Solid Biofuels Scenarios from Rural Agricultural and Forestry Residues for Mexican Industrial SMEs

Abstract

:1. Introduction

2. Current Situation of the Use of SBFs in the Mexican Industrial Sector

3. General Methodology

4. Cost-Benefit Model and Mitigation Model

| Overall cost-benefit of implementing SBFs in a SME niche. All monetary values in this study are expressed in constant year 2017 US dollars (USD). | |

| Algebraic difference between the present value investment costs of the mitigation option in the AS using SBF in the SME niche, and the present value investment cost spent in the BS in the same SME. | |

| Algebraic difference between the present value Operation and Maintenance (O&M) costs of the mitigation option in the AS using SBFs in the SME niche, and the present value (O&M) costs spent in the BS. | |

| The algebraic difference between the present value SBFs’ costs of the mitigation option in the AS using SBFs in the SME niche, and the present value energy costs spent in the BS. The costs of SBF and energy used in the BS can be found in Table S1 of the Supplementary Material. |

| Algebraic difference of the investment costs occurring in year a due to SBF implementation in the SME niche in the AS and the investment costs in the BS during period p. | |

| a = | Years = 1, 2, 3… p |

| p = | Analysis Period (32 years). |

| d = | Discount rate (10%), representing the current cost of financing according to [29]. |

| Algebraic difference of the cumulative annual O&M costs due to SBFs implementation in a SME niche in the AS, and the cumulative annual O&M costs in the BS, during the analysis period. |

| Algebraic difference between the annual cumulated costs during the analysis period of using SBFs in a SME niche in the AS, and the annual cumulated energy costs in the BS. |

| Cost-benefit in present value of the SBFs implementation in the AS of the SMEs niche related to the BS, from Equation (2). | |

| Total avoided GHG emissions due to SBFs in the AS of the SMEs niche related to the BS. See the following equation: |

| Total energy avoided by fuel f used in the BS during the analysis period, due to the implementation of SBFs in the AS of the studied SMEs niche. | |

| GHG emission factor from the energy source f in terms of CO2e in the BS. Table S2 in the Supplementary Material shows the GHG emission factors for fuelwood and fossil fuels used in the BS. SBFs are carbon neutral in the AS because they are sustainably produced exclusively from agricultural and forestry residues. |

5. Reference Year and Construction of the Baseline Scenario

- Brick kilns

- Limekilns

- Artisanal Mezcal

- Dairy products

- Craft breweries:

