Interior Permanent Magnet Synchronous Motor Drive System with Machine Learning-Based Maximum Torque per Ampere and Flux-Weakening Control

Abstract

:1. Introduction

2. MTPA and FW Control of IPMSM Drive

2.1. MTPA Control

2.2. Estimation of Permanent-Magnet Flux Linkage

2.3. Measuring Method of dq-Axis Inductance Differences

2.4. FW Control

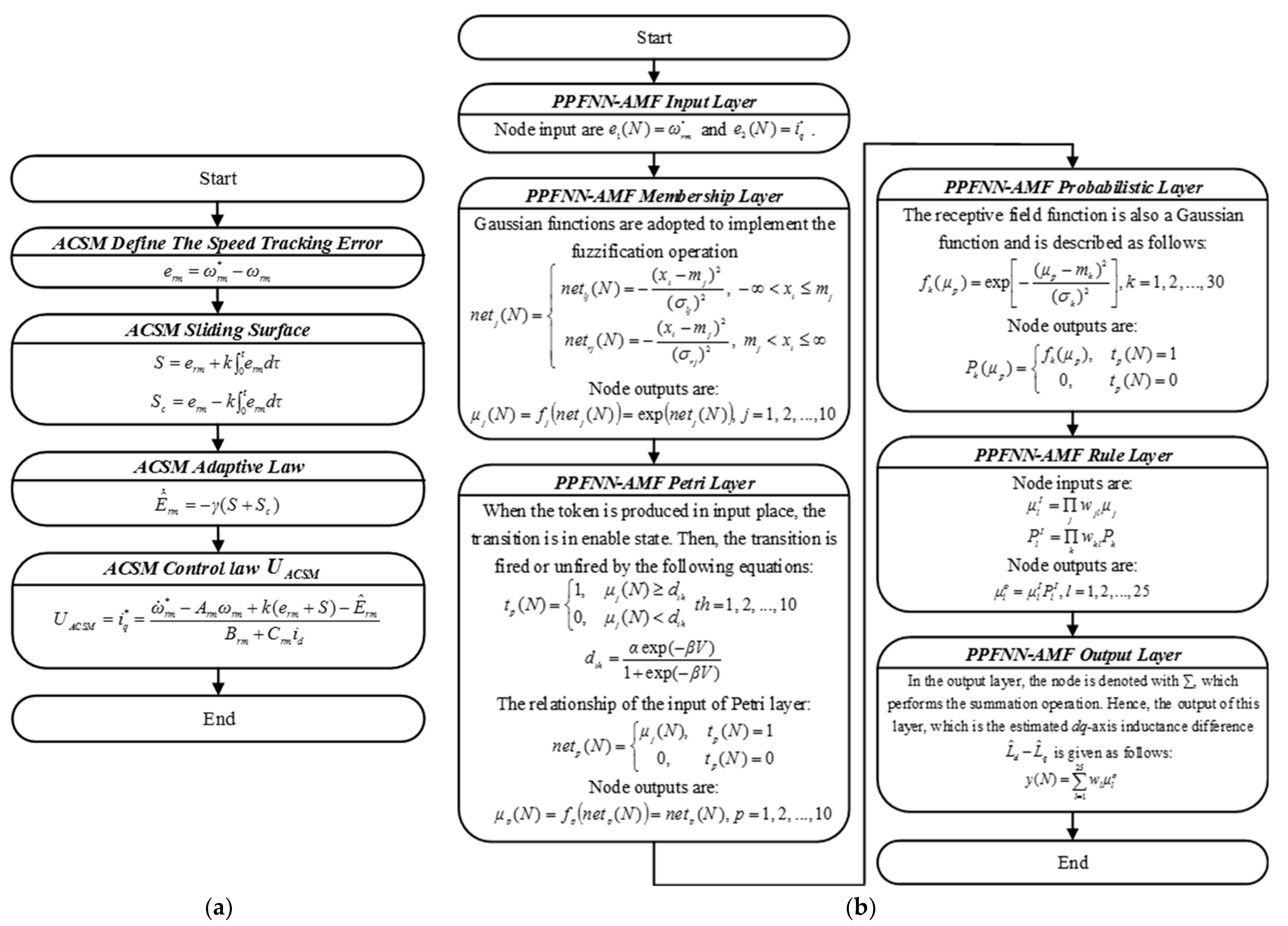

3. ACSM Speed Controller

4. PPFNN-AMF

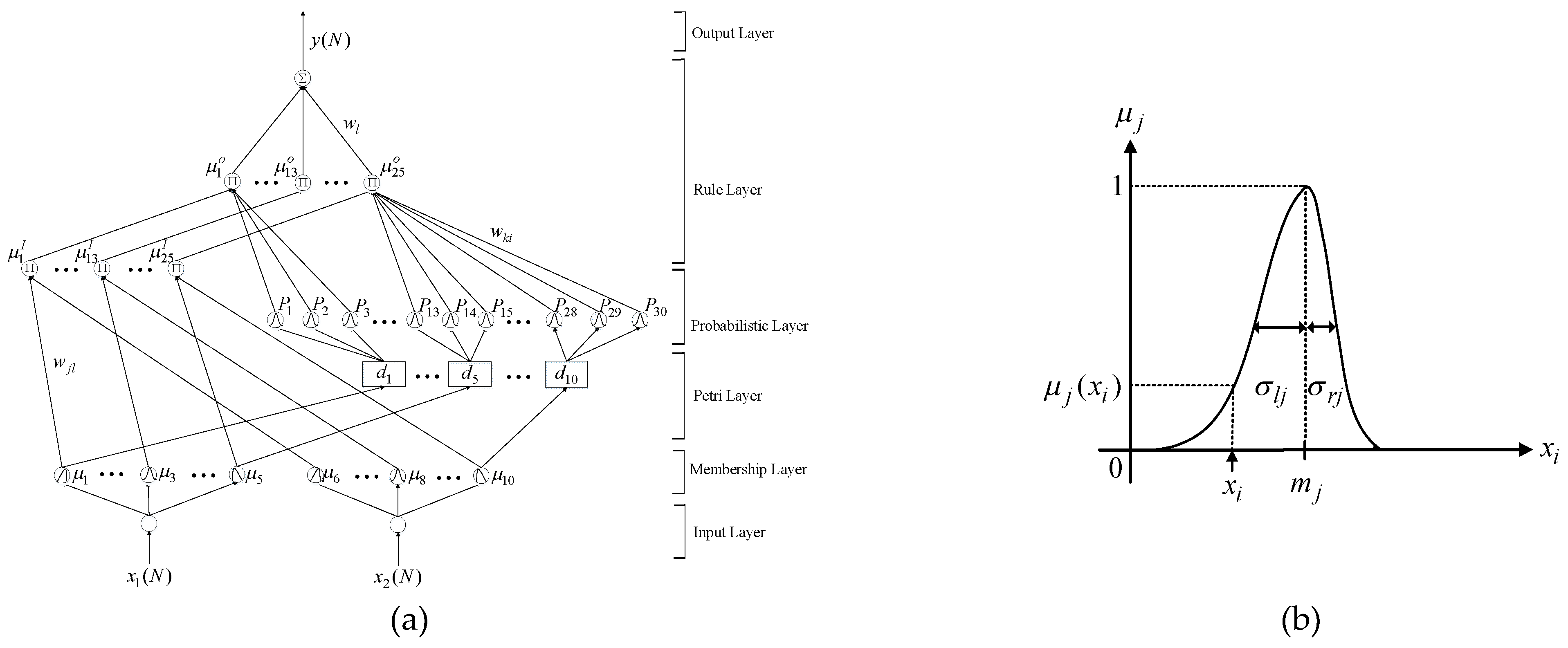

4.1. Network Structure

4.1.1. Membership Layer

4.1.2. Petri Layer

4.1.3. Probabilistic Layer

4.1.4. Rule Layer

4.1.5. Output Layer

4.2. Learning Algorithms

4.2.1. Output Layer

4.2.2. Membership Layer

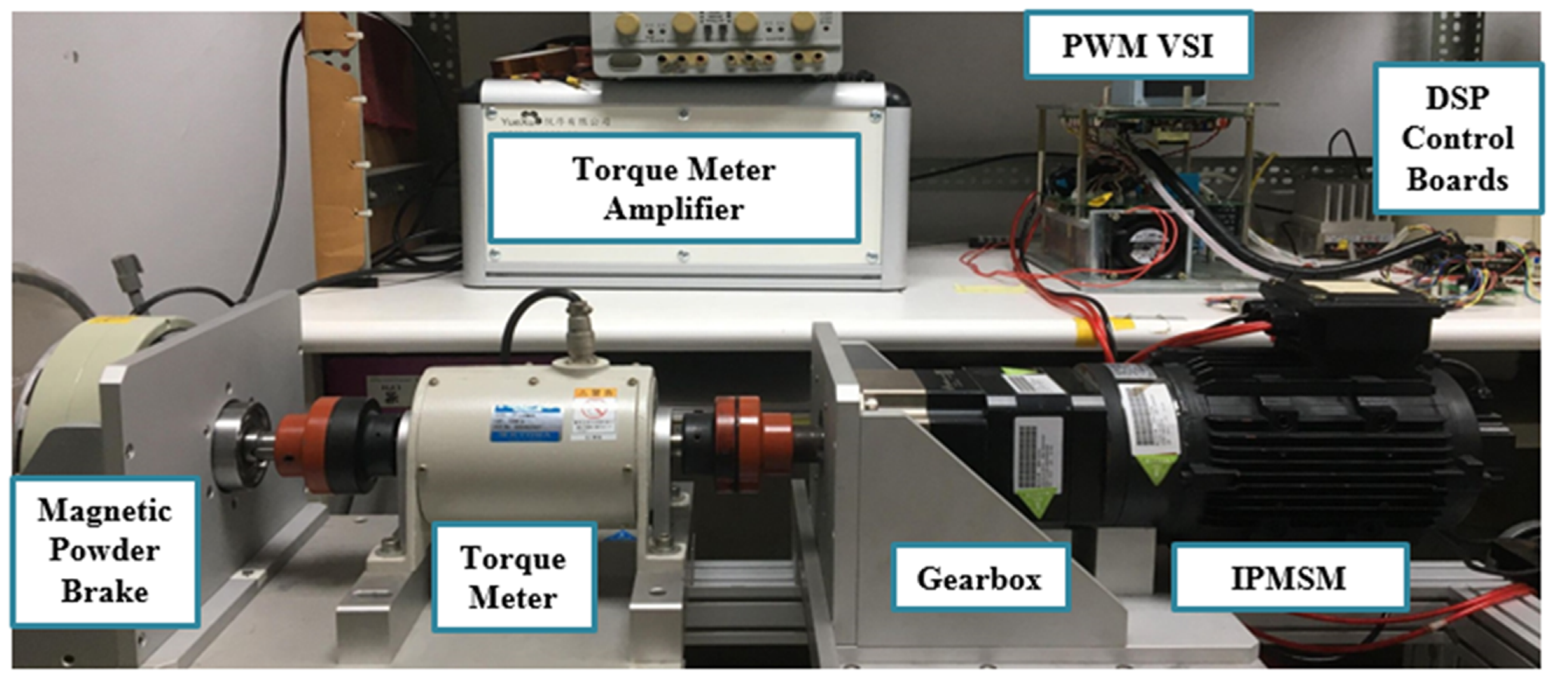

5. Experimental Results

