume co-product of the one implemented conversion pathway. |

| Biogas to bioLPG (biogas/ syngas reforming) | Heterogeneous biomass suitable for Anaerobic Digestion (AD). Mixed biomass compositions can be used but different feedstocks give different yields of biogas. Consistent supply of biomass preferable for consistent running of AD. Desulphurisation of biogas required. | By-products of agricultural and livestock industries (field and processing residues); sewage and wastewater; organic fraction of municipal waste | ~30,000 tpa raw biogas.Equivalent to approx. 160,000–500,000 tpa feedstock input (depending on type (food waste or biosolids such as animal manure) | Feedstock assessment carried out for preliminary production of biogas via AD. |

| Country | Feedstock Potential | References |

|---|---|---|

| Ghana | Agro-processing residues, field residues and waste from palm oil, fruit, cocoa, maize, rice, millet, sorghum, cowpea, cassava, soybean | [39,40,41] |

| Urban waste (sanitary waste and MSW) | [42,43,44] | |

| Kenya | Agro-processing residues, field residues and waste from coffee, pineapple, sugarcane refining, cassava, mango, sisal and livestock industries | [31,45,46] |

| MSW | [47] | |

| Rwanda | Agro-processing residues, field residues and waste from coffee, cassava, fruit processing and brewing industries | [48] |

| Urban waste (sanitary and MSW) | [49,50] |

| Capacity 1 (25 ktpa) | Capacity 2 (10 ktpa) | Capacity 3 (5 ktpa) | |

|---|---|---|---|

| BioLPG produced (ktpa) | 25 | 10 | 5 |

| Annual MSW input required (ktpa) | 167 | 67 | 33 |

| Total capital costs (US$ million) | 188 | 109 | 72 |

| Operating cost (US$ 000/year) | 13,503 | 7107 | 4611 |

| Capacity 1 (25 ktpa) | Capacity 2 (10 ktpa) | Capacity 3 (5 ktpa) | |

|---|---|---|---|

| BioLPG produced (ktpa) | 25 | 10 | 5 |

| Annual MSW input required (ktpa) | 676 | 270 | 135 |

| AD plant capital requirement (US$ million) | 41 | 16 | 8 |

| Cool LPG capital requirement * (US$ million) | 46 | 24 | 15 |

| Total capital costs (US$ million) | 86 | 40 | 23 |

| Operating cost (US$ 000/year) | 3930 | 2440 | 1680 |

| Triage Ranking | 2 | 5 | 3 | 4 | 1 |

|---|---|---|---|---|---|

| Country | Kenya | Ghana | Ghana | Rwanda | Rwanda |

| Case | Agro-Residue AD + Cool LPG | MSW IH2 | MSW AD + Cool LPG | MSW IH2 | MSW AD + Cool LPG |

| BioLPG Plant Capacity (tpa) | 10,000 | 25,000 | 10,000 | 25,000 | 10,000 |

| BioLPG Plant Capex (US$ millions) | 32 | 188 | 32 | 188 | 32 |

| Waste input (ktpa) | 270 | 166 | 270 | 166 | 270 |

| BioLPG Price (US$/tonne) | 750 | 750 | 750 | 850 | 850 |

| Fossil LPG Price (US$/tonne) | 779 | 796 | 796 | 903 | 903 |

| Gasoline Price (US$/tonne) | NA | 800 | NA | 800 | NA |

| Best Case (High IRR, tipping fee income) | |||||

| Tipping Fee (US$/tonne) | 10 | 10 | 10 | 10 | 10 |

| IRR (US$ 750/t) | 29.0% | 13.2% | 30.1% | ||

| IRR (US$ 850/t) | 15.8% | 34.9% | |||

| Base Case | |||||

| Tipping Fee * | 0 | 0 | 0 | 0 | 0 |

| (US$/t) | |||||

| IRR (US$ 750/t) | 14.0% | 11.3% | 15.4% | ||

| IRR (US$ 850/t) | 12.3% | 3.5% | |||

| Worst Case (Unattractive IRR, tipping fee cost) | |||||

| Tipping Fee * | −7 | −10 | −10 | −10 | −10 |

| (US$/t) | |||||

| IRR (US$ 750/t) | (negative IRR) | 7.6% | (negative IRR) | ||

| IRR (US$ 850/t) | 8.6% | (negative IRR) | |||

| Per New User (Based on the 4 Countries Studied) | For 500 Million New Users, 120 Million Households | |||||

|---|---|---|---|---|---|---|

| National Averages | Industry CapEx | Consumer CapEx | Total CapEx | Industry CapEx | Consumer CapEx | Total CapEx |

| Low | $27.6 per new user | $8.8 per new user | $36.5 per new user | $13.8 bn | $4.4 bn | $18.2 bn |

| High | $37.8 per new user | $15.0 per new user | $52.8 per new user | $18.9 bn | $7.5 bn | $26.4 bn |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, K.C.; Leach, M.; Black, M.J.; Tesfamichael, M.; Kemausuor, F.; Littlewood, P.; Marker, T.; Mwabonje, O.; Mulugetta, Y.; Murphy, R.J.; et al. BioLPG for Clean Cooking in Sub-Saharan Africa: Present and Future Feasibility of Technologies, Feedstocks, Enabling Conditions and Financing. Energies 2021, 14, 3916. https://doi.org/10.3390/en14133916

Chen KC, Leach M, Black MJ, Tesfamichael M, Kemausuor F, Littlewood P, Marker T, Mwabonje O, Mulugetta Y, Murphy RJ, et al. BioLPG for Clean Cooking in Sub-Saharan Africa: Present and Future Feasibility of Technologies, Feedstocks, Enabling Conditions and Financing. Energies. 2021; 14(13):3916. https://doi.org/10.3390/en14133916

Chicago/Turabian StyleChen, Kimball C., Matthew Leach, Mairi J. Black, Meron Tesfamichael, Francis Kemausuor, Patrick Littlewood, Terry Marker, Onesmus Mwabonje, Yacob Mulugetta, Richard J. Murphy, and et al. 2021. "BioLPG for Clean Cooking in Sub-Saharan Africa: Present and Future Feasibility of Technologies, Feedstocks, Enabling Conditions and Financing" Energies 14, no. 13: 3916. https://doi.org/10.3390/en14133916

APA StyleChen, K. C., Leach, M., Black, M. J., Tesfamichael, M., Kemausuor, F., Littlewood, P., Marker, T., Mwabonje, O., Mulugetta, Y., Murphy, R. J., Diaz-Chavez, R., Hauge, J., Saleeby, D., Evans, A. W., & Puzzolo, E. (2021). BioLPG for Clean Cooking in Sub-Saharan Africa: Present and Future Feasibility of Technologies, Feedstocks, Enabling Conditions and Financing. Energies, 14(13), 3916. https://doi.org/10.3390/en14133916