Optimization Algorithms: Optimal Parameters Computation for Modeling the Polarization Curves of a PEFC Considering the Effect of the Relative Humidity

Abstract

:1. Introduction

- Analyze the RH impact on the performance of a PEFC, the sparsity and noise of the collected data, and its influence on optimization problems;

- Compare the OA efficiency through an error metric in the computation of the optimal parameters for the mathematical model of a PEFC;

- Build prediction models for the polarization curves of a PEFC at different RH levels.

2. Experimental Setup

2.1. Lab-Scale FC Test System

2.2. Experimental Parameters Setup

3. Mathematical Model of PEFC

4. Optimization Algorithms

4.1. Principles

4.2. Multi-Verse Optimization (MVO)

4.3. Improved-Grey Wolf Optimizer (I-GWO)

4.4. Ant–Lion Optimizer (ALO)

4.5. Bird Swarm Algorithm (BSA)

4.6. Neural Network Algorithm (NNA)

5. Methodology

5.1. OF Construction

5.2. Boundary and Initial Conditions for the Mathematical Model of the PEFC

5.3. Input Parameters for OAs

- and are two positive constants which can be respectively called cognitive and social accelerated coefficients into the birds’ foraging behavior.

- and are two positive constants’ values between 0 and 2, related to the birds’ vigilance behavior.

- is the frequency in which each bird flies to another place.

