RETRACTED: A Critical Review on Recycling Composite Waste Using Pyrolysis for Sustainable Development

Abstract

:1. Introduction

- The increased utilization of composites in mass-production automobiles resulting from the development of high-volume thermoplastic composite-based technologies [3].

- The first significant group of wind turbines made of composite materials approaching their End-of-Life (EOL) in 2019–2020 and preparing to be dismantled [1].

- The COVID-19 epidemic hastening the retirement of airplanes (airplane mass decommissioning is predicted in the 2020s) [5].

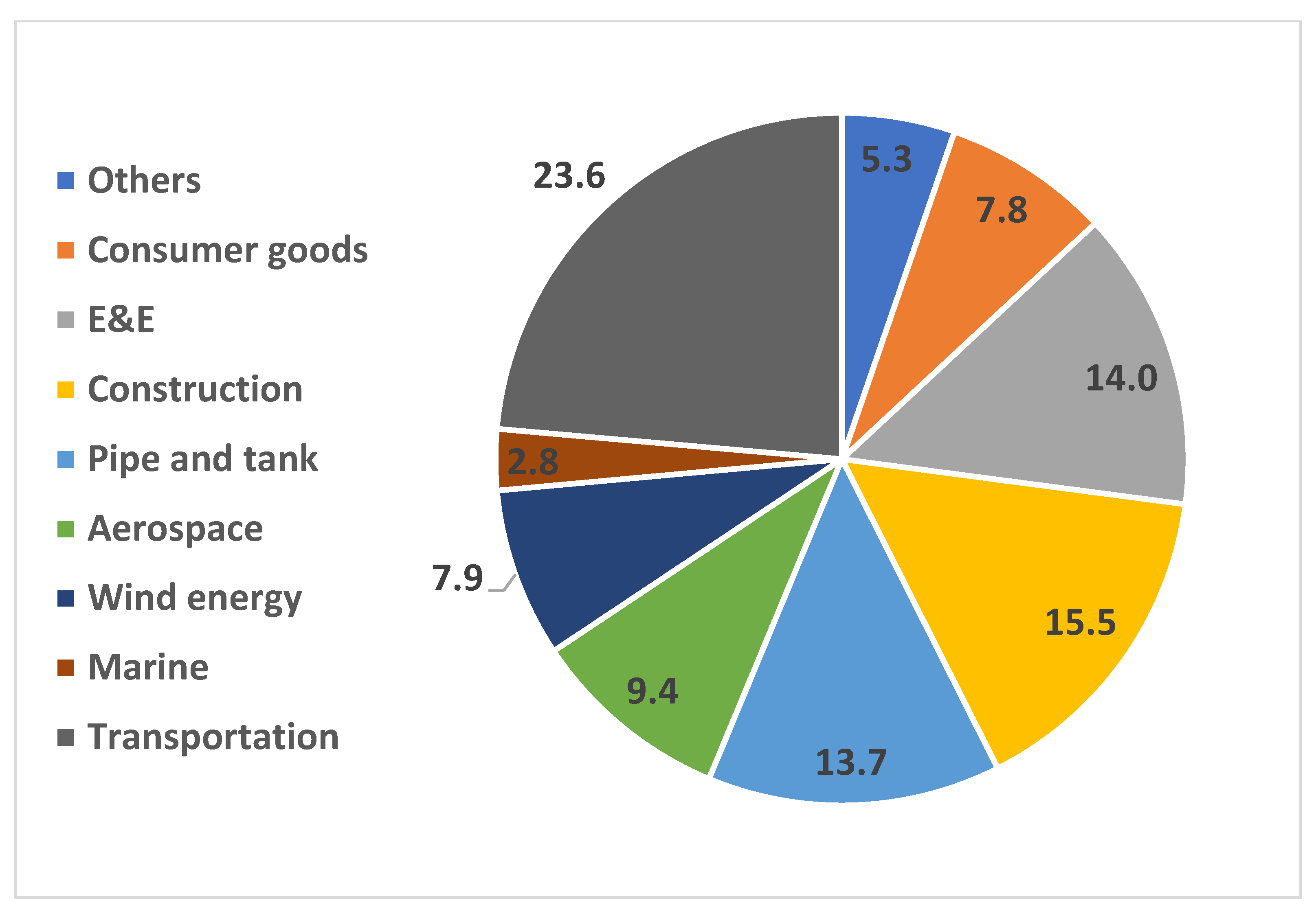

1.1. Composite Material Applications

1.1.1. Aerospace

1.1.2. Automotive

1.1.3. Marine

1.1.4. Wind Energy

1.1.5. Construction and Infrastructure

2. Review of Recycling Technologies

3. Recovery of CFRC/GFRC Utilizing Pyrolysis

3.1. Pyrolysis: Controlled Atmospheres

3.1.1. Vacuum Atmosphere

3.1.2. Nitrogen Atmosphere

3.1.3. Superheated Steam Atmosphere

3.2. Microwave Pyrolysis

3.3. Pyrolysis on Wind Turbine

4. Pyrolysis Products and Their Reuse

5. Discussion

- In an appropriate experimental facility, how well does pyrolysis perform for mixed and polluted scrape? In the majority of the work in the literature, there has been no mention of an FBR or any other reactor capable of processing mixed and polluted wastes.

- Determination of the optimal variables of pyrolysis and post-pyrolysis are necessary in order to better comprehend the impact of pyrolysis. For further enhancement of the quality of the recovered fibers, research on the optimum variables of pyrolysis is needed.

- In the literature, there is a gap in the examination of financial and energy-based evaluation of pyrolysis. The data will show that recycled fibers are better for the environment than EOL landfilling. Mathematical modeling may be built to show how pyrolysis and post-pyrolysis processing changes—as well as other important parameters—affect the cost and environmental effect.

- There are currently no commercially viable products created from short, thin, and nonaligned recovered fibers obtained by pyrolysis. More study on the use of recovered fibers is needed.

- When pyrolyzing a recycled composite, there is no information on fiber grading and fractionation to remove short fibers and retain excellent purity and strength without losing part of the fiber.

- How can the original fiber length and strength be preserved following pyrolysis? The longer the starting fiber, the longer the recovered fiber—although better understanding of the effects of thermal and oxidation treatment is needed to enhance product quality and lower costs.

- The lack of sizing on recycled fiber surfaces is a key study topic. This might result in inadequate adhesion among the polymer and recovered fibers, resulting in poor mechanical characteristics. The mechanical characteristics of recycled fibers might be significantly improved by pyrolysis resizing.

