Towards Net Zero Carbon Economy: Improving the Sustainability of Existing Industrial Infrastructures in the UK

Abstract

:1. Introduction

2. Methodology

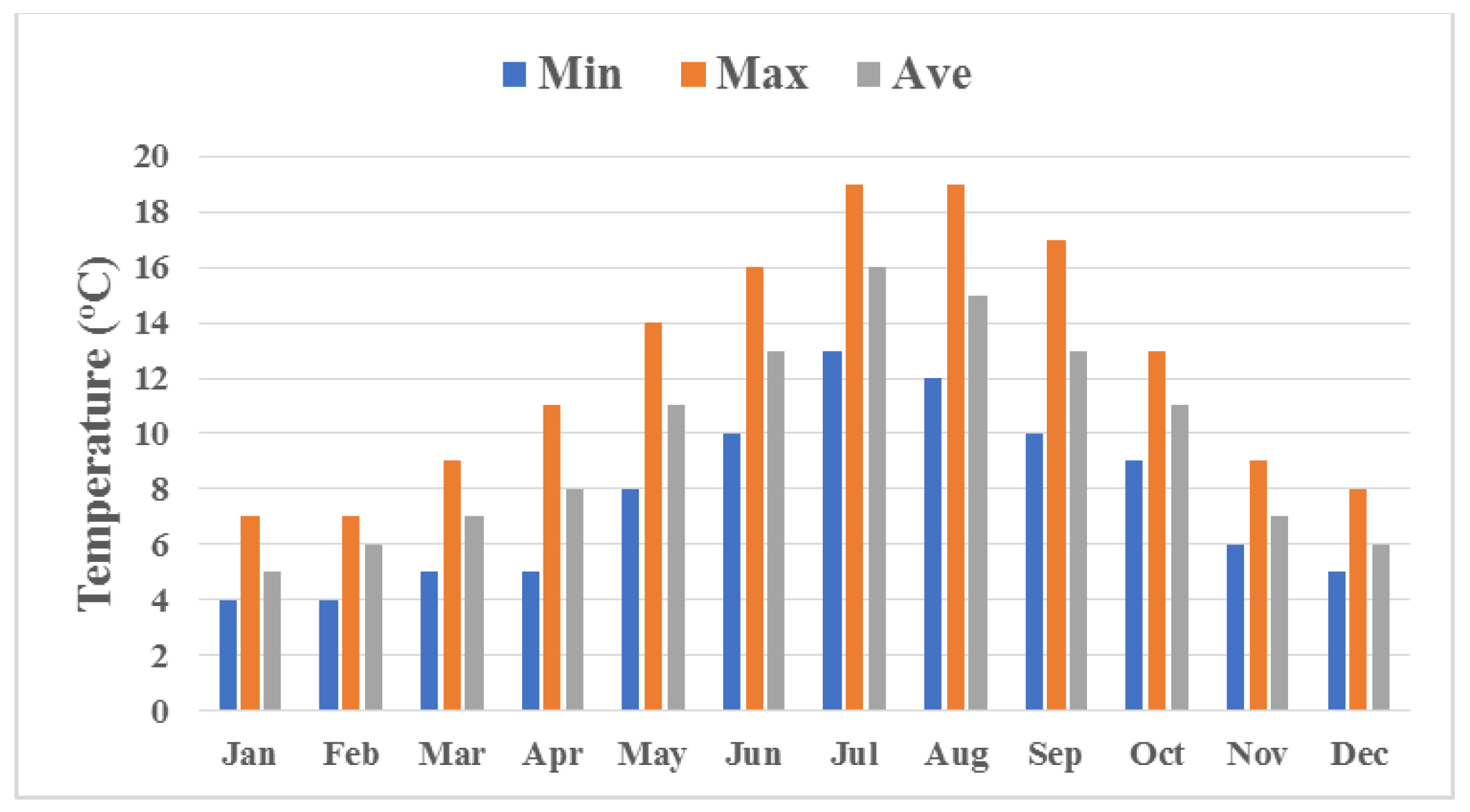

2.1. Description of the Case Study

2.2. Simulation Tool

3. Results and Discussion

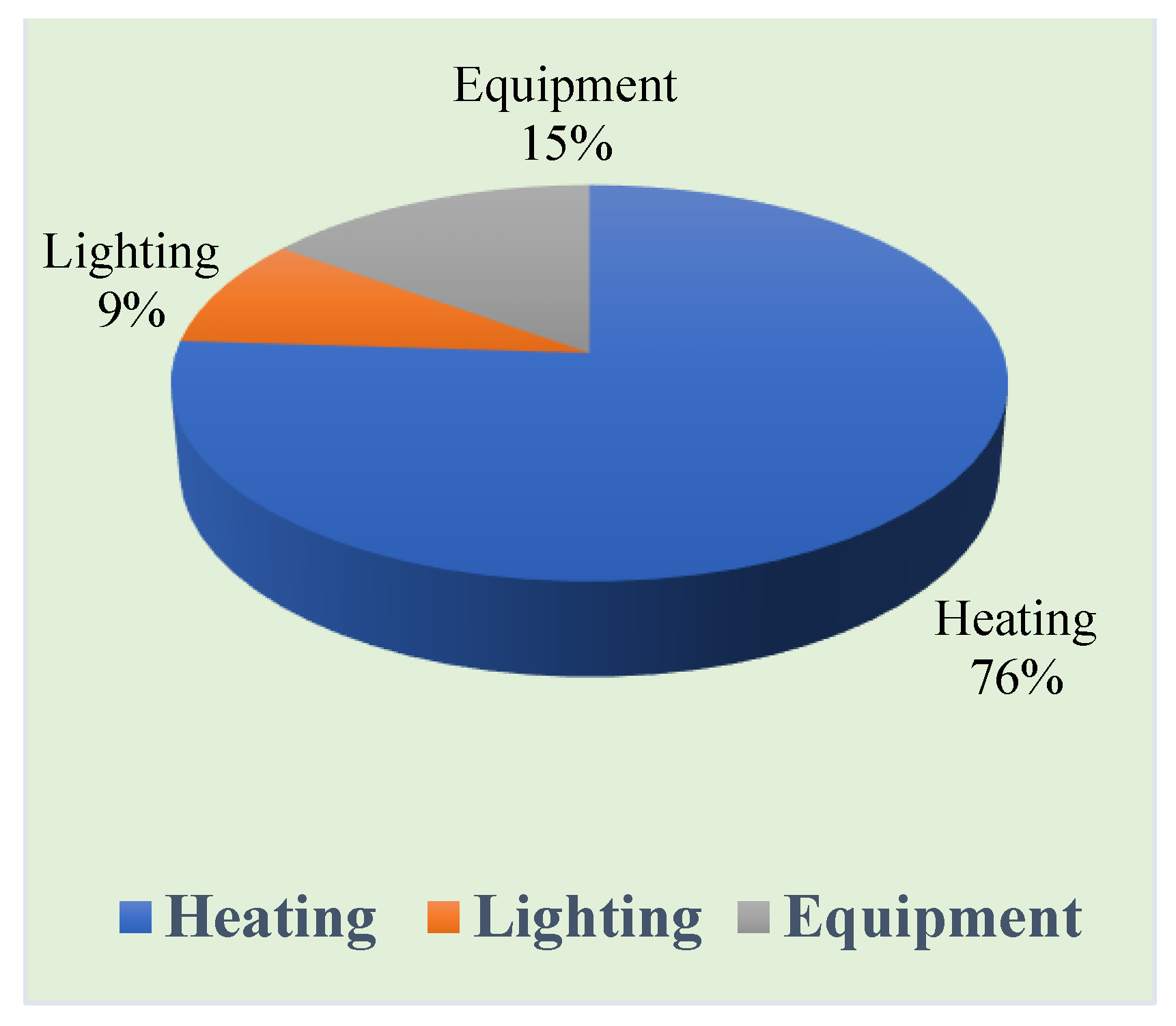

3.1. Carbon Assessment and Energy Consumption of the Current Building

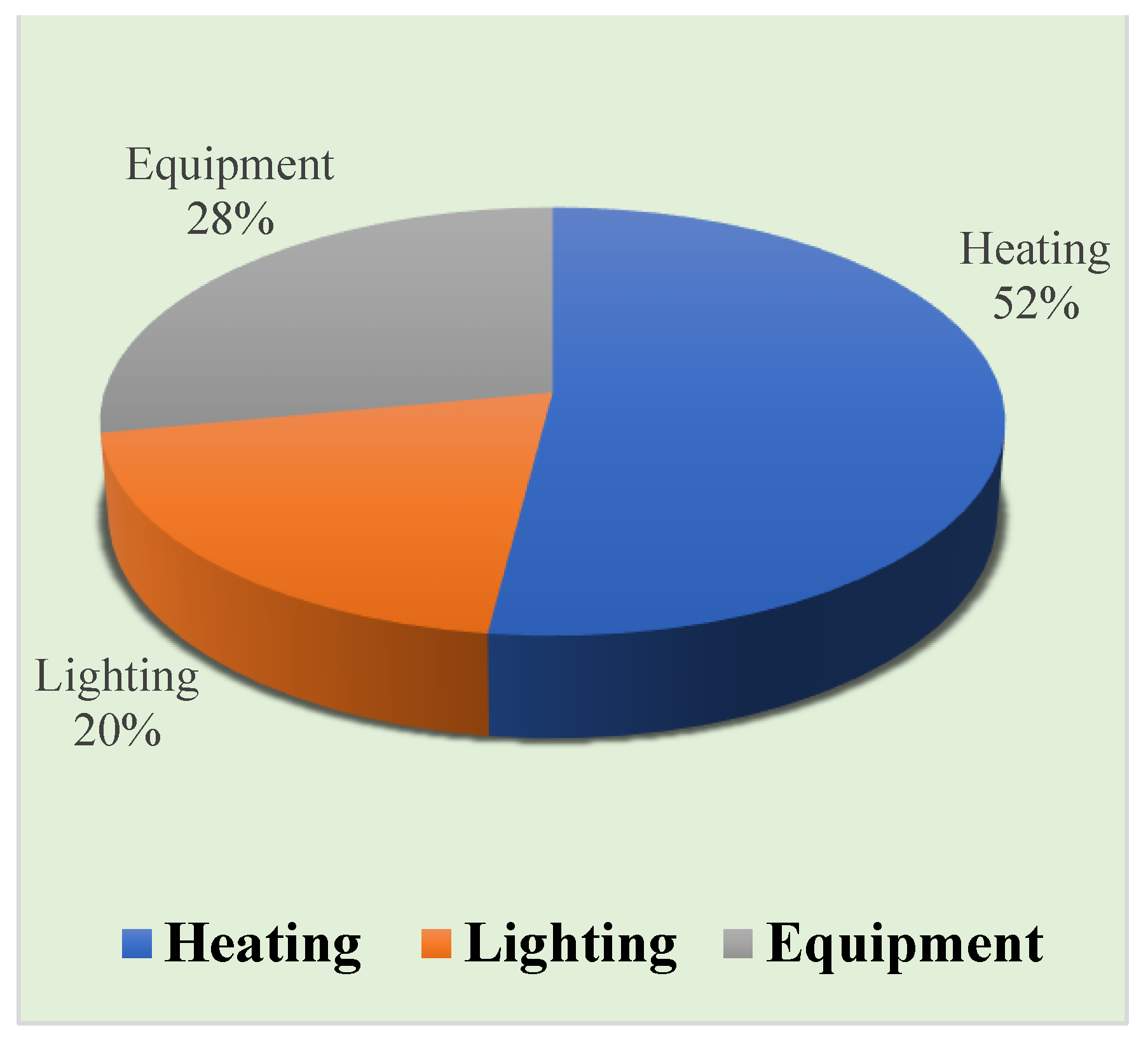

3.2. Carbon Assessment and Energy Consumption after Fabric Improvements

3.3. Production of Renewable Energy Onsite

3.4. Carbon Offsetting

3.5. Economic Analysis

4. Conclusions

- The current energy consumption of the building is 245.1 KWh/m2 and its current CO2 emissions is more than 28 tonnes annually.

- The combined installation of wall and floor insulations have significantly reduced the current energy consumption and CO2 emissions of the building by about 56.39%.

- There are an easy method of saving energy through the usage of energy efficient lights and equipment within the building.

