Prediction of the Water-Bearing Capacity of Coal Strata by Using the Macro and Micro Pore Structure Parameters of Aquifers

Abstract

:1. Introduction

2. Background and Method

2.1. Background of the Study Area

2.2. Experiment on the Pore Structure Characteristics

2.3. Weighting Method of Eigenvector Based on the GRA

3. Results

3.1. Measurement of Pore Structure Parameters

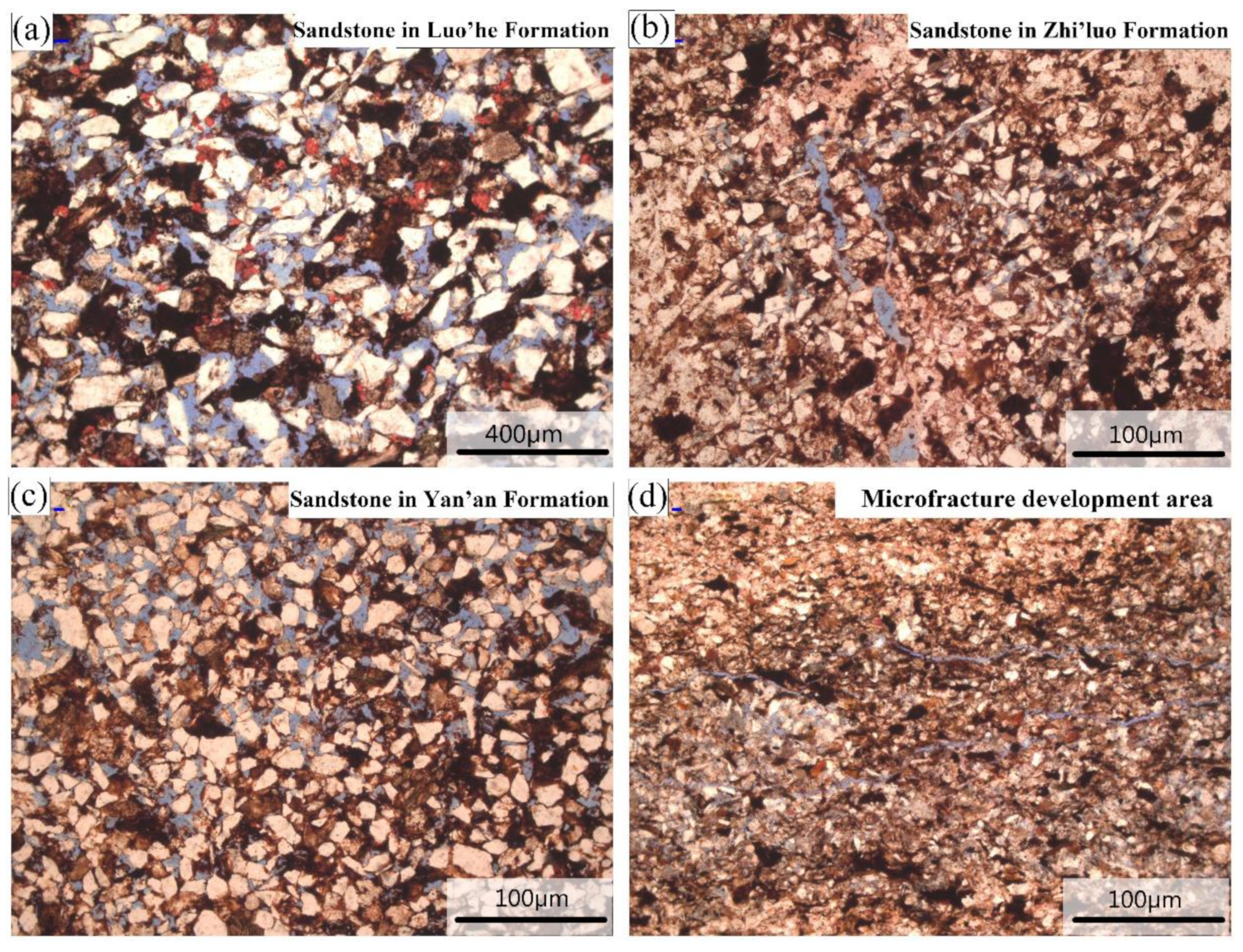

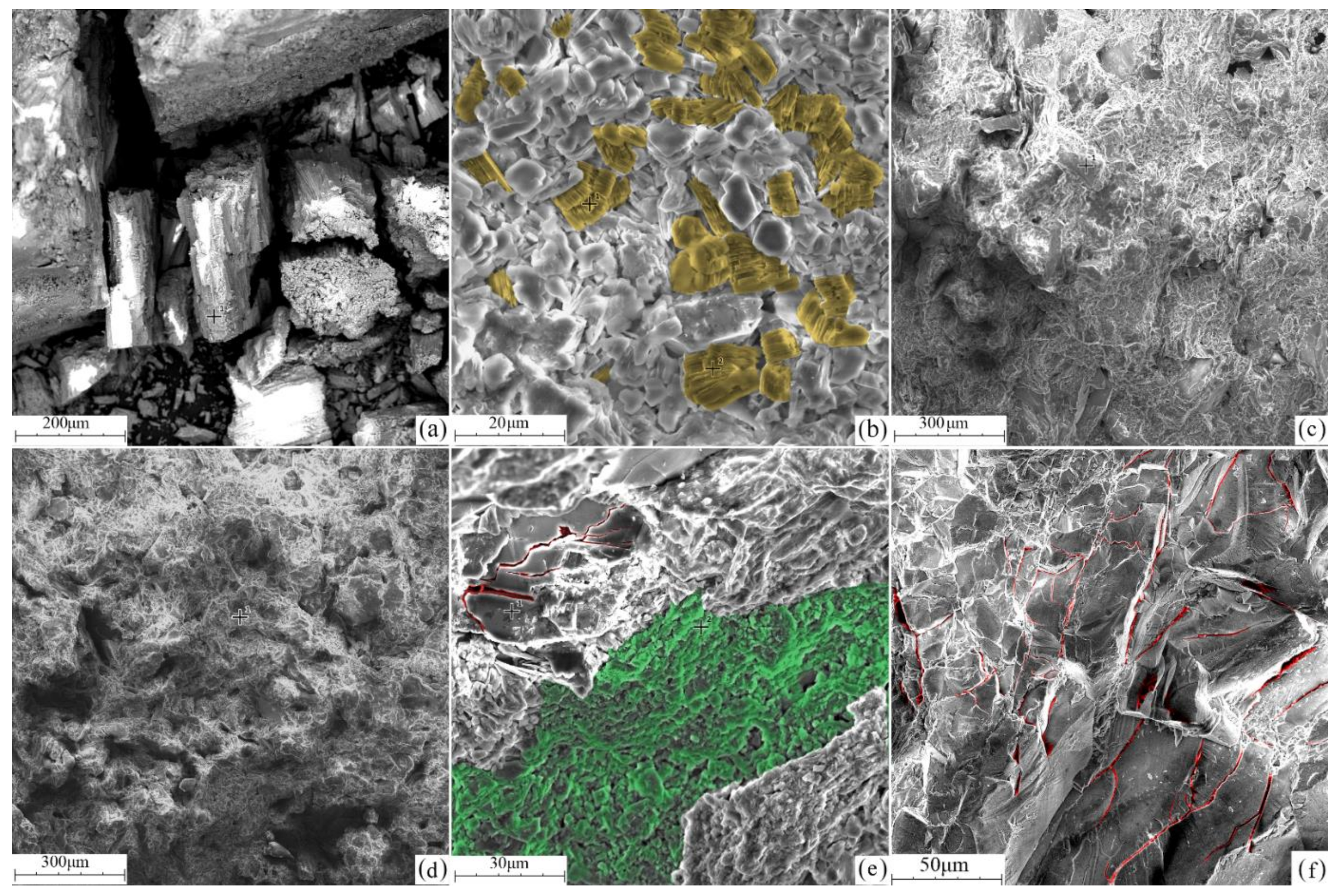

3.2. Macro Pore Characteristics of the Aquifer

3.3. Information Fusion of Micro Pore Parameters

4. Discussion

4.1. Micro Pore Structure Parameters of Various Types of Sandstone

4.2. Macro Pore Structure Parameters of Various Types of Sandstone

4.3. Evaluation Model of Formation Water-Bearing Capacity in the Guojiahe Coal Mine

5. Conclusions

- (1)

- The results of the microscopic experiment showed that the APD and PSC of Luo’he formation sandstone were larger than those of Zhi’luo formation sandstone, but the APD and PSC of Zhi’luo and Yan’an formation sandstone do not differ considerably. The pore connectivity of Luo’he formation sandstone was much better than that of Zhi’luo and Yan’an formation sandstone. The Luo’he formation is the main aquifer in this region.

- (2)

- The results of the macroscopic experiment revealed that the average porosity of Luo’he formation sandstone was 7.39% higher than that of Zhi’luo formation sandstone and 13.41% higher than that of Yan’an formation sandstone. The Luo’he and Zhi’luo formations exhibit weak compaction, develop pores and have strong water-bearing capacity. The porosity of the Yan’an formation is low, and its water-bearing capacity is weak. In addition, the NWA difference between sandstone in the Zhi’luo and Yan’an formations was 0.62%, and the difference between sandstone in the Luo’he and Zhi’luo formations was 2.31%. The water-carrying capacity of the sandstone in Luo’he and Zhi’luo formations was considerably higher than that of the sandstone in the Yan’an formation.