5.4. Error Metric for Predictions

5.5. Noise Metric for Experimental Data

6. Results and Discussion

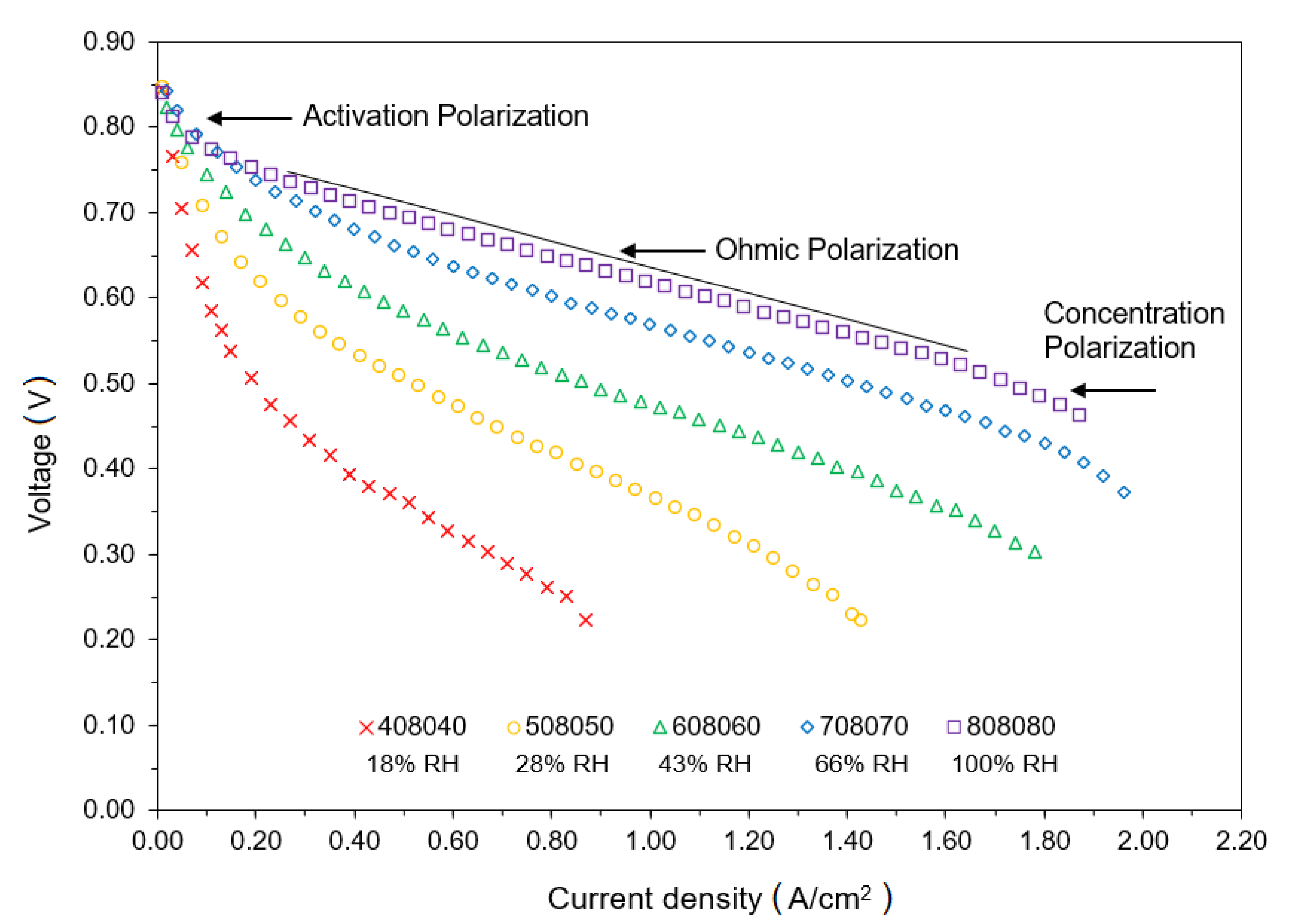

6.1. RH Impact on Performance of a PEFC

6.2. Sparsity and Noise of Experimentally Collected Data

6.3. Computed Unknown Parameters

7. Conclusions

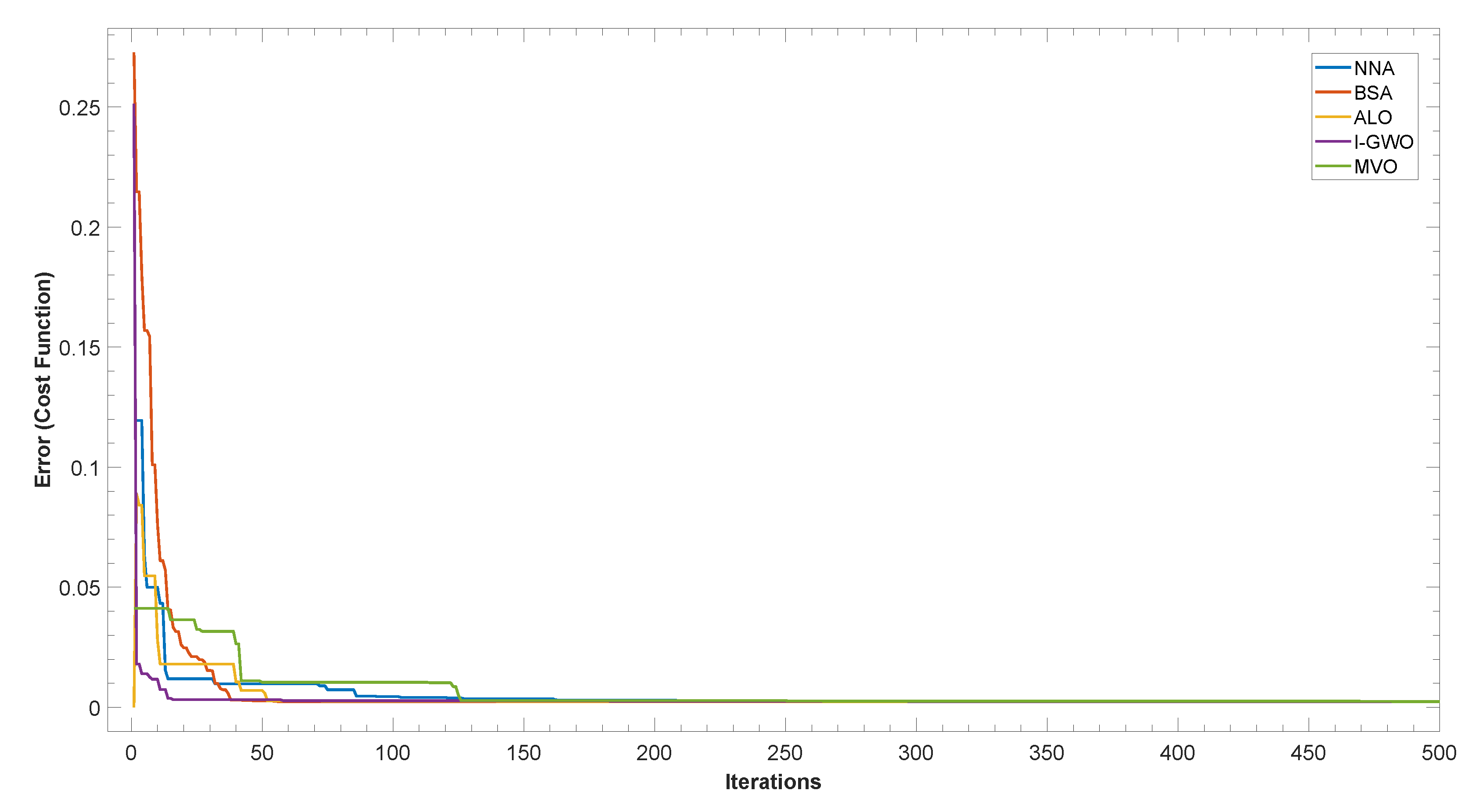

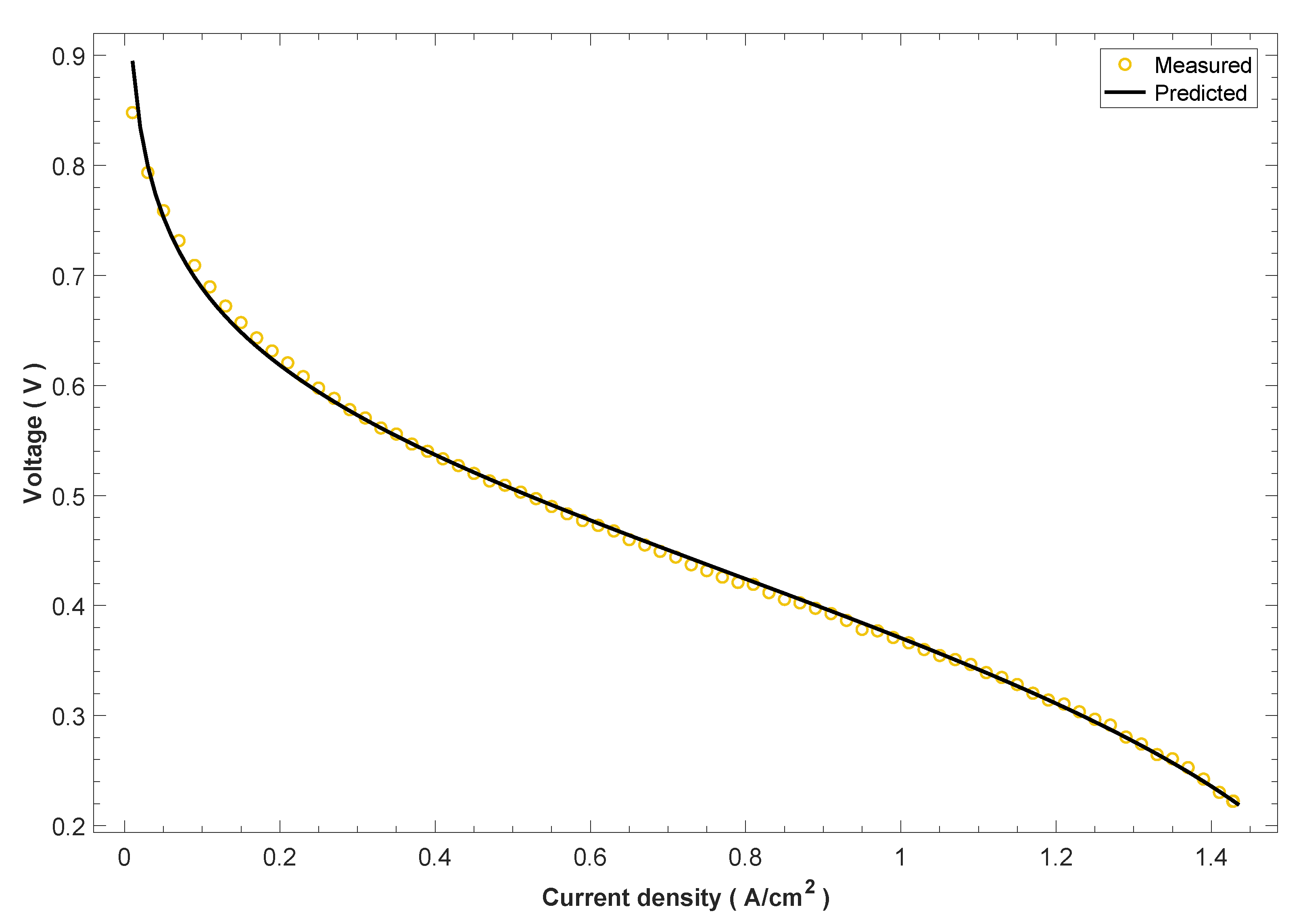

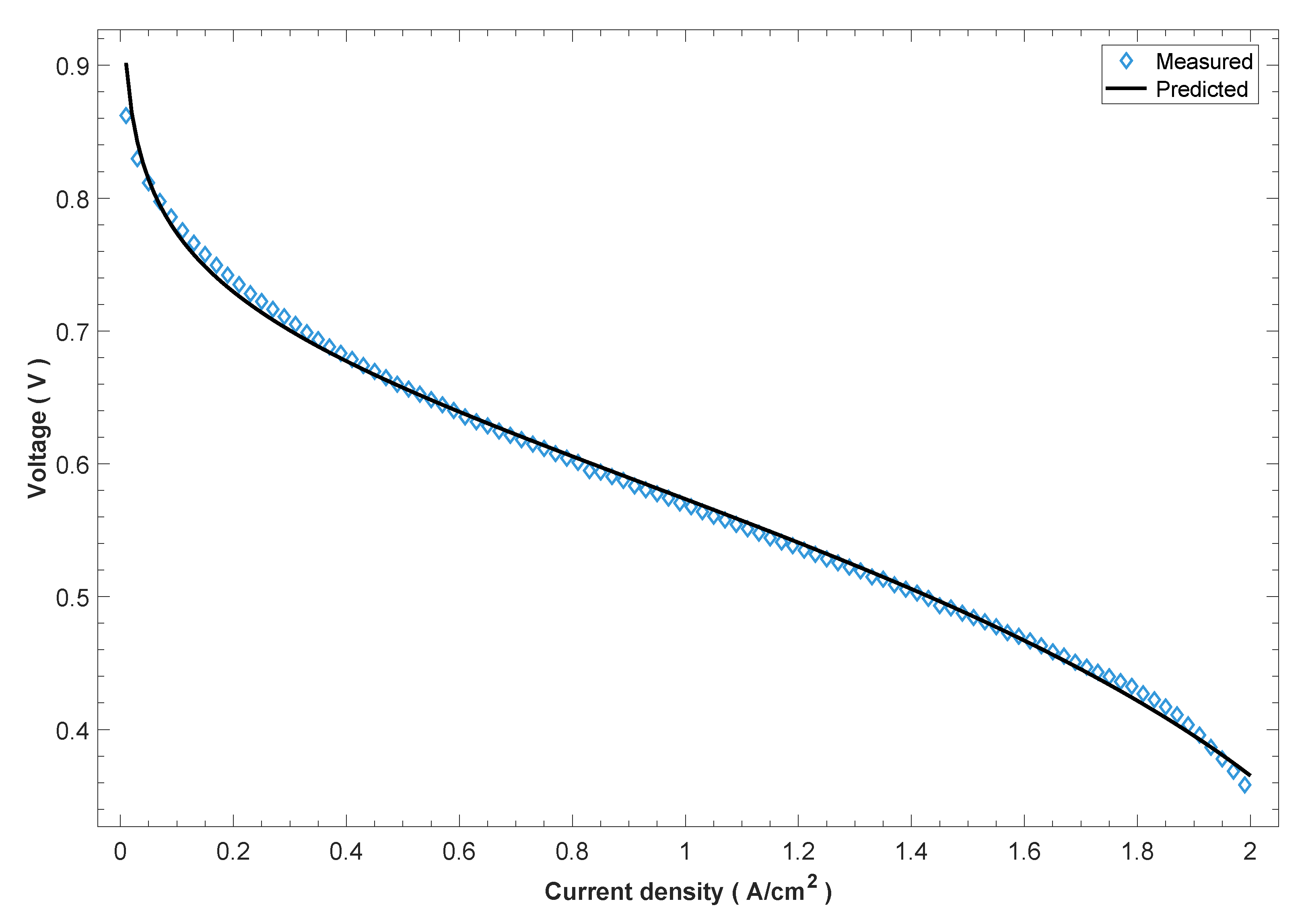

- In all cases, for the five different OAs (NNA, MVO, BSA, ALO, and I-GWO) applied in this PEFC optimization problem, well fittings between measured and predicted voltage points are reached when using the optimal values of the unknown parameters for PEFCs.

- Statistical performance measures have been made to evaluate the efficiency and competency of the five algorithms used to carry out this experiment, concluding that NNA proves to give the best results for the optimal values of PEFCs’ unknown parameters in almost all scenarios.

- NNA and MVO show a better response than the other three algorithms when only referring to the training time. Although NNA optimal values are better, focusing on the metric used to measure the error between measured and predicted voltage points.

- The optimal values for PEFCs’ unknown parameters were obtained at different RH percentages. The NNA optimizer performed the best training in three out of five scenarios, as, at RH values of 28% and 43%, I-GWO and BSA showed more accurate results when focusing on the statistical performance measures.