- Depending on the size of PV system, the installation of PV solar panels could reduce the CO2 emissions of the building by up to 4.6 tonnes annually.

- The company could join an international carbon-offsetting scheme and pay a minimum of £168 annually and become a carbon neutral business and this figure could be reduced further with the application of some or all the proposed methods of improvements.

- The installation of 60 m2 PV system is the highly recommended improvemnt that could be implemented from both environmental and economic point of view.

- The cost of the proposed improvment methods is significantly higher than that of all the existing carbon offsetting schemes.

5. Recommendations for Future Works

- ❖

- Investigating the effect of using biomass for heating as a carbon neutral source

- ❖

- Studying the possibility of producing clear energy on site using clean energy sources such as fuel cells and wind energy

- ❖

- Investigating the effect of changing the location of the same building on the performance of the building

- ❖

- Studying how human behavior profile could influence the performance of the building and how carbon literacy could help is saving energy.

- ❖

- Investigating how the results would change if the building size increased or decreased.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Parliament What Is Carbon Neutrality and How Can It Be Achieved by 2050? Available online: https://www.europarl.europa.eu/news/en/headlines/society/20190926STO62270/what-is-carbon-neutrality-and-how-can-it-be-achieved-by-2050 (accessed on 10 March 2021).

- Guterres, A. Carbon Neutrality by 2050: The World’s Most Urgent Mission. Available online: https://www.un.org/sg/en/content/sg/articles/2020–12–11/carbon-neutrality-2050-theworld’s-most-urgent-mission (accessed on 12 March 2021).

- Abdellatif, M.; Osman, Y.; Al Khaddar, R.M. Towards a Low Carbon Design: A case study of an Industrial Building. In Proceedings of the International Architecture and Art Congress, Istanbul, Turkey, 18–19 April 2020. [Google Scholar]

- Shepheard, M. UK Net Zero Target. Available online: https://www.instituteforgovernment.org.uk/explainers/net-zero-target (accessed on 12 March 2021).

- Kuriakose, J. What Would Carbon Neutrality Mean for the UK? Available online: https://www.bbc.co.uk/bitesize/articles/zfw4f4j (accessed on 15 March 2021).

- Gummer, J.; Chater, N.; Fankhauser, S.; Hoskins, B.; Johnson, P.; King, J.; Krebs, J.; Lequere, C.; Skea, J. Meeting Carbon Budgets. Progress Report to Parliament 2013; Committe on Climate Change: London, UK, 2013. [Google Scholar]

- Aldossary, N.A.; Rezgui, Y.; Kwan, A. Domestic energy consumption patterns in a hot and humid climate: A multiple-case study analysis. Appl. Energy 2014, 114, 353–365. [Google Scholar] [CrossRef]

- Šujanová, P.; Rychtáriková, M.; Sotto Mayor, T.; Hyder, A. A healthy, energy-efficient and comfortable indoor environment, a review. Energies 2019, 12, 1414. [Google Scholar] [CrossRef] [Green Version]