6. Construction of the Alternative Scenario

7. Results

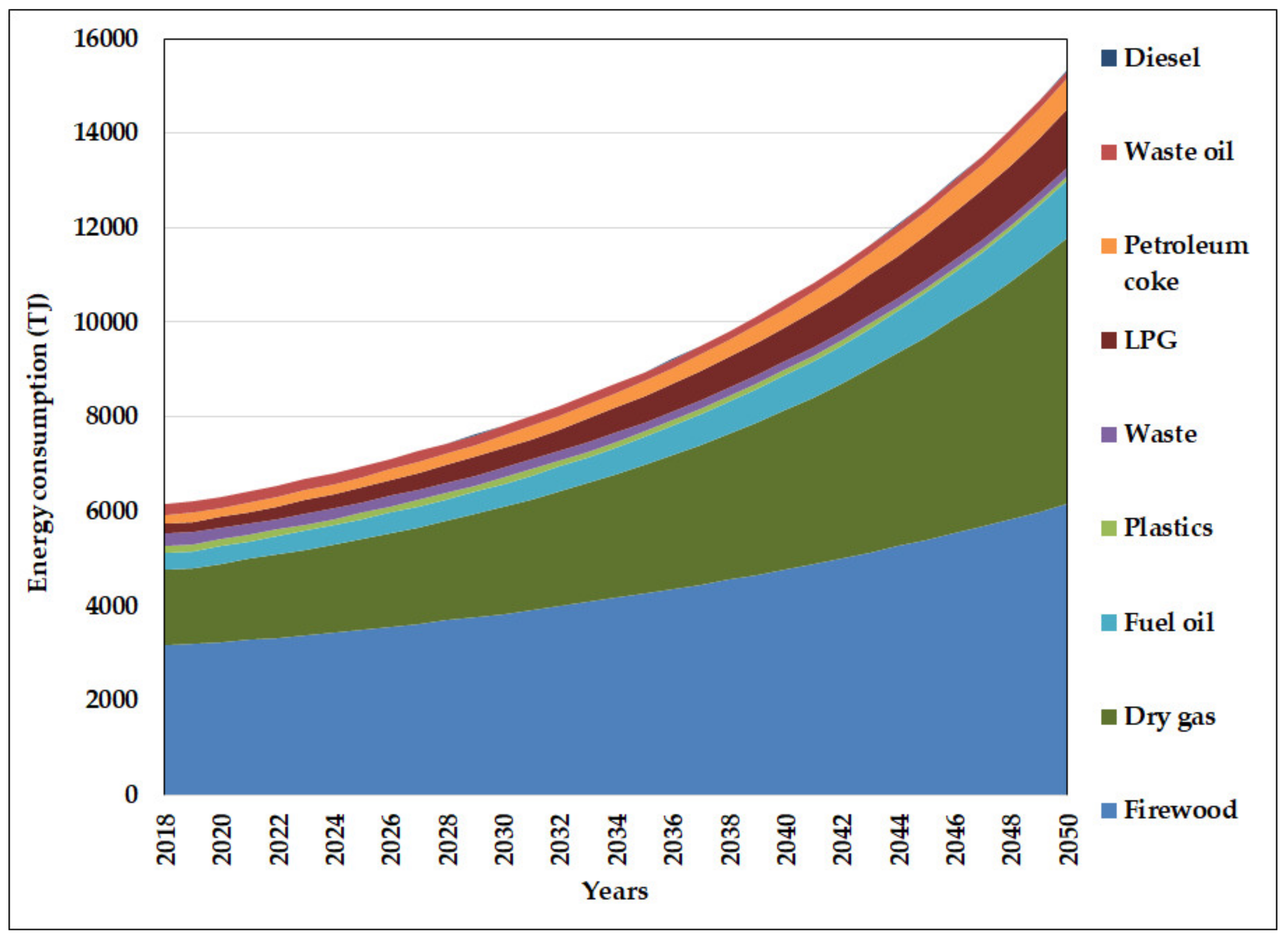

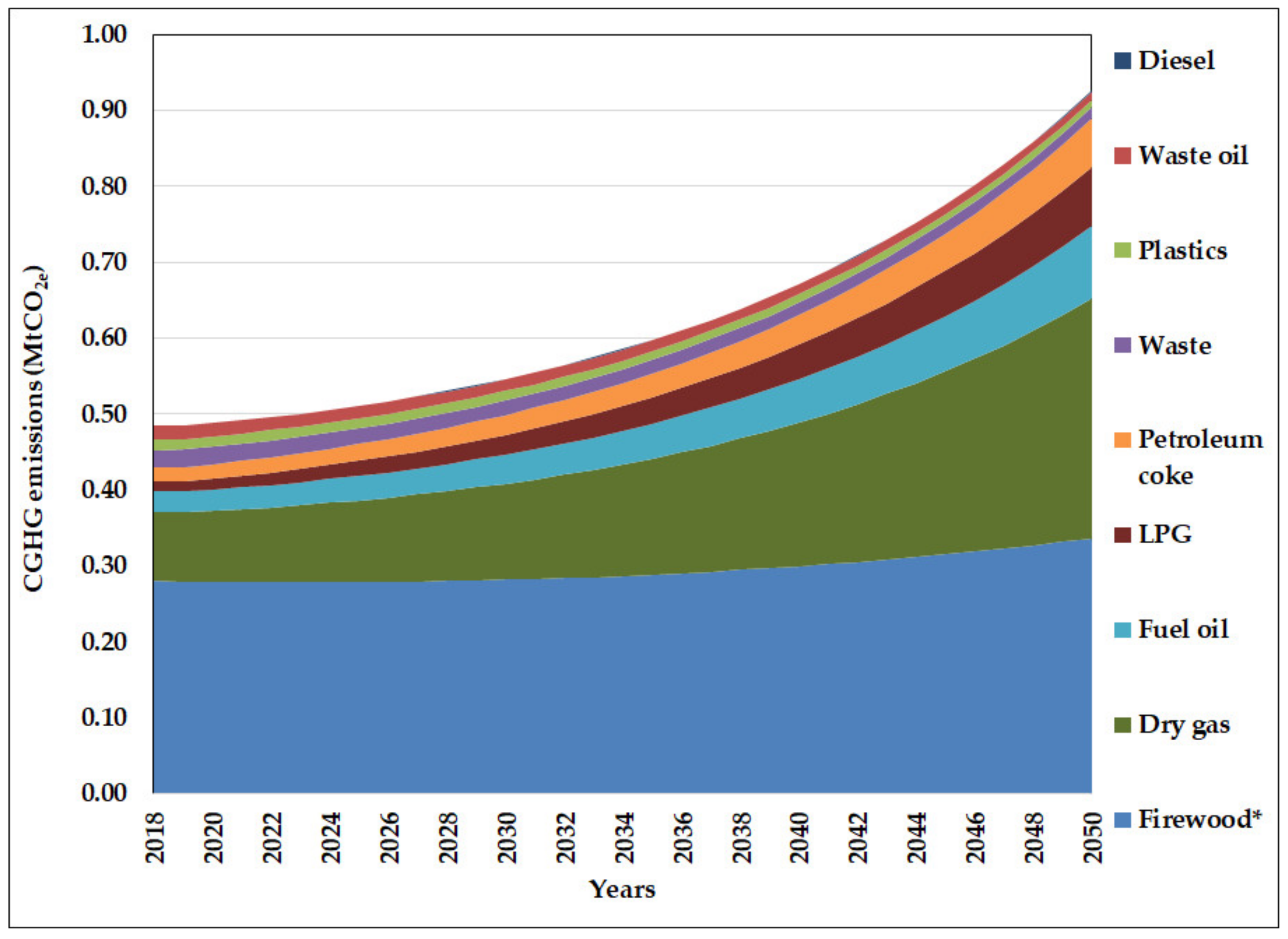

7.1. Energy and Environmental Results of the Baseline Scenario (BS)

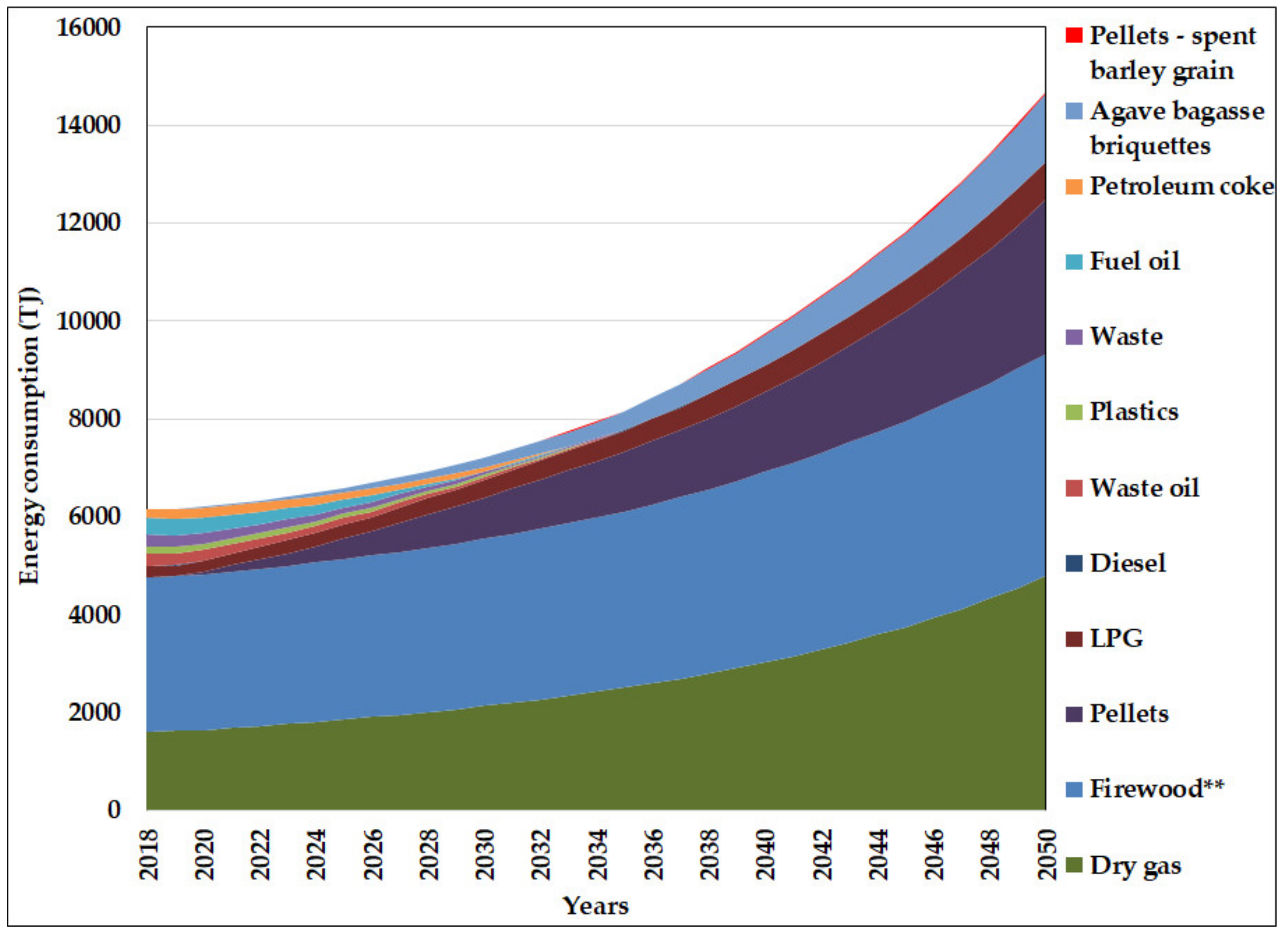

7.2. Energy and Environmental Results of the Alternative Scenario (AS)

