Hygrothermal and Acoustic Performance of Two Innovative Envelope Renovation Solutions Developed in the e-SAFE Project

Abstract

:1. Introduction

2. Methodology

2.1. Stationary and Dynamic Thermal Parameters

2.2. Internal and Surface Vapor Condensation

2.3. Acoustic Parameters and Descriptors

- Descriptors referring to the sound insulation capacity of the façade itself.

- Descriptors referring to the sound pressure level ensured indoors, and thus indirectly measuring the sound insulation capacity of the façade.

3. The Proposed Envelope Solutions

3.1. Typical Configurations for External Walls in The European Context

3.2. The Proposed Envelope Solutions

3.3. Climatic Context

4. Results and Discussion

4.1. Stationary and Dynamic Thermal Performance

4.2. Internal and Surface Vapor Condensation

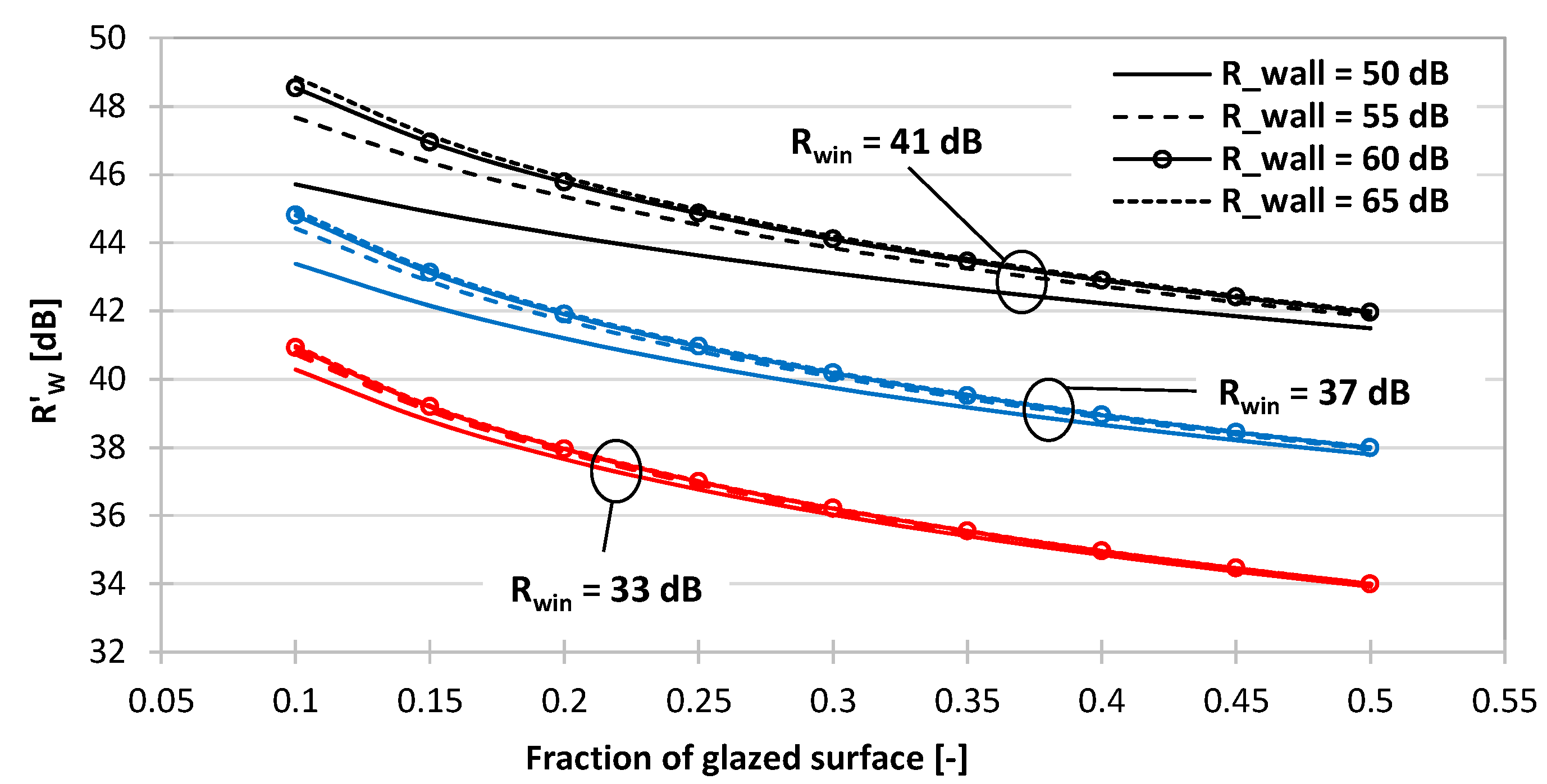

4.3. Sound Reduction Provided by Building Facades

- Rg = 33 dB (basic double glazing such as 6-12(air)-6, with aluminum frame).

- Rg = 37 dB (average double glazing with glass panes having different thicknesses, such as 6-12(air)-10, plus aluminum or PVC frame).

- Rg = 41 dB (double glazing with stratified safety glass, such as 10-12(air)-44.1, plus wood frame).

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- EU Buildings Database. Available online: https://ec.europa.eu/energy/en/eu-buildings-database (accessed on 26 May 2021).

- Filippidou, F.; Jimenez Navarro, J.P. Achieving the Cost-Effective Energy Transformation of Europe’s Buildings; EUR 29906 EN; Publications Office of the European Union: Luxembourg, 2019; Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC117739 (accessed on 26 May 2021).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European economic and social Committee and the Committee of the Regions. In A Renovation Wave for Europe—Greening our Buildings, Creating Jobs, Improving Lives; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- La Greca, P.; Margani, G. Seismic and energy renovation measures for sustainable cities: A critical analysis of the Italian scenario. Sustainability 2018, 10, 254. [Google Scholar] [CrossRef] [Green Version]