- Pyrolysis improved the mechanical characteristics of recovered fibers when contrasted with incineration, gasification, mechanical, and chemical techniques. On the other hand, an inappropriate set of pyrolysis conditions has a detrimental impact on these characteristics (such as poor heating rates and high residence time). This compromise will not be accepted if the recovered fibers are to be used in a high-grade composite application.

- It is unclear what effect fiber reclamation has on the performance of composites when compared to virgin and recovered composites with similar structures.

6. Conclusions and Future Research

- Mechanical separation, incineration, gasification, and slower pyrolysis in a kiln are costly or yield low characteristic fibers. Pyrolysis may be a realistic and promising approach, because it is efficient in recovery and produces high characteristic fibers. The essential pyrolysis variables, their influence on fiber characteristics, and the re-use of recycled fibers for new composites were highlighted in this paper.

- A successful commercial-scale pyrolysis program was implemented in Germany and the United Kingdom, and they have the ability to recycle CFRC in various forms. They may also recover longer and cleaner CFs, thanks to the big furnace and continuous flow.

- Pyrolysis, like any other recycling process, has several drawbacks, the most problematic of which is the probability of char development on the resultant fiber surface. Due to char, the mechanical characteristics of the recovered fibers will be substantially decreased. Chemical treatment and post-heating of the fibers both help to reduce char formation, but only to a limited extent.

- Pyrolysis in a nitrogen gas environment, unlike vacuum pyrolysis, may recycle both CFRC and GFRC.

- In pyrolysis, using a superheated steam atmosphere improves heat transmission, which accelerates the thermal breakdown and supports eliminating oxygen from the reactor. In comparison to other pyrolysis atmospheres, recycling CFRC with superheated steam leads to high retention of CF mechanical characteristics.

- According to the study, the higher the value of recycled CF, the lower the pyrolysis temperature.

- Microwave pyrolysis has enhanced the rate of heat while consuming a smaller quantity of energy, without interfering with the basic principle of pyrolysis. The method may recycle both CFRC and GFRC fibers while preserving greater mechanical characteristics.

- Both the oxidizing (air) and thermal (N2) atmospheres were important in determining surface properties. Surface defects were discovered in an oxidizing atmosphere, resulting in a decrease in TS and crystallite size. As a result, for a successful recycling process, a regulated and optimum temperature and residence duration in post-pyrolysis is advantageous.

- Recycling CFRC/GFRC by pyrolysis has great potential, since it recovers precious fibers and produces gas and liquid products.

- According to published research, the breakdown temperature of resin is complete between 450–500 °C in the case of GRFC. Meanwhile, CFRC breakdown temperatures are between 450–600 °C, depending on kind and whether it is cured or uncured. For post-pyrolysis in the air atmosphere, 500–600 °C was found to be the optimal temperature for oxidizing char and cleaning the fiber surface.

- It is important to identify the material cost reductions that may be achieved by using rCF. While rCF are cheaper than virgin fibers, they are inherently different from them, which has restricted the entry of rCF into the vCF market. Based on cost and performance, the task will be to modify the material in such a way that virgin fiber is replaced with recycled fiber.

- In the case of carbon fiber composite materials, pyrolysis can result in fibers that are short in length and discontinuous. There are certain advantages to using these fibers, such as: cost-effectiveness, light weight, a 3-dimensional complexity in the panels, and a secondary structure for airplane interiors. Thermochemically converted recycled fibers demonstrate good mechanical characteristics compared to virgin fibers.

- Recycled carbon fiber products in automobile applications deliver lighter and stronger components at high volume manufacturing rates, as well as considerable cost savings. Nonaligned and short fibers tend to generate excellent quality, 3D complicated, lightweight constructions for components and panels with complex forms.

- How effective/feasible is pyrolysis for mixed and polluted composite wastes?

- It is necessary to gain a better understanding of the influence of operational factors (heating temperature, reaction time, chemical solvent) on CF/GF. Further research into the optimum parameters is necessary to improve the quality of CF/GF.

- The impact of fiber recovery on composite quality (in comparison to vCF/vGF and remanufactured composites with rCF/rGF using the same structures) is unclear.

- How can rCF/rGF strength and length be compared to vCF/vGF using this method? Additional performance improvements will need a better understanding of pyrolysis interactions with chemical treatment.

- How could the total costs of the recycling and remanufacturing of composites be lowered so that pyrolysis may be used as a recycling technique on a large scale?

- The use of rCF/rGF after recovery from pyrolysis is a current field of study; such studies may play a major role in enhancing the characteristics of the products generated from them.

- Crosslinking of fibers also limits reusing of rCF/rGF in new composites. If RFs are re-aligned in the same way as vCF/vGF, their potential uses could be improved.

- Chemical treatment plays a role in improving the mechanical and physical characteristics of rCF/rGF. This involves research into the reaction of functional groups to resin interactions. Chemical treatment at the connection between these functional groups and the resin matrix may also be involved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ACMs | Advanced Composite Materials |

| Al | Aluminum |

| ATR | Attenuated total reflection |

| CF | Carbon fiber |

| CFRC | Carbon fiber-reinforced composite |

| CFRP | Carbon-fiber reinforced polymer |

| DTG | Differential thermogravimetry |

| E | Young modulus |

| E&E | Electrical and Electronic equipment |

| EOL | End-of-Life |

| FBP | Fluidized-bed process |

| FRC | Fiber-reinforced composites |

| FTIR | Fourier-transform infrared |

| GC | Chromatography |

| GF | Glass fiber |

| GFRC | Glass fibre reinforced composite |

| GFRP | Glass-fiber reinforced polymer |

| GS | Gravity separation |

| IATA | International Air Transport Association |

| MS | Mass spectroscopy |

| NA | Nitrogen atmosphere |

| NMP | N-methyl-2-pyrrolidinone |

| PP | Polypropylene |

| rCF | recycled carbon fiber |

| rGF | recycled glass fiber |

| RT | Room Temperature |

| SC | Secondary combustion |

| SEM | Scanning electron microscope |

| SGRE | Siemens Gamesa Renewable Energy |

| SMC | Sheet molding compound |

| TG | Thermogravimetric analysis a |

| TGA | Thermogravimetric analysis |

| TS | Tensile strength |

| vCF | Virgin carbon fiber |

| VCS | Vacuum centrifugal separation |

| vGF | Virgin glass fiber |

| VP | Vacuum pyrolysis |

| WPCBs | Waste printed circuit boards |

| XPS | X-ray photoelectron spectroscopy |

References

- Krauklis, A.E.; Karl, C.W.; Gagani, A.I.; Jørgensen, J.K. Composite Material Recycling Technology—State-of-the-Art and Sustainable Development for the 2020s. J. Compos. Sci. 2021, 5, 28. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Odijie, A.C.; Orok, E.O.; Ye, J. Economic aspects of fiber reinforced polymer composite recycling. Encycl. Renew. Sustain. Mater. 2020, 2, 377–397. [Google Scholar] [CrossRef]

