Indoor Thermal Environment Challenges of Light Steel Framing in the Southern European Context

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Approach

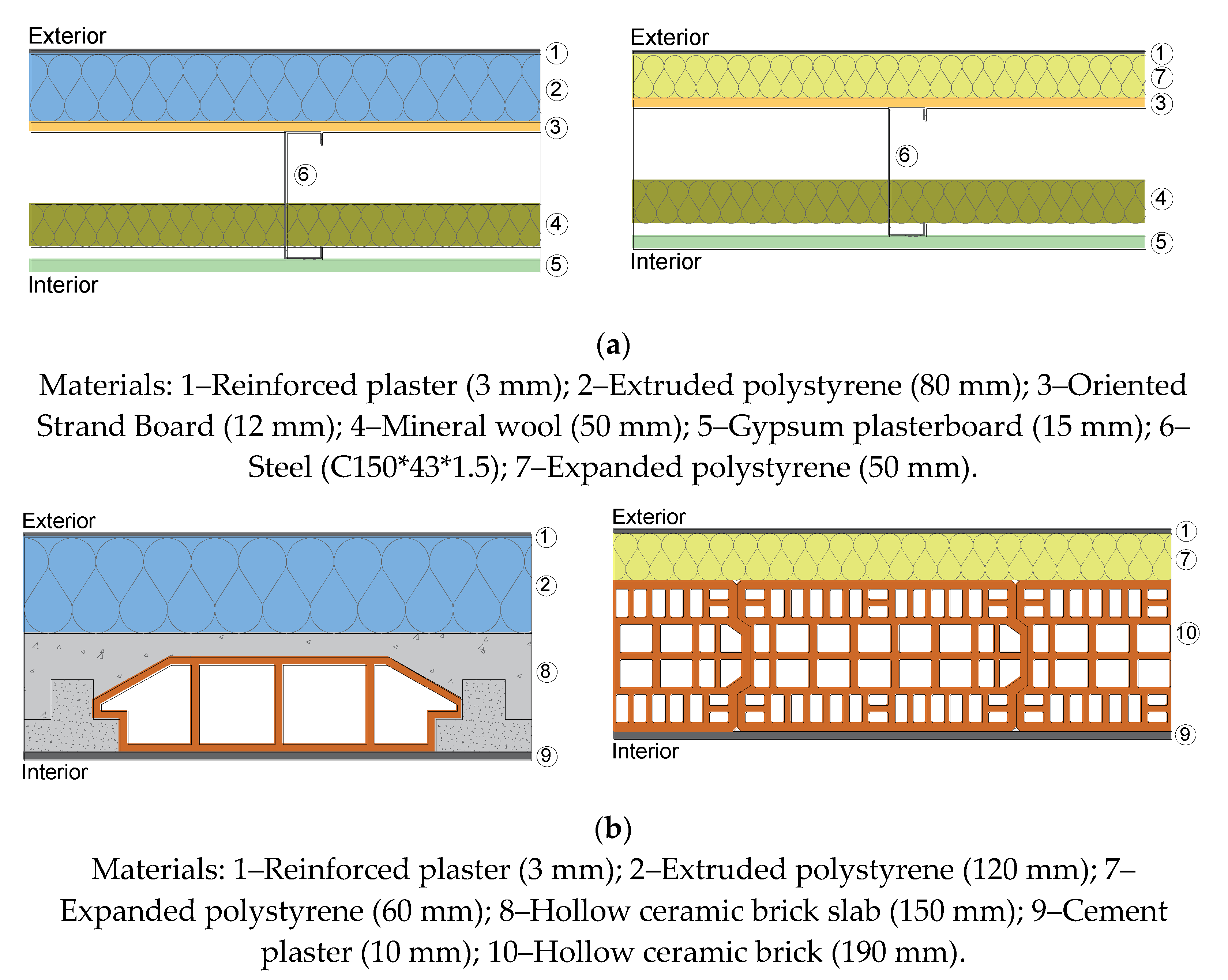

2.2. Experimental Test Cells

2.3. Indoor Thermal Environment and Thermal Comfort Assessment

2.4. Soil Temperature

2.5. Monitoring Equipment

- Outdoor environmental conditions (data logger: data collected using two ICP I-7015P input modules and two I-7561 modules):

- A weather station with the following sensors:

- -

- LP PYRA03AC pyranometer, measuring the global horizontal radiation (accuracy: ±5 W/m2);

- -

- DeltaOHM HD9007-A1 thermohygrometer, including a double anti-radiation shield (accuracy: ±0.1 °C and ±2% HR).