- The comparisons that are properly detailed in this paper give the authors enough information to confirm and conclude that the NNA optimizer has a better performance and shows the best results, comparing it with other highlighted OAs.

- The polarization curves obtained show the great influence that the RH has on the performance of a PEFC, obtaining a significant decrease in range operation of 1.4 A/cm2 when the RH is modified from 100% RH to 16% RH.

- Another RH impact on the performance of a PEFC is the increased presence of data sparsity and noise at low RH due to the PEFC works under critical operating conditions. Therefore, it also affects predicted curves that have a lower fit.

- To sum up, the data sparsity and noise also affect OAs, since it represents a higher difficulty in finding the optimal parameters that allow for reaching the best fitting of the polarization curves to data through the PEFC mathematical model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gutiérrez-Martín, F.; Da Silva-Álvarez, R.A.; Montoro-Pintado, P. Effects of wind intermittency on reduction of CO2 emissions: The case of the Spanish power system. Energy 2013, 61, 108–117. [Google Scholar] [CrossRef]

- Rodriguez, C.; Alaswad, A.; Benyounis, K.Y.; Olabi, A.G. Pretreatment techniques used in biogas production from grass. Renew. Sustain. Energy Rev. 2017, 68, 1193–1204. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Wu, H.; Wang, D.; Wang, Y.; Tong, Z.; Lin, F.; Olabi, A.G. Experimental study on a coiled tube solar receiver under variable solar radiation condition. Sol. Energy 2015, 122, 1080–1090. [Google Scholar] [CrossRef]

- Olabi, A.G. Renewable energy and energy storage systems. Energy 2017, 136, 54. [Google Scholar] [CrossRef]

- Kelly-Yong, T.L.; Lee, K.T.; Mohamed, A.R.; Bhatia, S. Potential of hydrogen from oil palm biomass as a source of renewable energy worldwide. Energy Policy 2007, 35, 5692–5701. [Google Scholar] [CrossRef]

- Wilberforce, T.; Alaswad, A.; Palumbo, A.; Dassisti, M.; Olabi, A.G. Advances in stationary and portable fuel cell applications. Int. J. Hydrogen Energy 2016, 41, 16509–16522. [Google Scholar] [CrossRef] [Green Version]

- Zappa, W.; Junginger, M.; van den Broek, M. Is a 100% renewable European power system feasible by 2050? Appl. Energy 2019, 233–234, 1027–1050. [Google Scholar] [CrossRef]

- Spiegel, C.; York, N.; San, C.; Lisbon, F.; Madrid, L.; City, M.; New, M.; San, D.; Singapore, J.S.; Toronto, S. Designing and Building Fuel Cells Library of Congress Cataloging-in-Publication Data; Mc Graw Hill: New York, NY, USA, 2021; p. 417. ISBN 0-07-148977-0. [Google Scholar]

