Recommendations for Running a Tandem of Adsorption Chillers Connected in Series and Powered by Low-Temperature Heat from District Heating Network

Abstract

:1. Introduction

Two-Bed Cycle Time Allocations

2. Materials & Methods

2.1. Mathematical Modeling

2.1.1. Adsorber/desorber

2.1.2. Condenser

2.1.3. Evaporator

2.2. Adsorption Equilibrium

2.2.1. Mass Balance

2.2.2. Performance

3. Results and Discussion

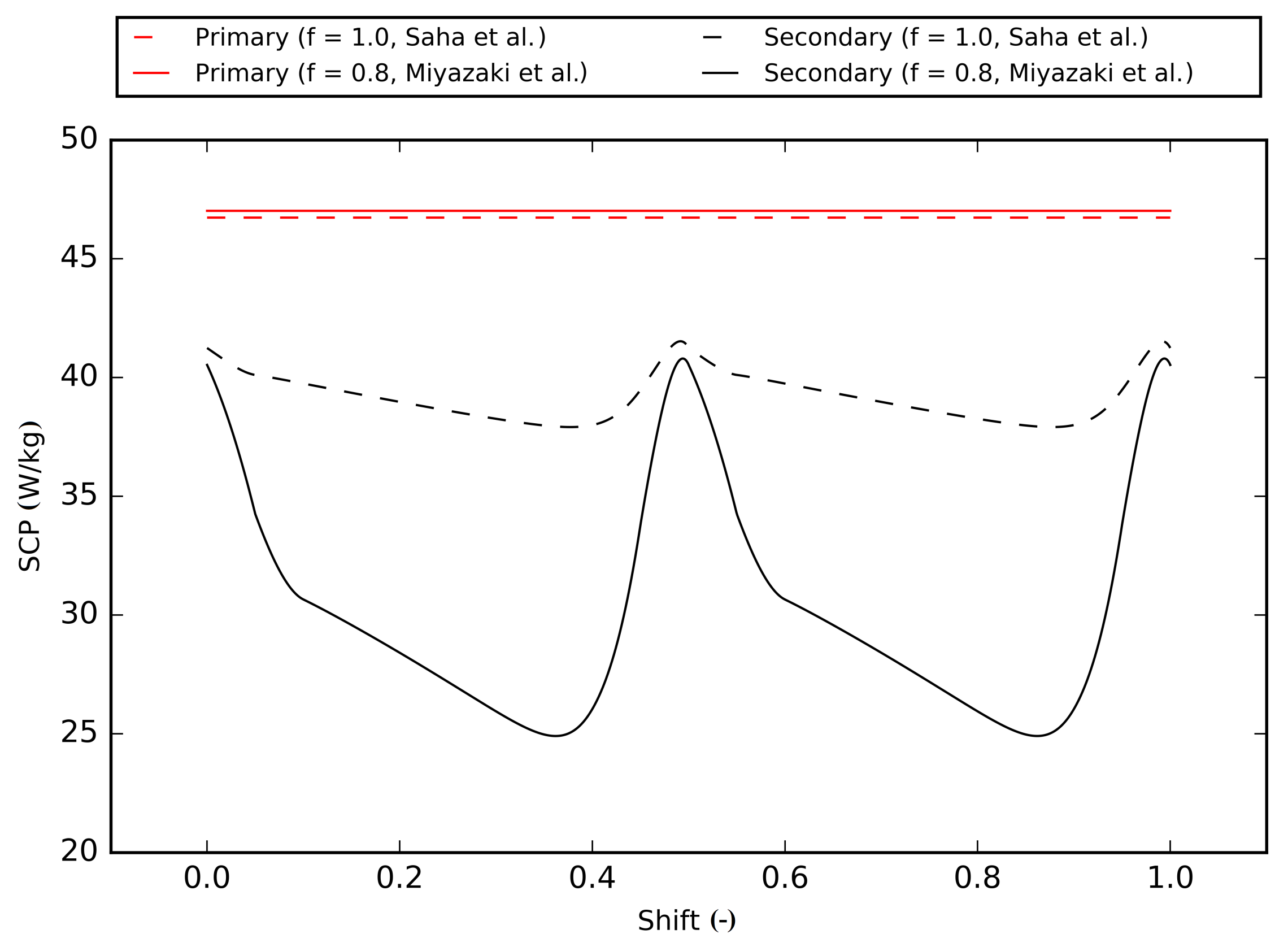

3.1. Synchronization of Operating Cycles

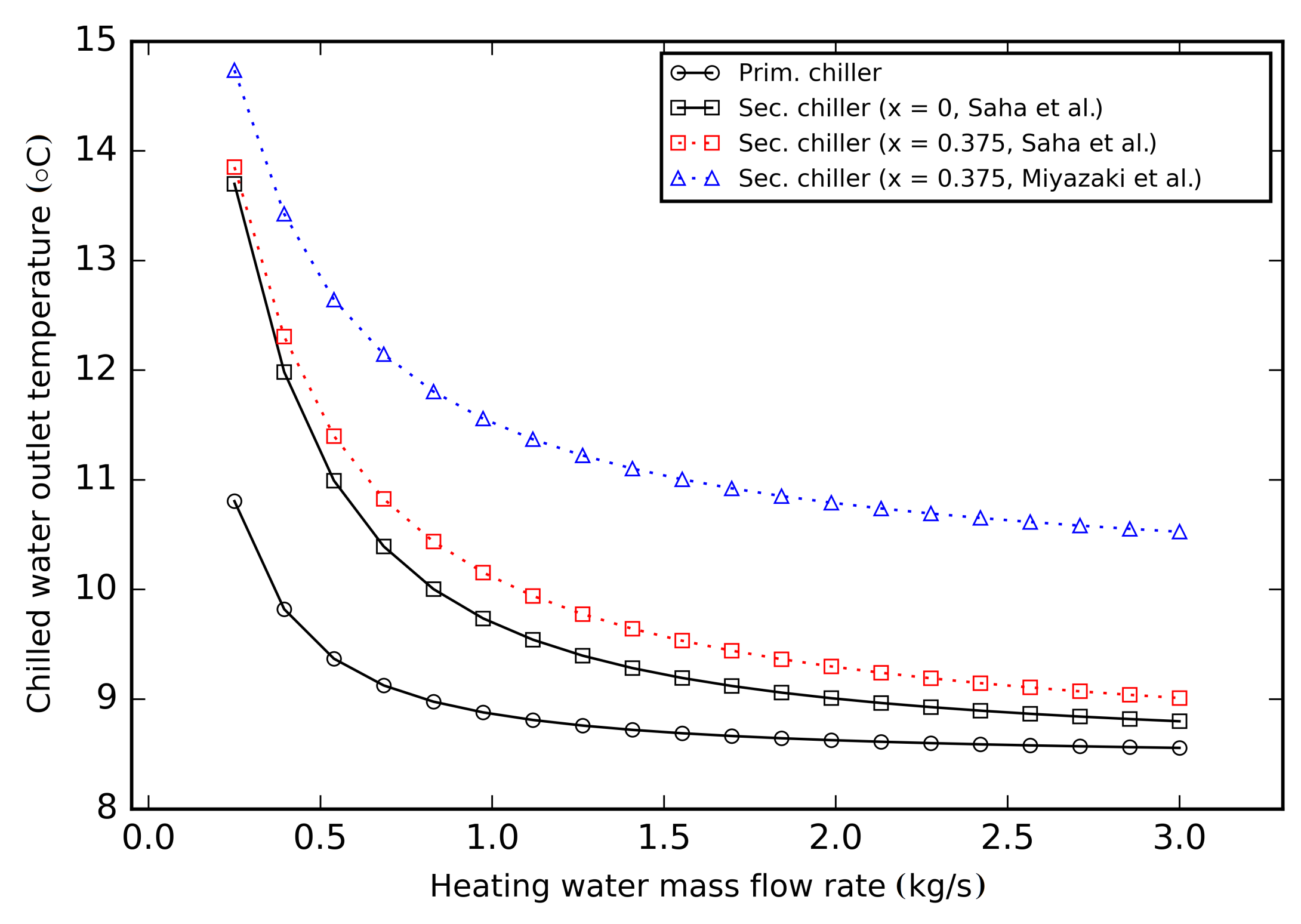

3.2. Heating Water Mass Flow Rate

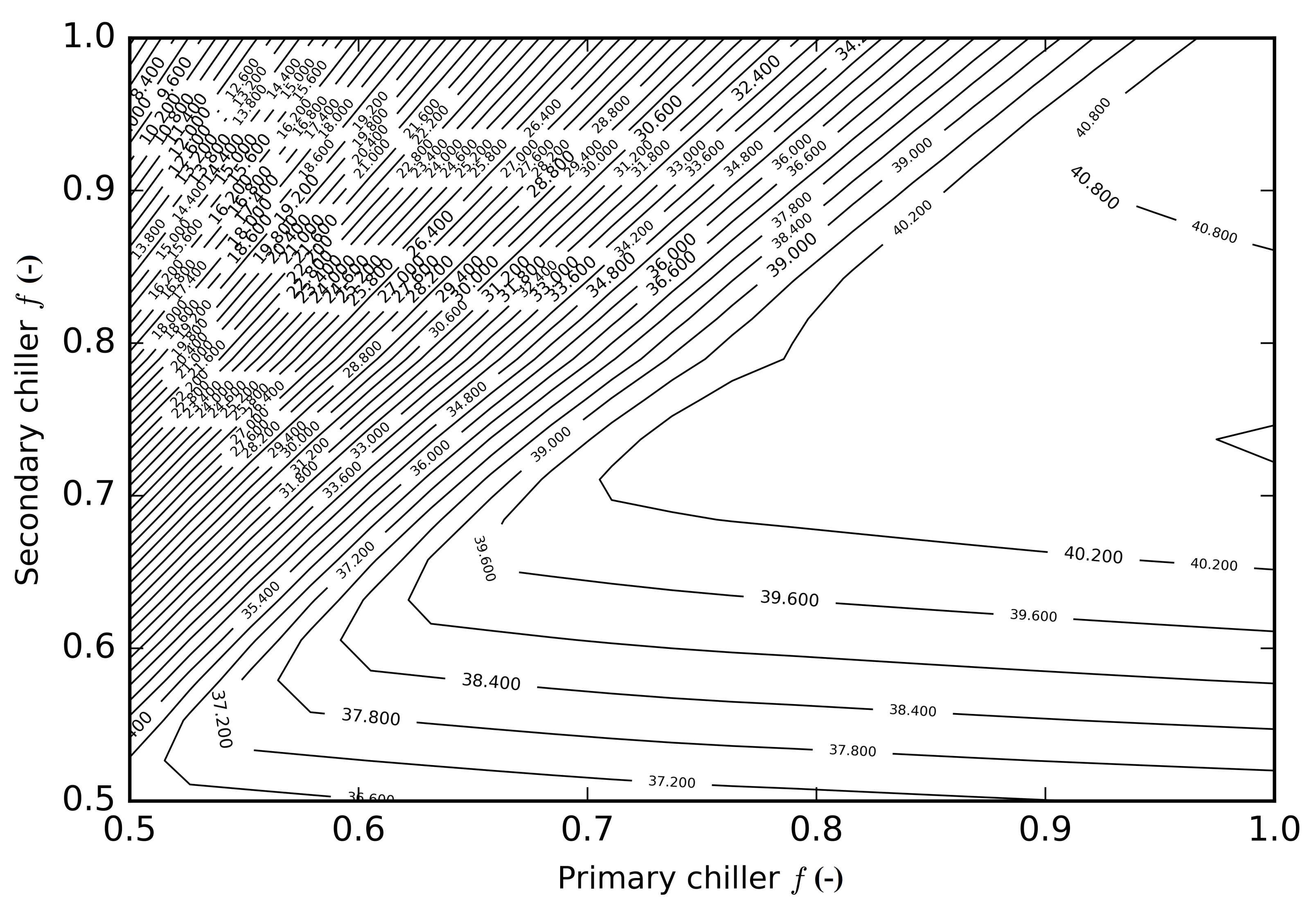

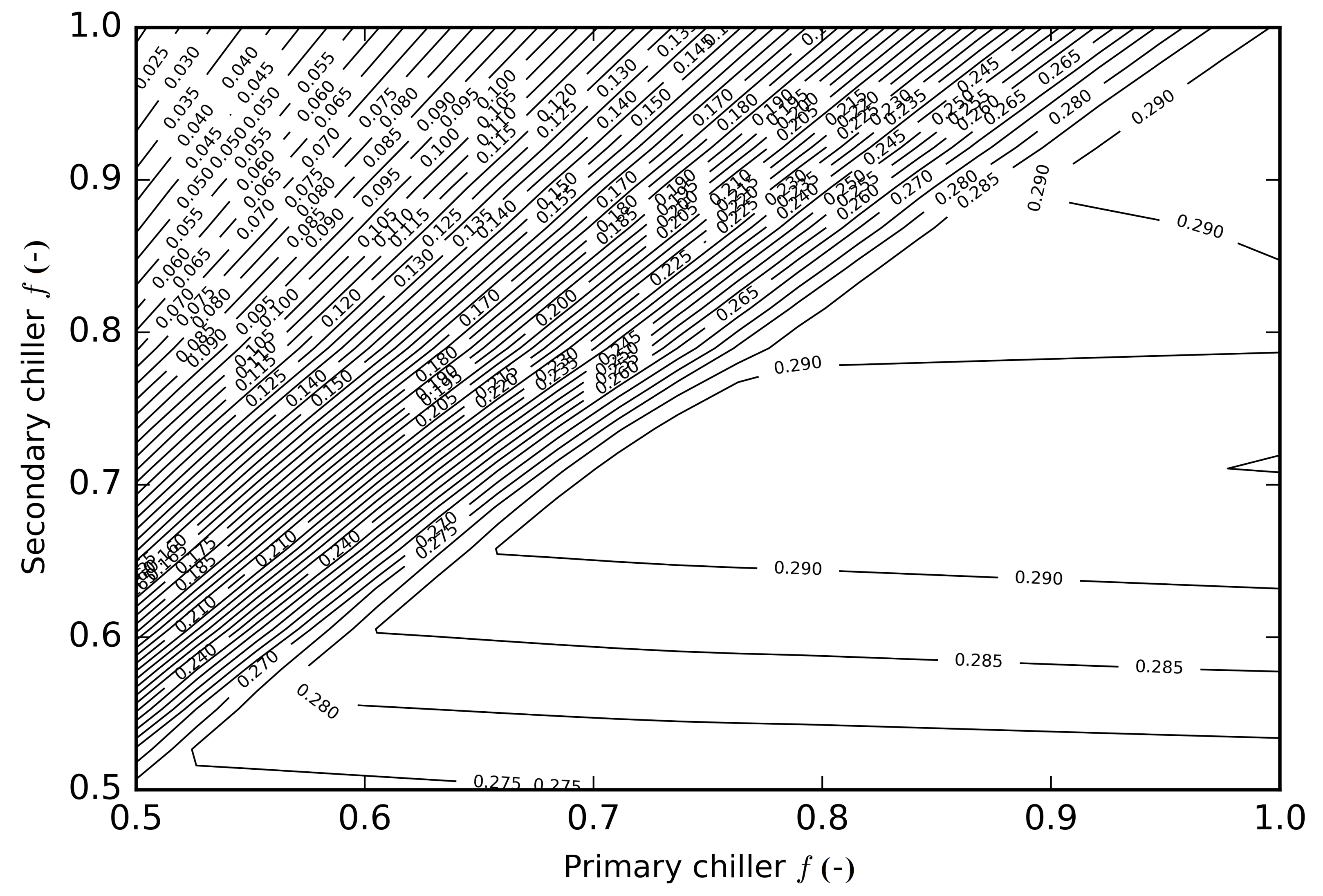

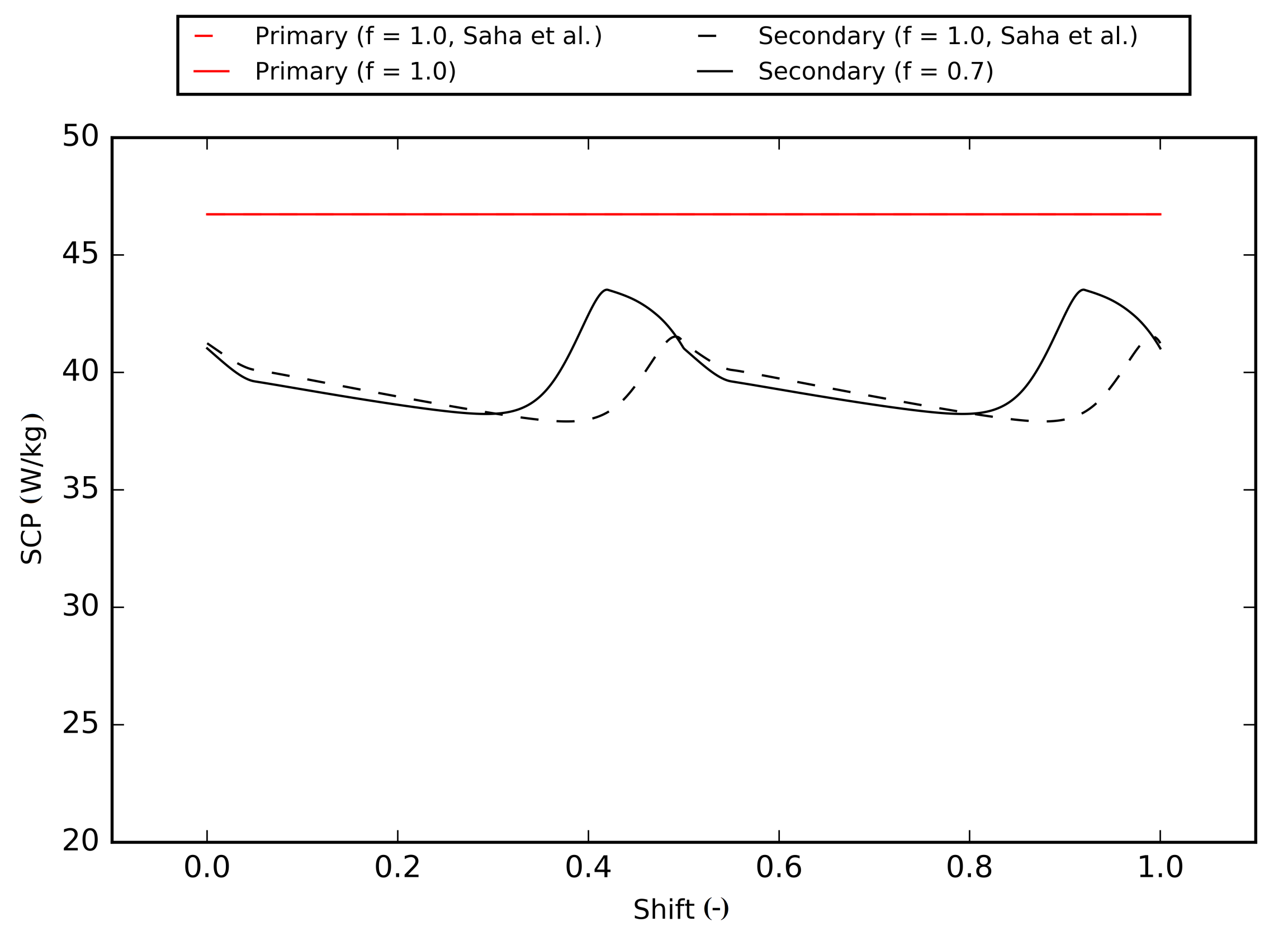

3.3. Secondary Chiller Performance Optimization

4. Conclusions

- The performance of a single stand-alone chiller is higher if it uses the optimal CTA. On the other hand, if two identical chillers are connected in series, and the accuracy of their synchronization cannot be controlled, the performance of the second device will be higher if both units use the symmetric CTA instead. The maximum performance drop is observed for and .

- The heating water outlet temperature in the secondary chiller is mainly controlled by the heating water mass flow rate. At the same time, this temperature is almost independent of the CTA that has been used in both chillers, and its sensitivity to the shift is very small. Regardless of the configuration, the difference between simulated outlet temperatures was always less than 1 °C.

- The degree of performance deterioration in the secondary chiller is the smallest if the adsorption/desorption time ratio in the primary chiller approaches 1.0, i.e., the primary chiller should use the symmetric CTA.

- The optimal adsorption/desorption time ratio for the secondary chiller is between = 0.6–0.7 (approx. 0.7 for the maximum SCP, and approx. 0.6 for the maximum COP).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CCHP | Combined Cooling, Heat and Power | |