- Lattke, F.; Cronhjort, Y. smartTES—Introduction to a New Retrofit Method; Technische Universität München: Munich, Germany, 2014. [Google Scholar]

- P2ENDURE Project. Plug & Play Building Renovation. Available online: https://www.p2endure-project.eu/en (accessed on 26 May 2021).

- EN ISO 6946:2017. Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods; European Committee for Standardization: Brussels, Belgium, 2017. [Google Scholar]

- Decreto del Presidente della Repubblica 26 agosto 1993, n. 412 Regolamento recante norme per la progettazione, l’installazione, l’esercizio e la manutenzione degli impianti termici degli edifici ai fini del contenimento dei consumi di energia, in attuazione dell’art. 4, comma 4, della legge 9 gennaio 1991, n. 10412/93. 1993. (In Italian)

- Gaglia, A.G.; Tsikaloudaki, A.G.; Laskos, C.M.; Dialynas, E.N.; Argiriou, A.A. The impact of the energy performance regulations’ updated on the construction technology, economics and energy aspects of new residential buildings: The case of Greece. Energy Build. 2017, 155, 225–237. [Google Scholar] [CrossRef]

- Touloupaki, E.; Theodosiou, T. Optimization of external envelope insulation thickness: A parametric study. Energies 2017, 10, 270. [Google Scholar] [CrossRef] [Green Version]

- Orden FOM /1635/2013 del 10 de septiembre por el que se actualiza el Documento Básico DB-HE. 2013. (In Spanish)

- Turkish Standards Institution. TS 825—Thermal Insulation Requirements for Buildings; Turkish Standards Institution: Ankara, Turkey, 2008.

- Österreichisches Institut für Bautechnik. OIB-330.6-009/15 OIB-Richtlinie 6; Österreichisches Institut für Bautechnik: Vienna, Austria, 2015. (In Austrian) [Google Scholar]

- Concerted Action-Energy Performance of Buildings, 2018, CA-EPBD, Implementing the Energy Performance of Buildings Directive—Featuring Country Reports 2018. Available online: https://epbd-ca.eu/archives/1859 (accessed on 26 May 2021).

