Risk of Using Capillary Active Interior Insulation in a Cold Climate

Abstract

:1. Introduction

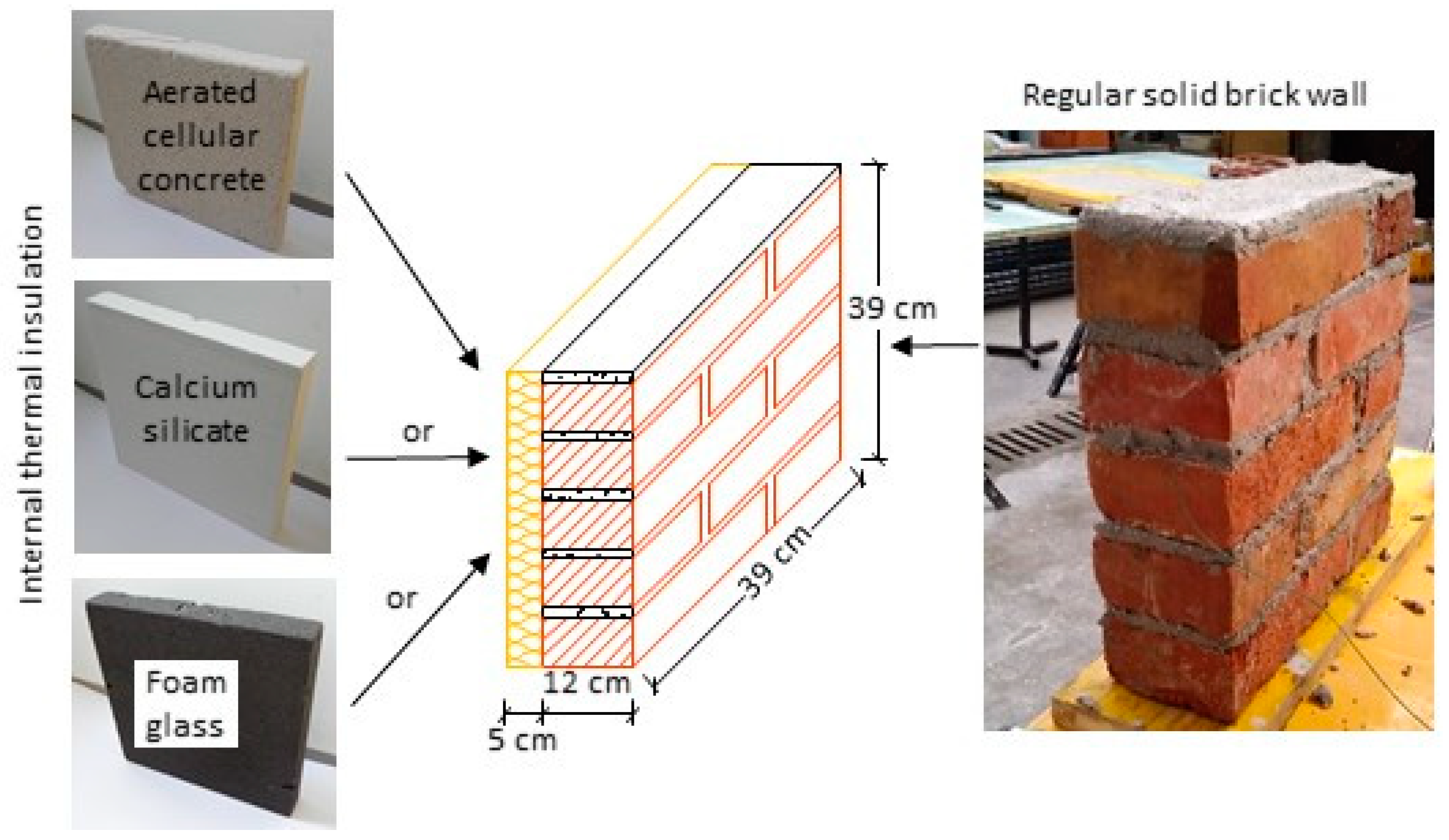

2. Materials and Methods

3. Experimental Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- De Mets, T.; Tilmans, A.; Loncour, X. Hygrothermal assessment of internal insulation systems of brick walls through numerical simulation and full-scale laboratory testing. Energy Procedia 2017, 132, 753–758. [Google Scholar] [CrossRef]

- Andreotti, M.; Bottino-Leone, D.; Calzolari, M.; Davoli, P. Applied Research of the Hygrothermal Behaviour of an Internally Insulated Historic Wall without Vapour Barrier: In Situ Measurements and Dynamic Simulations. Energies 2020, 13, 3362. [Google Scholar] [CrossRef]

- Biseniece, E.; Žogla, G.; Kamenders, A.; Purvinš, R.; Kašs, K.; Vanaga, R.; Blumberga, A. Thermal performance of internally insulated historic brick building incold climate: A long term case study. Energy Build. 2017, 152, 577–586. [Google Scholar] [CrossRef]

- Grunewald, J.; Ruisinger, U.; Häupl, H. The Rijksmuseum Amsterdam—hygrothermal analysis and dimensioning of thermal insulation. In Proceedings of the 3rd International Building Physics, Montreal, QC, Canada, 27–31 August 2016; pp. 345–352. [Google Scholar]

- Vereecken, E.; Roels, S. Capillary active interior insulation: Do the advantages really offset potential disadvantages? Mater. Struct. 2015, 48, 3009–3021. [Google Scholar] [CrossRef]

- Klõšeiko, P.; Arumägi, E.; Kalamees, T. Hygrothermal performance of internally insulated brick wall in cold climate: A case study in a historical school building. J. Build. Phys. 2015, 38, 444–464. [Google Scholar] [CrossRef]

