Analytical Design of Sculpted Rotor Interior Permanent Magnet Machines

Abstract

:1. Introduction

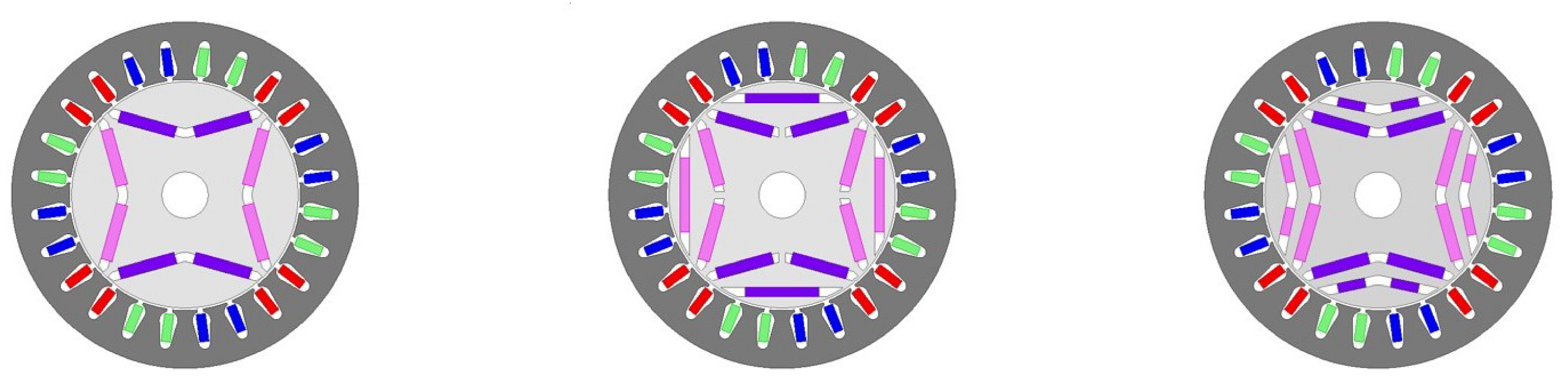

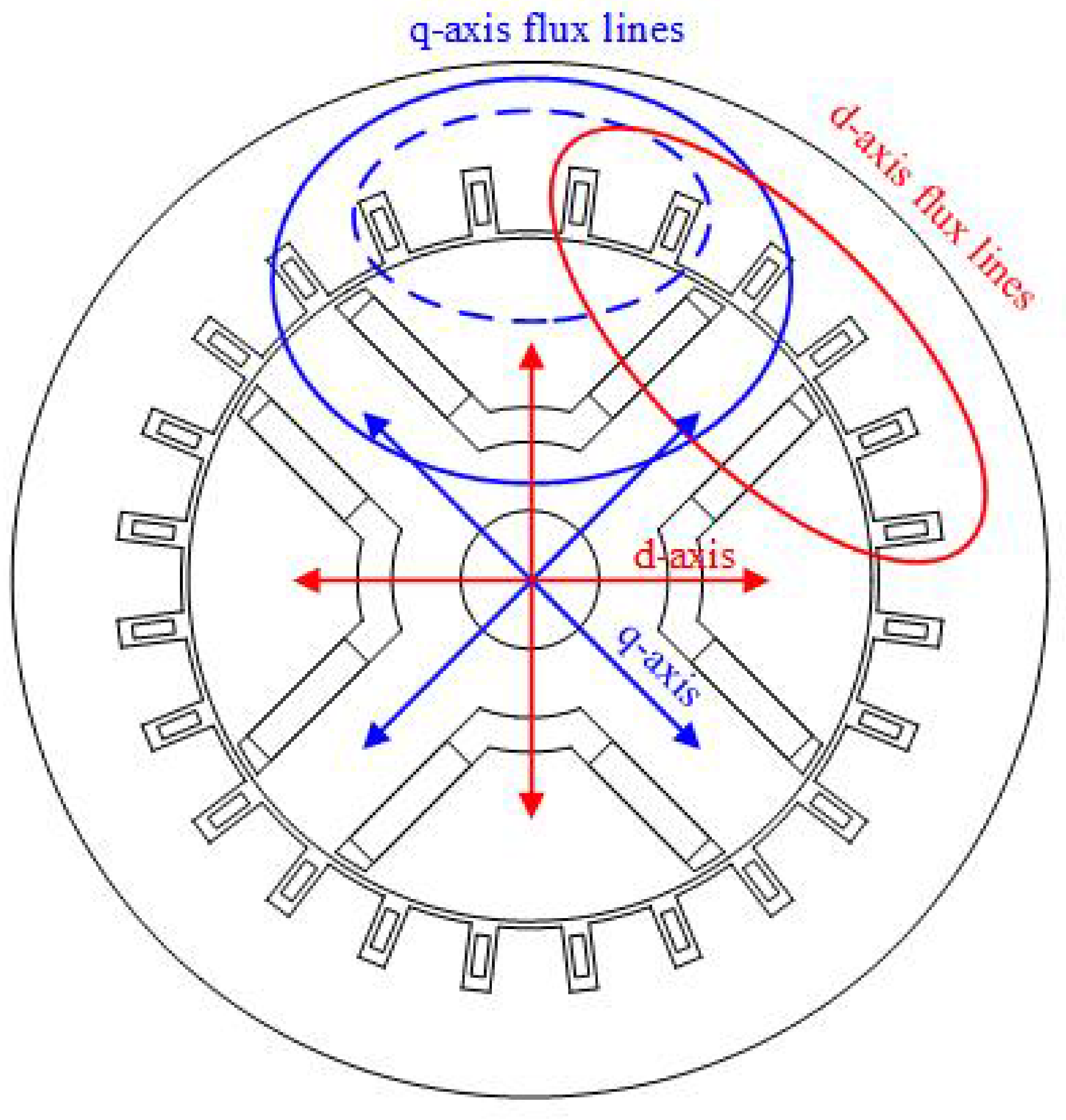

2. Flux Distribution and Control of IPM Machines

2.1. Flux Distribution

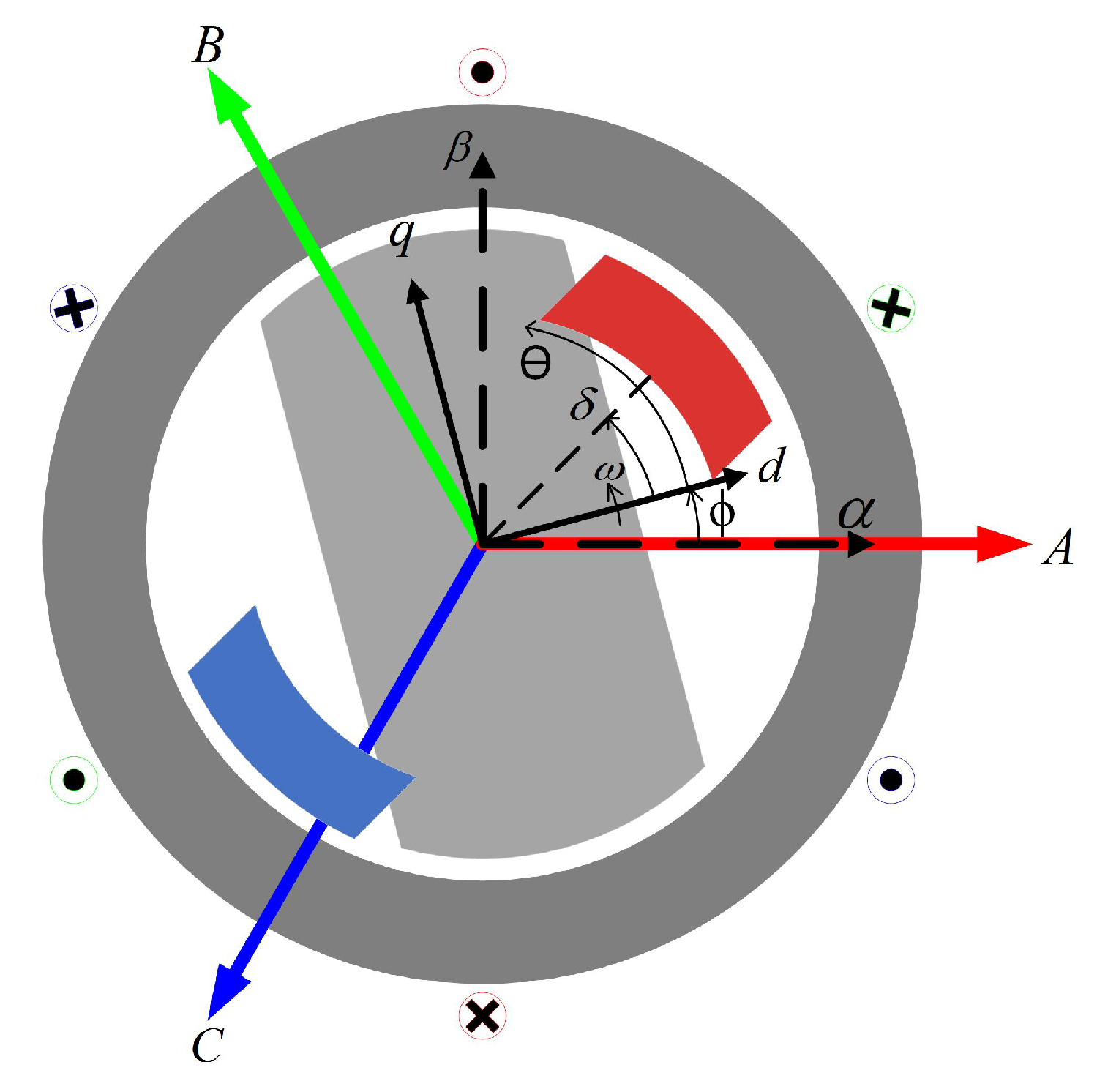

2.2. Control of IPM Machine

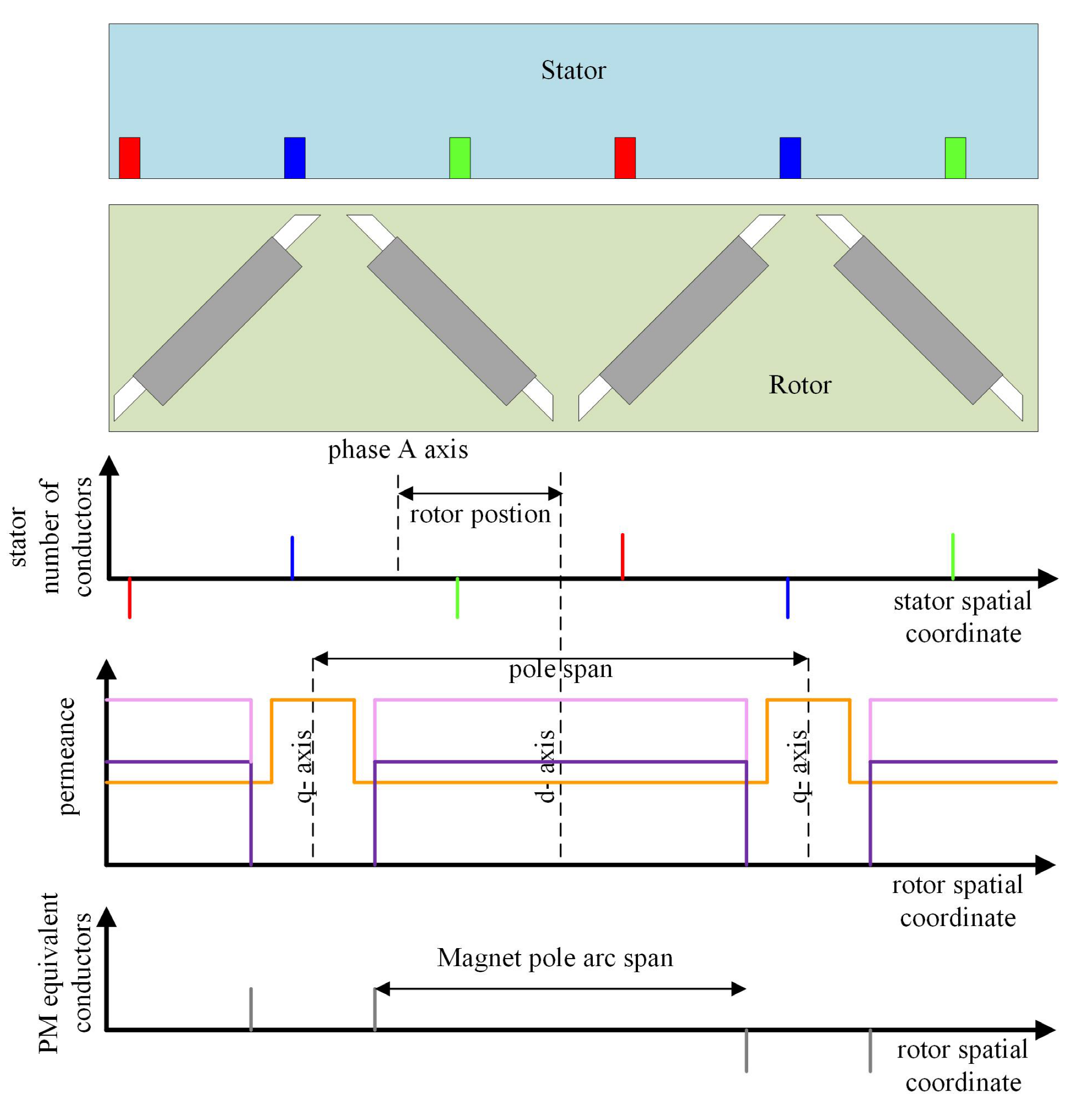

3. Analytical Model: MMF, Permeance, Flux, and Torque

3.1. Permeance Functions