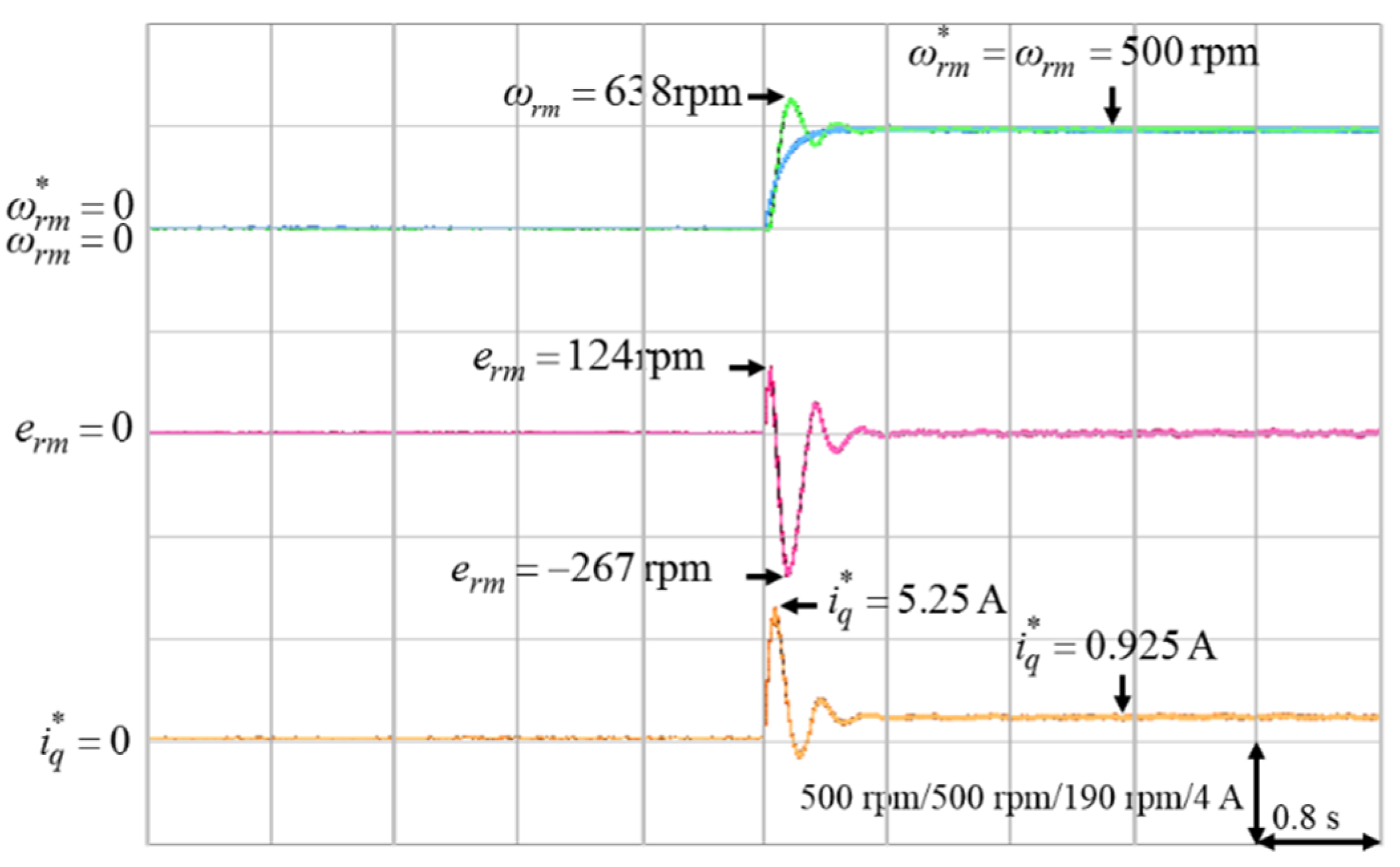

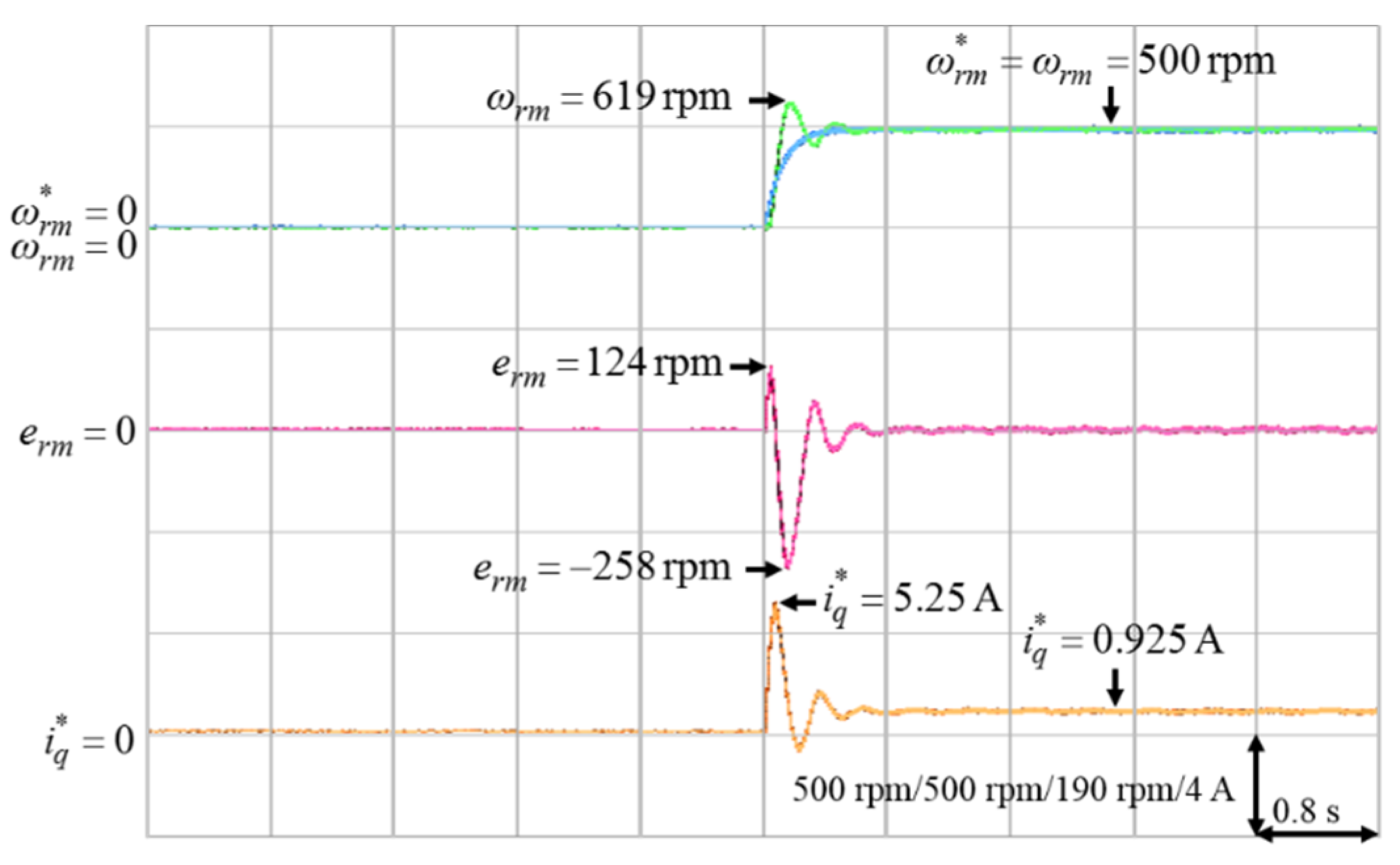

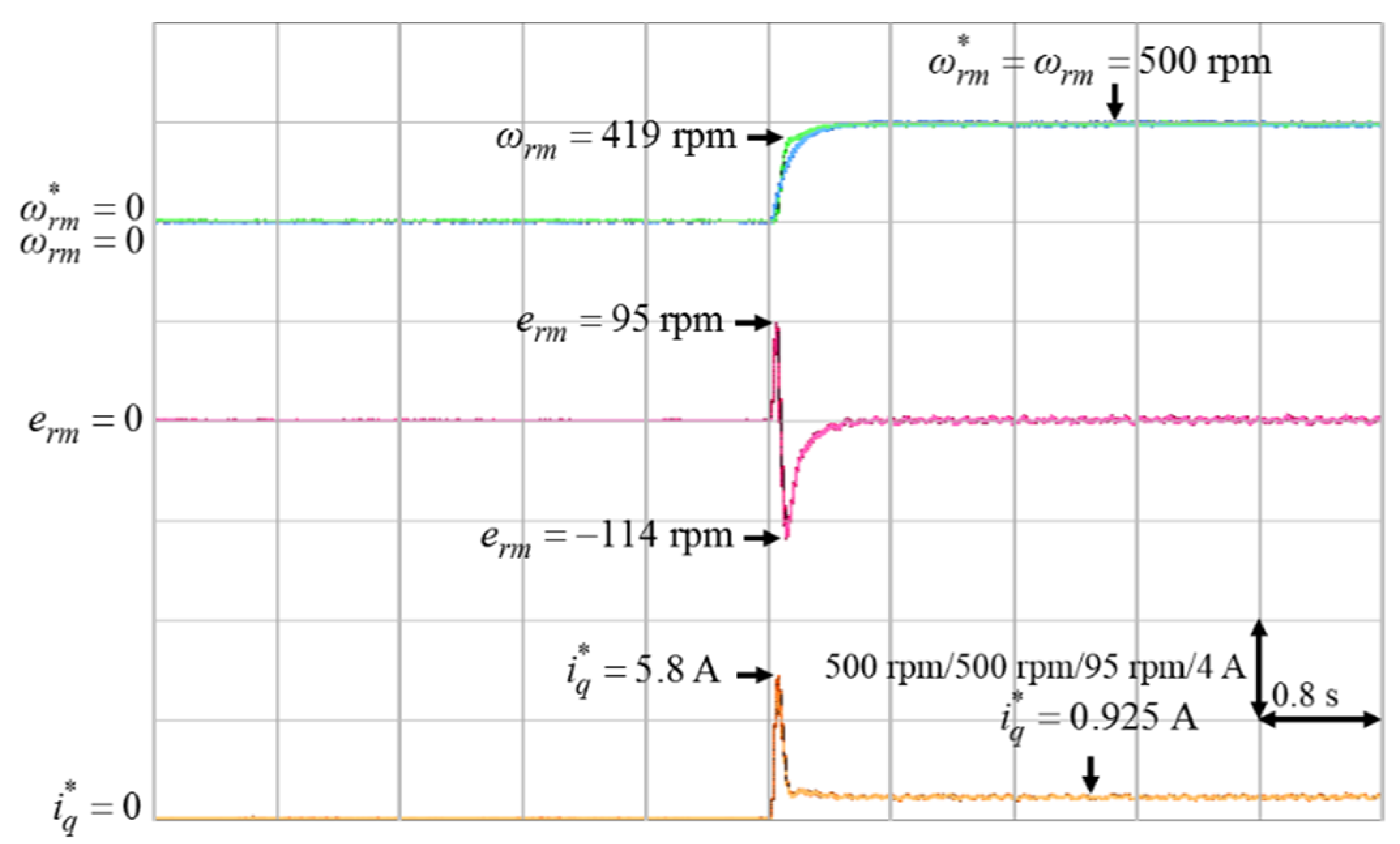

5.1. ACSM Speed Controller

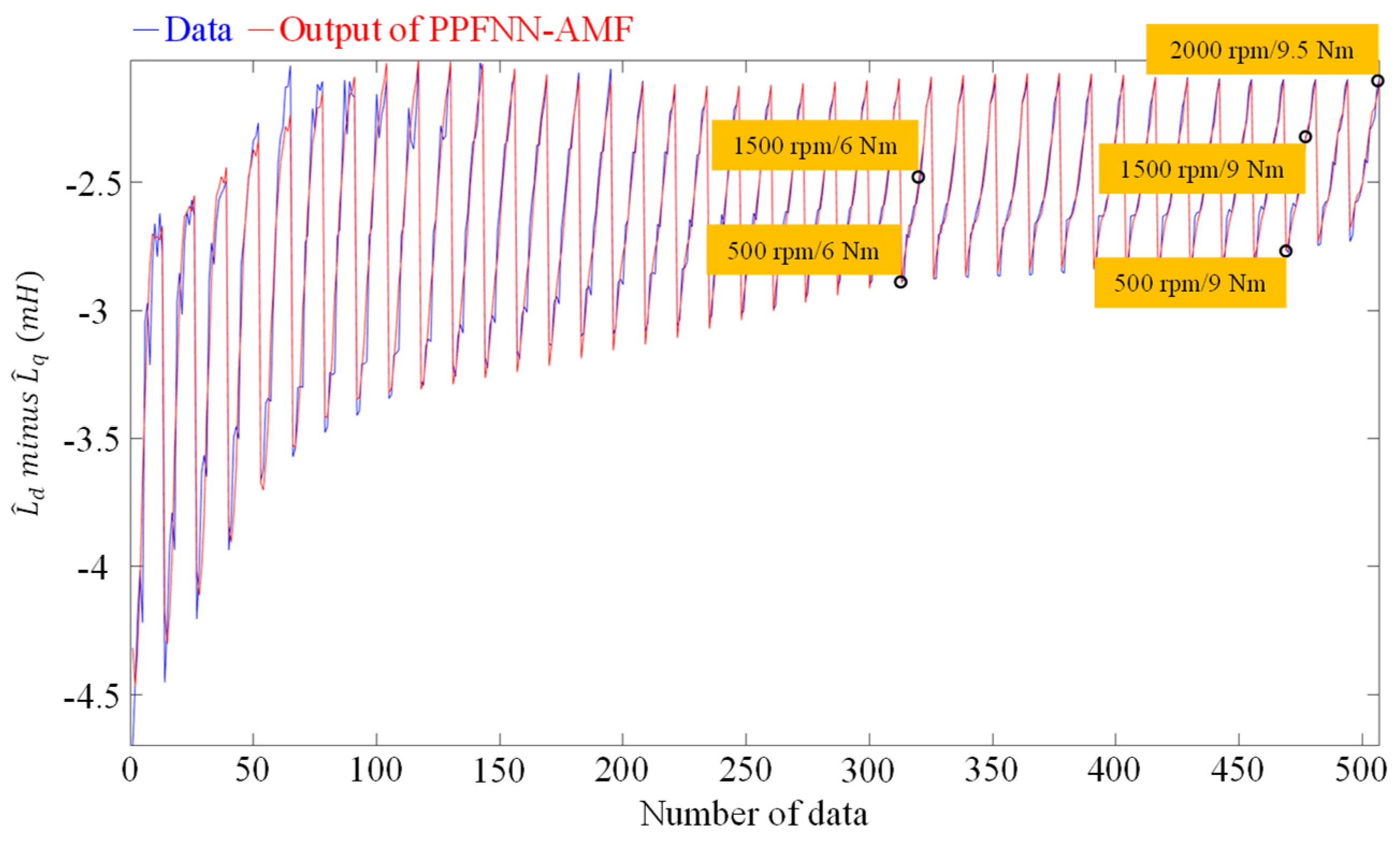

5.2. PPFNN-AMF Estimator

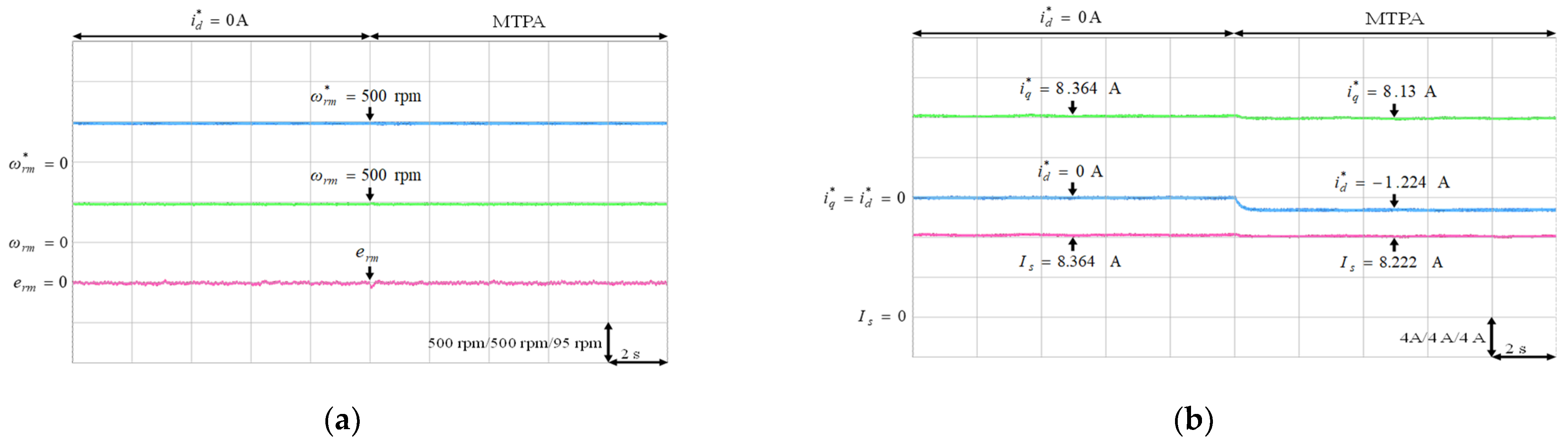

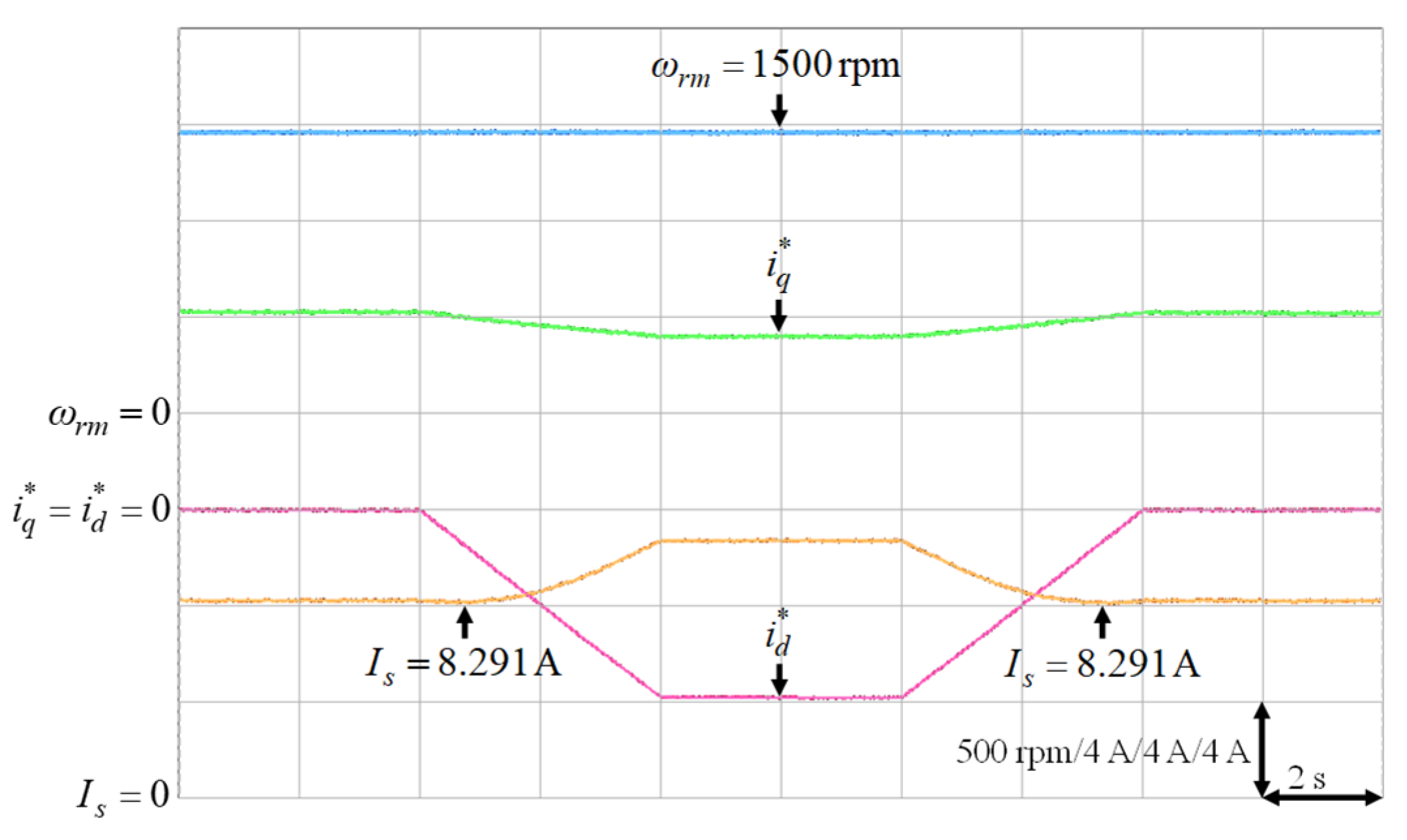

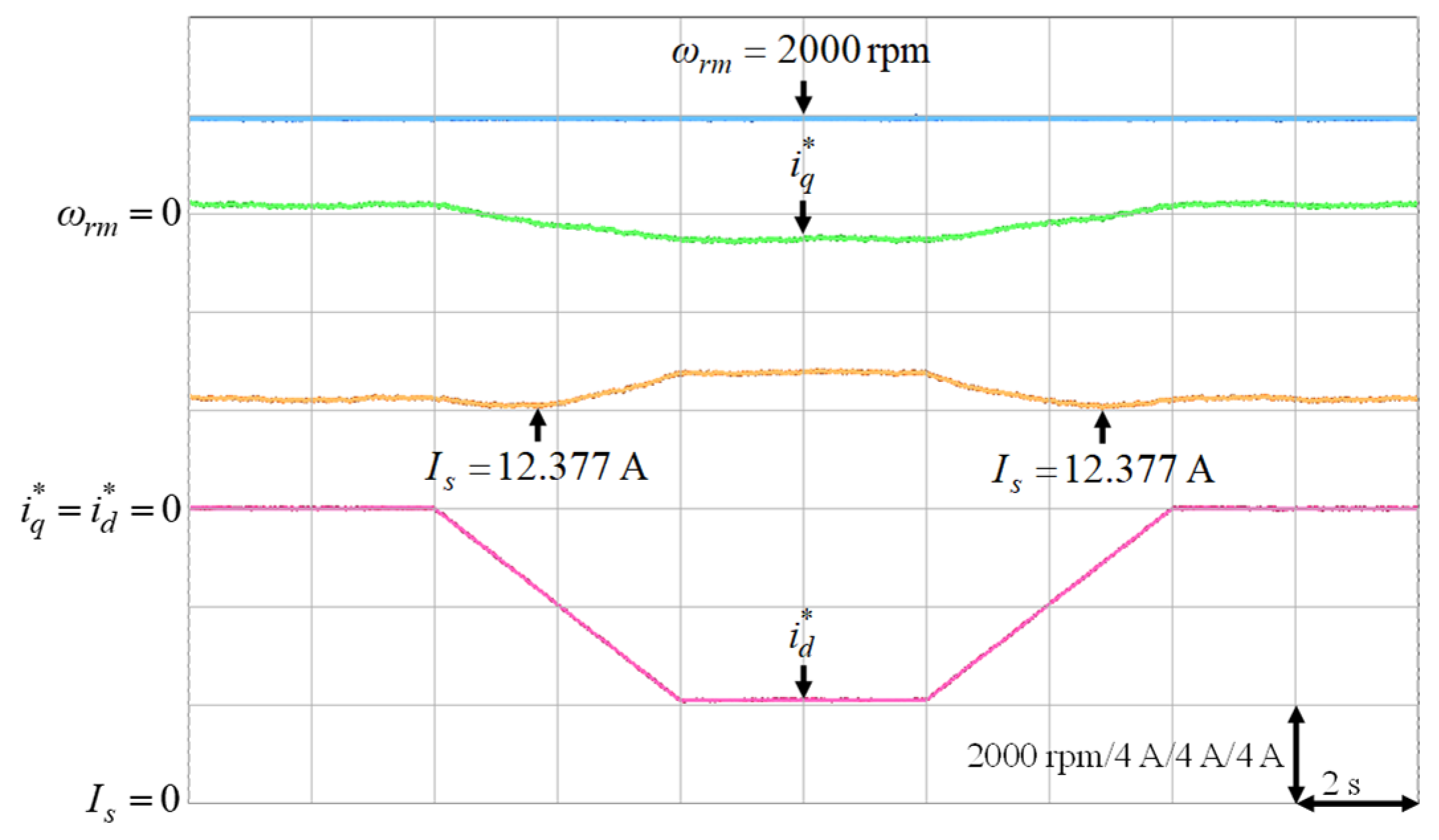

5.3. MTPA Control

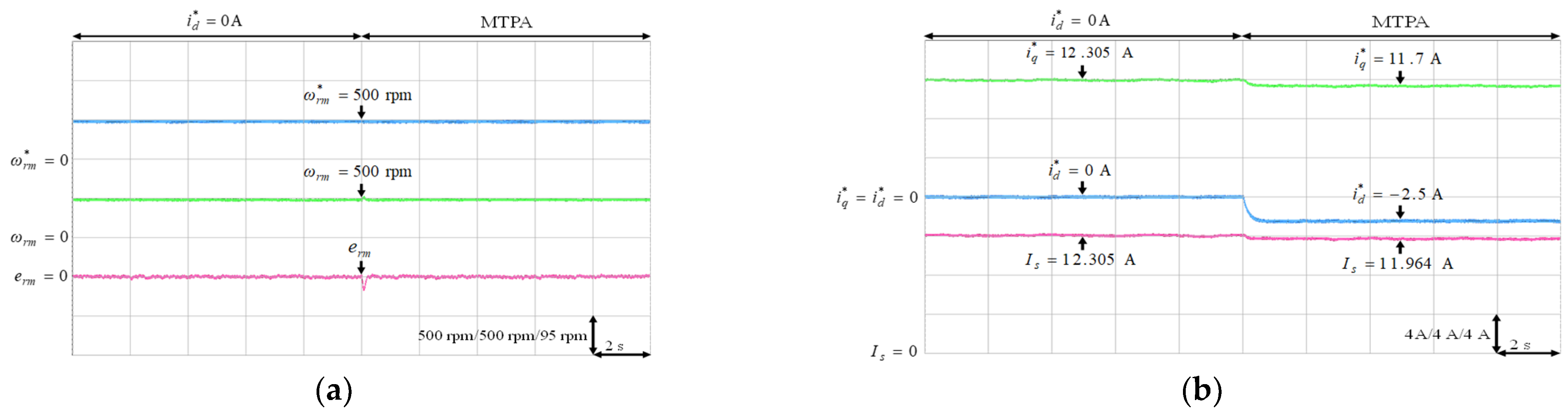

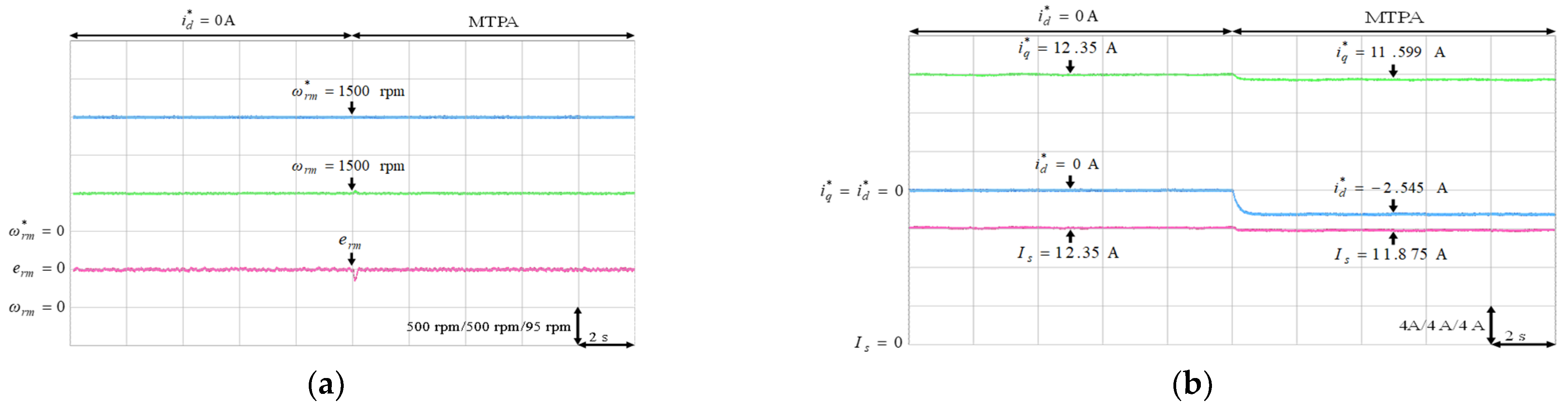

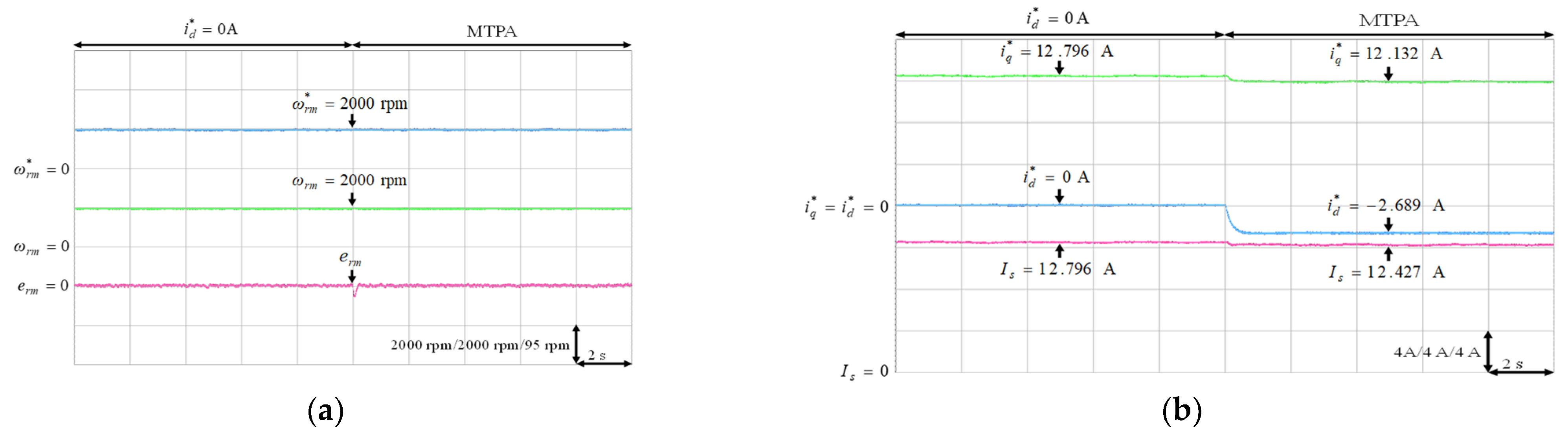

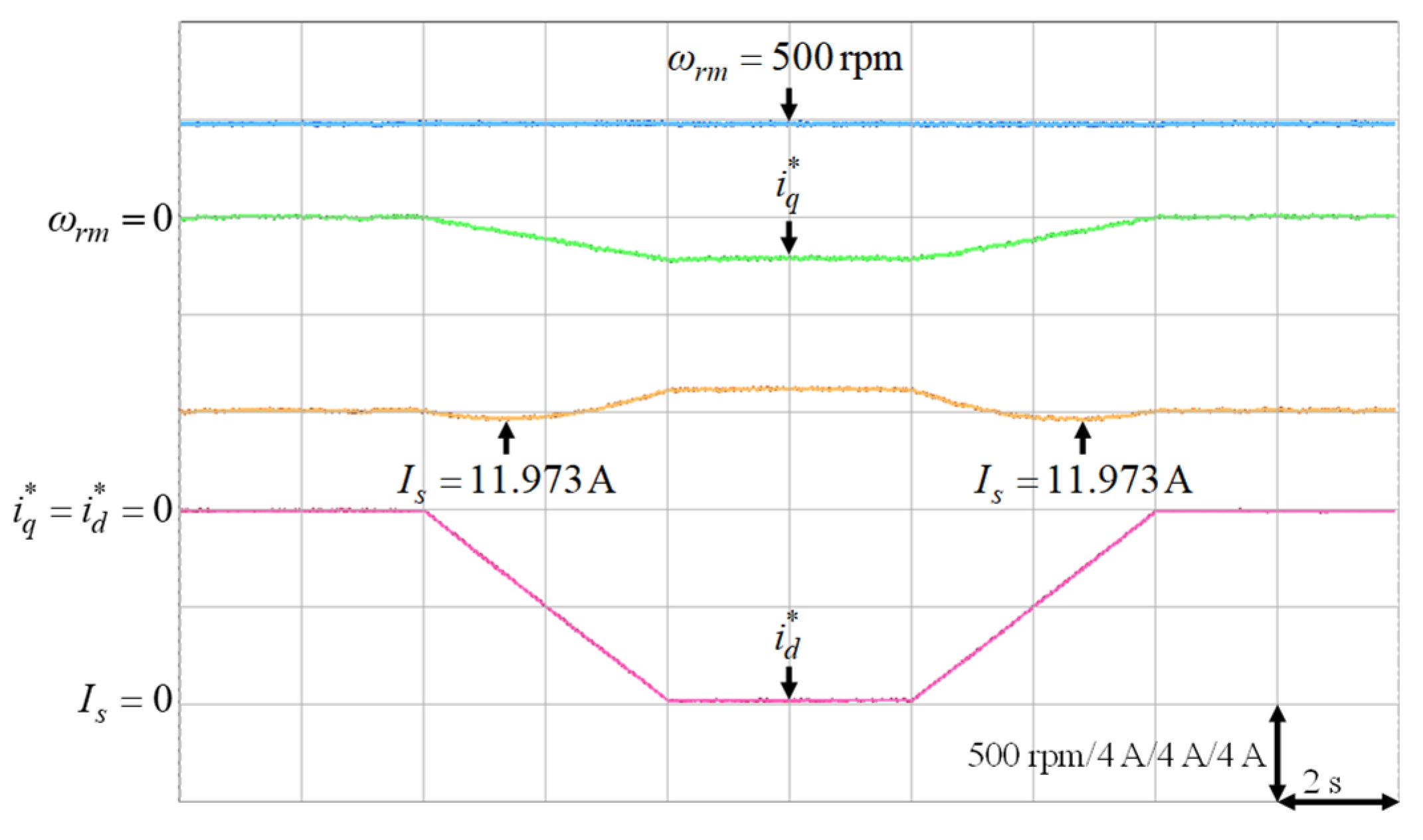

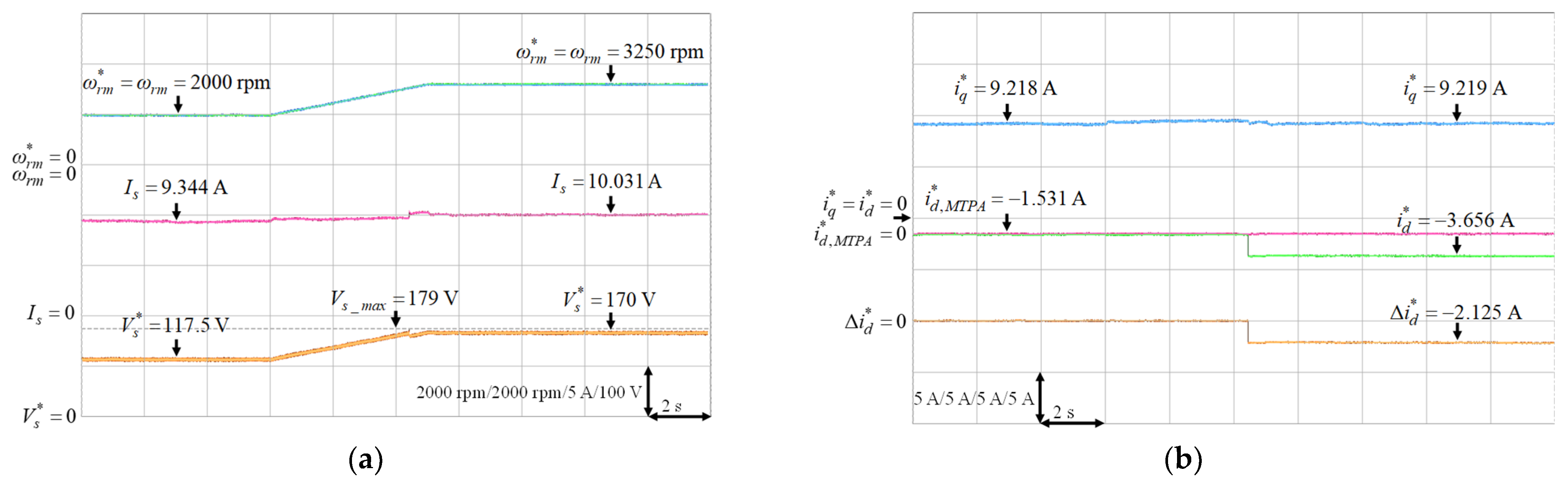

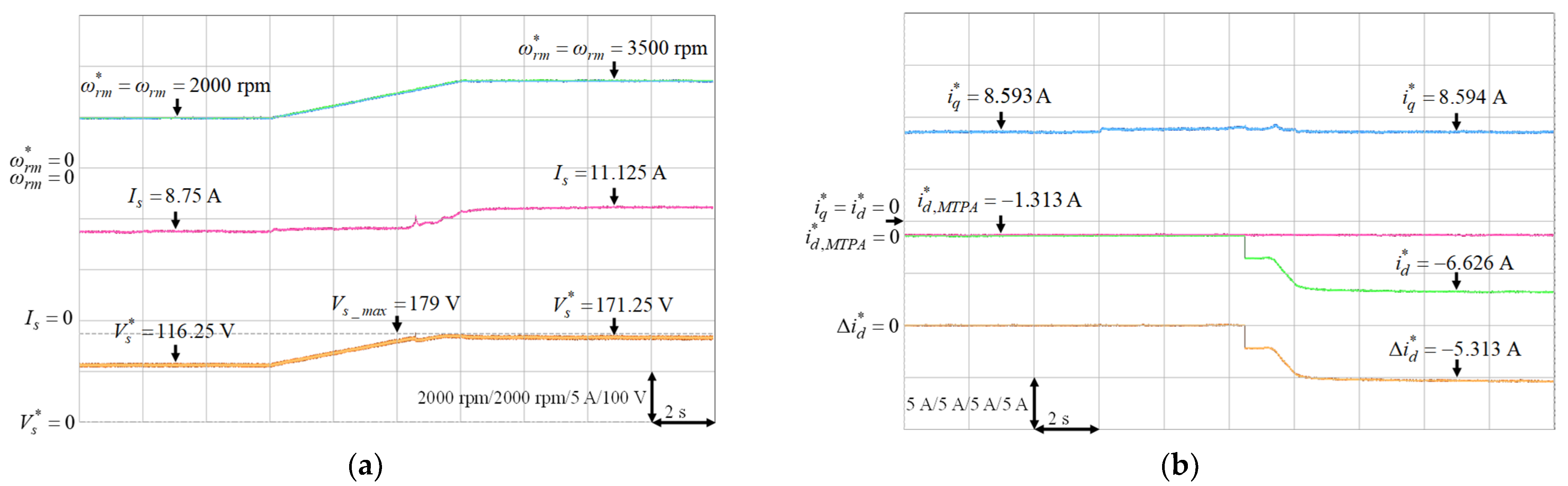

5.4. FW Control

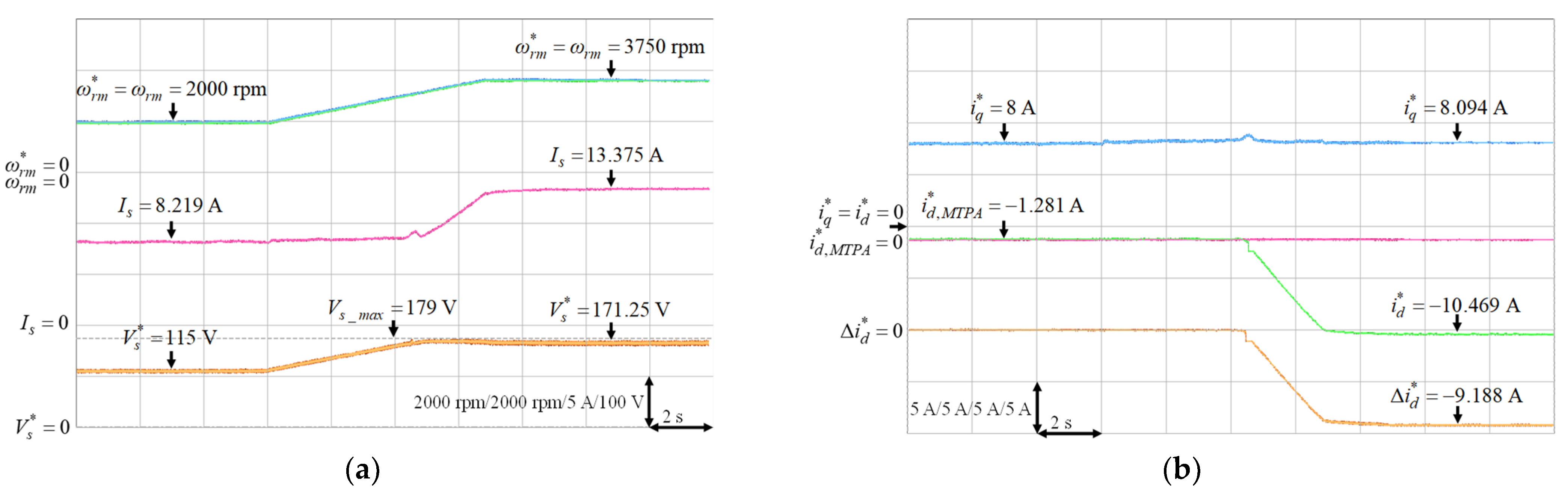