- Gharde, S.; Kandasubramanian, B. Mechanothermal and chemical recycling methodologies for the Fibre Reinforced Plastic (FRP). Environ. Technol. Innov. 2019, 14, 100311. [Google Scholar] [CrossRef]

- WindEurope–Cefic–EuCIA. Accelerating Wind Turbine Blade Circularity. White Paper. 2020. Available online: https://windeurope.org/wp-content/uploads/files/about-wind/reports/WindEurope-Accelerating-wind-turbine-bladecircularity.pdf (accessed on 11 August 2021).

- The International Air Transport Association (IATA). Helping Aircraft Decommissioning. 2020. Available online: https://www.iata.org/en/programs/environment/aircraft-decommissioning/ (accessed on 11 August 2021).

- Job, S. Recycling composites commercially. Reinf. Plast. 2014, 58, 32–38. [Google Scholar] [CrossRef]

- Liu, Y.; Farnsworth, M.; Tiwari, A. A review of optimisation techniques used in the composite recycling area: State-of-the-art and steps towards a research agenda. J. Clean. Prod. 2017, 140, 1775–1781. [Google Scholar] [CrossRef]

- Global Wind Energy Council. Global Wind Report. 2021. Available online: https://gwec.net/global-wind-report-2021/ (accessed on 20 August 2021).

- Holmes, M. Recycled carbon fiber composites become a reality. Reinf. Plast. 2018, 62, 148–153. [Google Scholar] [CrossRef]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.J.; Kuiper, P.; de Wit, H. Recycling of composite materials. Chem. Eng. Process. Process. Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Chen, T.; Kazerooni, D.; Ju, L.; Okonski, D.A.; Baird, D.G. Development of Recyclable and High-Performance In Situ Hybrid TLCP/Glass Fiber Composites. J. Compos. Sci. 2020, 4, 125. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Agbomerie, C.O.; Sotayo, A.; Wang, F.; Hou, X.; Ye, J. Recycling of Renewable Composite Materials in the Offshore Industry. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Gagani, A.I.; Krauklis, A.E.; Echtermeyer, A.T. Orthotropic fluid diffusion in composite marine structures. Experimental procedure, analytical and numerical modelling of plates, rods and pipes. Compos. Part A Appl. Sci. Manuf. 2018, 115, 196–205. [Google Scholar] [CrossRef]

- Rocha, I.B.C.M.; Parente, E., Jr.; Melo, A.M.C. A hybrid shared/distributed memory parallel genetic algorithm for optimization of laminate composites. Compos. Struct. 2014, 107, 288–297. [Google Scholar] [CrossRef]

- Gagani, A.; Krauklis, A.; Echtermeyer, A.T. Anisotropic fluid diffusion in carbon fiber reinforced composite rods: Experimental, analytical and numerical study. Mar. Struct. 2018, 59, 47–59. [Google Scholar] [CrossRef]

- Starkova, O.; Aniskevich, A. Modelling of moisture sorption by CFRP rebars with vinylester matrix. Adv. Compos. Lett. 2004, 13, 096369350401300603. [Google Scholar] [CrossRef]

- Gagani, A.I.; Krauklis, A.E.; Sæter, E.; Vedvik, N.P.; Echtermeyer, A.T. A novel method for testing and determining ILSS for marine and offshore composites. Compos. Struct. 2019, 220, 431–440. [Google Scholar] [CrossRef]

- Rubino, F.; Nisticò, A.; Tucci, F.; Carlone, P. Marine application of fiber reinforced composites: A review. J. Mar. Sci. Eng. 2020, 8, 26. [Google Scholar] [CrossRef]

- Jayalakshmi, C.G.; Inamdar, A.; Anand, A.; Kandasubramanian, B. Polymer matrix composites as broadband radar absorbing structures for stealth aircrafts. J. Appl. Polym. Sci. 2019, 136, 47241. [Google Scholar] [CrossRef]

- Marsh, G. What’s to be done with ‘spent’wind turbine blades? Renew. Energy Focus 2017, 22, 20–23. [Google Scholar] [CrossRef]

- Belton, P. What Happens to All the Old Wind Turbines? BBC News: Business. 22 February 2020. Available online: https://www.bbc.com/news/business-51325101 (accessed on 11 May 2021).

- Liu, P.; Barlow, C.Y. Wind turbine blade waste in 2050. Waste Manag. 2017, 62, 229–240. [Google Scholar] [CrossRef]

- Rescalvo, F.J.; Valverde-Palacios, I.; Suarez, E.; Roldán, A.; Gallego, A. Monitoring of carbon fiber-reinforced old timber beams via strain and multi resonant acoustic emission sensors. Sensors 2018, 18, 1224. [Google Scholar] [CrossRef] [PubMed]

- Asmatulu, E.; Twomey, J.; Overcash, M. Recycling of fiber reinforced composites and direct structural composite recycling concept. J. Compos. Mater. 2014, 48, 593–608. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Jensen, J.P.; Skelton, K. Wind turbine blade recycling: Experiences, challenges, and possibilities in a circular economy. Renew Sustain. Energy Rev. 2018, 97, 165–176. [Google Scholar] [CrossRef]

- Lefeuvre, A.; Garnier, S.; Jacquemin, L.; Pillain, B.; Sonnemann, G. Anticipating in-use stocks of carbon fiber reinforced polymers and related waste flows generated by the commercial aeronautical sector until 2050. Resour. Conserv. Recycl. 2017, 125, 264–272. [Google Scholar] [CrossRef]

- Erden, S.; Ho, K. Fiber-reinforced composites. In Fiber Technology for Fiber-Reinforced Composites; Woodhead Publishing: John Solston, UK, 2017; pp. 51–79. [Google Scholar]

- Pimenta, S.; Pinho, S.T. Recycling carbon fiber reinforced polymers for structural applications: Technology review and market outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef] [PubMed]