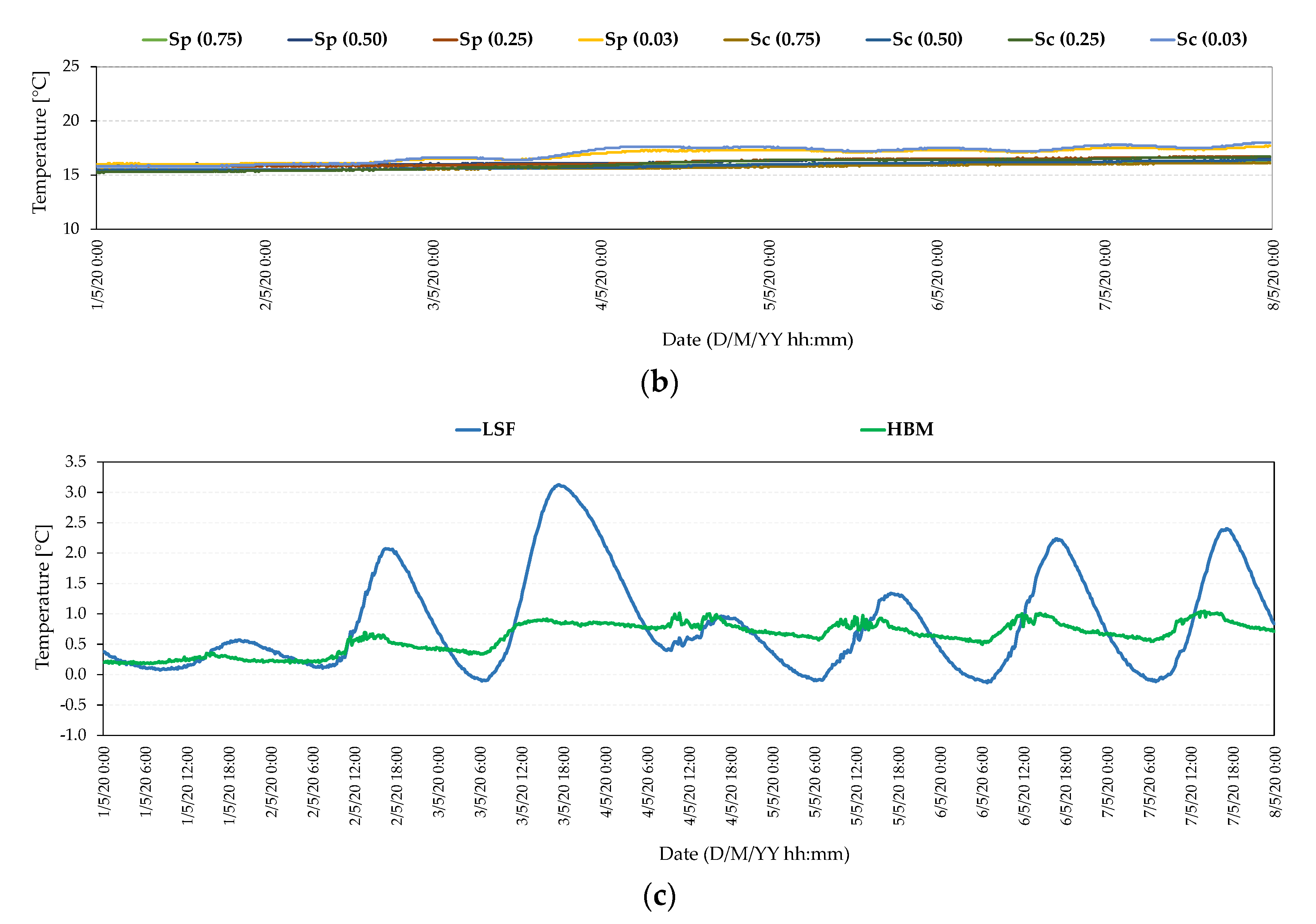

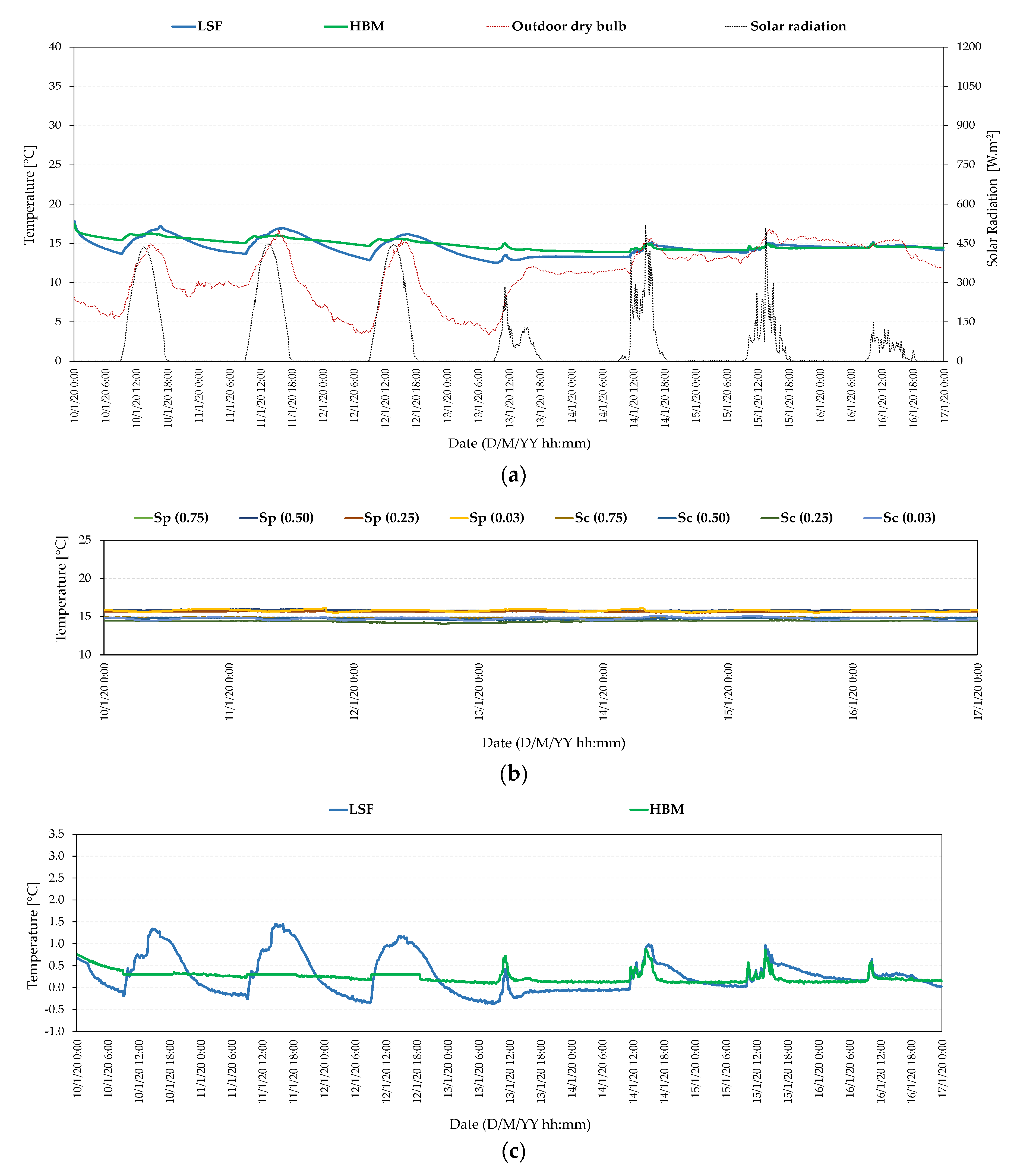

- Soil temperature—PT100 temperature probes were distributed at two different locations under the concrete slab of the LSF test cell, according to the schematic layout presented in Figure 1b. One location was under the centre of the slab (Sc) and the other on the periphery (Sp). Each location comprised four monitoring depths (0.03, 0.25, 0.50, and 0.75 m).

