A Review of Recent Advances in Emerging Alternative Heating and Cooling Technologies

Abstract

:1. Introduction

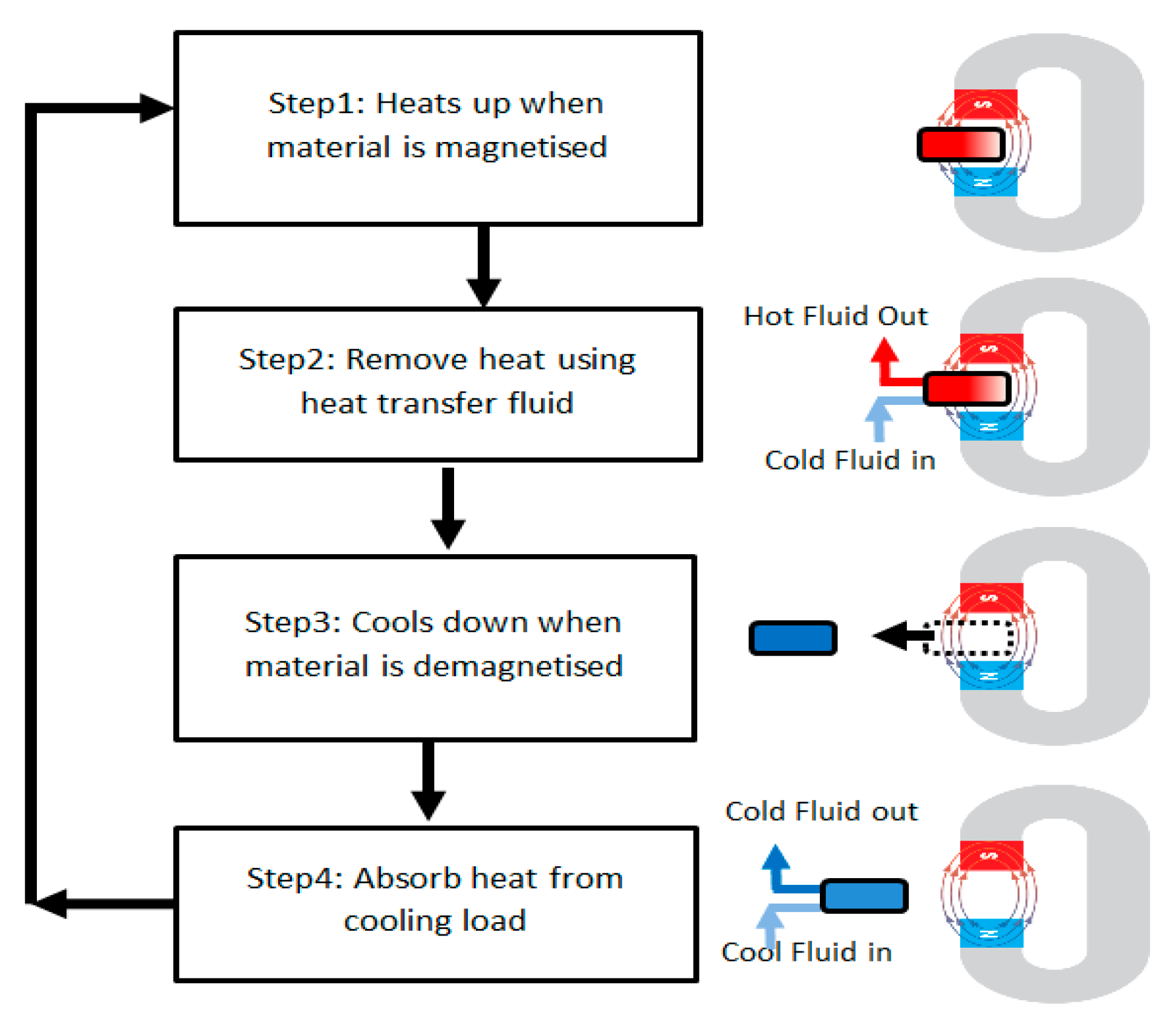

2. Magnetic Refrigeration

2.1. Basic Working Principles

2.2. Working Materials

2.3. Challenges and State of Development

2.4. Applications

2.5. Advantages and Disadvantages

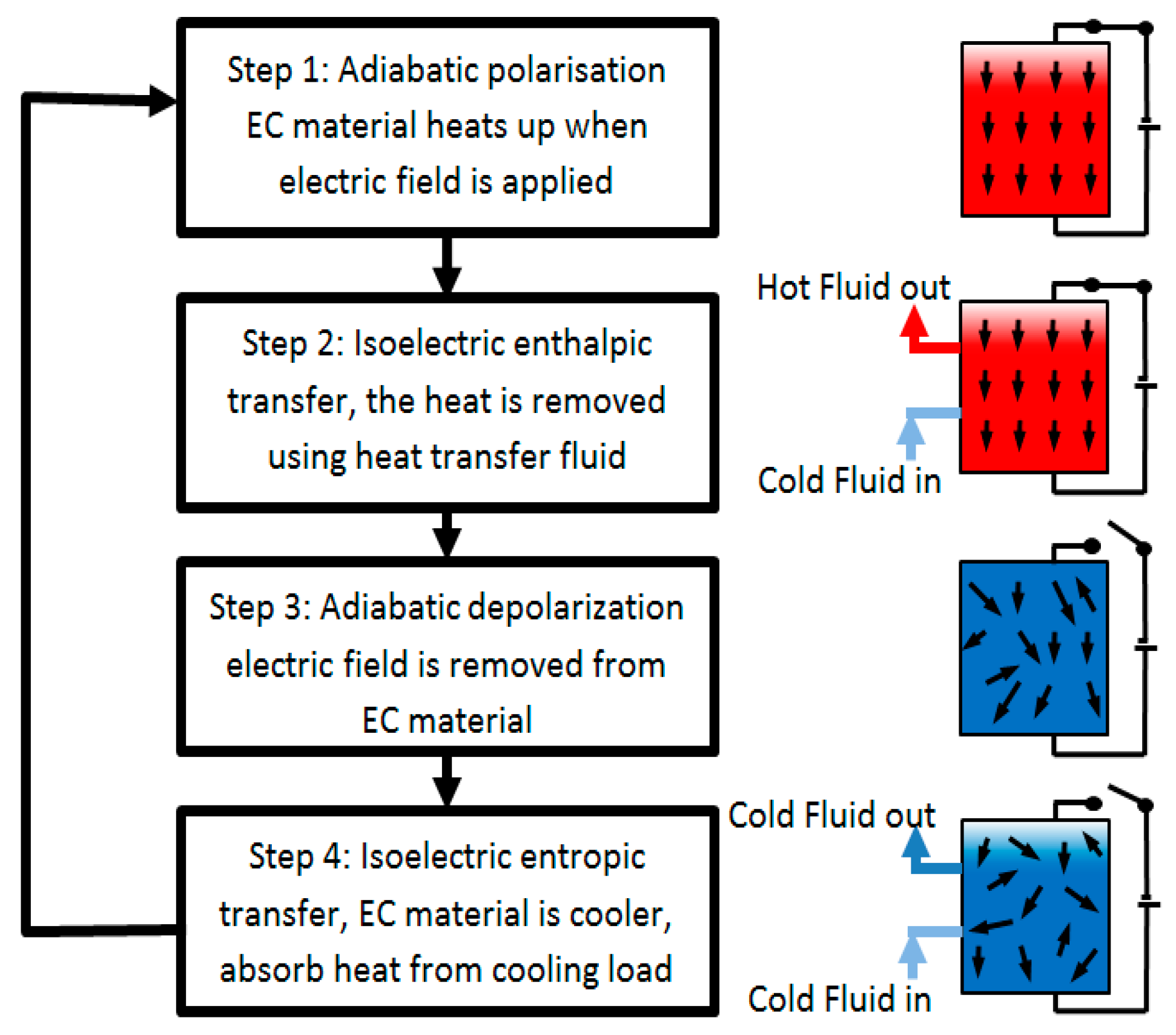

3. Electrocaloric Refrigeration

3.1. Basic Working Principles

3.2. Working Materials

3.3. Challenges and State of Development

3.4. Applications

3.5. Advantages and Disadvantages

4. Thermoelectric Refrigeration

4.1. Basic Working Principles

4.2. Working Materials

4.3. Challenges and State of Development

4.4. Applications

4.5. Advantages and Disadvantages

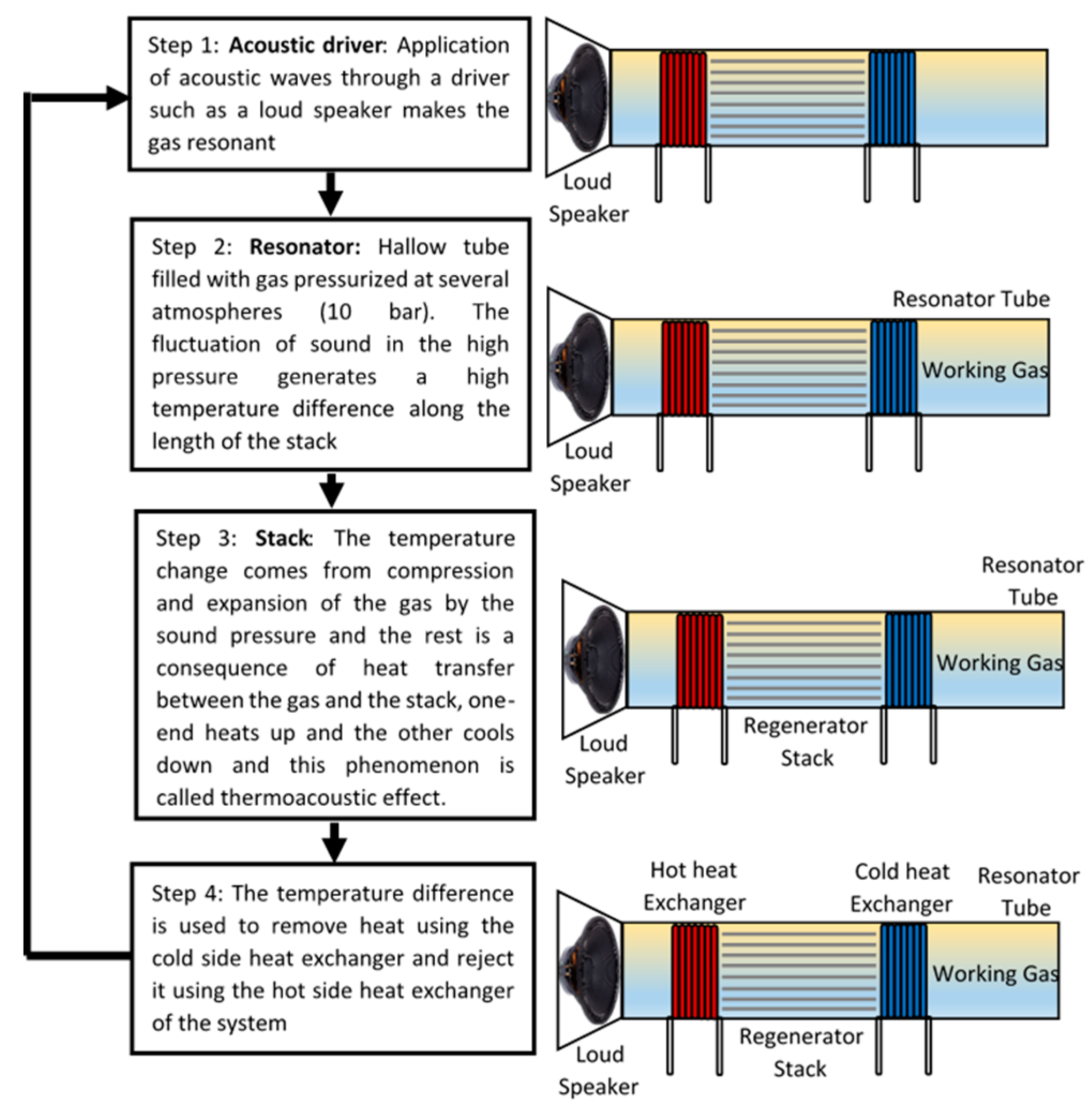

5. Thermoacoustic Refrigeration

5.1. Basic Working Principles

5.2. Working Materials

5.3. Challenges and State of Development

