The Effect of Hydraulic Diameter on Flow Boiling within Single Rectangular Microchannels and Comparison of Heat Sink Configuration of a Single and Multiple Microchannels

Abstract

:1. Introduction

2. Numerical Method

2.1. Governing Equations

2.2. Phase Change Model

2.3. Dynamic Contact Angle Treatment

2.4. Heat and Mass Transfer

3. Application of the Numerical Model

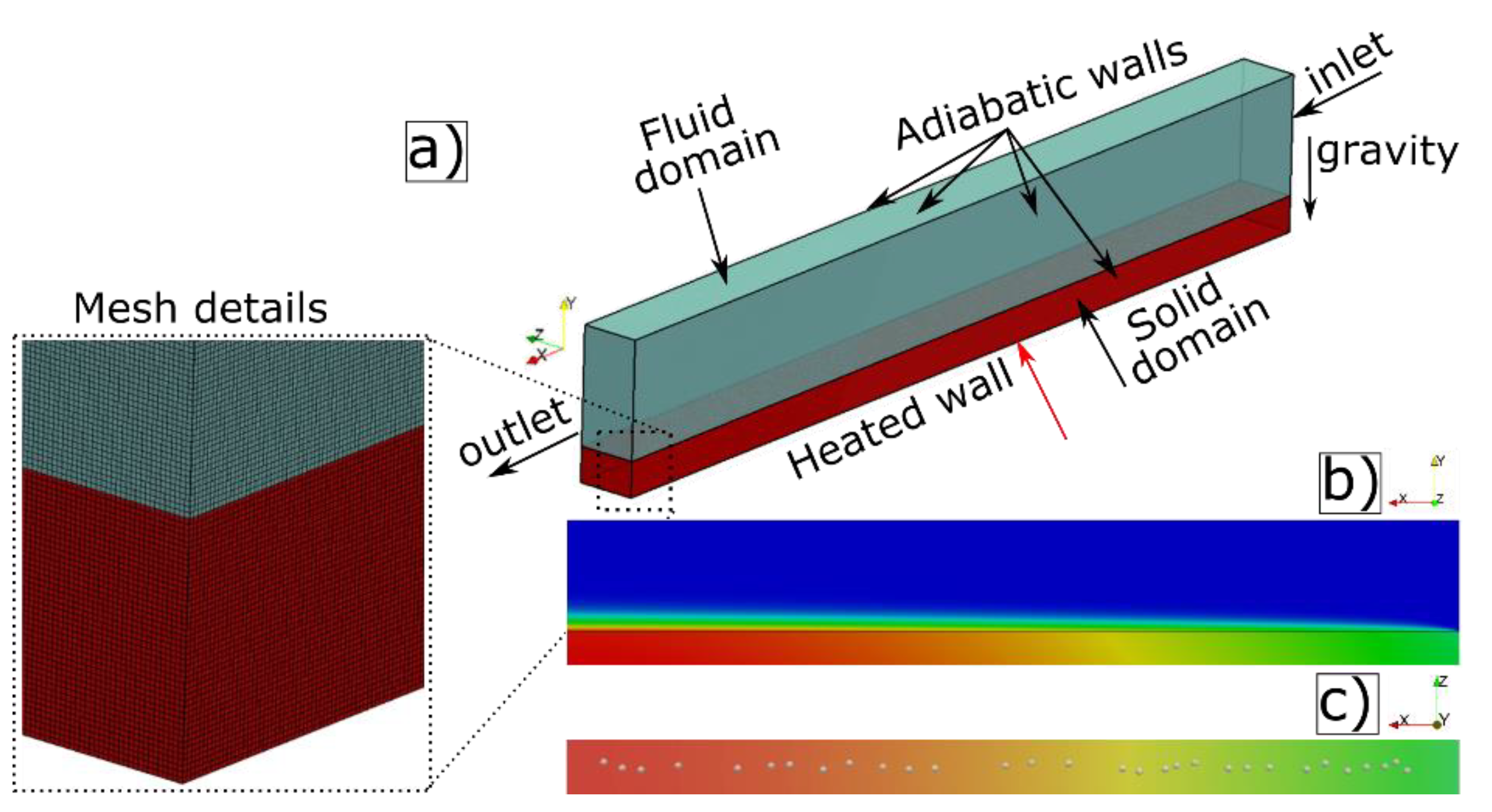

3.1. Computational Geometry and Boundary Conditions

3.2. Numerical Simulation Set-Up and Process

4. Numerical Simulation Results

4.1. Effect of Hydraulic Diameter for a Single Microchannel

- Smaller elongated bubbles/slugs are observed when the hydraulic diameter is increased.

