Experimental Study on the Effect of Temperature on the Mechanical Properties of Unconsolidated Silty Sandstones

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples Description

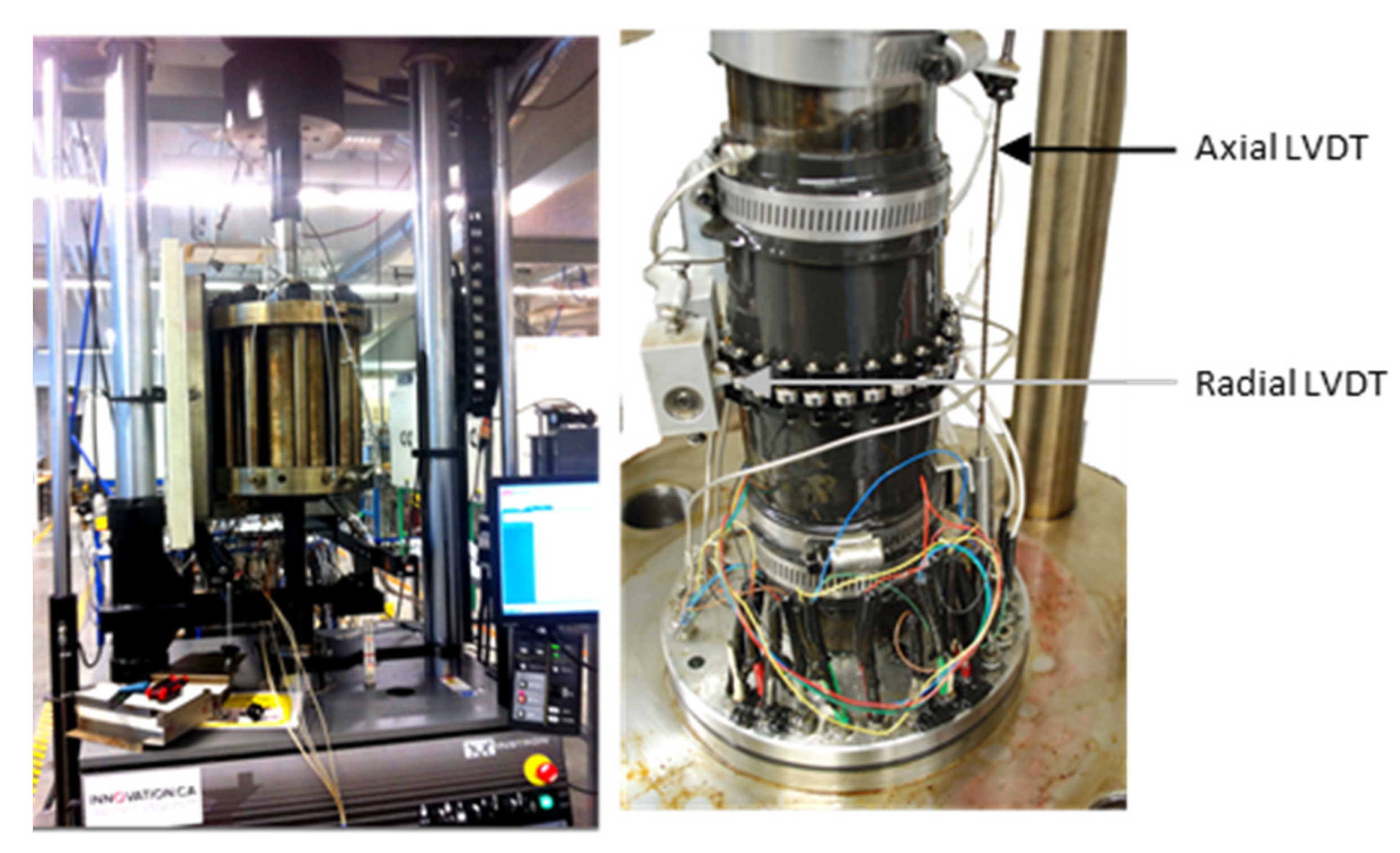

2.2. Equipment for Triaxial Testing

2.3. Experimental Procedure

3. Results and Discussion

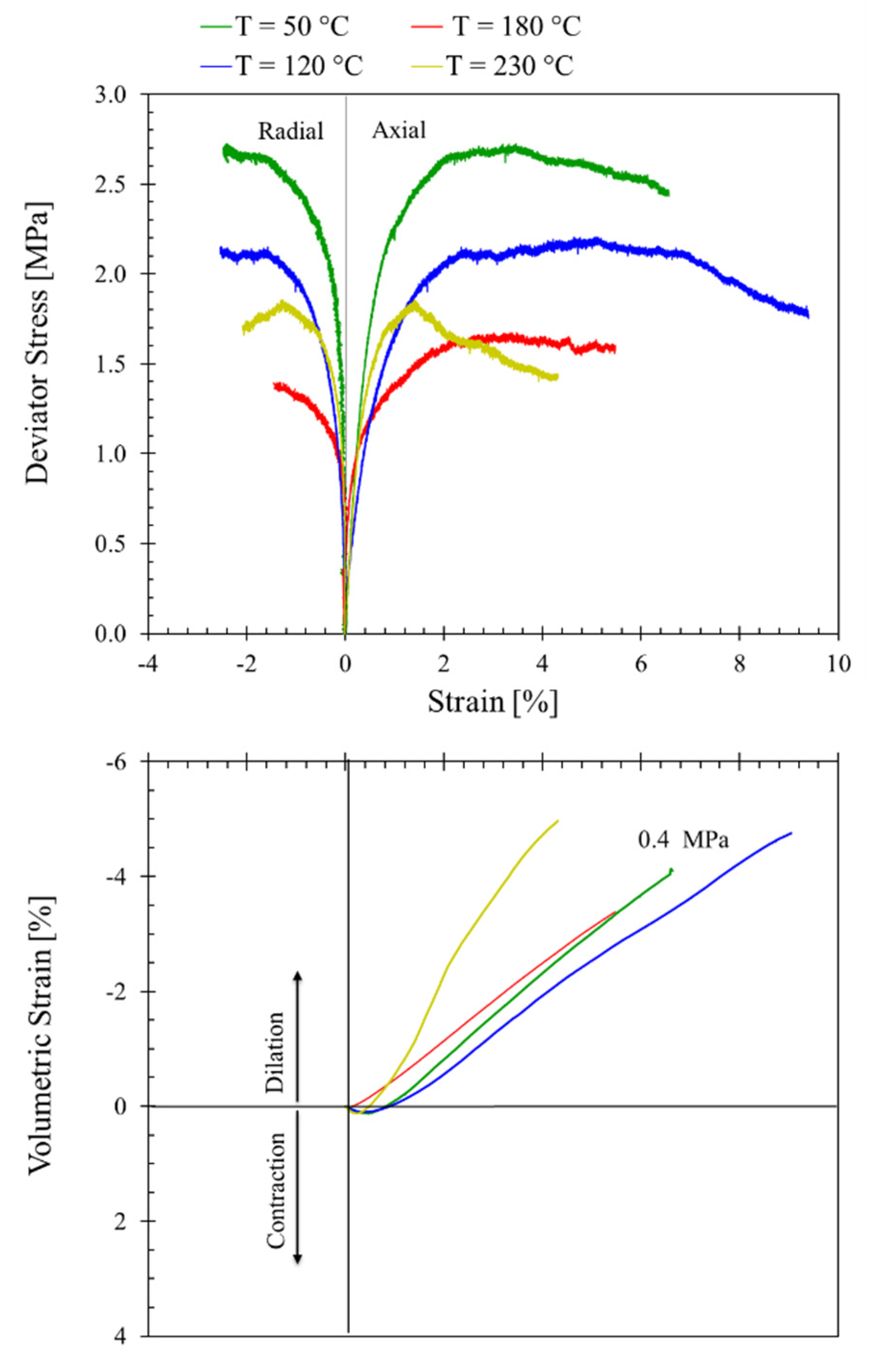

3.1. Tests at Effective Confining Stress of 0.4 MPa