- (3)

- An objective weighting model based on the similarity between indexes was proposed. This model was used to analyze pore structure parameters of various formations in the Guojiahe coal mine. The calculation model of water-bearing capacity of various formations was established. According to this model, the water-carrying capacity of 3# coal roof in the study area was analyzed. The results of previous mining studies indicated that there is a large-scale area with strong water inrush risk in the east of the study area, which is prone to water inrush if normal mining continues in the future. However, according to the model analysis in this paper, it was found that the actual water capacity in this area is medium, and there is no need to perform large-scale pumping, drilling or geophysical exploration before mining. The research results can save money for coal mining, which is beneficial for protecting the ecological environment and groundwater resources.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PP | Plane Porosity |

| APD | Average Pore Diameter |

| ASS | Average Specific Surface |

| PSC | Pore Sorting Coefficient |

| THC | Throat Homogenization Coefficient |

| NWA | Natural Water Absorption |

| SEM | Scanning Electron Microscope |

| GRA | Grey Relational Analysis |

| GCC | Grave Correlation Coefficient |

| GRG | Grey Relational Grade |

| Wm | Natural Water Absorption |

| ξi(k) | Grave Correlation Coefficient |

| ρ | Resolution coefficient |

| G(n,i) | Grey Relational Grade |

| Wi | Eigenvectort |

| CI | Consistency Index |

| RI | Random Consistency Indicator |

| CR | Consistency Ratio |

References

- Bárdossy, A.; Hörning, S. Gaussian and non-Gaussian inverse modeling of groundwater flow using copulas and random mixing. Water Resour. Res. 2016, 52, 4504–4526. [Google Scholar] [CrossRef] [Green Version]

- Bayram, A.; Oensoy, H. Sand and gravel mining impact on the surface water quality: A case study from the city of Tirebolu (Giresun Province, NE Turkey). Environ. Earth Sci. 2015, 73, 1997–2011. [Google Scholar] [CrossRef]

- Gordalla, B.C.; Ewers, U.; Frimmel, F.H. Hydraulic fracturing: A toxicological threat for groundwater and drinking-water? Environ. Earth Sci. 2013, 70, 3875–3893. [Google Scholar] [CrossRef]

- Howladar, M.F. Coal mining impacts on water environs around the Barapukuria coal mining area, Dinajpur, Bangladesh. Environ. Earth Sci. 2013, 70, 215–226. [Google Scholar] [CrossRef]

- Zeng, Y.; Wu, Q.; Liu, S.; Zhai, Y.; Lian, H.; Zhang, W. Evaluation of a coal seam roof water inrush: Case study in the Wangjialing coal mine, China. Mine Water Environ. 2017, 37, 174–184. [Google Scholar] [CrossRef]

- Karaman, A.; Seyhan, T.; Işık, M.F. Detecting the footprint of a longwall mine panel claimed to infringe on a permit boundary at the Soma–Darkale coalfield (Manisa, Turkey) using surface fractures and microgravity measurements. Environ. Earth Sci. 2013, 70, 1895–1902. [Google Scholar] [CrossRef]

- Quispe-Jofré, A.; Philimon, P.P.; Alfaro-Lira, S. Socio-environmental conflict over abandoned mining waste in Copaquilla, Chile. Environ. Sci. Pollut. Res. 2021, 7, 1–19. [Google Scholar] [CrossRef]

- Sasowsky, I.D.; Mylroie, J. Studies of Cave Sediments: Physical and Chemical Records of Paleoclimate; Springer: Cham, Switzerland, 2007. [Google Scholar]

- Zhang, Z.; Zou, Y.; Chen, J.; Wang, Y. Prediction model of land dynamic settlement in coal mining subsidence area. Trans. Chin. Soc. Agric. Eng. 2016, 32, 246–251. [Google Scholar]

- Pauli, L.; Markku, O. Optimal Environmental Policy for a Mine Under Polluting Waste Rocks and Stock Pollution. Environ. Resour. Econ. 2019, 73, 133–158. [Google Scholar]

- Su, R.J. Study and Analysis on Engineering Feature and Environmental Influence of Coal Mine. Adv. Mater. Res. 2012, 511, 175–178. [Google Scholar] [CrossRef]