- Indoor environmental conditions:

- Indoor air temperature—SHT31 temperature and relative humidity sensors (accuracy: ±0.3 °C and ±2% HR) were allfgiocated according to the schematic layout presented in Figure 1b. The sensors were distributed among an inferior level (0.1 m from the ground floor slab) and a superior level (2.4 m from the slab).

- Surface temperature—Type K thermocouples were used, whereby one thermocouple was placed in the centre of each interior surface.

3. Results and Discussion

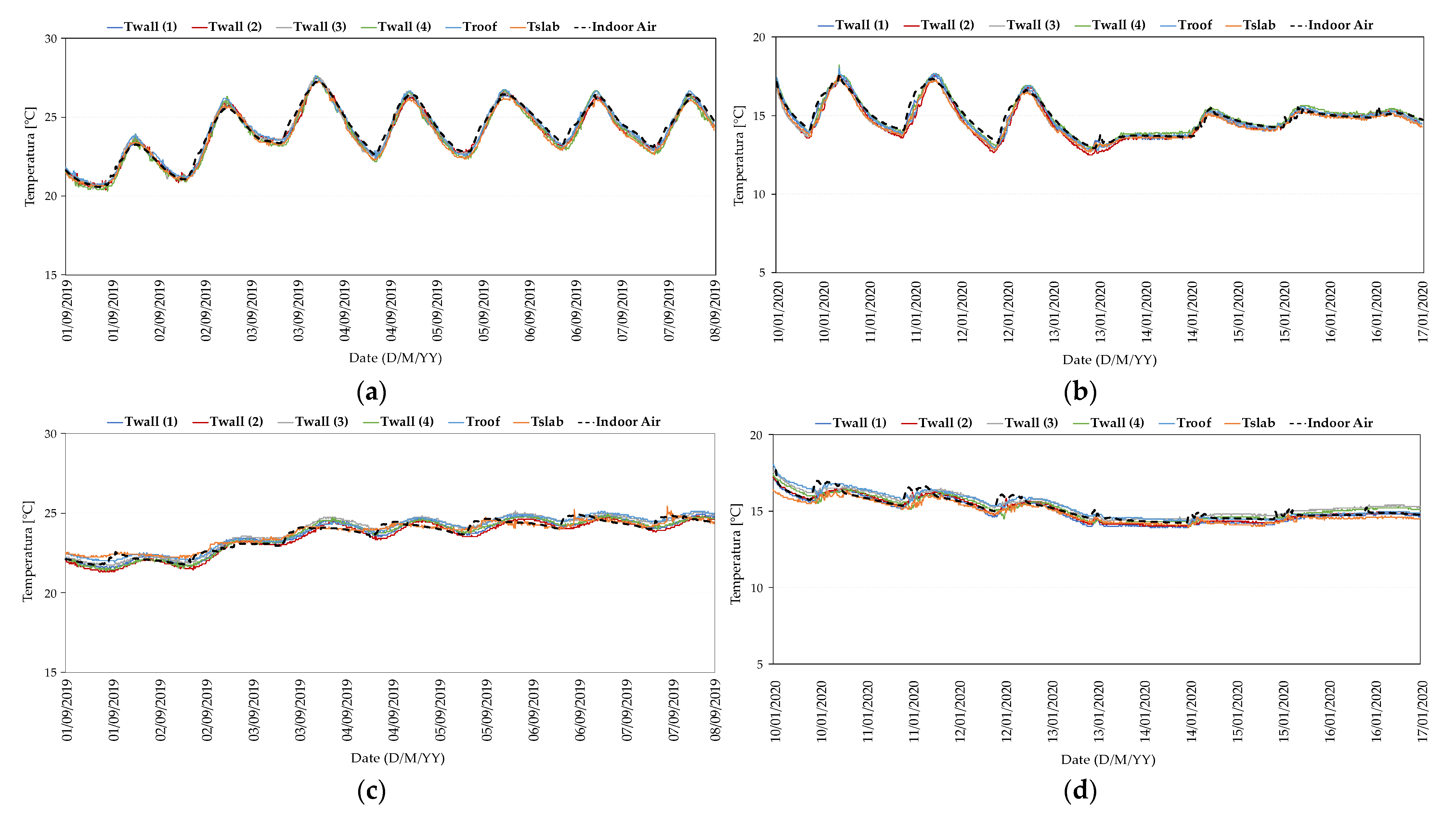

3.1. Indoor Thermal Environment—Representative Summer, Shoulder Season, and Winter Weeks

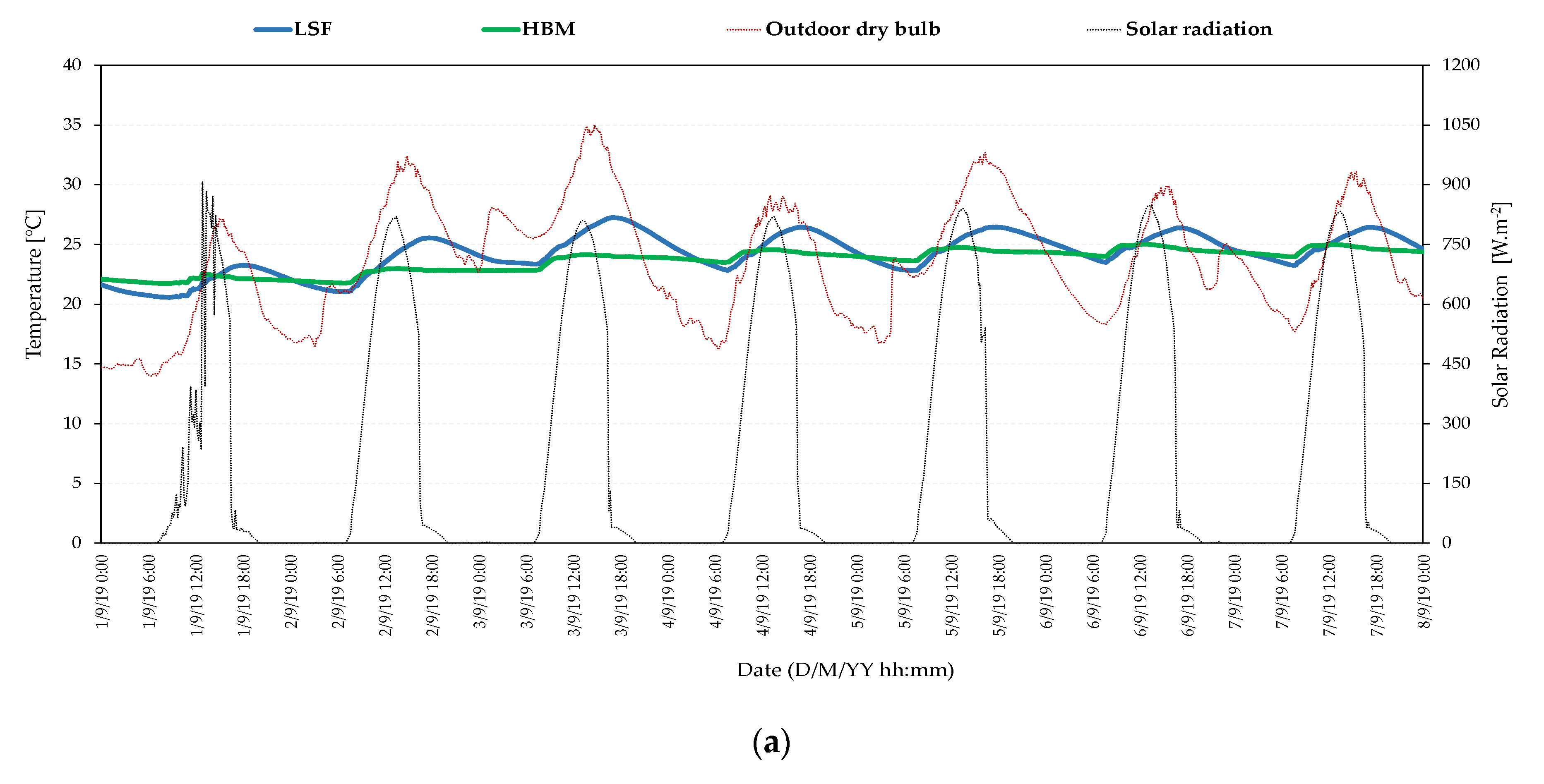

- Representative Summer Week

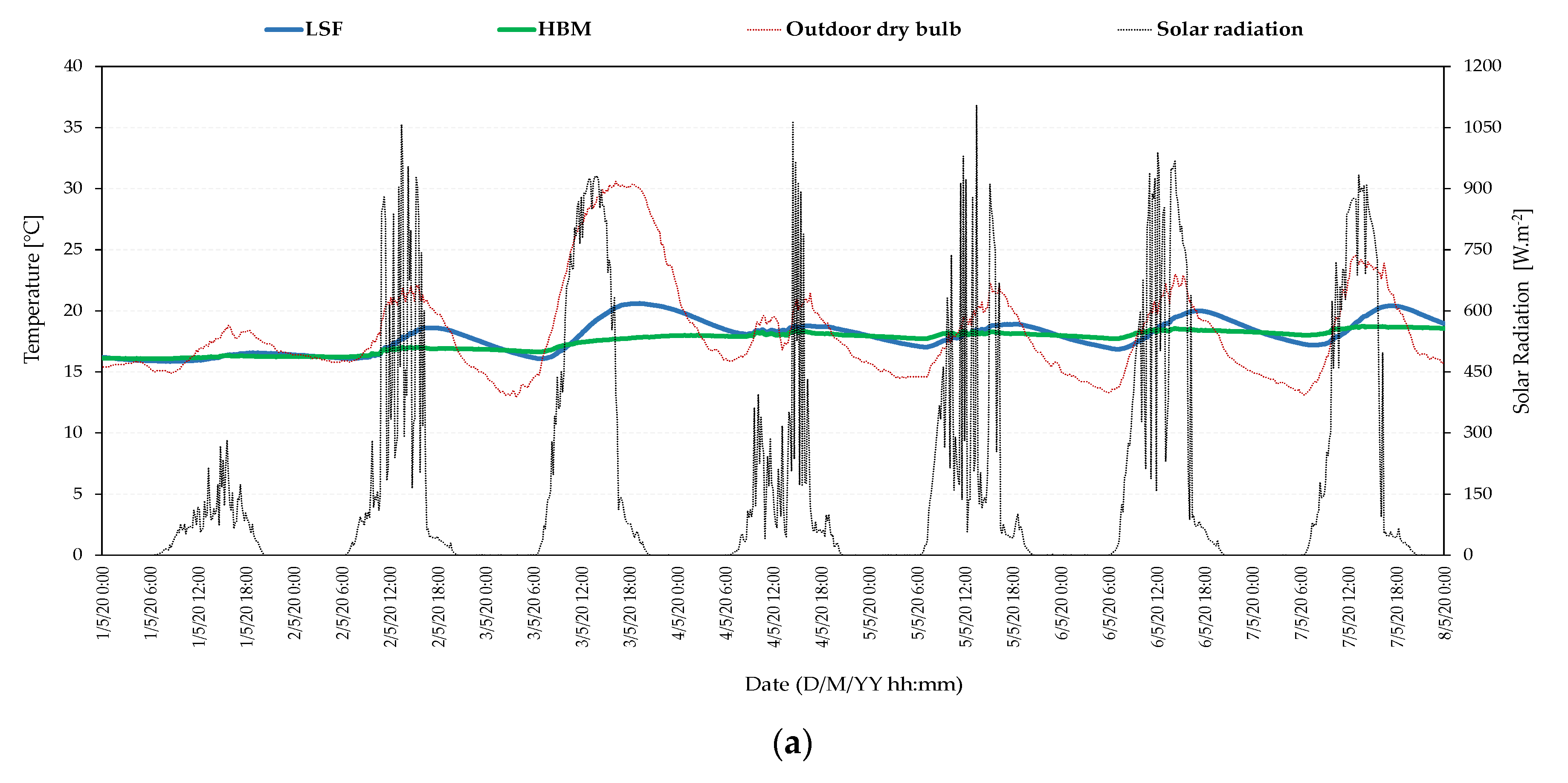

- Representative Shoulder Season Week

- Representative Winter Week

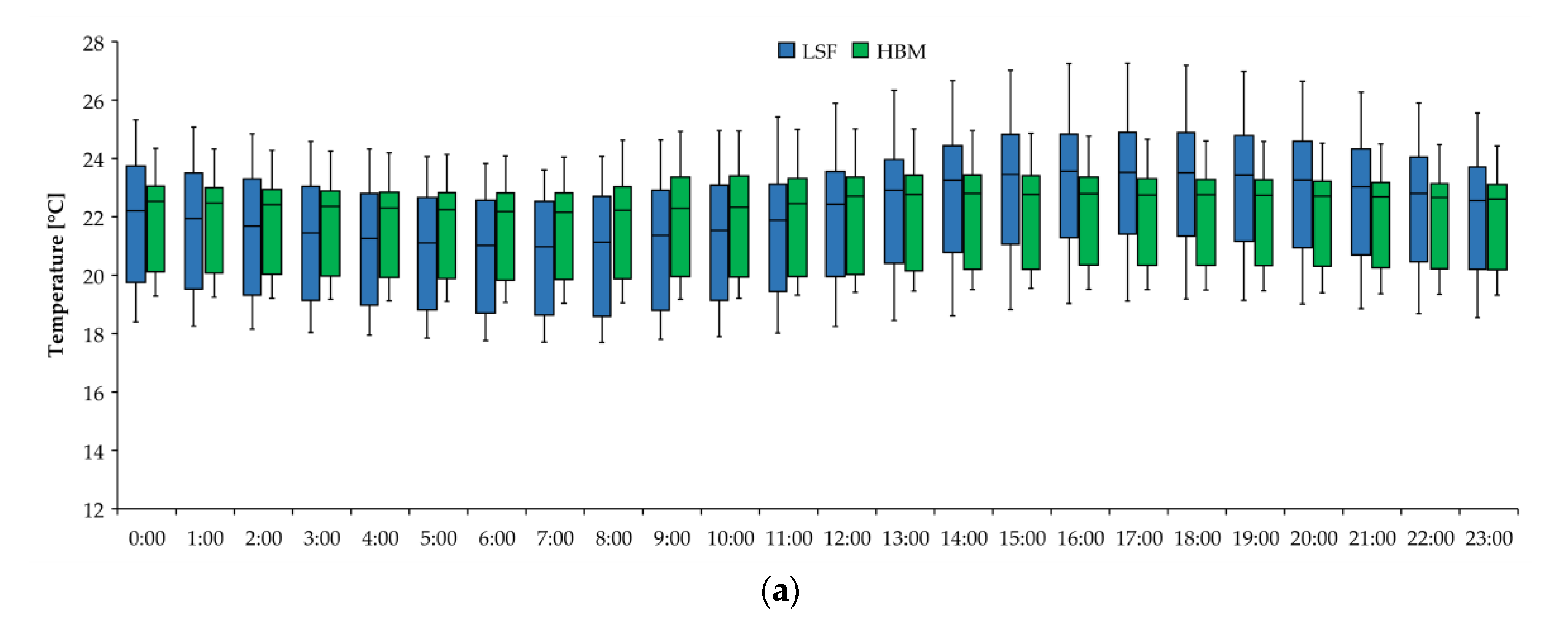

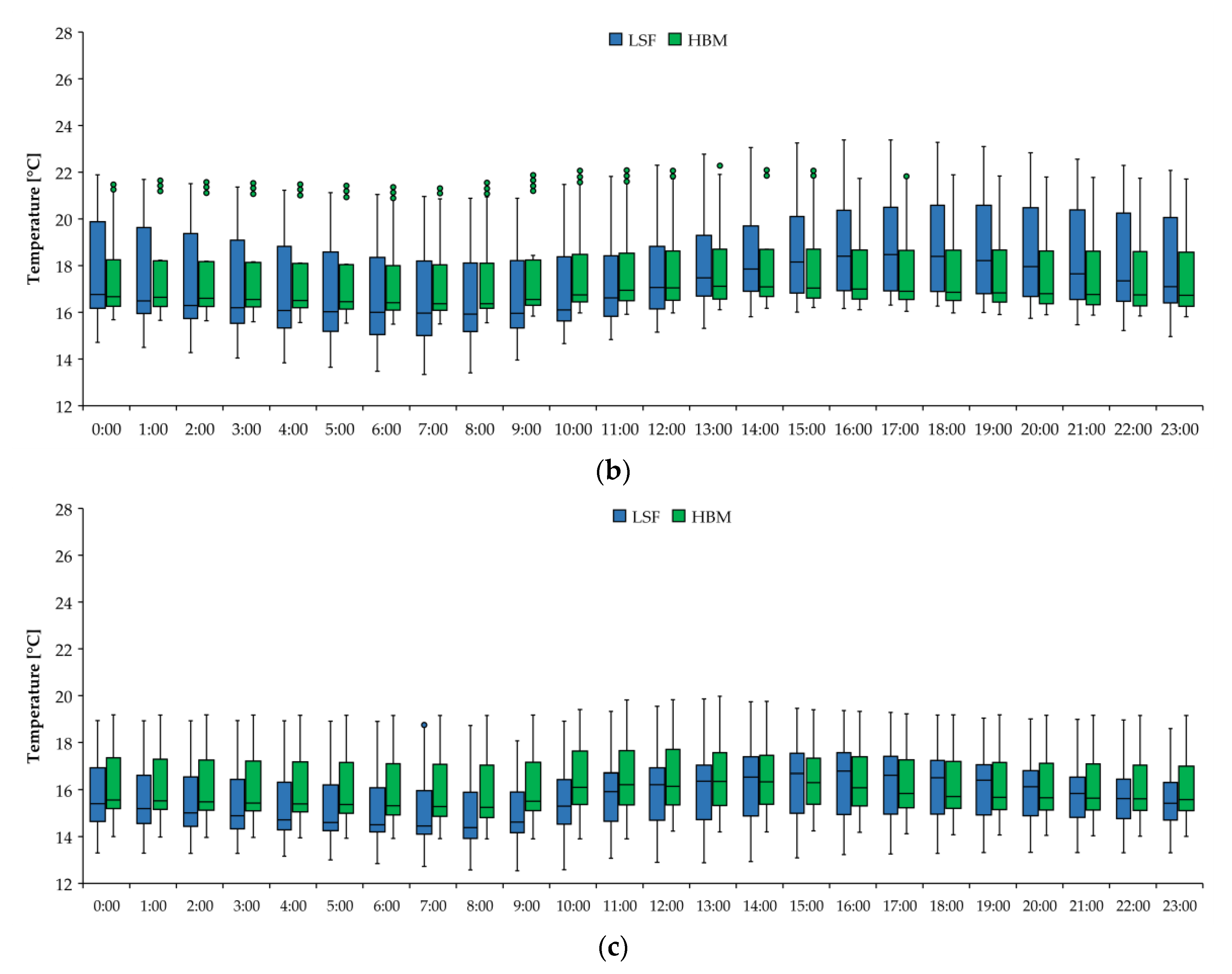

3.2. Indoor Thermal Environment—Annual and Daily Temperature Profiles

- Annual Indoor Air Temperature Profile

- Daily Indoor Air Temperature Profiles—Seasonal Representation

3.3. Indoor Thermal Comfort

4. Conclusions

- The analysis of the summer, shoulder season, and winter representative weeks evidenced noteworthy differences between the two test cells. The fluctuations in indoor air temperature in the HBM test cell were characterised by notable stability, even during demanding outdoor conditions. On the other hand, the LSF test cell presented more