3.2. Test at Effective Confining Stress of 4.0 and 8.2 MPa

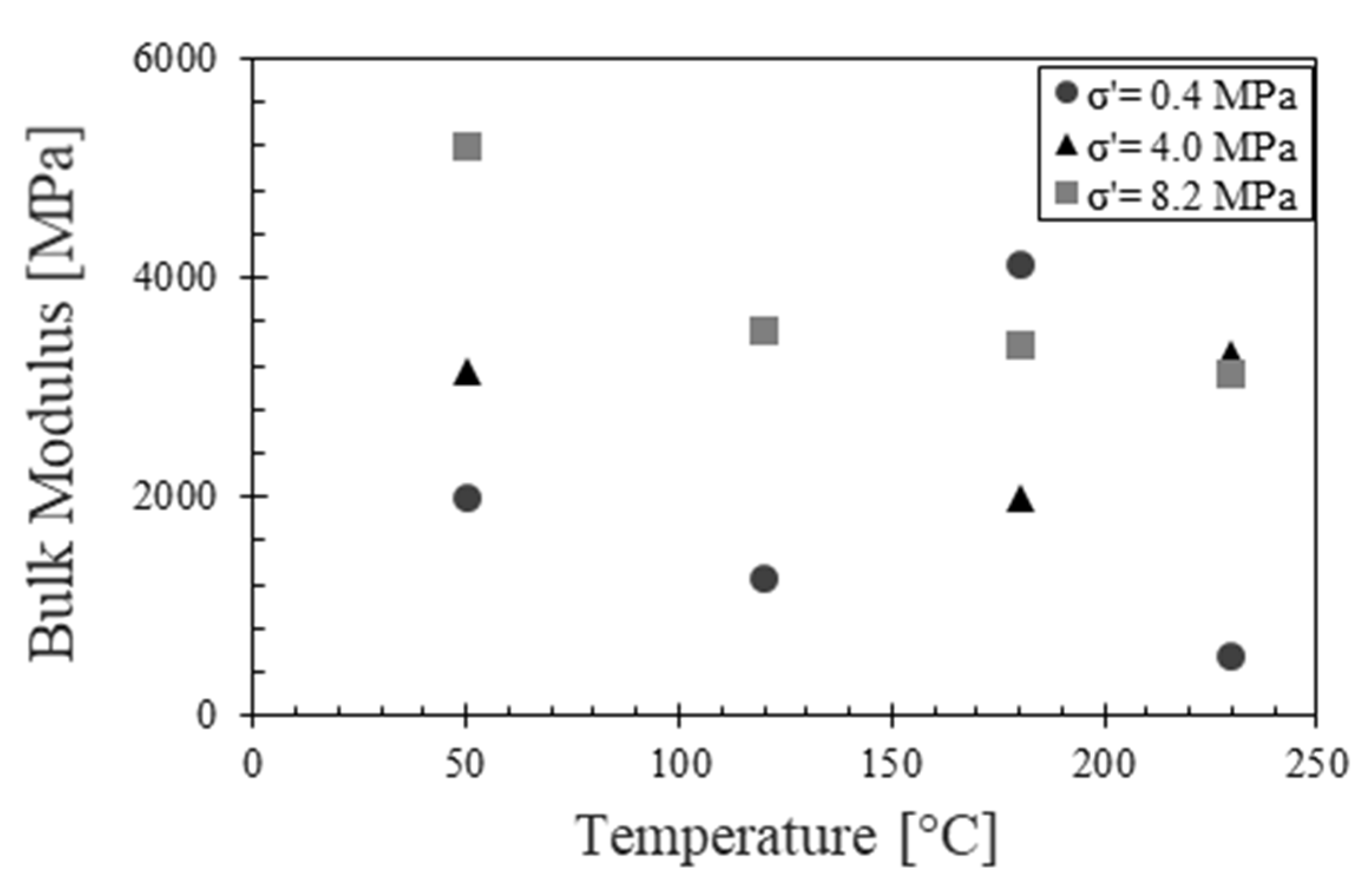

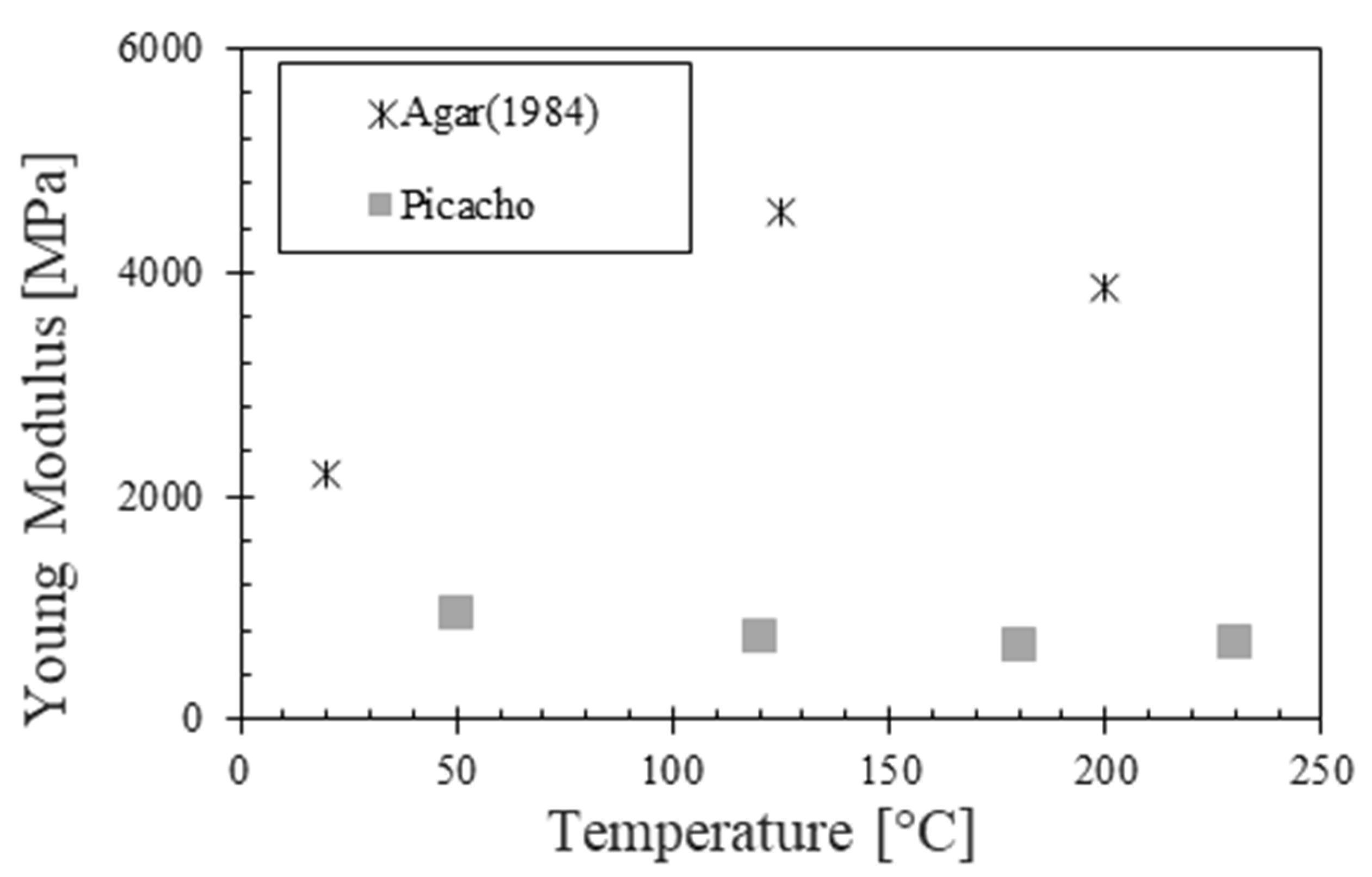