- Cousins, D.S.; Suzuki, Y.; Murray, R.E.; Samaniuk, J.R.; Stebner, A.P. Recycling glass fiber thermoplastic composites from wind turbine blades. J. Clean. Prod. 2019, 209, 1252–1263. [Google Scholar] [CrossRef]

- Yao, S.; Jin, F.; Rhee, K.Y.; Hui, D.; Park, S. Recent advances in carbon fiber-reinforced thermoplastic composites: A review. Compos. B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Bachmann, J.; Hidalgo, C.; Bricout, S. Environmental analysis of innovative sustainable composites with potential use in aviation sector—A life cycle assessment review. Sci. China Technol. Sci. 2017, 60, 1301–1317. [Google Scholar] [CrossRef]

- Hadi, P.; Ning, C.; Ouyang, W.; Xu, M.; Lin, C.S.; McKay, G. Toward environmentally benign utilization of nonmetallic fraction of waste printed circuit boards as modifier and precursor. Waste Manag. 2015, 35, 236–246. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Meng, F.; Barlow, C.Y. Wind turbine blade end-of-life options: An eco-audit comparison. J. Clean. Prod. 2019, 212, 1268–1281. [Google Scholar] [CrossRef]

- Pillain, B.; Loubet, P.; Pestalozzi, F.; Woidasky, J.; Erriguible, A.; Aymonier, C.; Sonnemann, G. Positioning supercritical solvolysis among innovative recycling and current waste management scenarios for carbon fiber reinforced plastics thanks to comparative life cycle assessment. J. Supercrit. Fluids 2019, 154, 104607. [Google Scholar] [CrossRef]

- Li, X.; Bai, R.; McKechnie, J. Environmental and financial performance of mechanical recycling of carbon fibre reinforced polymers and comparison with conventional disposal routes. J. Clean. Prod. 2016, 127, 451–460. [Google Scholar] [CrossRef]

- Prinçaud, M.; Aymonier, C.; Loppinet-Serani, A.; Perry, N.; Sonnemann, G. Environmental feasibility of the recycling of carbon fibers from CFRPs by solvolysis using supercritical water. ACS Sustain. Chem. Eng. 2014, 2, 1498–1502. [Google Scholar] [CrossRef]

- Nunes, A.O.; Viana, L.R.; Guineheuc, P.M.; da Silva Moris, V.A.; de Paiva JM, F.; Barna, R.; Soudais, Y. Life cycle assessment of a steam thermolysis process to recover carbon fibers from carbon fiber-reinforced polymer waste. Int. J. Life Cycle Assess 2017, 23, 1825–1838. [Google Scholar] [CrossRef]

- Witik, R.A.; Teuscher, R.; Michaud, V.; Ludwig, C.; Månson, J.A.E. Carbon fibre reinforced composite waste: An environmental assessment of recycling, energy recovery and landfilling. Compos. Part A Appl. Sci. Manuf. 2013, 49, 89–99. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Prabhakara, H.M.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef]

- Meng, F.; Olivetti, E.A.; Zhao, Y.; Chang, J.C.; Pickering, S.J.; McKechnie, J. Comparing life cycle energy and global warming potential of carbon fiber composite recycling technologies and waste management options. ACS Sustain. Chem. Eng. 2018, 6, 9854–9865. [Google Scholar] [CrossRef]

- Moriyama, A.; Hasegawa, T.; Nagaya, C.; Hamada, K.; Himaki, T.; Murakami, M.; Horie, M.; Takahashi, J.; Iwahashi, H.; Moritomi, H. Assessment of harmfulness and biological effect of carbon fiber dust generated during new carbon fiber recycling method. J. Hazard. Mater. 2019, 378, 120777. [Google Scholar] [CrossRef] [PubMed]

- Roberts, T. Rapid growth forecast for carbon fiber market. Reinf. Plast. 2007, 51, 10–13. [Google Scholar] [CrossRef]

- Rybicka, J.; Tiwari, A.; Leeke, G.A. Technology readiness level assessment of composites recycling technologies. J. Clean. Prod. 2016, 112, 1001–1012. [Google Scholar] [CrossRef]

- Rodrigues, G.G.M.; de Paiva, J.M.F.; do Carmo, J.B.; Botaro, V.R. Recycling of carbon fibers inserted in composite of DGEBA epoxy matrix by thermal degradation. Polym. Degrad. Stab. 2014, 109, 50–58. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling technologies for thermoset composite materials—Current status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Vo Dong, P.A.; Azzaro-Pantel, C.; Cadene, A.-L. Economic and environmental assessment of recovery and disposal pathways for CFRP waste management. Resour. Conserv. Recycl. 2018, 133, 63–75. [Google Scholar] [CrossRef]

- Thomason, J.L.; Nagel, U.; Yang, L.; Sáez, E. Regenerating the strength of thermally recycled glass fibres using hot sodium hydroxide. Compos. Part A Appl. Sci. Manuf. 2016, 87, 220–227. [Google Scholar] [CrossRef]

- Yang, L.; Sáez, E.R.; Nagel, U.; Thomason, J.L. Can thermally degraded glass fibre be regenerated for closed-loop recycling of thermosetting composites? Compos. Part A Appl. Sci. Manuf. 2015, 72, 167–174. [Google Scholar] [CrossRef]

- Nagel, U.; Yang, L.; Kao, C.C.; Thomason, J.L. Effects of thermal recycling temperatures on the reinforcement potential of glass fibers. Polym. Compos. 2018, 39, 1032–1040. [Google Scholar] [CrossRef]

- Pender, K.; Yang, L. Investigation of the potential for catalysed thermal recycling in glass fiber reinforced polymer composites by using metal oxides. Compos. A Appl. Sci. Manuf. 2017, 100, 285–293. [Google Scholar] [CrossRef]

- Pickering, S.J.; Kelly, R.M.; Kennerley, J.R.; Rudd, C.D.; Fenwick, N.J. A fluidised-bed process for the recovery of glass fibres from scrap thermoset composites. Compos. Sci. Technol. 2000, 60, 509–523. [Google Scholar] [CrossRef]

- Zheng, Y.; Shen, Z.; Ma, S.; Cai, C.; Zhao, X.; Xing, Y. A novel approach to recycling of glass fibers from nonmetal materials of waste printed circuit boards. J. Hazard. Mater. 2009, 170, 978–982. [Google Scholar] [CrossRef] [PubMed]

- Pender, K.; Yang, L. Investigation of catalyzed thermal recycling for glass fber-reinforced epoxy using fuidized bed process. Polym. Compos. 2019, 40, 3510–3519. [Google Scholar] [CrossRef]