- Cypriot Law n. 210 (I)/2012. The Regulation of the Energy Performance of Buildings (Amendment) Act 2012, 2012.

- Approved Document L1B. Conservation of Fuel and Power in Existing Dwellings; HM Government: London, UK, 2018.

- Energieeinsparverordnung—EnEV 2014. 2014. (In German)

- Law n. 4122/2013: The Energy Performance of Buildings; Greek Government: Athens, Greece, 2013.

- Inter-Ministerial Decree 26/06/2015. Applicazione delle Metodologie di Calcolo delle Prestazioni Energetiche e Definizione delle Prescrizioni e dei Requisiti Minimi degli Edifici. Ministero dello Sviluppo Economico. 2015. (In Italian)

- Staatsblad van het Koninkrijk der Nederlanden, STB 2018-291. 2018. (In Dutch)

- Forskrift om tekniske krav til byggverk. Byggteknisk forskrift—TEK17. 2017. (In Norwegian)

- Bienvenido-Huertas, D.; Oliveira, M.; Rubio-Bellido, C.; Marin, D. A comparative analysis of the international regulation of thermal properties in building envelope. Sustainability 2019, 11, 5574. [Google Scholar] [CrossRef] [Green Version]

- EN ISO 13786:2017. Thermal Performance of Building Components—Dynamic Thermal Characteristics—Calculation Methods; European Committee for Standardization: Brussels, Belgium, 2017. [Google Scholar]

- Marletta, L.; Evola, G.; Giuga, M. Using the dynamic thermal properties to assess the internal temperature swings in free running buildings. A general model and its validation according to ISO 13792. Energy Build. 2015, 87, 57–65. [Google Scholar] [CrossRef]

- Rossi, M.; Rocco, V.M. External walls design: The role of periodic thermal transmittance and internal areal heat capacity. Energy Build. 2014, 68, 732–740. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Rubio-Bellido, C.; Pulido-Arcas, J.A.; Perez-Fargallo, A. Towards the implementation of periodic thermal transmittance in Spanish building energy regulation. J. Build. Eng. 2020, 31, 101402. [Google Scholar] [CrossRef]

- Di Perna, C.; Stazi, F.; Ursini Casalena, A.; D’Orazio, M. Influence of the internal inertia of the building envelope on summertime comfort in buildings with high internal heat loads. Energy Build. 2011, 43, 200–206. [Google Scholar] [CrossRef]

- Criteri Ambientali Minimi per L’affidamento di Servizi di Progettazione e Lavori per la Nuova Costruzione, Ristrutturazione e Manutenzione di Edifici Pubblici; Italian Ministry of the Environment: Rome, Italy, 2015.

- Stazi, F.; Ulpiani, G.; Pergolini, M.; Di Perna, C. The role of areal heat capacity and decrement factor in case of hyper insulated buildings: An experimental study. Energy Build. 2018, 176, 310–324. [Google Scholar] [CrossRef]

- EN ISO 13788:2013. Hygrothermal Performance of Building Components and Building Elements—Internal Surface Temperature to Avoid Critical Surface Humidity and Interstitial Condensation—Calculation Methods; European Committee for Standardization: Brussels, Belgium, 2013. [Google Scholar]

- EN ISO 16283-3:2016. Acoustics—Field Measurement of Sound Insulation in Buildings and of Building Elements—Part 3: Façade Sound Insulation; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- Requirements and Drivers of EENSULATE Module, Deliverable 1.1 of the EENSULATE EU Project. 2016. Available online: https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5aeb8b494&appId=PPGMS (accessed on 26 May 2021).

- Austrian Standard: ÖNORM B 8115-2. Sound Insulation and Room Acoustics in Buildings, 2006.

- Belgian Standard NBN S 01-400-1:2008. Acoustics—Acoustical Criteria for Dwellings, 2008.