marked daily indoor air temperature fluctuations, and consequently more pronounced minimum and maximum daily indoor temperatures. Maximum differences between test cells of approximately 3.3 °C, 2.8 °C, and 1.9 °C were observed during the summer, shoulder season, and winter weeks, respectively;

- The differences in thermal mass between the test cells were observable when the outdoor conditions amplified the dynamic behaviour. For extreme cold or hot climates, the thermal mass may be overheated or overcooled for most of the time. In these situations, buildings with low and high thermal inertia may present very similar behaviours;

- The statistical analysis carried out over 12 months confirmed the patterns observed during the analysis of the representative weeks. Furthermore, it confirmed that the LSF test cell responded more closely to the outdoor environmental conditions due to the lower thermal inertia; however, the more volatile behaviour may be associated with drawbacks as well as advantages, especially if an intermittent residential occupation is considered;

- The statistical analysis revealed that the monthly temperature profiles showed similar median values for the two test cells; however, the differences in terms of interquartile ranges and peak values showed distinct scenarios regarding the indoor thermal environment of the test cells; therefore, we must stress the importance of using more detailed methodologies for indoor thermal assessments over simplified approaches to retrieve mean values. It is important to establish more time-dependent analyses to capture the differential responses of structures with very different dynamic behaviours;

- The thermal comfort analysis exposed large overcooling periods for both test cells. On the other hand, indoor thermal comfort conditions were observed during the warmer months of the year. The percentages of time outside the comfort range were identical in both test cells during the winter and shoulder season months and significantly different during the summer season. For the latter, the HBM test cell presented a higher percentage of time inside the comfort range;

- LSF buildings may be more prone to overheating during warmer conditions; therefore, passive cooling strategies may play an even more relevant role. Strategies to increase the structure’s thermal inertia, such as using elements for the internal envelope with higher heat capacity, may be an important design option;

- The ADI revealed a less favourable scenario for the LSF test cell. This test cell presented higher ADI values for ten of the twelve monitored months; however, the differences in terms of the magnitude of discomfort were fairly low. The most significant difference between test cells was registered in November. In this month, both test cells presented the same percentage of time outside the comfort range; however, the ADI values differed by nearly 0.6 °C. Nevertheless, this