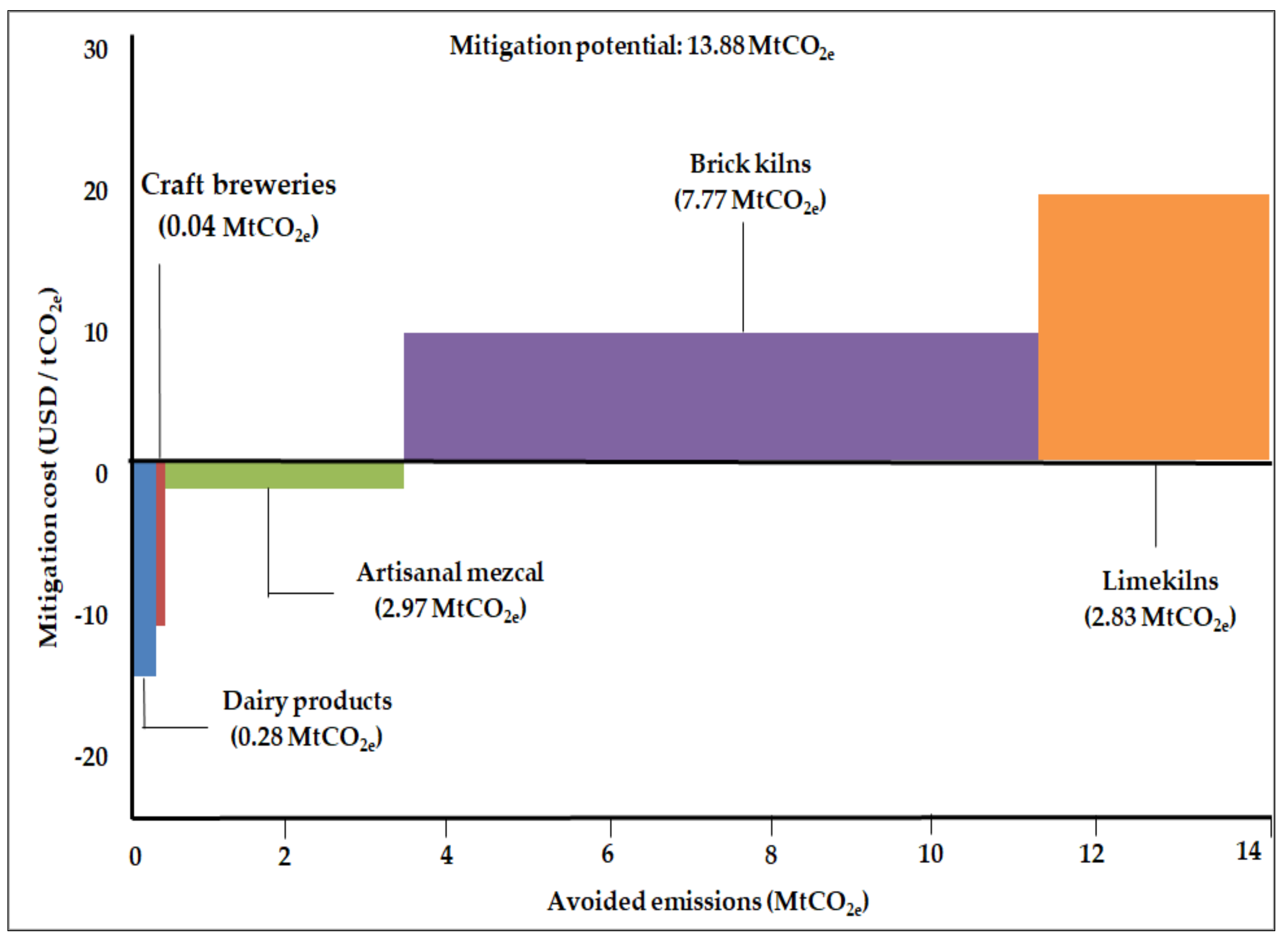

7.3. Economic Results by Industrial SME Niche

8. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- U.S. Energy Information Administration (EIA). International Energy Outlook 2019 with Projections to 2050. Available online: https://www.eia.gov/outlooks/ieo/pdf/ieo2019.pdf (accessed on 24 August 2021).