- Rasmussen, B.; Machimbarrena, M.; Fausti, P. Building Acoustics throughout Europe—Volume 2: Housing and Construction Types Country by Country. Report of the COST Action TU0901: Integrating and Harmonizing Sound Insulation Aspects in Sustainable Urban Housing Constructions. 2014. Available online: https://www.cost.eu/publications/building-acoustics-throughout-europe-volume-2-housing-and-construction-types-country-by-country/ (accessed on 26 May 2021).

- Lang, J.; Schönbäck, W.; Pierrard, R. Sound Insulation in Housing Construction; University of Technology: Wien, Austria, 2006. Available online: https://ifip.tuwien.ac.at/publications/EN/ (accessed on 26 May 2021).

- Körper, S. German regulations on building acoustics—The new standard DIN 4109. In Proceedings of the Inter Noise Conference, Madrid, Spain, 16–19 June 2019. [Google Scholar]

- Decree of the President of the Council of Ministers (DPCM) 5-12-1997. Requisiti Acustici Passivi Degli Edifici, 1997. (In Italian)

- Polish Standard PN-B-02151-3: 1999. Building Acoustics—Noise Protection of Apartments in Buildings—Sound Insulation in Buildings and of Building Elements—Requirements, 1999.

- Ministério do Ambiente, do Ordenamento do Território e do Desenvolvimento Regional, Decreto-Lei 96/2008. Regulamento dos Requisitos Acústicos dos Edifícios (RRAE) (Portuguese Building Acoustics Code), 2008. (In Portuguese)

- Machimbarrena, M.; Carrascal, T. The Spanish Acoustics Building Code (DB HR) and its first year of application. In Proceedings of the 2° Convention Nazionale del Gruppo di Acustica Edilizia, Florence, Italy, 13 December 2010. [Google Scholar]

- Bayazit, N.T.; Kurra, S.; Sentop, A.; Obilen, B.S. Acoustical classification and proposed methodology for performance assessment of buildings in Turkey. In Proceedings of the 23rd International Congress on Sound & Vibration, Athens, Greece, 10–14 July 2016. [Google Scholar]

- ISO 717-1:2013. Acoustics—Rating of Sound Insulation in Buildings and of Building Elements Airborne Sound Insulation; International Organization for Standardization: Geneve, Switzerland, 2013. [Google Scholar]

- EN ISO 12354-3:2017. Building Acoustics—Estimation of Acoustic Performance of Buildings from the Performance of Elements—Part 3: Airborne Sound Insulation Against Outdoor Sound; European Committee for Standardization: Brussels, Belgium, 2017. [Google Scholar]

- Typology Approach for Building Stock Energy Assessment. Main Results of the TABULA Project. 2012. Available online: https://episcope.eu/fileadmin/tabula/public/docs/report/TABULA_FinalReport_AppendixVolume.pdf (accessed on 26 May 2021).

- Barbagallo, F.; Margani, G.; Marino, E.M.; Moretti, A.; Tardo, C. Impact of retrofit of RC frames by CLT panels and friction dampers. In Proceedings of the 8th International Conference on Computational Methods in Structural Dynamics and Earthquake Engineering, CompDyn 2021, Streamed from Athens, Athens, Greece, 28–30 June 2021. [Google Scholar]

- Margani, G.; Evola, G.; Tardo, C.; Marino, E.M. Energy, seismic, and architectural renovation of RC framed buildings with prefabricated timber panels. Sustainability 2020, 12, 4845. [Google Scholar] [CrossRef]

- EN ISO 10456:2007. Building Materials and Products—Hygrothermal Properties—Tabulated Design Values and Procedures for Determining Declared and Design Thermal Values; European Committee for Standardization: Brussels, Belgium, 2007. [Google Scholar]

- PAN v.7.1.0.4 Software. Available online: https://www.anit.it/software-anit/pan/ (accessed on 26 May 2021).