difference may not be noticeable to the occupants in real conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Health Organization, Regional Office for Europe; Sarigiannis, D.A. Combined or Multiple Exposure to Health Stressors in Indoor Built Environments; World Health Organization: Copenhagen, Denmark, 2014. [Google Scholar]

- Ormandy, D.; Ezratty, V. Health and thermal comfort: From WHO guidance to housing strategies. Energy Policy 2012, 49, 116–121. [Google Scholar] [CrossRef]

- Sookchaiya, T.; Monyakul, V.; Thepa, S. Assessment of the thermal environment effects on human comfort and health for the development of novel air conditioning system in tropical regions. Energy Build. 2010, 42, 1692–1702. [Google Scholar] [CrossRef]

- Kaushik, A.; Arif, M.; Tumula, P.; Ebohon, O. Effect of thermal comfort on occupant productivity in office buildings: Response surface analysis. Build. Environ. 2020, 180, 107021. [Google Scholar] [CrossRef]

- Yao, Y.; Lian, Z.; Liu, W.; Shen, Q. Experimental study on physiological responses and thermal comfort under various ambient temperatures. Physiol. Behav. 2007, 93, 310–321. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Li, B.; Chen, L.; Chen, L.; Wu, J.; Zheng, J.; Li, W.; Yao, R. Impacts of Indoor Temperature and Velocity on Human Physiology in Hot Summer and Cold Winter Climate in China. In Proceedings of the Clima 2007 WellBeing Indoors, Helsinki, Finland, 10–14 June 2007. [Google Scholar]