- Yip, H.L.H.; Pickering, S.J.; Rudd, C.D. Characterisation of carbon fibres recycled from scrap composites using fluidised bed process. Plast. Rubber. Compos. 2002, 31, 278–282. [Google Scholar] [CrossRef]

- Pickering, S.J.; Turner, T.A.; Meng, F.; Morris, C.N.; Heil, J.P.; Wong, K.H.; Melendi-Espina, S. Developments in the Fluidised Bed Process for Fibre Recovery from Thermoset Composites. In Proceedings of the 2nd Annual Composites and Advanced Materials Expo, CAMX 2015, Dallas, TX, USA, 26–26 October 2015; pp. 2384–2394. [Google Scholar]

- Ribeiro, M.C.S.; Meira-Castro, A.C.; Silva, F.G.; Santos, J.; Meixedo, J.P.; Fiúza, A.; Dinis, M.L.; Alvim, M.R. Re-use assessment of thermoset composite wastes as aggregate and filler replacement for concrete-polymer composite materials: A case study regarding GFRP pultrusion wastes. Resour. Conserv. Recycl. 2015, 104, 417–426. [Google Scholar] [CrossRef]

- Wong, K.; Rudd, C.; Pickering, S.; Liu, X. Composites recycling solutions for the aviation industry. Sci. China Technol. Sci. 2017, 60, 1291–1300. [Google Scholar] [CrossRef]

- Gopalraj, S.K.; Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: Fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2020, 2, 1–21. [Google Scholar]

- Meyer, L.O.; Schulte, K.; Grove-Nielsen, E. CFRP-recycling following a pyrolysis route: Process optimization and potentials. J. Compos. Mater. 2009, 43, 1121–1132. [Google Scholar] [CrossRef]

- Giorgini, L.; Benelli, T.; Mazzocchetti, L.; Leonardi, C.; Zattini, G.; Minak, G.; Dolcini, E.; Tosi, C.; Montanari, I. Pyrolysis as a way to close a CFRC life cycle: Carbon fibers recovery and their use as feedstock for a new composite production. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2014; Volume 1599, pp. 354–357. [Google Scholar]

- Onwudili, J.A.; Miskolczi, N.; Nagy, T.; Lipóczi, G. Recovery of glass fibre and carbon fibres from reinforced thermosets by batch pyrolysis and investigation of fibre re-using as reinforcement in LDPE matrix. Compos. Part B Eng. 2016, 91, 154–161. [Google Scholar] [CrossRef]

- Louwes, A.C.; Basile, L.; Yukananto, R.; Bhagwandas, J.C.; Bramer, E.A.; Brem, G. Torrefied biomass as feed for fast pyrolysis: An experimental study and chain analysis. Biomass Bioenergy 2017, 105, 116–126. [Google Scholar] [CrossRef]

- Abdou, T.R.; Espinosa, D.C.R.; Tenório, J.A.S. Recovering of carbon fiber present in an industrial polymeric composite waste through pyrolysis method while studying the influence of resin impregnation process: Prepreg. In Towards Materials Resource Sustainability; Kirchain, R.E., Blanpain, B., Meskers, C., Eds.; REWAS 2016; Springer International Publishing: Berlin/Heidelberg, Germany, 2016; pp. 313–318. [Google Scholar]

- Habib Al Razi, K.M. Resourceful recycling process of waste desktop computers: A review study. Resour. Conserv. Recycl. 2016, 110, 30–47. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; Papadaskalopoulou, C.; Hofko, B.; Gschösser, F.; Falchetto, A.C.; Bueno, M.; Arraigada, M.; Sousa, J.; Ruiz, R.; Petit, C.; et al. Harvesting the unexplored potential of European waste materials for road construction. Resour. Conserv. Recycl. 2017, 116, 32–44. [Google Scholar] [CrossRef]

- Shen, Y. Effect of chemical pretreatment on pyrolysis of non-metallic fraction recycled from waste printed circuit boards. Waste Manag. 2018, 76, 537–543. [Google Scholar] [CrossRef]

- Shi, J.; Bao, L.; Kobayashi, R.; Kato, J.; Kemmochi, K. Reusing recycled fibers in high-value fiber-reinforced polymer composites: Improving bending strength by surface cleaning. Compos. Sci. Technol. 2012, 72, 1298–1303. [Google Scholar] [CrossRef]

- Limburg, M.; Stockschläder, J.; Quicker, P. Thermal treatment of carbon fibre reinforced polymers (Part 1: Recycling). Waste Manag. Res. 2019, 37, 73–82. [Google Scholar] [CrossRef]

- Mazzocchetti, L.; Benelli, T.; D’Angelo, E.; Leonardi, C.; Zattini, G.; Giorgini, L. Validation of carbon fibers recycling by pyro-gasification: The influence of oxidation conditions to obtain clean fibers and promote fiber/matrix adhesion in epoxy composites. Compos. Part A Appl. Sci. Manuf. 2018, 112, 504–514. [Google Scholar] [CrossRef]

- Zhou, Y.; Qiu, K. A new technology for recycling materials from waste printed circuit boards. J. Hazard. Mater. 2010, 175, 823–828. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Wu, W.; Qiu, K. Recovery of materials from waste printed circuit boards by vacuum pyrolysis and vacuum centrifugal separation. Waste Manag. 2010, 30, 2299–2304. [Google Scholar] [CrossRef] [PubMed]

- Long, L.; Sun, S.; Zhong, S.; Dai, W.; Liu, J.; Song, W. Using vacuum pyrolysis and mechanical processing for recycling waste printed circuit boards. J. Hazard. Mater. 2010, 177, 626–632. [Google Scholar] [CrossRef]

- Onwudili, J.A.; Insura, N.; Williams, P.T. Autoclave pyrolysis of carbon reinforced composite plastic waste for carbon fibre and chemicals recovery. J. Energy Inst. 2013, 86, 227–232. [Google Scholar] [CrossRef]

- Shi, J.; Wada, S.; Kemmochi, K.; Bao, L. Development of recycling system for fiber-reinforced plastics by superheated steam. In Key Engineering Materials; Trans Tech Publications: Zurich, Switzerland, 2011; Volume 464, pp. 414–418. [Google Scholar] [CrossRef]

- Shi, J.; Kemmochi, K.; Bao, L.M. Research in recycling technology of fiber reinforced polymers for reduction of environmental load: Optimum decomposition conditions of carbon fiber reinforced polymers in the purpose of fiber reuse. In Advanced Materials Research; Trans Tech Publications Ltd.: Zurich, Switzerland, 2012; Volume 343, pp. 142–149. [Google Scholar]

