Applicability of Concrete–Steel Composite Piles for Offshore Wind Foundations

Abstract

:1. Introduction

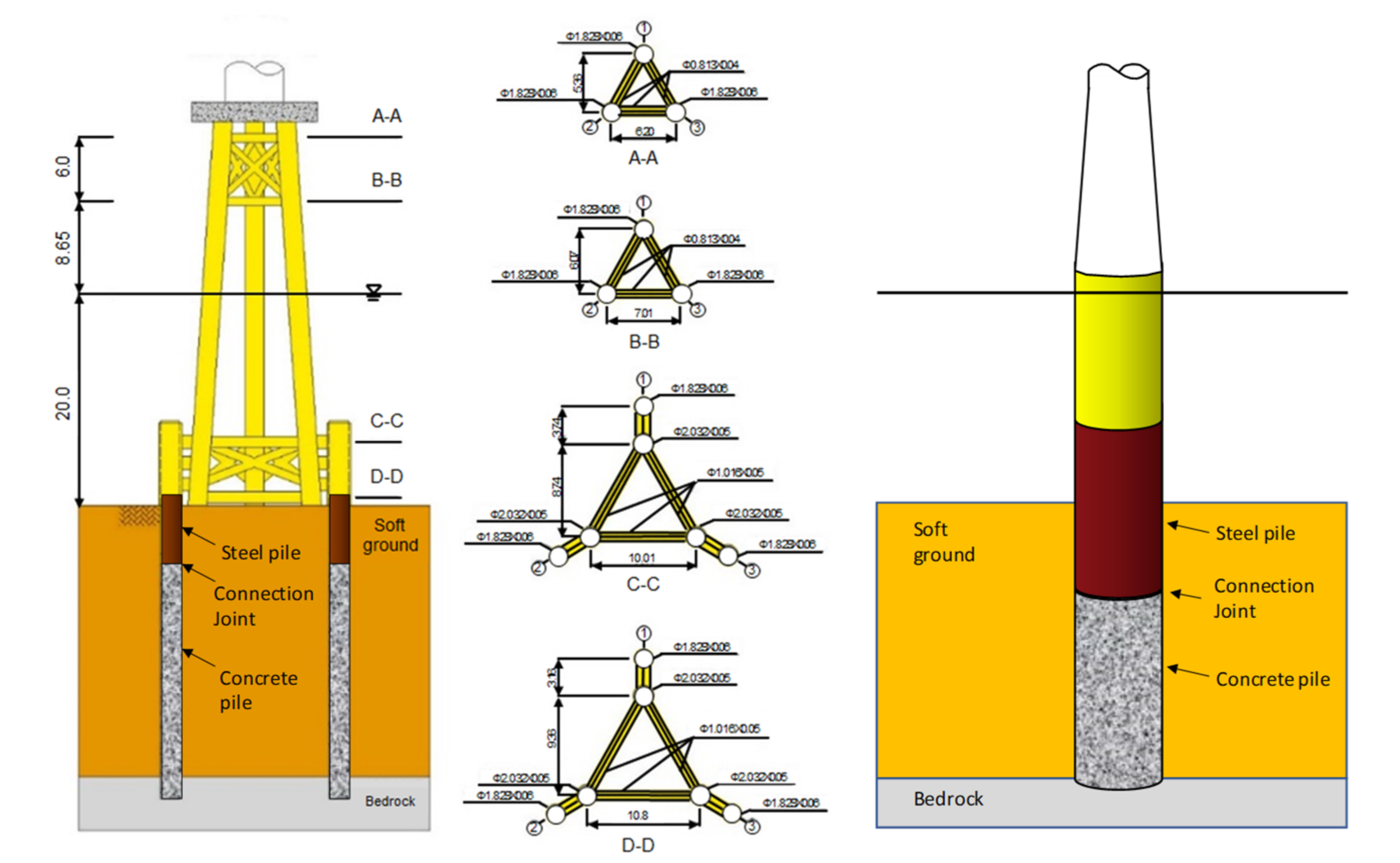

2. Design and Installation of Concrete-Steel Pile

2.1. Design Method

2.2. Installation Methods

2.3. Joint Integrity

3. Field Pile Load Tests

3.1. Soil Stratigraphy

3.2. Test Pile Geometery

3.3. Axial Pile Load Tests

3.4. Lateral Pile Load Tests

4. Results of Pile Load Tests

4.1. Axial Pile Load Tests

4.2. Lateral Pile Load Tests

5. Interpretation of Test Results

5.1. Axial Pile Load Tests

5.2. Lateral Pile Load Tests

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Burd, H.J.; Byrne, B.W.; McAdam, R.A.; Houlsby, G.T.; Martin, C.M.; Beuckelaers, W.J.A.P.; Zdravkovic, L.; Taborda, D.M.G.; Potts, D.M.; Jardine, R.J.; et al. Design Aspects for Monopile Foundations. In Proceedings of the TC 209 Workshop 19th ICSMGE, Seoul, Korea, 20 September 2017; pp. 35–44. [Google Scholar]

- Bhattacharya, S. Challenges in Design of Foundations for Offshore Wind Turbines. Eng. Technol. Ref. 2014, 1, 922. [Google Scholar] [CrossRef]

- Koh, J.H.; Ng, E.Y.K. Downwind Offshore Wind Turbines: Opportunities, Trends and Technical Challenges. Renew. Sustain. Energy Rev. 2016, 54, 797–808. [Google Scholar] [CrossRef]

- Willis, D.J.; Niezrecki, C.; Kuchma, D.; Hines, E.; Arwade, S.R.; Barthelmie, R.J.; Dipaola, M.; Drane, P.J.; Hansen, C.J.; Inalpolat, M.; et al. Wind Energy Research: State-of-the-Art and Future Research Directions Simulator for Wind Farm Applications. Renew. Energy 2018, 125, 133–154. [Google Scholar] [CrossRef]

- Oh, K.; Nam, W.; Sung, M.; Kim, J.; Epureanu, B.I. A Review of Foundations of Offshore Wind Energy Convertors: Current Status and Future Perspectives. Renew. Sustain. Energy Rev. 2018, 88, 16–36. [Google Scholar] [CrossRef]