- Golian, M.; Teshnizi, E.S.; Parise, M.; Terzić, J.; Milanović, S.; Vakanjac, V.R.; Mahdad, M.; Abbasi, M.; Taghikhani, H.; Saadat, H. A new analytical method for determination of discharge duration in tunnels subjected to groundwater inrush. Bull. Int. Assoc. Eng. Geol. 2021, 80, 3293–3313. [Google Scholar] [CrossRef]

- Harris, J.; Turner, J.; Kirsch, P. Case Study—Application of RISKGATE to Managing Strata Failure in an Australian Coalmine. In Proceedings of the Australian Ground Control Mining Conference, Sydney, NSW, Australia, 5–6 November 2014. [Google Scholar]

- Wu, Q.; Du, Z.; Zhao, Y.; Xu, H.; Zhang, X. Optimal location of water level sensors for monitoring mine water inrush based on the set covering model. Sci. Rep. 2021, 11, 1–12. [Google Scholar] [CrossRef]

- Wu, Q.; Xu, K.; Zhang, W.; Wei, Z. Roof aquifer water abundance evaluation: A case study in Taigemiao, China. Arab. J. Geosci. 2017, 10, 1–13. [Google Scholar] [CrossRef]

- Chen, L.; Feng, X.; Xu, D.; Zeng, W.; Zheng, Z. Prediction of Water Inrush Areas Under an Unconsolidated, Confined Aquifer: The Application of Multi-information Superposition Based on GIS and AHP in the Qidong Coal Mine, China. Mine Water Environ. 2018, 37, 786–795. [Google Scholar] [CrossRef]

- Yin, H.; Shi, Y.; Niu, H.; Xie, D.; Wei, J.; Lefticariu, L.; Xu, S. A GIS-based model of potential groundwater yield zonation for a sandstone aquifer in the Juye Coalfield, Shangdong, China. J. Hydrol. 2018, 557, 434–447. [Google Scholar] [CrossRef]

- Guo, X.; Huang, Z.; Zhao, L.; Han, W.; Ding, C.; Sun, X.; Yan, R.; Zhang, T.; Yang, X.; Wang, R. Pore structure and multi-fractal analysis of tight sandstone using MIP, NMR and NMRC methods: A case study from the Kuqa depression, China. J. Pet. Sci. Eng. 2019, 178, 544–558. [Google Scholar] [CrossRef]

- Hou, X.; Zhu, Y.; Chen, S.; Wang, Y.; Liu, Y. Investigation on pore structure and multifractal of tight sandstone reservoirs in coal bearing strata using LF-NMR measurements. J. Pet. Sci. Eng. 2020, 187, 106757. [Google Scholar] [CrossRef]

- Wang, F.; Yang, K.; Cai, J. Fractal Characterization of Tight Oil Reservoir Pore Structure Using Nuclear Magnetic Resonance and Mercury Intrusion Porosimetry. Fractals 2018, 26, 2. [Google Scholar] [CrossRef]

- Qu, K.; Guo, S. Investigation of the Pore Structure of Tight Sandstone Based on Multifractal Analysis from NMR Measurement: A Case from the Lower Permian Taiyuan Formation in the Southern North China Basin. Energies 2020, 13, 4067. [Google Scholar] [CrossRef]

- Anovitz, L.; Cole, D.R.; Jackson, A.; Rother, G.; Littrell, K.; Allard, L.F.; Pollington, A.; Wesolowski, D.J. Effect of quartz overgrowth precipitation on the multiscale porosity of sandstone: A (U)SANS and imaging analysis. Geochim. Cosmochim. Acta 2015, 158, 199–222. [Google Scholar] [CrossRef] [Green Version]

- Gong, L.; Nie, L.; Xu, Y. Geometrical and Topological Analysis of Pore Space in Sandstones Based on X-ray Computed Tomography. Energies 2020, 13, 3774. [Google Scholar] [CrossRef]

- Oluwadebi, A.G.; Taylor, K.G.; Ma, L. A case study on 3D characterisation of pore structure in a tight sandstone gas reservoir: The Collyhurst Sandstone, East Irish Sea Basin, northern England. J. Nat. Gas Sci. Eng. 2019, 68, 102917. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, Z.; Lin, W.; Xiong, S.; Luo, Y.; Liu, X.; Xia, D. Fractal study on pore structure of tight sandstone based on full-scale map. Int. J. Oil Gas Coal Technol. 2019, 22, 123–139. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, Z.; Lin, W.; Xiong, S.; Luo, Y.; Wang, Z.; Chen, T.; Xia, D.; Wu, Z. Study on Pore Structures of Tight Sandstone Reservoirs Based on Nitrogen Adsorption, High-Pressure Mercury Intrusion, and Rate-Controlled Mercury Intrusion. J. Energy Resour. Technol. 2019, 141, 1–26. [Google Scholar] [CrossRef]