- Kim, K.W.; Lee, H.M.; An, J.H.; Chung, D.C.; An, K.H.; Kim, B.J. Recycling and characterization of carbon fibers from carbon fiber reinforced epoxy matrix composites by a novel super-heated-steam method. J. Environ. Manag. 2017, 203, 872–879. [Google Scholar] [CrossRef]

- Jeong, J.S.; Kim, K.W.; An, K.H.; Kim, B.J. Fast recovery process of carbon fibers from waste carbon fibers-reinforced thermoset plastics. J. Environ. Manag. 2019, 247, 816–821. [Google Scholar] [CrossRef]

- Ye, S.Y.; Bounaceur, A.; Soudais, Y.; Barna, R. Parameter optimization of the steam thermolysis: A process to recover carbon fibers from polymer-matrix composites. Waste Biomass Valorization 2013, 4, 73–86. [Google Scholar] [CrossRef]

- Kim, K.W.; Jeong, J.S.; An, K.H.; Kim, B.J. A low energy recycling technique of carbon fibers-reinforced epoxy matrix composites. Ind. Eng. Chem. Res. 2018, 58, 618–624. [Google Scholar] [CrossRef]

- Obunai, K.; Fukuta, T.; Ozaki, K. Carbon fber extraction from waste CFRP by microwave irradiation. Compos. A Appl. Sci. Manuf. 2015, 78, 160–165. [Google Scholar] [CrossRef]

- Jiang, L.; Ulven, C.A.; Gutschmidt, D.; Anderson, M.; Balo, S.; Lee, M.; Vigness, J. Recycling carbon fiber composites using microwave irradiation: Reinforcement study of the recycled fiber in new composites. J. Appl. Polym. Sci. 2015, 132. Available online: https://onlinelibrary.wiley.com/doi/epdf/10.1002/app.42658 (accessed on 9 September 2021). [CrossRef]

- Beauson, J.; Lilholt, H.; Brøndsted, P. Recycling solid residues recovered from glass fibre-reinforced composites—A review applied to wind turbine blade materials. J. Reinf. Plast. Compos. 2014, 33, 1542–1556. [Google Scholar] [CrossRef]

- Pico, D.; Seide, G.; Gries, T. Thermo chemical processes: Potential improvement of the wind blades life cycle. Chem. Eng. Trans. 2014, 36, 211–216. [Google Scholar]

- Åkesson, D.; Krishnamoorthi, R.; Foltynowicz, Z.; Christέen, J.; Kalantar, A.; Skrifvars, M. Glass fibres recovered by microwave pyrolysis as a reinforcement for polypropylene. Polym. Polym. Compos. 2013, 21, 333–340. [Google Scholar] [CrossRef]

- Åkesson, D.; Foltynowicz, Z.; Christeen, J.; Skrifvars, M. Microwave pyrolysis as a method of recycling glass fibre from used blades of wind turbines. J. Reinf. Plast. Compos. 2012, 31, 1136–1142. [Google Scholar] [CrossRef]

- Åkesson, D.; Foltynowicz, Z.; Christéen, J.; Skrifvars, M. Products obtained from decomposition of glass fber-reinforced composites using microwave pyrolysis. Polimery 2013, 58, 582–586. [Google Scholar] [CrossRef]

- Jiang, G.; Pickering, S.J.; Walker, G.S.; Wong, K.H.; Rudd, C.D. Surface characterisation of carbon fibre recycled using fluidised bed. Appl. Surf. Sci. 2008, 254, 2588–2593. [Google Scholar] [CrossRef]

- Jiang, G.; Pickering, S.J. Structure–property relationship of recycled carbon fibres revealed by pyrolysis recycling process. J. Mater. Sci. 2016, 51, 1949–1958. [Google Scholar] [CrossRef]

- Bücheler, D.; Kaiser, A.; Henning, F. Using thermogravimetric analysis to determine carbon fiber weight percentage of fiber-reinforced plastics. Compos. Part B Eng. 2016, 106, 218–223. [Google Scholar] [CrossRef]

- Yun, Y.M.; Seo, M.W.; Koo, G.H.; Ra, H.W.; Yoon, S.J.; Kim, Y.K.; Lee, J.G.; Kim, J.H. Pyrolysis characteristics of GFRP (Glass Fiber Reinforced Plastic) under non-isothermal conditions. Fuel 2014, 137, 321–327. [Google Scholar] [CrossRef]

- Giorgini, L.; Leonardi, C.; Mazzocchetti, L.; Zattini, G.; Cavazzoni, M.; Montanari, I.; Tosi, C.; Benelli, T. Pyrolysis of fiberglass/polyester composites: Recovery and characterization of obtained products. FME Trans. 2016, 44, 405–414. [Google Scholar] [CrossRef]

- Giorgini, L.; Benelli, T.; Mazzocchetti, L.; Leonardi, C.; Zattini, G.; Minak, G.; Dolcini, E.; Cavazzoni, M.; Montanari, I.; Tosi, C. Recovery of carbon fibers from cured and uncured carbon fiber reinforced composites wastes and their use as feedstock for a new composite production. Polym. Compos. 2015, 36, 1084–1095. [Google Scholar] [CrossRef]

- Das, M.; Varughese, S. A novel sonochemical approach for enhanced recovery of carbon fiber from CFRP waste using mild acid-peroxide mixture. ACS Sustain. Chem. Eng. 2016, 4, 2080–2087. [Google Scholar]

- Yildirir, E.; Miskolczi, N.; Onwudili, J.A.; Németh, K.E.; Williams, P.T.; Sója, J. Evaluating the mechanical properties of reinforced LDPE composites made with carbon fibres recovered via solvothermal processing. Compos. Part B Eng. 2015, 78, 393–400. [Google Scholar] [CrossRef]

- Song, C.; Wang, F.; Liu, Y.; Wang, X.; Yang, B. Recycling carbon fiber from composite waste and its reinforcing effect on polyvinylidene fluoride composite: Mechanical, morphology, and interface properties. Polym. Compos. 2017, 38, 2544–2552. [Google Scholar] [CrossRef]

- Longana, M.L.; Ong, N.; Yu, H.; Potter, K.D. Multiple closed loop recycling of carbon fibre composites with the HiPerDiF (High Performance Discontinuous Fibre) method. Compos. Struct. 2016, 153, 271–277. [Google Scholar] [CrossRef]