- International Energy Agency (IEA). CO2 Emissions from Fuel Combustion. Available online: https://www.iea.org/reports/co2-emissions-from-fuel-combustion-overview (accessed on 24 August 2021).

- International Energy Agency (IEA). Renewable Energy for Industry. Available online: http://admin.indiaenvironmentportal.org.in/files/file/RenewableEnergyforIndustry.pdf (accessed on 24 July 2021).

- International Energy Agency (IEA). Global Bioenergy Consumption by Type of Source and Sector. 2018. Available online: https://www.iea.org/data-and-statistics/charts/global-bioenergy-consumption-by-type-of-source-and-sector-2018 (accessed on 24 July 2021).

- Malico, I.; Nepomuceno Pereira, R.; Gonçalves, A.C.; Sousa, M.O. Current Status and Future Perspectives for Energy Production from Solid Biomass in the European Industry. Renew. Sustain. Energy Rev. 2019, 112, 960–977. [Google Scholar] [CrossRef]

- European Pellets Council. Report Pellets 2019. Available online: https://epc.bioenergyeurope.org/bioenergy-europe-pellet-report-2019/ (accessed on 23 March 2021).

- U.S. Energy Information Administration (EIA). Wood and Wood Waste. Available online: https://www.eia.gov/energyexplained/biomass/wood-and-wood-waste.php (accessed on 22 July 2021).

- International Energy Agency (IEA). World Energy Balances. Available online: https://www.oecd-ilibrary.org/energy/data/iea-world-energy-statistics-and-balances/world-energy-balances_data-00512-en (accessed on 15 July 2021).

- International Energy Agency (IEA). World Energy Statistics 2018; OECD: Paris, France, 2018; ISBN 9789264301269. [Google Scholar]

- Mahato, N.; Sharma, K.; Sinha, M.; Baral, E.R.; Koteswararao, R.; Dhyani, A.; Cho, M.H.; Cho, S. Bio-Sorbents, Industrially Important Chemicals and Novel Materials from Citrus Processing Waste as a Sustainable and Renewable Bioresource: A Review. J. Adv. Res. 2020, 23, 61–82. [Google Scholar] [CrossRef] [PubMed]

- Tauro, R.; García, C.A.; Skutsch, M.; Masera, O. The Potential for Sustainable Biomass Pellets in Mexico: An Analysis of Energy Potential, Logistic Costs and Market Demand. Renew. Sustain. Energy Rev. 2018, 82, 380–389. [Google Scholar] [CrossRef]

- Fazzino, F.; Mauriello, F.; Paone, E.; Sidari, R.; Calabro, P. Integral Valorization of Orange Peel Waste through Optimized Ensiling: Lactic Acid and Bioethanol Production. Chemosphere 2021, 271, 129602. [Google Scholar] [CrossRef] [PubMed]

- Martins, L.C.; Monteiro, C.C.; Semedo, P.M.; Sá-Correia, I. Valorisation of Pectin-Rich Agro-Industrial Residues by Yeasts: Potential and Challenges. Appl. Microbiol. Biotechnol. 2020, 104, 6527–6547. [Google Scholar] [CrossRef]

- Jeong, D.; Park, H.; Jang, B.; Ju, Y.; Shin, M.; Oh, E.; Lee, E.; Kim, S. Recent Advances in the Biological Valorization of Citrus Peel Waste into Fuels and Chemicals. Bioresour. Technol. 2021, 323, 124603. [Google Scholar] [CrossRef] [PubMed]

- Zema, D.A.; Calabrò, P.S.; Folino, A.; Tamburino, V.; Zappia, G.; Zimbone, S.M. Valorisation of Citrus Processing Waste: A Review. Waste Manag. 2018, 80, 252–273. [Google Scholar] [CrossRef]

- Navarro Pineda, F.S.; Equihua-Sánchez, M.; Grande-Acosta, G.K.; Sacramento Rivero, J.C.; Islas-Samperio, J.M.; Bonales Revuelta, J.; Musule, R.; García, C.A.; Manzini, F. Assessment of the Environmental and Economic Performance of Heat Generation from Orange Peels and Sugarcane Straw. Bioenerg. Res. 2021. [Google Scholar] [CrossRef]

- Fernández Baca, M. La Energía de La Biomasa. Ing. Ind. 1994, 12, 21–29. [Google Scholar]

- International Renewable Energy Agency (IRENA). Solid Biomass Supply for Heat and Power: Technology Brief; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019; p. 51. ISBN 978-92-9260-107-2. [Google Scholar]

- Islas, J.; Manzini, F.; Masera, O.; Vargas, V. Solid Biomass to Heat and Power. In The Role of Bioenergy in the Emerging Bioeconomy; Elsevier: Amsterdam, The Netherlands, 2019; pp. 145–177. [Google Scholar]

- Honorato-Salazar, J.A.; Sadhukhan, J. Annual Biomass Variation of Agriculture Crops and Forestry Residues, and Seasonality of Crop Residues for Energy Production in Mexico. Food Bioprod. Process. 2020, 119, 1–19. [Google Scholar] [CrossRef]

- Hu, J.; Lei, T.; Wang, Z.; Yan, X.; Shi, X.; Li, Z.; He, X.; Zhang, Q. Economic, Environmental and Social Assessment of Briquette Fuel from Agricultural Residues in China—A Study on Flat Die Briquetting Using Corn Stalk. Energy 2014, 64, 557–566. [Google Scholar] [CrossRef]

- Sims Ralph, E.H. The Brilliance of Bioenergy: In Business and in Practice; Taylor and Francis: Abingdon, UK, 2013; p. 328. [Google Scholar]

- Secretaría de Energía (SENER). Reporte de Inteligencia Tecnológica Biocombustibles Sólidos. Available online: https://www.gob.mx/cms/uploads/attachment/file/306072/Inteligencia_Tecnologica_BCS_220218.pdf (accessed on 25 August 2021).