- Hawila, A.; Merabtine, A. A statistical-based optimization method to integrate thermal comfort in the design of low energy consumption building. J. Build. Eng. 2021, 33, 101661. [Google Scholar] [CrossRef]

- Ferreira, P.; Ruano, A.; Silva, S.; Conceição, E. Neural networks based predictive control for thermal comfort and energy savings in public buildings. Energy Build. 2012, 55, 238–251. [Google Scholar] [CrossRef] [Green Version]

- Bhamare, D.K.; Rathod, M.K.; Banerjee, J. Passive cooling techniques for building and their applicability in different climatic zones—The state of art. Energy Build. 2019, 198, 467–490. [Google Scholar] [CrossRef]

- Verbeke, S.; Audenaert, A. Thermal inertia in buildings: A review of impacts across climate and building use. Renew. Sustain. Energy Rev. 2018, 82, 2300–2318. [Google Scholar]

- Stazi, F. Thermal Inertia in Energy Efficient Building Envelopes; Butterworth-Heinemann: Oxford, UK, 2017; ISBN 978-0-12813-970-7. [Google Scholar]

- Stazi, F.; Tomassoni, E.; Bonfigli, C.; Di Perna, C. Energy, comfort and environmental assessment of different building envelope techniques in a Mediterranean climate with a hot dry summer. Appl. Energy 2014, 134, 176–196. [Google Scholar]

- Tonelli, C.; Grimaudo, M. Timber buildings and thermal inertia: Open scientific problems for summer behavior in Mediterranean climate. Energy Build. 2014, 83, 89–95. [Google Scholar]

- Soares, N.; Gaspar, A.R.; Santos, P.; Costa, J.J. Multi-Dimensional optimization of the incorporation of PCM-drywalls in lightweight steel-framed residential buildings in different climates. Energy Build. 2014, 70, 411–421. [Google Scholar] [CrossRef]

- Gorgolewski, M. Developing a simplified method of calculating U-values in light steel framing. Build. Environ. 2007, 42, 230–236. [Google Scholar] [CrossRef]

- Santos, P.; Simões da Silva, L.; Ungureanu, V. Energy Efficiency of Light-Weight Steel-Framed Buildings; European Convention for Constructional Steelwork (ECCS): Brussels, Belgium, 2012; ISBN 978-9-29147-105-8. [Google Scholar]

- Roque, E.; Santos, P.; Pereira, A. Thermal and Sound Insulation of Lightweight Steel Framed Façade Walls. Sci. Technol. Built Environ. 2018, 25, 156–176. [Google Scholar] [CrossRef]

- Hoes, P.; Trcka, M.; Hensen, J.L.M.; Hoekstra Bonnema, B. Investigating the potential of a novel low-energy house concept with hybrid adaptable thermal storage. Energy Convers. Manag. 2011, 52, 2442–2447. [Google Scholar] [CrossRef] [Green Version]

- Soares, N.; Costa, J.J.; Gaspar, A.R.; Santos, P. Review of passive PCM latent heat thermal energy storage systems towards buildings’ energy efficiency. Energy Build. 2013, 59, 82–103. [Google Scholar] [CrossRef]

- Rodrigues, L.T.; Gillott, M.; Tetlow, D. Summer overheating potential in a low-energy steel frame house in future climate scenarios. Sustain. Cities Soc. 2013, 7, 1–15. [Google Scholar] [CrossRef]

- Evola, G.; Marletta, L. The effectiveness of PCM wallboards for the energy refurbishment of lightweight buildings. Energy Procedia 2014, 62, 13–21. [Google Scholar] [CrossRef] [Green Version]

- Stazi, F.; Tomassoni, E.; Di Perna, C. Super-Insulated wooden envelopes in Mediterranean climate: Summer overheating, thermal comfort optimization, environmental impact on an Italian case study. Energy Build. 2017, 138, 716–732. [Google Scholar] [CrossRef]

- Rossi, M.; Rocco, V.M. External walls design: The role of periodic thermal transmittance and internal areal heat capacity. Energy Build. 2014, 68, 732–740. [Google Scholar] [CrossRef]

- Atsonios, I.; Mandilaras, I.; Founti, M. Thermal assessment of a novel drywall system insulated with VIPs. Energies 2019, 12, 2373. [Google Scholar] [CrossRef] [Green Version]

- Atsonios, I.A.; Mandilaras, I.D.; Manolitsis, A.; Kontogeorgos, D.A.; Founti, M.A. Experimental and Numerical investigation of the Energy Efficiency of a Lightweight Steel Framed building incorporating Vacuum Insulation Panels. In Proceedings of the EinB2017—6th International Conference “ENERGY in BUILDINGS 2017”, Athens, Greece, 21 October 2017. [Google Scholar]

- Lohmann, V.; Santos, P. Trombe Wall Thermal Behavior and Energy Efficiency of a Light Steel Frame Compartment: Experimental and Numerical Assessments. Energies 2020, 13, 2744. [Google Scholar] [CrossRef]

- Hurt, R.; Boehm, R.; Baghzouz, Y. University of Nevada Zero Energy House Project. In ACEEE Summer Study on Energy Efficiency in Buildings; ACEEE: Washington, DC, USA, 2006; pp. 128–138. [Google Scholar]

- Zhu, L.; Hurt, R.; Correia, D.; Boehm, R. Detailed energy saving performance analyses on thermal mass walls demonstrated in a zero energy house. Energy Build. 2009, 41, 303–310. [Google Scholar] [CrossRef]

- Givoni, B. Effectiveness of mass and night ventilation in lowering the indoor daytime temperatures. Part I: 1993 experimental periods. Energy Build. 1998, 28, 25–32. [Google Scholar] [CrossRef]

- Ogoli, D.M. Predicting indoor temperatures in closed buildings with high thermal mass. Energy Build. 2003, 35, 851–862. [Google Scholar] [CrossRef]

- Gregory, K.; Moghtaderi, B.; Sugo, H.; Page, A. Effect of thermal mass on the thermal performance of various Australian residential constructions systems. Energy Build. 2008, 40, 459–465. [Google Scholar] [CrossRef]

- Yilmaz, Z. Evaluation of energy efficient design strategies for different climatic zones: Comparison of thermal performance of buildings in temperate-humid and hot-dry climate. Energy Build. 2007, 39, 306–316. [Google Scholar] [CrossRef]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World map of the Köppen-Geiger climate classification updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef]

- Decreto-Lei de 20 de Agosto do Ministério da Economia e do Emprego; DL n.118/2013; Diário da República—I Série, No. 159; Ministério da Economia e do Emprego: Lisbon, Portugal, 2013; pp. 4988–5005.