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| IPMSMs | Interior permanent magnet synchronous motors |

| MTPA | Maximum torque per ampere |

| FW | Flux-weakening |

| PNN | Probabilistic neural network |

| PFNN | Probabilistic fuzzy neural network |

| PN | Petri net |

| AMFs | Asymmetric membership functions |

| PPFNN-AMF | Petri probabilistic fuzzy neural network with an asymmetric membership function |

| SMC | Sliding mode control |

| CSMC | Complementary sliding mode control |

| ACSM | Adaptive complementary sliding mode |

| VSI | Voltage source inverter |

| IGBTs | Insulated-gate bipolar transistors |

| SVPWM | Space vector pulse width modulation |

| PM | Permanent-magnet |

| PI | Proportional-integral |

References

- Mwasilu, F.; Kim, E.K.; Rafaq, M.S.; Jung, J.W. Finite-set model predictive control scheme with an optimal switching voltage vector technique for high-performance IPMSM drive applications. IEEE Trans. Ind. Inform. 2018, 14, 3840–3848. [Google Scholar] [CrossRef]

- Li, K.; Wang, Y. Maximum torque per ampere (MTPA) control for IPMSM drives using signal injection and an MTPA control law. IEEE Trans. Ind. Inform. 2019, 15, 5588–5598. [Google Scholar] [CrossRef]

- Kim, E.K.; Kim, J.; Choi, H.H.; Jung, J.W. Variable structure speed controller guaranteeing robust transient performance of an IPMSM Drive. IEEE Trans. Ind. Inform. 2019, 15, 3300–3310. [Google Scholar] [CrossRef]