- The increase in heat transfer rate has resulted in an increase in bubble growth rate and bubble coalescence, resulting in more elongated vapour slugs.

- The bubbles grow to occupy the entire cross-section with elongated or intermittent vapour slugs within few fractions of a millisecond.

- For the case of = 7.20 W, dry patches are formed only on the adiabatic side walls of the microchannel and mainly for the cases of hydraulic diameter = 200 and 150 . For the case of = 1.80 W, dry patches are formed mainly on the two side walls of each channel, but also sometimes on the top adiabatic wall, close to the inlet of the channel.

- A characteristic bullet shape nose can be seen in all cases. The curvature of the nose is increased with the decrease in hydraulic diameter for both examined values of heat transfer rate. An increase in the curvature is also observed by increasing heat transfer rate.

- For the simulations of low heat transfer rate, churn flow is the developed flow regime for the 50 channel, while churn flow is also seen in the first few milliseconds for the case of 100 , which then transitions into an intermittent vapour slug regime. For the cases of 150 and 200 , due to the comparatively delayed coalescence of the evaporating bubbles, a slug flow regime is developed.

- Liquid film evaporation is the main heat transfer mechanism for all cases. For the cases of 50 and 100 , this is evident throughout the numerical experiments, whereas for 150 and 200 , contact line evaporation is the main contributing heat transfer mechanism for the first two nucleation cycles and liquid film evaporation for the rest of the simulation.

- For the simulations of high heat transfer rate, churn flow is the flow regime for the 50 case, while an initial churn flow that transitions into a slug flow is evident for the other three cases. In other words, the increase in heat transfer rate did not affect qualitatively the flow characteristics of the 50 channel, whereas for the other three channels, higher bubble growth rates and comparatively more elongated slugs are observed.

- The difference in the two-phase flow regimes between the tested cases has also resulted in a different heat transfer performance.

- Heat transfer is deteriorated by increasing the hydraulic diameter of the channel when comparing the corresponding single and two-phase flow simulations, as shown by the time-averaged heat transfer coefficient difference comparison.

- The increase in the heat transfer rate indicated that the effect of channel diameter is more evident when the heat transfer rate is lower. Furthermore, when the heat transfer rate was increased a substantial enhancement of the heat transfer could be seen for microchannels of 200, 150, and 100 , whereas no important difference could be seen for the microchannel with the smallest hydraulic diameter.

- The trend representing the global Nusselt number curve of the single-phase simulations is identical, regardless the hydraulic diameter of the microchannel, and they all increase with the increase in hydraulic diameter. As expected, different trends could be seen when comparing the two-phase simulations.

- The variation of the time-averaged heat transfer coefficient difference versus the dimensionless length L* is much smoother for the case of small hydraulic diameter compared to the case of 200 .

4.2. Effect of Numbers of Parallel Microchannels

4.3. Temperature and Volume Fraction Comparison within Each Microchannel

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kandlikar, S.G.; Grande, W.J. Evolution of Microchannel Flow Passages--Thermohydraulic Performance and Fabrication Technology. Heat Transf. Eng. 2003, 24, 3–17. [Google Scholar] [CrossRef]

- Kandlikar, S.G. Fundamental issues related to flow boiling in minichannels and microchannels. Exp. Therm. Fluid Sci. 2002, 26, 389–407. [Google Scholar] [CrossRef]

- Qu, W.; Yoon, S.-M.; Mudawar, I. Two-Phase Flow and Heat Transfer in Rectangular Micro-Channels. J. Electron. Packag. 2004, 126, 288–300. [Google Scholar] [CrossRef]

- Mehendale, S.S.; Jacobi, A.; Shah, R.K. Fluid Flow and Heat Transfer at Micro- and Meso-Scales with Application to Heat Exchanger Design. Appl. Mech. Rev. 2000, 53, 175–193. [Google Scholar] [CrossRef]

- Theodore, D.P.D.; Bergman, L.; Lavine, A.S.; Frank, P. Incropera, Fundamentals of Heat and Mass Transfer, 8th ed.; Wiley: New York, NY, USA, 2017. [Google Scholar]

- Agostini, B.; Watel, B.; Bontemps, A.; Thonon, B. Boiling heat transfer in mini-channels: Influence of the hydraulic diameter. In Proceedings of the 21st IIR International Congress of Refrigeration, Washington, DC, USA, 17–22 August 2003; p. 8. [Google Scholar]

- Shah, M.M. Applicability of Correlations for Boiling/Condensing in Macrochannels to Minichannels. Heat Mass Transf. Res. J. 2018, 2.