3.2. Magneto Motive Forces (MMF)

3.2.1. Stator

3.2.2. Magnet

3.2.3. Second Reluctance Path Modification

3.3. Sculpt Feature Description: Equivalent Magnetizing Dipole Current

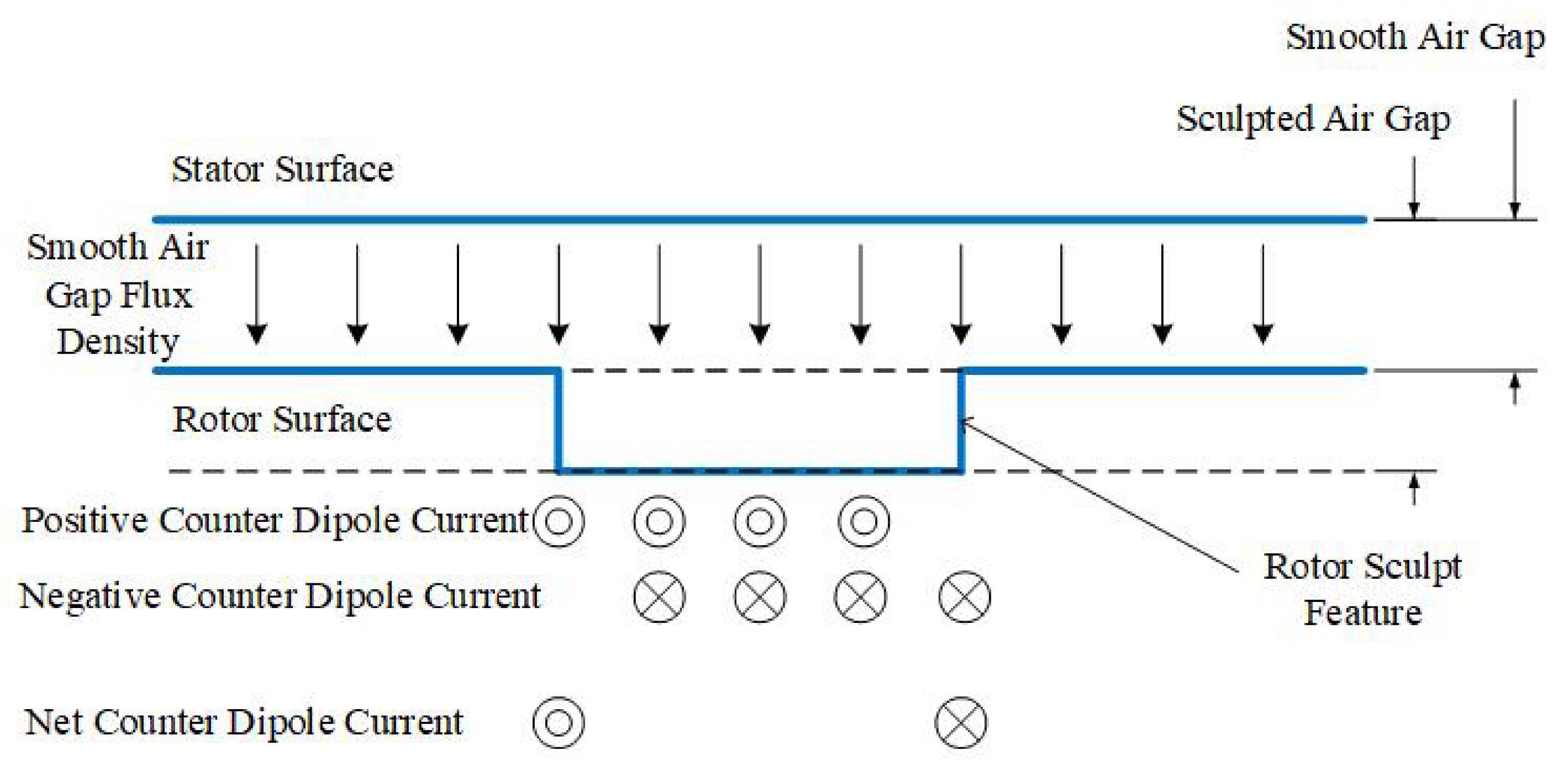

3.4. Flux Density

3.5. Torque

3.6. Rotation and Convolution

3.7. Comparative Analysis to Recent Analytical Methods

4. Application of Analytical Model to Example Machine

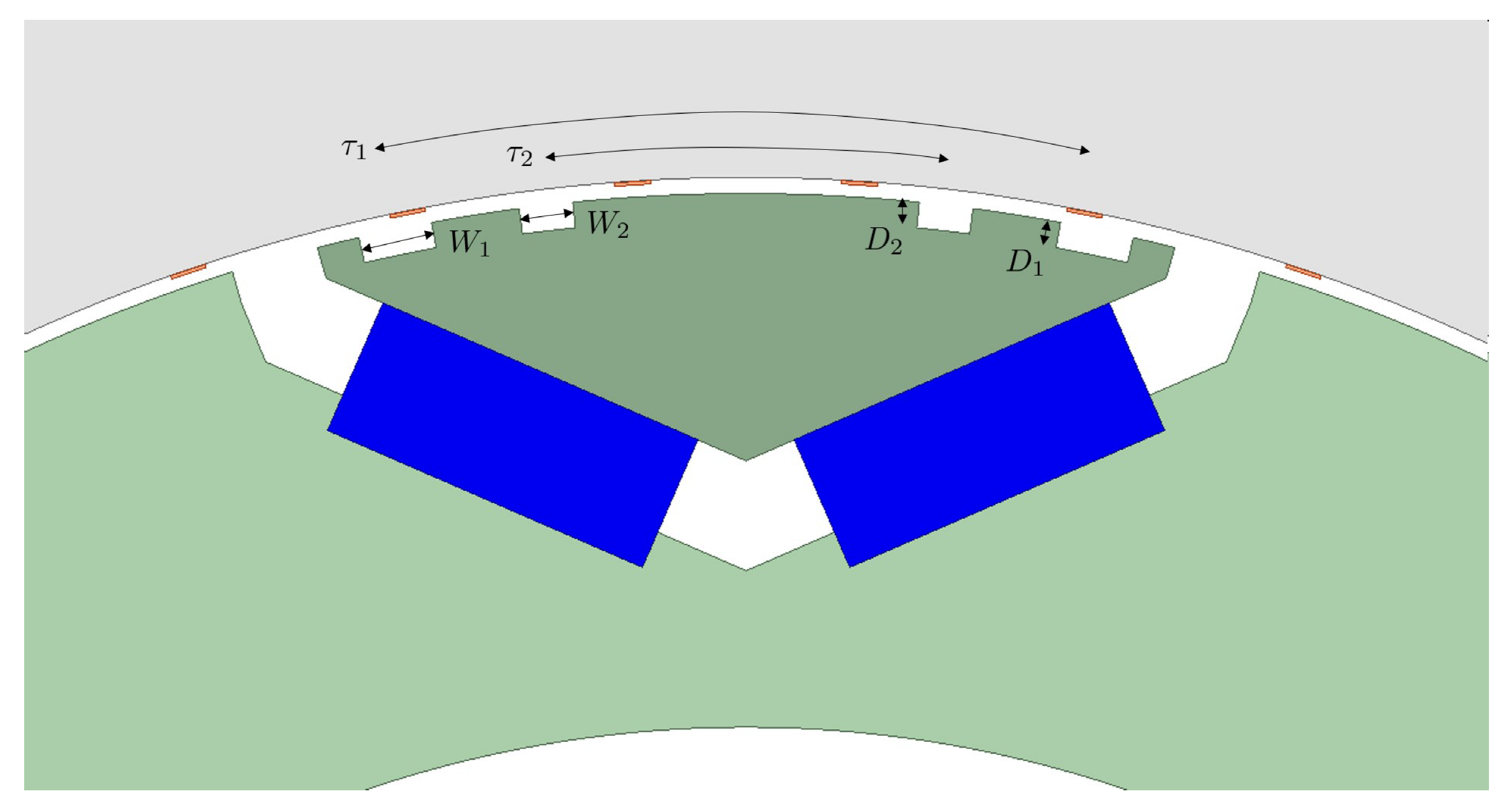

