Energy Intensity of Steel Manufactured Utilising EAF Technology as a Function of Investments Made: The Case of the Steel Industry in Poland

Abstract

:1. Introduction

2. Literature Review

2.1. Theoretical Background

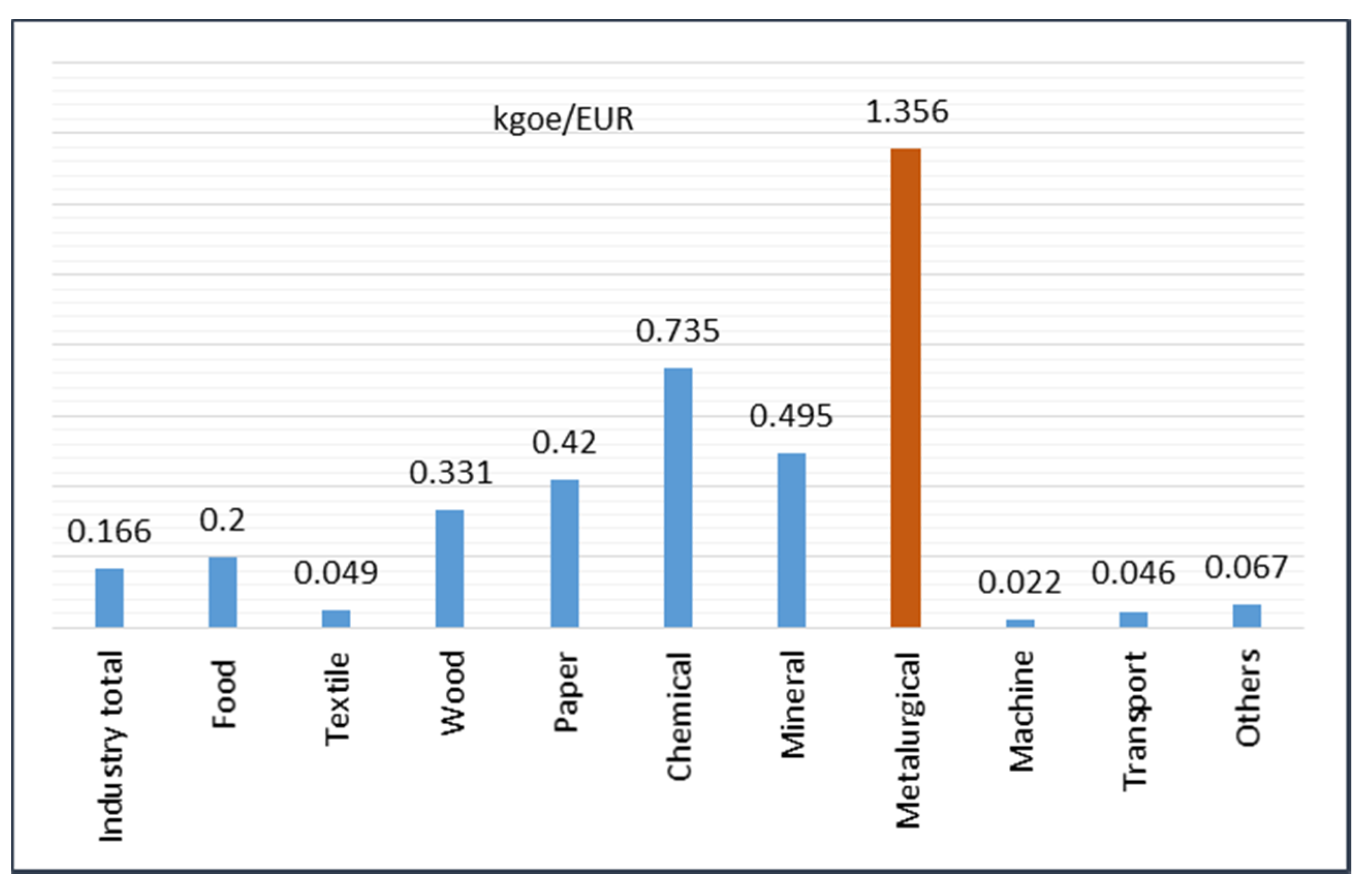

