A Systematic Review of HPM Energy Absorbers for Building Applications

Abstract

1. Introduction

- meeting the minimum requirements for physical and mechanical properties as well as durability and sustainability (defined in the commonly used design standards),

- meeting the minimum, pre-assumed requirements for shielding effectiveness (with regard to the individual needs of a particular project),

- achievement of a low manufacturing cost.

2. Claddings

3. Concrete and Mortar

4. Bricks and Hollow Masonry Units—Small-Sized Elements

5. Paint Coatings

6. Final Conclusions

6.1. Summary of Review

6.2. Implications for Practice

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Dras, M.; Kałuski, M.; Szafrańska, M. HPM pulses—Disturbances and systems interaction—Basic issues. Przegląd Elektrotechniczny 2015, 1, 13–16. (In Polish) [Google Scholar] [CrossRef]

- Schamiloglu, E. High power microwave sources and applications. In Proceedings of the International Microwave Symposium Digest, Fort Worth, TX, USA, 6–11 June 2004. [Google Scholar]

- Lu, Z.; Jian, C.; Wan, S.; Liu, P. Research on new technology on protection of electronic systems from high power electromagnetic pulse. In Proceedings of the Progress in Electromagnetics Research Symposium Proceedings, Xi’an, China, 22–26 March 2010. [Google Scholar]

- Schurig, D.; Mock, J.J.; Justice, B.J.; Cummer, S.A.; Pendry, J.B.; Starr, A.F.; Smith, D.R. Metamaterial electromagnetic cloak at microwave frequencies. Science 2006, 314, 977–980. [Google Scholar] [CrossRef]

- Lois, G. Electromagnetic Absorption of a Nickel Zinc Ferrite System at Low Frequency; The Ohio State University: Columbus, OH, USA, 1999. [Google Scholar]

- Liu, Y.; Luo, F.; Su, J.; Zhou, W.; Zhu, D. Electromagnetic and microwave absorption properties of the Nickel/Ti3SiC2 hybrid powders in X-band. J. Magn. Magn. Mater. 2014, 365, 126–131. [Google Scholar] [CrossRef]

- Yu, Y.; Ma, H.; Tian, X.; Du, H.; Xia, S.; Qu, S. Synthesis and electromagnetic absorption properties of micro-nano nickel powders prepared with liquid phase reduction method. J. Adv. Dielectr. 2016, 6, 1650025. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, J.; Liu, Q.; Yuan, J. Microwave absorption of electroless Ni–Co–P-coated SiO2 powder. Appl. Surf. Sci. 2009, 255, 6629–6633. [Google Scholar] [CrossRef]

- Fang, J.; Zha, W.; Kang, M.; Lu, S.; Cui, L.; Li, S. Microwave absorption response of nickel/graphene nanocomposites prepared by electrodeposition. J. Mater. Sci. 2013, 48, 8060–8067. [Google Scholar] [CrossRef]

- Zhang, H.; Tian, X.; Wang, C.; Luo, H.; Hu, J.; Shen, Y.; Xie, A. Facile synthesis of RGO/NiO composites and their excellent electromagnetic wave absorption properties. Appl. Surf. Sci. 2014, 314, 228–232. [Google Scholar] [CrossRef]

- Słonka, T.; Głowiński, J.; Baczyńska, T.; Hałat, A. Material Absorbing Electromagnetic Waves. PL Patent 203,956 B1; Filed 20 October 2003, Patented 30 November 2009 (In Polish).

- Regulation (EU) No 305/2011 of the European Parliament and of the European Council of 9 March 2011 laying down harmonised conditions for the marketing of construction products and repealing Council Directive 89/106/EEC. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32011R0305 (accessed on 1 July 2021).

- Act of 7 July 1994 construction law. Journal of Laws of the Republic of Poland, No. 89, item 414. Available online: https://www.global-regulation.com/translation/poland/2986349/the-act-of-7-july-1994%252c-construction-law.html (accessed on 1 July 2021).

- Act of 16 April 2004 on construction products. Journal of Laws of the Republic of Poland, No. 92, item 881. Available online: https://www.global-regulation.com/translation/poland/3353949/the-act-of-16-april-2004-on-the-protection-of-nature.html (accessed on 1 July 2021).

- Majcher, K.; Musiał, M.; Pakos, W.; Różański, A.; Sobótka, M.; Trapko, T. Methods of protecting buildings against HPM radiation—A review of materials absorbing the energy of electromagnetic waves. Materials 2020, 13, 5509. [Google Scholar] [CrossRef]

- Guan, H.; Liu, S.; Duan, Y.; Cheng, J. Cement based electromagnetic shielding and absorbing building materials. Cem. Concr. Compos. 2006, 28, 468–474. [Google Scholar] [CrossRef]

- Cao, J.; Chung, D.D.L. Colloidal graphite as an admixture in cement and as a coating on cement for electromagnetic interference shielding. Cem. Concr. Res. 2003, 33, 1737–1740. [Google Scholar] [CrossRef]

- Cao, J.; Chung, D.D.L. Coke powder as an admixture in cement for electromagnetic interference shielding. Carbon 2003, 41, 2433–2436. [Google Scholar] [CrossRef]

- Chen, P.W.; Chung, D.D.L. A comparative study of concretes reinforced with carbon, polyethylene, and steel fibers and their improvement by latex addition. ACI Mater. J. 1996, 93, 129–133. [Google Scholar] [CrossRef]

- Giergiczny, Z. Fly Ash in Cement and Concrete Composition, 2nd ed.; Publishing House of Silesian University of Technology: Gliwice, Poland, 2013. (In Polish) [Google Scholar]

- Wu, L.Z.; Ding, J.; Jiang, H.B.; Chen, L.F.; Ong, C.K. Particle size influence to the microwave properties of iron based magnetic particulate composites. J. Magn. Magn. Mater. 2005, 285, 233–239. [Google Scholar] [CrossRef]

- Meng, W.; Yuping, D.; Shunhua, L.; Xiaogang, L.; Zhijiang, J. Absorption properties of carbonyl-iron/carbon black double-layer microwave absorbers. J. Magn. Magn. Mater. 2009, 321, 3442–3446. [Google Scholar] [CrossRef]

- Pretorius, J.C.; Maharaj, B.T. Improvement of electromagnetic wave (EMW) shielding through inclusion of electrolytic manganese dioxide in cement and tile-based composites with application for indoor wireless communication systems. Int. J. Phys. Sci. 2013, 8, 295–301. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, W. Microwave absorbing properties of double-layer cementitious composites containing Mn–Zn ferrite. Cem. Concr. Compos. 2010, 32, 726–730. [Google Scholar] [CrossRef]

- Guan, B.; Ding, D.; Wang, L.F.; Wu, J.; Xiong, R. The electromagnetic wave absorbing properties of cement-based composites using natural magnetite powders as absorbers. Mater. Res. Express 2017, 4, 051603. [Google Scholar] [CrossRef]

- Wang, D.; Yang, P.; Hou, P.; Zhang, L.; Zhang, X.; Zhou, Z.; Xie, N.; Huang, S.; Cheng, X. Cement-based composites endowed with novel functions through controlling interface microstructure from Fe3O4@SiO2 nanoparticles. Cem. Concr. Compos. 2017, 80, 268–276. [Google Scholar] [CrossRef]