| CHP | Combined Heat and Power | |

| COP | Coefficient of Performance | |

| CTA | Cycle Time Allocation | |

| SCP | Specific Cooling Power | |

| Nomenclature | ||

| A | heat transfer area | |

| c | specific heat | |

| pre-exponential constant | ||

| activation energy of surface diffusion | ||

| L | latent heat | |

| M | mass | |

| mass flow rate | kg/s | |

| p | pressure | Pa |

| q | adsorbed amount of refrigerant vapor | |

| vapor adsorbed at equilibrium | ||

| R | universal gas constant | |

| adsorbent particle size | ||

| T | temperature | K |

| U | heat transfer coefficient | |

| isosteric phase indicator | - | |

| isosteric heat of adsorption | ||

| heat exchanger indicator | - | |

| Subscripts | ||

| adsorption/adsorber | ||

| chilled medium | ||

| condensation/condenser | ||

| cooling fluid | ||

| evaporation/evaporator | ||

| heat transfer fluid | ||

| inlet | ||

| referring to other metallic components (aluminum fins) | ||

| referring to other metallic components (copper tubes) | ||

| outlet | ||

| refrigerant | ||

| saturation | ||

| v | vapor from another bed | |

| w | water |

References

- Wu, D.; Wang, R. Combined cooling, heating and power: A review. Prog. Energy Combust. Sci. 2006, 32, 459–495. [Google Scholar] [CrossRef]

- Ma, W.; Fan, J.; Fang, S.; Hassan, N.; Zhang, Y.; Wu, X.; Li, Y.; Hu, R.; Liu, G. Energy efficiency indicators for combined cooling, heating and power systems. Energy Convers. Manag. 2021, 239, 114187. [Google Scholar] [CrossRef]

- Ommen, T.; Markussen, W.B.; Elmegaard, B. Lowering district heating temperatures—Impact to system performance in current and future Danish energy scenarios. Energy 2016, 94, 273–291. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Wang, R.R.; Oliveira, R. A review on adsorption working pairs for refrigeration. Renew. Sustain. Energy Rev. 2009, 13, 518–534. [Google Scholar] [CrossRef]

- Shmroukh, A.N.; Ali, A.H.H.; Ookawara, S. Adsorption working pairs for adsorption cooling chillers: A review based on adsorption capacity and environmental impact. Renew. Sustain. Energy Rev. 2015, 50, 445–456. [Google Scholar] [CrossRef]

- Li, X.; Hou, X.; Zhang, X.; Yuan, Z. A review on development of adsorption cooling—Novel beds and advanced cycles. Energy Convers. Manag. 2015, 94, 221–232. [Google Scholar] [CrossRef]

- Choudhury, B.; Saha, B.B.; Chatterjee, P.K.; Sarkar, J.P. An overview of developments in adsorption refrigeration systems towards a sustainable way of cooling. Appl. Energy 2013, 104, 554–567. [Google Scholar] [CrossRef]

- Sharafian, A.; Bahrami, M. Assessment of adsorber bed designs in waste-heat driven adsorption cooling systems for vehicle air conditioning and refrigeration. Renew. Sustain. Energy Rev. 2014, 30, 440–451. [Google Scholar] [CrossRef]

- Saha, B.; Boelman, E.; Kashiwagi, T. Computer simulation of a silica gel-water adsorption refrigeration cycle- the influence of operating conditions on cooling output and COP. ASHRAE Trans. 1995, 101, 348–357. [Google Scholar]

- Miyazaki, T.; Akisawa, A.; Saha, B.B.B.; El-Sharkawy, I.I.; Chakraborty, A. A new cycle time allocation for enhancing the performance of two-bed adsorption chillers. Int. J. Refrig. 2009, 32, 846–853. [Google Scholar] [CrossRef]

- El-Sharkawy, I.I.; Abdelmeguid, H.; Saha, B.B. Towards an optimal performance of adsorption chillers: Reallocation of adsorption/desorption cycle times. Int. J. Heat Mass Transf. 2013, 63, 171–182. [Google Scholar] [CrossRef]

- Glaznev, I.; Aristov, Y. The effect of cycle boundary conditions and adsorbent grain size on the water sorption dynamics in adsorption chillers. Int. J. Heat Mass Transf. 2010, 53, 1893–1898. [Google Scholar] [CrossRef]

- Chorowski, M.; Pyrka, P.; Rogala, Z.; Czupryński, P. Experimental Study of Performance Improvement of 3-Bed and 2-Evaporator Adsorption Chiller by Control Optimization. Energies 2019, 12, 3943. [Google Scholar] [CrossRef] [Green Version]