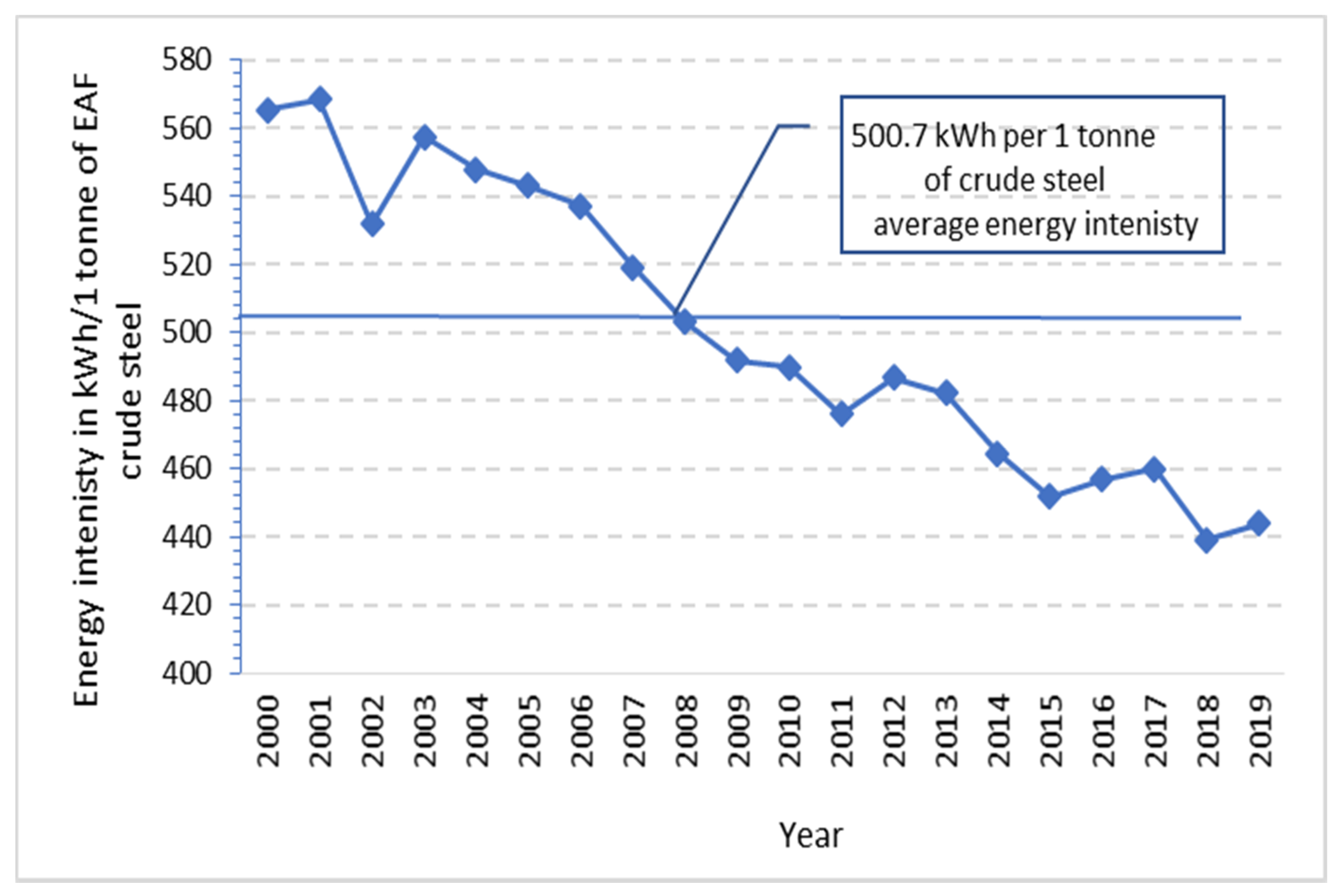

2.2. Energy Intensity in Steel Industry in Poland

3. Materials and Methods

4. Results and Discussion

4.1. Model 1

4.2. Model 2

4.3. Model 3

- in accordance with model (1):