- Sharaf, O.Z.; Orhan, M.F. An overview of fuel cell technology: Fundamentals and applications. Renew. Sustain. Energy Rev. 2014, 32, 810–853. [Google Scholar] [CrossRef]

- Von Spakovsky, M.R.; Olsommer, B. Fuel cell systems and system modeling and analysis perspectives for fuel cell development. Energy Convers. Manag. 2002, 43, 1249–1257. [Google Scholar] [CrossRef]

- Carrette, L.; Friedrich, K.A.; Stimming, U. Fuel Cells: Principles, Types, Fuels, and Applications. ChemPhysChem 2000, 1, 162–193. [Google Scholar] [CrossRef]

- Santarelli, M.G.; Torchio, M.F. Experimental analysis of the effects of the operating variables on the performance of a single PEMFC. Energy Convers. Manag. 2007, 48, 40–51. [Google Scholar] [CrossRef]

- Santarelli, M.G.; Torchio, M.F.; Cochis, P. Parameters estimation of a PEM fuel cell polarization curve and analysis of their behavior with temperature. J. Power Sources 2006, 159, 824–835. [Google Scholar] [CrossRef]

- Zhang, Q.; Lin, R.; Técher, L.; Cui, X. Experimental study of variable operating parameters effects on overall PEMFC performance and spatial performance distribution. Energy 2016, 115, 550–560. [Google Scholar] [CrossRef]

- Basu, S. Recent Trends in Fuel Cell Science and Technology; Springer: New York, NY, USA, 2021; p. 375. ISBN 0-387-35537-5. [Google Scholar]

- Yang, S.; Chellali, R.; Lu, X.; Li, L.; Bo, C. Modeling and optimization for proton exchange membrane fuel cell stack using aging and challenging P systems based optimization algorithm. Energy 2016, 109, 569–577. [Google Scholar] [CrossRef]

- Encalada, Á.; Espinoza-Andaluz, M. Compression Effects on Mass Transport Phenomena in digitally generated PEFC Gas Diffusion Layers by using OpenPNM. In Proceedings of the 2020 IEEE ANDESCON, Quito, Ecuador, 13–16 October 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Fawzi, M.; El-Fergany, A.A.; Hasanien, H.M. Effective methodology based on neural network optimizer for extracting model parameters of PEM fuel cells. Int. J. Energy Res. 2019, 43, 8136–8147. [Google Scholar] [CrossRef]

- Priya, K.; Sathishkumar, K.; Rajasekar, N. A comprehensive review on parameter estimation techniques for Proton Exchange Membrane fuel cell modelling. Renew. Sustain. Energy Rev. 2018, 93, 121–144. [Google Scholar] [CrossRef]

- Correa, J.; Farret, F.; Popov, V.; Simoes, M. Sensitivity analysis of the modeling parameters used in Simulation of proton exchange membrane fuel cells. IEEE Trans. Energy Convers. 2005, 20, 211–218. [Google Scholar] [CrossRef]

- Jia, J.; Li, Q.; Wang, Y.; Cham, Y.T.; Han, M. Modeling and Dynamic Characteristic Simulation of a Proton Exchange Membrane Fuel Cell. IEEE Trans. Energy Convers. 2009, 24, 283–291. [Google Scholar] [CrossRef]

- Djilali, N. Computational modelling of polymer electrolyte membrane (PEM) fuel cells: Challenges and opportunities. Energy 2007, 32, 269–280. [Google Scholar] [CrossRef]

- El-Hay, E.; El-Hameed, M.; El-Fergany, A. Steady-state and dynamic models of solid oxide fuel cells based on Satin Bowerbird Optimizer. Int. J. Hydrogen Energy 2018, 43, 14751–14761. [Google Scholar] [CrossRef]

- Ettihir, K.; Boulon, L.; Becherif, M.; Agbossou, K.; Ramadan, H. Online identification of semi-empirical model parameters for PEMFCs. Int. J. Hydrogen Energy 2014, 39, 21165–21176. [Google Scholar] [CrossRef]

- Tahmasbi, A.A.; Hoseini, A.; Roshandel, R. A new approach to multi-objective optimisation method in PEM fuel cell. Int. J. Sustain. Energy 2015, 34, 283–297. [Google Scholar] [CrossRef]

- Petrescu, S.; Petre, C.; Costea, M.; Malancioiu, O.; Boriaru, N.; Dobrovicescu, A.; Feidt, M.; Harman, C. A methodology of computation, design and optimization of solar Stirling power plant using hydrogen/oxygen fuel cells. Energy 2010, 35, 729–739. [Google Scholar] [CrossRef]

- Li, J.; Gao, N.; Cao, G.Y.; Zhu, X.J. Modeling of DIR-SOFC Based on Particle Swarm Optimization-Wavelet Network. In Advanced Materials Research; Advanced Materials and Processes II; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2012; Volume 557, pp. 2202–2207. [Google Scholar] [CrossRef]

- Abualigah, L.; Shehab, M.; Alshinwan, M.; Mirjalili, S.; Elaziz, M.A. Ant Lion Optimizer: A Comprehensive Survey of Its Variants and Applications. Arch. Comput. Methods Eng. 2020, 28, 1397–1416. [Google Scholar] [CrossRef]