| Climate Zone | Italy [8] | Greece [9,10] | Spain [11] * | Turkey [12] ** |

|---|---|---|---|---|

| A | HDD < 600 (Lampedusa: 568) | HDD < 1000 (Heraklion: 702) | Malaga (<100 m.a.s.l.) Granada (<50 m.a.s.l.) | Region 1: south-western (Antalya, Izmir) |

| B | 600 ≤ HDD < 900 (Catania: 833) | 1000 ≤ HDD < 1500 (Athens: 947) | Sevilla (<200 m.a.s.l.) Valencia (<50 m a.s.l.) | Region 2: coastal (Istanbul, Bursa) |

| C | 901 ≤ HDD < 1400 (Naples: 1034) | 1500 ≤ HDD < 2000 (Thessaloniki: 1677) | Barcelona (<250 m.a.s.l.) Madrid (<500 m.a.s.l.) | Region 3: central (Ankara) |

| D | 1401 ≤ HDD < 2100 (Rome: 1415) | HDD ≥ 3000 (Kastoria: 2420) | Valladolid (<800 m.a.s.l.) Lugo (<500 m.a.s.l.) | Region 4: eastern (Erzurum) |

| E | 2101 ≤ HDD < 3000 (Bologna: 2259) | - | Leon (all altitudes) | - |

| F | HDD ≥ 3000 (Cuneo: 3012) | - | - | - |

| Country | Zone | Walls | Roofs | Windows |

|---|---|---|---|---|

| Austria [13] | All | 0.35 | 0.20 | 1.40 |

| Belgium [14] | All | 0.24 | 0.24 | 1.50 |

| Cyprus [15] | All | 0.40 | 0.40 | 2.25 |

| England [16] | All | 0.28 | 0.16 * 0.18 ** | 1.60 |

| Germany [17] | All | 0.24 # 0.35 ## | 0.20 (flat) 0.24 (pitched) | 1.30 |

| Greece [18] | A | 0.60 | 0.50 | 3.20 |

| B | 0.50 | 0.45 | 3.00 | |

| C | 0.45 | 0.40 | 2.80 | |

| D | 0.40 | 0.35 | 2.60 | |

| Italy [19] | A, B | 0.40 | 0.32 | 3.00 |

| C | 0.36 | 0.32 | 2.00 | |

| D | 0.32 | 0.26 | 1.80 | |

| E | 0.28 | 0.24 | 1.40 | |

| F | 0.26 | 0.22 | 1.00 | |

| Netherlands [20] | All | 0.21 | 0.15 | 1.65 |

| Norway [21] | All | 0.22 | 0.18 | 1.20 |

| Portugal [22] | I1 | 0.50 | 0.40 | 2.80 |

| I2 | 0.40 | 0.35 | 2.40 | |

| I3 | 0.35 | 0.30 | 2.20 | |

| Spain [22] | A | 1.25 | 0.80 | 5.70 |

| B | 1.00 | 0.65 | 4.20 | |

| C | 0.75 | 0.50 | 3.10 | |

| D | 0.60 | 0.40 | 2.70 | |

| E | 0.55 | 0.35 | 2.50 | |

| Turkey [12] | Region 1 | 0.70 | 0.45 | 2.40 |

| Region 2 | 0.60 | 0.40 | 2.40 | |

| Region 3 | 0.50 | 0.30 | 2.40 | |

| Region 4 | 0.40 | 0.25 | 2.40 |

| Material | Density ρ (kg·m−3) | Maximum Tolerable Condensate (g·m−2) |

|---|---|---|

| Clay | 600–2000 | ≤500 |

| Concrete | 400–2400 | ≤500 |

| Wood and derived materials | 500–800 | ≤30·ρ·d |

| Plasters and mortars | 600–2000 | ≤30·ρ·d |

| Organic fibers with waterproof glue | 300–700 | ≤20·ρ·d |

| Organic fibers with non-waterproof glue | 300–700 | ≤5·ρ·d |

| Mineral fibers | 10–150 | ≤5000·ρ·d·λ·(1–1.7·λ)−1 |

| Cellular plastic materials | 10–80 | 5000·ρ·d·λ·(1–1.7·λ)−1 |

| Cat. | Descriptor | Symbol | Notes |

|---|---|---|---|

| (i) | Weighted apparent sound reduction index | R′W | - |

| (i) | Weighted apparent sound reduction index (plus spectrum adaptation term for traffic noise) | R′W + Ctr | 1 |