- Gou, S.; Nik, V.M.; Scartezzini, J.-L.; Zhao, Q.; Li, Z. Passive design optimization of newly-built residential buildings in Shanghai for improving indoor thermal comfort while reducing building energy demand. Energy Build. 2018, 169, 484–506. [Google Scholar] [CrossRef]

- Jazaeri, J.; Gordon, R.L.; Alpcan, T. Influence of building envelopes, climates, and occupancy patterns on residential HVAC demand. J. Build. Eng. 2019, 22, 33–47. [Google Scholar] [CrossRef]

- Watson, D. Climatatic Design: Energy Efficient Building Principles and Practices; McGraw-Hill: New York, NY, USA, 1983. [Google Scholar]

- Jannat, N.; Hussien, A.; Abdullah, B.; Cotgrave, A. A comparative simulation study of the thermal performances of the building envelope wall materials in the tropics. Sustainability 2020, 12, 4892. [Google Scholar] [CrossRef]

- Oree, V.; Khoodaruth, A.; Teemul, H. A case study for the evaluation of realistic energy retrofit strategies for public office buildings in the Southern Hemisphere. In Proceedings of the Building Simulation, Newcastle, UK, 12–14 September 2016; Springer: Berlin/Heidelberg, Germany, 2016; Volume 9, pp. 113–125. [Google Scholar]

- Seifhashemi, M.; Capra, B.R.; Milller, W.; Bell, J. The potential for cool roofs to improve the energy efficiency of single storey warehouse-type retail buildings in Australia: A simulation case study. Energy Build. 2018, 158, 1393–1403. [Google Scholar] [CrossRef]

- Liu, L.; Wu, D.; Li, X.; Hou, S.; Liu, C.; Jones, P.J. Effect of geometric factors on the energy performance of high-rise office towers in Tianjin, China. In Proceedings of the Building Simulation, San Francisco, CA, USA, 7–9 August 2017; Springer: Berlin/Heidelberg, Germany, 2017; Volume 10, pp. 625–641. [Google Scholar]

- Liu, L.; Lin, B.; Peng, B. Correlation analysis of building plane and energy consumption of high-rise office building in cold zone of China. In Proceedings of the Building Simulation, Hyderabad, India, 7–9 December 2015; Springer: Berlin/Heidelberg, Germany, 2015; Volume 8, pp. 487–498. [Google Scholar]

- Aste, N.; Del Pero, C. Energy retrofit of commercial buildings: Case study and applied methodology. Energy Effic. 2013, 6, 407–423. [Google Scholar] [CrossRef]

- Friess, W.A.; Rakhshan, K.; Davis, M.P. A global survey of adverse energetic effects of increased wall insulation in office buildings: Degree day and climate zone indicators. Energy Effic. 2017, 10, 97–116. [Google Scholar] [CrossRef]

- Ndiaye, D. The impact of building massing on net-zero achievability for office buildings. In Proceedings of the Building Simulation, Cambridge, UK, 11–12 September 2018; Springer: Berlin/Heidelberg, Germany, 2018; Volume 11, pp. 435–438. [Google Scholar]

- Ikedi, C.U.; Okoroh, M.I. Monitoring results of CO2 avoidance with an 8.5 kWh solar electric generator integrated in a high rise commercial building in UK. Int. J. Sustain. Built Environ. 2015, 4, 189–201. [Google Scholar] [CrossRef] [Green Version]

- Mariaud, A.; Acha, S.; Ekins-Daukes, N.; Shah, N.; Markides, C.N. Integrated optimisation of photovoltaic and battery storage systems for UK commercial buildings. Appl. Energy 2017, 199, 466–478. [Google Scholar] [CrossRef]

- Holiday Weather Liverpool, United Kingdom: Annual Weather Averages. Available online: https://www.holiday-weather.com/liverpool/averages/ (accessed on 5 April 2021).