4.1. Sculpting Geometry

4.2. Model Implementation

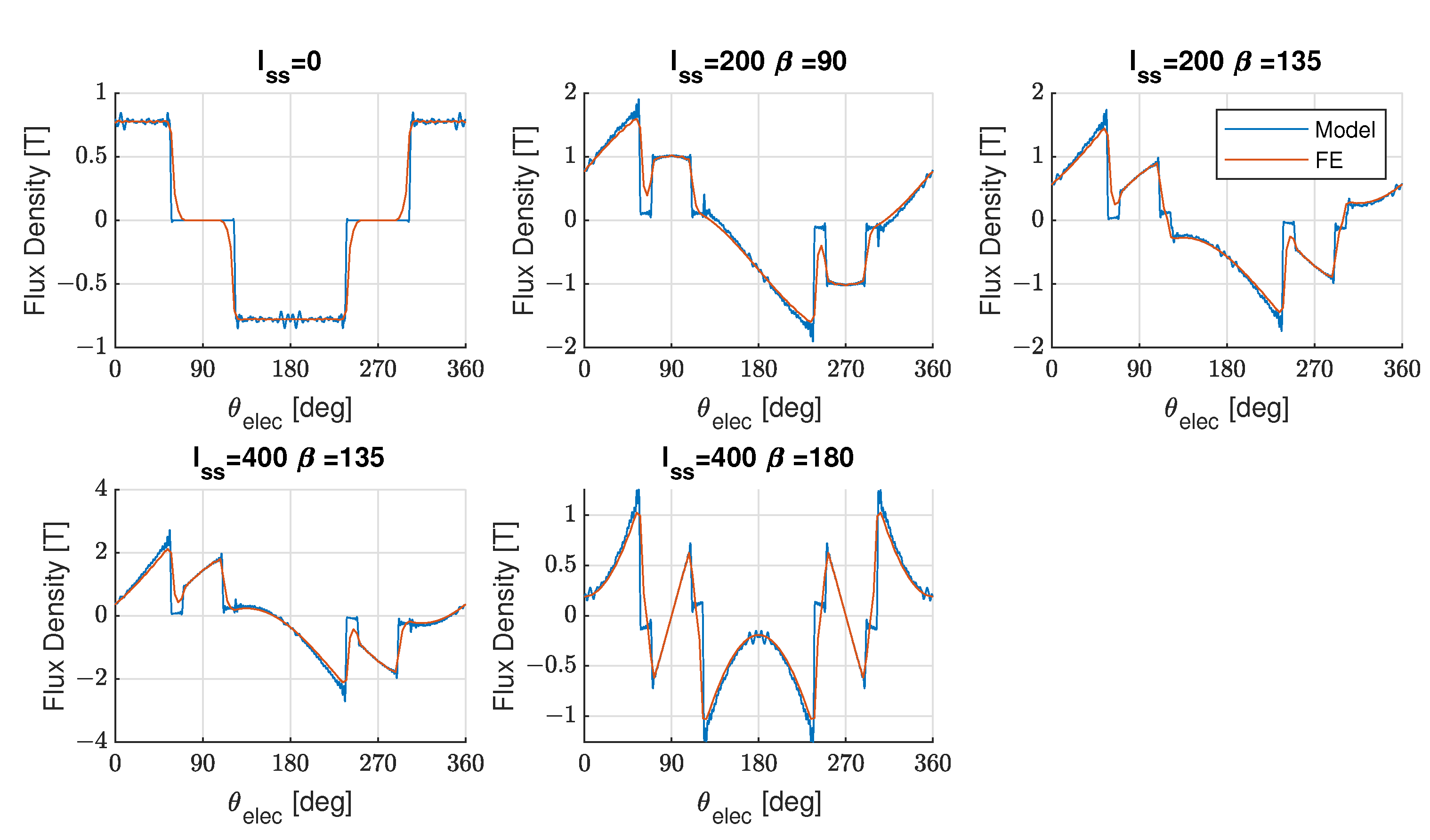

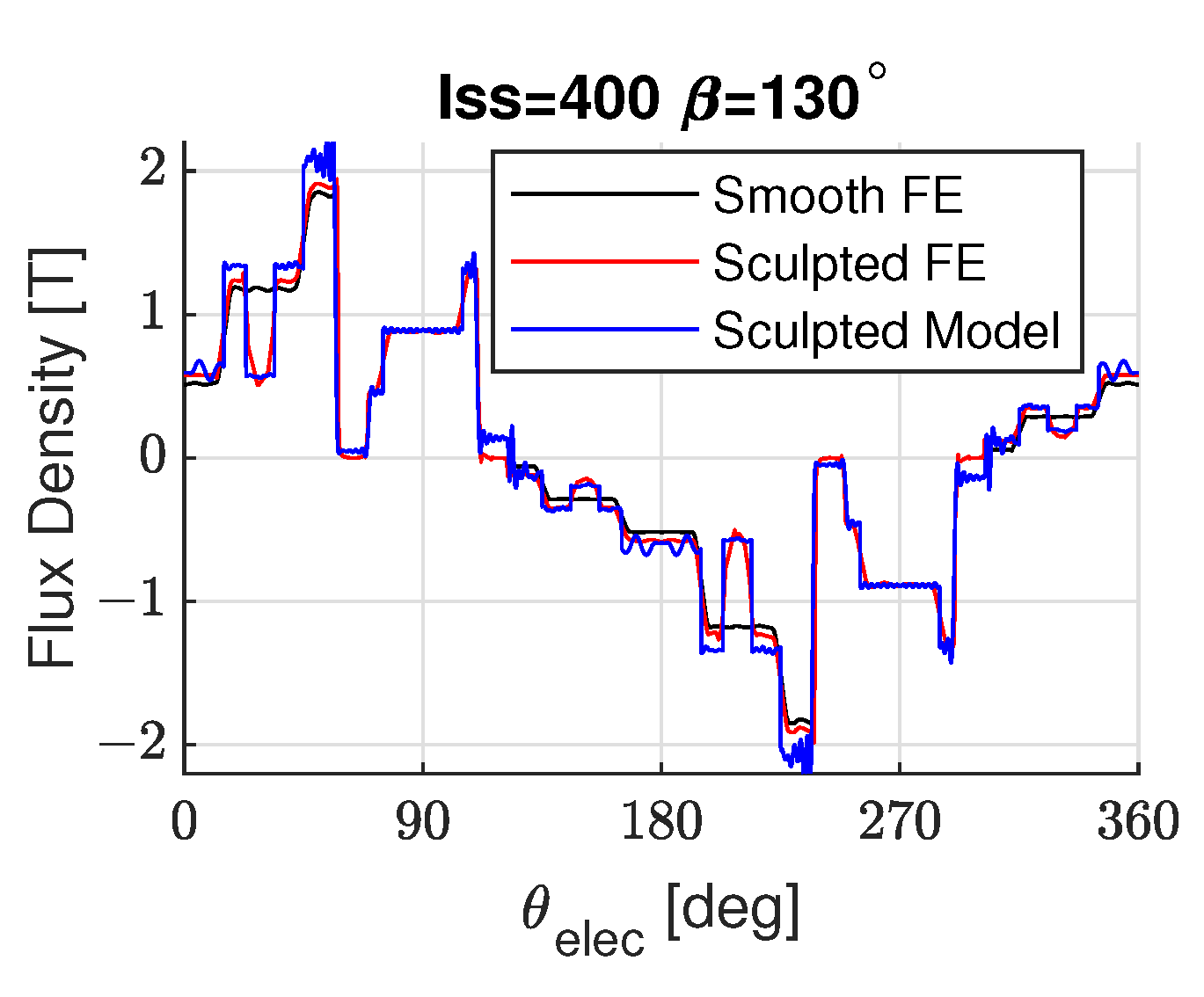

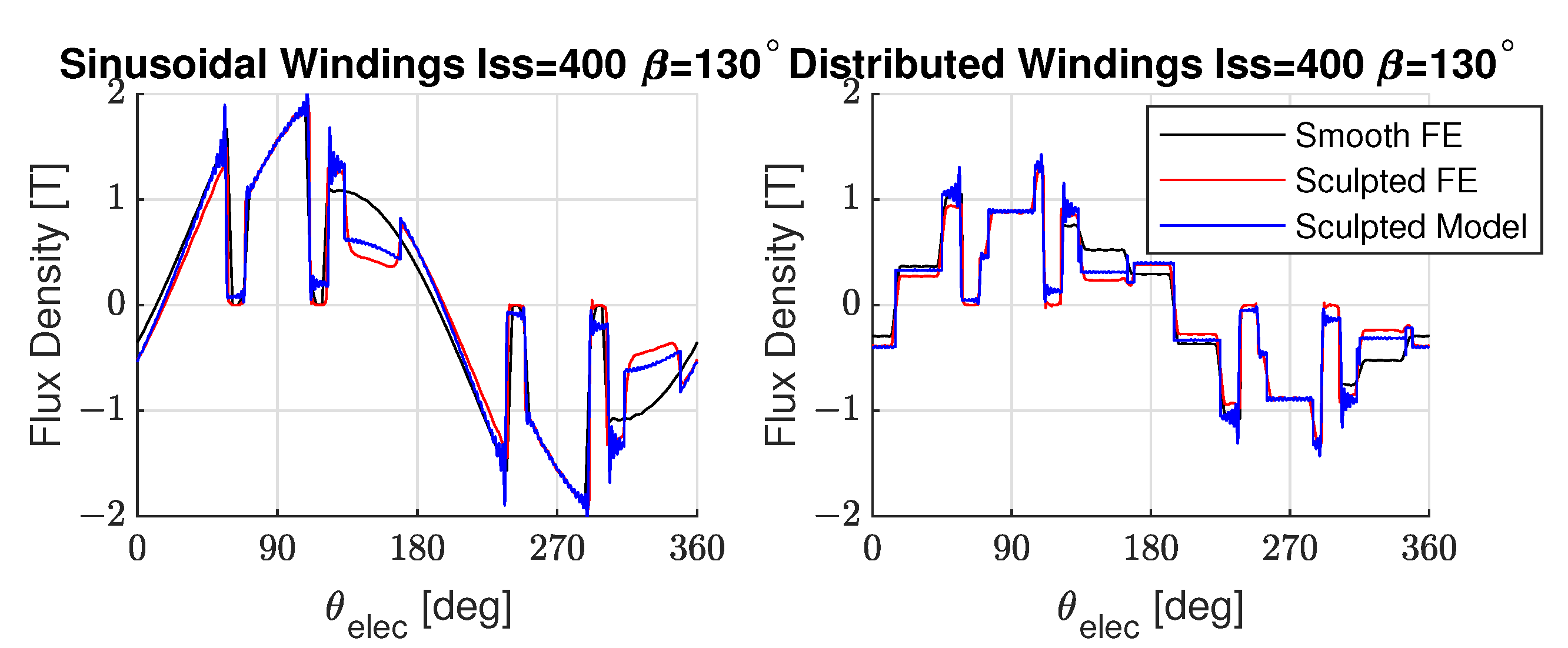

4.3. Model Validation: Radial Flux Density

4.4. Model Validation: Torque Ripple

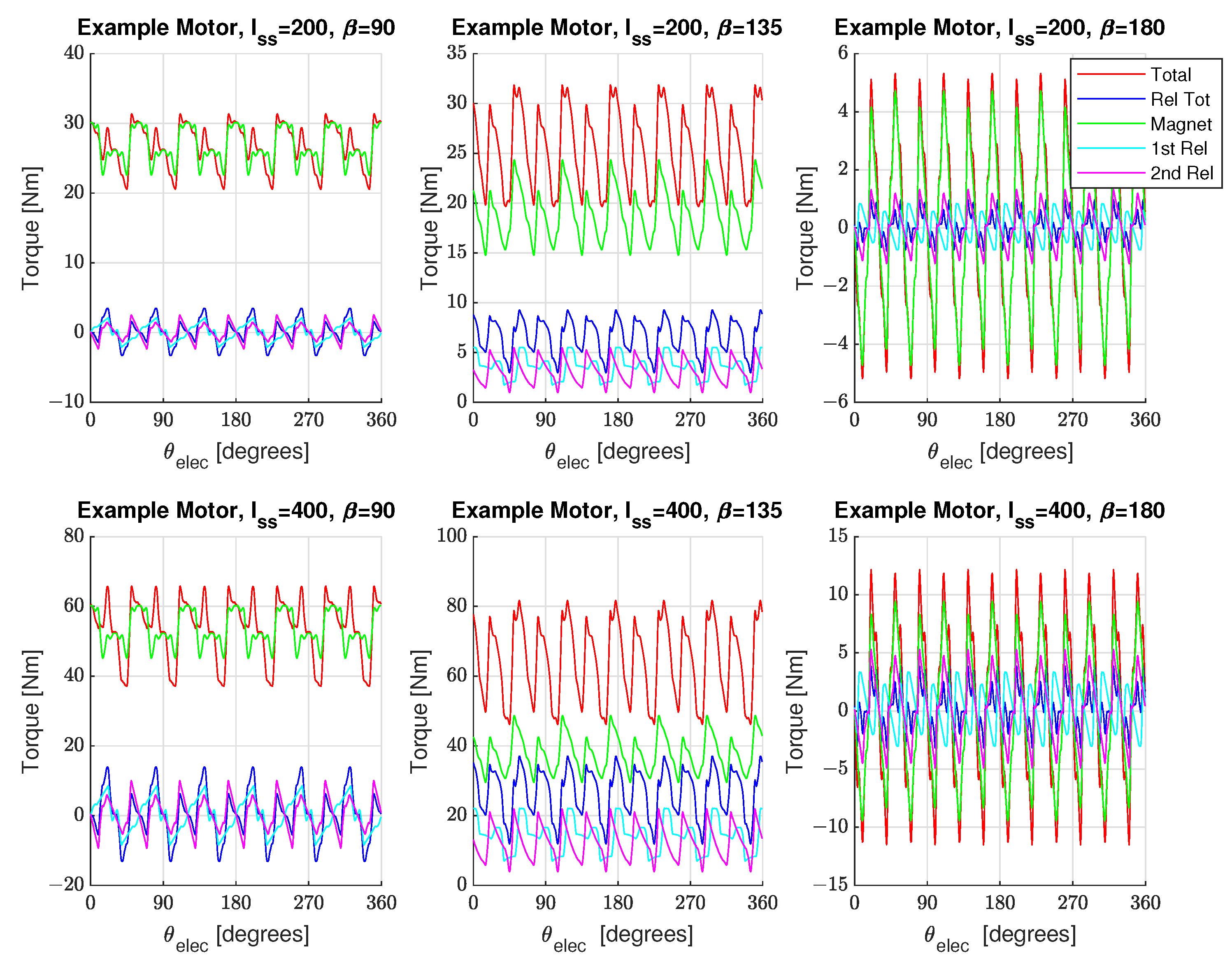

4.5. Torque Ripple Components

5. Investigation of Design Features

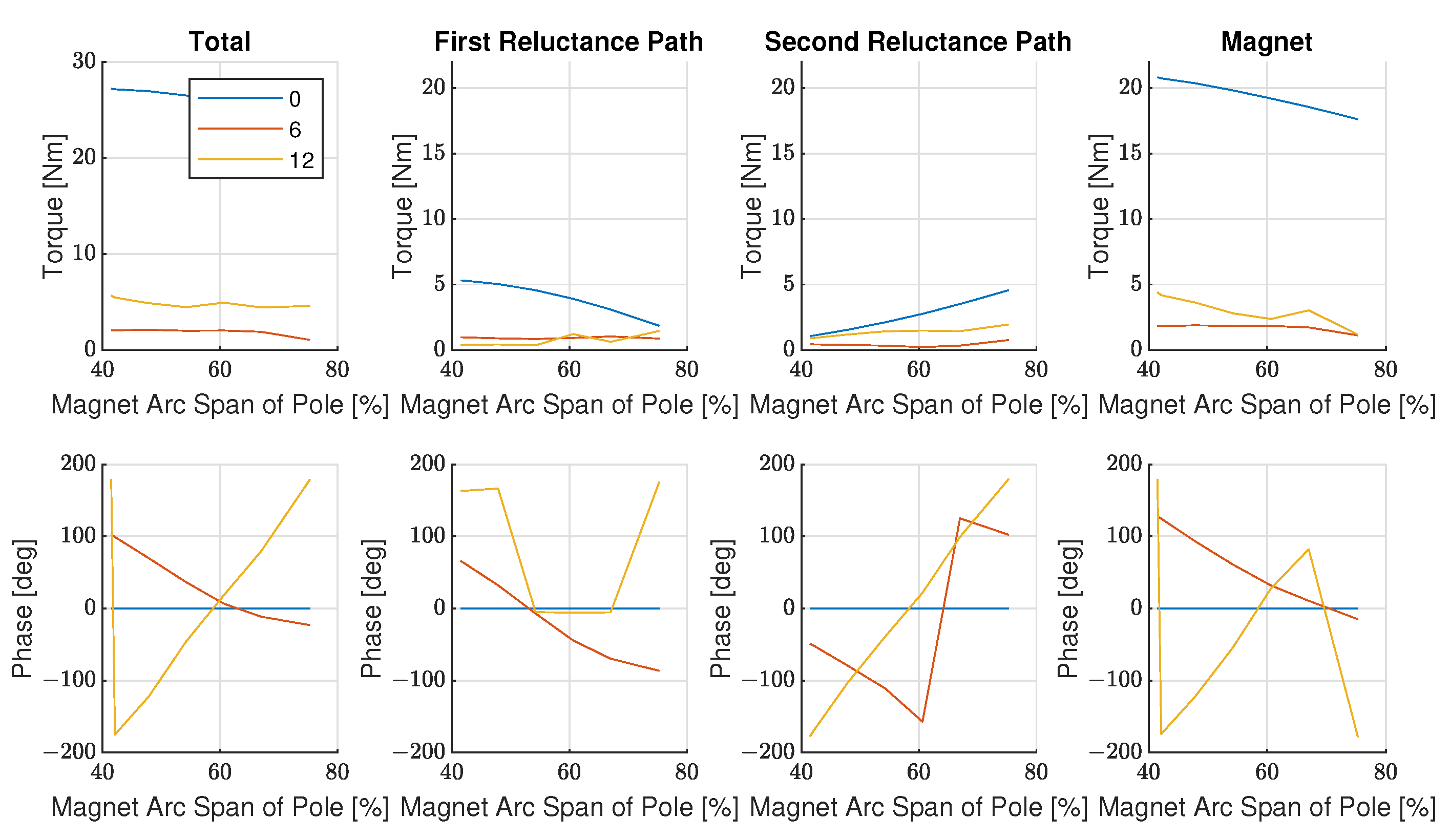

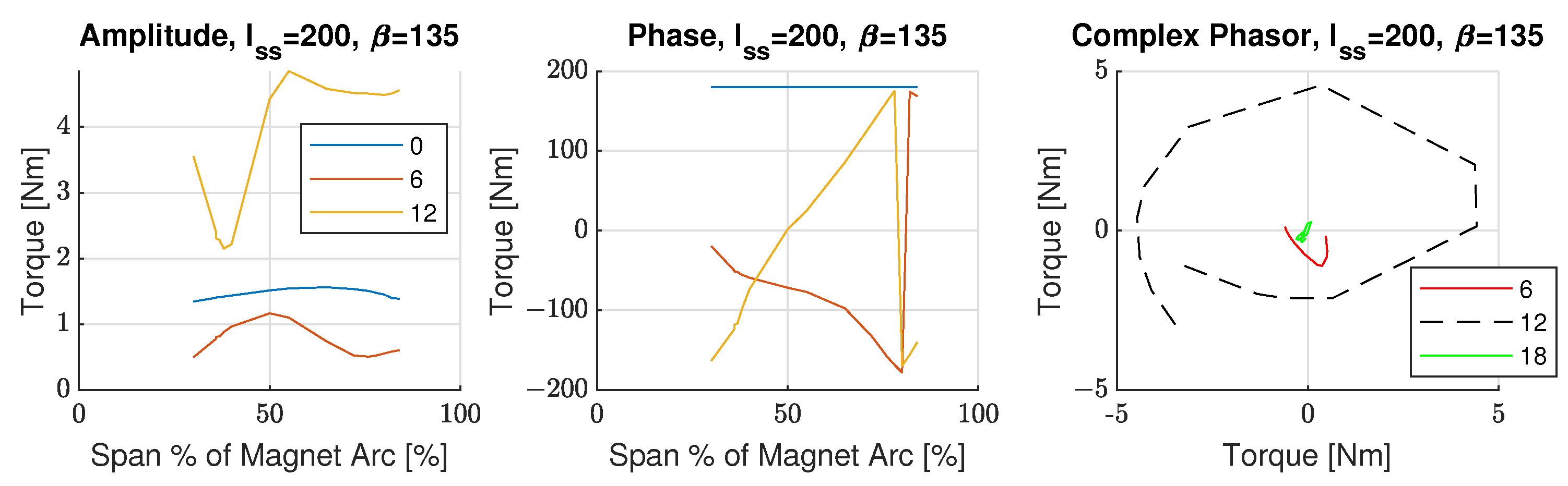