- Bradna, P.; Zima, J. Compositional analysis of epoxy matrices of carbon-fibre composites by pyrolysis—gas chromatography/mass spectrometry. J. Anal. Appl. Pyrolysis 1992, 24, 75–85. [Google Scholar] [CrossRef]

- Nahil, M.A.; Williams, P.T. Recycling of carbon fibre reinforced polymeric waste for the production of activated carbon fibres. J. Anal. Appl. Pyrolysis 2011, 91, 67–75. [Google Scholar] [CrossRef]

- Greco, A.; Maffezzoli, A.; Buccoliero, G.; Caretto, F.; Cornacchia, G. Thermal and chemical treatments of recycled carbon fibres for improved adhesion to polymeric matrix. J. Compos. Mater. 2013, 47, 369–377. [Google Scholar] [CrossRef]

- Cunliffe, A.M.; Jones, N.; Williams, P.T. Recycling of fibre-reinforced polymeric waste by pyrolysis: Thermo-gravimetric and bench-scale investigations. J. Anal. Appl. Pyrolysis 2003, 70, 315–338. [Google Scholar] [CrossRef]

- Cunliffe, A.M.; Williams, P.T. Characterisation of products from the recycling of glass fibre reinforced polyester waste by pyrolysis☆. Fuel 2003, 82, 2223–2230. [Google Scholar] [CrossRef]

- Stoeffler, K.; Andjelic, S.; Legros, N.; Roberge, J.; Schougaard, S.B. Polyphenylene sulfide (PPS) composites reinforced with recycled carbon fiber. Compos. Sci. Technol. 2013, 84, 65–71. [Google Scholar] [CrossRef]

- Torres, A.; De Marco, I.; Caballero, B.M.; Laresgoiti, M.F.; Legarreta, J.A.; Cabrero, M.A.; Gonzalez, A.; Chomon, M.J.; Gondra, K. Recycling by pyrolysis of thermoset composites: Characteristics of the liquid and gaseous fuels obtained. Fuel 2000, 79, 897–902. [Google Scholar] [CrossRef]

- Torres, A.; De Marco, I.; Caballero, B.M.; Laresgoiti, M.F.; Chomón, M.J.; Kondra, G. Recycling of the solid residue obtained from the pyrolysis of fiberglass polyester sheet molding compound. Adv. Polym. Technol. J. Polym. Process. Inst. 2009, 28, 141–149. [Google Scholar] [CrossRef]

- López, F.A.; Rodríguez, O.; Alguacil, F.J.; García-Díaz, I.; Centeno, T.A.; García-Fierro, J.L.; González, C. Recovery of carbon fibres by the thermolysis and gasification of waste prepreg. J. Anal. Appl. Pyrolysis 2013, 104, 675–683. [Google Scholar] [CrossRef]

- López, F.A.; Martín, M.I.; Alguacil, F.J.; Rincón, J.M.; Centeno, T.A.; Romero, M. Thermolysis of fibreglass polyester composite and reutilisation of the glass fibre residue to obtain a glass–ceramic material. J. Anal. Appl. Pyrolysis 2012, 93, 104–112. [Google Scholar] [CrossRef]

- Yun, Y.M.; Seo, M.W.; Ra, H.W.; Koo, G.H.; Oh, J.S.; Yoon, S.J.; Kim, Y.K.; Lee, J.G.; Kim, J.H. Pyrolysis characteristics of glass fiber-reinforced plastic (GFRP) under isothermal conditions. J. Anal. Appl. Pyrolysis 2015, 114, 40–46. [Google Scholar] [CrossRef]

- Overcash, M.; Twomey, J.; Asmatulu, E.; Vozzola, E.; Griffing, E. Thermoset composite recycling–Driving forces, development, and evolution of new opportunities. J. Compos. Mater. 2018, 52, 1033–1043. [Google Scholar] [CrossRef]

- Pinho, S.; Ferreira, M.; Almeida, M.F. A wet dismantling process for the recycling of computer printed circuit boards. Resour. Conserv. Recycl. 2018, 132, 71–76. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, Z.; Zhang, F.-S. Advanced degradation of brominated epoxy resin and simultaneous transformation of glass fiber from waste printed circuit boards by improved supercritical water oxidation processes. Waste Manag. 2016, 56, 423–430. [Google Scholar] [CrossRef]

- Meng, F.; McKechnie, J.; Pickering, S.J. An assessment of financial viability of recycled carbon fibre in automotive applications. Compos. Part A Appl. Sci. Manuf. 2018, 109, 207–220. [Google Scholar] [CrossRef]

- Gebisa, A.W.; Lemu, H.G. A case study on topology optimized design for additive manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2017, 276, 012026. [Google Scholar] [CrossRef]

- Meng, F.; McKechnie, J.; Turner, T.A.; Pickering, S.J. Energy and environmental assessment and reuse of fluidised bed recycled carbon fibres. Compos. Part A Appl. Sci. Manuf. 2017, 100, 206–214. [Google Scholar] [CrossRef]

| No. | References | Material | Reactor | Pyrolysis Products (wt%) | Application | Process Parameters | Oxidation Treatment | ||

|---|---|---|---|---|---|---|---|---|---|

| Solid | Liquid | Gas | |||||||

| 1 | Onwudili et al. [62] | CF from reinforced thermosets | Lab-scale batch reactor | 73.1 | 23.8 | 2.3 | Commercial LDPE | N2: 5 dm3/h, 500 °C, 45 min | 500 °C |

| 2 | Onwudili et al. [62] | GF from reinforced thermosets | Lab scale- batch reactor | 65.9 | 25.7 | 8.4 | Commercial LDPE | N2+SC: 500 °C, 30 min, 20 °C/min | 500 °C |

| 3 | Onwudili et al. [74] | Carbon reinforced composite plastic (CRCP) | 300 mL mini autoclave reactor | 72–77 | 22–25 | 2–4 | N2: 400–500 °C, <30 min SC: 450 °C, 2 h. | 450 °C | |

| 4 | Meyer et al. [60] | High tenacity CF | Lab scale TGA | - | - | - | Aerospace | N2: (60 mL/ min), 900 °C, 10 °C/min | 600 °C 60 cm3/min |

| 5 | Giorgini et al. [92] | GF from laminates waste | Batch reactor | 40–45 | 35–40 | 15–20 | 500–600 °C 150 min | 500 or 600 °C 10 to 60 min | |