- Gaitero, J.; Campillo, I.; Guerrero, A. Reduction of the calcium leaching rate of cement paste by addition of silica nanoparticles. Cem. Concr. Res. 2008, 38, 1112–1118. [Google Scholar] [CrossRef]

- Esfahani, A.S.; Katbab, A.A.; Dehkhoda, P.; Karami, H.R.; Barikani, M.; Sadeghi, S.H.H.; Ghorbani, A. Preparation and characterization of foamed polyurethane/silicone rubber/graphite nanocomposite as radio frequency wave absorbing material: The role of interfacial compatibilization. Compos. Sci. Technol. 2012, 72, 382–389. [Google Scholar] [CrossRef]

- Méjean, C.; Pometcu, L.; Benzerga, R.; Sharaiha, A.; Le Paven-Thivet, C.; Badard, M.; Pouliguen, P. Electromagnetic absorber composite made of carbon fibers loaded epoxy foam for anechoic chamber application. Mater. Sci. Eng. B 2017, 220, 59–65. [Google Scholar] [CrossRef]

- Xingjun, L.; Mingli, C.; Yan, L.; Xin, L.; Qian, L.; Rong, T.; Qi, W.; Yuping, D. A new absorbing foam concrete: Preparation and microwave absorbing properties. Adv. Concr. Constr. 2015, 3, 103–111. [Google Scholar] [CrossRef]

- Mehdiabadi, A.; Tabatabeinasab, M.; Spulbar, C.; Yazdi, A.K.; Birau, R. Are we ready for the challenge of Banks 4.0? Designing a roadmap for banking systems in Industry 4.0. Int. J. Financ. Stud. 2020, 8, 32. [Google Scholar] [CrossRef]

- Kumar, K.K.S.; Rao, C.R.K.; Vijayan, M.; Trivedi, D.C. EMI shielding: Methods and materials—A review. J. Appl. Polym. Sci. 2009, 112, 2073–2086. [Google Scholar] [CrossRef]

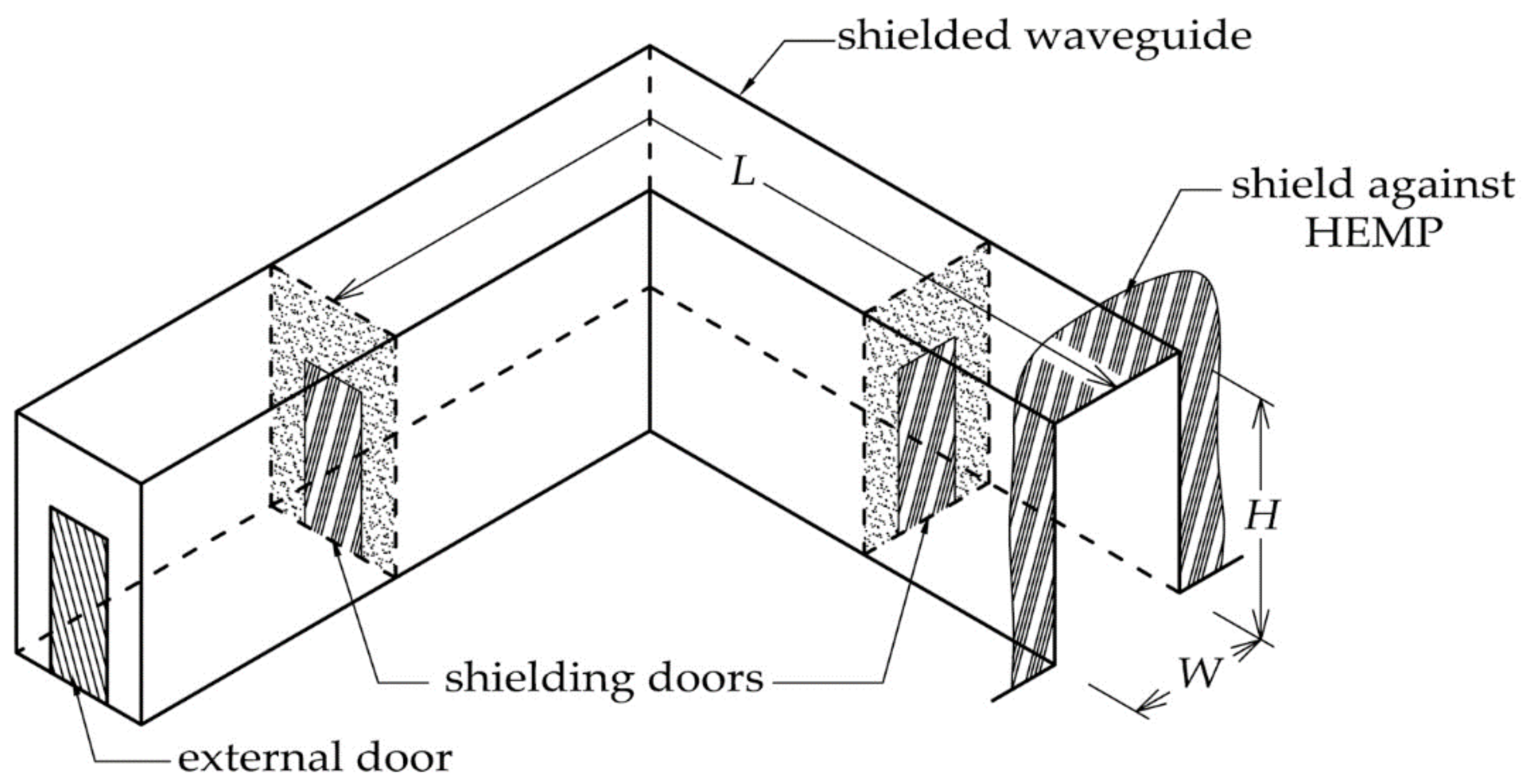

- Chmielińska, J.; Kuchta, M.; Kubacki, R.; Dras, M.; Wierny, K. Selected methods of protection of electronic devices against electromagnetic weapons. Przegląd Elektrotechniczny 2016, 92, 1–8. (In Polish) [Google Scholar] [CrossRef]

- Kessel, W. Electromagnetic Shielding. U.S. Patent 7,576,289 B2; Filed 17 May 2006, Patented 18 August 2009,