5.1. Magnet Pole Arc

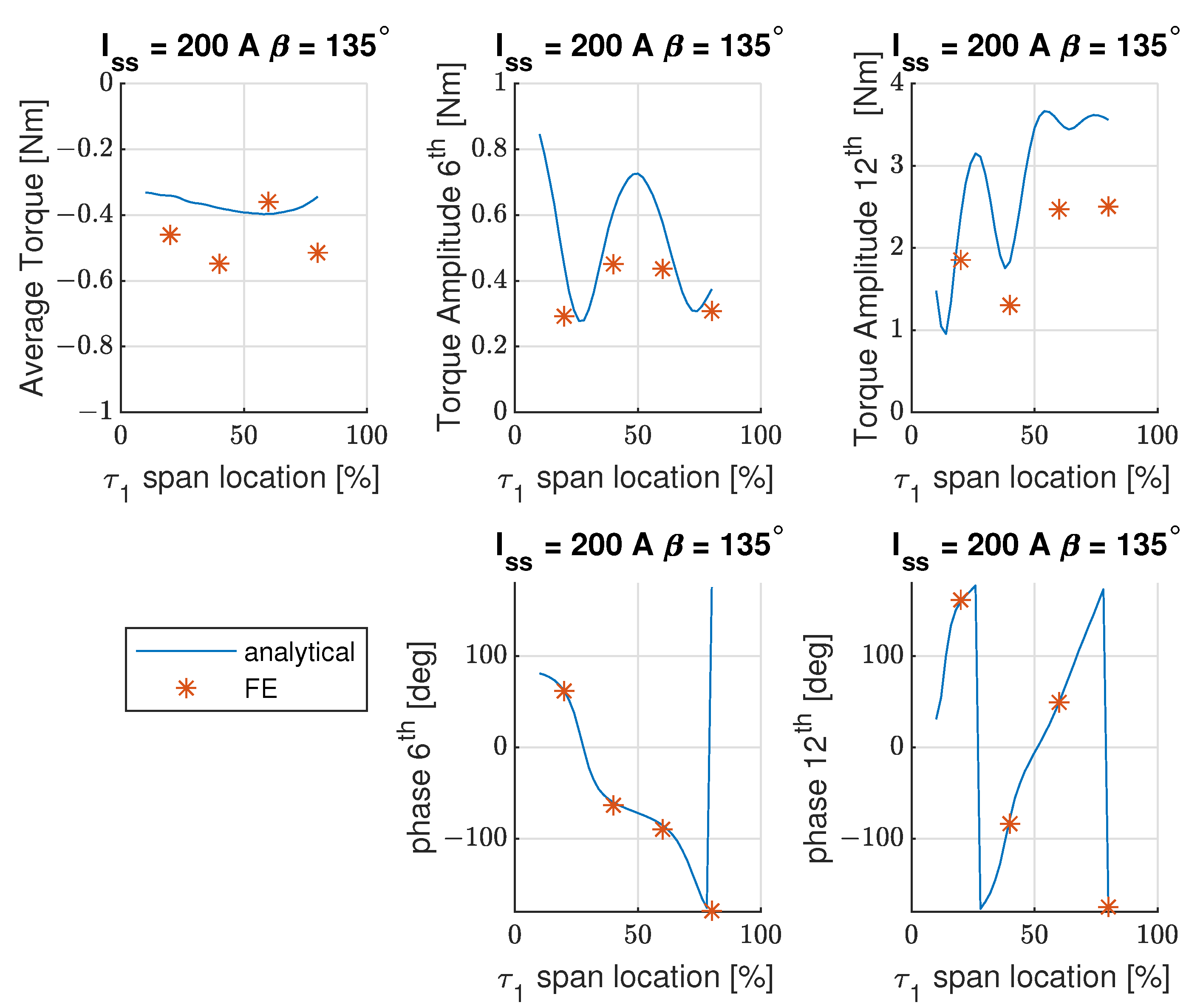

5.2. Single Pair Symmetrical Rotor Sculpt Feature

5.3. Single Asymmetrical Rotor Sculpt Feature

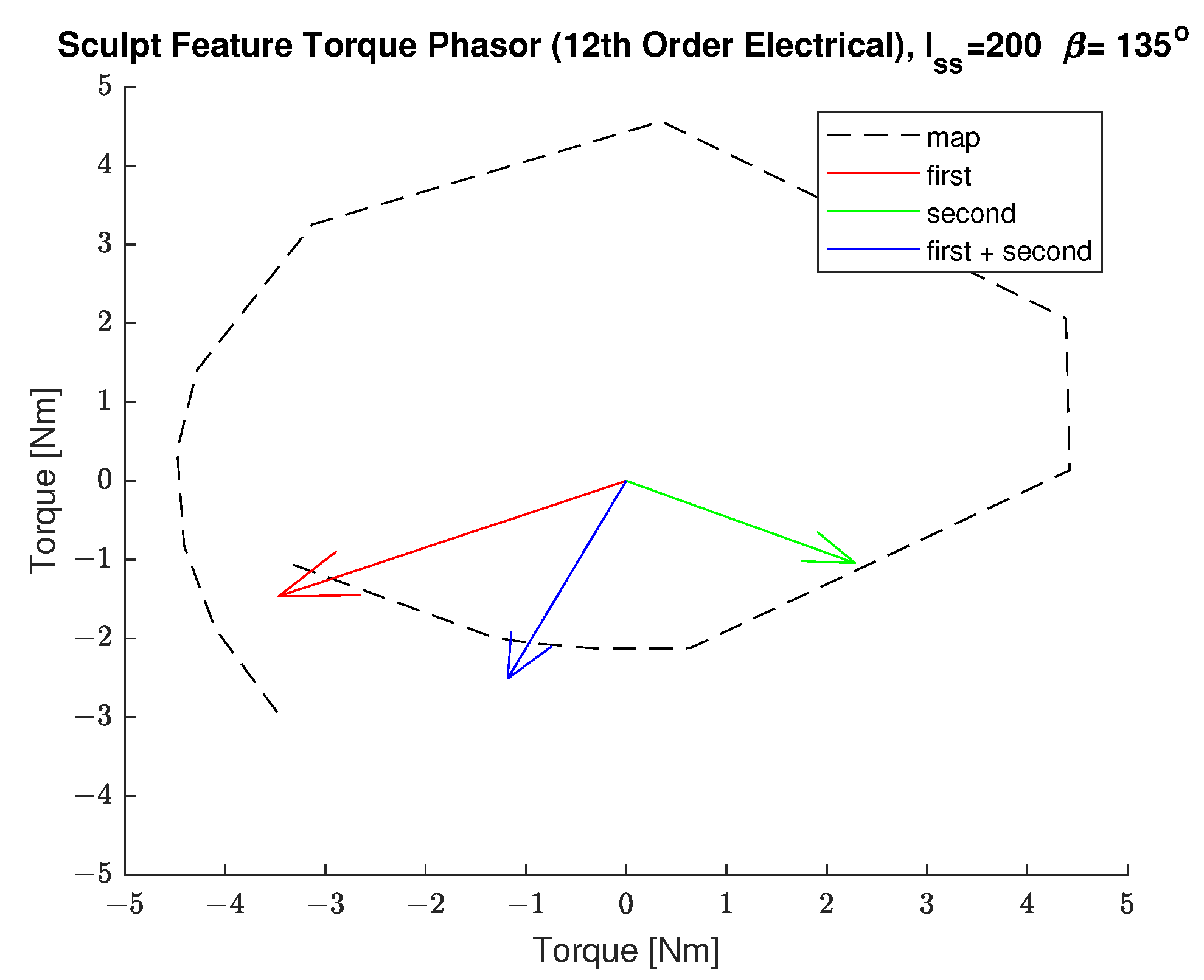

5.4. Two Symmetrical Rotor Sculpt Features

6. Conclusions

- A new analytical winding factor modeling approach for the single V IPM machine relating the rotor’s first reluctance feature, second reluctance feature, permanent magnet features, sculpt features, and stator windings to the resulting torque harmonics;

- An analytical modeling approach accounting for both symmetrical and torque aligning asymmetrical rotor sculpt features;

- Results from the analytical model providing valuable insights for identifying rotor feature design improvements;

- Design approach for placement of rotor sculpt features to minimize torque ripple while maintaining average torque;

- Demonstration of close agreement of radial flux density and torque harmonics results between the analytical model and that of finite element results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Momen, F.; Rahman, K.; Son, Y.; Savagian, P. Electrical propulsion system design of Chevrolet Bolt battery electric vehicle. In Proceedings of the 2016 IEEE Energy Conversion Congress and Exposition (ECCE), Milwaukee, WI, USA, 18–22 September 2016; pp. 1–8. [Google Scholar]

