Zigzag Multirod Laser Beam Merging Approach for Brighter TEM00-Mode Solar Laser Emission from a Megawatt Solar Furnace

Abstract

:1. Introduction

2. Description of the Multibeam Solar Laser Station

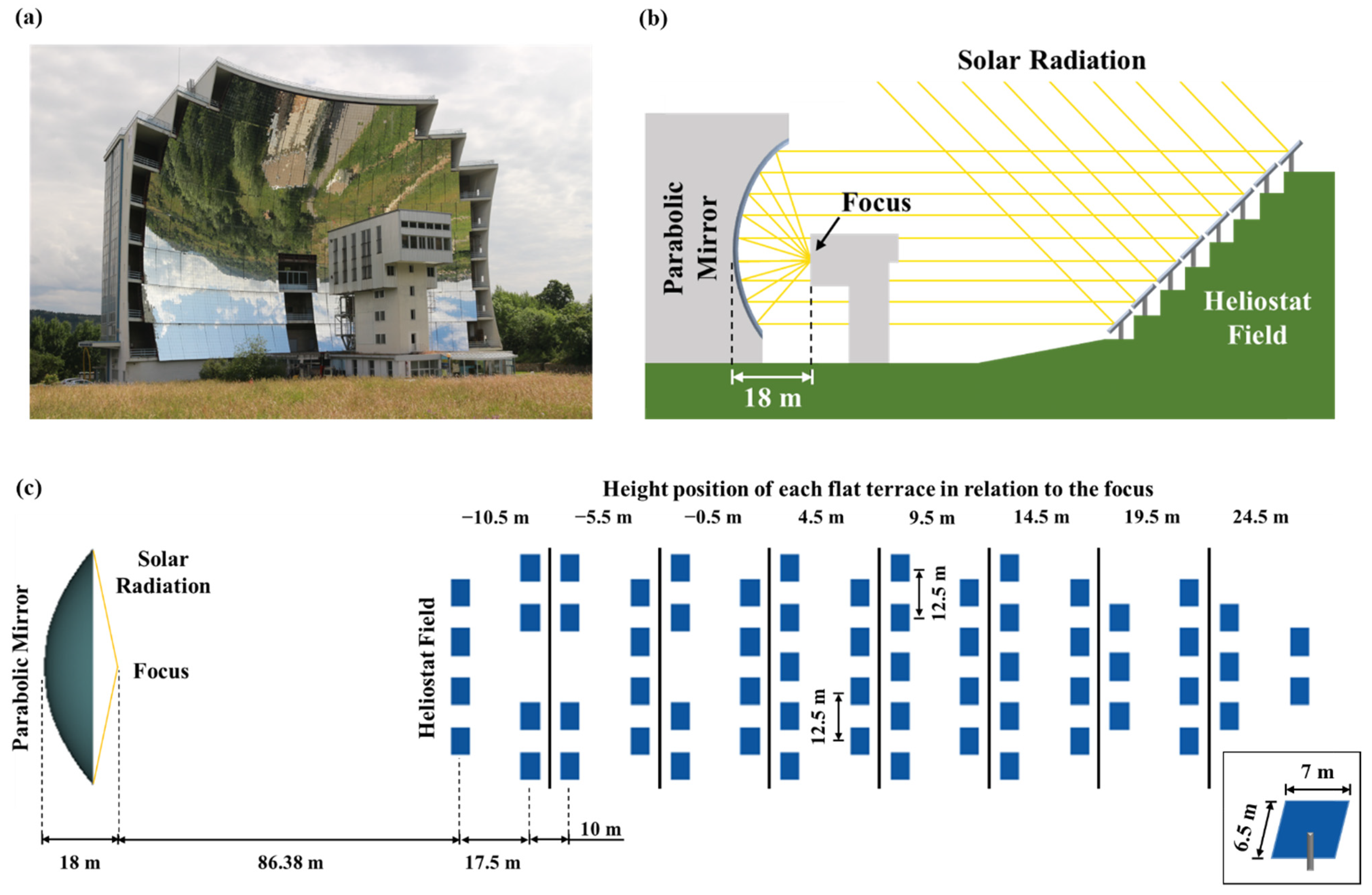

2.1. Megawatt Solar Furnace of PROMES-CNRS

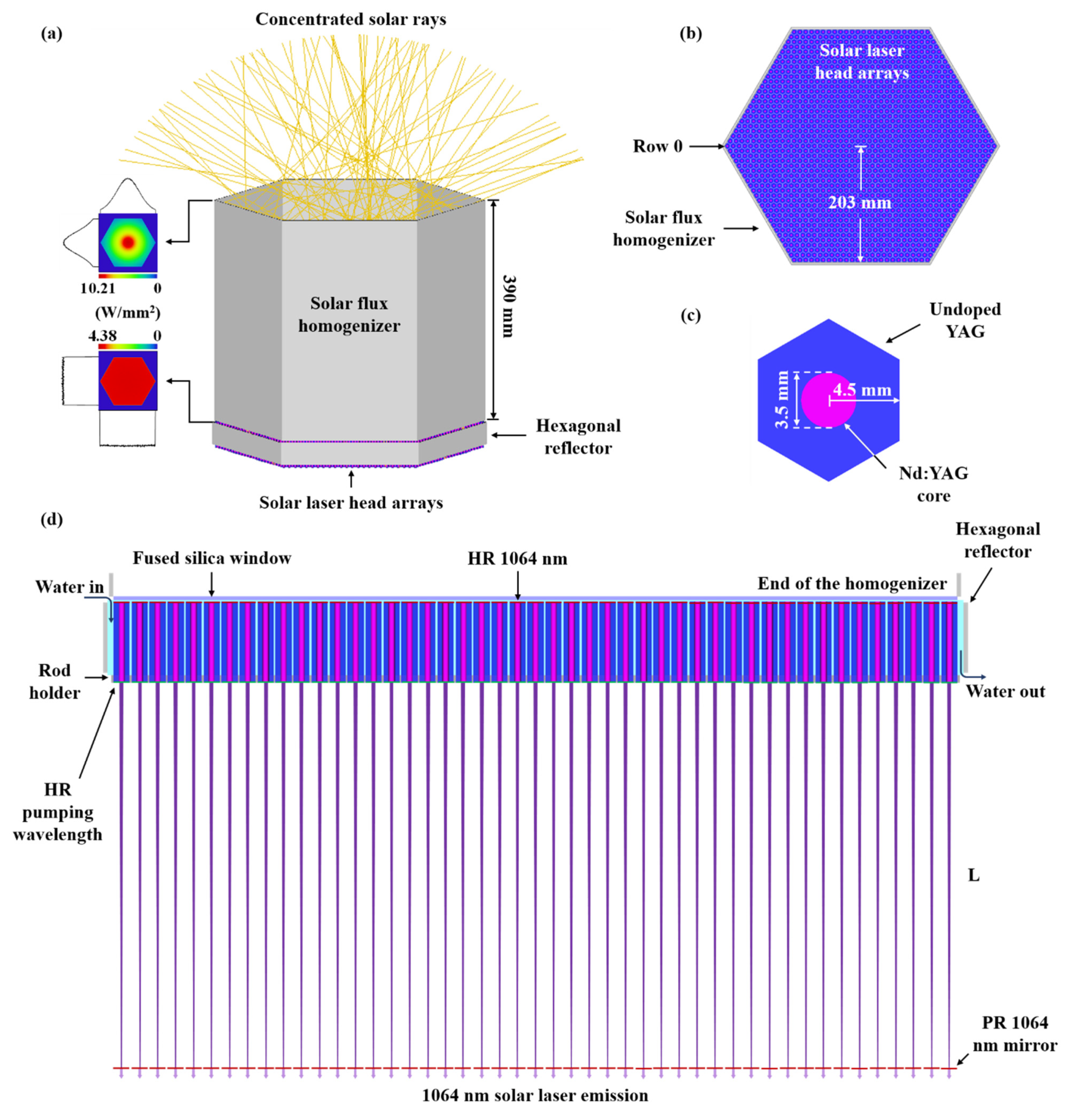

2.2. Solar Flux Homogenizer and Arrays of Core-Doped Nd:YAG Rods

3. Numerical Modeling of the Multibeam Solar Laser Station

3.1. Modeling of the Optical Design Parameters through Zemax® Software

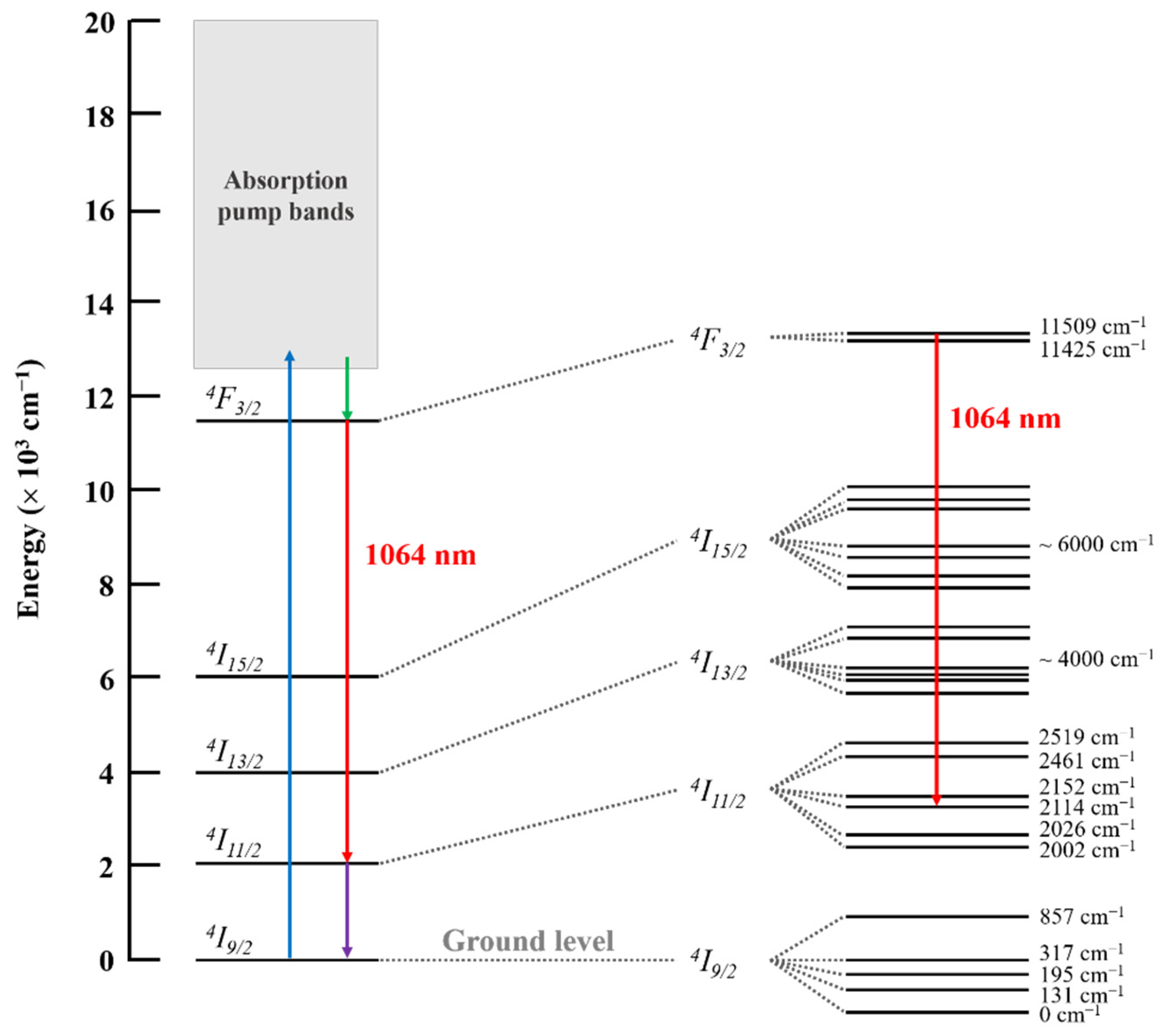

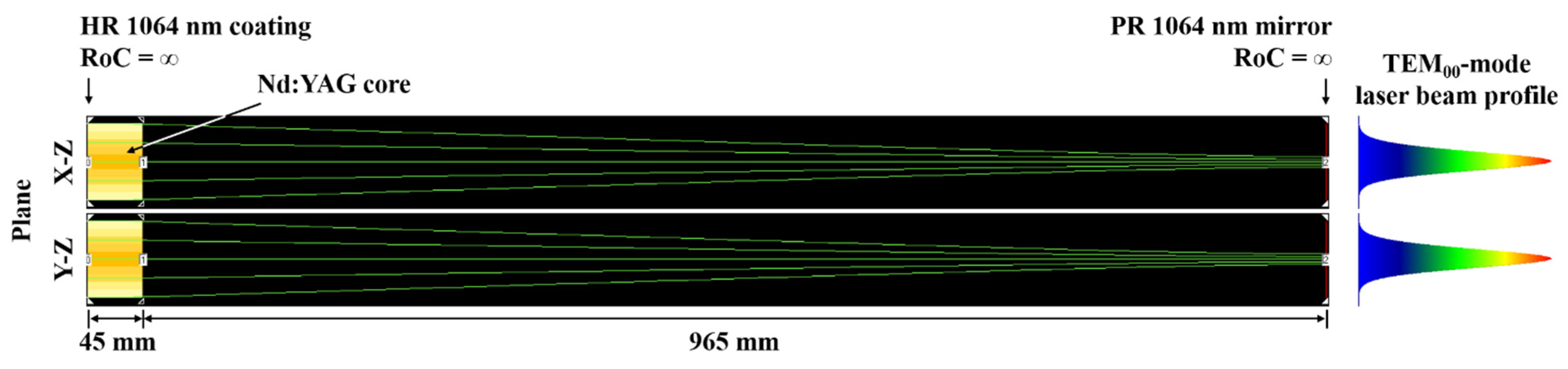

