Modelling, Design and Control of a Standalone Hybrid PV-Wind Micro-Grid System

Abstract

:1. Introduction

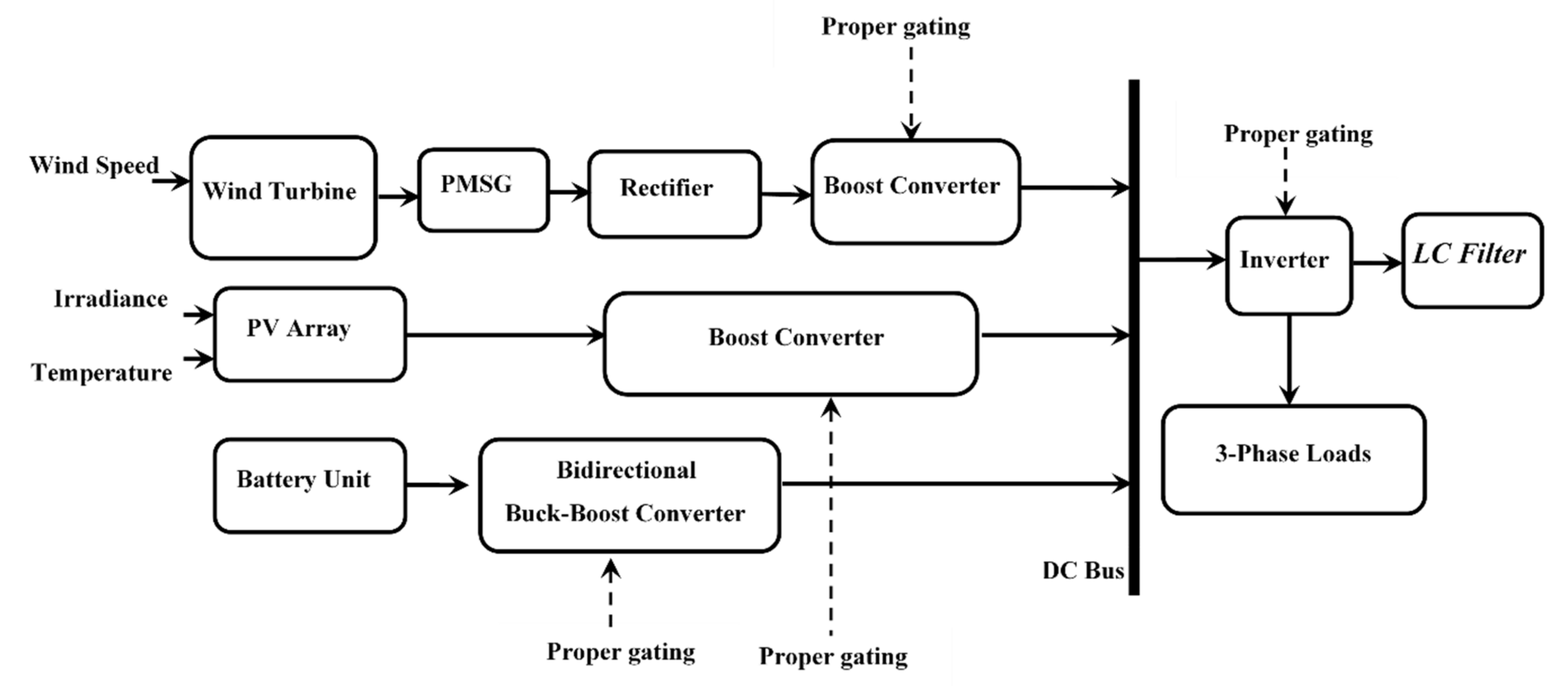

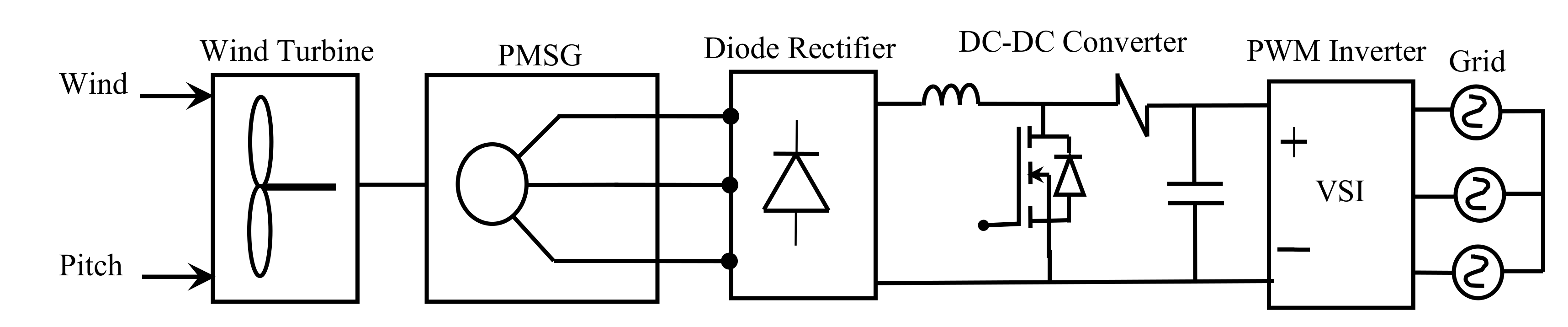

2. Micro-Grid System Configuration

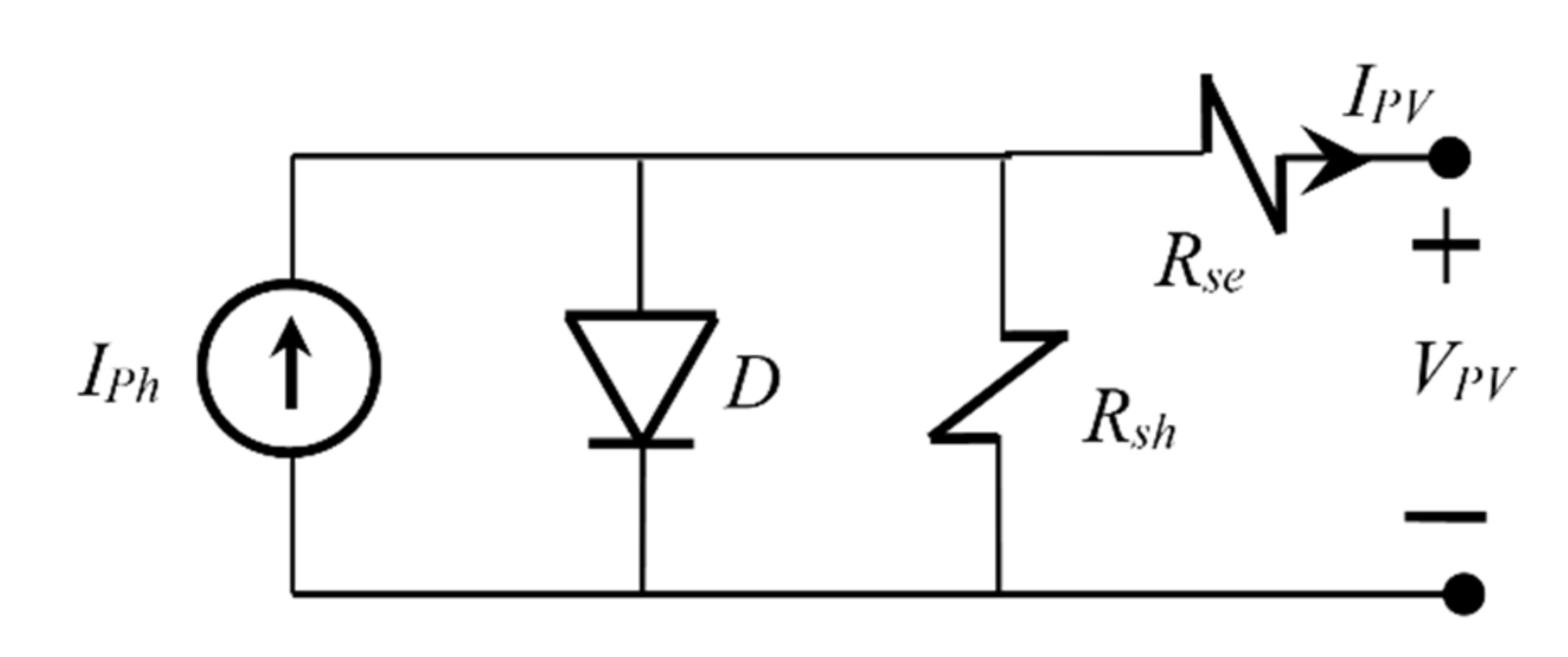

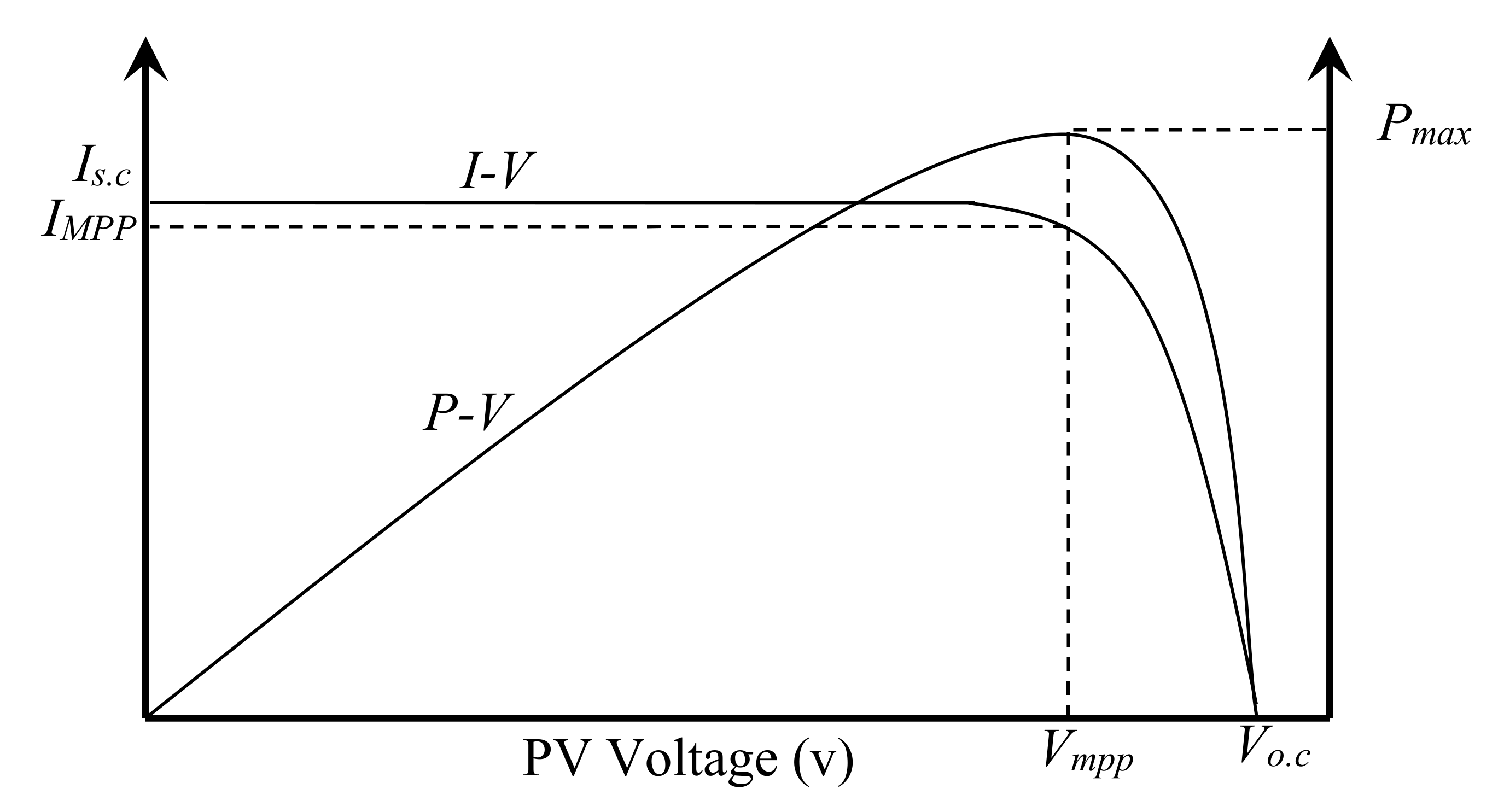

2.1. PV System