3.3. Effect of Temperature on the Samples’ Stiffness

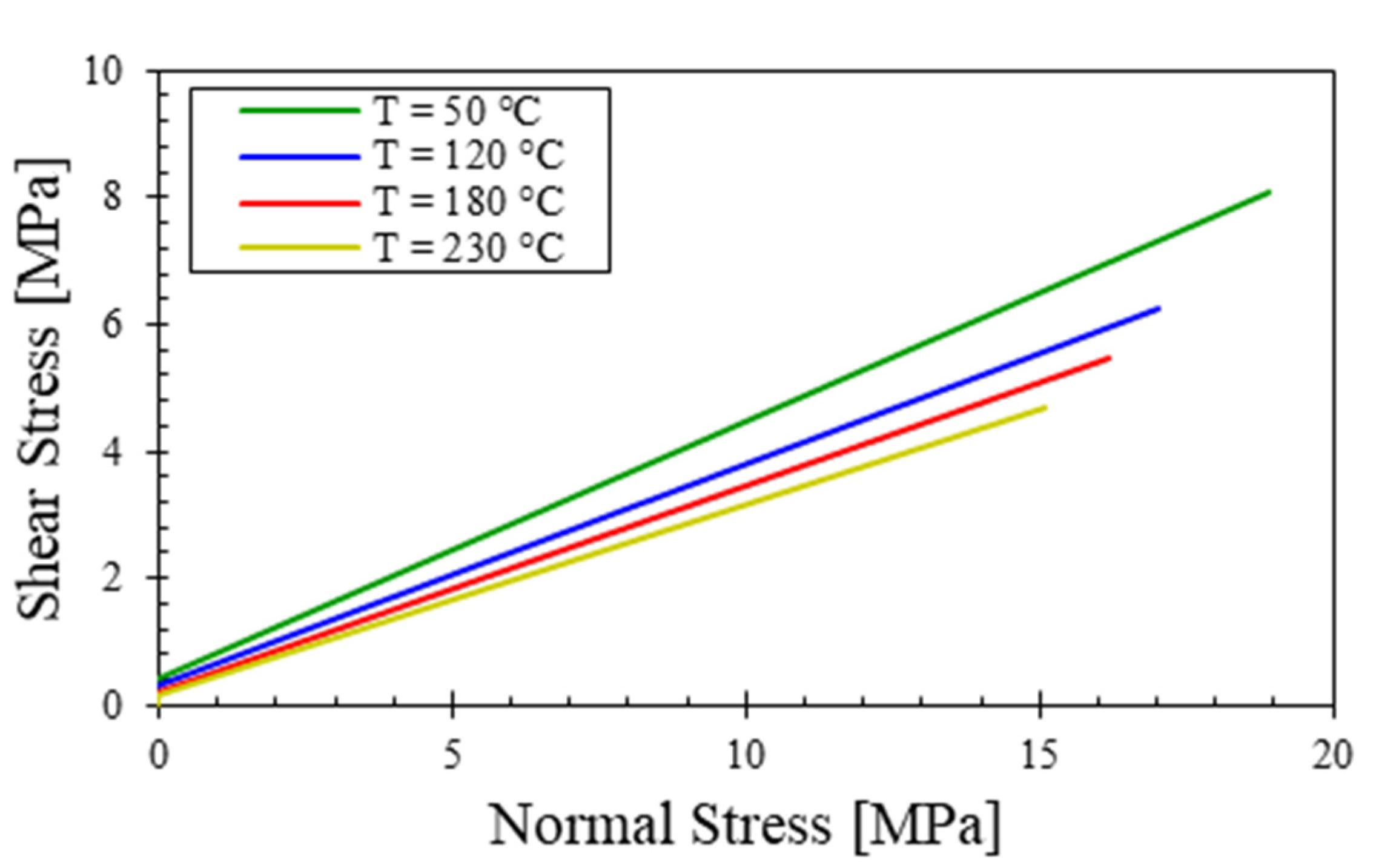

3.4. Effect of Temperature on the Yielding Parameters

- Temperature increases have a remarkable effect on the mechanical behavior of the unconsolidated silty sandstones. As the temperature increases, the strength parameter of the material reduces, showing a higher tendency to fail under high-temperature conditions.

