Optimizing the Size of Autonomous Hybrid Microgrids with Regard to Load Shifting

Abstract

:1. Introduction

2. Materials and Methods

2.1. Optimization Method, Criteria, and Evaluated Indicators

2.2. Mathematical Modeling of HES Components

2.2.1. Photovoltaic System

2.2.2. Wind Power System

2.2.3. Battery Energy Storage

2.2.4. Diesel Power System

2.3. Load Shifting Algorithm

3. Case Study

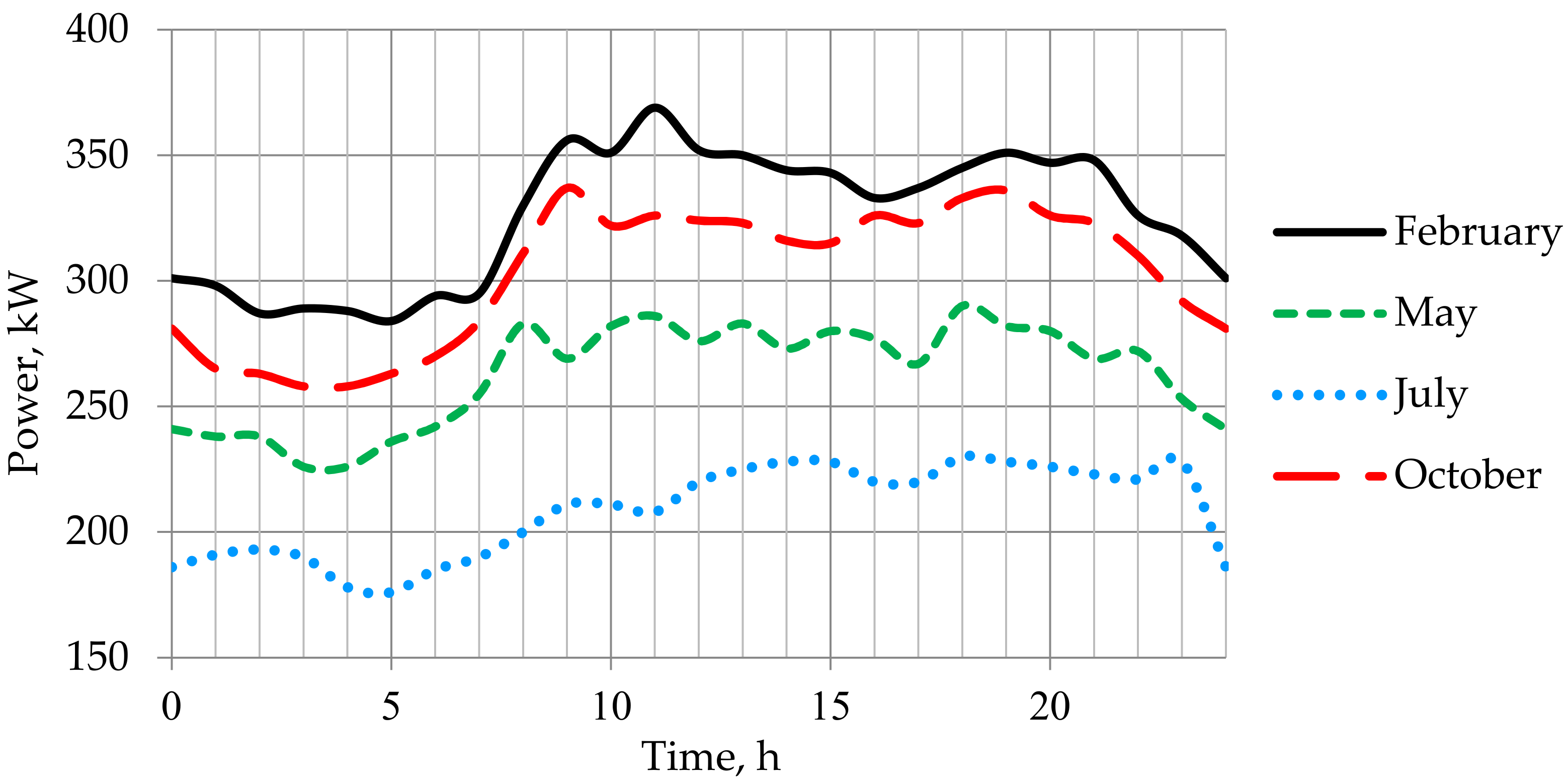

3.1. General Information on the Research Object

3.2. Specifications of the HES Components

3.2.1. Specifications of the PVPs

3.2.2. Specifications of the WTs