- De Lucas Herguedas, A.I.; del Peso Taranco, C.; Rodrígez García, E.; Prieto Paniagua, P. Biomasa, Biocombustibles y Sostenibilidad; Centro Tecnológico Agrario y Agroalimentario: Palencia, Spain, 2012; Volume 13, p. 109. ISBN 978-84-931891-5-0. [Google Scholar]

- Diario Oficial de la Federación (DOF). Programa Especial Para El Aprovechamiento de Energías Renovables. Available online: http://www.dof.gob.mx/nota_detalle.php?codigo=5342501&fecha=28/04/2014 (accessed on 27 August 2021).

- Xu, J.; Chang, S.; Yuan, Z.; Jiang, Y.; Liu, S.; Li, W.; Ma, L. Regionalized Techno-Economic Assessment and Policy Analysis for Biomass Molded Fuel in China. Energies 2015, 8, 13846–13863. [Google Scholar] [CrossRef] [Green Version]

- United Nations Industrial Development Organization (UNIDO). Renewable Energy in Industrial Applications. Available online: https://www.solarthermalworld.org/sites/default/files/unido_renewables_industrial_applications.pdf (accessed on 28 August 2021).

- Masera, O.R. La Bioenergía En México. Un Catalizador Del Desarrollo Sustentable; Mundi-Prensa México: Mexico City, Mexico, 2006; ISBN 968-7462-42-6. [Google Scholar]

- Johnson, T.; Alatorre, C.; Romo, Z.; Feng, L. México: Estudio Para La Disminución de Emisiones de Carbono (MEDEC); Primera Edición; Banco Internacional de Reconstrucción y Fomento/Banco Mundial: Washington, DC, USA, 2009; ISBN 978-958-8307-75-6. [Google Scholar]

- Ehrig, R.; Behrendt, F. Co-Firing of Imported Wood Pellets-An Option to Efficiently Save CO2 Emissions in Europe? Energy Policy 2013, 59, 283–300. [Google Scholar] [CrossRef]

- García, C.A.; Masera, O.; Riegelhaupt, E.; Ghilardi, A.; Skutsch, M.; Islas, J.; Manzini, F. Sustainable Bioenergy Options for Mexico: GHG Mitigation and Costs. Renew. Sustain. Energy Rev. 2015, 43, 545–552. [Google Scholar] [CrossRef]

- León, P.; Vidal, F.; Rodríguez, T.; Castro, A.; Arrazola, I.; García, A.; Martínez, S.; Hernández, R.; Castro, M. Estudio de La Cadena de Valor Del Sector Ladrillero Del Estado de Jalisco. Available online: https://semadet.jalisco.gob.mx/sites/semadet.jalisco.gob.mx/files/estudio_de_la_cadena_de_valor_del_sector_ladrillero_del_estado_de_jalisco.pdf (accessed on 20 June 2020).

- García, C.A.; Riegelhaupt, E.; Masera, O. Escenarios de Bioenergía En México: Potencial de Sustitución de Combustibles Fósiles y Mitigación de GEI. Rev. Mex. Física 2013, 59, 93–103. [Google Scholar]

- Islas, J.; Manzini, F.; Masera, O. A Prospective Study of Bioenergy Use in Mexico. Energy 2007, 32, 2306–2320. [Google Scholar] [CrossRef]

- Instituto Nacional de Geografía y Estadística (INEGI). Comunicado de Prensa Num. 617/20. El INEGI Presenta Resultados de La Segunda Edición Del ECOVID-IE y Del Estudio Sobre Demografía de Los Negocios 2020. Available online: https://inegi.org.mx/contenidos/saladeprensa/boletines/2020/OtrTemEcon/ECOVID-IE_DEMOGNEG.pdf (accessed on 28 July 2021).

- Bouille, D.; Carpio, C.; Sbroiavacca, N.D.; Dubrobsky, H.; Nadal, G.; Lallana, F.; Landavery, R.; Pistonesi, H.; Planchú, J.; Recalde, M.; et al. Propuesta de Instrumentos Para Facilitar Medidas de Eficiencia Energética En El Sector Industrial de México. Available online: https://www.gob.mx/conuee/acciones-y-programas/propuesta-de-instrumentos-para-facilitar-medidas-de-eficiencia-energetica-en-el-sector-industrial-de-mexico (accessed on 13 July 2021).

- Secretaría de Energía (SENER). Balance Nacional de Energía 2018. Available online: https://www.gob.mx/cms/uploads/attachment/file/528054/Balance_Nacional_de_Energ_a_2018.pdf (accessed on 10 April 2020).

- Secretaría de Energía (SENER). Sistema de Información Energética. Available online: http://sie.energia.gob.mx (accessed on 13 September 2020).

- CONADESUCA-SAGARPA. Reducción Del Consumo de Petróleo y Generación de Energía Eléctrica En Los Ingenios. Available online: https://www.gob.mx/cms/uploads/attachment/file/515516/Boletin_Tecnico_Informativo_Enero_2016.pdf (accessed on 18 September 2020).

- Alvarado Machuca, S.V.; Álvarez Sánchez, M.E.; Maldonado Torres, R.; Sánchez Velez, A.S. Consumo de leña en México: Hábitos de uso, problemática asociada y alternativas sostenibles de solución. In Agroforestería Para la Conservación de los Recursos Naturales y Productividad; Universidad Autónoma Chapingo: Texcoco, Mexico, 2018. [Google Scholar]

- Arias-Chalico, T. Situación Actual y Escenarios Para El Desarrollo Del Biogás En México Hacia 2024 y 2030. Available online: http://rembio.org.mx/newsite/wp-content/uploads/2020/11/Situacion-actual-y-escenarios-para-el-desarrollo-del-biogas-en-Mexico.pdf (accessed on 25 August 2021).