- Priya, K.; Sudhakar Babu, T.; Balasubramanian, K.; Sathish Kumar, K.; Rajasekar, N. A novel approach for fuel cell parameter estimation using simple Genetic Algorithm. Sustain. Energy Technol. Assess. 2015, 12, 46–52. [Google Scholar] [CrossRef]

- Gong, W.; Cai, Z. Accelerating parameter identification of proton exchange membrane fuel cell model with ranking-based differential evolution. Energy 2013, 59, 356–364. [Google Scholar] [CrossRef]

- Ye, M.; Wang, X.; Xu, Y. Parameter identification for proton exchange membrane fuel cell model using particle swarm optimization. Int. J. Hydrogen Energy 2009, 34, 981–989. [Google Scholar] [CrossRef]

- Fathy, A.; Rezk, H. Multi-verse optimizer for identifying the optimal parameters of PEMFC model. Energy 2018, 143, 634–644. [Google Scholar] [CrossRef]

- Ali, M.; El-Hameed, M.; Farahat, M. Effective parameters’ identification for polymer electrolyte membrane fuel cell models using grey wolf optimizer. Renew. Energy 2017, 111, 455–462. [Google Scholar] [CrossRef]

- Khodaei, H.; Hajiali, M.; Darvishan, A.; Sepehr, M.; Ghadimi, N. Fuzzy-based heat and power hub models for cost-emission operation of an industrial consumer using compromise programming. Appl. Therm. Eng. 2018, 137, 395–405. [Google Scholar] [CrossRef]

- Cao, Y.; Kou, X.; Wu, Y.; Jermsittiparsert, K.; Yildizbasi, A. PEM fuel cells model parameter identification based on a new improved fluid search optimization algorithm. Energy Rep. 2020, 6, 813–823. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef] [Green Version]

- Santana, J.; Espinoza-Andaluz, M.; Li, T.; Andersson, M. A Detailed Analysis of Internal Resistance of a PEFC Comparing High and Low Humidification of the Reactant Gases. Front. Energy Res. 2020, 8, 1–12. [Google Scholar] [CrossRef]

- Espinoza-Andaluz, M.; Santana, J.; Andersson, M. Empirical correlations for the performance of a PEFC considering relative humidity of fuel and oxidant gases. Int. J. Hydrogen Energy 2020, 45, 29763–29773. [Google Scholar] [CrossRef]

- Associates, S. Fuel Cell Test System Operating Manual 850C; Scribner Associates, Inc.: Southern Pines, NC, USA, 2021; Volume 1, pp. 1–66. [Google Scholar]

- Cooper, K.; Ramani, V.; Fenton, J.M.; Kurtz, H.R. Experimental Methods and Data Analyses for Polymer Electrolyte Fuel Cells; Scribner Associates, Inc.: Southern Pines, NC, USA, 2005; p. 119. [Google Scholar]

- Milewski, J.; Szczęśniak, A.; Szablowski, L. A discussion on mathematical models of proton conducting Solid Oxide Fuel Cells. Int. J. Hydrogen Energy 2019, 44, 10925–10932. [Google Scholar] [CrossRef]

- Bavarian, M.; Soroush, M. Mathematical modeling and steady-state analysis of a proton-conducting solid oxide fuel cell. J. Process. Control 2012, 22, 1521–1530. [Google Scholar] [CrossRef]

- Mann, R.F.; Amphlett, J.C.; Hooper, M.A.; Jensen, H.M.; Peppley, B.A.; Roberge, P.R. Development and application of a generalized steady-state electrochemical model for a PEM fuel cell. J. Power Sources 2000, 86, 173–180. [Google Scholar] [CrossRef]

- Squadrito, G.; Maggio, G.; Passalacqua, E.; Lufrano, F.; Patti, A. Empirical equation for polymer electrolyte fuel cell (PEFC) behaviour. J. Appl. Electrochem. 1999, 29, 1449–1455. [Google Scholar] [CrossRef]

- El-Fergany, A.A. Extracting optimal parameters of PEM fuel cells using Salp Swarm Optimizer. Renew. Energy 2018, 119, 641–648. [Google Scholar] [CrossRef]

- Cheng, J.; Zhang, G. Parameter fitting of PEMFC models based on adaptive differential evolution. Int. J. Electr. Power Energy Syst. 2014, 62, 189–198. [Google Scholar] [CrossRef]

- Kandidayeni, M.; Macias, A.; Khalatbarisoltani, A.; Boulon, L.; Kelouwani, S. Benchmark of proton exchange membrane fuel cell parameters extraction with metaheuristic optimization algorithms. Energy 2019, 183, 912–925. [Google Scholar] [CrossRef]

- Agwa, A.M.; El-Fergany, A.A.; Sarhan, G.M. Steady-State Modeling of Fuel Cells Based on Atom Search Optimizer. Energies 2019, 12, 1884. [Google Scholar] [CrossRef] [Green Version]

- Rao, Y.; Shao, Z.; Ahangarnejad, A.H.; Gholamalizadeh, E.; Sobhani, B. Shark Smell Optimizer applied to identify the optimal parameters of the proton exchange membrane fuel cell model. Energy Convers. Manag. 2019, 182, 1–8. [Google Scholar] [CrossRef]