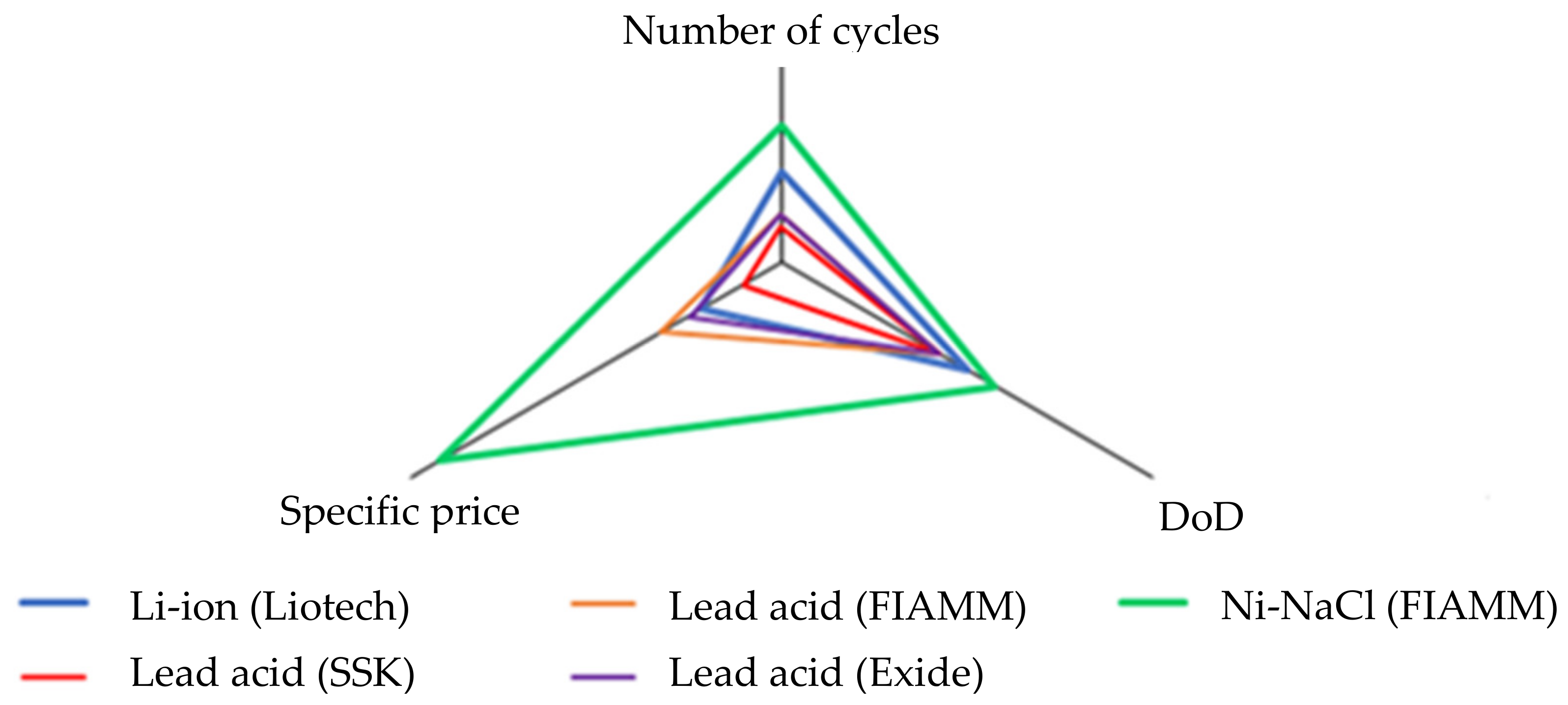

3.2.3. Specifications of Batteries

3.2.4. Specifications of the DGs

3.3. Economic and Environmental Parameters

4. Results

4.1. Size Optimization without Load Shifting

4.1.1. Basic Configuration Selection (Only DPS)

4.1.2. Optimization by NPC Criterion

4.1.3. Optimization by the NPC Criterion with Limited PB

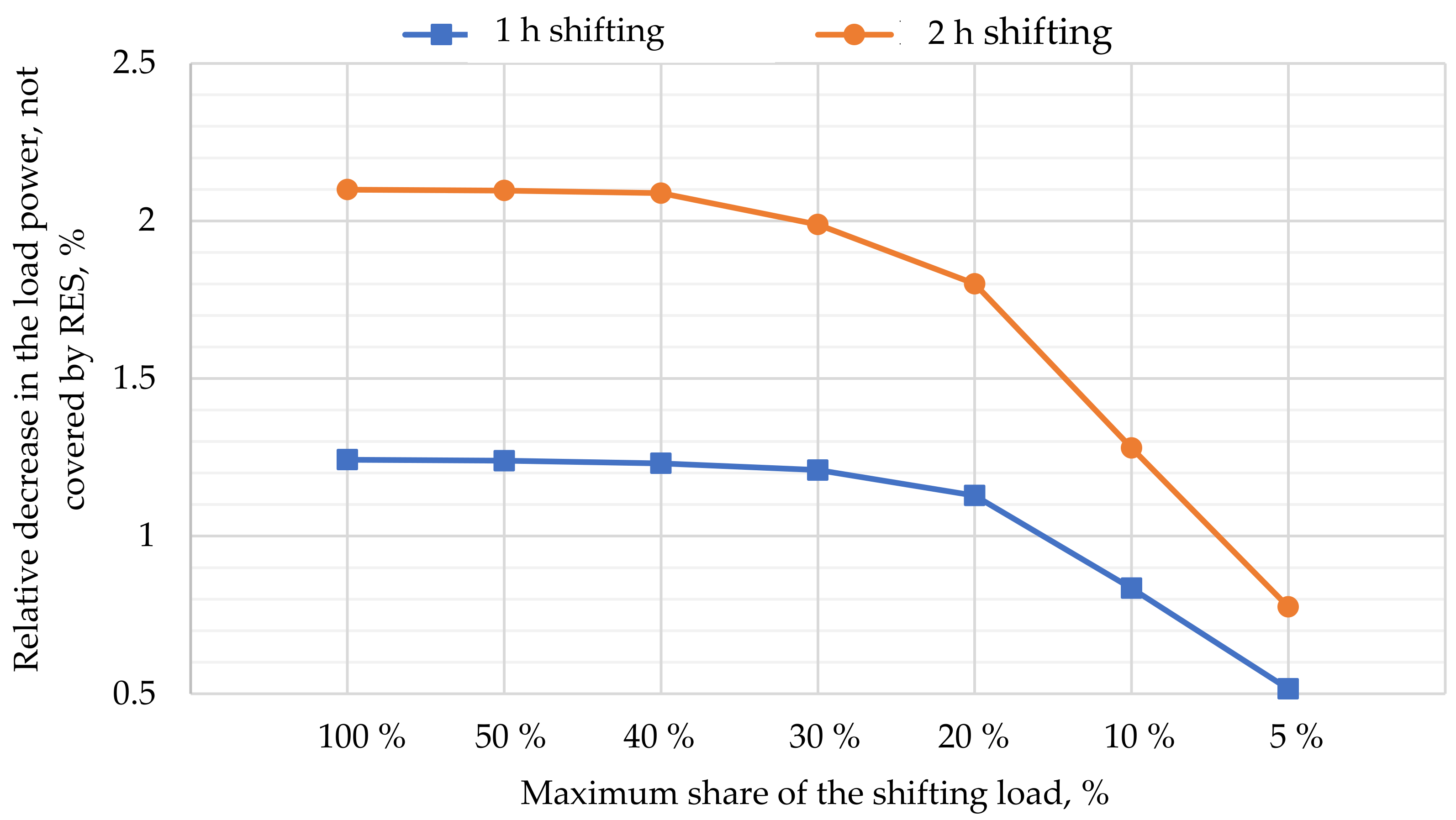

4.2. Size Re-Optimization with Load Shifting

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature and Abbreviations

| BES | battery energy storage; |

| CAPEX | capital expenditure; |

| DG | diesel generator; |

| DoD | depth of discharge; |

| DPS | diesel power system; |

| HES | hybrid energy system; |

| LCOE | levelized cost of electricity; |

| NPC | net present cost; |

| OPEX | operating expenditure; |

| PB | payback period; |

| PVP | photovoltaic panels; |

| PVS | photovoltaic system; |

| RES | renewable energy source; |

| WPS | wind power system; |

| WT | wind turbine. |

References

- Litvinenko, V.S.; Tsvetkov, P.S.; Dvoynikov, M.V.; Buslaev, G.V. Barriers to implementation of hydrogen initiatives in the context of global energy sustainable development. J. Min. Inst. 2020, 244, 428–438. [Google Scholar] [CrossRef]