- Roque, E.; Vicente, R.; Almeida, R.M.S.F. Opportunities of Light Steel Framing towards thermal comfort in southern European climates: Long-Term monitoring and comparison with the heavyweight construction. Build. Environ. 2021, 200, 107937. [Google Scholar] [CrossRef]

- Roque, E.; Vicente, R.; Almeida, R.M.S.F.; Ferreira, V.M. Energy consumption in intermittently heated residential buildings: Light Steel Framing vs hollow brick masonry constructive system. J. Build. Eng. 2021, 43, 103024. [Google Scholar] [CrossRef]

- European Committee for Standardization. Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods; EN ISO 6946:2007; European Committee for Standardization: Brussels, Belgium, 2007. [Google Scholar]

- International Organization for Standardization. Thermal Bridges in Building Construction—Heat Flows and Surface Temperatures—Detailed Calculations; ISO 10211:2017; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- International Organization for Standardization. Thermal Performance of Building Components—Dynamic Thermal Characteristics—Calculation Methods; ISO 13786:2017; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- International Organization for Standardization. Thermal Performance of Buildings—Determination of Air Permeability of Buildings—Fan Pressurization Method; ISO 9972:2015; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- European Committee for Standardization. Energy Performance of Buildings. Ventilation for Buildings—Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics; EN 16798-1:2019; European Committee for Standardization: Brussels, Belgium, 2019. [Google Scholar]

- European Committee for Standardization. Energy Performance of Buildings. Ventilation for Buildings—Part 2: Interpretation of the Requirements in EN 16798-1—Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics; EN 16798-2:2019; European Committee for Standardization: Brussels, Belgium, 2019. [Google Scholar]

- American Society of Heating and Air-Conditioning Engineers. ASHRAE Handbook: Fundamentals; American Society of Heating and Air-Conditioning Engineers: Peachtree Corners, GA, USA, 2013; ISBN 978-1-93650-445-9. [Google Scholar]

- American Society of Heating and Air-Conditioning Engineers. Thermal Environmental Conditions for Human Occupancy; ANSI/ASHRAE Standard 55-2020; American Society of Heating and Air-Conditioning Engineers: Peachtree Corners, GA, USA, 2020. [Google Scholar]

- Kasuda, T.; Archenbach, P.R. Earth Temperature and Thermal Diffusivity at Selected Stations in the United States; ASHRAE Trans.; National Bureau of Standards: Gaithersburg, MD, USA, 1965; Volume 71, Part 1. [Google Scholar]

- International Organization for Standardization. Ergonomics of the Thermal Environment—Instruments for Measuring Physical Quantities; ISO 7726:1998; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- International Organization for Standardization. Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria; ISO 7730:2005; International Organization for Standardization: Geneva, Switzerland, 2005. [Google Scholar]

| Thermal Parameters | LSF (Wall) | LSF (Roof) | HBM (Wall) | HBM (Roof) |

|---|---|---|---|---|

| k1 (kJ.m−2 °C−1) | 15.50 | 16.62 | 47.26 | 64.54 |

| f (-) | 0.792 | 0.719 | 0.130 | 0.247 |

| Y12 (W.m−2 °C−1) | 0.286 | 0.200 | 0.047 | 0.069 |

| Δt (h) | 3.20 | 3.90 | 8.90 | 7.30 |

| U-value (W.m−2 °C−1) | 0.36 | 0.28 | 0.36 | 0.28 |

| Test Cell | Indicator | Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | |

| LSF | % OCh | Zone 1 | 71 | - | - | - | - | - | - | - | - | - | - | - |

| Zone 2 | 29 | 100 | 100 | 100 | 95 | 84 | 22 | 12 | 4 | 24 | 100 | 100 | ||

| ADI | 5.03 | 4.23 | 3.75 | 3.21 | 2.38 | 1.13 | 0.13 | 0.06 | 0.01 | 0.14 | 2.49 | 3.86 | ||

| HBM | % OCh | Zone 1 | 71 | - | - | - | - | - | - | - | - | - | - | - |

| Zone 2 | 29 | 100 | 100 | 100 | 100 | 100 | - | - | - | - | 100 | 100 | ||

| ADI | 4.62 | 3.67 | 3.48 | 3.09 | 2.74 | 0.58 | - | - | - | - | 1.9 | 3.93 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roque, E.; Vicente, R.; Almeida, R.M.S.F. Indoor Thermal Environment Challenges of Light Steel Framing in the Southern European Context. Energies 2021, 14, 7025. https://doi.org/10.3390/en14217025

Roque E, Vicente R, Almeida RMSF. Indoor Thermal Environment Challenges of Light Steel Framing in the Southern European Context. Energies. 2021; 14(21):7025. https://doi.org/10.3390/en14217025

Chicago/Turabian StyleRoque, Eduardo, Romeu Vicente, and Ricardo M. S. F. Almeida. 2021. "Indoor Thermal Environment Challenges of Light Steel Framing in the Southern European Context" Energies 14, no. 21: 7025. https://doi.org/10.3390/en14217025

APA StyleRoque, E., Vicente, R., & Almeida, R. M. S. F. (2021). Indoor Thermal Environment Challenges of Light Steel Framing in the Southern European Context. Energies, 14(21), 7025. https://doi.org/10.3390/en14217025