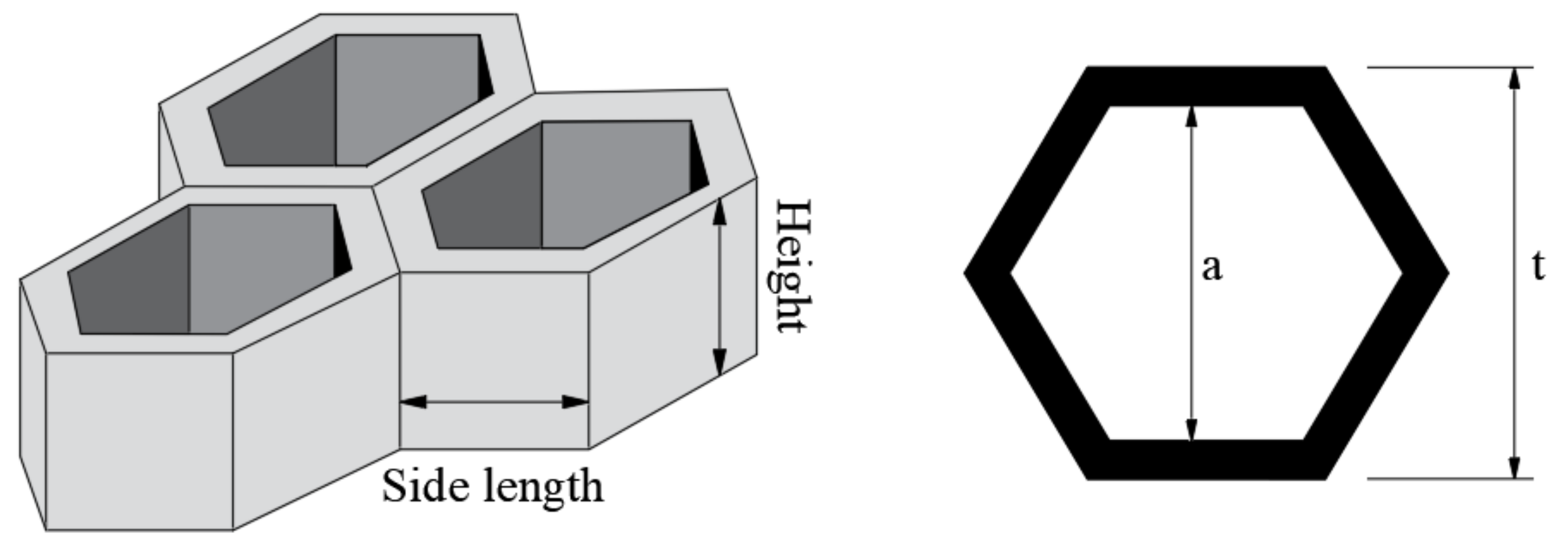

- Xie, S.; Ji, Z.; Yang, Y.; Hou, G.; Wang, J. Electromagnetic wave absorption properties of honeycomb structured plasterboards in S and C bands. J. Build. Eng. 2016, 217, 217–223. [Google Scholar] [CrossRef]

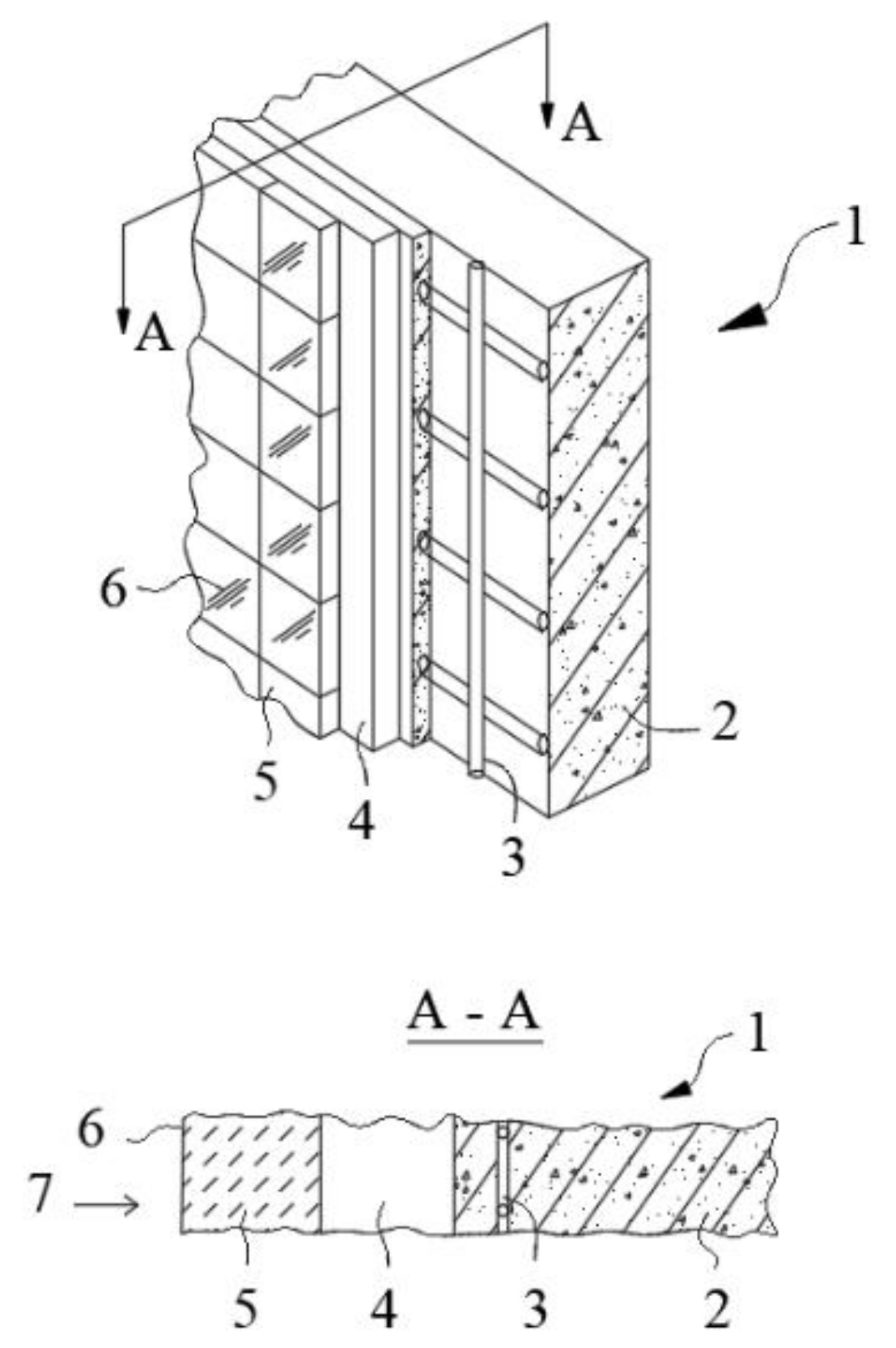

- Xie, S.; Yang, Y.; Hou, G.; Wang, J.; Ji, Z. Development of layer structured wave absorbing mineral wool boards for indoor electromagnetic radiation protection. J. Build. Eng. 2016, 5, 79–85. [Google Scholar] [CrossRef]

- Yuan, Q.P.; Lu, K.Y.; Fu, F. Process and structure of electromagnetic shielding plywood composite laminated with carbon fiber paper. Open Mater. Sci. J. 2014, 8, 99–107. [Google Scholar] [CrossRef]

- Hirose, K. Electromagnetic Wave Absorber. U.S. Patent 2014/0132439 A1; Filed 9 July 2013, Patented 15 May 2014,

- Joshi, V.; Kimura, K.; De Araujo, C.A.P.; Kiyokawa, H. Materials for Electromagnetic Wave Absorption Panels. U.S. Patent 5,853,889; Filed 13 January 1997, Patented 29 December 1998,

- Timmerman, A.T. Microwave-Absorbing Material. EP Patent 0 420 513 A1; Filed 21 September 1990, Patented 3 April 1995,

- Mayer, P.; Kaczmar, J.; Sowa, A.; Vogt, A.; Kołodziej, H.; Strzelecki, S. Energy-Absorbing Coating, Especially the Energy Electromagnetic and Mechanical Waves. Patent 405,814; Filed 28 October 2013, Patented 4 August 2014 (In Polish).