2.2. PMSG-Based Wind Energy System

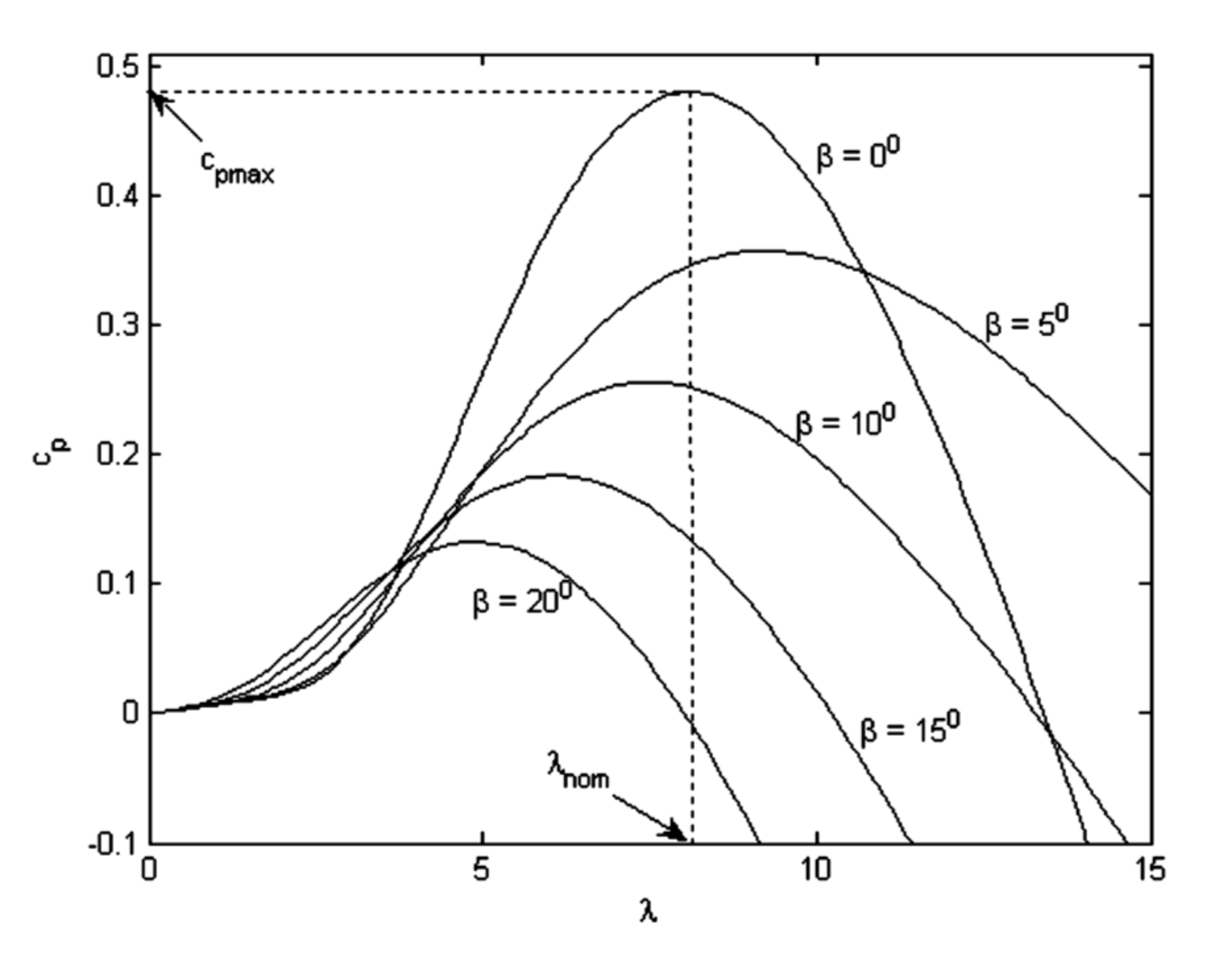

2.2.1. Wind Turbine Characteristics

2.2.2. Permanent Magnet Synchronous Generators

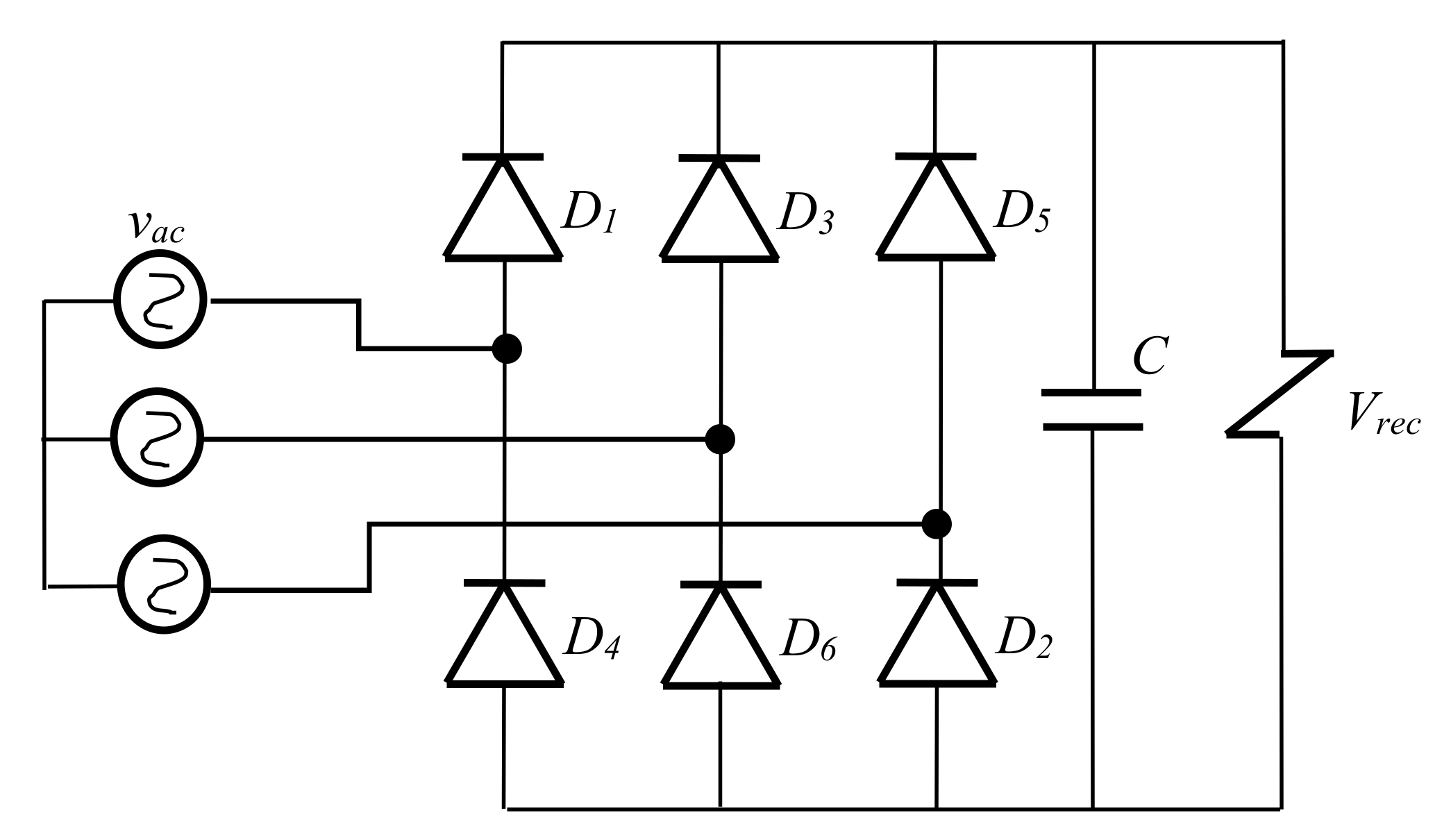

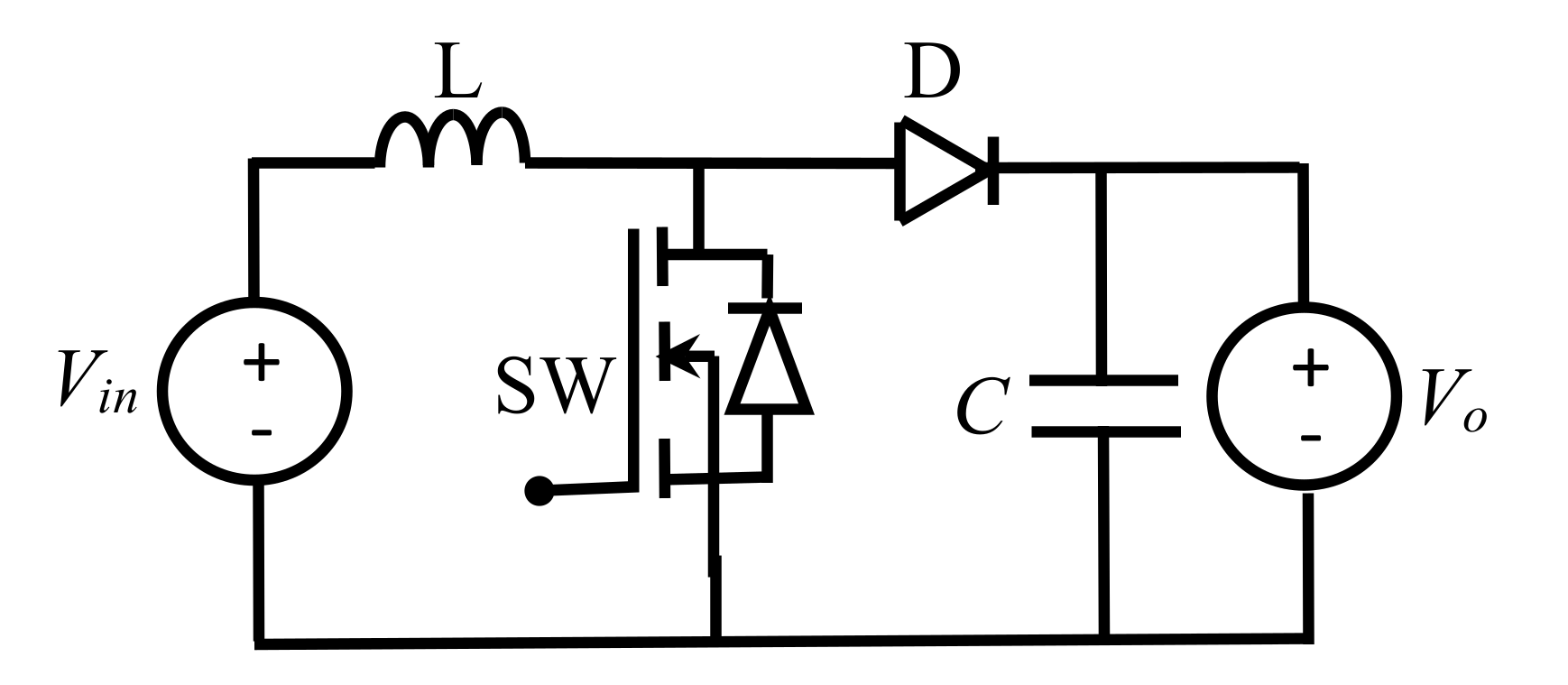

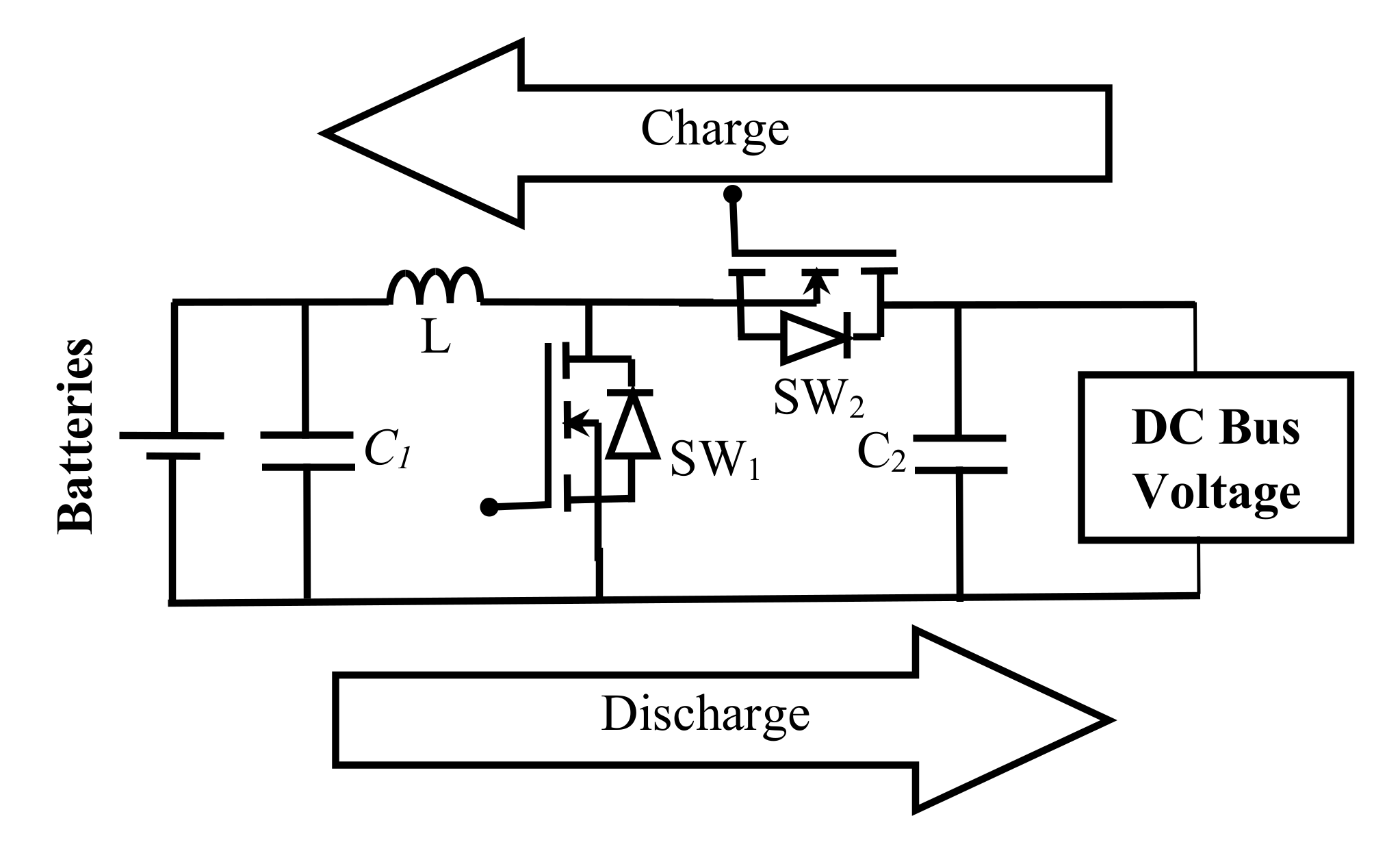

2.3. Power Electronic Devices