- -

- an increase in the consumption of steel scrap (X1) in electric furnaces by 1% will result in an increase in the production volume of EAF (Y) steel by 0.43%, with the second factor remaining unchanged, i.e., electricity (X2), in this model,

- -

- an increase in electricity consumption (X2) utilising EAF technology by 1% will increase the EAF steel production volume (Y) by 0.54%, with the first factor remaining unchanged, which, in this model, is scrap consumption (X1).

- in accordance with model (2):

- -

- an increase in the consumption of steel scrap (X1) in electric furnaces by a unit [tonne] will increase the consumption of electricity needed for the production of EAF (Y) steel by 356 kWh, with the second factor remaining unchanged, which, in this model, are investments (X2),

- -

- an increase in investments by PLN 1 million (X2) in electric steel mills will reduce electricity consumption in the production of EAF (Y) steel by 60 GWh, with the first factor remaining unchanged, which is the consumption of scrap in this model (X1).

- in accordance with model (3):

- -

- an increase in investment outlays by PLN 1 million in the plants manufacturing steel in EAF technology will lead to a reduction in unit electricity consumption by 16.8 kWh/1 tonne of crude steel (assuming that other factors are unchanged).

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Flues, F.; Rubbelke, D.; Vögele, S. An analysis of the economic determinants of energy efficiency in the European iron and steel industry. J. Clean. Prod. 2015, 104, 250–263. [Google Scholar] [CrossRef]

- Gajdzik, B.; Sroka, W. Resource Intensity vs. Investment in Production Installations—The Case of the Steel Industry in Poland. Energies 2021, 14, 443. [Google Scholar] [CrossRef]

- Wolniak, R.; Saniuk, S.; Grabowska, S.; Gajdzik, B. Identification of Energy Efficiency Trends in the Context of the Development of Industry 4.0 Using the Polish Steel Sector as an Example. Energies 2020, 13, 2867. [Google Scholar] [CrossRef]

- Hernández, A.G.; Paoli, L.; Cullen, J. Resource efficiency in steelmaking: Energy and materials combined. Energy Procedia 2017, 142, 2429–2434. [Google Scholar] [CrossRef]

- Grabara, J.; Tleppayev, A.; Dabylova, M.; Mihardjo, L.W.W.; Dacko-Pikiewicz, Z. Empirical Research on the Relationship Amongst Renewable Energy Consumption, Economic Growth and Foreign Direct Investment in Kazakhstan and Uzbekistan. Energies 2021, 14, 332. [Google Scholar] [CrossRef]

- Grondys, K.; Androniceanu, A.; Dacko-Pikiewicz, Z. Energy Management in the Operation of Enterprises in the Light of the Applicable Provisions of the Energy Efficiency Directive (2012/27/EU). Energies 2020, 13, 4338. [Google Scholar] [CrossRef]

- Shpak, N.; Kuzmin, O.; Melnyk, O.; Ruda, M.; Sroka, W. Implementation of a Circular Economy in Ukraine: The Context of European Integration. Resources 2020, 9, 96. [Google Scholar] [CrossRef]

- Šebestová, J.D.; Sroka, W. Sustainable development goals and SMEs decisions: Czech Republic vs. Poland. J. East. Eur. Central Asian Res. 2020, 7, 39–50. [Google Scholar] [CrossRef]