- Tian, X.; Hu, H. Test and study on electrical property of conductive concrete. Procedia Earth Planet. Sci. 2012, 5, 83–87. [Google Scholar] [CrossRef]

- Los, P.; Lukomska, A.; Jeziorska, R. Metal-polymer composites for electromagnetic interference shielding applications. Polimery 2016, 61, 663–669. [Google Scholar] [CrossRef]

- Chung, D.D.L. Dispersion of short fibers in cement. J. Mater. Civ. Eng. 2005, 17, 379–383. [Google Scholar] [CrossRef]

- Chung, D.D.L. Comparison of submicron-diameter carbon filaments and conventional carbon fibers as fillers in composite materials. Carbon 2001, 39, 1119–1125. [Google Scholar] [CrossRef]

- Chung, D.D.L. Materials for electromagnetic interference shielding. J. Mater. Eng. Perform. 2000, 9, 350–354. [Google Scholar] [CrossRef]

- Chiou, J.M.; Zheng, Q.; Chung, D.D.L. Electromagnetic interference shielding by carbon fiber reinforced cement. Composites 1989, 20, 379–381. [Google Scholar] [CrossRef]

- Kim, T.-J.; Park, C.K. Flexural and tensile strength developments of various shape carbon fiber-reinforced lightweight cementitious composites. Cem. Concr. Res. 1998, 28, 955–960. [Google Scholar] [CrossRef]

- Chung, D.D.L. Cement reinforced with short carbon fibers: A multifunctional material. Compos. Part B 2000, 31, 511–526. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, W. Electromagnetic shielding and absorption properties of fiber reinforced cementitious composites. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2012, 27, 172–176. [Google Scholar] [CrossRef]

- Laukaitis, A.; Sinica, M.; Balevičius, S.; Levitas, B. Investigation of electromagnetic wave absorber based on carbon fiber reinforced aerated concrete using time-domain method. Acta Phys. Pol. A 2008, 113, 1047–1050. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Li, B.Y.; Liu, S.H.; Hao, W.J. Electromagnetic wave absorption properties and mechanical properties of aramid fiber reinforced cement. Adv. Mater. Res. 2012, 512, 2873–2877. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, Y.; Hao, W. Electromagnetic wave absorption properties of glass fiber reinforced cement filled with carbon black. Adv. Mater. Res. 2014, 912–914, 127–130. [Google Scholar] [CrossRef]

- Yee, S.K.; Jenu, M.Z.M. Shielding effectiveness of concrete with graphite fine powder in between 50 MHz to 400 MHz. In Proceedings of the 2013 Asia-Pacific Symposium on Electromagnetic Compatibility (APEMC), Melbourne, Australia, 20–23 May 2013. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Ahmed, S.; Savi, P. Improvement in electromagnetic interference shielding effectiveness of cement composites using carbonaceous nano/micro inerts. Constr. Build. Mater. 2015, 85, 208–216. [Google Scholar] [CrossRef]

- Frenzel, T.; Stumpf, J.; Koch, M. Shielding effectiveness of original and modified building materials. Adv. Radio Sci. 2007, 5, 69–73. [Google Scholar] [CrossRef][Green Version]

- Wen, S.; Chung, D.D.L. Electromagnetic interference shielding reaching 70 dB in steel fiber cement. Cem. Concr. Res. 2004, 34, 329–332. [Google Scholar] [CrossRef]

- De Leo, R.; Gradoni, G.; Mazzoli, A.; Moglie, F.; Moriconi, G.; Primiani, W.M. DSP cement composites for electromagnetic shielding: Practice and experimental analysis. In Proceedings of the 2009 International Symposium on Electromagnetic Compatibility-EMC Europe, International Symposium on Electromagnetic Compatibility, Athens, Greece, 11–12 June 2009. [Google Scholar] [CrossRef]

- Nam, I.W.; Lee, H.K.; Sim, J.B.; Choi, S.M. Electromagnetic characteristics of cement matrix materials with carbon nanotubes. ACI Mater. J. 2012, 109, 363–370. [Google Scholar] [CrossRef]

- Yafei, S.; Peiwei, G.; Hailong, P.; Honwei, L.; Xiaolin, L.; Kai, S. Electromagnetic wave absorbing and mechanical properties of cement-based composite panel with different nanomaterials. Adv. Compos. Lett. 2017, 26, 6–11. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, W. Three-layer microwave absorber using cement-based composites. Mag. Concr. Res. 2011, 63, 157–162. [Google Scholar] [CrossRef]

- Wu, F.; Hao, W.; Zhang, Y.; Wang, M.; Chen, D.; Yi, Y.; Zhao, H.; Dong, Y.; Yu, X. The double-layer matching design of broad-band foam cement absorbing panel for electromagnetic pollution control. Appl. Mech. Mater. 2013, 401–403, 924–928. [Google Scholar] [CrossRef]

- Guan, H.; Liu, S.; Duan, Y. Expanded polystyrene as an admixture in cement-based composites for electromagnetic absorbing. J. Mater. Eng. Perform. 2007, 16, 68–72. [Google Scholar] [CrossRef]

- Hongtao, G.; Shunhua, L.; Yuping, D.; Yanbo, Z. Investigation of the electromagnetic characteristics of cement based composites filled with EPS. Cement Concr. Comp. 2007, 29, 49–54. [Google Scholar] [CrossRef]

- Chung, D.D.L.; Zheng, Q.J. Electronic properties of carbon fiber reinforced gypsum plaster. Compos. Sci. Technol. 1989, 36, 1–6. [Google Scholar] [CrossRef]