| (i) | Weighted standardized level difference | D2m,nT,W | 2 |

| (i) | Weighted standardized level difference (plus spectrum adaptation term for traffic noise) | DnT,W + Ctr | 3 |

| (ii) | A-weighted maximum indoor sound pressure level (measured with fast time weighting) | LAF,max | - |

| (ii) | A-weighted equivalent indoor sound pressure level | LAeq | 4 |

| (ii) | A-weighted day–evening–night (den) indoor noise level | Lden | - |

| Country | Descriptor | Requirement |

|---|---|---|

| Austria [33] | R′res,w + Ctr | It must keep above a threshold value that depends on the outdoor noise level measured in front of the façade |

| Belgium [34] | DA,tr | DA,tr ≥ (LAeq(outdoor) − 34 dB) and DA,tr ≥ 26 dB (≥34 dB for bedrooms near airports and railways) |

| Croatia [35] | LAeq,day (indoor) | Dwellings: LAeq,day ≤ 40 dB; offices: LAeq,day ≤ 35 dB |

| LAeq,night (indoor) | Dwellings: LAeq,night ≤ 30 dB; offices: LAeq,night ≤ 25 dB | |

| Denmark [36] | LAeq,24h (indoor) | LAeq,24h ≤ 30 dB |

| Finland [36] | LAeq,7-22 (indoor) | LAeq,7-22 ≤ 35 dB |

| LAeq,22-7 (indoor) | LAeq,22-7 ≤ 30 dB | |

| France [35] | DnT,W + Ctr | (DnT,w + Ctr) ≥ 30 dB |

| Germany [37] | LAeq,day (indoor) | LAeq,day ≤ 35 dB |

| LAeq,night (indoor) | LAeq,night ≤ 25 dB | |

| Greece [32] | LAeq (indoor) | LAeq ≤ 35 dB (during public quiet hours) |

| Iceland [32] | LAeq,24h (indoor) | LAeq,24h ≤ 30 dB |

| LAFmax,22-6 (indoor) | LAmax,22-6 ≤ 45 dB | |

| Italy [38] | D2m,nT,W | Dwellings: D2m,nT,W ≥ 40 dB; offices: D2m,nT,W ≥ 42 dB Hospitals: D2m,nT,W ≥ 45 dB; schools: D2m,nT,W ≥ 48 dB |

| Netherlands [32] | D2m,nT,W + Ctr | (D2m,nT,W + Ctr) ≥ 23 dB |

| Lden (indoor) | Lden ≤ 30 dB | |

| Norway [32] | LAeq,24h (indoor) | LAeq,24h ≤ 30 dB |

| LAFmax,23-7 (indoor) | LAmax,23-7 ≤ 45 dB | |

| Poland [39] | RA | It must keep above a threshold value that depends on the outdoor noise level measured in front of the façade |

| Portugal [40] | D2m,nT,w | Dwellings: D2m,nT,w ≥ 33 dB; offices: D2m,nT,w ≥ 30 dB |

| Spain [41] | D2m,nT,w + Ctr | It must keep above a threshold value that depends on the outdoor A-weighted sound pressure level 1 |

| Sweden [32] | LAeq,24h (indoor) | LAeq,24h ≤ 30 dB |

| LAFmax,22-6 (indoor) | LAmax,22-6 ≤ 45 dB | |

| Turkey [42] | D2m,nT,w + Ctr | It must keep above a threshold value that depends on the outdoor A-weighted day–evening–night (den) noise level 2. |