2.3.1. Three-Phase Diode Rectifier of PMSGs

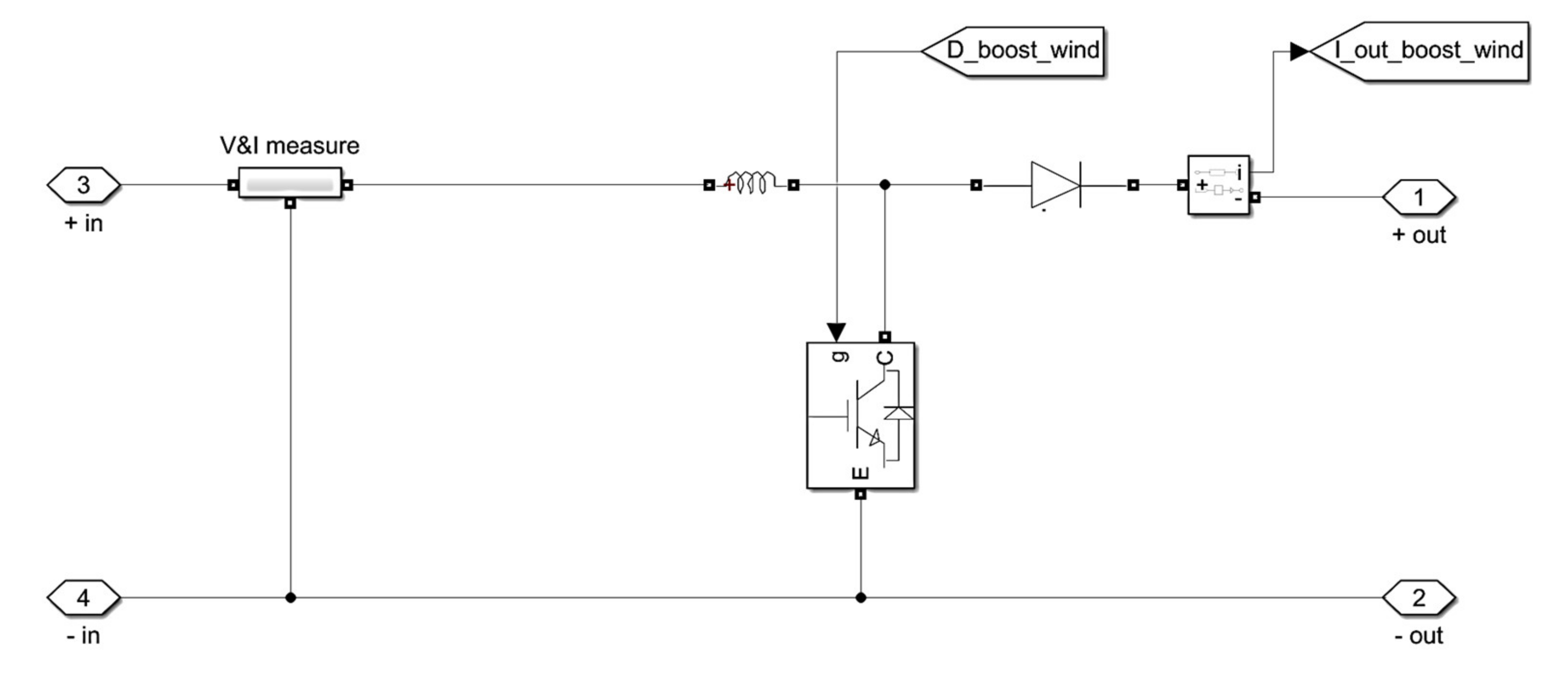

2.3.2. Boost Converter

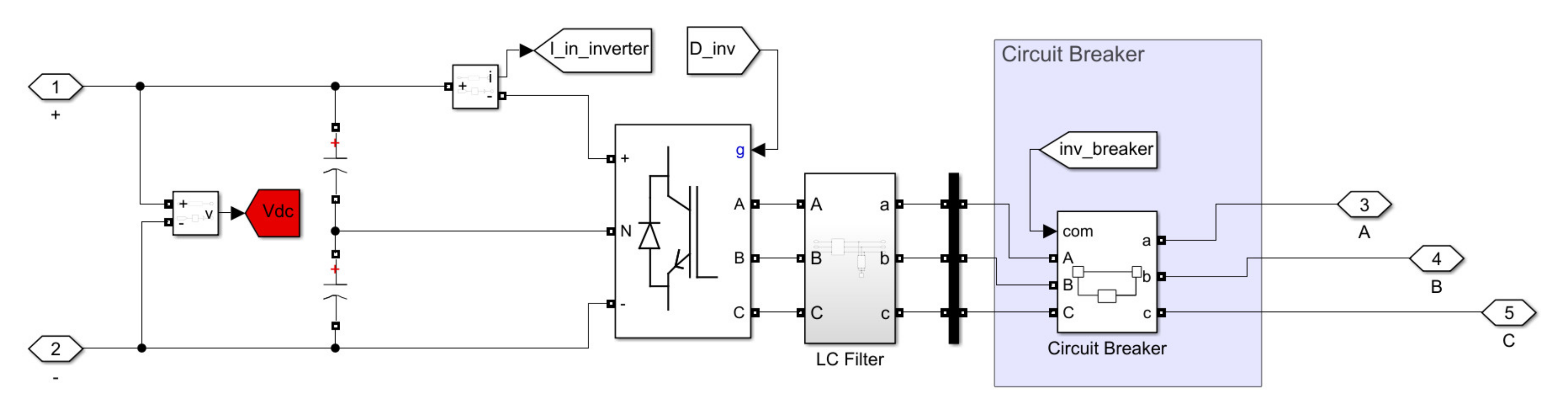

2.3.3. Inverters

2.3.4. Bidirectional DC–DC Converter with a Battery Storage System

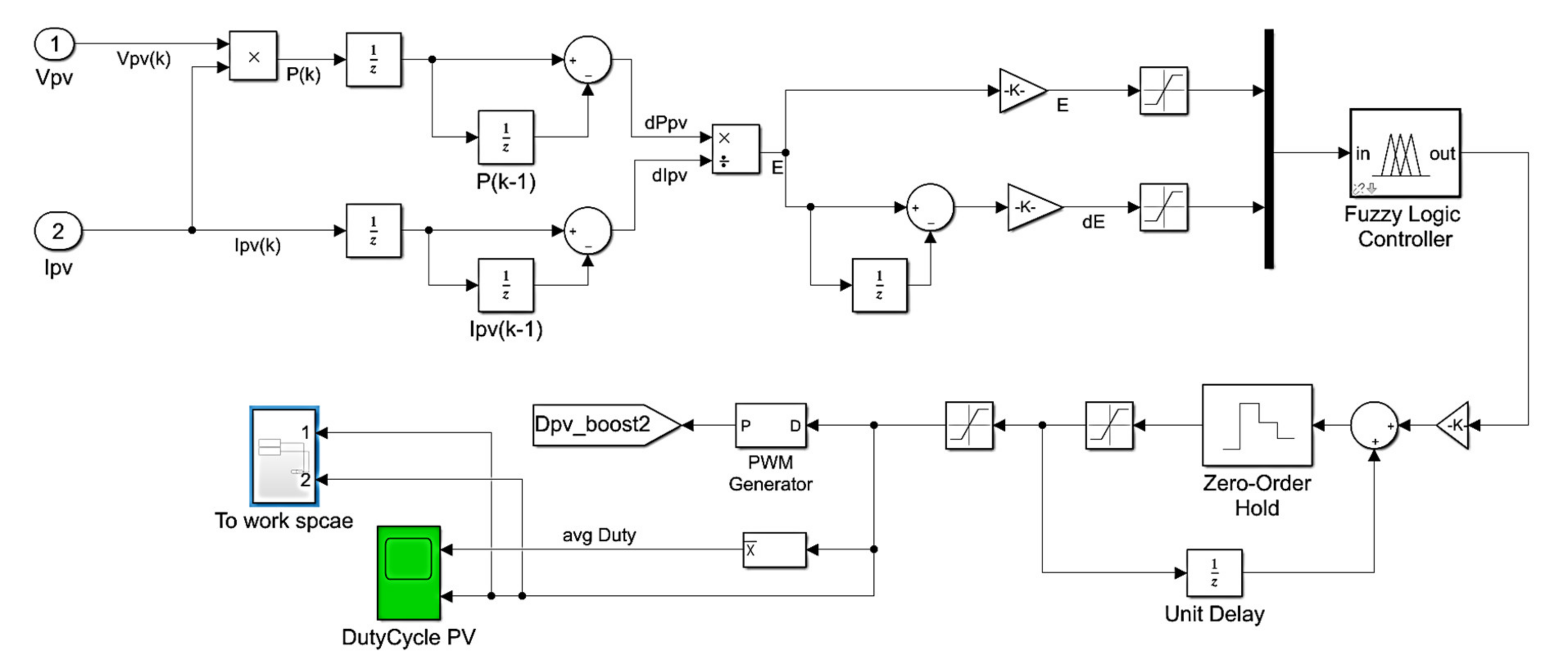

3. Control System

3.1. Bidirectional DC–DC Converter with Battery Storage System