- Yang, D.; Mok, H.; Lee, J.; Han, S. Adaptive torque estimation for an IPMSM with cross-coupling and parameter variations. Energies 2017, 10, 167. [Google Scholar] [CrossRef]

- Lin, F.J.; Hung, Y.C.; Chen, J.M.; Yeh, C.M. Sensorless IPMSM drive system using saliency back-EMF-based intelligent torque observer with MTPA control. IEEE Trans. Ind. Inform. 2014, 10, 1226–1241. [Google Scholar]

- Pairo, H.; Shoulaie, A. Operating region and maximum attainable speed of energy-efficient control methods of interior permanent-magnet synchronous motors. IET Power Electron. 2017, 10, 555–567. [Google Scholar] [CrossRef]

- Jung, S.; Hong, J.; Nam, K. Current minimizing torque control of the IPMSM using Ferrari’s method. IEEE Trans. Power Electron. 2013, 28, 5603–5617. [Google Scholar] [CrossRef]

- Liu, T.H.; Chen, Y.; Wu, M.J.; Dai, B.C. Adaptive controller for an MTPA IPMSM drive system without using a high-frequency sinusoidal generator. IET J. Eng. 2017, 2017, 13–25. [Google Scholar] [CrossRef]

- Sun, T.; Wang, J.; Chen, X. Maximum torque per ampere (MTPA) control for interior permanent magnet synchronous machine drives based on virtual signal injection. IEEE Trans. Power Electron. 2015, 30, 5036–5045. [Google Scholar] [CrossRef]

- Liu, Q.; Hameyer, K. High-performance adaptive torque control for an IPMSM with real-time MTPA operation. IEEE Trans. Energy Convers. 2017, 32, 571–581. [Google Scholar] [CrossRef]

- Schoonhoven, G.; Nasir Uddin, M. MTPA- and FW-based robust nonlinear speed control of IPMSM drive using Lyapunov stability criterion. IEEE Trans. Ind. Appl. 2016, 52, 4365–4374. [Google Scholar] [CrossRef]

- Miyajima, T.; Fujimoto, H.; Fujitsuna, M. A precise model-based design of voltage phase controller for IPMSM. IEEE Trans. Power Electron. 2013, 28, 5655–5664. [Google Scholar] [CrossRef]

- Bolognani, S.; Calligaro, S.; Petrella, R. Adaptive flux-weakening controller for interior permanent magnet synchronous motor drives. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 236–248. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, X.; Wang, J.; Niu, F.; Zhung, J.; Fang, Y.; Wu, L. Improved flux-weakening control of IPMSMs based on torque feedforward technique. IEEE Trans. Power Electron. 2018, 33, 10970–10978. [Google Scholar] [CrossRef]