- Hossein Alizadeh, R.; Shakouri, G.H.; Amalnick, M.S.; Taghipour, P. Economic sizing of a hybrid (PV-WT-FC) renewable energy system (HRES) for stand-alone usages by an optimization-simulation model: Case study of Iran. Renew. Sustain. Energy Rev. 2016, 54, 139–150. [Google Scholar] [CrossRef] [Green Version]

- Sychev, Y.A.; Abramovich, B.N.; Zimin, R.Y.; Kuznetsov, P.A. Mathematical modeling of harmonic correction by parallel active filter in conditions of distributed generation. J. Phys. Conf. Ser. 2019, 1333, 032081. [Google Scholar] [CrossRef]

- IEA. Total Installed Power Capacity by Fuel and Technology 2019–2025. Available online: https://www.iea.org/data-and-statistics/charts/total-installed-power-capacity-by-fuel-and-technology-2019–2025-main-case (accessed on 6 June 2021).

- Belsky, A.A.; Dobush, V.; Haikal, S.F. Operation of a single-phase autonomous inverter as a part of a low-power wind complex. J. Min. Inst. 2019, 239, 564–569. [Google Scholar] [CrossRef]

- Dobush, V.S.; Belsky, A.A.; Skamyin, A.N. Electrical complex for autonomous power supply of oil leakage detection systems in pipelines. J. Phys. Conf. Ser. 2020, 1441, 012021. [Google Scholar] [CrossRef]

- Abramovich, B.N.; Ustinov, D.A.; Abdallah, W.J. Development and design of a mobile power plant in the form of a standalone power supply. J. Phys. Conf. Ser. 2021, 1753, 1–28. [Google Scholar] [CrossRef]

- Lukutin, B.V.; Muravyev, D.I.; Ryzhkova, A.V. The efficiency of combined electrothermal and electrochemical accumulation of electricity of a photovoltaic power plant. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1019, p. 012053. [Google Scholar] [CrossRef]

- Elistratov, V.V. Energy supply of autonomous territories based on renewable energy sources. In Proceedings of the 2020 7th International Conference on Energy Efficiency and Agricultural Engineering (EE&AE), Ruse, Bulgaria, 12–14 November 2020; pp. 1–3. [Google Scholar] [CrossRef]

- Kaabeche, A.; Ibtiouen, R. Techno-economic optimization of hybrid photovoltaic/wind/diesel/battery generation in a stand-alone power system. Sol. Energy 2014, 103, 171–182. [Google Scholar] [CrossRef]

- Luna-Rubio, R.; Trejo-Perea, M.; Vargas-Vázquez, D.; Ríos-Moreno, G.J. Optimal sizing of renewable hybrids energy systems: A review of methodologies. Sol. Energy 2012, 86, 1077–1088. [Google Scholar] [CrossRef]

- García-Triviño, P.; Torreglosa, J.P.; Jurado, F. Optimised operation of power sources of a PV/battery/hydrogen-powered hybrid charging station for electric and fuel cell vehicles. IET Renew. Power Gener. 2019, 13, 3022–3032. [Google Scholar] [CrossRef]

- Abramovich, B.N.; Babanova, I.S. Development of neural network models to predict and control power consumption in mineral mining industry. Min. Inf. Anal. Bull. 2018, 5, 206–213. [Google Scholar] [CrossRef]

- Bolshunova, O.M.; Korzhev, A.A.; Vatlina, A.M. Power stabilization system for the regulated electric drive of transport vehicles. J. Phys. Conf. Ser. 2021, 1753, 012014. [Google Scholar] [CrossRef]

- Bhuiyan, F.A.; Yazdani, A.; Primak, S.L. Optimal sizing approach for islanded microgrids. IET Renew. Power Gener. 2015, 9, 166–175. [Google Scholar] [CrossRef]