| LAeq (indoor) | LAeq ≤ 30 dB (during occupancy, new buildings) LAeq ≤ 34 dB (during occupancy, existing buildings) |

| Wall Structure ID 1 (Uninsulated Solid Brick Wall) | Wall Structure ID 2 (Uninsulated Cavity Walls) | Wall Structure ID 3 (Uninsulated Concrete Walls) |

|---|---|---|

|

|

|

| Material | Density (kg·m−3) | Thermal Conductivity (W·m−1·K−1) | Specific Heat (J·kg−1·K−1) | Water Vapor Resistance (-) |

|---|---|---|---|---|

| External plaster (lime) | 1800 | 0.90 | 1000 | 10 |

| Internal plaster (gypsum) | 1300 | 0.57 | 1000 | 10 |

| Cement mortar | 2000 | 1.4 | 1000 | 10 |

| Unventilated air cavity | 1.2 | * | 1000 | 1 |

| Solid brick | 1800 | 0.72 | 1000 | 10 |

| Hollow clay brick (12 cm) | 775 | 0.38 | 840 | 10 |

| Hollow clay brick (8 cm) | 715 | 0.40 | 840 | 10 |

| Reinforced concrete | 2400 | 2.00 | 1000 | 80 |

| Materials Added by The e-SAFE Solutions | ||||

| CLT panel (10 cm) | 420 | 0.12 | 1600 | 60 |

| Wood fiber | 50 | 0.038 | 2100 | 1.1 |

| Partially ventilated air cavity (2 cm) | 1.2 | ** | 1000 | 1 |

| Cladding (open wooden slats) | 460 | 0.13 | 1660 | 1 |

| Wall ID | Surface Mass (kg·m−2) | U (W·m−2·K−1) | YIE (W·m−2·K−1) | Attenuation Factor (-) | Phase Shift (h) | Internal Areal Heat Capacity (kJ·m−2·K−1) |

|---|---|---|---|---|---|---|

| 1 | 530 | 1.71 | 0.425 | 0.25 | 10.2 | 66.1 |

| 2 | 248.5 | 1.07 | 0.575 | 0.54 | 7.3 | 55.2 |

| 3 | 440 | 3.20 | 1.555 | 0.49 | 5.6 | 74.6 |

| Solution 2. | Insulation Thickness (cm) | Surface Mass (kg·m−2) | U (W·m−2·K−1) | YIE (W·m−2·K−1) | Attenuation Factor (-) | Phase Shift (h) | Internal Areal Heat Capacity (kJ·m−2·K−1) |

|---|---|---|---|---|---|---|---|

| e-CLT | 6 | 294.9 | 0.30 | 0.025 | 0.08 | 14.5 | 48.5 |

| e-PANEL | 8 | 252.1 | 0.32 | 0.040 | 0.13 | 11.5 | 48.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Evola, G.; Costanzo, V.; Marletta, L. Hygrothermal and Acoustic Performance of Two Innovative Envelope Renovation Solutions Developed in the e-SAFE Project. Energies 2021, 14, 4006. https://doi.org/10.3390/en14134006

Evola G, Costanzo V, Marletta L. Hygrothermal and Acoustic Performance of Two Innovative Envelope Renovation Solutions Developed in the e-SAFE Project. Energies. 2021; 14(13):4006. https://doi.org/10.3390/en14134006

Chicago/Turabian StyleEvola, Gianpiero, Vincenzo Costanzo, and Luigi Marletta. 2021. "Hygrothermal and Acoustic Performance of Two Innovative Envelope Renovation Solutions Developed in the e-SAFE Project" Energies 14, no. 13: 4006. https://doi.org/10.3390/en14134006

APA StyleEvola, G., Costanzo, V., & Marletta, L. (2021). Hygrothermal and Acoustic Performance of Two Innovative Envelope Renovation Solutions Developed in the e-SAFE Project. Energies, 14(13), 4006. https://doi.org/10.3390/en14134006