- CIBSE, T. Energy Benchmarks; The Chartered Institution of Building Services Engineers: London, UK, 2008. [Google Scholar]

- Fontanini, A.; Olsen, M.G.; Ganapathysubramanian, B. Thermal comparison between ceiling diffusers and fabric ductwork diffusers for green buildings. Energy Build. 2011, 43, 2973–2987. [Google Scholar] [CrossRef] [Green Version]

- Dombaycı, Ö.A.; Gölcü, M.; Pancar, Y. Optimization of insulation thickness for external walls using different energy-sources. Appl. Energy 2006, 83, 921–928. [Google Scholar] [CrossRef]

- Li, Y.F.; Chow, W.K. Optimum insulation-thickness for thermal and freezing protection. Appl. Energy 2005, 80, 23–33. [Google Scholar] [CrossRef]

- Bojic, M.; Yik, F.; Leung, W. Thermal insulation of cooled spaces in high rise residential buildings in Hong Kong. Energy Convers. Manag. 2002, 43, 165–183. [Google Scholar] [CrossRef]

- Lu, M.; Lai, J. Review on carbon emissions of commercial buildings. Renew. Sustain. Energy Rev. 2020, 119, 109545. [Google Scholar] [CrossRef]

- Eroglu, M.; Dursun, E.; Sevencan, S.; Song, J.; Yazici, S.; Kilic, O. A mobile renewable house using PV/wind/fuel cell hybrid power system. Int. J. Hydrogen Energy 2011, 36, 7985–7992. [Google Scholar] [CrossRef]

- Castillo-Cagigal, M.; Gutiérrez, A.; Monasterio-Huelin, F.; Caamaño-Martín, E.; Masa, D.; Jiménez-Leube, J. A semi-distributed electric demand-side management system with PV generation for self-consumption enhancement. Energy Convers. Manag. 2011, 52, 2659–2666. [Google Scholar] [CrossRef] [Green Version]

- Omer, S.A.; Wilson, R.; Riffat, S.B. Monitoring results of two examples of building integrated PV (BIPV) systems in the UK. Renew. Energy 2003, 28, 1387–1399. [Google Scholar] [CrossRef]

- Carbon Footprint Ltd. Carbon Offset Options. Available online: https://www.carbonfootprint.com/offset.aspx?o=0.023&r=ShopOffset (accessed on 1 May 2021).

| Items | Depiction | Thicknesses (mm) | U-Magnitude (W/m2 K) |

|---|---|---|---|

| External wall | Steel sheet metal | 10 | 5.880 |

| Internal Partitions | Plasterboard-Cavity-Plasterboard | 10-50-10 | 1.870 |

| Doors | Wooden door | 37 | 2.200 |

| Skylight | Double glazing | 24 | 2.300 |

| Roof | Steel sheet metal-Insulation-Plasterboard | 10-150-10 | 0.193 |

| Floor | Reinforced concrete | 100 | 3.950 |

| Electricity | ||

|---|---|---|

| KWh/m2 | KgCO2/m2 | |

| Current performance | 245.1 | 127.2 |

| Benchmarks | 95 | 52.3 |

| Items | Depiction | Thicknesses (mm) | U-Magnitude (W/m2 K) |

|---|---|---|---|

| External wall | Steel sheet metal-Insulation-Plasterboard | 10-50-10 | 0.531 |

| Internal Partitions | Plasterboard-Cavity-Plasterboard | 10-50-10 | 1.87 |

| Doors | Wooden door | 37 | 2.20 |

| Skylight | Double glazing | 24 | 2.3 |

| Roof | Steel sheet metal-Insulation-Plasterboard | 10-150-10 | 0.193 |

| Floor | Reinforced concrete-Insulation-Chipboard flooring | 100-25-20 | 0.892 |