- Bozorg-Haddad, O. Advanced Optimization by Nature-Inspired Algorithms; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Abd-Alsabour, N. Nature as a Source for Inspiring New Optimization Algorithms. In Proceedings of the 9th International Conference on Signal Processing Systems, ICSPS, Auckland, New Zealand, 27–30 November 2017; Association for Computing Machinery: New York, NY, USA, 2017; pp. 51–56. [Google Scholar] [CrossRef]

- Nadimi-Shahraki, M.H.; Taghian, S.; Mirjalili, S. An improved grey wolf optimizer for solving engineering problems. Expert Syst. Appl. 2021, 166, 113917. [Google Scholar] [CrossRef]

- Mirjalili, S. The Ant Lion Optimizer. Adv. Eng. Softw. 2015, 83, 80–98. [Google Scholar] [CrossRef]

- Anderson, T.R. Biology of the Ubiquitous House Sparrow: From Genes to Populations; Oxford University Press: Oxford, UK, 2006. [Google Scholar]

- Meng, X.B.; Gao, X.; Lu, L.; Liu, Y.; Zhang, H. A new bio-inspired optimisation algorithm: Bird Swarm Algorithm. J. Exp. Theor. Artif. Intell. 2016, 28, 673–687. [Google Scholar] [CrossRef]

- Sadollah, A.; Sayyaadi, H.; Yadav, A. A dynamic metaheuristic optimization model inspired by biological nervous systems: Neural network algorithm. Appl. Soft Comput. 2018, 71, 747–782. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Hatamlou, A. Multi-Verse Optimizer: A Nature-Inspired Algorithm for Global Optimization. Neural Comput. Appl. 2016, 27, 495–513. [Google Scholar] [CrossRef]

- Bally, V.; Caramellino, L. Total variation distance between stochastic polynomials and invariance principles. Ann. Probab. 2019, 47, 3762–3811. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Lin, R.; Liu, D.; Xu, J.; Feng, B. Investigation of the effect of humidity at both electrode on the performance of PEMFC using orthogonal test method. Int. J. Hydrogen Energy 2019, 44, 13737–13743. [Google Scholar] [CrossRef]