- Hussain, H.I.; Slusarczyk, B.; Kamarudin, F.; Thaker, H.M.T.; Szczepańska-Woszczyna, K. An Investigation of an Adaptive Neuro-Fuzzy Inference System to Predict the Relationship among Energy Intensity, Globalization, and Financial Development in Major ASEAN Economies. Energies 2020, 13, 850. [Google Scholar] [CrossRef] [Green Version]

- Shpak, N.; Melnyk, O.; Horbal, N.; Ruda, M.; Sroka, W. Assessing the implementation of the circular economy in the EU countries. Forum Sci. Oecon. 2021, 9, 25–39. [Google Scholar] [CrossRef]

- Popp, J.; Kovács, S.; Oláh, J.; Divéki, Z.; Balázs, E. Bioeconomy: Biomass and biomass-based energy supply and demand. New Biotechnol. 2020, 60, 76–84. [Google Scholar] [CrossRef]

- Gajdzik, B. Environmental aspects, strategies and waste logistic system based on the example of metallurgical company. Metalurgija 2009, 48, 63–67. [Google Scholar]

- Gajdzik, B. Comprehensive classification of environmental aspects in a manufacturing enterprise. Metalurgija 2012, 51, 541–544. [Google Scholar]

- Gajdzik, B. Concentration on knowledge and change management at metallurgical company. Metalurgija 2008, 47, 142–144. [Google Scholar]

- Gielen, D.; Taylor, P. Indicators for industrial energy efficiency in India. Energy 2009, 34, 962–969. [Google Scholar] [CrossRef]

- Mariyakhan, K.; Mohamued, E.A.; Asif Khan, M.; Popp, J.; Oláh, J. Does the level of absorptive capacity matter for carbon intensity? Evidence from the USA and China. Energies 2020, 13, 407. [Google Scholar] [CrossRef] [Green Version]

- Kan, K.; Mativenga, P.; Marnewick, A. Understanding energy use in the South African manufacturing industry. Procedia CIRP 2020, 91, 445–451. [Google Scholar] [CrossRef]

- Androniceanu, A. Transparency in public administration as a challenge for a good democratic governance. Adm. SI Manag. Public 2021, 36, 149–164. [Google Scholar] [CrossRef]

- Dasgupta, S.; Roy, J. Analysing energy intensity trends and decoupling of growth from energy use in Indian manufacturing industries during 1973–1974 to 2011–2012. Energy Effic. 2016, 10, 925–943. [Google Scholar] [CrossRef]

- Arens, M.; Worrell, E.; Schleich, J. Energy intensity development of the German iron and steel industry between 1991 and 2007. Energy 2012, 45, 786–797. [Google Scholar] [CrossRef] [Green Version]

- Quadera, M.; Ahmed, S.; Ghazillaa, R.; Ahmed, S.; Dahari, M. A comprehensive review on energy efficient CO2 breakthrough technologies for sustainable green iron and steel manufacturing. Renew. Sustain. Energy Rev. 2015, 50, 594–614. [Google Scholar] [CrossRef]

- Mousa, E.; Wang, C.; Riesbeck, J.; Larsson, M. Biomass applications in iron and steel industry: An overview of challenges and opportunities. Renew. Sustain. Energy Rev. 2016, 65, 1247–1266. [Google Scholar] [CrossRef]

- Chan, D.Y.-L.; Huang, C.-F.; Lin, W.-C.; Hong, G.-B. Energy efficiency benchmarking of energy-intensive industries in Taiwan. Energy Convers. Manag. 2014, 77, 216–220. [Google Scholar] [CrossRef]

- Oda, J.; Akimoto, K.; Tomoda, T.; Nagashima, M.; Wada, K.; Sano, F. International comparisons of energy efficiency in power, steel, and cement industries. Energy Policy 2012, 44, 118–129. [Google Scholar] [CrossRef]

- He, H.; Guan, H.; Zhu, X.; Lee, H. Assessment on the energy flow and carbon emissions of integrated steelmaking plants. Energy Rep. 2017, 3, 29–36. [Google Scholar] [CrossRef]