- Wang, X.; Zeng, X.; Li, J.; Yang, X.; Wang, H. A Review on Recent Advancements of Substructures for Offshore Wind Turbines. Energy Convers. Manag. 2018, 158, 103–119. [Google Scholar] [CrossRef]

- Mathern, A.; Von der Haar, C.; Marx, S. Concrete Support Structures for Offshore Wind Turbines: Current Status, Challenges, and Future Trends. Energies 2021, 14, 1995. [Google Scholar] [CrossRef]

- Fellenius, B.; Kim, S.; Chung, S. Long-Term Monitoring of Strain in Instrumented Piles. J. Geotech. Geoenviron. Eng. 2009, 135, 1583–1595. [Google Scholar] [CrossRef]

- Shin, Y.; Kim, M.; Ko, J.; Jeong, S. Proposed Design Chart of Mechanical Joints on Steel-PHC Composite Piles. Mater. Struct. 2014, 47, 1221–1238. [Google Scholar] [CrossRef]

- Korea Institute of Energy Technology Evaluation and Planning. Development of Hybrid Substructure Systems for Offshore Wind Power; Korea Institute of Energy Technology Evaluation and Planning: Seoul, Korea, 2013. [Google Scholar]

- Haiderali, A.E.; Madabhushi, S.P.G. Enhancing the Lateral Capacity of Monopiles in Sand using Reinforced Concrete Footings. In Proceedings of the XVI ECSMGE Geotechnical Engineering for Infrastructure and Development; ICE Publishing: London, UK, 2015; ISBN 978-0-7277-6067-8. [Google Scholar] [CrossRef]

- Kim, H.G.; Kim, B.J.; Lee, K. Analysis of Piled Concrete Foundation for a 3-MW Class Offshore Wind Turbine along the Southwest Coast in Korea. J. Mar. Sci. Eng. 2020, 8, 215. [Google Scholar] [CrossRef] [Green Version]

- Matlock, H. Correlations for Design of Laterally Loaded Piles in Soft Clay. In Proceedings of the 2nd Offshore Technology Conference, Houston, TX, USA, 22–24 April 1970; pp. 577–597. [Google Scholar]