3.2. Optimization of the TEM00-Mode Laser Extraction from Each Core-Doped Nd:YAG Medium through LASCAD™ Software

4. Extraction of Multiple TEM00-Mode Laser Beams with Higher Brightness

- In Zemax®, a long detector volume was added for each of the N Nd:YAG cores of the array. Its length (LDET) was N × LROD, with LROD being the rod length. The number of pixels in the z-axis was N × PZ, with PZ being the number of pixels from the previous case of laser beam extraction from each rod. Each Nd:YAG core occupied a different portion of the corresponding detector.

- After running the Zemax® simulation, N text files were exported, with the absorbed pump flux/volume data from each detector volume.

- Tables with information about each z-plane and voxel are crucial for the LASCAD™ analysis. Therefore, the lines with z-plane and voxel data from the different N text files were copied to replace the empty ones in the text file from one of the detectors. In Figure 8, the data from the detectors of rods 2 to 11 were used to replace the corresponding lines in the text file from rod 1 detector, since it already contained the absorbed pump flux/volume data of the Nd:YAG core in the detector volume’s first portion. This helped in maintaining the same structure of a typical file directly exported from a detector volume in Zemax®. This single text file, with all the information of the core-doped Nd:YAG rods, was then imported into LASCAD™.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lando, M.; Kagan, J.A.; Shimony, Y.; Kalisky, Y.Y.; Noter, Y.; Yogev, A.; Rotman, S.R.; Rosenwaks, S. Solar-pumped solid state laser program. In Proceedings of the 10th Meeting on Optical Engineering in Israel, Jerusalem, Israel, 22 September 1997; Shladov, I., Rotman, S.R., Eds.; International Society for Optics and Photonics: Bellingham, WA, USA, 1997; Volume 3110, p. 196. [Google Scholar] [CrossRef]