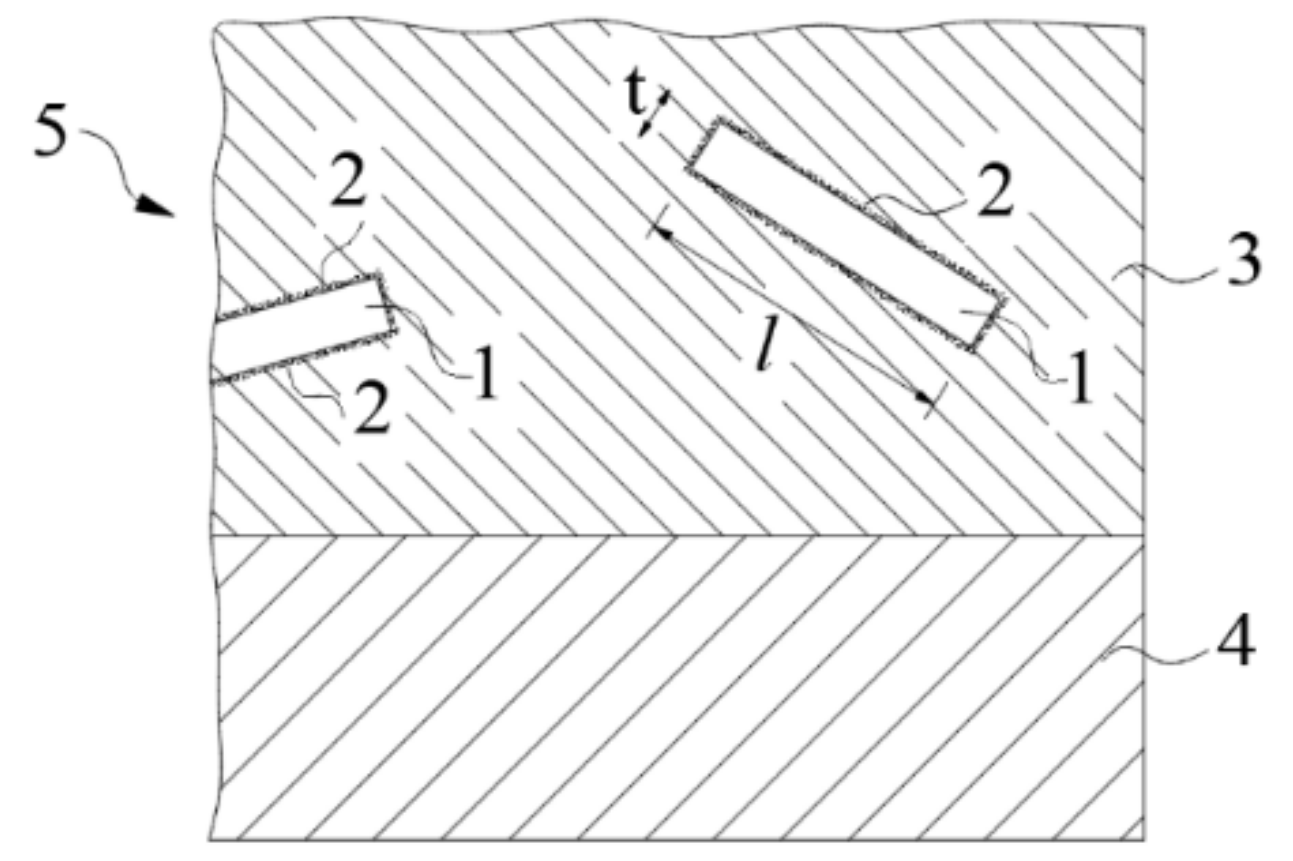

- Kołodziej, H.; Vogt, A.; Sowa, A.E.; Cichy, A.; Strzelecki, S. Electromagnetic Energy Absorbing Material. UK Patent GB 2379331A; Filed 28 March 2001, Patented 5 March 2003,

- Bantsis, G.; Sikalidis, C.; Betsiou, M.; Yioultsis, T.; Xenos, T. Electromagnetic absorption, reflection and interference shielding in X-band frequency range of low cost ceramic building bricks and sandwich type ceramic tiles using mill scale waste as an admixture. Ceram. Int. 2011, 37, 3535–3545. [Google Scholar] [CrossRef]

- Bantsis, G.; Sikalidis, C.; Betsiou, M.; Yioultsis, T.; Bourliva, A. Ceramic building materials for electromagnetic interference shielding using metallurgical slags. Adv. Appl. Ceram. 2011, 110, 233–237. [Google Scholar] [CrossRef]

- Zhang, X.Z.; Sun, W. Investigation on microwave absorbing properties of double-layer cementitious composites. Adv. Mat. Res. 2009, 79–82, 1843–1846. [Google Scholar] [CrossRef]

- Meshram, M.R.; Agrawal, N.K.; Sinha, B.; Misra, P.S. A study on the behaviour of M-type barium hexagonal ferrite based microwave absorbing paints. B. Mater. Sci. 2002, 25, 169–173. [Google Scholar] [CrossRef]

- Folgueras, L.; Alves, M.; Rezende, M.C. Microwave absorbing paints and sheets based on carbonyl iron and polyaniline: Measurement and simulation of their properties. J. Aerosp. Technol. Manag. 2010, 2, 63–70. [Google Scholar] [CrossRef]

- Stander, M. Radar Absorptive Coating. U.S. Patent 3,599,210; Filed 18 November 1969, Patented 10 August 1971,

- Chassay, G.; Citerne, J.; Floc’h, J.M.; Guyader, J.; Laurent, Y.; L’Haridon, P.; Rolland, A.; Verdier, P. Electromagnetic Radiation Absorbing Material, in Particular Microwaves, its Manufacturing Process and its Application as a Coating Material. French Patent 2 695 760; Filed 17 February 1988, Patented 18 March 1994 (In French).

- Shumaker, G.P.; May, B.W. Multi-Fiber Species Artificial Dielectric Radar Absorbing Material and Method for Producing Same. U.S. Patent 5,661,484; Filed 5 July 1996, Patented 26 August 1997,

| Ref. No. | Year | Product | Description |

|---|---|---|---|

| [35] | 2016 | Honeycomb structured plasterboards | 6 mm and 9 mm thick boards containing carbon (0.6% wt.) absorb EM waves in S and C bands. The reflection coefficient of 10 dB (90% electromagnetic wave absorption) is obtained in the frequency range of 2.5–8 GHz. |

| [36] | 2016 | Mineral wool boards with carbon black | SE amounts to 10 dB in the frequency ranges of 2–3 GHz and 7–18 GHz for a single-layer board containing 3% CB. The SE of a double layer mineral wool board exceeds 10 dB in the frequency range of 2–18 GHz. |

| [37] | 2014 | Plywood composite laminated with carbon fiber paper | The absorption level reaches more than 30 dB in the frequency range 30 MHz–1 GHz. Optimal plywood production parameters are pressing pressure of 1.2 MPa, temperature of 110 ± 5 °C, and a double amount of glue, i.e., 380 g/m2. |

| [38] | 2014 | EM wave absorber with a cementitious matrix | The absorber contains 1–20 µm long carbon nanotubes (2–10% wt.). It is characterised by a complex relative permittivity (ε) of 2–10 and a dielectric loss angle (tanδ) equal to or greater than 0.35 in the frequency range of 1–110 GHz. |

| [39] | 1998 | EM wave absorbing panels | The 13 mm thick absorber layer consists of 50% polycarbonate resin and 50% BaTiO3 + BiFeO3 (at weight ratio of 1/3). Reflection loss from −18.5 to −24 dB is obtained in the frequency range of 1.1–1.3 GHz. |

| [40] | 1995 | Elastomer matrix composite with TiO2 and CB additions | The main microwave absorbing component is pure silicon carbide or silicon carbide with titanium dioxide and carbon black additions. The best damping is obtained for a 2.09 mm thick layer (density of 2.04 g/cm3) at the frequency of 8.6 GHz and for a 1.18 mm (density of 1.93 g/cm3) at the frequency of 17 GHz. |

| [41] | 2014 | Coating absorbing EM and mechanical waves | The product is characterised by the ease of installation in all types of building structures. Reduction of EM radiation of 28–58.2 dB in the frequency range of 1–10 GHz is achieved. |

| Number of Layers | Layer | Cement | Fe2O3 | NiO | MWNT | Water | Superplasticiser | Dispersing Agent | Ceramic Granulate | Thickness [mm] |

|---|---|---|---|---|---|---|---|---|---|---|

| Two | top | 945 | - | - | 4.725 | 253 | 7.56 | 3.78 | - | 14 |

| bottom | 675 | 283 | 94 | - | 256.5 | 5.40 | - | - | 14 | |

| Three | top | 360 | - | - | - | 70 | 2.52 | - | 150 | 6 |

| middle | 540 | - | - | 2.7 | 140.4 | 4.32 | 2.7 | - | 11 | |

| bottom | 540 | 228 | 75.6 | - | 205.2 | 4.32 | - | - | 11 |

| Layer | Cement | W/C Ratio | Cement/Sand Ratio | Superplasticiser [% wt.] * | Rubber [% wt.] *,** | Ferrite [% wt.] * | Carbon Fibers [% wt.] * |

|---|---|---|---|---|---|---|---|

| top | 1 | 0.3 | 1/1.5 | 0.5 | 10 | - | - |

| middle | 1 | 0.3 | 1/1.5 | 0.5 | - | 30 | - |

| bottom | 1 | 0.3 | 1/1.5 | 0.5 | - | 30 | 2 |

| Ref. No. | Year | Product | Description |

|---|---|---|---|

| [45] | 2001 | Cementitious matrix composite with carbon fibers | SE of 40 dB is reached at the frequency of 1 GHz for 1.5% vol. of carbon fibers 0.1 µm in diameter. |