- Poulos, H.G. Behavior of Laterally Loaded Piles: I—Single Piles. J. Soil Mech. Found. Div. 1971, 97, 711–731. [Google Scholar] [CrossRef]

- Reese, L.C. Laterally Loaded Piles: Program Documentation. J. Geotech. Eng. Div. 1977, 103, 287–305. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. ASTM D1143/D1143M-20, Standard Test Methods for Deep Foundation Elements Under Static Axial Compressive Load; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Davisson, M. High Capacity Piles. In Proceedings, Soil Mechanics Lecture Series on Innovations in Foundation Construction; ASCE, Illinois Section: Chicago, IL, USA, 1972. [Google Scholar]

- Iskander, M.G.; Stachula, A. Wave Equation Analyses of Fiber-Reinforced Polymer Composite Piling. J. Compos. Constr. 2002, 6, 88–96. [Google Scholar] [CrossRef]

- Korean Geotechnical Society (KGS). Design Standards for Foundation Structures; Ministry of Land, Transport and Maritime Affairs: Seoul, Korea, 2008. [Google Scholar]

- Ministry of Land, Transport and Maritime Affairs. Bridge Design Specifications (in Korean); Ministry of Land, Transport and Maritime Affairs: Gwacheon, Korea, 2008. [Google Scholar]

- American Petroleum Institute. Recommended Practice for Planning, Designing and Constructing Fixed Offshore Platforms-Working Stress Design. RP 2A-WSD; American Petroleum Institute: Washington, DC, USA, 2010. [Google Scholar]

- Jeanjean, P. Re-Assessment of P-Y Curves for Soft Clay from Centrifuge Testing and Finite Element Modeling. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 2009; p. 17861. [Google Scholar]

| Pile Type | Diameter (mm) | Thickness (mm) | Section Area (mm2) | Elastic Modulus (MPa) | Yielding Stress (MPa) | Allowable Stress (MPa) | Material |

|---|---|---|---|---|---|---|---|

| Steel pile | 500 | 12 | 18,400 | 210,000 | 240 | 140 | SPS 400 |

| PHC pile | 500 | 80 | 105,600 | 40,000 | 80 | 20 | Type-A |

| Mechanical Joint | Material | Size (mm) | Elastic Modulus (MPa) | Yielding Stress (MPa) | Allowable Stress (MPa) | 10% Increased Allowable Stress (MPa) | |

|---|---|---|---|---|---|---|---|

| Part | Name | ||||||

| Part 1 | N.C.P. Joint | SC450 | - | 210,000 | 240 | 140 | 154 |

| Part 2 | PHC bend | SC450 | - | 210,000 | 240 | 140 | 154 |

| Part 3 | Side plate | SS400 | 14 t | 210,000 | 240 | 140 | 154 |

| Part 4 | PHC pile | fck = 80 MPa | A-Type | 35,000 | 80 | 20 | 22 |

| Part 5 | Steel pile | SS400 | 500 × 12 t | 210,000 | 240 | 140 | 154 |

| Part 6 | Bolts | SCR420B | M14 × 25 | 210,000 | 900 | 530 | 583 |

| Site | Layer | Average Depth Below Seafloor, m | Water Content, w% | Total Unit Weight, γ, kN/m3 | Plasticity Index, Ip, % | Undrained Shear Strength, su, kPa | SPT n Value | qu (MPa) |

|---|---|---|---|---|---|---|---|---|

| Site A | Unit I | 0–3 | 48 | 18 | 20 | 70–80 | 9 | - |

| Unit II | 3–25 | 50.4 | 18 | 27.5 | 30–70 | 3–6 | - | |

| Unit III | 25– | - | - | - | - | over 30 | - | |

| Site B | Unit I | 0–3 | 50 | 18 | 21 | 20–30 | 4 | 0.4 |

| Unit II | 3–35 | 52 | 18 | 28 | 20–80 | 3–7 | 0.4–1.1 | |

| Unit III | 35– | - | - | - | - | over 30 | - |

| Case | Types of Composite Pile Foundations | Diameter (mm) | Length of Upper Steel Pile (m) | Length of Lower Pre-Stressed Con’c Pile (m) | Total Pile Length (m) | Ratio of Upper Steel Pile (%) * | Types of Pile Load Tests | Installation Methods | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Dynamic Axial | Static Axial | Static Lateral | |||||||||