- Dufo-López, R.; Bernal-Agustín, J.L.; Yusta-Loyo, J.M. Multi-objective optimization minimizing cost and life cycle emissions of stand-alone PV–wind-diesel systems with batteries storage. Appl. Energy 2011, 88, 4033–4041. [Google Scholar] [CrossRef]

- Ogunjuyigbe, A.S.O.; Ayodele, T.R.; Akinola, O.A. Optimal allocation and sizing of PV/Wind/Split-diesel/Battery hybrid energy system for minimizing life cycle cost, carbon emission and dump energy of remote residential building. Appl. Energy 2016, 171, 153–171. [Google Scholar] [CrossRef]

- Baghdadi, F.; Mohammedi, K.; Diaf, S.; Behar, O. Feasibility study and energy conversion analysis of stand-alone hybrid renewable energy system. Energy Convers. Manag. 2015, 105, 471–479. [Google Scholar] [CrossRef]

- Rajanna, S.; Saini, R.P. Development of optimal integrated renewable energy model with battery storage for a remote Indian area. Energy 2016, 111, 803–817. [Google Scholar] [CrossRef]

- García-Vera, Y.E.; Dufo-López, R.; Bernal-Agustín, J.L. Techno-economic feasibility analysis through optimization strategies and load shifting in isolated hybrid microgrids with renewable energy for the non-interconnected zone (NIZ) of Colombia. Energies 2020, 13, 6146. [Google Scholar] [CrossRef]

- Sedighi, M.; Moradzadeh, M. Impact of demand response program on hybrid renewable energy system planning. In Demand Response Application in Smart Grids; Nojavan, S., Zare, K., Eds.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Alotaibi, M.A.; Alolah, A.; Ahmed, M.A. A novel demand response strategy for sizing of hybrid energy system with smart grid concepts. IEEE Access 2021, 9, 20277. [Google Scholar] [CrossRef]

- Amrollahi, M.H.; Bathaee, S.M.T. Techno-economic optimization of hybrid photovoltaic/wind generation together with energy storage system in a stand-alone micro-grid subjected to demand response. Appl. Energy 2017, 202, 66–77. [Google Scholar] [CrossRef]

- Gil Mena, A.J.; Bouakkaz, A.; Haddad, S. Online Load-Scheduling Strategy and Sizing Optimization for a Stand-Alone Hybrid System. J. Energy Eng. 2021, 147, 04020078. [Google Scholar] [CrossRef]

- Kumar, S.; Kaur, T.; Upadhyay, S.; Sharma, V.; Vatsal, D. Optimal Sizing of Stand Alone Hybrid Renewable Energy System with Load Shifting. Energy Sources Part. A Recovery Util. Environ. Eff. 2020. [Google Scholar] [CrossRef]

- Chauhan, A.; Saini, R.P. Size optimization and demand response of a stand-alone integrated renewable energy system. Energy 2017, 124, 59–73. [Google Scholar] [CrossRef]

- Kharrich, M.; Kamel, S.; Abdeen, M.; Mohammed, O.H. Developed approach based on equilibrium optimizer for optimal design of hybrid PV/Wind/Diesel/Battery microgrid in Dakhla, Morocco. IEEE Access 2021, 9, 13655–13670. [Google Scholar] [CrossRef]

- Tcvetkov, P. Climate Policy Imbalance in the Energy Sector: Time to Focus on the Value of CO2 Utilization. Energies 2021, 14, 411. [Google Scholar] [CrossRef]

- Fleck, B.; Huot, M. Comparative life-cycle assessment of a small wind turbine for residential off-grid use. Renew. Energy 2009, 34, 2688–2696. [Google Scholar] [CrossRef]

- Dufo-López, R.; Bernal-Agustín, J.L.; Domínguez-Navarro, J.A. Generation management using batteries in wind farms: Economical and technical analysis for Spain. Energy Policy 2009, 37, 126–139. [Google Scholar] [CrossRef]

- Suhane, P.; Rangnekar, S.; Khare, A.; Mittal, A. Sizing and performance analysis of standalone wind-photovoltaic based hybrid energy system using ant colony optimization. IET Renew. Power Generation 2016, 10, 964–972. [Google Scholar] [CrossRef]

- Bosikov, I.I.; Klyuev, R.V.; Kelekhsaev, V.B. Development of indicators for performance functioning natural-industrial system evaluation at the mining and processing complex using the analytical hierarchy method. In Proceedings of the 2017 International Conference on Industrial Engineering, Applications and Manufacturing, ICIEAM 2017, Chelyabinsk, Russia, 16–19 May 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Renewables.ninja. Available online: https://www.renewables.ninja (accessed on 6 June 2021).