- The effect of temperature on the mechanical properties of silty sandstones is mediated by the effect of confining stress. At lower effective confinement stress (0.4 MPa), the effect of temperature is more noticeable on the material’s strength, which is associated with the possibility of the sample deforming. On the other hand, at high and medium effective confining stress (4.0 and 8.2 MPa), the effect of temperature on the material’s strength is less noticeable since confining prevents sample deformation.

- Generally, silty sandstones subjected to higher temperatures become more ductile, although this behavior may change due to the fines content associated with high temperatures.

- These results show the remarkable effect of the temperature on the mechanical behavior for the unconsolidated silty sandstones and then, it is necessary to take into account the change of these parameters through thermal operations. Failure to take this effect into account may lead to several operational and environmental issues associated with the lower strength of these types of soft rocks.

4. Comparison with Canadian Sands

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shafiei, A.; Dusseault, M.B. Geomechanics of thermal viscous oil production in sandstones. J. Pet. Sci. 2013, 103, 121–139. [Google Scholar] [CrossRef]

- ANH. Produccion Fiscalizada de Petroleo por Campo (Barriles Promedio por Dia Calendario—BPDC). 2014. Available online: https://www.anh.gov.co/estadisticas-del-sector/sistemas-integrados-operaciones/estad%C3%ADsticas-producción (accessed on 25 September 2021).

- Trigos, E.M.; Gonzales, A.R.; Pinilla, J.M.; Munoz, S.M.; Mercado, D.P. Feasibility study of applying steamflooding in a reservoir with high shale/sand: Teca field. In Proceedings of Trinidad and Tobago Energy Resources Conference, Port of Spain, Trinidad and Tobago, 27–30 June 2010. [Google Scholar] [CrossRef]

- Geoestudios. Cartografía Geológica Cuenca Cordillera Oriental-Sector Soapaga. ANH. Bogota, Colombia. 2006. Available online: https://www.anh.gov.co/Informacion-Geologica-y-Geofisica/Tesis/CARTOGRAFIA%20GEOLOGICA%20SOAPAGA-C.ORIENTAL%202005.pdf (accessed on 25 September 2021).

- Nissan, A.H.; Grunberg, I. The viscosity of hydrocarbons. In Proceedings of the Third World Petroleum Congress, The Hague, The Netherlands, 28 May–6 June 1951; pp. 279–311. [Google Scholar]

- Serdengecti, S.; Boozer, G.D. The effect of strain rate and temperature on behavior of rocks subjected to triaxial compression. In Proceedings of the 4th U.S. Symposium on Rock Mechanics, University Park, PA, USA, 30 March–1 April 1961. [Google Scholar]

- Mobarack, S.A.; Somerton, W.H. The effect of temperature and pressure on wave velocities in porous rocks. In Proceedings of the Fall Meeting of the Society of Petroleum Engineers of AIME, New Orleans, LA, USA, 3 October 1971. [Google Scholar]

- Agar, J.G. Geotechnical Behavior of Oil Sand at Elevated Temperatures. Ph.D. Thesis, The University of Alberta, Edmonton, AB, Canada, 1984. [Google Scholar] [CrossRef]

- Kosar, K.M. Geotechnical Properties of Oil Sands and Related Strata. Ph.D. Thesis, The University of Alberta, Edmonton, AB, Canada, 1989. [Google Scholar] [CrossRef]

- Chalaturnyk, R.J. Geomechanics of the Steam Assisted Gravity Drainage Process in Heavy Oil Reservoirs. Ph.D. Thesis, The University of Alberta, Edmonton, AB, Canada, 1995. [Google Scholar] [CrossRef]