| Type-1 500 mm composite pile (Site A) | Pile-1 | Steel pile (12 t **) + Pre-stressed concrete (80 t) | 500 | 4.4 | 18 | 22.4 | 20% | √ | Driving | ||

| Pile-2 | Steel pile (12 t) + Pre-stressed concrete (80 t) | 500 | 5.0 | 14 | 19 | 26% | √ | Driving | |||

| Pile-3 | Steel pile (12 t) + Pre-stressed concrete (80 t) | 500 | 10.5 | 13 | 23.5 | 45% | √ | Augering + water jetting | |||

| Type-2 1000 mm composite pile and Pre-stressed concrete pile (Site B) | Pile-4 | Steel pile (16 t) + Pre-stressed concrete (130 t) | 1000 | 8.0 | 25 | 33 | 24% | √ | √ | Augering + water jetting | |

| Pile-5 | Pre-stressed concrete (130 t) | 1000 | 0.0 | 29 | 29 | 0% | √ | √ | Augering + water jetting | ||

| Pile-6 | Steel pile (16 t) + Pre-stressed concrete (130 t) | 1000 | 15.0 | 25 | 38 | 40% | √ | Augering + water jetting | |||

| Pile-7 | Pre-stressed concrete (130 t) | 1000 | 0.0 | 37.5 | 37.5 | 0% | √ | Driving | |||

| Pile No. | Pile Type | Embedded Depth (GL-m) | Hammer Stroke (m) | Output Values | ||||

|---|---|---|---|---|---|---|---|---|

| Skin Friction (kN) | End Bearing Capacity (kN) | Total Bearing Capacity (kN) | Allowable Bearing Capacity | |||||

| CAPWAP (S.F = 2.5) | Davisson (S.F = 2.0) | |||||||

| Pile-4 | Upper steel pile (D1000, 16 t, 8 m) + Lower PHC (D1000, 130 t, 25 m) | 32.0 | 0.7 | 1040 | 3410 | 4450 | 1780 | 2225 |

| 33.0 | 2.0 | 2902 | 3220 | 6122 | 2449 | 3061 | ||

| Pile-5 | PHC (D1000, 130 t, 30 m) | 27.5 | 1.0 | 800 | 3170 | 4050 | 1620 | 2025 |

| 1.5 | 900 | 3630 | 4530 | 1812 | 2265 | |||

| 28.5 | 0.7 | 900 | 3270 | 4170 | 1660 | 2085 | ||

| 1.0 | 970 | 3560 | 4530 | 1812 | 2265 | |||

| 29.0 | 0.5 | 910 | 3639 | 4549 | 1820 | 2275 | ||

| 1.0 | 1010 | 4190 | 5200 | 2080 | 2660 | |||

| 1.5 | 1120 | 4980 | 6100 | 2440 | 3050 | |||

| Pile-7 | PHC (D1000, 130 t, 47 m) | 32.5 | 0.5 | 670 | 3260 | 3930 | 1572 | 1965 |

| 1.0 | 730 | 3460 | 4190 | 1676 | 2095 | |||

| 1.5 | 780 | 3700 | 4480 | 1792 | 2240 | |||

| 37.5 | 0.7 | 4390 | 5270 | 9660 | 3864 | 4830 | ||

| 1.0 | 4560 | 5960 | 10,520 | 4208 | 5260 | |||

| 1.5 | 4890 | 6430 | 11,320 | 4528 | 5660 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, Y.; Langford, T.; Cho, K.; Park, J.; Ko, J. Applicability of Concrete–Steel Composite Piles for Offshore Wind Foundations. Energies 2021, 14, 4794. https://doi.org/10.3390/en14164794

Shin Y, Langford T, Cho K, Park J, Ko J. Applicability of Concrete–Steel Composite Piles for Offshore Wind Foundations. Energies. 2021; 14(16):4794. https://doi.org/10.3390/en14164794

Chicago/Turabian StyleShin, Yunsup, Thomas Langford, Kyunghwan Cho, Jongheon Park, and Junyoung Ko. 2021. "Applicability of Concrete–Steel Composite Piles for Offshore Wind Foundations" Energies 14, no. 16: 4794. https://doi.org/10.3390/en14164794