- Steiner, D.; Taborek, J. Flow Boiling Heat Transfer in Vertical Tubes Correlated by an Asymptotic Model. Heat Transf. Eng. 1992, 13, 43–69. [Google Scholar] [CrossRef]

- Ishibashi, E.; Nishikawa, K. Saturated boiling heat transfer in narrow spaces. Int. J. Heat Mass Transf. 1969, 12, 863–893. [Google Scholar] [CrossRef]

- Aritomi, M.; Miyata, T.; Horiguchi, M.; Sudi, A. Thermo-hydraulics of boiling two-phase flow in high conversion light water reactors (thermo-hydraulics at low velocities). Int. J. Multiph. Flow 1993, 19, 51–63. [Google Scholar] [CrossRef]

- Tran, T.N.; Wambsganss, M.W.; Chyu, M.C.; France, D.M. A Correlation for Nucleate Flow Boiling in Small Channels; Compact Heat Exchangers for the Process Industries: Illinois, IL, USA, 1997; p. 30. Available online: https://digital.library.unt.edu/ark:/67531/metadc695152/m1/1 (accessed on 28 July 2021).

- Kandlikar, S.G.; Steinke, M.E. Predicting Heat Transfer during Flow Boiling in Minichannels and Microchannels. In Proceedings of the ASHRAE Trans., ASHRAE Transactions, Atlanta, GA, USA, 3 July 2003; pp. 667–676. [Google Scholar]

- Xu, Y.; Fang, X.; Li, G.; Li, D.; Yuan, Y. An experimental study of flow boiling heat transfer of R134a and evaluation of existing correlations. Int. J. Heat Mass Transf. 2016, 92, 1143–1157. [Google Scholar] [CrossRef]

- Fang, X.; Zhuang, F.; Chen, C.; Wu, Q.; Chen, Y.; Chen, Y.; He, Y. Saturated flow boiling heat transfer: Review and assessment of prediction methods. Heat Mass Transf. 2018, 55, 197–222. [Google Scholar] [CrossRef]

- Lee, J.; Mudawar, I. Fluid flow and heat transfer characteristics of low temperature two-phase micro-channel heat sinks—Part 1: Experimental methods and flow visualization results. Int. J. Heat Mass Transf. 2008, 51, 4315–4326. [Google Scholar] [CrossRef]

- Harirchian, T.; Garimella, S.V. Microchannel size effects on local flow boiling heat transfer to a dielectric fluid. Int. J. Heat Mass Transf. 2008, 51, 3724–3735. [Google Scholar] [CrossRef] [Green Version]

- Harirchian, T.; Garimella, S.V. Effects of channel dimension, heat flux, and mass flux on flow boiling regimes in microchannels. Int. J. Multiph. Flow 2009, 35, 349–362. [Google Scholar] [CrossRef] [Green Version]

- Harirchian, T.; Garimella, S.V. The critical role of channel cross-sectional area in microchannel flow boiling heat transfer. Int. J. Multiph. Flow 2009, 35, 904–913. [Google Scholar] [CrossRef] [Green Version]

- Cooper, M. Heat Flow Rates in Saturated Nucleate Pool Boiling-A Wide-Ranging Examination Using Reduced Properties; Elsevier BV: Amsterdam, The Netherlands, 1984; pp. 157–239. [Google Scholar]

- Wang, Y.; Sefiane, K. Effects of heat flux, vapour quality, channel hydraulic diameter on flow boiling heat transfer in variable aspect ratio micro-channels using transparent heating. Int. J. Heat Mass Transf. 2012, 55, 2235–2243. [Google Scholar] [CrossRef]

- Wang, Y.; Sefiane, K.; Wang, Z.G.; Harmand, S. Analysis of two-phase pressure drop fluctuations during micro-channel flow boiling. Int. J. Heat Mass Transf. 2014, 70, 353–362. [Google Scholar] [CrossRef]

- Chung, P.-Y.; Kawaji, M. The effect of channel diameter on adiabatic two-phase flow characteristics in microchannels. Int. J. Multiph. Flow 2004, 30, 735–761. [Google Scholar] [CrossRef]