- Hemmati, H.; Biswas, A.; Djordjevic, I.B. Deep-Space Optical Communications: Future Perspectives and Applications. Proc. IEEE 2011, 99, 2020–2039. [Google Scholar] [CrossRef]

- Rather, J.D.G.; Gerry, E.T.; Zeiders, G.W. Investigation of possibilities for solar powered high energy lasers in space. NASA Tech. Rep. Serv. 1977. Available online: https://ntrs.nasa.gov/search.jsp?R=19770019534 (accessed on 15 March 2020).

- Vasile, M.; Maddock, C.A. Design of a formation of solar pumped lasers for asteroid deflection. Adv. Sp. Res. 2012, 50, 891–905. [Google Scholar] [CrossRef] [Green Version]

- Yabe, T.; Uchida, S.; Ikuta, K.; Yoshida, K.; Baasandash, C.; Mohamed, M.S.; Sakurai, Y.; Ogata, Y.; Tuji, M.; Mori, Y.; et al. Demonstrated fossil-fuel-free energy cycle using magnesium and laser. Appl. Phys. Lett. 2006, 89, 261107. [Google Scholar] [CrossRef]

- Graydon, O. A sunny solution. Nat. Photonics 2007, 1, 495–496. [Google Scholar] [CrossRef]

- Oliveira, M.; Liang, D.; Almeida, J.; Vistas, C.R.; Gonçalves, F.; Martins, R. A path to renewable Mg reduction from MgO by a continuous-wave Cr:Nd:YAG ceramic solar laser. Sol. Energy Mater. Sol. Cells 2016, 155, 430–435. [Google Scholar] [CrossRef]

- Kiss, Z.J.; Lewis, H.R.; Duncan, R.C., Jr. Sun Pumped Continuous Optical Maser. Appl. Phys. Lett. 1963, 2, 93–94. [Google Scholar] [CrossRef]

- Lando, M.; Kagan, J.; Linyekin, B.; Dobrusin, V. A solar-pumped Nd:YAG laser in the high collection efficiency regime. Opt. Commun. 2003, 222, 371–381. [Google Scholar] [CrossRef]

- Yabe, T.; Ohkubo, T.; Uchida, S.; Yoshida, K.; Nakatsuka, M.; Funatsu, T.; Mabuti, A.; Oyama, A.; Nakagawa, K.; Oishi, T.; et al. High-efficiency and economical solar-energy-pumped laser with Fresnel lens and chromium codoped laser medium. Appl. Phys. Lett. 2007, 90, 261120. [Google Scholar] [CrossRef]

- Liang, D.; Almeida, J. Highly efficient solar-pumped Nd:YAG laser. Opt. Express 2011, 19, 26399. [Google Scholar] [CrossRef]

- Dinh, T.H.; Ohkubo, T.; Yabe, T.; Kuboyama, H. 120 watt continuous wave solar-pumped laser with a liquid light-guide lens and an Nd:YAG rod. Opt. Lett. 2012, 37, 2670. [Google Scholar] [CrossRef]

- Xu, P.; Yang, S.; Zhao, C.; Guan, Z.; Wang, H.; Zhang, Y.; Zhang, H.; He, T. High-efficiency solar-pumped laser with a grooved Nd:YAG rod. Appl. Opt. 2014, 53, 3941. [Google Scholar] [CrossRef]

- Guan, Z.; Zhao, C.; Li, J.; He, D.; Zhang, H. 32.1 W/m2 continuous wave solar-pumped laser with a bonding Nd:YAG/YAG rod and a Fresnel lens. Opt. Laser Technol. 2018, 107, 158–161. [Google Scholar] [CrossRef]