5.4. Applications

5.5. Advantages and Disadvantages

6. Stirling Refrigeration

6.1. Basic Working Principles

- Alpha engine: this type has two power pistons, and that makes it heavier than the other two types (beta and gamma). Both pistons are connected to a crankshaft, where the hot and cold pistons are 90 degrees apart, the crankshaft moves in and out within two cylinders. The alpha engine works on the following principle:

- Expansion: The gas heats up and expands and drives both pistons in the crankshaft.

- Transfer: Then the momentum of the flywheel carries the engine through the next 90 degrees, this causes most of the air to be transferred over to the cold cylinder.

- Contraction: The majority of the expanded gas shifts over to the cold cylinder, it cools and contracts which sucks both pistons outwards, away from the crankshaft.

- Transfer: The same transfer operation is repeated to transfer the air to the hot cylinder and thus complete the cycle.

- Beta engine: this type has one cylinder, one piston and a displacer which shuttles the air back and forth with the cylinder. When the displacer moves away from the hot side, it forces the air to go to the cold side, and thus the air heats up, expands, and the piston gets pushed outwards. Reversely, when the displacer moves towards the hot end, it causes the air to go to the cold side and cools down, contracts and the piston gets sucked inwards. In beta engine, the displacer and the piston are 90° apart.

- Gamma (low-temperature differential): Gamma engine works by using the temperature difference between two metal plates, and this particular engine is complex as it has many components. Gamma engine is composed of two plates (bottom & top or hot & cold), displacer (contains a displacer cylinder and a rod), flywheel and a power piston with its supporting rod.