- Lintao, Y.; Marshall, A.M.; Wanatowski, D.; Stace, R.; Ekneligoda, T. Effect of high temperatures on sandstone—A computed tomography scan study. Int. J. Phys. 2017, 17, 75–90. [Google Scholar] [CrossRef]

- Wei, S.; Yang, Y.; Su, C.; Cardosh, S.R.; Wang, H. Experimental study of the effect of high temperature on the mechanical properties of coarse sandstone. Appl. Surf. Sci. 2019, 9, 2424. [Google Scholar] [CrossRef]

- Luo, J.; Wang, L. High-temperature mechanical properties of mudstone in the process of underground coal gasification. Rock Mech. Rock Eng. 2011, 44, 749–754. [Google Scholar] [CrossRef]

- Dengo, C.A.; Covey, M.C. Structure of the Eastern Cordillera of Colombia: Implications for trap styles and regional tectonics. Am. Assoc. Pet. Geol. Bull. 1993, 77, 1315–1337. [Google Scholar] [CrossRef]

- ASTM D6913-04. Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis; ASTM International: West Conshohocken, PA, USA, 2009; Available online: www.astm.org (accessed on 25 September 2021).

- ASTM D422-63. Standard Test Method for Particle-Size Analysis of Soils; ASTM International: West Conshohocken, PA, USA, 2009; Available online: www.astm.org (accessed on 25 September 2021).

- Folk, R. Petrology of the Sedimentary Rocks, 2nd ed.; Hemphill Publishing: Austin, TX, USA, 1980. [Google Scholar] [CrossRef]

- Research Council of Alberta. Geology of the McMurray Formation, Part III, General Geology of the McMurray Area; Alberta Geological Survey: Edmonton, AB, Canada, 1959. [Google Scholar]

- Yu, J.; Chen, S.; Chen, X.; Zhang, Y.; Cai, Y. Experimental investigation on mechanical properties and permeability evolution of red sandstone after heat treatments. J. Zhejiang Univ. Sci. 2015, 16, 749–759. [Google Scholar] [CrossRef]

- Dwivedi, R.D.; Goel, R.K.; Prasad, V.V.R.; Sinha, A. Thermo-mechanical properties of Indian and other granites. Int. J. Rock Mech. Min. Sci. 2008, 45, 303–315. [Google Scholar] [CrossRef]

- Wang, X.; Chalaturnyk, R.; Huang, H.; Leung, J. Permeability variations associated with various stress state during pore pressure injection. In Proceedings of the 49th U.S. Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 29 June–1 July 2015. [Google Scholar]

- Charley, R.C.; Stevens, E.; Sheth, N. Suggested test method for determination of degree of saturation of soil samples by B value measurement. Geotech. Test. J. 1979, 2, 158–162. [Google Scholar] [CrossRef]

- ASTM D7181-20. Standard Test Method for Consolidated Drained Triaxial Compression Test for Soils; ASTM International: West Conshohocken, PA, USA, 2020; Available online: www.astm.org (accessed on 25 September 2021).

- Arias-Buitrago, J.A.; Alzate-Espinosa, G.; Arbelaez-Londono, A.; Morales, C.B.; Chalaturnyk, R.J.; Zambrano, G. Influence of confining stress in petrophysical properties changes during thermal recovery in silty sands Colombia. In Proceedings of the SPE Latin America and Caribbean Heavy and Extra Heavy Oil Conference, Lima, Peru, 19–20 October 2016. [Google Scholar] [CrossRef]

- Huertas, F.J. Transformation reactions in phyllosilicates at low temperature: An experimental approach. Diagenesis Low-Temp. Metamorphism. Theory Methods Reg. Asp. 2007, 3, 65–74. [Google Scholar]

- Girsperger, U.; Thompson, S.; Bruce, A. Thermal expansion, compressibility and volumetric changes of quartz obtained by single crystal dilatometry to 700 °C and 3.5 Kilobars. Schweiz. Mineral. Petrogr. Mitt. 2002, 82. [Google Scholar] [CrossRef]