- Liang, D.; Vistas, C.R.; Tibúrcio, B.D.; Almeida, J. Solar-pumped Cr:Nd:YAG ceramic laser with 6.7% slope efficiency. Sol. Energy Mater. Sol. Cells 2018, 185, 75–79. [Google Scholar] [CrossRef]

- Liang, D.; Almeida, J.; Vistas, C.R.; Guillot, E. Solar-pumped Nd:YAG laser with 31.5 W/m2 multimode and 7.9 W/m2 TEM00-mode collection efficiencies. Sol. Energy Mater. Sol. Cells 2017, 159, 435–439. [Google Scholar] [CrossRef]

- Hwang, I.H.; Lee, J.H. Efficiency and threshold pump intensity of CW solar-pumped solid-state lasers. IEEE J. Quantum Electron. 1991, 27, 2129–2134. [Google Scholar] [CrossRef]

- Koechner, W. Solid-State Laser Engineering, 5th ed.; Springer Series in Optical Sciences; Springer: Berlin/Heidelberg, Germany, 1999; ISBN 978-3-662-14221-9. [Google Scholar]

- Clarkson, W.A. Thermal effects and their mitigation in end-pumped solid-state lasers. J. Phys. D. Appl. Phys. 2001, 34, 2381–2395. [Google Scholar] [CrossRef]

- Lupei, V.; Lupei, A.; Gheorghe, C.; Ikesue, A. Emission sensitization processes involving Nd3+ in YAG. J. Lumin. 2016, 170, 594–601. [Google Scholar] [CrossRef]

- Weksler, M.; Shwartz, J. Solar-pumped solid-state lasers. IEEE J. Quantum Electron. 1988, 24, 1222–1228. [Google Scholar] [CrossRef]

- Ostermeyer, M.; Brandenburg, I. Simulation of the extraction of near diffraction limited Gaussian beams from side pumped core doped ceramic Nd:YAG and conventional laser rods. Opt. Express 2005, 13, 10145. [Google Scholar] [CrossRef]

- Sträßer, A.; Ostermeyer, M. Improving the brightness of side pumped power amplifiers by using core doped ceramic rods. Opt. Express 2006, 14, 6687. [Google Scholar] [CrossRef]

- Almeida, J.; Liang, D. Design of a high brightness solar-pumped laser by light-guides. Opt. Commun. 2012, 285, 5327–5333. [Google Scholar] [CrossRef]

- Liang, D.; Almeida, J. Design of ultrahigh brightness solar-pumped disk laser. Appl. Opt. 2012, 51, 6382. [Google Scholar] [CrossRef]

- Liang, D.; Almeida, J. Multi-Fresnel lenses pumping approach for improving high-power Nd:YAG solar laser beam quality. Appl. Opt. 2013, 52, 5123. [Google Scholar] [CrossRef]

- Garcia, D.; Liang, D.; Almeida, J. Core-doped Nd:YAG disk solar laser uniformly pumped by six Fresnel lenses. In Proceedings of the 8th Iberoamerican Optics Meeting and 11th Latin American Meeting on Optics, Lasers, and Applications, Porto, Portugal, 18 November 2013; Martins Costa, M.F.P.C., Ed.; International Society for Optics and Photonics: Bellingham, WA, USA, 2013; Volume 8785, p. 87850W. [Google Scholar] [CrossRef]

- Strite, T.; Gusenko, A.; Grupp, M.; Hoult, T. Multiple Laser Beam Material Processing. Biul. Inst. Spaw. 2016, 60, 30–33. [Google Scholar] [CrossRef] [Green Version]

- Eifel, S.; Holtkamp, J. Multi-Beam Technology Boosts Cost Efficiency. Available online: https://www.industrial-lasers.com/micromachining/article/16485583/multibeam-technology-boosts-cost-efficiency (accessed on 17 May 2020).