- Kawahara, A.; Sadatomi, M.; Okayama, K.; Kawaji, M.; Chung, P.M.-Y. Effects of Channel Diameter and Liquid Properties on Void Fraction in Adiabatic Two-Phase Flow through Microchannels. Heat Transf. Eng. 2005, 26, 13–19. [Google Scholar] [CrossRef]

- Gunnasegaran, P.; Mohammed, H.A.; Shuaib, N.; Saidur, R. The effect of geometrical parameters on heat transfer characteristics of microchannels heat sink with different shapes. Int. Commun. Heat Mass Transf. 2010, 37, 1078–1086. [Google Scholar] [CrossRef]

- Sahar, A.M.; Wissink, J.; Mahmoud, M.; Karayiannis, T.G.; Ishak, I.D.M.S.A. Effect of hydraulic diameter and aspect ratio on single phase flow and heat transfer in a rectangular microchannel. Appl. Therm. Eng. 2017, 115, 793–814. [Google Scholar] [CrossRef]

- Sathishkumar, D.; Jayavel, S. Effect of Channel Confinement and Hydraulic Diameter on Heat Transfer in a Micro-channel; Springer Gabler: Berlin, Germany, 2018; pp. 441–448. [Google Scholar]

- Leng, C.; Wang, X.-D.; Wang, T.-H.; Yan, W.-M. Optimization of thermal resistance and bottom wall temperature uniformity for double-layered microchannel heat sink. Energy Convers. Manag. 2015, 93, 141–150. [Google Scholar] [CrossRef]

- Wang, Z.-H.; Wang, X.-D.; Yan, W.-M.; Duan, Y.-Y.; Lee, D.-J.; Xu, J.-L. Multi-parameters optimization for microchannel heat sink using inverse problem method. Int. J. Heat Mass Transf. 2011, 54, 2811–2819. [Google Scholar] [CrossRef]

- Hedau, G.; Dey, P.; Raj, R.; Saha, S.K. Experimental and numerical investigation of the effect of number of parallel microchannels on flow boiling heat transfer. Int. J. Heat Mass Transf. 2020, 158, 119973. [Google Scholar] [CrossRef]

- Lee, W.H. A Pressure Iteration Scheme for Two-Phase Flow Modeling. In Multiphase Transport Fundamentals, Reactor Safety, Applications; Hemisphere Publishing: Washington, DC, USA, 1980. [Google Scholar] [CrossRef]

- Dai, H.; Chen, W.; Cheng, Q.; Liu, Y.; Dong, X. Analysis of thermo-hydraulic characteristics in the porous-wall microchannel with microencapsulated phase change slurry. Int. J. Heat Mass Transf. 2021, 165, 120634. [Google Scholar] [CrossRef]

- Georgoulas, A.; Koukouvinis, P.; Gavaises, M.; Marengo, M. Numerical investigation of quasi-static bubble growth and detachment from submerged orifices in isothermal liquid pools: The effect of varying fluid properties and gravity levels. Int. J. Multiph. Flow 2015, 74, 59–78. [Google Scholar] [CrossRef] [Green Version]

- Georgoulas, A.; Andredaki, M.; Marengo, M. An Enhanced VOF Method Coupled with Heat Transfer and Phase Change to Characterise Bubble Detachment in Saturated Pool Boiling. Energies 2017, 10, 272. [Google Scholar] [CrossRef] [Green Version]

- Teodori, E.; Pontes, P.; Moita, A.; Georgoulas, A.; Marengo, M.; Moreira, A. Sensible Heat Transfer during Droplet Cooling: Experimental and Numerical Analysis. Energies 2017, 10, 790. [Google Scholar] [CrossRef] [Green Version]

- Georgoulas, A.; Vontas, K.; Andredaki, M.; Nikas, K.S.; Marengo, M. Numerical Investigation of Droplet Impact on Smooth Surfaces with Different Wettability Characteristics: Implementation of a dynamic contact angle treatment in OpenFOAM. In Proceedings of the ILASS–Europe 2017. 28th Conference on Liquid Atomization and Spray Systems; Universitat Politecnica de Valencia, Valencia, Spain, 6–9 September 2017; pp. 1–8. [Google Scholar]