- Bayer, P.; Aklin, M. The European Union Emissions Trading System reduced CO2 emissions despite low prices. Proc. Natl. Acad. Sci. USA 2020, 117, 8804–8812. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- IEA. Projected Costs of Generating Electricity 2020. Available online: https://www.iea.org/reports/projected-costs-of-generating-electricity-2020 (accessed on 6 June 2021).

- Tolstouhov, D.A. Ensuring the competitiveness of nuclear energy. In Proceedings of the “Breakthrough” project: Place and Advantages of the Project in the Development of the Global Energy System, Ekaterinburg, Russia, 7–8 June 2016; Available online: http://www.innov-rosatom.ru/events/proriv/nauchno-prakticheskaya-konferentsiya-proektnoe-napravlenie-proryv-2016/ae13c91a88ffe014e4cd1e8c9ba4a826.pdf (accessed on 14 July 2021). (In Russian).

- Zhukovskiy, Y.L.; Lavrik, A.Y.; Buldysko, A.D. Energy demand side management in stand-alone power supply system with renewable energy sources. J. Phys. Conf. Ser. 2021, 1753, 012059. [Google Scholar] [CrossRef]

- Tostado-Véliz, M.; Icaza-Alvarez, D.; Jurado, F. A novel methodology for optimal sizing photovoltaic-battery systems in smart homes considering grid outages and demand response. Renew. Energy 2021, 170, 884–896. [Google Scholar] [CrossRef]

- Lujano-Rojas, J.M.; Monteiro, C.; Dufo-López, R.; Bernal-Agustín, J.L. Optimum load management strategy for wind/diesel/battery hybrid power systems. Renew. Energy 2012, 44, 288–295. [Google Scholar] [CrossRef]

| PVP Model | Rated Power, W | Price, EUR | Dimensions, m | Efficiency, % | KT, %/°C |

|---|---|---|---|---|---|

| HVL-330/HJT | 330 | 174 | 1.671 × 1.002 | 19.70 | 0.285 |

| HVL-395/HJT | 395 | 212 | 1.996 × 1.002 | 19.75 | 0.285 |

| HVL-125/O | 125 | 53 | 1.300 × 1.100 | 8.74 | 0.29 |

| WT Model | Rated Power, kW | Hub Height, m | Speed, m/s | Price, EUR | Specific Price, EUR /kW | ||

|---|---|---|---|---|---|---|---|

| Cut-In | Rated | Cut-Off | |||||

| Vestas V25 | 200 | 30 | 3.5 | 11,5 | 25 | 148,900 | 750 |

| Vestas V27 | 225 | 30 | 3.5 | 14 | 25 | 166,000 | 740 |

| Vestas V47 | 660 | 65 | 4 | 15 | 50 | 455,800 | 690 |

| Vestas V66 | 1650 | дo 80 | 4 | 15 | 50 | 950,500 | 580 |

| Parameter | Battery | ||||||

|---|---|---|---|---|---|---|---|

| Manufacturer | Liotech | FIAMM | FIAMM | SSK | Exide | ||

| Model | LFP270 | SONICK 48TL160H | 12SMG130 | 6-GP-180 | PC12/180 FT | ||

| Type | Lithium-ion | Nickel-saline | Lead acid | ||||

| Characteristics | |||||||

| Capacity, Ah | 270 | 160 | 130 | 180 | 165 | ||

| Rated discharge current, A | 54 | 40 | 13 | 18 | 16.5 | ||

| Voltage, V | 3.2 | 48 | 12 | 12 | 12 | ||

| DoD, % | 70 | 80 | 60 | 60 | 60 | ||

| Number of cycles | 3000 | 4500 | 1600 | N.I. | 1600 (C10) | ||

| Weight, kg | 10 | 105 | 54 | 63 | 58 | ||

| Operational temperature, °C | 0… +50 (C) −40… 50 (D) | −25… +60 | +10… +30 | +10… +30 | +10… +30 | ||