- Gillner, A.; Finger, J.; Gretzki, P.; Niessen, M.; Bartels, T.; Reininghaus, M. High Power Laser Processing with Ultrafast and Multi-Parallel Beams. J. Laser Micro/Nanoeng. 2019, 14, 129–137. [Google Scholar] [CrossRef]

- Olsen, F.O.; Hansen, K.S.; Nielsen, J.S. Multibeam fiber laser cutting. J. Laser Appl. 2009, 21, 133–138. [Google Scholar] [CrossRef]

- Fazilov, A.; Riskiev, T.T.; Abdurakhmanov, A.A.; Bakhramov, S.A.; Makhkamov, S.; Mansurov, M.M.; Mukhamediev, E.J.; Paiziev, S.D.; Klychev, S.I.; Saribaev, A.S.; et al. Concentrated solar energy conversion to powerful laser radiation on neodymium activated yttrium-aluminum garnet. Appl. Sol. Energy 2008, 44, 93–96. [Google Scholar] [CrossRef]

- Tibúrcio, B.D.; Liang, D.; Almeida, J.; Garcia, D.; Vistas, C.R. Dual-rod pumping concept for TEM00-mode solar lasers. Appl. Opt. 2019, 58, 3438. [Google Scholar] [CrossRef] [PubMed]

- Almeida, J.; Liang, D.; Tibúrcio, B.D.; Garcia, D.; Vistas, C.R. Numerical modeling of a four-rod pumping scheme for improving TEM00-mode solar laser performance. J. Photonics Energy 2019, 9, 1. [Google Scholar] [CrossRef]

- Liang, D.; Almeida, J.; Garcia, D.; Tibúrcio, B.D.; Guillot, E.; Vistas, C.R. Simultaneous solar laser emissions from three Nd:YAG rods within a single pump cavity. Sol. Energy 2020, 199, 192–197. [Google Scholar] [CrossRef]

- Costa, H.; Almeida, J.; Liang, D.; Garcia, D.; Catela, M.; Tibúrcio, B.D.; Vistas, C.R. Design of a multibeam solar laser station for a megawatt solar furnace. Opt. Eng. 2020, 59, 086103. [Google Scholar] [CrossRef]

- Almeida, J.; Liang, D.; Costa, H.; Garcia, D.; Tibúrcio, B.D.; Catela, M.; Vistas, C.R. Seven-rod pumping concept for simultaneous emission of seven TEM00-mode solar laser beams. J. Photonics Energy 2020, 10, 038001. [Google Scholar] [CrossRef]

- Costa, H.; Almeida, J.; Liang, D.; Tibúrcio, B.D.; Garcia, D.; Catela, M.; Vistas, C.R. Quasi-Gaussian Multibeam Solar Laser Station for a Megawatt Solar Furnace. J. Sol. Energy Res. Updat. 2021, 8, 11–20. [Google Scholar] [CrossRef]

- Liang, D.; Almeida, J.; Tibúrcio, B.D.; Catela, M.; Garcia, D.; Costa, H.; Vistas, C.R. Seven-Rod Pumping Approach for the Most Efficient Production of TEM00 Mode Solar Laser Power by a Fresnel Lens. J. Sol. Energy Eng. 2021, 143, 061004. [Google Scholar] [CrossRef]

- Liang, D.; Almeida, J. Solar-Pumped TEM00 Mode Nd:YAG laser. Opt. Express 2013, 21, 25107. [Google Scholar] [CrossRef] [PubMed]

- Liang, D.; Almeida, J.; Vistas, C.R.; Guillot, E. Solar-pumped TEM00 mode Nd:YAG laser by a heliostat-Parabolic mirror system. Sol. Energy Mater. Sol. Cells 2015, 134, 305–308. [Google Scholar] [CrossRef]

- Almeida, J.; Liang, D.; Vistas, C.R.; Bouadjemine, R.; Guillot, E. 5.5 W continuous-wave TEM00-mode Nd:YAG solar laser by a light-guide/2V-shaped pump cavity. Appl. Phys. B 2015, 121, 473–482. [Google Scholar] [CrossRef]