- Vontas, K.; Boscariol, C.; Andredaki, M.; Georgoulas, A.; Crua, C.; Walther, J.H.; Marengo, M. Droplet Impact on Suspended Metallic Meshes: Effects of Wettability, Reynolds and Weber Numbers. Fluids 2020, 5, 81. [Google Scholar] [CrossRef]

- Brackbill, J.U.; Kothe, D.B.; Zemach, C. A continuum method for modeling surface tension. J. Comput. Phys. 1992, 100, 335–354. [Google Scholar] [CrossRef]

- Hardt, S.; Wondra, F. Evaporation model for interfacial flows based on a continuum-field representation of the source terms. J. Comput. Phys. 2008, 227, 5871–5895. [Google Scholar] [CrossRef]

- Kistler, S.F.; Wetting, I.H.O.; Berg, i.J.C. (Eds.) Wettability; Dekker: New York, NY, USA, 1993; pp. 311–429. [Google Scholar]

- Vontas, K.; Andredaki, M.; Georgoulas, A.; Miché, N.; Marengo, M. The effect of surface wettability on flow boiling characteristics within microchannels. Int. J. Heat Mass Transf. 2021, 172, 121133. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Huber, M.L.; McLinden, M.O. NIST reference fluid thermodynamic and transport properties-REFPROP V 7.0, 23. Natl Std. Ref. Data Series 2002, 155. [Google Scholar]

- Karayiannis, T.; Mahmoud, M. Flow boiling in microchannels: Fundamentals and applications. Appl. Therm. Eng. 2017, 115, 1372–1397. [Google Scholar] [CrossRef]

| Case | No. of Cells (×106) | ||||||

|---|---|---|---|---|---|---|---|

| Solid | Fluid | ||||||

| I | 50 | 75 | 37.5 | 90 | 37.5 | 1.0125 | 3.375 |

| II | 100 | 150 | 75.0 | 90 | 75.0 | 2.0250 | 6.750 |

| III | 150 | 225 | 112.5 | 90 | 112.5 | 3.0375 | 13.125 |

| IV | 200 | 300 | 150.0 | 90 | 150.0 | 4.0500 | 13.500 |

| 351.05 | 100,000 | 736.78 | 1.63 | 6.01 × 10−7 | 6.37 × 10−6 | 0.153 | 0.02 |

| 7840 | 500 | 16.2 |

| Heat Transfer Rate Q (kW) | Heat Transfer Rate Q (kW) | |||||||

|---|---|---|---|---|---|---|---|---|

| 50 | 3.26 | 2400 | 271 | = 80 | 7.20 | = 200 | ||

| 100 | 0.81 | 600 | 135 | = 40 | = 100 | |||

| 150 | 0.36 | 267 | 90 | = 26.67 | = 66.67 | |||

| 200 | 0.20 | 150 | 67 | = 20 | = 50 |

| For W and | For W and | |||||

|---|---|---|---|---|---|---|

| Single-Phase | Two-Phase | % Difference (%) | Single-Phase | Two-Phase | % Difference (%) | |

| 50 | 1.851 | 2.542 | 37.4 | 1.851 | 2.539 | 37.2 |

| 100 | 3.087 | 3.887 | 25.9 | 3.091 | 4.163 | 34.7 |

| 150 | 4.443 | 5.427 | 22.6 | 4.472 | 5.609 | 25.4 |

| 200 | 5.866 | 7.168 | 22.2 | 6.011 | 7.912 | 31.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vontas, K.; Andredaki, M.; Georgoulas, A.; Miché, N.; Marengo, M. The Effect of Hydraulic Diameter on Flow Boiling within Single Rectangular Microchannels and Comparison of Heat Sink Configuration of a Single and Multiple Microchannels. Energies 2021, 14, 6641. https://doi.org/10.3390/en14206641

Vontas K, Andredaki M, Georgoulas A, Miché N, Marengo M. The Effect of Hydraulic Diameter on Flow Boiling within Single Rectangular Microchannels and Comparison of Heat Sink Configuration of a Single and Multiple Microchannels. Energies. 2021; 14(20):6641. https://doi.org/10.3390/en14206641

Chicago/Turabian StyleVontas, Konstantinos, Manolia Andredaki, Anastasios Georgoulas, Nicolas Miché, and Marco Marengo. 2021. "The Effect of Hydraulic Diameter on Flow Boiling within Single Rectangular Microchannels and Comparison of Heat Sink Configuration of a Single and Multiple Microchannels" Energies 14, no. 20: 6641. https://doi.org/10.3390/en14206641