6.2. Working Materials

6.3. Challenges and State of Development

6.4. Applications

6.5. Advantages and Disadvantages

7. Barocaloric Refrigeration

7.1. Basic Working Principles

7.2. Working Materials

7.3. Challenges and State of Development

7.4. Application

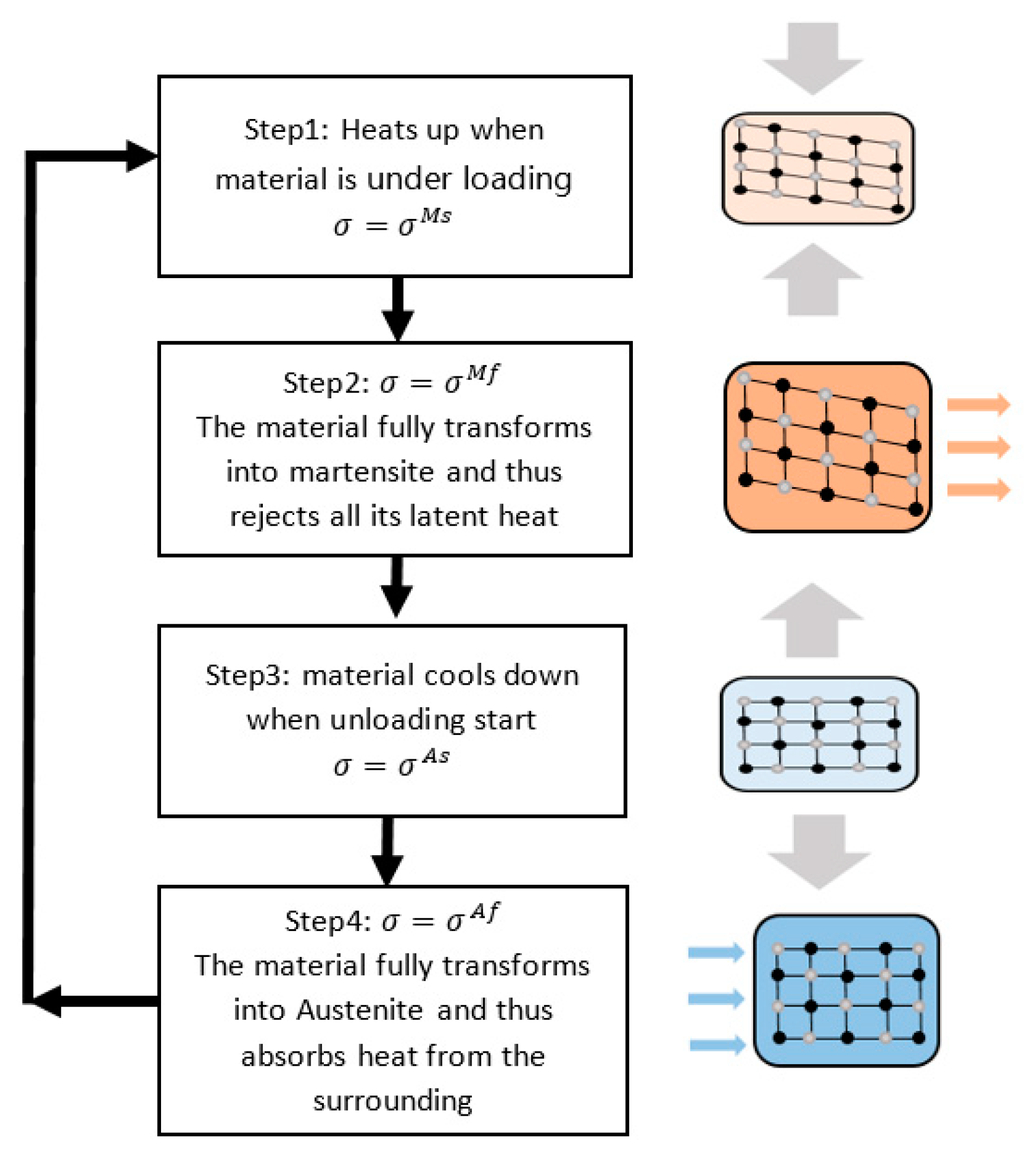

8. Elastocaloric Refrigeration

8.1. Basic Working Principles

8.2. Working Materials

8.3. Challenges and State of Development

8.4. Application

8.5. Advantages and Disadvantages

- is scalable;

- its core material is completely environmentally friendly, cheap, and abundant;

- and it has a high efficiency and high COPs.

9. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ožbolt, M.; Kitanovski, A.; Tušek, J.; Poredoš, A. Electrocaloric vs. magnetocaloric energy conversion. Int. J. Refrig. 2014, 37, 16–27. [Google Scholar] [CrossRef]

- Tassou, S.A.; Lewis, J.; Ge, Y.; Hadawey, A.; Chaer, I. A review of emerging technologies for food refrigeration applications. Appl. Therm. Eng. 2010, 30, 263–276. [Google Scholar] [CrossRef] [Green Version]

- Franco, V.; Blázquez, J.; Ipus, J.; Law, J.; Moreno-Ramírez, L.; Conde, A. Magnetocaloric effect: From materials research to refrigeration devices. Prog. Mater. Sci. 2018, 93, 112–232. [Google Scholar] [CrossRef]

- Aprea, C.; Greco, A.; Maiorino, A. Magnetic refrigeration: A promising new technology for energy saving. Int. J. Ambient. Energy 2014, 37, 294–313. [Google Scholar] [CrossRef] [Green Version]

- Eriksed, D. Active Magnetic Regenerator Refrigeration with Rotary Multi-Bed Technology. Ph.D. Thesis, Technical University of Denmark, Lyngby, Denmark, 2016. [Google Scholar]

- Olsen, U.L.; Bahl, C.R.; Engelbrecht, K.; Nielsen, K.K.; Tasaki, Y.; Takahashi, H. Modeling of in-vehicle magnetic refrigeration. Int. J. Refrig. 2014, 37, 194–200. [Google Scholar] [CrossRef] [Green Version]

- Gatti, J.; Muller, C.; Vasile, C.; Brumpter, G.; Haegel, P.; Lorkin, T. Magnetic heat pumps–Configurable hydraulic distribution for a magnetic cooling system. Int. J. Refrig. 2014, 37, 165–175. [Google Scholar] [CrossRef]

- Govindaraju, V.; Vilathgamuwa, D.M.; Ramanujan, R. Modelling of a magnetocaloric system for cooling in the kilowatt range. Int. J. Refrig. 2014, 43, 143–153. [Google Scholar] [CrossRef]

- Albertini, F.; Bennati, C.; Bianchi, M.; Branchini, L.; Cugini, F.; De Pascale, A.; Fabbrici, S.; Melino, F.; Ottaviano, S.; Peretto, A.; et al. Preliminary Investigation on a Rotary Magnetocaloric Refrigerator Prototype. Energy Procedia 2017, 142, 1288–1293. [Google Scholar] [CrossRef]

- Li, Z.; Shen, J.; Li, K.; Gao, X.; Guo, X.; Dai, W. Assessment of three different gadolinium-based regenerators in a rotary-type magnetic refrigerator. Appl. Therm. Eng. 2019, 153, 159–167. [Google Scholar] [CrossRef]

- Huang, B.; Lai, J.; Zeng, D.; Zheng, Z.; Harrison, B.; Oort, A.; Van Dijk, N.; Brück, E. Development of an experimental rotary magnetic refrigerator prototype. Int. J. Refrig. 2019, 104, 42–50. [Google Scholar] [CrossRef]

- He, J.; Wu, J.; Lu, B.; Liu, C. Comparative study on the series, parallel and cascade cycles of a multi-mode room temperature magnetic refrigeration system. Int. J. Refrig. 2020, 117, 94–103. [Google Scholar] [CrossRef]

- Kutjak, Z.; Rozic, B.; Pirc, R. Electrocaloric Effect: Theory, Measurements, and Applications; Wiley: Hoboken, NJ, USA, 2015. [Google Scholar]

- Mischenko, A. Giant Electrocaloric Effect in Thin-Film PbZr0.95Ti0.05O3. Science 2006, 311, 1270–1271. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Crossley, S. Electrocaloric Materials and Devices. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 2013. [Google Scholar]

- Echa.europa.eu. Lead-Substance Information-ECHA. 2019. Available online: https://echa.europa.eu/substance-information/-/substanceinfo/100.028.273 (accessed on 19 December 2019).

- Zaitouni, H.; Hajji, L.; Mezzane, D.; Choukri, E.; Alimoussa, A.; Ben Moumen, S.; Rožič, B.; El Marssi, M.; Kutnjak, Z. Direct electrocaloric, structural, dielectric, and electric properties of lead-free ferroelectric material Ba0.9Sr0.1Ti1−xSnxO3 synthesized by semi-wet method. Phys. B Condens. Matter 2019, 566, 55–62. [Google Scholar] [CrossRef] [Green Version]

- Abomostafa, H.; Ellamey, M. Studying the mechanical properties of Barium Strontium Titanate ceramics by an ultrasonic pulse-echo technology. J. Ovonic Res. 2018, 14, 307–316. [Google Scholar]

- Aprea, C.; Greco, A.; Maiorino, A.; Masselli, C. A comparison between different materials in an active electrocaloric regenerative cycle with a 2D numerical model. Int. J. Refrig. 2016, 69, 369–382. [Google Scholar] [CrossRef]

- Molin, C.; Peräntie, J.; Le Goupil, F.; Weyland, F.; Sanlialp, M.; Stingelin, N.; Novak, N.; Lupascu, D.C.; Gebhardt, S.E. Comparison of direct electrocaloric characterization methods exemplified by 0.92 Pb(Mg1/3 Nb2/3 )O3-0.08 PbTiO3 multilayer ceramics. J. Am. Ceram. Soc. 2017, 100, 2885–2892. [Google Scholar] [CrossRef]