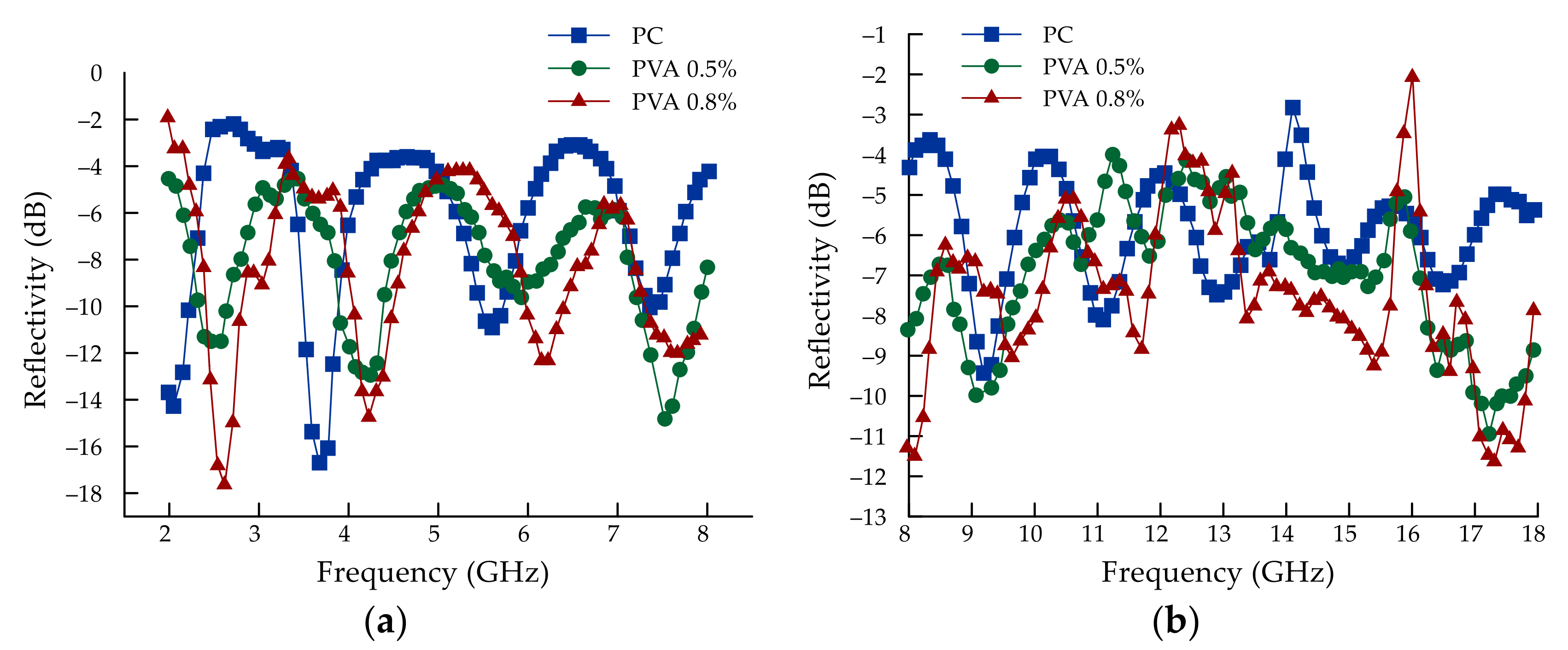

| [50] | 2012 | Cementitious composite reinforced with steel fibers, carbon fibers, and synthetic vinyl polymers (PVA) | SE exceeds 50 dB at frequencies above 1.8 GHz for steel fiber content of 3% vol. The minimum reflection coefficient amounts to approximately 7 dB for concrete containing 0.5% carbon fibers in the frequency range of 8–18 GHz. The reflectivity of concrete reinforced with PVA fibers changes with frequency and the minimum SE value is less than 10 dB. |

| [51] | 2008 | Aerated concrete moulded into truncated pyramids with addition of carbon fibers | In the frequency range of 2–18 GHz, the absorber in the shape of an 80 mm high pyramid is characterised by reflection coeff. of −21 to −30 dB, while the reflection coeff. of an absorber in the shape of a 45 mm high pyramid is in the range of −18 to −27 dB. |

| [53] | 2014 | Cement filled with carbon black and glass fibers | The minimum reflection loss equals −11.2 dB at 18 GHz for glass fiber content of 9% wt. and carbon black content of 5% wt.; the thickness of sample is 10 mm. |