- Arias-Chalico, T. Tecnologías de Aprovechamiento de Biomasa Forestal Para Energía En México Viabilidad y Recomendaciones Generales Para Su Selección. Available online: https://energypedia.info/index.php?title=File:GIZ_Tecnologías_biomasa_forestal_2015.pdf&page=1 (accessed on 18 October 2020).

- Durán-García, M.D.; Weber, B.; Jiménez-García, J.A. Análisis de Sustentabilidad Del Empleo de BCS Para Calor de Proceso. Rev. de Desarro. Urbano y Sustentable 2019, 5, 1–12. [Google Scholar] [CrossRef]

- Instituto Nacional de Estadística y Geografía (INEGI). Encuesta Mensual de La Industria Manufacturera (EMIM) 2007–2019. Base 2008. Available online: https://www.inegi.org.mx/programas/emim/2007/ (accessed on 20 June 2020).

- Asociación de Cerveceros Artesanales de México (ACERMEX). Reporte de La Industria Cervecera Independiente Mexicana 2018. Available online: http://acermex.org/wp-content/uploads/2020/01/Reporte-de-la-Industria-.-Acermex-2actua.pdf (accessed on 20 November 2020).

- Consejo Regulador de Mezcal. Informe Estadístico 2020. Available online: https://www.gob.pe/institucion/pronacej/informes-publicaciones/1758100-informe-estadistico-2020 (accessed on 13 December 2020).

- Bhattacharyya, S.C. Energy Economics: Concepts, Issues, Markets and Governance; Springer: London, UK, 2011. [Google Scholar]

- Grande-Acosta, G.; Islas-Samperio, J. Towards a Low-Carbon Electric Power System in Mexico. Energy Sustain. Dev. 2017, 37, 99–109. [Google Scholar] [CrossRef]

- Instituto Nacional de Ecología y Cambio Climático (INECC). Estudio Para Desarrollar Un Modelo de Negocio Piloto En Ladrilleras Artesanales, Para Reducir Emisiones de Contaminantes Climáticos de Vida Corta y Gases de Efecto Invernadero, Así Como Mejorar La Calidad de Vida de Los Actores Clave. Available online: https://www.gob.mx/cms/uploads/attachment/file/493391/Ladrilleras_versi_n_final-2019.pdf (accessed on 25 August 2021).

- Guerrero Gómez, G.; Espinel Blanco, E.; Sánchez Acevedo, H.G. Análisis de Temperaturas Durante La Cocción de Ladrillos Macizos y Sus Propiedades Finales. Tecnura 2017, 21, 118. [Google Scholar] [CrossRef] [Green Version]

- Instituto Nacional de Ecología y Cambio Climático (INECC). Apoyo a la Iniciativa de Planificación Nacional sobre Contaminantes Climáticos de Vida Corta en México. Available online: https://www.gob.mx/cms/uploads/attachment/file/40813/2013_snap_mexico_esp.pdf (accessed on 25 August 2021).

- Henriques, M.F.; Valença Schwob, M.R.; Pinto Rodrigues, J.A. Manual de Eficiencia Energética En La Industria Ladrillera; Instituto Nacional de Tecnología: Rio de Janeiro, Brazil, 2015. [Google Scholar]

- Cárdenas, B.; Aréchiga, U.; Munguía, J.L.; Márquez, C.; Campos, A. Evaluación Preliminar Del Impacto Ambiental Por La Producción Artesanal de Ladrillo: Eficiencia Energética y Calidad Del Aire; Universidad Autónoma Metropolitana: Mexico City, Mexico; Instituto Nacional De Ecología: Mexico City, Mexico, 2012. [Google Scholar]

- Cova Orozco, A.; Morales Zendero, L.A.; Ibáñez Sosa, G.; Ochoa Lomelin, A.; Leñero Ríos, M.; Camacho Zepeda, D.A.; Cornejo González, N.A.; Estrada Hernández, Á.; Camacho López, S. Proyecto de Aplicación Profesional (PAP). Available online: https://rei.iteso.mx/bitstream/handle/11117/5219/Proyecto+ladrilleras.pdf?sequence=2 (accessed on 28 August 2020).

- Climate Technology Centre & Network. Horno MK2. Available online: https://www.ctc-n.org/sites/www.ctc-n.org/files/UNFCCC_docs/ref34x13_35.pdf (accessed on 30 September 2020).

- Instituto Nacional de Ecología y Cambio Climático (INECC). Análisis de Mercado Del Sector de La Construcción y Proyecto Piloto a Nivel Región Basado En Un Portafolio de Políticas Con El Objetivo de Reducir Los Contaminantes Climáticos de Vida Corta, de Ladrilleras Artesanales En México. Available online: https://www.gob.mx/cms/uploads/attachment/file/253631/8_CGCV_2016_Ana_lisis_de_Mercado_Ladrilleras_Artesanales_CDMEX.pdf (accessed on 25 August 2021).

- Serrano Medrano, M.; Ghilardi, A.; Masera, O. Fuelwood Use Patterns in Rural Mexico: A Critique to the Conventional Energy Transition Model. Hist. Agrar. 2019, 77, 81–104. [Google Scholar] [CrossRef]

- Durán Alca, J.C.; Mendoza Murillo, R. Influencia de La Sílice En El Proceso de Calcinación Para Reducir El Contenido de Requemado En El Óxido de Calcio; Universidad Nacional de San Agustín de Arequipa: Arequipa, Peru, 2017; p. 73. [Google Scholar]

- Ministerio para la Transición Ecológica y el Reto Demográfico (MITECO). Fabricación de Cal (Emisiones de Proceso). Available online: https://www.miteco.gob.es/es/calidad-y-evaluacion-ambiental/temas/sistema-espanol-de-inventario-sei-/040614-descarbonatac-fabric-cal_tcm30-429852.pdf (accessed on 25 August 2021).