- Aprea, C.; Greco, A.; Maiorino, A.; Masselli, C. Electrocaloric refrigeration: An innovative, emerging, eco-friendly refrigeration technique. J. Phys. Conf. Ser. 2017, 796, 12019. [Google Scholar] [CrossRef]

- Shi, J.; Zhu, R.; Liu, X.; Bi-Jun, F.; Yuan, N.; Ren, Y.; Luo, H. Large Electrocaloric Effect in Lead-Free (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 Ceramics Prepared via Citrate Route. Materials 2017, 10, 1093. [Google Scholar] [CrossRef]

- Aprea, C.; Greco, A.; Maiorino, A.; Masselli, C. Solid-state refrigeration: A comparison of the energy performances of caloric materials operating in an active caloric regenerator. Energy 2018, 165, 439–455. [Google Scholar] [CrossRef]

- Lu, S.; Li, J.; Cheng, M.; Li, Q.; Li, F.; Lv, Z.; Zhang, Y.; Lu, C.; Li, S. Joule heating-A significant factor in electrocaloric effect. Ceram. Int. 2019, 45, 16992–16998. [Google Scholar] [CrossRef]

- Guvenc, C.M.; Adem, U. Influence of aging on electrocaloric effect in Li+ doped BaTiO3 ceramics. J. Alloy. Compd. 2019, 791, 674–680. [Google Scholar] [CrossRef]

- Plaznik, U.; Vrabelj, M.; Kutnjak, Z.; Malič, B.; Rožič, B.; Poredoš, A.; Kitanovski, A. Numerical modelling and experimental validation of a regenerative electrocaloric cooler. Int. J. Refrig. 2019, 98, 139–149. [Google Scholar] [CrossRef]

- Shi, J.; Han, D.; Li, Z.; Yang, L.; Lu, S.-G.; Zhong, Z.; Chen, J.; Zhang, Q.; Qian, X. Electrocaloric Cooling Materials and Devices for Zero-Global-Warming-Potential, High-Efficiency Refrigeration. Joule 2019, 3, 1200–1225. [Google Scholar] [CrossRef]

- Zhao, D.; Tan, G. A review of thermoelectric cooling: Materials, modeling and applications. Appl. Therm. Eng. 2014, 66, 15–24. [Google Scholar] [CrossRef]

- Navarro-Peris, E.; Corberan, J.M.; Ancik, Z. Evaluation of the potential recovery of compressor heat losses to enhance the efficiency of refrigeration systems by means of thermoelectric generation. Appl. Therm. Eng. 2015, 89, 755–762. [Google Scholar] [CrossRef]

- Pietrzyk, K.; Ohara, B.; Watson, T.; Gee, M.; Avalos, D.; Lee, H. Thermoelectric module design strategy for solid-state refrigeration. Energy 2016, 114, 823–832. [Google Scholar] [CrossRef]

- Cao, L.; Han, J.; Duan, L.; Huo, C. Design and Experiment Study of a New Thermoelectric Cooling Helmet. Procedia Eng. 2017, 205, 1426–1432. [Google Scholar] [CrossRef]

- Xu, W.; Liu, Y.; Marcelli, A.; Shang, P.; Liu, W. The complexity of thermoelectric materials: Why we need powerful and brilliant synchrotron radiation sources? Mater. Today Phys. 2018, 6, 68–82. [Google Scholar] [CrossRef]

- Moria, H.; Ahmed, M.; Alghanmi, A.; Mohamad, T.I.; Yaakob, Y. Experimental Study of Solar Based Refrigerator Using Thermoelectric Effect. Energy Procedia 2019, 158, 198–203. [Google Scholar] [CrossRef]

- Tian, X.-X.; Asaadi, S.; Moria, H.; Kaood, A.; Pourhedayat, S.; Jermsittiparsert, K. Proposing tube-bundle arrangement of tubular thermoelectric module as a novel air cooler. Energy 2020, 208, 118428. [Google Scholar] [CrossRef]

- Shen, L.; Zhang, W.; Liu, G.; Tu, Z.; Lu, Q.; Chen, H.; Huang, Q. Performance enhancement investigation of the thermoelectric cooler with segmented configuration. Appl. Therm. Eng. 2020, 168, 114852. [Google Scholar] [CrossRef]

- Cuce, E.; Guclu, T.; Cuce, P.M. Improving thermal performance of thermoelectric coolers (TECs) through a nanofluid driven water to air heat exchanger design: An experimental research. Energy Convers. Manag. 2020, 214, 112893. [Google Scholar] [CrossRef]

- Verma, S.S. Thermo-acoustic refrigeration. IOSR J. Mech. Civil Eng. 2014. [Google Scholar]