- International Energy Agency. Energy Technology Perspectives 2012; International Energy Agency: Paris, France, 2012. [Google Scholar]

- Gajdzik, B.; Gawlik, R.; Skoczypiec, S. Forecasting-Scenario-Heuristic method proposal for assessment of feasibility of steel production scenarios in Poland—Managerial implications for production engineering. Arch. Civ. Mech. Eng. 2018, 18, 1651–1660. [Google Scholar] [CrossRef]

- Gajdzik, B.; Piątkowski, J.; Kliś, P. Prognostic methodology of forecasts steel production for Poland until 2022. Metalurgija 2020, 51, 129–132. [Google Scholar]

- He, K.; Wang, L.; Li, X. Review of the energy consumption and production structure of China’s steel industry: Current situation and future development. Metals 2020, 10, 302. [Google Scholar] [CrossRef] [Green Version]

- World Steel Association. Steel Statistics Yearbook 2018; World Steel Association: Belgium, Brussels, 2019. [Google Scholar]

- Androniceanu, A.-M.; Caplescu, R.D.; Tvaronaviciene, M.; Dobrin, C. The interdependencies between economic growth, energy consumption and pollution in Europe 2021. Energies 2021, 14, 2577. [Google Scholar] [CrossRef]

- Arasto, A.; Tsupari, E.; Kärki, J.; Sihvonen, M.; Lilja, J. Costs and Potential of Carbon Capture and Storage at an Integrated Steel Mill. Energy Procedia 2013, 37, 7117–7124. [Google Scholar] [CrossRef] [Green Version]

- Flores-Granobles, M.; Saeys, M. Minimizing CO2 emissions with renewable energy: A comparative study of emerging technologies in the steel industry. Energy Environ. Sci. 2020, 13, 1923–1932. [Google Scholar] [CrossRef]

- Kim, Y.; Worrell, E. International comparison of CO2 emission trends in the iron and steel industry. Energy Policy 2002, 30, 827–838. [Google Scholar] [CrossRef]

- Kot, S.; Haque, A.U.; Kozlovski, E. Strategic SCM’s Mediating Effect on the Sustainable Operations: Multinational Perspective. Organizacija 2019, 52, 219–235. [Google Scholar] [CrossRef] [Green Version]

- Haider, S.; Mishra, P.P. Benchmarking energy use of iron and steel industry: A data envelopment analysis. Benchmarking Int. J. 2019, 26, 1314–1335. [Google Scholar] [CrossRef]

- Lee, K.-H. Drivers and Barriers to Energy Efficiency Management for Sustainable Development. Sustain. Dev. 2014, 23, 16–25. [Google Scholar] [CrossRef]

- Rojas-Cardenas, J.C.; Hasanbeigi, A.; Sheinbaum-Pardo, C.; Price, L. Energy efficiency in the Mexican iron and steel industry from an international perspective. J. Clean. Prod. 2017, 158, 335–348. [Google Scholar] [CrossRef]

- Fisher-Vanden, K.; Hu, Y.; Jefferson, G.; Rock, M.; Toman, M. Factors influencing energy intensity in four Chinese industries. Energy J. 2016, 37, 153–178. [Google Scholar] [CrossRef]

- Carmona, L.G.; Whiting, K.; Carrasco, A.; Sousa, T. The evolution of resource efficiency in the United Kingdom’s steel sector: An exergy approach. Energy Convers. Manag. 2019, 196, 891–905. [Google Scholar] [CrossRef]

- Haseeb, M.; Kot, S.; Hussain, H.I.; Kamarudin, F. The natural resources curse-economic growth hypotheses: Quantile–on–Quantile evidence from top Asian economies. J. Clean. Prod. 2020, 279, 123596. [Google Scholar] [CrossRef]

- Worrell, E.; Price, L.; Neelis, M.; Galitsky, C.; Zhou, N. World Best Practice Energy Intensity Values for Selected Industrial Sectors; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2007. [Google Scholar]