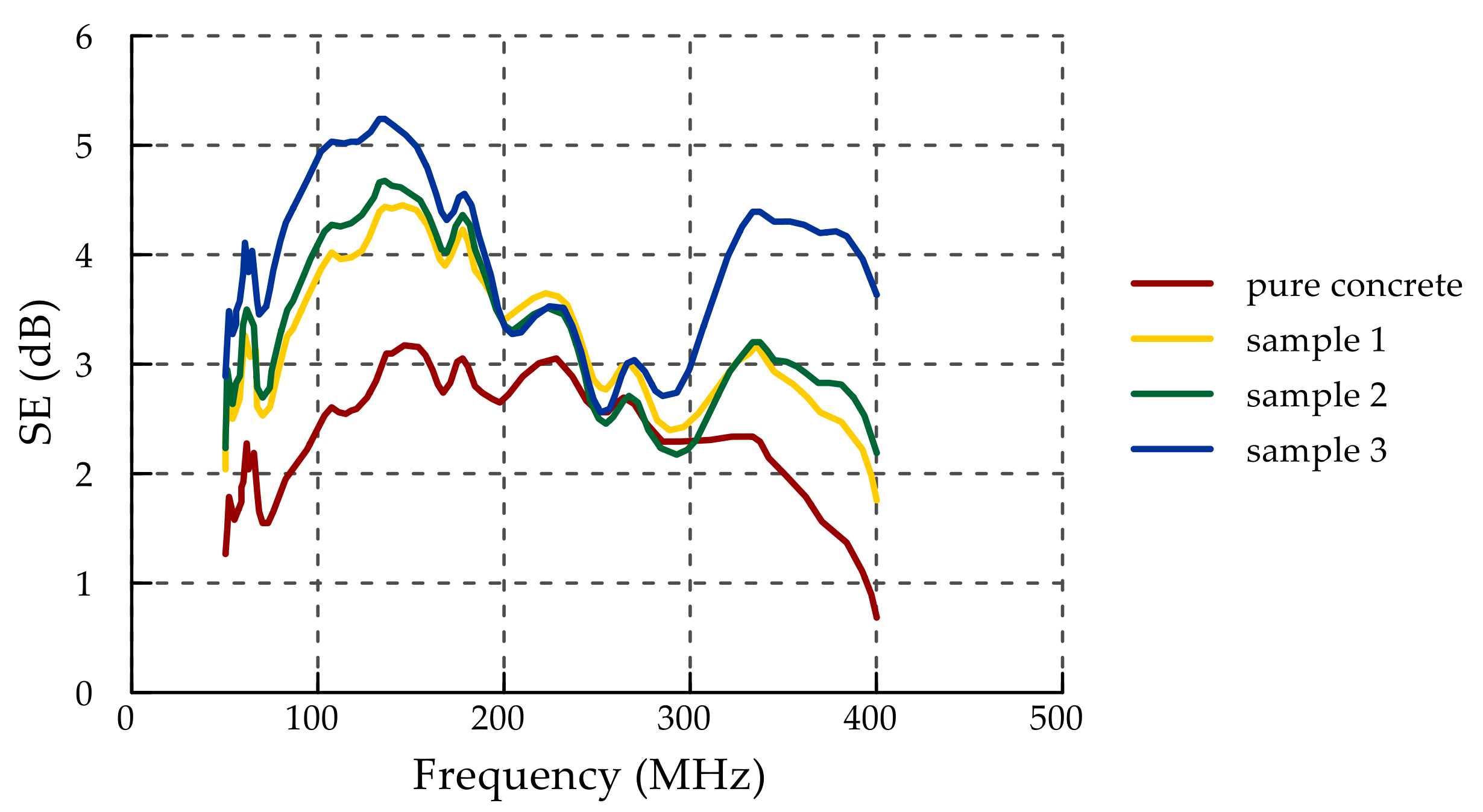

| [54] | 2013 | Concrete samples filled with graphite powder | The addition of graphite powder (12% wt.) increases the SE of a 20 cm thick concrete element by 2.4 dB at 360 MHz; reflection is the dominant mechanism that has an impact on shielding effectiveness. |

| [55] | 2015 | Cement-based composite materials with additions derived from agricultural production waste | For 0.5% content of pyrolysed nutshells, the SE increases by 353%, 223%, 126% and 83% at 0.9 GHz, 1.56 GHz, 2.46 GHz and 10 GHz, respectively. |

| [56] | 2007 | Gypsum boards | Shielding effectiveness increases considerably when the usual polyethylene sheeting is replaced with aluminium sheeting. |

| [56] | 2007 | Steel fiber reinforced concrete slabs | The addition of steel fiber extends the range of frequencies (to higher frequencies) for which protection is more effective. |

| [57] | 2004 | Cement paste with stainless steel fibers | SE reaches 70 dB at 1.5 GHz and 60 dB at 1.0 GHz for fiber content of 0.72% vol; fiber diameter: 8 µm; fiber length: 6 mm. |

| [58] | 2009 | Cement-based composite with the addition of steel fibers and/or graphite powder | SE reaches over 70 dB in the frequency range 1.0–2.5 GHz for hybrid sample containing both additions (10% wt each); SE decreases during drying, resulting in a value of about 50 dB after 6 months. |

| [59] | 2012 | Cementitious matrix composites containing multi-walled nanotubes | Addition of 1.5% wt. results in improved SE across the overall frequency range (45 MHz to 18 GHz), in particular, by 32% at 0.8 MHz. |

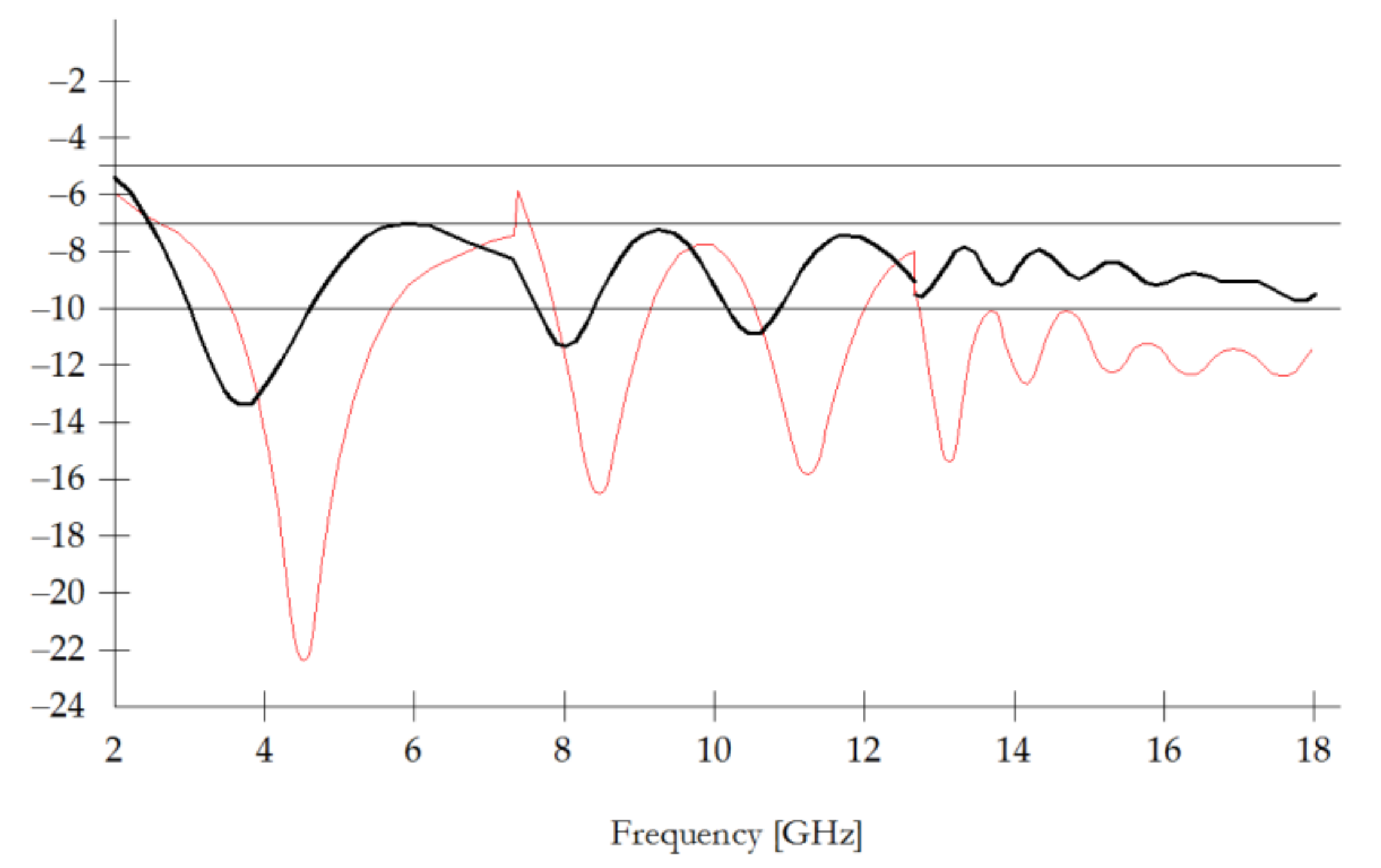

| [60] | 2017 | Sandwich cementitious matrix panels containing MWNT, Fe2O3 nanoparticles, and NiO nanoparticles | Reflectivity reaches −13 dB at a frequency of about 4.0 GHz for a two-layer panel and −22 dB at about 4.5 GHz for a three-layer panel. |