- Wei, G.-W. GRA method for multiple attribute decision making with incomplete weight information in intuitionistic fuzzy setting. Knowl. Based Syst. 2010, 23, 243–247. [Google Scholar] [CrossRef]

- Zhang, S.-F.; Liu, S.-Y. A GRA-based intuitionistic fuzzy multi-criteria group decision making method for personnel selection. Expert Syst. Appl. 2011, 38, 11401–11405. [Google Scholar] [CrossRef]

- Wei, G.-W. Gray relational analysis method for intuitionistic fuzzy multiple attribute decision making. Expert Syst. Appl. 2011, 38, 11671–11677. [Google Scholar] [CrossRef]

- Yazdani, M.; Kahraman, C.; Zarate, P.; Onar, S.C. A fuzzy multi attribute decision framework with integration of QFD and grey relational analysis. Expert Syst. Appl. 2019, 115, 474–485. [Google Scholar] [CrossRef] [Green Version]

- Younas, M.; Jaffery, S.H.I.; Khan, M.; Khan, M.A.; Ahmad, R.; Mubashar, A.; Ali, L. Multi-objective optimization for sustainable turning Ti6Al4V alloy using grey relational analysis (GRA) based on analytic hierarchy process (AHP). Int. J. Adv. Manuf. Technol. 2019, 105, 1175–1188. [Google Scholar] [CrossRef]

- Altintas, K.; Vayvay, O.; Apak, S.; Cobanoglu, E. An Extended GRA Method Integrated with Fuzzy AHP to Construct a Multidimensional Index for Ranking Overall Energy Sustainability Performances. Sustainability 2020, 12, 1602. [Google Scholar] [CrossRef] [Green Version]

- Qiu, M.; Huang, F.; Wang, Y.; Guan, T.; Shi, L.; Han, J. Prediction model of water yield property based on GRA, FAHP and TOPSIS methods for Ordovician top aquifer in the Xinwen coalfield of China. Environ. Earth Sci. 2020, 79, 1–14. [Google Scholar] [CrossRef]

- Robert, K.; Witold, K.; Lech, G. An Effective Belt Conveyor for Underground Ore Transportation Systems. IOP Conf. 2017, 95, 042047. [Google Scholar]

- Krol, R. Studies of The Durability of Belt Conveyor Idlers with Working Loads Taken into Account. IOP Conf. Ser. Earth Environ. Sci. 2017, 95, 42054. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Xu, H.; Tang, D.; Mathews, J.P.; Li, S.; Tao, S. Coal seam porosity and fracture heterogeneity of macrolithotypes in the Hancheng Block, eastern margin, Ordos Basin, China. Int. J. Coal Geol. 2016, 159, 18–29. [Google Scholar] [CrossRef]

- Li, P.; Zheng, M.; Bi, H.; Wu, S.; Wang, X. Pore throat structure and fractal characteristics of tight oil sandstone: A case study in the Ordos Basin, China. J. Pet. Sci. Eng. 2017, 149, 665–674. [Google Scholar] [CrossRef]

- Shi, L.; Qiu, M.; Wang, Y.; Qu, X.; Liu, T. Evaluation of water inrush from underlying aquifers by using a modified water-inrush coefficient model and water-inrush index model: A case study in Feicheng coalfield, China. Hydrogeol. J. 2019, 27, 2105–2119. [Google Scholar] [CrossRef]

- Hou, P.; Gao, F.; Ju, Y.; Liang, X.; Zhang, Z.; Cheng, H.; Gao, Y. Experimental investigation on the failure and acoustic emission characteristics of shale, sandstone and coal under gas fracturing. J. Nat. Gas Sci. Eng. 2016, 35, 211–223. [Google Scholar] [CrossRef]

- Huang, W.; Lu, S.; Hersi, O.S.; Wang, M.; Deng, S.; Lu, R. Reservoir spaces in tight sandstones: Classification, fractal characters, and heterogeneity. J. Nat. Gas Sci. Eng. 2017, 46, 80–92. [Google Scholar] [CrossRef]

- Lin, W.; Li, X.; Yang, Z.; Lin, L.; Xiong, S.; Wang, Z.; Wang, X.; Xiao, Q. A New Improved Threshold Segmentation Method for Scanning Images of Reservoir Rocks Considering Pore Fractal Characteristics. Fractals 2018, 26, 1840003. [Google Scholar] [CrossRef] [Green Version]

- Gupta, S.; Kua, H.W. Effect of water entrainment by pre-soaked biochar particles on strength and permeability of cement mortar. Constr. Build. Mater. 2018, 159, 107–125. [Google Scholar] [CrossRef]