- Reddy, B.S.; Ray, B.K. Understanding industrial energy use: Physical energy intensity changes in Indian manufacturing sector. Energy Policy 2011, 39, 7234–7243. [Google Scholar] [CrossRef] [Green Version]

- Sheinbaum, C.; Ozawa, L.; Castillo, D. Using logarithmic mean Divisia index to analyze changes in energy use and carbon dioxide emissions in Mexico’s iron and steel industry. Energy Econ. 2010, 32, 1337–1344. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Chunxia, Z.; Aden, N.; Xiuping, L.; Fangqin, S. Comparison of iron and steel production energy use and energy intensity in China and the US. J. Clean Prod. 2014, 65, 108–119. [Google Scholar] [CrossRef] [Green Version]

- Lu, B.; Chen, G.; Chen, D.; Yu, W. An energy intensity optimization model for production system in iron and steel industry. Appl. Therm. Eng. 2016, 100, 285–295. [Google Scholar] [CrossRef]

- Wiboonchutikula, P.; Chaivichayachat, B.; Chontanawat, J. Sources of Energy Intensity Change of Thailand’s Steel Industry in the Decade of Global Turbulent Time. Singap. Econ. Rev. 2014, 59, 1450027. [Google Scholar] [CrossRef]

- Dans, E. Corporate Social Responsibility is Turning Green, and That’s A Good Thing. Forbes 2018. Available online: https://www.forbes.com/sites/enriquedans/2018/09/14/corporate-social-responsibility-is-turning-green-and-thats-a-good-thing/#50f3472a4dca (accessed on 14 June 2019).

- Hodulova, K. Green Corporate Social Responsibility; Cards Climate Change Platform: Sofia, Bulgaria, 2019; Available online: https://co2cards.com/green-corporate-social-responsibility (accessed on 14 June 2019).

- Popescu, C.R.G. An Exploratory Study Based on a Questionnaire Concerning Green and Sustainable Finance, Corporate Social Responsibility, and Performance: Evidence from the Romanian Business Environment. J. Risk Financ. Manag. 2019, 12, 162. [Google Scholar] [CrossRef] [Green Version]

- MacGregor, R.K.; Sroka, W.; Pelikánová, R.M. A comparative study of the CSR attitude of front-line employees of luxury fashion businesses: Fun or free for sustainability? Pol. J. Manag. Stud. 2020, 21, 240–255. [Google Scholar] [CrossRef]

- MacGregor, R.K.; Sroka, W.; Pelikánová, R.M. The CSR perception of front-line employees of luxury fashion businesses. Organizacija 2020, 53, 198–211. [Google Scholar] [CrossRef]

- Sroka, W.; Vveinhardt, J. Is a CSR policy an equally effective vaccine against workplace mobbing and psychosocial stressors? Int. J. Environ. Res. Public Health 2020, 17, 7292. [Google Scholar] [CrossRef]

- Sroka, W.; Vveinhardt, J. Nepotism and favouritism: How harmful are these phenomena? Forum Sci. Oecon. 2020, 8, 79–91. [Google Scholar] [CrossRef]

- Nadanyiova, M.; Majerova, J.; Gajanova, L. The usage of the CSR concept and its communication in Slovak companies in the process of globalization. SHS Web Conf. 2021, 91, 01024. [Google Scholar] [CrossRef]

- Nadanyiova, M.; Gajanova, L.; Majerova, J. Green Marketing as a Part of the Socially Responsible Brand’s Communication from the Aspect of Generational Stratification. Sustainability 2020, 12, 7118. [Google Scholar] [CrossRef]

- Prindle, B.; Eldridge, M.; Eckhardt, M.; Frederick, A. The Twin Pillars of Sustainable Energy: Synergies between Energy Efficiency and Renewable Energy Technology and Policy. ACEEE Report Number E074. 2007. Available online: http://www.paenergyfuture.psu.edu/pubs/aceee_reports/aceee2007sustainable.pdf (accessed on 28 June 2013).