| [61] | 2011 | Layered cementitious matrix composite absorbers with rubber powder, manganese-zinc ferrite and carbon fibers | The three-layer absorber is characterised by reflection loss below −10 dB in the frequency range of 8–18 GHz. |

| [62] | 2013 | Layered absorber made of carbon coating (with graphite and black carbon), foamed cement (reinforced with polypropylene fibers) and metal reflecting layer | In the frequency range of 2–4 GHz the absorption band of the produced composite was 100% below −10 dB and 95% below −14 dB, with a maximum absorption of −19.6 dB at 2.45 Hz. |

| [63,64] | 2007 | Cement-based composites filled with EPS beads | Minimum SE amounts to about 15 dB in the frequency range of 8–18 GHz dB for a 20 mm thick sample with 60% vol. EPS beads 1.0 mm in diameter. |

| [65] | 1989 | Gypsum plaster reinforced with carbon fiber | SE increases with fiber content, reaching 22 dB at 1.5 GHz for a plaster thickness of 4.35 mm and a fiber content of 2.0% wt. For fiber content of 0.3% and plaster thickness of 3.85 mm SE amounts to 10 dB at 1.5 GHz. |

| [66] | 2003 | Energy absorbing material | The composite material exhibits strong electromagnetic energy absorption in the range of radio and microwave frequencies and better magnetic and dielectric loss properties compared to its components, among other things, very soft ferromagnetic material (developed by the authors of patent [66]) and ferrite powder. |

| Ref. No. | Year | Product | Description |

|---|---|---|---|

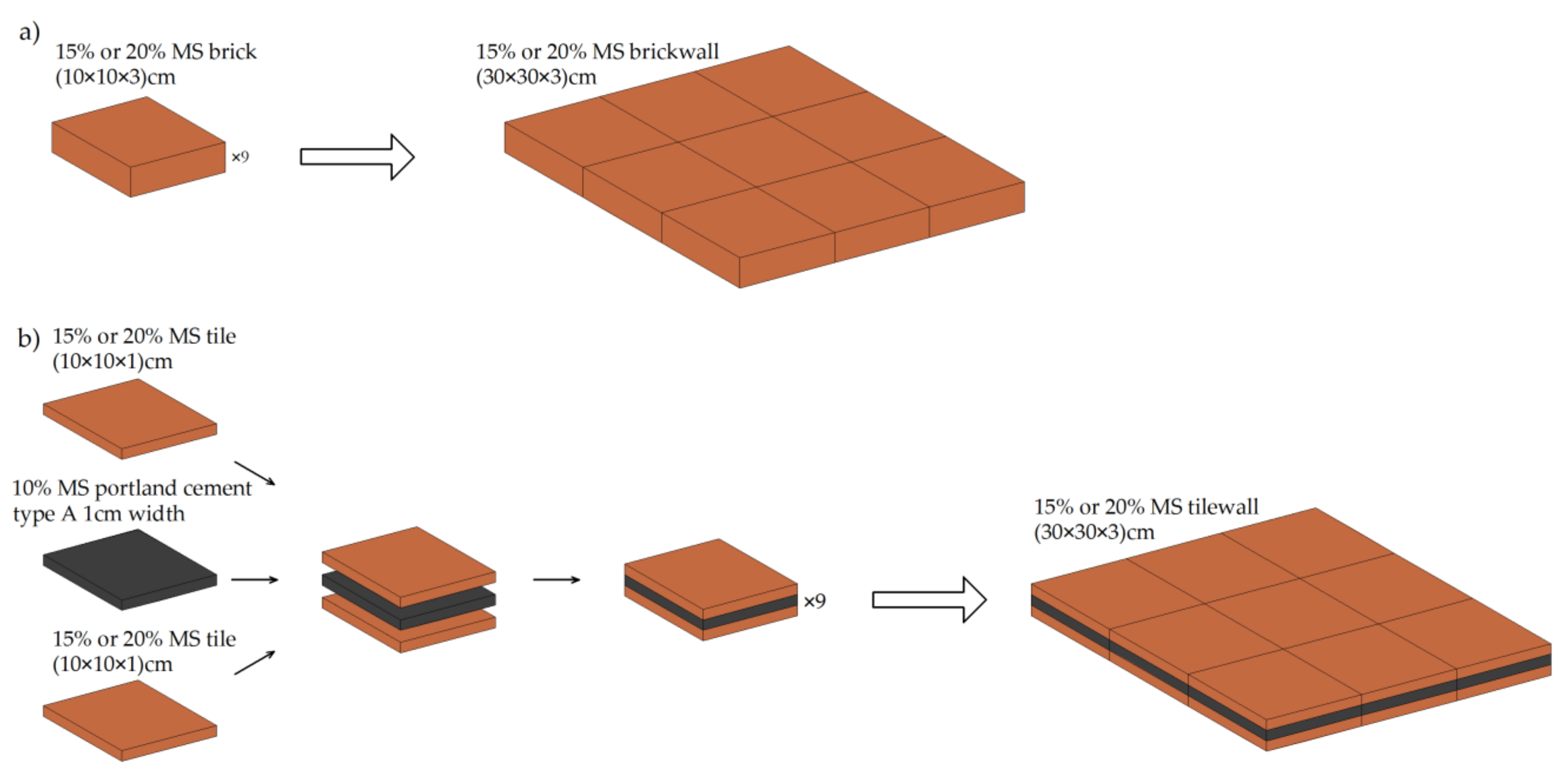

| [67] | 2011 | Ceramic bricks and tiles with mill scale admixture |

|

| [68] | 2011 | Ceramic elements with metallurgical slag admixture |

|

| [69] | 2009 | Double-layer cementitious tiles with ferrite and carbon fibers admixture |

|

| Ref. No. | Year | Product | Description |

|---|---|---|---|

| [70] | 2002 | Ferrite-containing single- and double-layer paints | Single-layer paint (thickness of 1.12 mm):

|

| [71] | 2010 | Paints and sheets based on magnetic and dielectric materials |

|

| [72,74] | 1971, 1997 | Composite coating: fibers in dielectric binder |

|

| [74] | 1988 | Coatings based on aluminosilicates mixed with aluminium nitride |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Majcher, K.; Musiał, M.; Pakos, W.; Różański, A.; Sobótka, M.; Trapko, T. A Systematic Review of HPM Energy Absorbers for Building Applications. Energies 2021, 14, 6061. https://doi.org/10.3390/en14196061

Majcher K, Musiał M, Pakos W, Różański A, Sobótka M, Trapko T. A Systematic Review of HPM Energy Absorbers for Building Applications. Energies. 2021; 14(19):6061. https://doi.org/10.3390/en14196061

Chicago/Turabian StyleMajcher, Krzysztof, Michał Musiał, Wojciech Pakos, Adrian Różański, Maciej Sobótka, and Tomasz Trapko. 2021. "A Systematic Review of HPM Energy Absorbers for Building Applications" Energies 14, no. 19: 6061. https://doi.org/10.3390/en14196061

APA StyleMajcher, K., Musiał, M., Pakos, W., Różański, A., Sobótka, M., & Trapko, T. (2021). A Systematic Review of HPM Energy Absorbers for Building Applications. Energies, 14(19), 6061. https://doi.org/10.3390/en14196061