- Vistas, C.R.; Liang, D.; Almeida, J. Solar-pumped TEM00 mode laser simple design with a grooved Nd:YAG rod. Sol. Energy 2015, 122, 1325–1333. [Google Scholar] [CrossRef]

- Liang, D.; Almeida, J.; Vistas, C.R.; Oliveira, M.; Gonçalves, F.; Guillot, E. High-efficiency solar-pumped TEM00-mode Nd:YAG laser. Sol. Energy Mater. Sol. Cells 2016, 145, 397–402. [Google Scholar] [CrossRef]

- Duocastella, M.; Arnold, C.B. Bessel and annular beams for materials processing. Laser Photonics Rev. 2012, 6, 607–621. [Google Scholar] [CrossRef]

- Catela, M.; Liang, D.; Vistas, C.R.; Garcia, D.; Tibúrcio, B.D.; Costa, H.; Almeida, J. Six-rod/six-beam concept for revitalizing TEM00 mode lamp-pumped lasers. Opt. Eng. 2020, 59, 126108. [Google Scholar] [CrossRef]

- Guillot, E.; Rodriguez, R.; Boullet, N.; Sans, J.-L. Some details about the third rejuvenation of the 1000 kWth solar furnace in Odeillo: Extreme performance heliostats. In Proceedings of the AIP Conference Proceedings; 2018; Volume 2033, p. 040016. Available online: https://aip.scitation.org/doi/abs/10.1063/1.5067052 (accessed on 24 August 2021). [CrossRef]

- SFERA Access to PROMES Facilities. Available online: http://sfera.sollab.eu/index.php?page=access_promes (accessed on 6 May 2020).

- ASTM G173-03(2012). Standard Tables for Reference Solar Spectral Irradiances: Direct Normal and Hemispherical on 37° Tilted Surface; ASTM: West Conshohocken, PA, USA, 2012. [Google Scholar] [CrossRef]

- Zhao, B.; Changming, Z.; He, J.; Yang, S. The study of active medium for solar-pumped solid-state lasers. Acta Opt. Sin. 2007, 27, 1797–1801. [Google Scholar]

- Almeida, J.; Liang, D.; Vistas, C.R.; Guillot, E. Highly efficient end-side-pumped Nd:YAG solar laser by a heliostat–parabolic mirror system. Appl. Opt. 2015, 54, 1970. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costa, H.; Almeida, J.; Liang, D.; Catela, M.; Garcia, D.; Tibúrcio, B.D.; Vistas, C.R. Zigzag Multirod Laser Beam Merging Approach for Brighter TEM00-Mode Solar Laser Emission from a Megawatt Solar Furnace. Energies 2021, 14, 5437. https://doi.org/10.3390/en14175437

Costa H, Almeida J, Liang D, Catela M, Garcia D, Tibúrcio BD, Vistas CR. Zigzag Multirod Laser Beam Merging Approach for Brighter TEM00-Mode Solar Laser Emission from a Megawatt Solar Furnace. Energies. 2021; 14(17):5437. https://doi.org/10.3390/en14175437

Chicago/Turabian StyleCosta, Hugo, Joana Almeida, Dawei Liang, Miguel Catela, Dário Garcia, Bruno D. Tibúrcio, and Cláudia R. Vistas. 2021. "Zigzag Multirod Laser Beam Merging Approach for Brighter TEM00-Mode Solar Laser Emission from a Megawatt Solar Furnace" Energies 14, no. 17: 5437. https://doi.org/10.3390/en14175437

APA StyleCosta, H., Almeida, J., Liang, D., Catela, M., Garcia, D., Tibúrcio, B. D., & Vistas, C. R. (2021). Zigzag Multirod Laser Beam Merging Approach for Brighter TEM00-Mode Solar Laser Emission from a Megawatt Solar Furnace. Energies, 14(17), 5437. https://doi.org/10.3390/en14175437