- Secretaría del Medio Ambiente y Recursos Naturales (SEMARNAT); Instituto Nacional de Cambio Climático (INECC). Componente 5: Medidas Para La Implementación Temprana Del Convenio de Minamata. Informe Final. Available online: https://www.gob.mx/cms/uploads/attachment/file/341246/Informe_Final_Compilado_Componente_5.pdf (accessed on 25 August 2021).

- Diario Oficial de la Federación (DOF). Norma Oficial Mexicana NOM-070-SCFI-2016, Bebidas Alcohólicas-Mezcal-Especificaciones. Available online: https://dof.gob.mx/nota_detalle.php?codigo=5472787&fecha=23/02/2017&print=true (accessed on 25 August 2021).

- Mezcal Oaxaca. Proceso y Producción Del Mezcal. Available online: http://www.mezcal-oaxaca.com/procesoyproducciondelmezcal.html (accessed on 25 August 2021).

- García, M.; Méndez, R. El Consumo de Leña En La Producción de Mezcal. El Caso de Santiago Matatlán, Oaxaca. Available online: http://www.fao.org/3/AD096S/AD096S03.htm#ch2 (accessed on 25 August 2021).

- Diario Oficial de la Federación (DOF). Lista de Combustibles 2018 Que Se Considerarán Para Identificar a Los Usuarios Con Un Patrón de Alto Consumo, Así Como Los Factores Para Determinar Las Equivalencias En Términos de Barriles Equivalentes de Petróleo. Available online: https://www.dof.gob.mx/nota_detalle_popup.php?codigo=5417918 (accessed on 25 August 2021).

- Palma, F.; Pérez, P.; Meza, V. Diagnóstico de La Cadena de Valor Mezcal En Las Regiones de Oaxaca. Available online: http://www.coplade.oaxaca.gob.mx/wp-content/uploads/2017/04/Perfiles/AnexosPerfiles/6.CVMEZCAL.pdf (accessed on 28 March 2020).

- Servicio Nacional de Sanidad y Calidad Agroalimentaria (SENASA). Pasteurización. Available online: http://www.senasa.gob.ar/senasa-comunica/noticias/pasteurizacion (accessed on 25 August 2021).

- Luluaga, S.; Nuñez, M. Guia de Elaboración de Quesos Artesanales. Available online: http://www.alimentosargentinos.gob.ar/contenido/procal/proyectospiloto/2009/2009_Lacteos_Tucuman_01_guiaQuesos.pdf (accessed on 25 August 2021).

- Riva, G. Utilization of Renewable Energy Sources and Energy- Saving Echnologies by Small-Scale Milk Plants and Collection Centres. Available online: http://www.fao.org/3/T0515E/T0515E00.htm (accessed on 25 August 2021).

- Bleier, B.; Callahan, A.; Farmer, S.; Min, H. Craft Beer Production. Sr. Des. Rep. 2013, 53, 15–17. [Google Scholar]

- Sperandio, G.; Amoriello, T.; Carbone, K.; Fedrizzi, M.; Monteleone, A.; Tarangioli, S.; Pagano, M. Increasing the Value of Spent Grain from Craft Microbreweries for Energy Purposes. Chem. Eng. Trans. 2017, 58, 487–492. [Google Scholar] [CrossRef]

- Los Cervecistas. El Proceso de Fabricación de La Cerveza. Available online: https://www.loscervecistas.es/el-proceso-defabricacion-de-la-cerveza/ (accessed on 23 July 2021).

- Instituto Nacional de Ecología y Cambio Climático (INECC). Rutas de Instrumentación de Las Contribuciones Nacionalmente Determinadas En Materia de Mitigación de Gases y Compuestos de Efecto Invernadero (GyCEI) Del Sector Industria (Cemento, Acero, Calero y Azucarero) En México, Como Insumo Para La Sexta Comunicación Nacional de Cambio Climático. Available online: https://www.gob.mx/cms/uploads/attachment/file/462290/5_Industria_Intensiva_V2.pdf (accessed on 25 August 2021).

- Gobierno de la República. Lista de Combustibles 2020 Que Se Considerarán Para Identificar a Los Usuarios Con Un Patrón de Alto Consumo, Así Como Los Factores Para Determinar Las Equivalencias En Términos de Barriles Equivalentes de Petróleo. Available online: https://www.gob.mx/cms/uploads/attachment/file/302306/Lista_de_combustibles_2018.pdf (accessed on 26 November 2020).

- Chavez, G. Uso de Bagazo de La Industria Mezcalera Como Materia Prima Para Generar Energía. Ingenierías 2010, 13, 8–16. [Google Scholar]

- Herrera-Camacho, J.; Modesto Sánchéz, N.; Martínez-Palacios, A. Prospectiva Estratégica Para El Aprovechamiento Del Bagazo Residual de Agave Generado al Producir Mezcal En Michoacán. In Proceedings of the X Congreso Internacional de Gestión, Calidad y Competitividad Empresarial, Morelia, Michoacán, Mexico, 8–9 October 2015; pp. 1536–1569. [Google Scholar]

- Transformación Carbón Energía. Resultado de Las Pruebas Con Briquetas de Biomasa de Agave. Available online: https://carbondiversionamericalatina.files.wordpress.com/2011/11/resultado-laboratorio-briquetas-tce-espac3b1ol.pdf (accessed on 25 August 2021).