| Limits | (1 × ) | (1 × ) | (m) | |||

|---|---|---|---|---|---|---|

| Upper | −0.8532 | 9.80 | −9.54 | 23.00 | 0.80 | 0.5000 |

| Lower | −1.1997 | 3.60 | −26.00 | 13.00 | 0.10 | 0.0136 |

| Gas Temperature (C) | RH (%) | (A/cm2) |

|---|---|---|

| 40 | 18.00 | 1.0277 |

| 50 | 27.70 | 1.6372 |

| 60 | 42.62 | 2.1890 |

| 70 | 65.57 | 2.3779 |

| 80 | 100.00 | 2.4529 |

| OA | M | p | d | FQ | ||||

|---|---|---|---|---|---|---|---|---|

| NNA [56] | 500 | 50 | 6 | * | * | * | * | * |

| BSA [55] | 500 | 50 | 6 | 1.5 | 1.5 | 1 | 1 | 3 |

| ALO [53] | 500 | 50 | 6 | * | * | * | * | * |

| I-GWO [52] | 500 | 50 | 6 | * | * | * | * | * |

| MVO [57] | 500 | 50 | 6 | * | * | * | * | * |

| RH (%) | 18.00 | 27.70 | 42.62 | 65.57 | 100.00 |

|---|---|---|---|---|---|

| aTV (1 × 10−3) | 7.550 | 4.351 | 3.055 | 2.565 | 2.028 |

| Parameters | NNA | BSA | ALO | I-GWO | MVO |

|---|---|---|---|---|---|

| −1.1149 | −1.1149 | −1.1994 | −1.1154 | −1.1997 | |

| 9.7999 | 9.7999 | 7.9154 | 9.7918 | 7.9091 | |

| −25.9999 | −25.9999 | −25.9999 | −25.9999 | −25.9999 | |

| 13.0000 | 13.0000 | 13.0000 | 13.0004 | 13.0000 | |

| (m) | 0.8000 | 0.8000 | 0.8000 | 0.7997 | 0.8000 |

| 0.0645 | 0.0645 | 0.0645 | 0.06440 | 0.0645 | |

| 1.8664 | 1.8664 | 1.8665 | 1.8664 | 1.8665 | |

| (s) | 35.8161 | 28.1427 | 34.8917 | 87.3449 | 30.7480 |

| 3.1351 | 3.1351 | 3.1353 | 3.1352 | 3.1353 | |

| 3.1353 | 3.4024 | 3.6350 | 3.1376 | 3.3613 | |

| 7.2980 | 9504.9800 | 11,392.5770 | 48.9820 | 5320.4450 |

| Parameters | NNA | BSA | ALO | I-GWO | MVO |

|---|---|---|---|---|---|

| −1.0192 | −1.0320 | −1.1828 | −1.1194 | −1.1997 | |

| 9.7997 | 9.5129 | 6.1490 | 7.5609 | 5.7752 | |

| −24.4553 | −24.4632 | −24.4484 | −24.4732 | −24.4214 | |

| 14.2717 | 14.2110 | 22.2903 | 14.2064 | 14.1801 | |

| (m) | 0.8000 | 0.7994 | 0.8000 | 0.7993 | 0.8000 |

| 0.0582 | 0.0578 | 0.0587 | 0.05779 | 0.0579 | |

| 5.8480 | 5.8490 | 5.8490 | 5.8490 | 5.8500 | |

| (s) | 68.9683 | 88.9019 | 82.6906 | 201.3102 | 80.6157 |

| 4.9934 | 4.9944 | 4.9949 | 4.9955 | 4.9959 | |

| 5.2459 | 6.3568 | 6.6148 | 5.1094 | 6.4502 | |

| 6.5355 | 4079.0520 | 4193.5260 | 163.7320 | 4009.5830 |

| Parameters | NNA | BSA | ALO | I-GWO | MVO |

|---|---|---|---|---|---|

| −0.9891 | −0.9891 | −1.1605 | −1.0420 | −1.1997 | |

| 9.7999 | 9.8000 | 5.9719 | 8.6177 | 5.0981 | |

| −20.3072 | −20.3074 | −20.3087 | −20.3098 | −20.2981 | |

| 22.9999 | 22.9999 | 23.0000 | 22.9994 | 22.6254 | |

| (m) | 0.7999 | 0.7999 | 0.8000 | 0.7996 | 0.7997 |

| 0.0753 | 0.0753 | 0.0753 | 0.07520 | 0.07435 | |

| 7.9120 | 7.9120 | 7.9130 | 7.9130 | 7.9190 | |

| (s) | 191.0309 | 135.0847 | 111.0385 | 385.0889 | 108.358416 |

| 1.1456 | 1.1455 | 1.1458 | 1.1459 | 1.1476 | |

| 1.3451 | 1.4892 | 1.4107 | 1.1553 | 1.6837 | |

| 6011.3840 | 7731.1360 | 7497.3040 | 142.4000 | 9409.8590 |

| Parameters | NNA | BSA | ALO | I-GWO | MVO |

|---|---|---|---|---|---|

| −0.9696 | −0.9692 | −1.0620 | −1.0076 | −1.1997 | |

| 9.7916 | 9.7999 | 7.7240 | 8.9422 | 4.6376 | |

| −15.0015 | −15.0028 | −14.9989 | −14.9991 | −15.0440 | |

| 22.9999 | 22.9999 | 23.0000 | 22.9785 | 23.0000 | |

| (m) | 0.7999 | 0.7999 | 0.8000 | 0.7997 | 0.8000 |

| 0.0657 | 0.0657 | 0.0658 | 0.0657 | 0.0655 | |

| 5.7980 | 5.7980 | 5.7990 | 5.8000 | 5.8000 | |

| (s) | 298.3339 | 141.1235 | 88.8788 | 168.1751 | 130.6152 |

| 0.6724 | 0.6724 | 0.6725 | 0.6728 | 0.6729 | |

| 0.9459 | 1.2206 | 9.0701 | 0.6787 | 1.1342 | |

| 6883.3250 | 10,564.2350 | 5710.6560 | 116.0200 | 8616.5400 |

| Parameters | NNA | BSA | ALO | I-GWO | MVO |

|---|---|---|---|---|---|

| −0.9843 | −0.9843 | −1.1993 | −0.9906 | −1.1997 | |

| 9.8000 | 9.7999 | 4.9772 | 9.6620 | 4.9669 | |

| −9.5400 | −9.5400 | −9.5400 | −9.5413 | −9.5400 | |

| 23.0000 | 23.0000 | 23.0000 | 22.9963 | 23.0000 | |

| (m) | 0.8000 | 0.7999 | 0.8000 | 0.7988 | 0.8000 |

| 0.0703 | 0.0703 | 0.0703 | 0.0701 | 0.0705 | |

| 3.5840 | 3.5840 | 3.5850 | 3.5870 | 3.5850 | |

| (s) | 95.4813 | 75.8022 | 159.2261 | 230.6826 | 110.6548 |

| 2.3894 | 2.3894 | 2.3903 | 2.3931 | 2.3907 | |

| 3.8519 | 6.7273 | 3.9850 | 2.5145 | 5.4944 | |

| 3668.1860 | 7889.4520 | 3649.9570 | 173.5280 | 5206.5160 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Encalada-Dávila, Á.; Echeverría, S.; Santana-Villamar, J.; Cedeño, G.; Espinoza-Andaluz, M. Optimization Algorithms: Optimal Parameters Computation for Modeling the Polarization Curves of a PEFC Considering the Effect of the Relative Humidity. Energies 2021, 14, 5631. https://doi.org/10.3390/en14185631

Encalada-Dávila Á, Echeverría S, Santana-Villamar J, Cedeño G, Espinoza-Andaluz M. Optimization Algorithms: Optimal Parameters Computation for Modeling the Polarization Curves of a PEFC Considering the Effect of the Relative Humidity. Energies. 2021; 14(18):5631. https://doi.org/10.3390/en14185631

Chicago/Turabian StyleEncalada-Dávila, Ángel, Samir Echeverría, Jordy Santana-Villamar, Gabriel Cedeño, and Mayken Espinoza-Andaluz. 2021. "Optimization Algorithms: Optimal Parameters Computation for Modeling the Polarization Curves of a PEFC Considering the Effect of the Relative Humidity" Energies 14, no. 18: 5631. https://doi.org/10.3390/en14185631