- Abbas, A.K.; Flori, R.E.; Alsaba, M.; Dahm, H.; Alkamil, E.H. Integrated approach using core analysis and wireline measurement to estimate rock mechanical properties of the Zubair Reservoir, Southern Iraq. J. Pet. Sci. Eng. 2018, 166, 406–419. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, Y.; Yuan, H.; Zhang, D.; Agostini, F.; Skoczylas, F. Pore structure characterization of tight sandstone from Sbaa Basin, Algeria: Investigations using multiple fluid invasion methods. J. Nat. Gas Sci. Eng. 2018, 59, 414–426. [Google Scholar] [CrossRef]

- Lo, H.-W.; Liou, J.J. A novel multiple-criteria decision-making-based FMEA model for risk assessment. Appl. Soft Comput. 2018, 73, 684–696. [Google Scholar] [CrossRef]

| Sample ID | Type | PP (%) | APD (μm) | ASS (μm−1) | PSC | THC |

|---|---|---|---|---|---|---|

| XY-1 | Sandstone in Luo’he Formation | 20.15 | 51.9 | 1.18 | 0.63 | 28.74 |

| XY-2 | 19.57 | 47.7 | 1.17 | 0.61 | 26.74 | |

| XY-3 | 18.71 | 48.22 | 1.14 | 0.6 | 26.82 | |

| XY-4 | 19.25 | 45.33 | 1.11 | 0.61 | 27.52 | |

| XY-5 | 18.32 | 44.79 | 1.06 | 0.62 | 28.14 | |

| XY-6 | 18.99 | 49.75 | 1.09 | 0.6 | 27.13 | |

| XY-7 | Sandstone in Zhi’luo Formation | 13.74 | 28.4 | 0.98 | 0.53 | 19.26 |

| XY-8 | 14.24 | 32.3 | 1.07 | 0.54 | 21.56 | |

| XY-9 | 14.57 | 27.2 | 1.03 | 0.57 | 18.69 | |

| XY-10 | 13.32 | 26.75 | 0.97 | 0.56 | 20.88 | |

| XY-11 | 14.55 | 27.64 | 1.01 | 0.54 | 19.76 | |

| XY-12 | 13.67 | 26.88 | 1.04 | 0.57 | 20.65 | |

| XY-13 | Sandstone in Yan’an Formation | 7.07 | 13.7 | 0.62 | 0.5 | 15.47 |

| XY-14 | 6.31 | 12.4 | 0.61 | 0.48 | 16.44 | |

| XY-15 | 5.54 | 11.1 | 0.55 | 0.46 | 14.41 | |

| XY-16 | 6.62 | 12.7 | 0.64 | 0.49 | 14.74 | |

| XY-17 | 4.57 | 10.3 | 0.51 | 0.44 | 13.59 | |

| XY-18 | 5.21 | 10.8 | 0.53 | 0.47 | 14.21 |

| Sample ID | Type | Depth/m | Porosity/% | Overburden Pressure/Mpa |

|---|---|---|---|---|

| XY-1 | Coarse sandstone | 100 | 22.4 | 1.04 |

| XY-2 | 150 | 22.25 | 1.56 | |

| XY-3 | 200 | 21.93 | 2.08 | |

| XY-4 | 250 | 21.76 | 2.60 | |

| XY-5 | 300 | 21.62 | 3.12 | |

| XY-6 | 350 | 21.4 | 3.64 | |

| XY-7 | Medium sandstone | 500 | 15.21 | 5.19 |

| XY-8 | 530 | 14.8 | 5.51 | |

| XY-9 | 550 | 14.51 | 5.71 | |

| XY-10 | 570 | 14.31 | 5.92 | |

| XY-11 | 600 | 14.12 | 6.23 | |

| XY-12 | 620 | 14.03 | 6.44 | |

| XY-13 | Fine sandstone | 630 | 8.60 | 6.54 |

| XY-14 | 640 | 8.55 | 6.65 | |

| XY-15 | 650 | 8.48 | 6.75 | |

| XY-16 | 660 | 8.45 | 6.86 | |

| XY-17 | 670 | 8.40 | 6.96 | |

| XY-18 | 680 | 8.38 | 7.06 |

| Sample ID | Type | Natural/g | Drying/g | Water-Saturated/g | NWA/% | Average NWA/% |