- Report IEA (International Enery Agency). Iron and Steel Technology Roadmap; Launch Webinar; IEA: Paris, France, 08 October 2020; Available online: https://www.iea.org/reports/iron-and-steel-technology-roadmap (accessed on 10 August 2021).

- Paladan, N.N.; Florida, J.S. Reducing Energy Consumption as a Social Responsibility: Towards a Sustainable Energy Supply. Int. J. Innov. Manag. 2013, 1, 29–40. [Google Scholar]

- Selko, A. Steps Industry can Take to Reduce Energy Consumption. An Action Guide to Reduce Consumption of Water, Air, Gas, Electric, and Steam. 2012. Available online: http://www.industryweek.com/companies-amp-executives/steps-industry-can-take-reduce-energy-consumption (accessed on 28 June 2013).

- Bonvoisin, J.; Stark, R.; Seliger, G. Field of Research in Sustainable Manufacturing. In Sustainable Manufacturing: Challenges, Solutions and Implementation; Stark, R., Seliger, G., Bonvoisin, J., Eds.; Sustainable Production, Life Cycle Engineering and Management; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Gajdzik, B. Modelling the impact of investments on energy intensity in the Polish steel industry as a step towards Industry 4.0. In Proceedings of the 29th International Conference on Metallurgy and Materials-Metal, Brno, Czech Republic, 20–22 May 2020; pp. 1210–1215. [Google Scholar]

- National Report Energy Efficiency Trends and Policies in Poland in Years 2006–2016; Prepared in Framework of ODYSSEE-MURE Project Entitled “Monitoring EU and National Energy Efficiency Targets”; Central Statistical Office & The Polish National Energy Conservation Agency, Warsaw, Poland, 2018. Available online: https://www.odyssee-mure.eu/ (accessed on 10 June 2021).

- Gospodarka Paliwowo-Energetyczna w Latach 2017 i 2018. Available online: https://stat.gov.pl/obszary-tematyczne/srodowisko-energia/energia/gospodarka-paliwowo-energetyczna-w-latach-2016-i-2017,4,13.html (accessed on 10 June 2021).

- Efektywność Wykorzystania Energii w Latach 2000–2010. Warszawa 2012. Available online: https://stat.gov.pl/cps/rde/xbcr/gus/SE_efektywnosc_wykorzystania_energii_2000-2010.pdf (accessed on 10 June 2021).

- Efektywność Wykorzystania Energii w Latach 2008–2018 (Table 3: Energy Intensity of Production). Available online: https://stat.gov.pl/obszary-tematyczne/srodowisko-energia/energia/efektywnosc-wykorzystania-energii-w-latach-2008-2018,5,15.html (accessed on 10 June 2021).

- Hutnicza Izba Przemysłowo-Handlowa. Polish Steel Association. Available online: https://www.hiph.org/GLOWNA/aktual.php (accessed on 10 June 2021).

- Gajdzik, B.; Sroka, W. Analytic study of the capital restructuring processes in metallurgical enterprises around the world and in Poland. Metalurgija 2012, 51, 265. [Google Scholar]

- National Bureau of Statistics of China. China Energy Statistics Yearbook 2016–2017; China Statistics Press: Beijing, China, 2018. [Google Scholar]

- Gajdzik, B.; Grabowska, S.; Saniuk, S.; Wieczorek, T. Sustainable Development and Industry 4.0: A Bibliometric Analysis Identifying Key Scientific Problems of the Sustainable Industry 4.0. Energies 2020, 13, 4254. [Google Scholar] [CrossRef]