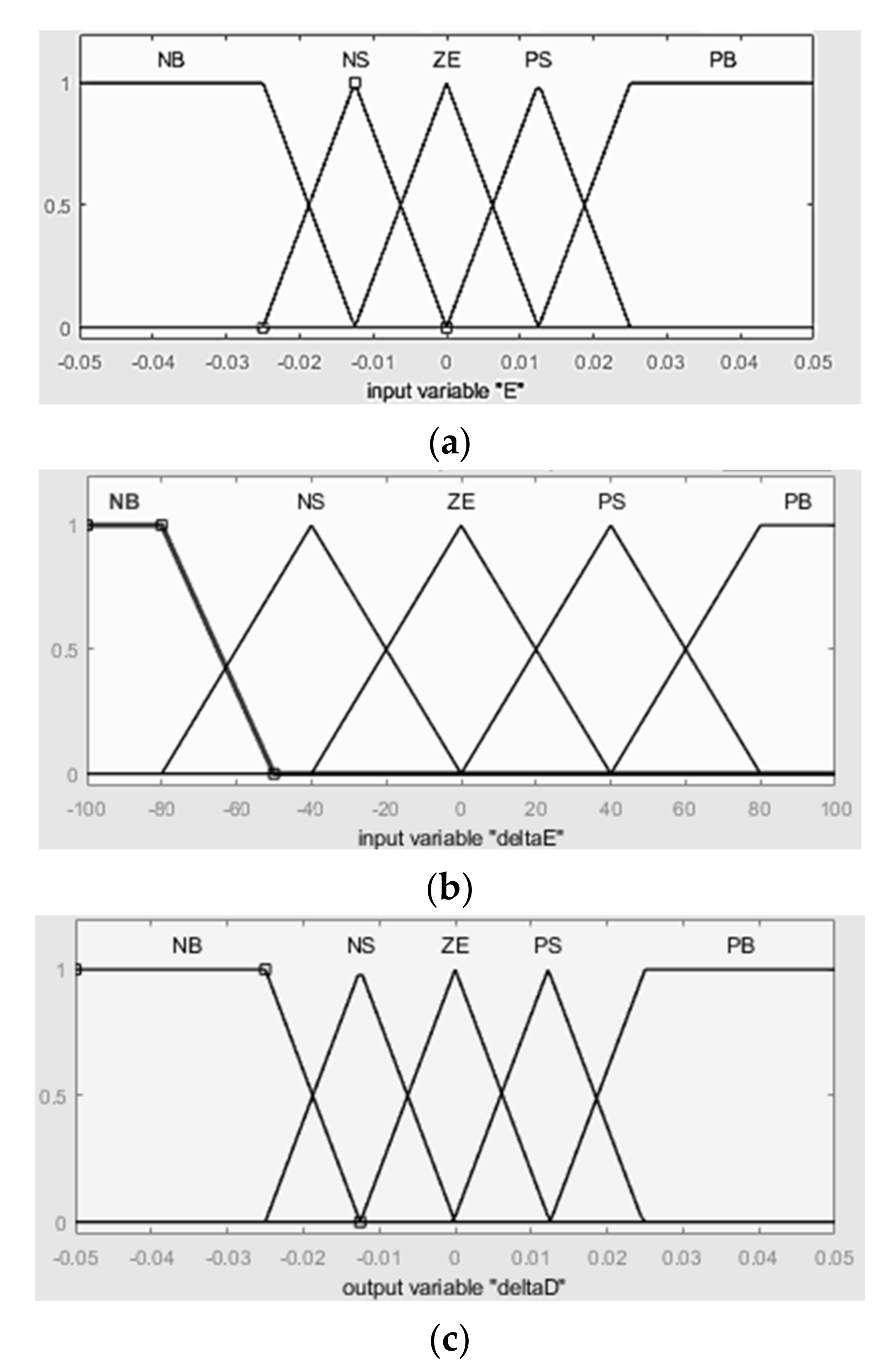

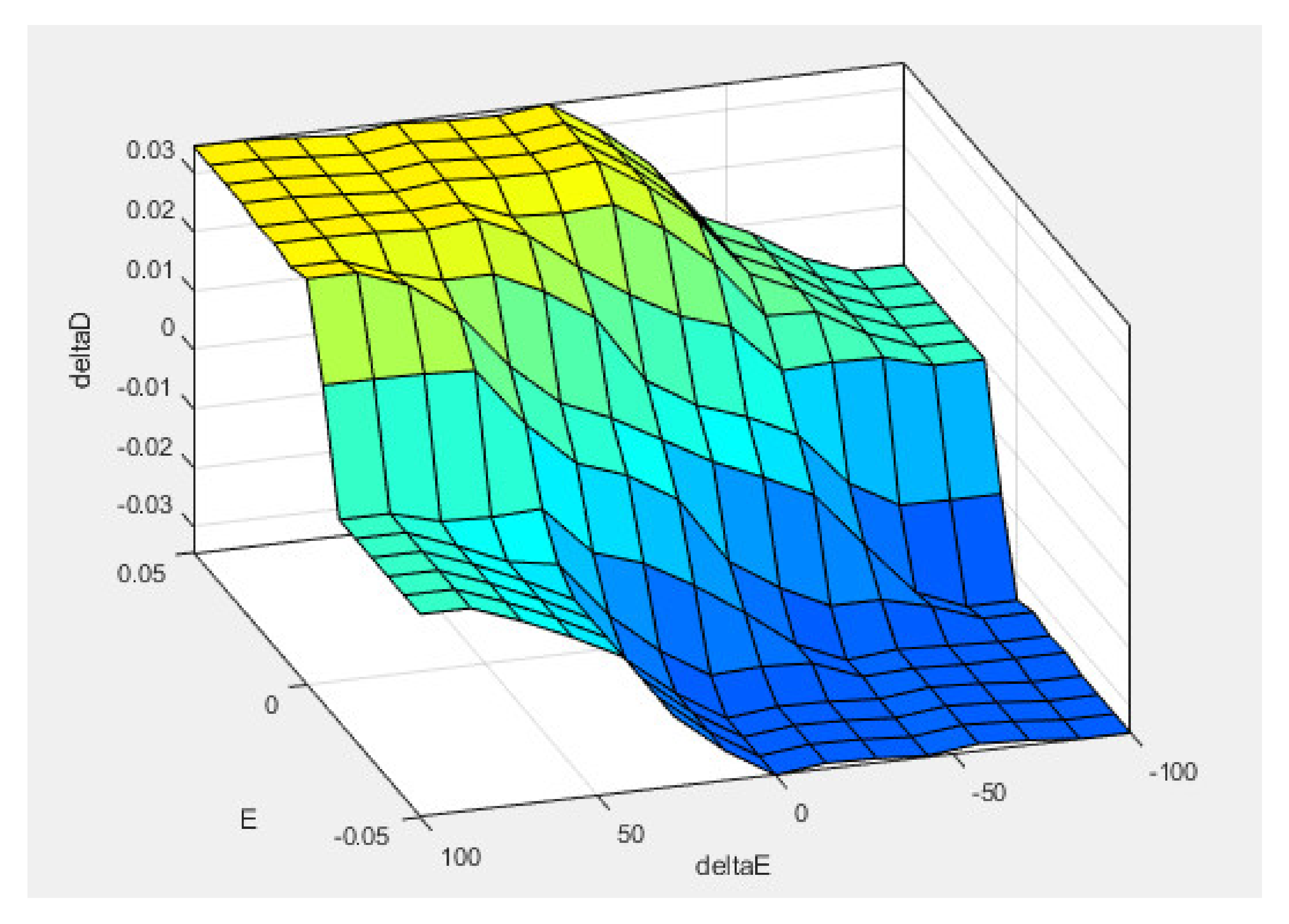

3.1.1. Fuzzification

3.1.2. Inference Method

3.2. WECS Controllers

3.3. Bidirectional DC–DC Converter Control

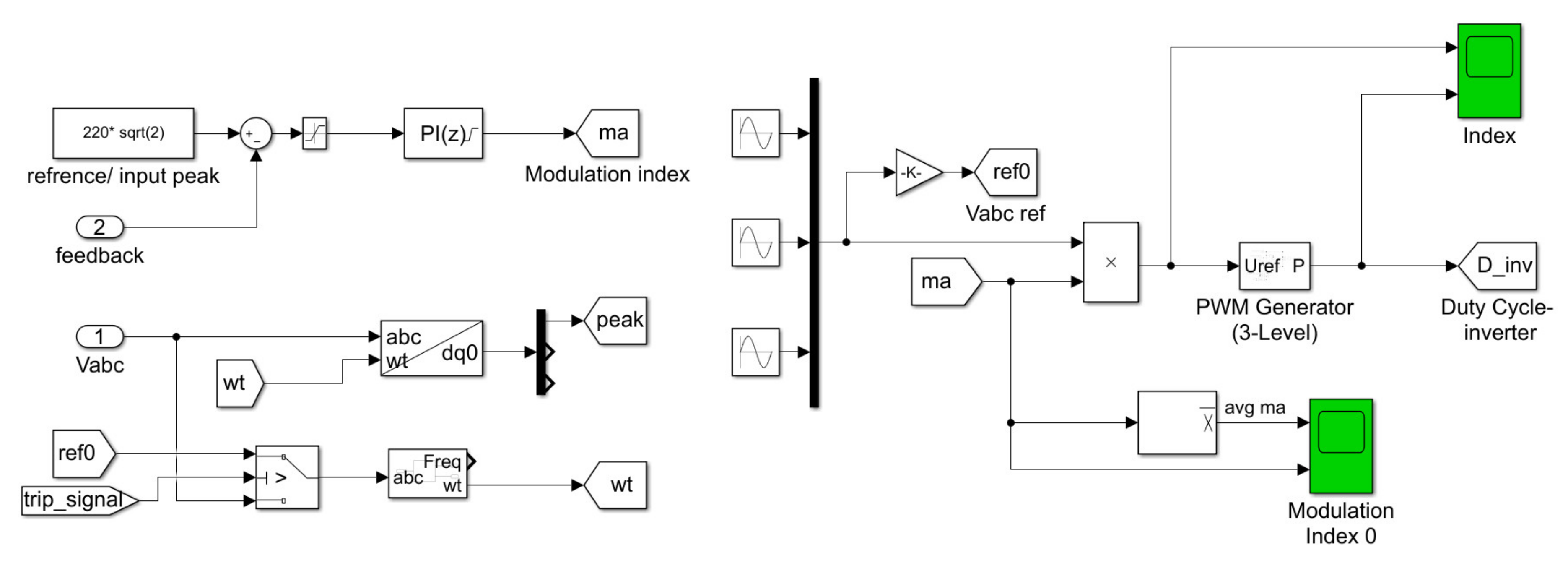

3.4. Inverter Unit Control

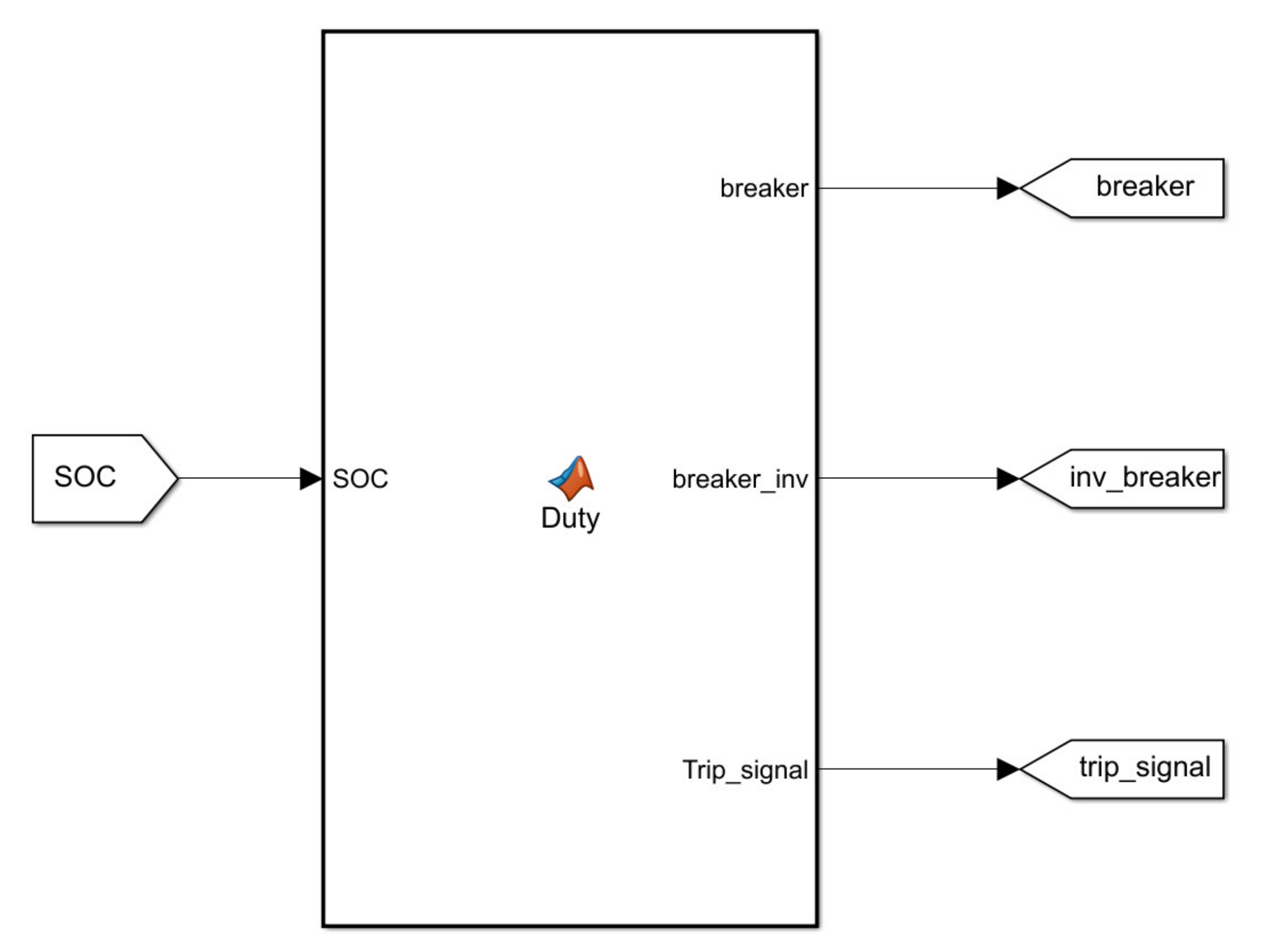