|---|---|---|---|---|---|---|

| XY-1 | Sandstone in Luo’he Formation | 399.4 | 374.6 | 402.7 | 7.5 | 7.53 |

| XY-2 | 373.7 | 356 | 382.4 | 7.42 | ||

| XY-3 | 390.4 | 365.6 | 393.4 | 7.6 | ||

| XY-4 | 394.4 | 366.9 | 394.2 | 7.44 | ||

| XY-5 | 383.2 | 357.2 | 384.2 | 7.56 | ||

| XY-6 | 401.4 | 390.5 | 420.3 | 7.63 | ||

| XY-7 | Sandstone in Zhi’luo Formation | 392.5 | 385.6 | 406.4 | 5.4 | 5.31 |

| XY-8 | 416.8 | 410.2 | 431.5 | 5.2 | ||

| XY-9 | 416.6 | 408.9 | 430.4 | 5.25 | ||

| XY-10 | 415 | 408.8 | 430.8 | 5.37 | ||

| XY-11 | 412.3 | 404.1 | 425.6 | 5.33 | ||

| XY-12 | 408.6 | 391.2 | 411.9 | 5.3 | ||

| XY-13 | Sandstone in Yan’an Formation | 437 | 432.3 | 452.1 | 4.57 | 4.6 |

| XY-14 | 461.2 | 447.3 | 467.6 | 4.53 | ||

| XY-15 | 442.8 | 433.2 | 452.9 | 4.55 | ||

| XY-16 | 460.6 | 451.7 | 472.7 | 4.65 | ||

| XY-17 | 416.6 | 408.9 | 427.7 | 4.6 | ||

| XY-18 | 450.8 | 444.2 | 465 | 4.68 |

| Scale | Meaning | Expression of the GRG |

|---|---|---|

| 1 | The two factors have the same importance | 0 < G(n,i)-G(n,j) < 0.01 |

| 2 | One factor was slightly important than the other | 0.01 < G(n,i)-G(n,j) < 0.3 |

| 3 | One factor is important to other factors | 0.03 < G(n,i)-G(n,j) < 0.06 |

| 4 | One factor is more important than other factors | 0.06 < G(n,i)-G(n,j) < 0.09 |

| 5 | One factor is much more important than the other factors | G(n,i)-G(n,j) > 0.09 |

| PP | APD | ASS | PSC | THC | Porosity | NWA | Wi | |

|---|---|---|---|---|---|---|---|---|

| PP | 0 | −0.009 | 0.075 | 0.012 | −0.066 | 0.000 | −0.024 | 0.1139 |

| APD | 0.009 | 0 | 0.084 | 0.022 | −0.057 | 0.010 | −0.015 | 0.1187 |

| ASS | −0.075 | −0.084 | 0 | −0.063 | −0.141 | −0.075 | −0.099 | 0.0326 |

| PSC | −0.012 | −0.022 | 0.063 | 0 | −0.078 | −0.012 | −0.037 | 0.0724 |

| THC | 0.066 | 0.057 | 0.141 | 0.078 | 0 | 0.066 | 0.042 | 0.3555 |

| Porosity | 0.000 | −0.010 | 0.075 | 0.012 | −0.066 | 0 | −0.025 | 0.1139 |

| NWA | 0.024 | 0.015 | 0.099 | 0.037 | −0.042 | 0.025 | 0 | 0.1930 |

| Sandstone in Luo’he Formation | Sandstone in Zhi’luo Formation | Sandstone in Yan’an Formation | ||||||

|---|---|---|---|---|---|---|---|---|

| ID | L | Average | ID | L | Average | ID | L | Average |

| 1 | 0.986 | 0.917 | 7 | 0.407 | 0.423 | 13 | 0.097 | 0.076 |

| 2 | 0.895 | 8 | 0.467 | 14 | 0.131 | |||

| 3 | 0.895 | 9 | 0.397 | 15 | 0.055 | |||

| 4 | 0.909 | 10 | 0.436 | 16 | 0.110 | |||

| 5 | 0.904 | 11 | 0.408 | 17 | 0.011 | |||

| 6 | 0.915 | 12 | 0.425 | 18 | 0.052 | |||

| Borehole | Borehole | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| G36-1 | 160 | 30 | 26 | 161 | G19-1 | 265 | 32 | 12 | 257 |