| Metallurgical | Chemical | Mineral | Total | Industry Total | |||||

|---|---|---|---|---|---|---|---|---|---|

| % | Mtoe | % | Mtoe | % | Mtoe | % | Mtoe | Mtoe | |

| 2000 | 26 | 4.86 | 21 | 3.81 | 14 | 2.67 | 61 | 11.34 | 18.56 |

| 2018 | 17 | 2.99 | 16 | 2.85 | 18 | 3.15 | 52 | 8.99 | 17.37 |

| No. | Year | EAF Production in Thousands of Tonnes | Steel Scrap Used in the EAF in Tonnes | Scrap per 1000 Tonnes of EAF Steel | Energy Used in the EAF in GWh | Energy kWh/1 Tonne of Crude Steel in the EAF | Investments (Cumulative) in PLN Million |

|---|---|---|---|---|---|---|---|

| 1 | 2000 | 3290 | 3,540,209 | 1076 | 1860 | 565 | 272 |

| 2 | 2001 | 2814 | 3,054,446 | 1085 | 1599 | 568 | 389 |

| 3 | 2002 | 2561 | 2,872,406 | 1122 | 1362 | 532 | 439 |

| 4 | 2003 | 3037 | 3,178,588 | 1047 | 1693 | 557 | 477 |

| 5 | 2004 | 3717 | 4,177,197 | 1124 | 2036 | 548 | 546 |

| 6 | 2005 | 3443 | 3,926,662 | 1140 | 1870 | 543 | 810 |

| 7 | 2006 | 4241 | 4,796,388 | 1131 | 2278 | 537 | 1414 |

| 8 | 2007 | 4434 | 4,979,142 | 1123 | 2301 | 519 | 2324 |

| 9 | 2008 | 4503 | 5,044,314 | 1120 | 2264 | 503 | 3221 |

| 10 | 2009 | 3893 | 4,356,850 | 1119 | 1914 | 492 | 3983 |

| 11 | 2010 | 3998 | 4,459,250 | 1115 | 1958 | 490 | 4225 |

| 12 | 2011 | 4355 | 4,867,957 | 1118 | 2073 | 476 | 4575 |

| 13 | 2012 | 4132 | 4,612,867 | 1116 | 2011 | 487 | 4876 |

| 14 | 2013 | 3551 | 3,960,351 | 1115 | 1712 | 482 | 5163 |

| 15 | 2014 | 3492 | 3,883,164 | 1112 | 1621 | 464 | 5438 |

| 16 | 2015 | 3492 | 4,238,013 | 1214 | 1577 | 452 | 5763 |

| 17 | 2016 | 3877 | 4,366,044 | 1126 | 1771 | 457 | 6178 |

| 18 | 2017 | 4624 | 5,149,505 | 1114 | 2127 | 460 | 6443 |

| 19 | 2018 | 4765 | 5,258,195 | 1104 | 2092 | 439 | 6878 |

| 20 | 2019 | 4077 | 4,484,285 | 1100 | 1810 | 444 | 7228 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gajdzik, B.; Sroka, W.; Vveinhardt, J. Energy Intensity of Steel Manufactured Utilising EAF Technology as a Function of Investments Made: The Case of the Steel Industry in Poland. Energies 2021, 14, 5152. https://doi.org/10.3390/en14165152

Gajdzik B, Sroka W, Vveinhardt J. Energy Intensity of Steel Manufactured Utilising EAF Technology as a Function of Investments Made: The Case of the Steel Industry in Poland. Energies. 2021; 14(16):5152. https://doi.org/10.3390/en14165152

Chicago/Turabian StyleGajdzik, Bożena, Włodzimierz Sroka, and Jolita Vveinhardt. 2021. "Energy Intensity of Steel Manufactured Utilising EAF Technology as a Function of Investments Made: The Case of the Steel Industry in Poland" Energies 14, no. 16: 5152. https://doi.org/10.3390/en14165152

APA StyleGajdzik, B., Sroka, W., & Vveinhardt, J. (2021). Energy Intensity of Steel Manufactured Utilising EAF Technology as a Function of Investments Made: The Case of the Steel Industry in Poland. Energies, 14(16), 5152. https://doi.org/10.3390/en14165152