- Marincioni, V.; Marra, G.; Altamirano-Medina, H. Development of predictive models for the probabilistic moisture risk assessment of internal wall insulation. Build. Environ. 2018, 137, 257–267. [Google Scholar] [CrossRef]

- Zhou, X.; Carmeliet, J.; Derome, D. Influence of envelope properties on interior insulation solutions for masonry walls. Build. Environ. 2018, 135, 246–256. [Google Scholar] [CrossRef]

- Jensen, N.F.; Bjarlov, S.P.; Rode, C.; Moller, E.B. Hygrothermal assessment of four insulation systems for interior retrofitting of solid masonry walls through calibrated numerical simulations. Build. Environ. 2020, 180, 107031. [Google Scholar] [CrossRef]

- Vereecken, E.; Roels, S. A comparison of the hygric performance of interior insulation systems: A hot box–cold box experiment. Energy Build. 2014, 80, 37–44. [Google Scholar] [CrossRef]

- Campbell, N.; McGrath, T.; Nanukuttan, S.; Brown, S. Monitoring the hygrothermal and ventilation performance of retrofitted clay brick solid wall houses with internal insulation: Two UK case studies. Case Stud. Constr. Mater. 2017, 7, 163–179. [Google Scholar] [CrossRef] [Green Version]

- Walker, R.; Pavía, S. Thermal and moisture monitoring of an internally insulated historic brick wall. Build. Environ. 2018, 133, 178–186. [Google Scholar] [CrossRef]

- Klun, M.; Antolinc, D.; Bosiljkov, V. Out-of-Plane Experimental Study of Strengthening Slender Non-Structural Masonry Walls. Appl. Sci. 2021, 11, 9098. [Google Scholar] [CrossRef]

- Toplotna Izolacija: Multipor Plošče. Available online: www.ytong.si/si/docs/Multipor_2018.pdf (accessed on 16 September 2021).

- PROMATECT–MC® die Klimaplatte. Available online: www.bdb.at/NL/2010/140729/201308.pdf (accessed on 16 September 2021).

- GEOCELL SCHAUMGLAS. Available online: www.geocell-schaumglas.eu/ (accessed on 16 September 2021).

- Digital Sensor for Temperature, Humidity, and Atmospheric Pressure FHAD 46-Cx. Available online: www.ahlborn.com/download/pdfs/kap08/eng/fhad46e.pdf (accessed on 16 September 2021).

- ISO 13788:2012. Hygrothermal Performance of Building Components and Building Elements–Internal Surface Temperatures to Avoid Critical Surface Humidity and Interstitial Condensation–Calculation Methods. Available online: https://www.iso.org/standard/51615.html (accessed on 18 October 2021).

- Pinterić, M. Building Physics; Springer International Publishing AG: Cham, Switzerland, 2017; pp. 99–146. [Google Scholar]

- January Weather Forecast and Climate. Available online: www.weather-atlas.com/en/slovenia/bled-weather-january (accessed on 16 September 2021).

- Slovenian Environment Agency. Podatki za Pravilnik o Učinkoviti Rabi Energije. Available online: Meteo.arso.gov.si/met/sl/climate/tables/pravilnik-ucinkoviti-rabi-energije/ (accessed on 16 September 2021).

- Ministrstvo za Okolje in Proctor. Tehnična Smernica TSG-1-004: 2010, Učinkovita Raba Energije. Available online: www.zaps.si/img/admin/file/WWW%20ZAPS/ARH%201_14/1_14_2%20Tehnicna%20smernica_raba%20energije_TSG-1-004_2010.pdf (accessed on 16 September 2021).

- Uranjek, M.; Bokan-Bosiljkov, V. Influence of freeze–thaw cycles on mechanical properties of historical brick masonry. Constr. Build. Mater. 2015, 84, 416–428. [Google Scholar] [CrossRef]

| Interior Insulation Material | Literature λ (W/mK) | Experimental λ (W/mK) |

|---|---|---|

| Aerated cellular concrete | 0.043–0.045 [14] | 0.05 |

| Calcium silicate (Promatect MC) | 0.053 [15] | 0.07 |

| Foam glass | 0.05 [16] | 0.05 |

| Original brick wall | / | 0.3 1 |

| Outside conditions: | Tout = −5 °C, | RHout = 0.82 (82%) | |

| Inside conditions: | Tin = 20 °C, | RHin = 0.65 (65%) | |

| Thickness d (cm) | Thermal conductivity λ (W m−1 K−1) | Water vapour resistance factor μ 1 | |

| Original brick wall | 12 | 0.3 | 7 [22] |

| Aerated cellular concrete | 6 | 0.05 | 3 [14] |

| Calcium silicate | 6 | 0.07 | 3 [15] |

| Foam glass | 6 | 0.05 | μ → ∞ [16] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antolinc, D.; Černe, K.; Jagličić, Z. Risk of Using Capillary Active Interior Insulation in a Cold Climate. Energies 2021, 14, 6890. https://doi.org/10.3390/en14216890

Antolinc D, Černe K, Jagličić Z. Risk of Using Capillary Active Interior Insulation in a Cold Climate. Energies. 2021; 14(21):6890. https://doi.org/10.3390/en14216890

Chicago/Turabian StyleAntolinc, David, Katarina Černe, and Zvonko Jagličić. 2021. "Risk of Using Capillary Active Interior Insulation in a Cold Climate" Energies 14, no. 21: 6890. https://doi.org/10.3390/en14216890

APA StyleAntolinc, D., Černe, K., & Jagličić, Z. (2021). Risk of Using Capillary Active Interior Insulation in a Cold Climate. Energies, 14(21), 6890. https://doi.org/10.3390/en14216890