- Hart, S.J.; Shaffer, R.E.; Rose-Pehrsson, S.L.; McDonald, J.R. Using physics-based modeler outputs to train probabilistic neural networks for unexploded ordnance (UXO) classification in magnetometry surveys. IEEE Trans. Geosci. Remote Sens. 2001, 39, 797–804. [Google Scholar] [CrossRef]

- Jin, X.; Srinivasan, D.; Cheu, R.L. Classification of freeway traffic patterns for incident detection using constructive probabilistic neural networks. IEEE Trans. Neural Netw. 2001, 12, 1173–1187. [Google Scholar] [CrossRef]

- Lin, F.J.; Lu, K.C.; Ke, T.H.; Li, H.Y. Reactive power control of three-phase PV system during grids faults using Takagi-Sugeno-Kang probabilistic fuzzy neural network control. IEEE Trans. Ind. Electron. 2015, 62, 5516–5528. [Google Scholar] [CrossRef]

- Wai, R.J.; Muthusamy, R. Design of fuzzy-neural-network inherited backstepping control for robot manipulator including actuator dynamics. IEEE Trans. Fuzzy Syst. 2014, 22, 709–722. [Google Scholar] [CrossRef]

- Lin, F.J.; Huang, M.S.; Yeh, P.Y.; Tsai, H.C.; Kuan, C.H. DSP-based probabilistic fuzzy neural network control for li-ion battery charger. IEEE Trans. Power Electron. 2012, 27, 3782–3794. [Google Scholar] [CrossRef]

- Murata, T. Petrinets: Properties, analysis and applications. Proc. IEEE 1989, 77, 541–580. [Google Scholar] [CrossRef]

- Kaur, K.; Rana, R.; Kumar, N.; Singh, M.; Mishra, S. A colored petri net based frequency support scheme using fleet of electric vehicles in smart grid environment. IEEE Trans. Power Syst. 2016, 31, 4638–4649. [Google Scholar] [CrossRef]

- Wang, P.; Ma, L.; Goverde, R.M.P.; Wang, Q. Rescheduling trains using Petri nets and heuristic search. IEEE Trans. Intell. Transp. Syst. 2016, 17, 726–735. [Google Scholar] [CrossRef]

- Lin, F.J.; Chen, S.G.; Li, S.; Chou, H.T.; Lin, J.R. Online auto-tuning technique for IPMSM servo drive by intelligent identification of moment of inertia. IEEE Trans. Ind. Inform. 2020, 16, 7579–7590. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, Y.; Zhang, X.; Liang, J. A new reaching law for antidisturbance sliding-mode control of PMSM speed regulation system. IEEE Trans. Power Electron. 2020, 35, 4117–4126. [Google Scholar] [CrossRef]

- Wang, A.; Wei, S. Sliding mode control for permanent magnet synchronous motor drive based on an improved exponential reaching law. IEEE Access 2019, 7, 146866–146875. [Google Scholar] [CrossRef]

- Jin, H.; Zhao, X. Approach angle-based saturation function of modified complementary sliding mode control for PMLSM. IEEE Access 2019, 7, 126014–126024. [Google Scholar] [CrossRef]

- Lin, F.J.; Hung, Y.C.; Tsai, M.T. Fault-tolerant control for six-phase PMSM drive system via intelligent complementary sliding-Mode control using TSKFNN-AMF. IEEE Trans. Ind. Electron. 2013, 60, 5747–5762. [Google Scholar] [CrossRef]

- Liang, C.Y.; Su, J.P. A new approach to the design of a fuzzy sliding mode controller. Fuzzy Sets Syst. 2003, 139, 111–124. [Google Scholar] [CrossRef]

- Kim, E.; Kim, J.; Nguyen, H.T.; Choi, H.H.; Jung, J. Compensation of parameter uncertainty using an adaptive sliding mode control strategy for an interior permanent magnet synchronous motor drive. IEEE Access 2019, 7, 11913–11923. [Google Scholar] [CrossRef]

- Choi, H.H.; Vu, N.T.T.; Jung, J.W. Digital implementation of an adaptive speed regulator for a PMSM. IEEE Trans. Power Electron. 2011, 26, 3–8. [Google Scholar] [CrossRef]

- Rahman, M.M.; Uddin, M.N. Third harmonic injection based nonlinear control of IPMSM drive for wide speed range operation. IEEE Trans. Ind. Appl. 2019, 55, 3174–3184. [Google Scholar] [CrossRef]

- Xu, W.; Lorenz, R.D. High-frequency injection-based stator flux linkage and torque estimation for DB-DTFC implementation on IPMSMs considering cross-saturation effects. IEEE Trans. Ind. Appl. 2014, 50, 3805–3815. [Google Scholar] [CrossRef]

- Slotine, J.J.E.; Li, W. Applied Nonlinear Control; Prentice-Hall: Englewood Cliffs, NJ, USA, 1991. [Google Scholar]

- Kim, S.; Yoon, Y.; Sul, S.; Ide, K. Maximum torque per ampere (MTPA) control of an IPM machine based on signal injection considering inductance saturation. IEEE Trans. Power Electron. 2013, 28, 488–497. [Google Scholar] [CrossRef]

| Items | Units | Quantities |

|---|---|---|

| Torque | Nm | 50 |

| Rated current | A | 2.15 |

| Coil resistance | ohm | 11.14 |

| Mass of powder | g | 60 |

| Maximum rotating speed | rpm | 1800 |

| Items | Units | Quantities |

|---|---|---|

| Pole number | – | 8 |

| Rated power | W | 2000 |

| Rated line voltage | V(rms) | 220 |

| Rated current | A(rms) | 10.6 |

| Rated torque | Nm | 9.5 |

| Rated speed | rpm | 2000 |

| d-axis inductance | mH | 3.48 |

| q-axis inductance | mH | 6.16 |

| Magnetic flux | Wb | 0.143 |

| Resistance | ohm | 0.57 |

| Viscous damping | Nm/(rad/sec) | |

| Inertia | Nm/(rad/sec2) |

| Operating Speed | Load Torque | Training Data | Output of PPFNN-AMF | Error |

|---|---|---|---|---|

| 500 rpm | 6 Nm | 2.8876 mH | 2.8945 mH | 0.239% |

| 9 Nm | 2.7611 mH | 2.7688 mH | 0.279% | |

| 1500 rpm | 6 Nm | 2.4563 mH | 2.4148 mH | 1.689% |

| 9 Nm | 2.3204 mH | 2.3258 mH | 0.233% | |

| 2000 rpm | 9.5 Nm | 2.0977 mH | 2.1034 mH | 0.272% |

| Operating Speed | Load Torque | Method | Stator Current |

|---|---|---|---|

| 500 rpm | 6 Nm | gradually changed | 8.290 A |

| Proposed MTPA scheme | 8.222 A | ||

| 9 Nm | gradually changed | 11.973 A | |

| Proposed MTPA scheme | 11.964 A | ||

| 1500 rpm | 6 Nm | gradually changed | 8.291 A |

| Proposed MTPA scheme | 8.283 A | ||

| 9 Nm | gradually changed | 11.873 A | |

| Proposed MTPA scheme | 11.875 A | ||

| 2000 rpm | 9.5 Nm | gradually changed | 12.377 A |

| Proposed MTPA scheme | 12.427 A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, F.-J.; Liao, Y.-H.; Lin, J.-R.; Lin, W.-T. Interior Permanent Magnet Synchronous Motor Drive System with Machine Learning-Based Maximum Torque per Ampere and Flux-Weakening Control. Energies 2021, 14, 346. https://doi.org/10.3390/en14020346

Lin F-J, Liao Y-H, Lin J-R, Lin W-T. Interior Permanent Magnet Synchronous Motor Drive System with Machine Learning-Based Maximum Torque per Ampere and Flux-Weakening Control. Energies. 2021; 14(2):346. https://doi.org/10.3390/en14020346

Chicago/Turabian StyleLin, Faa-Jeng, Yi-Hung Liao, Jyun-Ru Lin, and Wei-Ting Lin. 2021. "Interior Permanent Magnet Synchronous Motor Drive System with Machine Learning-Based Maximum Torque per Ampere and Flux-Weakening Control" Energies 14, no. 2: 346. https://doi.org/10.3390/en14020346

APA StyleLin, F.-J., Liao, Y.-H., Lin, J.-R., & Lin, W.-T. (2021). Interior Permanent Magnet Synchronous Motor Drive System with Machine Learning-Based Maximum Torque per Ampere and Flux-Weakening Control. Energies, 14(2), 346. https://doi.org/10.3390/en14020346