| Price, EUR | 310 | 11,400 | 830 | 360 | 790 | ||

| Calculated characteristics | |||||||

| C1 max, kWh | 0.9 | 7.7 | 1.6 | 2.2 | 2.0 | ||

| Rated discharge power, kW | 0.173 | 1.920 | 0.156 | 0.216 | 0.198 | ||

| Specific price, EUR /kWh | 345 | 1480 | 520 | 165 | 395 | ||

| Rated Power, kW | Engine | Model | Price, EUR | Diesel Fuel Consumption (L/h) When the Load Is… | ||

|---|---|---|---|---|---|---|

| 50% | 75% | 100% | ||||

| 60 | YMZ | AD-60-T400 | 11,270 | 9.3 | 11.6 | 16.3 |

| 100 | AD-100-T400 | 10,700 | 16.8 | 24.1 | 31.4 | |

| 200 | AD-200-T400 | 15,600 | 29.3 | 42.6 | 56.1 | |

| 240 | AD-240-T400 | 16,600 | 34.8 | 50.7 | 66.9 | |

| 320 | AD-320-T400 | 31,700 | 45.9 | 66.9 | 88.2 | |

| 400 | AD-400-T400 | 33,700 | 55.6 | 81.6 | 108.1 | |

| Parameter | Measure | Value |

|---|---|---|

| Diesel price | EUR/t | 860 |

| Discount rate | % | 7 |

| DG’s resource before overhaul | hours | 25,000 |

| DG’s overhaul cost | % of DG’s CAPEX | 10 |

| Specific consumption of diesel engine oil | g/kWh | 0.5 |

| Diesel engine oil price | EUR/kg | 6 |

| Batteries cycles | pcs. | 3000 |

| WPS OPEX | EUR/kW/year | 29 |

| PVS OPEX | EUR/kW/year | 11.5 |

| BESS OPEX | % of CAPEX BES/year | 1 |

| Installation price (WPS, PVS, DPS) | % CAPEX equipment | 50 |

| Installation price (BESS, inverters) | % CAPEX equipment | 25 |

| Configuration | Technical and Economic Indicators | ||||||

|---|---|---|---|---|---|---|---|

| DG Rated Power, kW | Capex | Opex (1-st Year) | NPC | LCOE | CO2 | ||

| DG1 | DG2 | DG3 | Thousand EUR | Thousand EUR | Million EUR | EUR/kWh | t/Year |

| 450 | – | – | 71.1 | 522.1 | 33.27 | 0.208 | 1610 |

| 310 | 140 | – | 57.4 | 515.2 | 32.87 | 0.206 | 1591 |

| 240 | 140 | 70 | 51.6 | 512.9 | 32.70 | 0.205 | 1583 |

| N | Config. | DPS | WPS | PVS | BES | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Rated Power, kW | Number of WTs | Power, kW | Number of PVPs | Power, kW | Number of Batteries | Capacity, kWh | ||||