- Jackowski, M.; Niedźwiecki, Ł.; Jagiełło, K.; Uchańska, O.; Trusek, A. Brewer’s Spent Grains—Valuable Beer Industry by-Product. Biomolecules 2020, 10, 1669. [Google Scholar] [CrossRef] [PubMed]

- Mussatto, S.I.; Dragone, G.; Roberto, I.C. Brewers’ Spent Grain: Generation, Characteristics and Potential Applications. J. Cereal Sci. 2006, 43, 1–14. [Google Scholar] [CrossRef]

- Reinold, M.R. Manual Prático de Cervejaria; ADEN Editora e Comunicações: Sao Paulo, Brazil, 1997. [Google Scholar]

- Made in China. Pellet Biomasa Generador de Vapor Para La Industria de Cerveza. Available online: https://es.made-in-china.com/co_oukerg/product_Biomass-Pellet-Steam-Generator-for-Beer-Industry_ehnhrihry.html (accessed on 25 August 2021).

| Niche | Activity Level | Production (2018) | Units | AAGR (2018–2050) | Information Source for 2018 Data and Historical Trends from AAGR |

|---|---|---|---|---|---|

| Brick kilns | Bricks production and others | 225,923 | Thousand pieces | −1.3% | [44] |

| Limekilns | Lime production | 970,515 | tons | 2.1% | [44] |

| Dairy companies | Industrialized milk production | 30,193 | thousand litres | −2.9% | [44] |

| Dairy products (cheeses) production | 55,519 | tons | 6.0% | [44] | |

| Craft breweries | Craft beer production | 189,250 | hectolitres | 2.9% | [45] |

| Artisanal Mezcal | Mezcal production | 5089 | thousand litres | 5.9% | [46] |

| Kiln | Concept | Year | Cost | Units | Reference |

|---|---|---|---|---|---|

| MK2 | Investment | 2012 | 10,700.00 | USD | [55] |

| Operation | 2018 | 5.04 | USD/Thousand | [49] | |

| Maintenance | 2018 | 0.06 | USD/Thousand | [49] | |

| Traditional | Investment | 2018 | 72,067.90 | USD | [49] |

| Operation | 2018 | 5.04 | USD/Thousand | [49] | |

| Maintenance | 2018 | 0.30 | USD/Thousand | [49] | |

| Horizontal multi-chamber | Investment | 2018 | 120,113.16 | USD | [49] |

| Operation | 2018 | 52.83 | USD/Thousand | [49] | |

| Maintenance | 2018 | 0.50 | USD/Thousand | [49] |

| Guy | Process | Indicator | Reference |

|---|---|---|---|

| Simple plants | Pasteurization | 180 MJ/t of processed milk | [68] |

| Cheese and yogurt production | 180 MJ/t of processed cheese | [68] | |

| Complex plants | Pasteurization | 250 MJ/t of processed milk | [68] |

| Cheese and yogurt production | 450 MJ/t of processed cheese | [68] |

| Niche | End-Use | Process | Biomass Inputs | SBFs Shape | Technology |

|---|---|---|---|---|---|

| Brick kilns | Heat generation | Brick firing | Forest residues | Firewood | MK2 oven |

| Limekilns | Calcination | Forest residues | Pellets | Conventional boilers | |

| Artisanal mezcal | Pineapple cooking Distillation | Agave bagasse | Briquettes | Conventional oven | |

| Dairy products | Steam generation | Pasteurization Process heat | Forest residues | Pellets | Biomass boiler |

| Craft beer | Maceration Wort boiling Sterilization and cleaning | Spent barley grain | Pellets | Biomass boiler |

| Niche | Fossil Energy Avoided | Accumulated Avoided Fossil Energy | CGHG Avoided Emissions in | Cumulative Avoided CGHG Emissions | Emissions Avoided Compared to BS |

|---|---|---|---|---|---|

| 2050 | 2018–2050 | 2050 | 2018–2050 | 2018–2050 | |

| (TJ) | (TJ) | (MtCO2e) | (MtCO2e) | % | |

| Brick kilns | 644.7 | 18,330.6 | 0.10 | 7.77 | 37.6% |

| Limekilns | 2694.7 | 36,505.1 | 0.20 | 2.83 | 13.7% |

| Artisanal Mezcal * | 1373.0 | 15,027.4 | 0.17 | 2.97 | 14.4% |

| Dairy products | 442.5 | 535.8 | 0.03 | 0.28 | 1.4% |

| Craft breweries | 49.8 | 4481.4 | 0.003 | 0.04 | 0.2% |

| Total | 5204.7 | 74,880.3 | 0.51 | 13.88 | 67.2% |

| Niche | Investment | O&M | Fuel | Cost-Benefit | Mitigation Cost |

|---|---|---|---|---|---|

| Million USD (MUSD) | USD/tCO2e | ||||

| Brick kilns | 83.25 | −0.21 | −5.46 | 77.59 | 9.99 |

| Limekilns | - | - | 55.90 | 55.90 | 19.74 |

| Dairy products | 0.21 | - | −4.25 | −4.05 | −14.30 |

| Craft breweries | 0.06 | - | −0.46 | −0.40 | −10.68 |

| Artisanal mezcal | - | - | −2.89 | −2.89 | −0.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruíz-Carmona, O.; Islas-Samperio, J.M.; Larrondo-Posadas, L.; Manzini, F.; Grande-Acosta, G.K.; Álvarez-Escobedo, C. Solid Biofuels Scenarios from Rural Agricultural and Forestry Residues for Mexican Industrial SMEs. Energies 2021, 14, 6560. https://doi.org/10.3390/en14206560

Ruíz-Carmona O, Islas-Samperio JM, Larrondo-Posadas L, Manzini F, Grande-Acosta GK, Álvarez-Escobedo C. Solid Biofuels Scenarios from Rural Agricultural and Forestry Residues for Mexican Industrial SMEs. Energies. 2021; 14(20):6560. https://doi.org/10.3390/en14206560

Chicago/Turabian StyleRuíz-Carmona, Oscar, Jorge M. Islas-Samperio, Lourdes Larrondo-Posadas, Fabio Manzini, Genice K. Grande-Acosta, and Christian Álvarez-Escobedo. 2021. "Solid Biofuels Scenarios from Rural Agricultural and Forestry Residues for Mexican Industrial SMEs" Energies 14, no. 20: 6560. https://doi.org/10.3390/en14206560

APA StyleRuíz-Carmona, O., Islas-Samperio, J. M., Larrondo-Posadas, L., Manzini, F., Grande-Acosta, G. K., & Álvarez-Escobedo, C. (2021). Solid Biofuels Scenarios from Rural Agricultural and Forestry Residues for Mexican Industrial SMEs. Energies, 14(20), 6560. https://doi.org/10.3390/en14206560