| Electricity | |||||

|---|---|---|---|---|---|

| KWh/m2 | KWh | KgCO2/m2 | KgCO2 | Reduction of CO2 (%) | |

| Current performance | 245.1 | 54,109.6 | 127.2 | 28,083 | - |

| Wall | 191.3 | 42,241.5 | 99.3 | 21,923 | 21.93 |

| Floor | 183.3 | 40,477.2 | 95.1 | 21,008 | 25.19 |

| Wall and Floor | 106.9 | 23,598.0 | 55.5 | 12,247 | 56.39 |

| Benchmarks | 95 | - | 52.3 | - | - |

| Size of PV (kWp) | Area of the Roof (m2) | Generated Electricity (KWh) | CO2 Reduction (Tonne/Year) | Annual Electricity Saving% (Current Building) | Annual Electricity Saving% (with Insulations) |

|---|---|---|---|---|---|

| 5.8 | 30 | 4460 | 2.3 | 8 | 19 |

| 11.5 | 60 | 8920 | 4.6 | 16 | 38 |

| Scheme | Price/Tonne | Certified Body |

|---|---|---|

| Global Portfolio | £6 | Verified Carbon Standard |

| UK Tree Planting | £12.9 | Verified Carbon Standard |

| Reforestation in Kenya | £9.5 | Verified Carbon Standard |

| Americas Portfolio | £7 | Verified Carbon Standard or The Gold Standard |

| Community Projects | £8 | The Gold Standard |

| Global Portfolio | UK Tree Planting | Reforestation in Kenya | Americas Portfolio | Community Projects | |

|---|---|---|---|---|---|

| Current performance | 168 | 362 | 267 | 197 | 225 |

| Wall insulation | 132 | 283 | 208 | 153 | 175 |

| Floor insulation | 126 | 271 | 200 | 147 | 168 |

| Wall and Floor insulation | 73 | 158 | 116 | 86 | 98 |

| 30 m2 PV | 155 | 333 | 245 | 180 | 206 |

| 60 m2 PV | 141 | 303 | 223 | 164 | 188 |

| Wall and Floor insulation+ 30 m2 PV | 60 | 128 | 94 | 70 | 80 |

| Wall and Floor insulation + 60 m2 PV | 46 | 99 | 73 | 54 | 61 |

| Improvement | Estimated Total Cost (£) |

|---|---|

| Current performance | 0 |

| Wall insulation | 24,300 |

| Floor insulation | 23,800 |

| Wall and Floor insulation | 48,100 |

| 30 m2 PV | 7300 |

| 60 m2 PV | 10,600 |

| Wall and Floor insulation+ 30 m2 PV | 55,400 |

| Wall and Floor insulation + 60 m2 PV | 58,700 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shubbar, A.; Nasr, M.; Falah, M.; Al-Khafaji, Z. Towards Net Zero Carbon Economy: Improving the Sustainability of Existing Industrial Infrastructures in the UK. Energies 2021, 14, 5896. https://doi.org/10.3390/en14185896

Shubbar A, Nasr M, Falah M, Al-Khafaji Z. Towards Net Zero Carbon Economy: Improving the Sustainability of Existing Industrial Infrastructures in the UK. Energies. 2021; 14(18):5896. https://doi.org/10.3390/en14185896

Chicago/Turabian StyleShubbar, Ali, Mohammed Nasr, Mayadah Falah, and Zainab Al-Khafaji. 2021. "Towards Net Zero Carbon Economy: Improving the Sustainability of Existing Industrial Infrastructures in the UK" Energies 14, no. 18: 5896. https://doi.org/10.3390/en14185896

APA StyleShubbar, A., Nasr, M., Falah, M., & Al-Khafaji, Z. (2021). Towards Net Zero Carbon Economy: Improving the Sustainability of Existing Industrial Infrastructures in the UK. Energies, 14(18), 5896. https://doi.org/10.3390/en14185896