- Namiki, K.; Murota, K.; Shoji, M. High Performance Motor and Inverter System for a Newly Developed Electric Vehicle. SAE Tech. Pap. Ser. 2018. [Google Scholar] [CrossRef]

- Jurkovic, S.; Rahman, K.; Bae, B.; Patel, N.; Savagian, P. Next generation chevy volt electric machines; design, optimization and control for performance and rare-earth mitigation. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015; pp. 5219–5226. [Google Scholar]

- Kanayama, T.; Yanagida, E.; Kano, S.; Geller, B.; Nakao, Y.; Fukao, M. Development of New Hybrid System for Mid-Size SUV. SAE Tech. Pap. Ser. 2020. [Google Scholar] [CrossRef]

- Jensen, W.R.; Pham, T.Q.; Foster, S.N. Comparison of Multi-objective Optimization Methods Applied to Electrical Machine Design. In Evolutionary Multi-Criterion Optimization; Deb, K., Goodman, E., Coello Coello, C.A., Klamroth, K., Miettinen, K., Mostaghim, S., Reed, P., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 719–730. [Google Scholar]

- Han, S.; Jahns, T.M.; Soong, W.L. Torque Ripple Reduction in Interior Permanent Magnet Synchronous Machines Using the Principle of Mutual Harmonics Exclusion. In Proceedings of the 2007 IEEE Industry Applications Annual Meeting, New Orleans, LA, USA, 23–27 September 2007; pp. 558–565. [Google Scholar] [CrossRef]

- Pellegrino, G.; Guglielmi, P.; Vagati, A.; Villata, F. Core Losses and Torque Ripple in IPM Machines: Dedicated Modeling and Design Tradeoff. IEEE Trans. Ind. Appl. 2010, 46, 2381–2391. [Google Scholar] [CrossRef] [Green Version]

- Vagati, A.; Pastorelli, M.; Francheschini, G.; Petrache, S.C. Design of low-torque-ripple synchronous reluctance motors. IEEE Trans. Ind. Appl. 1998, 34, 758–765. [Google Scholar] [CrossRef]

- Zhu, Z.; Howe, D.; Bolte, E.; Ackermann, B. Instantaneous magnetic field distribution in brushless permanent magnet DC motors. I. Open-circuit field. IEEE Trans. Magn. 1993, 29, 124–135. [Google Scholar] [CrossRef]

- Zhu, Z.; Howe, D.; Chan, C. Improved analytical model for predicting the magnetic field distribution in brushless permanent-magnet machines. IEEE Trans. Magn. 2002, 38, 229–238. [Google Scholar] [CrossRef] [Green Version]

- Tang, C.; Shen, M.; Fang, Y.; Pfister, P.D. Comparison of Subdomain, Complex Permeance, and Relative Permeance Models for a Wide Family of Permanent-Magnet Machines. IEEE Trans. Magn. 2021, 57, 1–5. [Google Scholar] [CrossRef]

- Mi, C.; Filippa, M.; Liu, W.; Ma, R. Analytical method for predicting the air-gap flux of interior-type permanent-magnet machines. IEEE Trans. Magn. 2004, 40, 50–58. [Google Scholar] [CrossRef]

- Tariq, A.R.; Nino-Baron, C.E.; Strangas, E.G. Iron and Magnet Losses and Torque Calculation of Interior Permanent Magnet Synchronous Machines Using Magnetic Equivalent Circuit. IEEE Trans. Magn. 2010, 46, 4073–4080. [Google Scholar] [CrossRef]

- Dajaku, G.; Gerling, D. Air-Gap Flux Density Characteristics of Salient Pole Synchronous Permanent-Magnet Machines. IEEE Trans. Magn. 2012, 48, 2196–2204. [Google Scholar] [CrossRef]

- Koo, B.; Nam, K. Analytical Torque Ripple Prediction Using Air-Gap Permeance and MMF Functions in PM Synchronous Motors. In Proceedings of the 2018 21st International Conference on Electrical Machines and Systems (ICEMS), Jeju, Korea, 7 October 2018; pp. 302–307. [Google Scholar] [CrossRef]

- Pina, A.J.; Xu, L. Modeling of synchronous reluctance motors aided by permanent magnets with asymmetric rotor poles. In Proceedings of the 2015 IEEE International Electric Machines Drives Conference (IEMDC), Coeur d’Alene, ID, USA, 10–13 May 2015; pp. 412–418. [Google Scholar] [CrossRef]

- Li, Q.; Fan, T.; Wen, X. Armature-Reaction Magnetic Field Analysis for Interior Permanent Magnet Motor Based on Winding Function Theory. IEEE Trans. Magn. 2013, 49, 1193–1201. [Google Scholar] [CrossRef]

- Aggarwal, A.; Strangas, E.G.; Agapiou, J. Analysis of Unbalanced Magnetic Pull in PMSM Due to Static Eccentricity. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 4507–4514. [Google Scholar]

- Aggarwal, A.; Strangas, E.G. Review of Detection Methods of Static Eccentricity for Interior Permanent Magnet Synchronous Machine. Energies 2019, 12, 4105. [Google Scholar] [CrossRef] [Green Version]

- Du, Z.S.; Lipo, T.A. Torque Ripple Minimization in Interior Permanent Magnet Machines Using Axial Pole Shaping. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; pp. 6922–6929. [Google Scholar] [CrossRef]

- Jang, S.; Park, H.; Choi, J.; Ko, K.; Lee, S. Magnet Pole Shape Design of Permanent Magnet Machine for Minimization of Torque Ripple Based on Electromagnetic Field Theory. IEEE Trans. Magn. 2011, 47, 3586–3589. [Google Scholar] [CrossRef]

- Lee, S.; Kang, G.; Hur, J.; Kim, B. Stator and Rotor Shape Designs of Interior Permanent Magnet Type Brushless DC Motor for Reducing Torque Fluctuation. IEEE Trans. Magn. 2012, 48, 4662–4665. [Google Scholar] [CrossRef]

- Evans, S.A. Salient pole shoe shapes of interior permanent magnet synchronous machines. In Proceedings of the The XIX International Conference on Electrical Machines—ICEM 2010, Rome, Italy, 6–8 September 2010; pp. 1–6. [Google Scholar] [CrossRef]

- Seo, U.; Chun, Y.; Choi, J.; Han, P.; Koo, D.; Lee, J. A Technique of Torque Ripple Reduction in Interior Permanent Magnet Synchronous Motor. IEEE Trans. Magn. 2011, 47, 3240–3243. [Google Scholar] [CrossRef]

- Wang, K.; Zhu, Z.Q.; Ombach, G.; Chlebosz, W. Optimal rotor shape with third harmonic for maximizing torque and minimizing torque ripple in IPM motors. In Proceedings of the 2012 XXth International Conference on Electrical Machines, Marseille, France, 2–5 September 2012; pp. 397–403. [Google Scholar] [CrossRef]

- Kioumarsi, A.; Moallem, M.; Fahimi, B. Mitigation of Torque Ripple in Interior Permanent Magnet Motors by Optimal Shape Design. IEEE Trans. Magn. 2006, 42, 3706–3711. [Google Scholar] [CrossRef]

- Shimizu, Y.; Morimoto, S.; Sanada, M.; Inoue, Y. Reduction of torque ripple in double-layered IPMSM for automotive applications by rotor structure modification. In Proceedings of the 2017 IEEE 12th International Conference on Power Electronics and Drive Systems (PEDS), Honolulu, HI, USA, 12–15 December 2017; pp. 429–434. [Google Scholar] [CrossRef]

- Yamazaki, K.; Kumagai, M.; Ikemi, T.; Ohki, S. A Novel Rotor Design of Interior Permanent-Magnet Synchronous Motors to Cope with Both Maximum Torque and Iron-Loss Reduction. IEEE Trans. Ind. Appl. 2013, 49, 2478–2486. [Google Scholar] [CrossRef]

- Kang, G.; Son, Y.; Kim, G.; Hur, J. A Novel Cogging Torque Reduction Method for Interior-Type Permanent-Magnet Motor. IEEE Trans. Ind. Appl. 2009, 45, 161–167. [Google Scholar] [CrossRef]

- Liang, J.; Parsapour, A.; Moallem, M.; Fahimi, B. Asymmetric Rotor Surface Design in Interior Permanent Magnet Synchronous Motors for Torque Ripple Mitigation. In Proceedings of the 2019 IEEE International Electric Machines Drives Conference (IEMDC), San Deigo, CA, USA, 15 May 2019; pp. 727–732. [Google Scholar] [CrossRef]