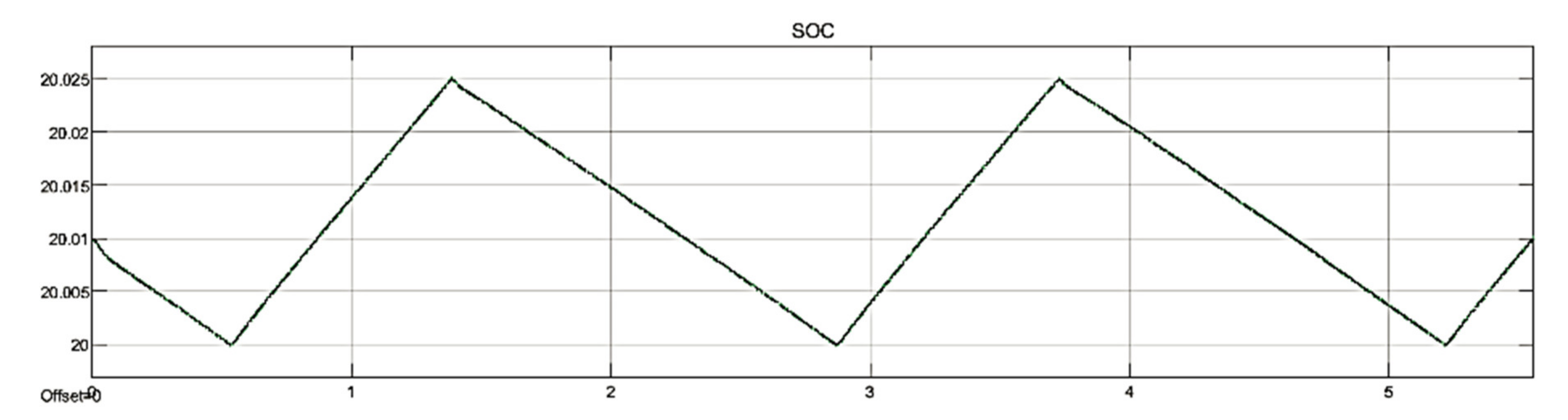

3.5. Battery Protection Controller

- (1)

- Normal condition where the batteries SOC is running between 20% and 80%.

- (2)

- Overcharging condition, where the batteries’ SOC is exceeding 80%.

- (3)

- Over-discharging condition, where the batteries’ SOC is running below 20%.