- Bolton, M.D. The strength and dilatancy of sands. Geotechnique 1986, 36, 65–78. [Google Scholar] [CrossRef]

- Yang, Z.X.; Yang, J.; Wang, L.Z. On the influence of inter-particle friction and dilatancy in granular materials: A numerical analysis. Granular Matter 2012, 14, 433–447. [Google Scholar] [CrossRef]

- U.S. Army Engineer Waterways Experiment Station. Calculation of stress and strain from triaxial test data on undrained soil specimens. J. Terramech. 1971, 8, 73. [Google Scholar] [CrossRef][Green Version]

- Zimmerman, R.W.; Somerton, W.H.; King, M.S. Compressibility of porous rocks. J. Geophys. Res. Solid Earth 1986, 91, 12765–12777. [Google Scholar] [CrossRef]

- Morales-Monsalve, C.; Lara-Restrepo, I.; Araujo-Guerrero, E.; Alzate-Espinosa, G.A.; Arbelaez-Londono, A.; Naranjo-Agudelo, A. Effect of temperature on the strength parameters at the plastic domain for unconsolidated sandstones. Geotech. Geol. Eng. 2018, 36, 3537–3549. [Google Scholar] [CrossRef]

- Popescu, M.E. An Introduction to Geotechnical Engineering; Holtz, R.D., Kovacs, W.D., Eds.; Prentice-Hall: Englewood Cliff, NJ, USA, 1986; p. 733. [Google Scholar] [CrossRef]

- Campanella, R.G.; Mitchell, J.K. Influence of temperature variations on soil behavior. J. Soil Mech. Found. Div. 1968, 94, 709–734. [Google Scholar] [CrossRef]

- Dusseault, M.B. The Geotechnical Characteristics of Athabasca Oil Sands. Ph.D. Thesis, The University of Alberta, Edmonton, AB, Canada, 1977. [Google Scholar] [CrossRef]

| Test | Temperature [°C] | Effective Confining Stress [MPa] |

|---|---|---|

| 1 | 50 | 8.2 |

| 2 | 50 | 4.0 |

| 3 | 50 | 0.4 |

| 4 | 120 | 8.2 |

| 5 | 120 | 4.0 |

| 6 | 120 | 0.4 |

| 7 | 180 | 8.2 |

| 8 | 180 | 4.0 |

| 9 | 180 | 0.4 |

| 10 | 230 | 8.2 |

| 11 | 230 | 4.0 |

| 12 | 230 | 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arias-Buitrago, J.A.; Alzate-Espinosa, G.A.; Arbelaez-Londoño, A.; Zambrano-Narvaez, G.; Chalaturnyk, R. Experimental Study on the Effect of Temperature on the Mechanical Properties of Unconsolidated Silty Sandstones. Energies 2021, 14, 7007. https://doi.org/10.3390/en14217007

Arias-Buitrago JA, Alzate-Espinosa GA, Arbelaez-Londoño A, Zambrano-Narvaez G, Chalaturnyk R. Experimental Study on the Effect of Temperature on the Mechanical Properties of Unconsolidated Silty Sandstones. Energies. 2021; 14(21):7007. https://doi.org/10.3390/en14217007

Chicago/Turabian StyleArias-Buitrago, Juan Alejandro, Guillermo A. Alzate-Espinosa, Alejandra Arbelaez-Londoño, Gonzalo Zambrano-Narvaez, and Rick Chalaturnyk. 2021. "Experimental Study on the Effect of Temperature on the Mechanical Properties of Unconsolidated Silty Sandstones" Energies 14, no. 21: 7007. https://doi.org/10.3390/en14217007

APA StyleArias-Buitrago, J. A., Alzate-Espinosa, G. A., Arbelaez-Londoño, A., Zambrano-Narvaez, G., & Chalaturnyk, R. (2021). Experimental Study on the Effect of Temperature on the Mechanical Properties of Unconsolidated Silty Sandstones. Energies, 14(21), 7007. https://doi.org/10.3390/en14217007