- Bhansali, P.S.; Patunkar, P.P.; Gorade, S.V.; Adhav, S.S.; Botre, S.S. An Overview Of Stack Design For A Thermoacoustic Refrigerator. Int. J. Res. Eng. Technol. 2015, 4, 68–72. [Google Scholar]

- Nathad, A.; Ahmed, F.; Khalid, M.O.; Kumar, R.; Hafeez, H. Experimental Analysis of an Economical Lab Demonstration Prototype of a Thermo Acoustic Refrigerator (TAR). Energy Procedia 2018, 157, 343–354. [Google Scholar] [CrossRef]

- Saechan, P.; Jaworski, J.A. Thermoacoustic cooler to meet medical storage needs of rural communities in developing countries. Therm. Sci. Eng. Process 2018, 7, 164–175. [Google Scholar] [CrossRef] [Green Version]

- Mishra, A.; Choudhary, A.K.; Tomar, T.; Korody, J. Thermoacoustic Refrigerator for High Temperature Gradient. MATEC Web Conf. 2018, 144, 04003. [Google Scholar] [CrossRef]

- Wang, H.; Yu, G.; Hu, J.; Wu, Z.; Hou, M.; Zhang, L.; Luo, E. A novel looped low-temperature heat-driven thermoacoustic refrigerator operating in room temperature range. Energy Procedia 2019, 158, 1653–1659. [Google Scholar] [CrossRef]

- Xu, J.; Luo, E.; Hochgreb, S. Study on a heat-driven thermoacoustic refrigerator for low-grade heat recovery. Appl. Energy 2020, 271, 115167. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Z.; Zhang, L.; Hu, J.; Luo, E. Traveling-wave thermoacoustic refrigerator for room temperature application. Int. J. Refrig. 2020, 120, 90–96. [Google Scholar] [CrossRef]

- Gao, X.Q.; Shen, J.; He, X.N.; Tang, C.C.; Li, K.; Dai, W.; Li, Z.X.; Jia, J.C.; Gong, M.Q.; Wu, J.F. Improvements of a room-temperature magnetic refrigerator combined with Stirling cycle refrigeration effect. Int. J. Refrig. 2016, 67, 330–335. [Google Scholar] [CrossRef]

- Ahmed, H.; Almajri, A.K.; Mahmoud, S.; Al-Dadah, R.; Ahmad, A. CFD modelling and parametric study of small scale Alpha type Stirling Cryocooler. Energy Procedia 2017, 142, 1668–1673. [Google Scholar] [CrossRef]

- Hachem, H.; Gheith, R.; Aloui, F.; Ben Nasrallah, S. Optimisation of an air-filled Beta type Stirling refrigerator. Int. J. Refrig. 2017, 76, 296–312. [Google Scholar] [CrossRef]

- Gadelkareem, M.T.; EldeinHussin, A.; Hennes, G.M.; El-Ehwany, A.A. Stirling cycle for hot and cold drinking water dispenser. Int. J. Refrig. 2019, 99, 126–137. [Google Scholar] [CrossRef]

- Bom, N.M.; Imamura, W.; Usuda, E.O.; Paixao, L.S.; Carcalho AM, G. Giant barocaloric effects in natural rubber: A relevant step toward solid-state cooling. ASC Macro Lett. 2017, 7, 470–471. [Google Scholar] [CrossRef] [Green Version]

- Aprea, C.; Greco, A.; Maioriono, A.; Masselli, C. Enhancing the Heat Transfer in an Active Barocaloric Cooling System Using Ethylene-Glycol Based Nanofluids as Secondary Medium. Energies 2019, 12, 2902. [Google Scholar] [CrossRef] [Green Version]

- Lagoudas, D. Shape Memory Alloys; Springer: New York, NY, USA, 2011. [Google Scholar]

- Tušek, J.; Engelbrecht, K.; Pryds, N. Elastocaloric effect of a Ni-Ti plate to be applied in a regenerator-based cooling device. Sci. Technol. Built Environ. 2016, 22, 489–499. [Google Scholar] [CrossRef]

- Qian, S.; Wang, Y.; Yuan, L.; Yu, J. A heat-driven elastocaloric cooling system. Energy 2019, 182, 881–899. [Google Scholar] [CrossRef]

- Ossmer, H. Elastocaloric Microcooling. Ph.D. Thesis, Karlsruhe Institute of Technology (KIT), Karlsruhe, Germany, 2017. [Google Scholar]

- Kirsch, S.; Schmidt, M.; Welsch, F.; Michaelis, N.; Schütze, A.; Seelecke, S. Development of a shape memory-based air conditioning system. In Proceedings of the 59th Ilmenau Scientific Colloquium, Ilmenau, Germany, 11–15 September 2017. [Google Scholar]

- Kabirifar, P.; Žerovnik, A.; Ahčin, Ž.; Porenta, L.; Brojan, M.; Tušek, J. Elastocaloric Cooling: State-of-the-art and Future Challenges in Designing Regenerative Elastocaloric Devices. Stroj. Vestn. J. Mech. Eng. 2019, 65, 615–630. [Google Scholar] [CrossRef] [Green Version]