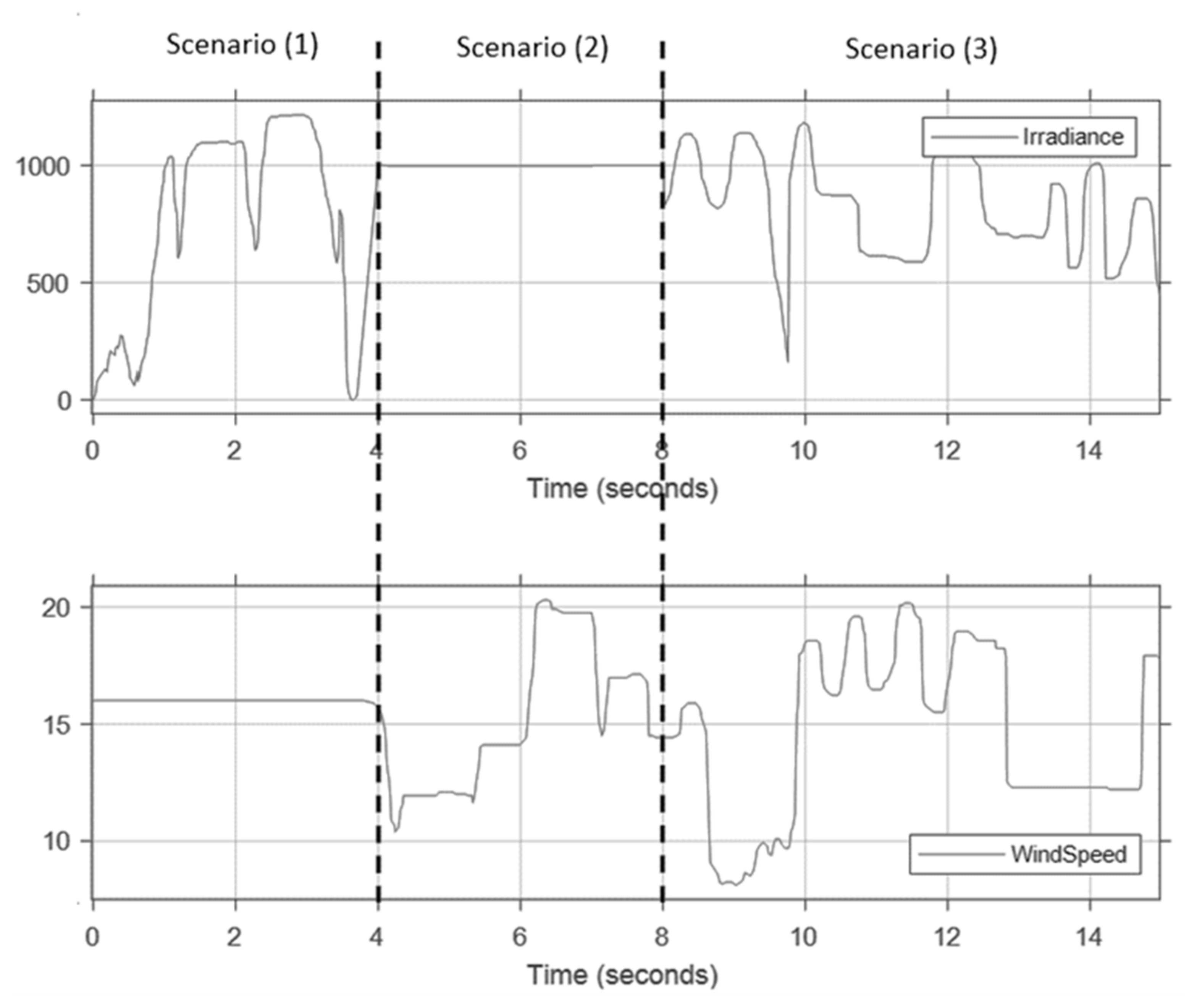

4. Simulation and Results

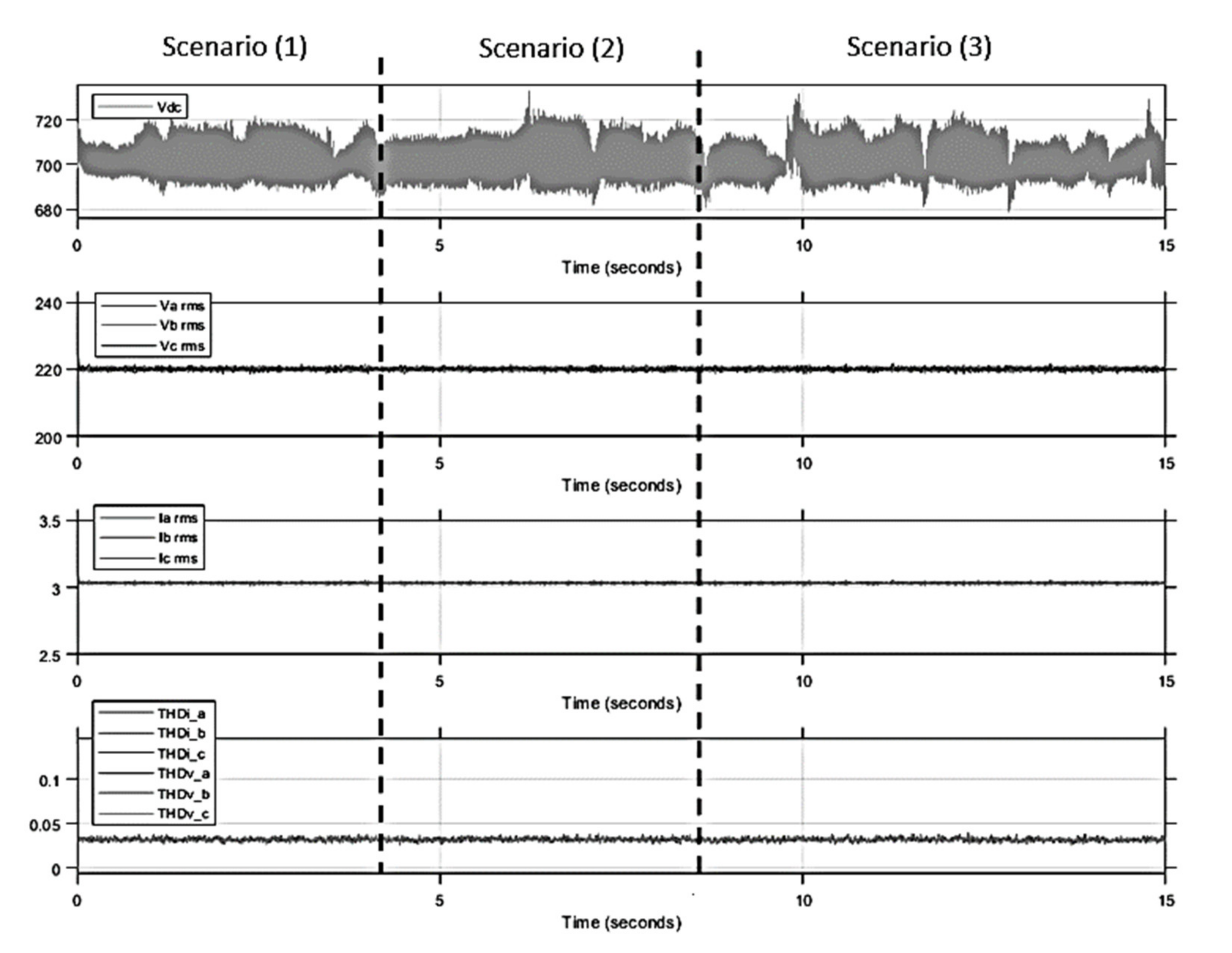

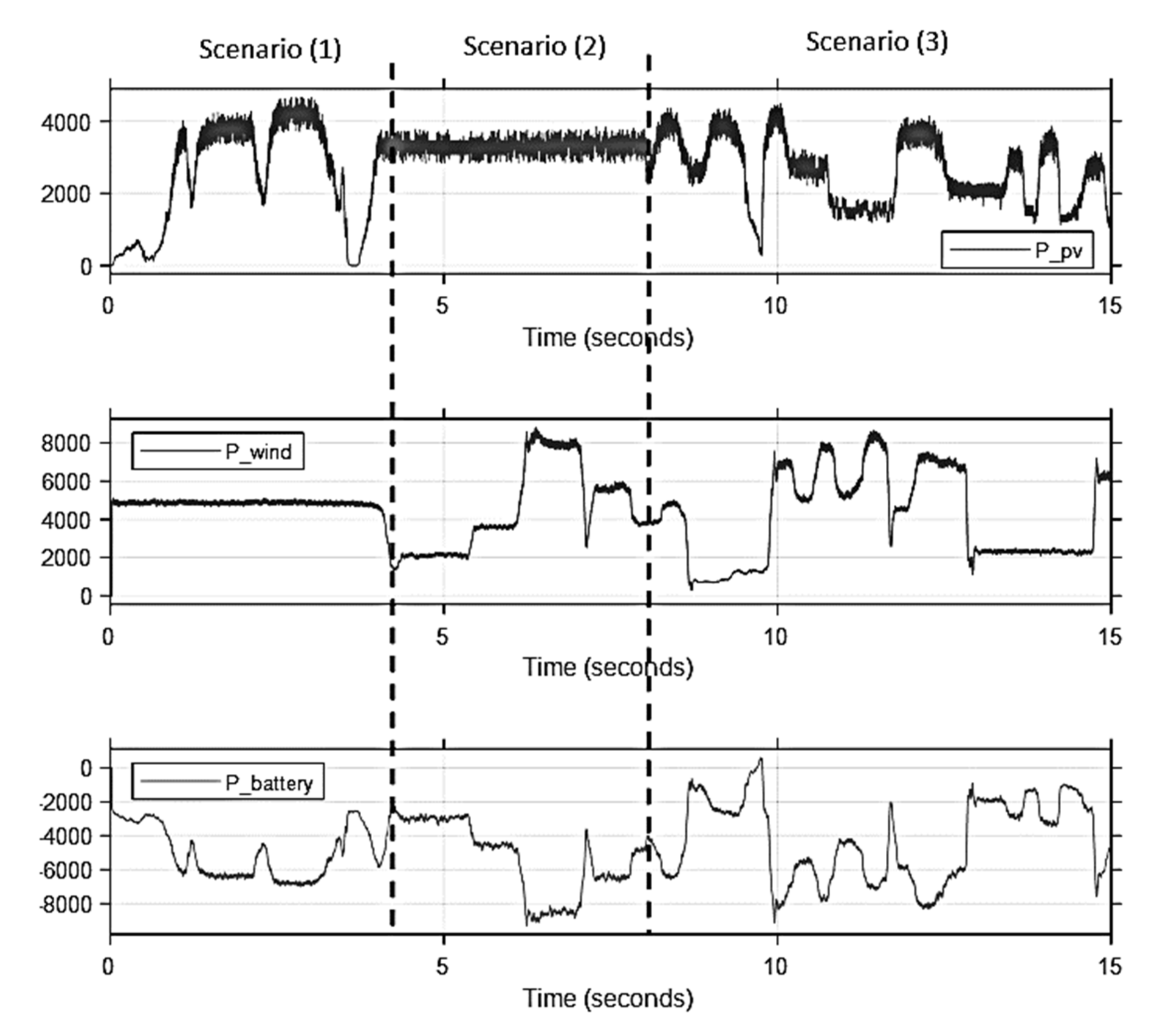

4.1. Normal Condition

- (1)

- In the period between t = (0 to 4 s), the effect of the PV system is examined under variable irradiance and fixed wind speed. The irradiance is changed between (0–1200) W/m2 with a constant wind speed of 16 m/s.

- (2)

- The effect of the wind system is examined under variable wind speed and fixed irradiance in the period between t = (4 s to 8 s). The irradiance has been fixed at 1000 W/m2, so the effect of the wind controller is simply observed.

- (3)

- In the remaining simulation time, the system is examined under variable irradiance and variable wind speed for (t > 8 s).

4.2. Overcharging Condition

4.3. Overdischarging Condition

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bendary, A.F.; Ismail, M.M. Battery charge management for hybrid PV/wind/fuel cell with storage battery. Energy Procedia 2019, 162, 107–116. [Google Scholar] [CrossRef]

- Elavarasan, R.M.; Ghosh, A.; Mallick, T.K.; Krishnamurthy, A.; Saravanan, M. Investigations on performance enhancement measures of the bidirectional converter in PV–wind interconnected microgrid system. Energies 2019, 12, 2672. [Google Scholar] [CrossRef] [Green Version]

- Muriithi, G.; Chowdhury, S. Optimal energy management of a grid-tied solar PV-battery microgrid: A Reinforcement learning approach. Energies 2021, 14, 2700. [Google Scholar] [CrossRef]

- Shan, Y.; Hu, J.; Chan, K.W.; Fu, Q.; Guerrero, J.M. Model predictive control of bidirectional DC-DC converters and AC/DC interlinking converters—A new control method for PV-wind-battery microgrids. IEEE Trans. Sustain. Energy 2019, 10, 1823–1833. [Google Scholar] [CrossRef]

- Mahesh, A.; Sandhu, K.S. Hybrid wind/photovoltaic energy system developments: Critical review and findings. Renew. Sustain. Energy Rev. 2015, 52, 1135–1147. [Google Scholar] [CrossRef]

- Berardi, U.; Tomassoni, E.; Khaled, K. A smart hybrid energy system grid for energy efficiency in remote areas for the army. Energies 2020, 13, 2279. [Google Scholar] [CrossRef]

- Murty, V.V.S.N.; Kumar, A. Multi-objective energy management in microgrids with hybrid energy sources and battery energy storage systems. Prot. Control Mod. Power Syst. 2020, 5, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Alhasnawi, B.N.; Jasim, B.H.; Esteban, M.D. A new robust energy management and control strategy for a hybrid microgrid system based on green energy. Sustainability 2020, 12, 5724. [Google Scholar] [CrossRef]

- Kumar, G.R.P.; Sattianadan, D.; Vijayakumar, K. A survey on power management strategies of hybrid energy systems in microgrid. Int. J. Electr. Comput. Eng. IJECE 2020, 10, 1667–1673. [Google Scholar] [CrossRef]

- Datta, U.; Kalam, A.; Shi, J. Hybrid PV–wind renewable energy sources for microgrid application: An overview. In Hybrid-Renewable Energy Systems in Microgrids; Elsevier BV: Amsterdam, The Netherlands, 2018; pp. 1–22. [Google Scholar]

- Rehman, S.; Habib, H.U.R.; Wang, S.; Buker, M.S.; Alhems, L.M.; Al Garni, H.Z. Optimal design and model predictive control of standalone HRES: A real case study for residential demand side management. IEEE Access 2020, 8, 29767–29814. [Google Scholar] [CrossRef]

- Fathy, A.; Kaaniche, K.; Alanazi, T.M. Recent approach Based social spider optimizer for optimal sizing of hybrid PV/wind/battery/diesel integrated microgrid in Aljouf region. IEEE Access 2020, 8, 57630–57645. [Google Scholar] [CrossRef]