- Zajaczkowski, B. Performance analysis and cycle time optimization of a single evaporator three-bed solid-sorption refrigeration system driven by low-temperature heat source. In Proceedings of the 24th IIR International Congress of Refrigeration, Yokohama, Japan, 16–22 August 2015; International Institute of Refrigeration, International Institute of Refrigeration: Yokohama, Japan, 2015; Volume 1, pp. 1–8. [Google Scholar]

- Gado, M.; Elgendy, E.; Elsayed, K.; Fatouh, M. Performance enhancement of an adsorption chiller by optimum cycle time allocation at different operating conditions. Adv. Mech. Eng. 2019, 11. [Google Scholar] [CrossRef]

- Sztekler, K. Optimisation of Operation of Adsorption Chiller with Desalination Function. Energies 2021, 14, 2668. [Google Scholar] [CrossRef]

- Lee, W.S.; Park, M.Y.; Lee, S.S.; Duong, X.Q.; Cao, N.V.; Kwon, O.K.; Chung, J.D. Effect of adsorption and desorption cycle time allocation on the performance of an adsorption chiller. J. Mech. Sci. Technol. 2021, 35, 323–331. [Google Scholar] [CrossRef]

- Halon, T.; Pelinska-Olko, E.; Szyc, M.; Zajaczkowski, B. Predicting Performance of a District Heat Powered Adsorption Chiller by Means of an Artificial Neural Network. Energies 2019, 12, 3328. [Google Scholar] [CrossRef] [Green Version]

- Gadd, H.; Werner, S. Achieving low return temperatures from district heating substations. Appl. Energy 2014, 136, 59–67. [Google Scholar] [CrossRef] [Green Version]

- Chorowski, M.; Rogala, Z.; Pyrka, P. System options for cooling of buildings making use of district heating heat. Int. J. Refrig. 2016, 70, 183–195. [Google Scholar] [CrossRef]

- Boelman, E.; Saha, B.; Kashiwagi, T. Experimental investigation of a silica gel-water adsorption refrigeration cycle- the influence of operating conditions on cooling output and COP. ASHRAE Trans. 1995, 101, 358–366. [Google Scholar]

- Zajaczkowski, B. Optimizing performance of a three-bed adsorption chiller using new cycle time allocation and mass recovery. Appl. Therm. Eng. 2016, 100, 744–752. [Google Scholar] [CrossRef]

- Sakoda, A.; Suzuki, M. Fundamental study on solar powered adsorption cooling system. J. Chem. Eng. Jpn. 1984, 17, 52–57. [Google Scholar] [CrossRef] [Green Version]

- Aristov, Y.I.; Tokarev, M.M.; Freni, A.; Glaznev, I.S.; Restuccia, G. Kinetics of water adsorption on silica Fuji Davison RD. Microporous Mesoporous Mater. 2006, 96, 65–71. [Google Scholar] [CrossRef]

| Symbol | Value | Unit | Symbol | Value | Unit |

|---|---|---|---|---|---|

| 3.73 | 4186 | ||||

| 1.91 | 905 | ||||

| 2.46 | 386 | ||||

| 4115.23 | 924 | ||||

| 2557.54 | 47 | ||||

| 1602.56 | 24.28 | ||||

| 1724.14 | 12.45 | ||||

| 2.54 × 10 | 50 | ||||

| 4.2 × 10 | 64.04 | ||||

| 2.5 × 10 | 51.20 | ||||

| 2.8 × 10 | |||||

| 1.74 × 10 |

| Symbol | Value | Unit | Symbol | Value | Unit |

|---|---|---|---|---|---|

| 65 | °C | 1.3 | |||

| 31 | °C | 1.3 + 1.6 | |||

| 14 | °C | 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nalepa, B.; Halon, T. Recommendations for Running a Tandem of Adsorption Chillers Connected in Series and Powered by Low-Temperature Heat from District Heating Network. Energies 2021, 14, 4791. https://doi.org/10.3390/en14164791

Nalepa B, Halon T. Recommendations for Running a Tandem of Adsorption Chillers Connected in Series and Powered by Low-Temperature Heat from District Heating Network. Energies. 2021; 14(16):4791. https://doi.org/10.3390/en14164791

Chicago/Turabian StyleNalepa, Bartlomiej, and Tomasz Halon. 2021. "Recommendations for Running a Tandem of Adsorption Chillers Connected in Series and Powered by Low-Temperature Heat from District Heating Network" Energies 14, no. 16: 4791. https://doi.org/10.3390/en14164791