- Greco, A.; Aprea, C.; Maiorino, A.; Masselli, C. A review of the state of the art of solid-state caloric cooling processes at room-temperature before 2019. Int. J. Refrig. 2019, 106, 66–88. [Google Scholar] [CrossRef]

| Technology | State of Development | Barriers | Presently Available Capacity | Technical Information | Efficiency/COP of Currently Available Systems | Current/Potential Area | |||

|---|---|---|---|---|---|---|---|---|---|

| Key Material | Material’s Availability | Working Principle | Technology Readiness Levels (TRL) | ||||||

| Magnetocaloric | R&D focuses on MCM and machine design optimization | Materials are not available, and the technology can’t be used for large scale with the available current fabrication technologies | >Up to 890 W >The technology doesn’t store energy as the energy gets rejected under a specific circumstance | Rare earth magnets | 95% of the global material production is in China | Rotating magnet to expose the paramagnetic materials to a magnetic field—moving part | 3 to 4 | Highest of 9.44 at 17.8 W (1.1 kg of Gd; HTF: water) | Mobile refrigerators and cryogenic temperatures |

| Lowest of 0.7 at 0.46 W (70 g of GdEr/Gd; HTF: Helium) | |||||||||

| Electrocaloric | >R&D shifted into lead-free materials as lead is classified as a toxic substance >Manufacturing of electrocaloric material and electrodes >Compact structures that offer high electric field | To produce high EC, large electric fields and required and they cause stress in the internal structure which results in chemical degradation and electromechanical breakdown | Few watts to 2 kW | Ferroelectrics, relaxor ferroelectrics & Antiferroelectric | Lead-based material available but more research into lead-free materials are required | Electric field | 1 to 2 | 7 to 10 | Wearable coolers and heating and cooling of vehicles seats |

| Thermoelectric | Current research focuses on: >Improvement of the intrinsic efficiencies of thermoelectric materials >Optimization of cooling system’s thermal design | Thermoelectric devices have great potential energy efficiency; however, these cannot be produced economically at large scale with current fabrication technologies | Few watts | Semiconductors | Available | DC current | 4 | 0.3–0.8 | PC processors, car seats temperature control and portable food and beverage storages |

| Thermoacoustic | >Structural and mechanical design >Heat transfer within a stack and with heat exchangers> Different gases | thermoacoustic prime mover generally requires a high-temperature heat source to achieve effective acoustic power output, which is a huge barrier to utilizing the low-grade heat source | Few watts to 6.5 kW | No special material except those of the components | Available | Sound waves | 4 | up to 3.2 | cryogenic temperatures, food applications, heavy-duty vehicles and domestic appliances |

| Stirling | studies on combining Stirling cycle with other novel technologies like magnetic refrigeration to generate higher cooling performance | Manufacturing cost and the challenges of differential expansion and linear generator design is a major barrier to the introduction of Stirling-cycle heat-pumps and refrigerators, particularly when competing against the very large-scale production of vapour compression technology | Few watts to 1 kW | No special material except those of the components | Available | Mechanical movement—moving parts | 4 | <1 | Cryocoolers, water dispensers, portable refrigerators and freezers and beverages vending machines. |

| Barocaloric | Early R&D stage (materials and cycles) | Natural rubber has a very short fatigue life | Few watts on modeling | Natural Rubber | Available | Stress in tension or compression—moving parts | 4 | 6 | Miniature cryocoolers |

| Elastocaloric | Materials characterization, system engineering and stress strategies | System’s complexity and a large number of components | <1 kW | Shape Memory Alloys | Available | Stress in tension, torsion or compression—moving parts | 3 to 4 | >9 | Domestic cooling and heating devices, large heat pumps for large scale cooling and heating as well as in heating and cooling vehicles |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ismail, M.; Yebiyo, M.; Chaer, I. A Review of Recent Advances in Emerging Alternative Heating and Cooling Technologies. Energies 2021, 14, 502. https://doi.org/10.3390/en14020502

Ismail M, Yebiyo M, Chaer I. A Review of Recent Advances in Emerging Alternative Heating and Cooling Technologies. Energies. 2021; 14(2):502. https://doi.org/10.3390/en14020502

Chicago/Turabian StyleIsmail, Mubarak, Metkel Yebiyo, and Issa Chaer. 2021. "A Review of Recent Advances in Emerging Alternative Heating and Cooling Technologies" Energies 14, no. 2: 502. https://doi.org/10.3390/en14020502

APA StyleIsmail, M., Yebiyo, M., & Chaer, I. (2021). A Review of Recent Advances in Emerging Alternative Heating and Cooling Technologies. Energies, 14(2), 502. https://doi.org/10.3390/en14020502