| DG1 | DG2 | DG3 | ||||||||

| 1 | D | 240 | 140 | 70 | – | – | – | – | – | – |

| 2 | D/W | 250 | 140 | 60 | 9 | 2025 | – | – | – | – |

| 3 | D/W+B | 250 | 140 | 60 | 9 | 2025 | – | – | 0 | 0 |

| 4 | D/W/PV | 240 | 140 | 70 | 7 | 1575 | 2520 | 995 | – | – |

| 5 | D/PV | 240 | 140 | 70 | – | – | 4360 | 1722 | – | – |

| 6 | D/PV+B | 240 | 140 | 70 | – | – | 4360 | 1722 | 4200 | 3780 |

| 7 | D/W/PV+B | 240 | 140 | 70 | 7 | 1575 | 2520 | 995 | 1480 | 1332 |

| N | Configuration | Technical and Economic Indicators | |||||

|---|---|---|---|---|---|---|---|

| CAPEX, | Opex (1-st Year), | NPC, | LCOE, | CO2, | PB, | ||

| Thousand EUR | Thousand EUR | Million EUR | EUR/kWh | t/Year | Years | ||

| 1 | D | 51.6 | 512.9 | 32.70 | 0.205 | 1583 | – |

| 2 | D/W | 2966.2 | 283.4 | 20.97 | 0.131 | 694 | 9.2 |

| 3 | D/W+B | 2966.2 | 283.4 | 20.97 | 0.131 | 694 | 9.2 |

| 4 | D/W/PV | 3449.2 | 207.7 | 16.67 | 0.104 | 469 | 8.4 |

| 5 | D/PV | 2008.0 | 331.6 | 23.08 | 0.145 | 963 | 8.2 |

| 6 | D/PV+B | 3873.8 | 280.0 | 21.66 | 0.136 | 565 | 11.1 |

| 7 | D/W/PV+B | 4106.7 | 190.5 | 16.16 | 0.101 | 328 | 9.2 |

| Config. | PB, Years | DPS | WPS | PVS | BES | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Rated Power, kW | Number of WTs | Power, kW | Number of PVPs | Power, kW | Number of Batt. | Capacity, kWh | ||||

| DG1 | DG2 | DG3 | ||||||||

| D/W/PV(5) | 5 | 240 | 140 | 70 | 2 | 450 | 1250 | 494 | 0 | 0 |

| D/W/PV/B(6) | 6 | 2 | 450 | 1910 | 754 | 460 | 414 | |||

| D/W/PV(6) | 6 | 3 | 675 | 1950 | 770 | 0 | 0 | |||

| D/W/PV/B(7) | 7 | 4 | 900 | 1800 | 711 | 800 | 720 | |||

| D/W/PV(7) | 7 | 5 | 1125 | 2000 | 1722 | 0 | 0 | |||

| Config. | CAPEX, Thousand EUR | OPEX (1-st Year), Thousand EUR | NPC, Million EUR | LCOE, EUR/kWh | CO2, t/Year | PB, Years |

|---|---|---|---|---|---|---|

| D/W/PV(5) | 1259.9 | 307.5 | 20.81 | 0.130 | 890 | 5 |

| D/W/PV/B(6) | 1760.2 | 280.0 | 19.54 | 0.122 | 770 | 6 |

| D/W/PV(6) | 1897.9 | 260.5 | 18.44 | 0.116 | 716 | 6 |

| D/W/PV/B(7) | 2509.5 | 235.2 | 17.47 | 0.109 | 576 | 7 |

| D/W/PV(7) | 2568.0 | 228.3 | 17.10 | 0.107 | 578 | 7 |

| Load Shifting | Re-Optimization | DPS | WPS | PVS | BES | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Rated Power, kW | Number of WTs | Power, kW | Number of PVPs | Power, kW | Number of Batt. | Capacity, kWh | ||||

| DG1 | DG2 | DG3 | ||||||||

| no | – | 240 | 140 | 70 | 7 | 1575 | 2520 | 995 | 1480 | 1332 |

| 1 h. max | + | 7 | 1575 | 2520 | 995 | 1375 | 1238 | |||

| 2 h. max | + | 7 | 1575 | 2520 | 995 | 1295 | 1166 | |||

| Load Shifting | Re-Optimization | CAPEX, Thousand EUR | OPEX (1-st Year), Thousand EUR | NPC, Milliom EUR | LCOE, EU /kWh | CO2, t/Year | PB, Years |

|---|---|---|---|---|---|---|---|

| no | – | 4106.7 | 190.5 | 16.16 | 0.101 | 328 | 9.2 |

| 1 h. max | + | 4059.7 | 189.3 | 16.08 | 0.101 | 332 | 9.1 |

| 2 h. max | + | 4024.1 | 189.3 | 16.03 | 0.100 | 336 | 9.0 |

| 2 h. max | – | 4106.7 | 188.2 | 16.04 | 0.100 | 322 | 9.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lavrik, A.; Zhukovskiy, Y.; Tcvetkov, P. Optimizing the Size of Autonomous Hybrid Microgrids with Regard to Load Shifting. Energies 2021, 14, 5059. https://doi.org/10.3390/en14165059

Lavrik A, Zhukovskiy Y, Tcvetkov P. Optimizing the Size of Autonomous Hybrid Microgrids with Regard to Load Shifting. Energies. 2021; 14(16):5059. https://doi.org/10.3390/en14165059

Chicago/Turabian StyleLavrik, Alexander, Yuri Zhukovskiy, and Pavel Tcvetkov. 2021. "Optimizing the Size of Autonomous Hybrid Microgrids with Regard to Load Shifting" Energies 14, no. 16: 5059. https://doi.org/10.3390/en14165059