- Liang, J.; Parsapour, A.; Yang, Z.; Caicedo-Narvaez, C.; Moallem, M.; Fahimi, B. Optimization of Air-Gap Profile in Interior Permanent-Magnet Synchronous Motors for Torque Ripple Mitigation. IEEE Trans. Transp. Electrif. 2019, 5, 118–125. [Google Scholar] [CrossRef]

- Yamazaki, K.; Utsunomiya, K. Mechanism of Torque Ripple Generation by Time and Space Harmonic Magnetic Fields in Interior Permanent Magnet Synchronous Motors. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Virtual, 23–26 August 2020; Volume 1, pp. 232–238. [Google Scholar] [CrossRef]

- Islam, R.; Husain, I.; Fardoun, A.; McLaughlin, K. Permanent-Magnet Synchronous Motor Magnet Designs with Skewing for Torque Ripple and Cogging Torque Reduction. IEEE Trans. Ind. Appl. 2009, 45, 152–160. [Google Scholar] [CrossRef]

- Cao, R.; Mi, C.; Cheng, M. Quantitative Comparison of Flux-Switching Permanent-Magnet Motors with Interior Permanent Magnet Motor for EV, HEV, and PHEV Applications. IEEE Trans. Magn. 2012, 48, 2374–2384. [Google Scholar] [CrossRef]

- Wu, D.; Zhu, Z.Q. Design Tradeoff Between Cogging Torque and Torque Ripple in Fractional Slot Surface-Mounted Permanent Magnet Machines. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Liu, X.; Chen, H.; Zhao, J.; Belahcen, A. Research on the Performances and Parameters of Interior PMSM Used for Electric Vehicles. IEEE Trans. Ind. Electron. 2016, 63, 3533–3545. [Google Scholar] [CrossRef]

- Pellegrino, G.; Vagati, A.; Guglielmi, P.; Boazzo, B. Performance Comparison Between Surface-Mounted and Interior PM Motor Drives for Electric Vehicle Application. IEEE Trans. Ind. Electron. 2012, 59, 803–811. [Google Scholar] [CrossRef] [Green Version]

- Pellegrino, G.; Vagati, A.; Boazzo, B.; Guglielmi, P. Comparison of Induction and PM Synchronous Motor Drives for EV Application Including Design Examples. IEEE Trans. Ind. Appl. 2012, 48, 2322–2332. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Shang, F.; Brown, I.P.; Krishnamurthy, M. Comparative Study of Interior Permanent Magnet, Induction, and Switched Reluctance Motor Drives for EV and HEV Applications. IEEE Trans. Transp. Electrif. 2015, 1, 245–254. [Google Scholar] [CrossRef]

- Zarko, D.; Ban, D.; Lipo, T. Analytical calculation of magnetic field distribution in the slotted air gap of a surface permanent-magnet motor using complex relative air-gap permeance. IEEE Trans. Magn. 2006, 42, 1828–1837. [Google Scholar] [CrossRef]

- Wu, L.J.; Zhu, Z.Q.; Staton, D.; Popescu, M.; Hawkins, D. An Improved Subdomain Model for Predicting Magnetic Field of Surface-Mounted Permanent Magnet Machines Accounting for Tooth-Tips. IEEE Trans. Magn. 2011, 47, 1693–1704. [Google Scholar] [CrossRef]

- Kim, B.; Lipo, T.A. Analysis of a PM Vernier Motor with Spoke Structure. IEEE Trans. Ind. Appl. 2016, 52, 217–225. [Google Scholar] [CrossRef]

- Dajaku, G. Open-Circuit Air-Gap Field Calculation of a New PM Machine Having a Combined SPM and Spoke-Type Magnets. IEEE Trans. Magn. 2020, 56, 1–9. [Google Scholar] [CrossRef]

- Dajaku, G. Analytical Analysis of Electromagnetic Torque and Magnet Utilization Factor for Two Different PM Machines with SPM and HUPM Rotor Topologies. IEEE Trans. Magn. 2021, 57, 1–9. [Google Scholar] [CrossRef]

- Kwon, J.W.; Li, M.; Kwon, B.I. Design of V-Type Consequent-Pole IPM Machine for PM Cost Reduction with Analytical Method. IEEE Access 2021, 9, 77386–77397. [Google Scholar] [CrossRef]

- Hoang, K.D. Simplified Analytical Model for Rapid Evaluation of Interior PM Traction Machines Considering Magnetic Nonlinearity. IEEE Open J. Ind. Electron. Soc. 2020, 1, 340–354. [Google Scholar] [CrossRef]

- Hu, W.; Zhang, X.; Lei, Y.; Du, Q.; Shi, L.; Liu, G. Analytical Model of Air-Gap Field in Hybrid Excitation and Interior Permanent Magnet Machine for Electric Logistics Vehicles. IEEE Access 2020, 8, 148237–148249. [Google Scholar] [CrossRef]

- Ghahfarokhi, M.M.; Amiri, E.; Boroujeni, S.T.; Aliabad, A.D. On-Load Analytical Modeling of Slotted Interior Magnet Synchronous Machines Using Magnetic Islands Method. IEEE Access 2020, 8, 95360–95367. [Google Scholar] [CrossRef]

- Hajdinjak, M.; Miljavec, D. Analytical Calculation of the Magnetic Field Distribution in Slotless Brushless Machines with U-Shaped Interior Permanent Magnets. IEEE Trans. Ind. Electron. 2020, 67, 6721–6731. [Google Scholar] [CrossRef]

- Mirazimi, M.S.; Kiyoumarsi, A. Magnetic Field Analysis of SynRel and PMASynRel Machines with Hyperbolic Flux Barriers Using Conformal Mapping. IEEE Trans. Transp. Electrif. 2020, 6, 52–61. [Google Scholar] [CrossRef]

- Hayslett, S.; Strangas, E. Design and Analysis of Aligned Axis Interior Permanent Magnet Machines Considering Saturation. In Proceedings of the 2019 IEEE International Electric Machines Drives Conference (IEMDC), San Diego, CA, USA, 12–15 May 2019; pp. 686–692. [Google Scholar] [CrossRef]

- Thike, R.; Pillay, P. Mathematical Model of an Interior PMSM with Aligned Magnet and Reluctance Torques. IEEE Trans. Transp. Electrif. 2020, 6, 647–658. [Google Scholar] [CrossRef]

- Toliyat, H.A. Electric Machines: Modeling, Condition Monitoring, and Fault Diagnosis; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Taghipour Boroujeni, S.; Zamani, V. A Novel Analytical Model for No-Load, Slotted, Surface-Mounted PM Machines: Air Gap Flux Density and Cogging Torque. IEEE Trans. Magn. 2015, 51, 1–8. [Google Scholar] [CrossRef]

- Cheng, D.K. Field and Wave Electromagnetics; Addison-Wesley: Boston, MA, USA, 1989. [Google Scholar]

| Permeance Term | Minimum Airgap | Maximum Airgap |

|---|---|---|

| First Reluctance Path | ||

| Second Reluctance Path | ∞ | |

| Permanent Magnet Path | ∞ |

| Parameter | Value | Unit |

|---|---|---|

| Pole Pairs | 4 | |

| Stator Slots | 48 | |

| Number of Phases | 3 | |

| Stack Length | 83 | mm |

| Rotor Diameter | 161.15 | mm |

| Airgap Length | 0.75 | mm |

| Magnet Pole Arc % of Pole Pitch | 63.8 | % |

| Barrier Type | Single V | |

| Magnet Thickness | 6.48 | mm |

| Magnet Width | 16 × 2 | mm |

| Permanent Magnet Remnant | 1.19 | T |

| Permeability of Iron | ∞ | H/m |

| Permeability of Bridge Features | H/m |

| Feature | Value | Unit |

|---|---|---|

| 82 | % of magnet pole arc | |

| 46.5 | % of magnet pole arc span | |

| 5.5 | % of pole span | |

| 5.5 | % of pole span | |

| 1.2 | mm | |

| 1.2 | mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hayslett, S.; Strangas, E. Analytical Design of Sculpted Rotor Interior Permanent Magnet Machines. Energies 2021, 14, 5109. https://doi.org/10.3390/en14165109

Hayslett S, Strangas E. Analytical Design of Sculpted Rotor Interior Permanent Magnet Machines. Energies. 2021; 14(16):5109. https://doi.org/10.3390/en14165109

Chicago/Turabian StyleHayslett, Steven, and Elias Strangas. 2021. "Analytical Design of Sculpted Rotor Interior Permanent Magnet Machines" Energies 14, no. 16: 5109. https://doi.org/10.3390/en14165109

APA StyleHayslett, S., & Strangas, E. (2021). Analytical Design of Sculpted Rotor Interior Permanent Magnet Machines. Energies, 14(16), 5109. https://doi.org/10.3390/en14165109