- Luo, Y.; Yang, D.; Yin, Z.; Zhou, B.; Sun, Q. Optimal configuration of hybrid-energy microgrid considering the correlation and randomness of the wind power and photovoltaic power. IET Renew. Power Gener. 2020, 14, 616–627. [Google Scholar] [CrossRef]

- Yahaya, A.A.; Al-Muhaini, M.; Heydt, G.T. Optimal design of hybrid DG systems for microgrid reliability enhancement. IET Gener. Transm. Distrib. 2020, 14, 816–823. [Google Scholar] [CrossRef]

- Samy, M.; Mosaad, M.I.; Barakat, S. Optimal economic study of hybrid PV-wind-fuel cell system integrated to unreliable electric utility using hybrid search optimization technique. Int. J. Hydrog. Energy 2021, 46, 11217–11231. [Google Scholar] [CrossRef]

- Lamichhane, A.; Zhou, L.; Yao, G.; Luqman, M. LCL Filter based grid-connected photovoltaic system with battery energy storage. In Proceedings of the 2019 14th IEEE Conference on Industrial Electronics and Applications (ICIEA), Xi’an, China, 19–21 June 2019; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2019; pp. 1569–1574. [Google Scholar]

- 1STH-215-P Solar Panel from 1Soltech Specifications. Available online: http://www.posharp.com/1sth-215-p-solar-panel-from-1soltech_p1621902445d.aspx (accessed on 25 July 2021).

- Al-Mahmodi, M.; Al-Quraan, A. On-grid solar energy system—A study case in Irbid. In Proceedings of the 6th Global Conference on Renewable Energy and Energy Efficiency for Desert Regions (GCREEDER 2018), Amman, Jordan, 3–5 April 2018. [Google Scholar]

- Rathore, A.; Patidar, N. Reliability assessment using probabilistic modelling of pumped storage hydro plant with PV-wind based standalone microgrid. Int. J. Electr. Power Energy Syst. 2019, 106, 17–32. [Google Scholar] [CrossRef]

- Al-Quraan, A.; Stathopoulos, T.; Pillay, P. Comparison of wind tunnel and on site measurements for urban wind energy estimation of potential yield. J. Wind. Eng. Ind. Aerodyn. 2016, 158, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Stathopoulos, T.; Alrawashdeh, H.; Al-Quraan, A.; Blocken, B.; Dilimulati, A.; Paraschivoiu, M.; Pilay, P. Urban wind energy: Some views on potential and challenges. J. Wind Eng. Ind. Aerodyn. 2018, 179, 146–157. [Google Scholar] [CrossRef]

- Yang, D.; Jiang, C.; Cai, G.; Huang, N. Optimal sizing of a wind/solar/battery/diesel hybrid microgrid based on typical scenarios considering meteorological variability. IET Renew. Power Gener. 2019, 13, 1446–1455. [Google Scholar] [CrossRef]

- Xie, H.; Zheng, S.; Ni, M. Microgrid development in China: A method for renewable energy and energy storage capacity configuration in a megawatt-level isolated microgrid. IEEE Electrif. Mag. 2017, 5, 28–35. [Google Scholar] [CrossRef]

- Shaqour, A.; Farzaneh, H.; Yoshida, Y.; Hinokuma, T. Power control and simulation of a building integrated stand-alone hybrid PV-wind-battery system in Kasuga City, Japan. Energy Rep. 2020, 6, 1528–1544. [Google Scholar] [CrossRef]

- Benlahbib, B.; Bouarroudj, N.; Mekhilef, S.; Abdeldjalil, D.; Abdelkrim, T.; Bouchafaa, F.; Lakhdari, A. Experimental investigation of power management and control of a PV/wind/fuel cell/battery hybrid energy system microgrid. Int. J. Hydrog. Energy 2020, 45, 29110–29122. [Google Scholar] [CrossRef]

- Belouda, M.; Hajjaji, M.; Sliti, H.; Mami, A. Bi-objective optimization of a standalone hybrid PV-Wind-battery system generation in a remote area in Tunisia. Sustain. Energy Grids Netw. 2018, 16, 315–326. [Google Scholar] [CrossRef]

- MathWorks, Implement Model of Variable Pitch Wind Turbine. Available online: https://www.mathworks.com/help/physmod/sps/powersys/ref/windturbine.html (accessed on 25 July 2021).