| G36-2 | 217 | 54 | 32 | 225 | G19-2 | 333 | 17 | 4 | 313 |

| G36-3 | 241 | 36 | 27 | 238 | G31-1 | 200 | 53 | 9 | 206 |

| G36-4 | 200 | 28 | 30 | 198 | G32-5 | 191 | 45 | 48 | 198 |

| G37-1 | 198 | 40 | 27 | 201 | G32-7 | 152 | 57 | 15 | 165 |

| G37-2 | 234 | 22 | 43 | 227 | G33-1 | 128 | 28 | 0 | 129 |

| G37-3 | 294 | 42 | 19 | 288 | G33-2 | 136 | 17 | 20 | 133 |

| G38-1 | 248 | 54 | 41 | 253 | G33-3 | 151 | 42 | 12 | 157 |

| G14-1 | 220 | 33 | 25 | 217 | G33-4 | 152 | 55 | 9 | 163 |

| G14-2 | 162 | 46 | 17 | 169 | G33-5 | 146 | 39 | 12 | 151 |

| G15-2 | 131 | 33 | 24 | 136 | G33-6 | 159 | 20 | 1 | 154 |

| G15-3 | 42 | 39 | 43 | 59 | G33-7 | 198 | 26 | 25 | 194 |

| G15-4 | 135 | 36 | 53 | 143 | G33-8 | 217 | 44 | 34 | 220 |

| G15-5 | 206 | 48 | 43 | 213 | G34-1 | 151 | 34 | 30 | 155 |

| 15-6 | 181 | 69 | 32 | 198 | G34-2 | 139 | 68 | 29 | 159 |

| G16-1 | 180 | 31 | 25 | 180 | G34-3 | 134 | 77 | 43 | 158 |

| G16-2 | 154 | 46 | 28 | 162 | G34-4 | 190 | 51 | 43 | 198 |

| G16-3 | 167 | 54 | 57 | 180 | G34-5 | 268 | 70 | 39 | 278 |

| G16-4 | 280 | 56 | 32 | 283 | G34-6 | 309 | 43 | 40 | 305 |

| G16-5 | 316 | 53 | 38 | 315 | G34-7 | 205 | 40 | 10 | 206 |

| G16-6 | 114 | 40 | 0 | 121 | G35-1 | 146 | 50 | 8 | 156 |

| G16-7 | 244 | 56 | 24 | 250 | G35-2 | 147 | 52 | 24 | 159 |

| G17-1 | 143 | 61 | 22 | 159 | G35-3 | 159 | 48 | 36 | 169 |

| G17-2 | 237 | 53 | 20 | 242 | G35-4 | 319 | 42 | 23 | 312 |

| G17-3 | 324 | 33 | 26 | 313 | G3 | 193 | 151 | 35 | 244 |

| G17-4 | 357 | 33 | 22 | 343 | G5-2 | 211 | 185 | 24 | 273 |

| G17-5 | 170 | 32 | 30 | 171 | G5-3 | 224 | 124 | 79 | 264 |

| bk-1 | 308 | 32 | 4 | 296 | G6-1 | 145 | 31 | 20 | 147 |

| bk-2 | 292 | 24 | 34 | 281 | G6-2 | 139 | 27 | 16 | 140 |

| bk-3 | 308 | 41 | 10 | 300 | G6-3 | 142 | 29 | 12 | 143 |

| bk-4 | 348 | 165 | 77 | 395 | G6-4 | 153 | 55 | 45 | 167 |

| c1 | 365 | 53 | 11 | 358 | G6-5 | 240 | 51 | 29 | 243 |

| C9 | 190 | 31 | 22 | 189 | G6-6 | 294 | 41 | 20 | 289 |

| c10 | 237 | 47 | 17 | 238 | G7-2 | 143 | 50 | 37 | 155 |

| c11 | 281 | 46 | 18 | 279 | G7-3 | 360 | 46 | 18 | 351 |

| C14 | 200 | 24 | 20 | 195 | G7-5 | 159 | 34 | 10 | 161 |

| C15 | 180 | 42 | 6 | 183 | G8-3 | 201 | 42 | 28 | 204 |

| C17 | 228 | 33 | 14 | 224 | G8-4 | 329 | 30 | 4 | 315 |

| C21 | 171 | 36 | 22 | 174 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, L.; Liu, T.; Zhang, X.; Xu, D.; Gao, W. Prediction of the Water-Bearing Capacity of Coal Strata by Using the Macro and Micro Pore Structure Parameters of Aquifers. Energies 2021, 14, 4865. https://doi.org/10.3390/en14164865

Shi L, Liu T, Zhang X, Xu D, Gao W. Prediction of the Water-Bearing Capacity of Coal Strata by Using the Macro and Micro Pore Structure Parameters of Aquifers. Energies. 2021; 14(16):4865. https://doi.org/10.3390/en14164865

Chicago/Turabian StyleShi, Longqing, Tianhao Liu, Xiaoyang Zhang, Dongjing Xu, and Weifu Gao. 2021. "Prediction of the Water-Bearing Capacity of Coal Strata by Using the Macro and Micro Pore Structure Parameters of Aquifers" Energies 14, no. 16: 4865. https://doi.org/10.3390/en14164865

APA StyleShi, L., Liu, T., Zhang, X., Xu, D., & Gao, W. (2021). Prediction of the Water-Bearing Capacity of Coal Strata by Using the Macro and Micro Pore Structure Parameters of Aquifers. Energies, 14(16), 4865. https://doi.org/10.3390/en14164865