| 6 | Giorgini et al. [93] | (1) Uncured T700S, 12 K CF (2) Cured T700S, 12 K CF | Batch Pilot plant | 65–70 55–60 | 10–15 25–30 | 15–20 15–20 | New composit | 450–600 °C 150 min, 8 °C/min | 500–600 °C |

| 7 | Zhou and Qiu [71] | WPCBs (GF) | A lab-scale reactor | 75.7 | 20 | 4.3 | - | VP: 600 °C, 30 min | - |

| 8 | Zhou et al. [72] | WPCBs (GF) | A lab-scale reactor | 72.2 | 21.45 | 6.35 | - | VCS: 400 °C, 1200 rpm, 6–10 min | - |

| 9 | Bradna and Zima [98] | Epoxy resin with CF | Py-GC/MS | - | - | - | - | 700 °C | |

| 10 | Nahil and Williams [99] | Polybenzoxazine resin with woven CF | Static bed batch reactor | 70–83.6 | 14–24.6 | 0.7–3.8 | Activated carbon fibers | N2: 350–700 °C, 60 min, 5 °C/min | 500 °C |

| 11 | Long et al. [73] | WPCBs (GF) | - | 74.7 | 15 | 10.3 | - | (1) VP: 550 °C, 120 min (2) GS + calcination: 600 °C, 10 min | - |

| 12 | Greco et al. [100] | Cured CF | - | - | - | - | Aeronautic | 550 °C, 20 min | 550 °C, 90 min |

| 13 | Cunliffe et al. [101] | (1) Thermoset polyester/styrene resin with GF (12%) (2) Thermoset polyester/styrene resin with GF (30%) (3) Phenolic resin with GF (31%) (4) Phenolic resin with CF (5) Epoxy resin with GF and CF (45%) (6) Polypropylene resin with GF tape (75%) (7) Vinylester resin with GF woven (70%) | Static-Bed reactor | 38.3–82.9 32.6 84.4–94.3 65 65.3–81.7 78.9 83.4 | 14.5–47.4 64.1 5.1–12 30.4 18–31.7 20 15 | 2.6–14.4 3.3 0.6–4.6 4.6 0.2–3 1.1 1.6 | Autombile, electric and circuit board | N2: 200 cm3/min 350–800 °C 60 min | 400−800 °C |

| 14 | Cunliffe and Williams [102] | Commercial polyester/GF (30%) automotive waste | Fixed Bed reactor | 39.3 | 39.6 | 5.8 | Autombile | N2: 3000 cm3/min 450 °C, 90 min | Muffle furnace 450 °C |

| 15 | Stoeffler et al. [103] | Cured & uncured CF | batch oven | - | - | - | Aerospace | 400 °C | - |

| 16 | Torres et al. [104] & Torres et al. [105] | GF polyester from SMC | Stainless steel Autoclave | 72.6–82.6 | 9.7–14.9 | 6.1–12.8 | Recovery of GF for composite | N2: 1 dm3/min 300–700 °C 30 min | - |

| 17 | López et al. [106] | T300/3 k CF | pilot-scale | 58.4–61.5 | 28.5–30.7 | 10–10.9 | - | 350–700 °C | 500 °C |

| 18 | López et al. [107] | GF from Polyester fiber glass | Thermolytic reactor | 68 | 24 | 8 | Ceramic | 550 °C 180 min | 1450 °C |

| 19 | Yun et al. [91] | GFRP from the Byproduct | TGA | - | - | - | - | N2: 200 mL/min RT-900 °C 5–20 °C/min | - |

| 20 | Yun et al. [108] | GFRP from the Byproduct | Batch Type Pyrolyzer Thermo Balance Reactor Wire Mesh Reactor | - - 20–80 | - - 15–50 | - - 5–15 | - - - | (1) N2: 1 L/min 500–900 °C 15 °C/min (2) N2: 0.315 L/min500–800 °C N2: 1 L/min (3) 600–1000 2,4,6,8 and 10 s | - - - |

| Thermal Analysis | Mechanical Testing | Morphological Testing | Others |

|---|---|---|---|

| TGA ATR-FTIR | TS (MPa), E(MPa), Elongation (%) | SEM, AFM, XPS | Adhesion, Micro bond, fiber pullout, Image analysis for fiber length distribution |

| Reference | Fiber Output | TS (MPa) | E (MPa) | Elongation (%) | Diameter | Stiffness | Fiber Length (mm) |

|---|---|---|---|---|---|---|---|

| Onwudili et al. [62] | GF | 11 | 428 | - | - | - | - |

| Stoeffler et al. [103] | CF | 680–720% increase | 680% increase | 20–35% increase | 6.5 | - | 5.6 |

| Giorgini et al. [92] | GF | 14 | 530 | - | - | - | - |

| López et al. [106] | CF | 2537–2544 | 210–220 | - | 6.70–7.00 | - | |

| Nahil and Williams [99] | CF | 2340–3270 910–1250 | 230–233 182–233 | 0.91–1.25 - | - - | - - | - - |

| Greco et al. [100] | CF | - | 8% reduction | - | 6.2 | 14% reduction | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdallah, R.; Juaidi, A.; Savaş, M.A.; Çamur, H.; Albatayneh, A.; Abdala, S.; Manzano-Agugliaro, F. RETRACTED: A Critical Review on Recycling Composite Waste Using Pyrolysis for Sustainable Development. Energies 2021, 14, 5748. https://doi.org/10.3390/en14185748

Abdallah R, Juaidi A, Savaş MA, Çamur H, Albatayneh A, Abdala S, Manzano-Agugliaro F. RETRACTED: A Critical Review on Recycling Composite Waste Using Pyrolysis for Sustainable Development. Energies. 2021; 14(18):5748. https://doi.org/10.3390/en14185748

Chicago/Turabian StyleAbdallah, Ramez, Adel Juaidi, Mahmut A. Savaş, Hüseyin Çamur, Aiman Albatayneh, Samer Abdala, and Francisco Manzano-Agugliaro. 2021. "RETRACTED: A Critical Review on Recycling Composite Waste Using Pyrolysis for Sustainable Development" Energies 14, no. 18: 5748. https://doi.org/10.3390/en14185748

APA StyleAbdallah, R., Juaidi, A., Savaş, M. A., Çamur, H., Albatayneh, A., Abdala, S., & Manzano-Agugliaro, F. (2021). RETRACTED: A Critical Review on Recycling Composite Waste Using Pyrolysis for Sustainable Development. Energies, 14(18), 5748. https://doi.org/10.3390/en14185748