- Nadjemi, O.; Nacer, T.; Hamidat, A.; Salhi, H. Optimal hybrid PV/wind energy system sizing: Application of cuckoo search algorithm for Algerian dairy farms. Renew. Sustain. Energy Rev. 2017, 70, 1352–1365. [Google Scholar] [CrossRef]

- Hu, J.; Shan, Y.; Xu, Y.; Guerrero, J. A coordinated control of hybrid ac/dc microgrids with PV-wind-battery under variable generation and load conditions. Int. J. Electr. Power Energy Syst. 2019, 104, 583–592. [Google Scholar] [CrossRef] [Green Version]

- Ben Ali, I.; Turki, M.; Belhadj, J.; Roboam, X. Optimized fuzzy rule-based energy management for a battery-less PV/wind-BWRO desalination system. Energy 2018, 159, 216–228. [Google Scholar] [CrossRef] [Green Version]

- Zhang, T.; Yue, D.; O’Grady, M.J.; O’Hare, G.M.P. Transient oscillations analysis and modified control strategy for seamless mode transfer in micro-grids: A wind-PV-ES hybrid system case study. Energies 2015, 8, 13758–13777. [Google Scholar] [CrossRef] [Green Version]

- Beykverdi, M.; Jalilvand, A.; Ehsan, M. Cooperative energy management of hybrid DC renewable grid using decentralized control strategies. Energies 2016, 9, 859. [Google Scholar] [CrossRef] [Green Version]

- El-Hendawi, M.; Gabbar, H.A.; El-Saady, G.; Ibrahim, E.-N.A. Control and EMS of a Grid-Connected Microgrid with Economical Analysis. Energies 2018, 11, 129. [Google Scholar] [CrossRef] [Green Version]

- Cheng, C.-H. Implementation of a small type DC microgrid based on fuzzy control and dynamic programming. Energies 2016, 9, 781. [Google Scholar] [CrossRef] [Green Version]

- Luna, A.C.; Diaz, N.L.; Graells, M.; Vasquez, J.C.; Guerrero, J.M. Mixed-integer-linear-programming-based energy management system for hybrid PV-wind-battery microgrids: Modeling, design, and experimental verification. IEEE Trans. Power Electron. 2017, 32, 2769–2783. [Google Scholar] [CrossRef] [Green Version]

- Lin, S.; Wang, Y.; Liu, M.; Fan, G.; Yang, Z.; Li, Q. Stochastic optimal dispatch of PV/wind/diesel/battery microgrids using state-space approximate dynamic programming. IET Gener. Transm. Distrib. 2019, 13, 3409–3420. [Google Scholar] [CrossRef]

- Al-Quraan, A.; Alrawashdeh, H. Correlated capacity factor strategy for yield maximization of wind turbine energy. In Proceedings of the 2018 5th International Conference on Renewable Energy: Generation and Applications (ICREGA), Al Ain, United Arab Emirates, 26–28 February 2018; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2018; pp. 264–267. [Google Scholar]

- Al-Quraan, A.A.; Pillay, P.; Stathopoulos, T. Use of a wind tunnel for urban wind power estimation. In Proceedings of the 2014 IEEE Power and Energy Society General Meeting, Conference & Exposition, National Harbor, MD, USA, 27–31 July 2014; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2014; pp. 1–5. [Google Scholar]

- Al-Quraan, A.; Stathopoulos, T.; Pillay, P. Estimation of urban wind energy—Equiterre building case in montreal. In Proceedings of the International Civil Engineering for Sustainability and Resilience Conference (CESARE’14), Irbid, Jordan, 24–27 April 2014. [Google Scholar]

- Al-Masri, H.M.K.; Al-Quraan, A.; Abuelrub, A.; Ehsani, M. Optimal coordination of wind power and pumped hydro energy storage. Energies 2019, 12, 4387. [Google Scholar] [CrossRef] [Green Version]

- Al-Quraan, A.; Al-Masri, H.; Radaideh, A. New method for assessing the energy potential of wind sites—A case study in Jordan. Univers. J. Electr. Electron. Eng. 2020, 7, 209–218. [Google Scholar] [CrossRef]

- Al-Quraan, A.; Al-Mahmodi, M.; Radaideh, A.; Al-Masri, H.M.K. Comparative study between measured and estimated wind energy yield. Turk. J. Electr. Eng. Comput. Sci. 2020, 28, 2926–2939. [Google Scholar] [CrossRef]

- Balasubramanian, G.; Singaravelu, S. Fuzzy logic controller for the maximum power point tracking in photovoltaic system. Int. J. Comput. Appl. 2012, 41, 22–28. [Google Scholar] [CrossRef]

- Radaideh, A.; Al-Quraan, A.; Al-Masri, H.; Albataineh, Z. Rolling horizon control architecture for distributed agents of thermostatically controlled loads enabling long-term grid-level ancillary services. Int. J. Electr. Power Energy Syst. 2021, 127, 106630. [Google Scholar] [CrossRef]

- Chakir, A.; Tabaa, M.; Moutaouakkil, F.; Medromi, H.; Julien-Salame, M.; Dandache, A.; Alami, K. Optimal energy management for a grid connected PV-battery system. Energy Rep. 2020, 6, 218–231. [Google Scholar] [CrossRef]

- Shivam, K.; Tzou, J.-C.; Wu, S.-C. A multi-objective predictive energy management strategy for residential grid-connected PV-battery hybrid systems based on machine learning technique. Energy Convers. Manag. 2021, 237, 114103. [Google Scholar] [CrossRef]

- Wu, Z.; Xia, X. Optimal switching renewable energy system for demand side management. Sol. Energy 2015, 114, 278–288. [Google Scholar] [CrossRef] [Green Version]

- Zupančič, J.; Filipič, B.; Gams, M. Genetic-programming-based multi-objective optimization of strategies for home energy-management systems. Energy 2020, 203, 117769. [Google Scholar] [CrossRef]

- Guichi, A.; Talha, A.; Berkouk, E.M.; Mekhilef, S. Energy management and performance evaluation of grid connected PV-battery hybrid system with inherent control scheme. Sustain. Cities Soc. 2018, 41, 490–504. [Google Scholar] [CrossRef]

- Aghajani, G.; Ghadimi, N. Multi-objective energy management in a micro-grid. Energy Rep. 2018, 4, 218–225. [Google Scholar] [CrossRef]

| Load Sizing | DC Bus Voltage | 700 Vdc |

| Load Power Required | 2 kW | |

| Battery Sizing | Batteries capacity | 102 Ah |

| Battery Voltage | 96 Vdc | |

| Batteries capacity | 9.8 kWh | |

| Batteries strings (parallel) | 1 | |

| Batteries per string (series) | 4 | |

| PV Array Sizing | PV module | Soltech 1STH-215-P |

| Max power per module | 213 W | |

| Max current | 7.35 A | |

| Max voltage | 29 V | |

| Parallel Strings | 6 | |

| Series Modules per string | 3 | |

| PMSG | Rated Power | 3 kW |

| Rated Speed | 360 RPM |

| dE E | NB | NS | ZE | PS | PB |

|---|---|---|---|---|---|

| NB | NB | NB | NB | NS | ZE |

| NS | NB | NB | NS | ZE | ZE |

| ZE | NB | NS | ZE | PS | PB |

| PS | ZE | ZE | PS | PB | PB |

| PB | ZE | PS | PB | PB | PB |

| References | Energy Sources | Required Data | Storage System | Energy Management System Strategy | Optimization Objectives | Energy Management System Approach |

|---|---|---|---|---|---|---|

| Wu et al. [47] | PV | irradiance | Battery | Grid-connected | Minimize the cost of electricity | Linear programming/intuitive control |

| Zupančič et al. [48] | PV | Load, electricity price and irradiance | Battery | Grid-connected | Minimizing the operational cost and maximizing the green factor | Multi objective |

| Guichi et al. [49] | PV | Load, irradiance | Battery | Grid-connected | Satisfy the batteries, loads and grid energy requirements | Flow chart |

| Aghajani et al. [50] | PV, wind turbine and fuel cell | Load, irradiance, wind speed and temperature | Battery | Grid-connected | Minimizing the operational cost and CO2 emission | Multi-objective optimization using MOPSO algorithm |

| Our proposed | PV, wind energy system | Load, irradiance, and wind speed | Battery | Standalone | Satisfying the demand, protecting the batteries bank and prolong batteries life | Flowchart and control algorithm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Quraan, A.; Al-Qaisi, M. Modelling, Design and Control of a Standalone Hybrid PV-Wind Micro-Grid System. Energies 2021, 14, 4849. https://doi.org/10.3390/en14164849

Al-Quraan A, Al-Qaisi M. Modelling, Design and Control of a Standalone Hybrid PV-Wind Micro-Grid System. Energies. 2021; 14(16):4849. https://doi.org/10.3390/en14164849

Chicago/Turabian StyleAl-Quraan, Ayman, and Muhannad Al-Qaisi. 2021. "Modelling, Design and Control of a Standalone Hybrid PV-Wind Micro-Grid System" Energies 14, no. 16: 4849. https://doi.org/10.3390/en14164849